Samsung CLP 320, CLP 325 Service Manual

Service Manual

The keynote of Product

- Model series : CLP-320/325 CLP-320N/CLP-321N(Network model) CLP-325W (Wireless model)

-Speed(Color/Mono) : 4/16 ppm(A4). 4/17ppm(Let)

-Printing resolution : Max. 2,400 x 600 dpi

-Emulation : SPL-C / PCL-6(Network Model)

-Memory : 32MB (USB Model)

256MB (Network/Wireless Model)

Color Laser Printer

CLP-320/325 Series

CLP-320/325/326/320N/321N/325W

-Processor : Jupiter5(360MHz,CLP-320/325/320N/325W)

-Interface : IEEE 802.3,Ethernet(10/100Mbps)

Wireless: IEEE 802.11b/g(Only wireless model)

-Toner Cartridge

•Initial : 1K Toner(K), 0.7K Toner(C,M,Y, each)

•Sales : 1.5K Toner(K), 1K toner(C, M, Y each)

-Printer Life : 100,000 pages

Monthly Max. Duty : 20,000 pages/month

Contents

chapter 1 Precautions

1.1Safety Warning……………………………………………………… 1-1

1.2Caution for safety…………………………………………………… 1-2

1.3ESD Precautions… ………………………………………………… 1-5

chapter 2 Product Overview

2.1Product Specifications……………………………………………… 2-1

2.1.1Product Overview……………………………………………… 2-1

2.1.2Prouduct Specification………………………………………… 2-2

2.1.3Model Comparison Table……………………………………… 2-10

2.2System Overview…………………………………………………… 2-11

2.2.1System Structure… …………………………………………… 2-11

2.2.2 Main PBA Description… ……………………………………… 2-18

2.2.3CRUM…………………………………………………………… 2-25

2.3S/W Structure and Descriptions…………………………………… 2-26

2.3.1Architecture… ………………………………………………… 2-26

2.3.2Language Monitor……………………………………………… 2-26

2.3.3Status Monitor… ……………………………………………… 2-26

2.3.4Network Interface……………………………………………… 2-27

2.3.5 Printer Driver <-> Status Monitor… ………………………… 2-27

2.3.6System F/W Flow……………………………………………… 2-28

2.3.7CRUM Overview… …………………………………………… 2-29

2.3.8Initailize Flow…………………………………………………… 2-30

chapter 3 Disassembly and Reassembly

3.1 |

Precautions when replacing parts………………………………… |

3-1 |

3.1.1 Precautions when assembling and disassembling………… |

3-1 |

|

3.1.2 Preautions when handling PBA… …………………………… |

3-1 |

|

3.1.3 Releasing Plastic Latches… ………………………………… |

3-1 |

|

3.2 |

Parts for Maintenance and Repair………………………………… |

3-2 |

Contents

3.2.1 Replacement interval for parts with a limited life…………… |

3-2 |

3.2.2 Printer Cleaning……………………………………………… |

3-3 |

3.3 Information Related to Disassembly and Assembly… ………… |

3-4 |

3.3.1 Special service parts… ……………………………………… |

3-4 |

3.3.2 Screws used in the printer… ………………………………… |

3-5 |

3.4Disassembly Procedure… ………………………………………… 3-7

3.4.1Cover… ………………………………………………………… 3-7

3.4.2ITB… …………………………………………………………… 3-9

3.4.3Fuser unit… …………………………………………………… 3-9

3.4.4HVPS board… ………………………………………………… 3-10

3.4.5Main PBA… …………………………………………………… 3-11

3.4.6SMPS board… ………………………………………………… 3-11

3.4.7LSU……………………………………………………………… 3-12

3.4.8Holder Pad……………………………………………………… 3-12

3.4.9Transfer roller………………………………………………… 3-13

3.4.10OPE PBA……………………………………………………… 3-14

3.4.11Pick up roller… ……………………………………………… 3-15

chapter 4 Alignment and Troubleshooting

4.1 Alignment and Adjustments……………………………………… 4-1

4.1.1Control Panel…………………………………………………… 4-1

4.1.2Jam Removal………………………………………………… 4-9

4.1.3Firmware upgrade…………………………………………… 4-13

4.1.4Periodic Defective Image…………………………………… 4-14

4.1.5 Using the smart pane program… …………………………… |

4-15 |

4.1.6 How to use EDC (Engine Diagnostic Control) Mode… …… |

4-17 |

4.2 Troubleshooting…………………………………………………… |

4-22 |

4.2.1 Procedure of Checking the Symptoms……………………… |

4-22 |

4.2.2 Troubleshooting Checklist… ………………………………… |

4-23 |

4.2.3 Solving General Printing Problems… ……………………… |

4-24 |

4.2.4 Solving Print Quality Problems… …………………………… |

4-32 |

4.2.5Common Windows Problems………………………………… 4-50

4.2.6Common Macintosh Problems… …………………………… 4-51

Contents

4.2.7 |

Common Linux Problems… ………………………………… |

4-52 |

4.2.8 |

Major Problems Trouble shooting… ………………………… |

4-56 |

chapter 5 System Diagram

5.1Block Diagram… …………………………………………………… 5-1

5.2Connection Diagram……………………………………………… 5-2

chapter 6 Reference Information

6.1 |

Tool for Troubleshooting… ………………………………………… |

6-1 |

6.2 |

Acronyms and Abbreviations… …………………………………… |

6-2 |

6.3 |

Select a location for the printer… ………………………………… |

6-4 |

6.4 A4 ISO 19798 Standard Pattern………………………………… |

6-5 |

|

attached Parts Catalog

Precautions

1. Precautions

In order to prevent accidents and damages to the equipment please read the precautions listed below carefully before servicing the product and follow them closely.

1.1 Safety warning

(1)Only to be serviced by a factory trained service technician.

High voltages and lasers inside this product are dangerous. This product should only be serviced by a factory trained service technician.

(2)Use only Samsung replacement parts.

There are no user serviceable parts inside the product. Do not make any unauthorized changes or additions to the product as these could cause the product to malfunctions and create an electric shocks or fire hazards.

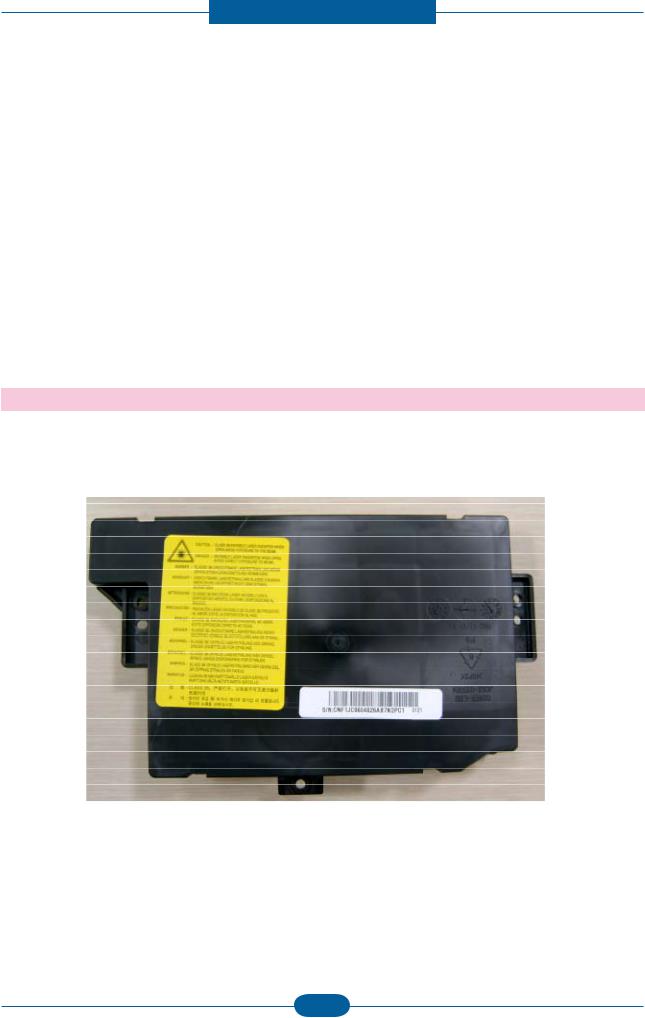

(3)Laser Safety Statement

The product is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J for Class 1(1) laser products, and elsewhere, it is certified as a Class I laser product conforming to the requirements of IEC 825. Class I laser products are not considered to be hazardous. The laser system and product are designed so there is never any human access to laser radiation above a

Class I level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the product with the protective cover removed from Laser/Scanner assembly. The reflected beam, although invisible, can damage your eyes.

When using this product, these basic safety pre-cautions should always be followed to reduce risk of fire, electric shock, and personal injury.

Service Manual |

1-1 |

Samsung Electronics |

|

Precautions

1.2 Caution for safety

1.2.1 Toxic material

This product contains toxic materials that could cause illness if ingested.

(1)If the LCD control panel is damaged, it is possible for the liquid inside to leak. This liquid is toxic. Contact with the skin should be avoided. Wash any splashes from eyes or skin immediately and contact your doctor. If the liquid gets into the mouth or is swallowed, see a doctor immediately.

(2)Please keep imaging unit and toner cartridge away from children. The toner powder contained in the imaging unit and toner cartridge may be harmful, and if swallowed, you should contact a doctor.

1.2.2 Electric shock and fire safety precautions

Failure to follow the following instructions could cause electric shock or potentially cause a fire.

(1)Use only the correct voltage, failure to do so could damage the product and potentially cause a fire or electric shock.

(2)Use only the power cable supplied with the product. Use of an incorrectly specified cable could cause the cable to overheat and potentially cause a fire.

(3)Do not overload the power socket, this could lead to overheating of the cables inside the wall and could lead to a fire.

(4)Do not allow water or other liquids to spill into the product, this can cause electric shock. Do not allow paper clips, pins or other foreign objects to fall into the product, these could cause a short circuit leading to an electric shock or fire hazard.

(5)Never touch the plugs on either end of the power cable with wet hands, this can cause electric shock. When servicing the product, remove the power plug from the wall socket.

(6)Use caution when inserting or removing the power connector. When removing the power connector, grip it firmly and pull. The power connector must be inserted completely, otherwise a poor contact could cause overheating possibly leading to a fire.

(7)Take care of the power cable. Do not allow it to become twisted, bent sharply around corners or wise damaged. Do not place objects on top of the power cable. If the power cable is damaged it could overheat and cause a fire. Exposed cables could cause an electric shock. Replace the damaged power cable immediately, do not reuse or repair the damaged cable. Some chemicals can attack the coating on the power cable, weakening the cover or exposing cables causing fire and shock risks.

(8)Ensure that the power sockets and plugs are not cracked or broken in any way. Any such defects should be repaired immediately. Take care not to cut or damage the power cable or plugs when moving the machine.

(9)Use caution during thunder or lightning storms. Samsung recommends that this machine be disconnected from the power source when such weather conditions are expected. Do not touch the machine or the power cord if it is still connected to the wall socket in these weather conditions.

(10)Avoid damp or dusty areas, install the product in a clean well ventilated location. Do not position the machine near a humidifier or in front of an air conditioner. Moisture and dust built up inside the machine can lead to overheating and cause a fire or cause parts to rust.

(11)Do not position the product in direct sunlight. This will cause the temperature inside the product to rise possibly leading to the product failing to work properly and in extreme conditions could lead to a fire.

(12)Do not insert any metal objects into the machine through the ventilator fan or other part of the casing, it could make contact with a high voltage conductor inside the machine and cause an electric shock.

Service Manual |

1-2 |

Samsung Electronics |

|

Precautions

1.2.3 Handling precautions

The following instructions are for your own personal safety to avoid injury and so as not to damage the product.

(1)Ensure the product is installed on a level surface, capable of supporting its weight. Failure to do so could cause the product to tip or fall.

(2)The product contains many rollers, gears and fans. Take great care to ensure that you do not catch your fingers, hair or clothing in any of these rotating devices.

(3)Do not place any small metal objects, containers of water, chemicals or other liquids close to the product which if spilled could get into the machine and cause damage or a shock or fire hazard.

(4)Do not install the machine in areas with high dust or moisture levels, beside on open window or close to a humidifier or heater. Damage could be caused to the product in such areas.

(5)Do not place candles, burning cigarettes, etc on the product, These could cause a fire.

1.2.4 Assembly / Disassembly precautions

Replace parts carefully and always use Samsung parts. Take care to note the exact location of parts and also cable routing before dismantling any part of the machine. Ensure all parts and cables are replaced correctly. Please carry out the following procedures before dismantling the product or replacing any parts.

(1)Check the contents of the machine memory and make a note of any user settings. These will be erased if the main board or network card is replaced.

(2)Ensure that power is disconnected before servicing or replacing any electrical parts.

(3)Disconnect interface cables and power cables.

(4)Only use approved spare parts. Ensure that part number, product name, any voltage, current or temperature rating are correct.

(5)When removing or re-fitting any parts do not use excessive force, especially when fitting screws into plastic.

(6)Take care not to drop any small parts into the machine.

(7)Handling of the OPC Drum

-The OPC Drum can be irreparably damaged if it exposed to light.

Take care not to expose the OPC Drum either to direct sunlight or to fluorescent or incandescent room lighting. Exposure for as little as 5 minutes can damage the surface of the photoconductive properties and will result in print quality degradation. Take extra care when servicing the product. Remove the OPC Drum and store it in a black bag or other lightproof container. Take care when working with the Covers (especially the top cover) open as light is admitted to the OPC area and can damage the OPC Drum.

-Take care not to scratch the green surface of OPC Drum Unit.

If the green surface of the Drum Cartridge is scratched or touched the print quality will be compromised.

Service Manual |

1-3 |

Samsung Electronics |

|

Precautions

1.2.5 Disregarding this warning may cause bodily injury

(1)Be careful with high temperature components.

The fuser unit works at a high temperature. Use caution when working on the product. Wait for the fuser to cool down before disassembly.

(2)Be careful when working around the rotating parts.

When operating a product, keep all bodily items and clothing away from moving parts [e.g. fingers, hair, tie, etc.] (Paper feeding entrance, motor, fan, etc.).

(3)When moving the product :

-When transporting/installing the equipment, employ four persons and be sure to hold the lifting handles.

-Be sure not to hold the movable parts or units (e.g. the control panel, DADF) when transporting the equipment.

-Be sure to use a dedicated outlet with 110V/220V power input.

-The equipment must be grounded for safety.

-Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

-Provide proper ventilation since the equipment emits a slight amount of ozone.

-The equipment must be installed near the socket outlet and must be accessible.

-Be sure to fix and plug in the power cable securely after the installation so that no one trips over it.

Service Manual |

1-4 |

Samsung Electronics |

|

Precautions

1.3 ESD precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly called “Electrostatically Sensitive (ES) Devices” or ESDs. Examples of typical ESDs are: integrated circuits,some field effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused by static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1.Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge on your body by touching a known earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface, such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the assembly.

3.Use only a grounded tip soldering iron to solder or desolder ESDs.

4.Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can generate electrical charges sufficient to damage ESDs.

5.Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to damage ESDs.

6.Do not remove a replacement ESD from its protective packaging until immediately before installing it.

Most replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a comparable conductive material.

7.Immediately before removing the protective shorting material from the leads of a replacement ESD, touch the protective material to the chassis or circuit assembly into which the device will be installed.

8.Maintain continuous electrical contact between the ESD and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9.Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the brushing together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to damage an ESD.

Service Manual |

1-5 |

Samsung Electronics |

|

Product spec and feature

2. Product spec and feature

2.1 Product Specifications

2.1.1 Product Overview

Item |

Descriptions |

|

Basic Model |

CLP-320/325 |

|

|

|

|

Series Model |

CLP-320N : Network Model |

|

|

CLP-325W : Wireless Model |

|

|

|

|

Main Specification |

1. Speed |

|

|

|

• Up to 16 ppm in A4 (17 ppm in Letter) |

|

|

• Up to 4 ppm in A4 (4 ppm in Letter) |

|

2. |

Printing Resolution |

|

|

• Max. 2400x600 dpi effective output |

|

3. |

Processor |

|

|

• Jupiter5 (360MHz,CLP-320/325/320N/325W) |

|

4. |

Printer Language Emulations |

|

|

• SPL-C (CLP-320/325/320N/325W), PCL-6 (320N/325W) |

|

5. |

Memory |

|

|

• FLASH ROM |

|

|

- 2MB : CLP-320/325 |

|

|

- 32MB : CLP-320N/325W |

|

|

• DDR2 SDRAM |

|

|

- 32MB : CLP-320/325 |

|

|

- 256MB : CLP-320N/325W |

|

|

• EEPROM memory |

|

|

- CLP-325 (8KB) |

|

|

- CLP-325W (64KB) |

|

|

- CLP-320N (32KB) |

|

6. |

Interfaces |

|

|

• One USB port (CLP-320/325/320N/325W) |

|

|

• One 10/100 Base T network connector (CLP-320N/325W) |

|

|

• One IEEE802.11b/g/n (CLP-325W) |

|

7. |

Control Panel |

|

|

• No LCD,3 keys ,7single LEDs and 1 dual LEDs |

|

8. Toner cartridge |

|

|

|

• Black : 1K (initial) / 1.5K (sales) |

|

|

• Color : 0.7K (initial) / 1K (sales) |

|

9. Color |

|

|

|

• There are two kinds of colors. (Gray and Black) |

|

|

|

Service Manual |

2-1 |

Samsung Electronics |

|

Product spec and feature

2.1.2 Prouduct Specification

Specifications are correct at the time of printing. Product specifications are subject to change without notice. See below for product specifications.

2.1.2.1 General Print Engine

Item |

|

CLP-320/325 |

CLP-320N/CLP-325W |

Print Speed |

Simplex |

B&W : 17ppm@Letter |

B&W : 17ppm@Letter |

|

|

|

|

|

|

16ppm@A4 |

16ppm@A4 |

|

|

|

|

|

|

Color : 4ppm@A4,.Letter |

Color : 4ppm@A4,.Letter |

|

|

|

|

|

Duplex |

NA |

NA |

|

|

|

|

Print Emulation |

|

SPL-C |

PCL-6 |

|

|

|

|

Auto Emulation Sensing |

NA |

NA |

|

|

|

|

|

Font |

Type |

NA |

NA |

|

Number |

NA |

NA |

|

|

|

|

Power Save |

|

Yes (5/10/15/30/60/120min.) |

Yes (5/10/15/30/60/120min.) |

|

|

|

|

Resolution |

Normal |

Up to 2400X600dpi Class |

Up to 2400X600dpi Class |

|

|

(Default 1200x600 dpi) |

(Default 1200x600 dpi) |

|

|

|

|

|

|

Optical: 600x600 Dpi |

Optical: 600x600 Dpi |

|

|

|

|

|

RET |

NA |

NA |

|

|

|

|

Toner Save |

|

NA |

NA |

|

|

|

|

FPOT |

From Ready |

Less than 26 sec ( Color ) |

Less than 26 sec ( Color ) |

|

|

|

|

|

|

Less than 14 sec ( B&W ) |

Less than 14 sec ( B&W ) |

|

|

|

|

|

From Idle |

Less than 57 sec ( Color ) |

Less than 57 sec ( Color ) |

|

|

Less than 45 sec (B&W) |

Less than 45 sec (B&W) |

|

|

|

|

|

From Cold Boot |

Less than 57 sec ( Color ) |

Less than 57 sec ( Color ) |

|

|

|

|

|

|

Less than 45 sec (B&W) |

Less than 45 sec (B&W) |

Duplex Print |

|

NA |

NA |

|

|

|

|

Printable Area |

|

210 x 297 mm (A4) |

210 x 297 mm (A4) |

|

|

|

|

|

|

216 x 279 mm (Letter) |

216 x 279 mm (Letter) |

|

|

|

|

|

|

216 x 355.6 mm (Legal) |

216 x 355.6 mm (Legal) |

|

|

|

|

Print Margin |

|

Side Margin: 4.23±2mm |

Side Margin: 4.23±2mm |

|

|

|

|

|

|

Top Margin: 4.23±3mm |

Top Margin: 4.23±3mm |

|

|

|

|

Service Manual |

2-2 |

Samsung Electronics |

|

Product spec and feature

2.1.2.2 Controller & S/W

Item |

CLP-320/325 |

CLP-320N/CLP-325W |

|

MPU |

Jupiter5 (360Mhz) |

Jupiter5 (360Mhz) |

|

|

|

|

|

Memory |

Standard / Max. |

256MB/256MB |

256MB/256MB |

|

|

|

|

|

Type |

DDR2 SDRAM (32MB) |

DDR2 SDRAM (256MB) |

|

|

|

|

|

Expand Memory Slot &Type |

NA |

NA |

|

|

|

|

|

Compression Technology |

YES |

YES |

|

|

|

|

Supporting OS |

Microsoft Windows: |

Microsoft Windows: |

|

|

|

2000/2003/XP(Include 64bit),Vista |

2000/2003/XP(Include 64bit),Vista |

|

|

MacOS:10.3 ~ 10.6 |

MacOS:10.3 ~ 10.6 |

|

|

Linux(Printer only)OS: |

Linux(Printer only)OS: |

|

|

Red Hat 8~9, Fedora Core 1~4 |

Red Hat 8~9, Fedora Core 1~4 |

|

|

Mandrake 9.2~10.1 |

Mandrake 9.2~10.1 |

|

|

SuSE 8.2~9.2 |

SuSE 8.2~9.2 |

|

|

|

|

Default Driver |

SPL-C |

SPL-C |

|

|

|

|

|

Driver feature |

Microsoft Windows: |

Microsoft Windows: |

|

|

|

-Watermark |

-Watermark |

|

|

-N-up printing |

-N-up printing |

|

|

-Poster printing |

-Poster printing |

|

|

-Manual Dulpex |

-Manual Dulpex |

|

|

-Quality(Best,Normal,Draft) |

-Quality(Best,Normal,Draft) |

|

|

-Color mode(Color, Gray scale) |

-Color mode(Color, Gray scale) |

|

|

-Device Color Support |

-Device Color Support |

|

|

-Color Management Support |

-Color Management Support |

|

|

[Mac] |

[Mac] |

|

|

-N-up printing |

-N-up printing |

|

|

-Quality(Best,Normal,Draft) |

-Quality(Best,Normal,Draft) |

|

|

-Color mode(Color, Gray scale) |

-Color mode(Color, Gray scale) |

|

|

[Linux] |

[Linux] |

|

|

- N-up printing |

- N-up printing |

|

|

-Quality(Best,Normal,Draft) |

-Quality(Best,Normal,Draft) |

|

|

[Common] |

[Common] |

|

|

-N/W Install |

-N/W Install |

|

|

during driver install |

during driver install |

|

|

|

|

WHQL |

Windows 2000 including vista |

Windows 2000 including vista |

|

|

|

|

|

Service Manual |

2-3 |

Samsung Electronics |

|

Product spec and feature

Item |

CLP-320/325 |

CLP-320N/CLP-325W |

Language Locallization |

[Windows] |

[Windows] |

|

- Korean,English,French,Germa |

- Korean,English,French,Germa |

|

N,Italian,Spanish,Russian,Dutch, |

N,Italian,Spanish,Russian,Dutch, |

|

E.Portuguese,B.Portuguese,Fi |

E.Portuguese,B.Portuguese,Fi |

|

Nish,Swedish,Norwegian,Danish |

Nish,Swedish,Norwegian,Danish |

|

S.Chinese,T.Chinese,Polish, |

S.Chinese,T.Chinese,Polish, |

|

Hungarian,Greek,Czech,Turkish |

Hungarian,Greek,Czech,Turkish |

|

[Mac] |

[Mac] |

|

- Korean,English,French,GermaN, |

- Korean,English,French,GermaN, |

|

Italian,Spanish, S.Chinese, |

Italian,Spanish, S.Chinese, |

|

T.Chinese, E.Portuguese, Dutch |

T.Chinese, E.Portuguese, Dutch |

|

[Linux] |

[Linux] |

|

- English Only |

- English Only |

|

|

|

Smart Panel |

USB |

320N : USB/Network |

|

|

325W : USB/Network/Wireless |

|

|

Network |

|

|

|

|

Default Install |

Default Install |

|

|

|

Network |

NA |

Set IP.SWAS &SWS (Linux, Mac |

Management |

|

not support, SWAS&SWS need I |

|

|

explorer 5.0 or Higher) |

|

|

NA Management |

|

|

|

Smart Thru |

NA |

Smart Thru 4 |

|

|

|

Service Manual |

2-4 |

Samsung Electronics |

|

Product spec and feature

2.1.2.3 Interface

Item |

|

CLP-320/325 |

CLP-320N/CLP-325W |

Interface |

Parallel |

NA |

NA |

|

|

|

|

|

USB |

USB 2.0 |

USB 2.0 |

|

|

|

|

|

Network |

NA |

Ethernet 10/100 base Tx |

|

|

|

|

|

Wireless |

NA |

802.11 b/g (only 325W) |

Network |

Protocol |

NA |

TCP/IP,IPP,SNMPv2 |

Interface |

|

|

|

Network OS |

NA |

- Microsoft Windows: |

|

|

|

|

98/ME/2000/XP(32/64Bit) |

|

|

|

2003 Server(32/64Bit)/ Vista |

|

|

|

- Mac OS: 10.3,10.4(Printing |

|

|

|

OnTCP/IP) |

|

|

|

- Linux OS: Red Hat 8~9, |

|

|

|

Fedora Core 1~4 |

|

|

|

Mandrake 9.2~10.1 & Suse |

|

|

|

8.2~9.2 |

|

|

|

- Unix HP-UX, Solaris,SunOS |

|

|

|

SCO UNIX |

|

|

|

|

User |

LCD |

NA |

NA |

Interface |

|

|

|

OP UI |

Key 3 EA, LED 8EA |

Key 3 EA, LED 8EA |

|

|

|

|

|

|

Sound UI |

NA |

NA |

|

|

|

|

Service Manual |

2-5 |

Samsung Electronics |

|

Product spec and feature

2.1.2.4 Paper Handling

Item |

|

CLP-320/325 |

CLP-320N/CLP-325W |

Capacity |

Cassette |

130 Sheets @ 80 g/ |

130 Sheets @ 80 g/ |

|

|

Envelop : 5 Sheets |

Envelop : 5 Sheets |

|

|

Transparency : 1 Sheets |

Transparency : 1 Sheets |

|

|

Label, thick paper : 5 Sheets |

Label, thick paper : 5 Sheets |

|

|

GlossyPhoto220 g/ : 1 Sheets |

GlossyPhoto220 g/ : 1 Sheets |

|

|

|

|

|

MP Tray |

NA |

NA |

|

|

|

|

|

Option Cassette |

80 Sheets @ 80 g/ |

80 Sheets @ 80 g/ |

|

|

Envelop : 5 Sheets |

Envelop : 5 Sheets |

|

|

Transparency : 1 Sheets |

Transparency : 1 Sheets |

|

|

Label , thick paper : 5 Sheets |

Label , thick paper : 5 Sheets |

|

|

GlossyPhoto220 g/ : 1 Sheets |

GlossyPhoto220 g/ : 1 Sheets |

|

|

|

|

Output Capacity |

|

Face Down: 100Sheets/20lb |

Face Down: 100Sheets/20lb |

|

|

Envelop ; 5 Sheets |

Envelop ; 5 Sheets |

|

|

Transparency ; 1 Sheets |

Transparency ; 1 Sheets |

|

|

Label , thick paper ; 10 Sheets |

Label , thick paper ; 10 Sheets |

|

|

|

|

Output Full Sensing |

No |

No |

|

|

|

|

|

Duplex |

|

Manual Duplex |

Manual Duplex |

|

|

|

|

Paper Type |

Cassette |

A4, A5,A6, Letter, Legal, |

A4, A5,A6, Letter, Legal, |

|

|

Executive, Folio, ISO B5, JIS B5 |

Executive, Folio, ISO B5, JIS B5 |

|

|

|

|

|

|

Transparency;(Mono Print Only) |

Transparency;(Mono Print Only) |

|

|

|

|

|

MP Tray |

NA |

NA |

|

|

|

|

|

Option Tray |

NA |

NA |

|

|

|

|

Paper Weight |

Cassette |

16~43 lb. (60 to 163g/ ) |

16~43 lb. (60 to 163g/ ) |

|

|

|

|

Paper Path |

Standard output |

Bottom to Top Front (FIFO) |

Bottom to Top Front (FIFO) |

|

|

|

|

|

Straight Through |

NA |

NA |

|

|

|

|

Paper Size |

Max |

216 x 355.6mm(8.5”x14”) |

216 x 355.6mm(8.5”x14”) |

|

|

|

|

|

Min |

76 x 160mm(3”x6.3”) |

76 x 160mm(3”x6.3”) |

|

|

|

|

Jam Rate |

Cassette |

1/3,000 |

1/3,000 |

|

|

|

|

Multi-Feed Rate |

Cassette |

1/1,500 |

1/1,500 |

|

|

|

|

Printing Skew |

Top |

1.5/201.4mm (Cassette) |

1.5/201.4mm (Cassette) |

|

|

|

|

|

Side |

2.0/270.4mm (Cassette) |

2.0/270.4mm (Cassette) |

|

|

|

|

Service Manual |

2-6 |

Samsung Electronics |

|

Product spec and feature

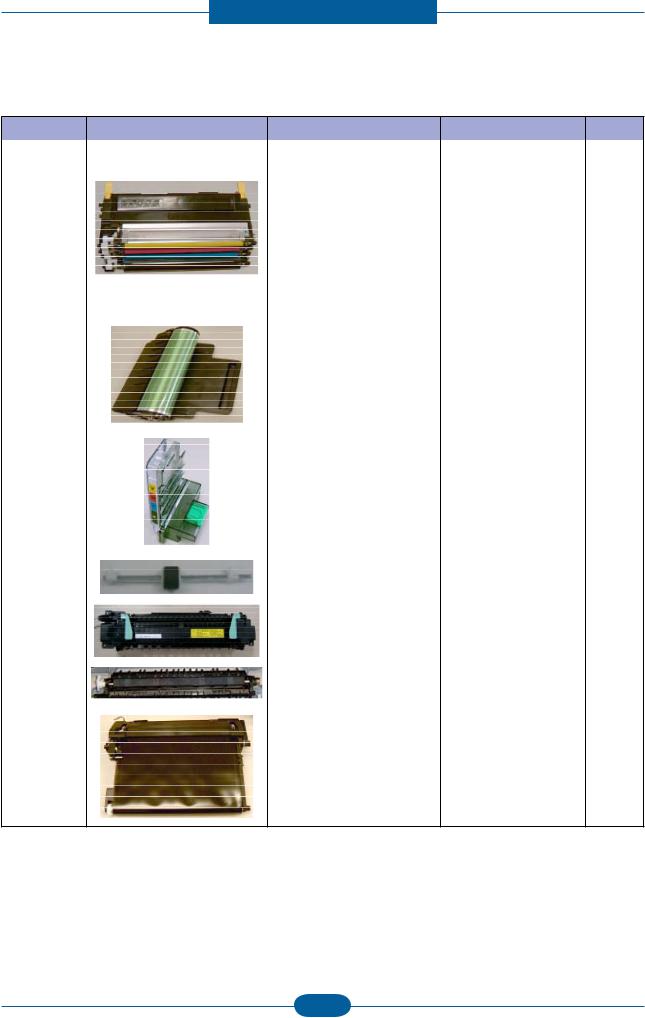

2.1.2.5 Consumables

Item |

Image |

Pages Printed |

Part number |

Remark |

Black Toner |

|

Approx. Initial : 1,000 Pages* |

CLT-K407S, |

CRU |

cartridge |

|

Sales : 1,500 Pages* |

CLT-K4072S (Black) |

|

|

|

|

|

|

Color Toner |

|

Approx. Initial : 700 Pages* |

CLT-C407S, |

|

cartridge |

|

Sales : 1,000 Pages* |

CLT-C4072S (Cyan) |

|

|

|

|

CLT-M407S, |

|

|

|

|

CLT-M4072S (Magenta) |

|

|

|

|

CLT-Y407S, |

|

|

|

|

CLT-Y4072S (Yellow) |

|

|

|

|

|

|

Imagine unit |

|

Approx. 24000 images* |

CLT-R407 |

|

|

|

|

|

|

Waste Toner |

|

Approx. 10,000 images |

CLT-W409 |

|

|

|

|

|

|

Pick-up roller |

|

Approx. 50,000 pages |

JC97-03028A |

FRU |

|

|

|

|

|

Fuser unit |

|

Approx. 50,000 pages(B&W) |

JC91-00978A(220V) |

|

|

|

/ 12,500 pages (Color) |

JC91-00997A(110V) |

|

|

|

|

|

|

T2 roller |

|

Approx. 50,000 pages(B&W) |

JC95-01197A |

|

|

|

/ 12,500 pages (Color) |

|

|

|

|

|

|

|

ITB |

|

Approx. 50,000 pages(B&W) |

JC96-05874A |

|

/12,500 pages (Color)

* Average A4-/letter-sized page count based on Std. ISO 19798 of individual colors on each page. Usage conditions and print patterns may cause results to vary.

Service Manual |

2-7 |

Samsung Electronics |

|

Product spec and feature

2.1.2.6 Reliability & Service

Item |

CLP-320/325 |

CLP-320N/CLP-325W |

Max Monthly Duty |

20,000 image |

20,000 image |

|

(Color: 16,000/ Mono: 4,000) |

(Color: 16,000/ Mono: 4,000) |

|

|

|

SET Life Cycle |

100,000image or 5 years |

100,000image or 5 years |

|

whichever comes first |

whichever comes first |

|

|

|

MTBF |

40,000 images |

40,000 images |

|

(color 32,000 images and black |

(color 32,000 images and black |

|

8,000 images : total 40,000 |

8,000 images : total 40,000 image) |

|

image) |

|

|

|

|

MTTR |

<30 min. |

<30 min. |

|

|

|

Real-time Clock |

No |

No |

|

|

|

System record |

Total image count |

Total image count |

|

Total page count (color/mono) |

Total page count (color/mono) |

|

Imaging unit Information |

Imaging unit Information |

|

Transfer roller life |

Transfer roller life |

|

Transfer belt life |

Transfer belt life |

|

Toner information |

Toner information |

|

Tray roller life |

Tray roller life |

|

|

|

Minimum System Requirement |

Pentium400MHZ, 64MB RAM, |

Pentium400MHZ, 64MB RAM, |

|

300MB HDD, Internet Explorer 5.0 |

300MB HDD, Internet Explorer 5.0 |

|

|

|

Service Manual |

2-8 |

Samsung Electronics |

|

Product spec and feature

2.1.2.7 Environment

Item |

|

CLP-320/325 |

CLP-320N/CLP-325W |

Power |

Ready |

Less than 160W |

Less than 160W |

Consumption |

|

|

|

Average |

Less than 350W |

Less than 350W |

|

|

|

(Currency:5A(110V)/3A(220V) |

(Currency:5A(110V)/3A(220V) |

|

|

|

|

|

Max/Peak |

700W/1KW |

700W/1KW |

|

|

|

|

|

Sleep/Power off |

Less than 5W/0.45W |

Less than 8W/0.45W (325W) |

|

|

|

Less than 6W (320N) |

|

|

|

|

Power Supply |

Input Voltage |

AC 110V~127V, AC 220V~240V |

AC 110V~127V, AC 220V~240V |

|

|

AC 120V/AC 220V(EXP version) |

AC 120V/AC 220V(EXP version) |

|

|

|

|

|

Input Frequency |

50 / 60Hz(+/- 3Hz) |

50 / 60Hz(+/- 3Hz) |

|

|

|

|

Noise |

Printing |

Mono : 46dBA |

Mono : 46dBA |

|

|

Color : 48dBA |

Color : 48dBA |

|

|

|

|

|

Standby |

Background noise level |

Background noise level |

|

|

|

|

|

Sleep |

Background noise level |

Background noise level |

|

|

|

|

Warm Up Time |

From Cold Status |

Less than 35 seconds |

Less than 35 seconds |

|

(At rated volt) |

|

|

|

|

|

|

Temperature |

Operating |

10~32.5 |

10~32.5 |

|

|

|

|

|

Storage (Un-Packed) |

5~35 |

5~35 |

|

|

|

|

|

Storage (Packed) |

-20~50 |

-20~50 |

|

|

|

|

Humidity |

Operating |

20 ~ 80% RH |

20 ~ 80% RH |

|

|

|

|

|

Storage (Un-Packed) |

20 ~ 80% RH |

20 ~ 80% RH |

|

|

|

|

|

Storage (Packed) |

10~90% RH |

10~90% RH |

|

|

|

|

Altitude |

|

Normal: 0~3000ft (0~1000m) |

Normal: 0~3000ft (0~1000m) |

|

|

|

|

|

|

High: 3001~6600ft( ~2000m) |

High: 3001~6600ft( ~2000m) |

|

|

|

|

|

|

Higher: 6601~9900ft( ~3000m) |

Higher: 6601~9900ft( ~3000m) |

|

|

|

|

|

|

Highest;9901~13000ft( ~4000m) |

Highest;9901~13000ft( ~4000m) |

|

|

|

|

2.1.2.8 Accessory

Item |

|

CLP-320/325 |

CLP-320N/CLP-325W |

|

Quick setup guide |

Yes |

Yes |

||

|

|

|

|

|

Owner’s manual |

Yes |

Yes |

||

|

|

|

|

|

S/W CD ROM |

1 : for Driver |

1 |

: for Driver |

|

|

|

|

|

|

|

|

|

2 |

: for Network |

|

|

|

|

|

S/W |

1 CD for Driver, SmarThru 4 |

1 CD for Driver, SmartThru 4, EUG |

1 CD for Driver, SmartThru 4, EUG |

|

|

|

|

|

|

Toner Cartridge |

4 EA (0.7K/0.5K yield ISO 19752 |

4 |

EA (0.7K/0.5K yield ISO 19752 |

|

|

|

5% Coverage) |

5% Coverage) |

|

|

|

|

||

Power Cable |

1 EA |

1 EA |

||

|

|

|

|

|

Printer Cable |

1 EA |

1 |

EA |

|

|

|

|

|

|

Service Manual |

2-9 |

Samsung Electronics |

|

Product spec and feature

2.1.3 Model Comparison Table

Samsung |

Samsung |

HP |

CLP-325/325W |

CLP-315/315W |

CP-1215 |

Image

Print speed (M/C) |

16/4ppm |

16/4ppm |

12/8ppm |

|

|

|

|

|

|

FPOT |

14/26 sec |

14/26 sec |

24/30 sec |

|

|

|

|

|

|

Resolution |

Up to 2400 dpi |

Up to 2400 dpi |

2400 HP ImageREt |

|

|

|

|

|

|

CPU |

375 MHz |

375 MHz |

264 MHz |

|

|

|

|

|

|

Std Memory |

32 MB (256 MB) |

32 MB |

16 MB (16MB) |

|

|

|

|

|

|

Emulation |

PCL6(325W), SPL-C |

SPL-C |

GDI |

|

|

|

|

|

|

Duplex |

Manual |

Manual |

Manual |

|

|

|

|

|

|

Paper Handling |

130 CST |

150 CST |

150 CST |

|

|

|

|

|

|

Output |

80 sheet |

80 sheet |

125 |

|

|

|

|

|

|

Noise |

45dB/ 47dB |

45dB/ 47dB |

47dB |

|

(Color/Black) |

(Color/Black) |

|||

|

|

|||

|

|

|

|

|

Max. Monthly Duty |

20,000 |

20,000 |

25,000 |

|

|

|

|

|

|

Size |

388 x 313 x 243 |

388 x 314 x 237 |

398.7 x 452 x 253 |

|

|

|

|

|

|

Weight |

11kg (TBD) |

11kg |

17.6 kg |

|

|

|

|

|

|

Interface |

USB 2.0, Wireless(325W) |

USB 2.0, Wireless(315W) |

USB 2.0 |

|

|

|

|

|

|

Toner |

1.5K/1K (1K/0.7K) |

1.5K/1K (1K/0.7K) |

2.2K/1.4K(0.75K) |

|

|

|

|

|

|

|

1W Soft Power |

|

|

|

Etc |

Print Screen Button (325) |

|

9 LED |

|

DLNA Printing (325W) |

|

|||

|

|

|

||

|

WPS Button (325W) |

|

|

Service Manual |

2-10 |

Samsung Electronics |

|

Product spec and feature

2.2 System Overview

This chapter describes the functions and operating principles of the main components.

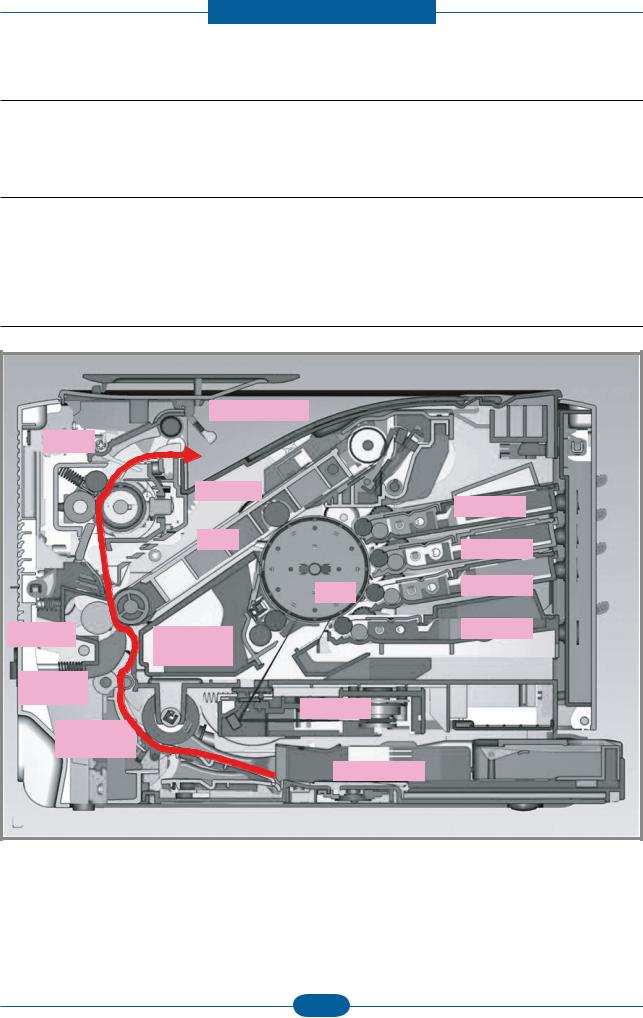

2.2.1 System Structure

The Printer function consists of the Engine part and the Main Controller part, and the Engine part consists of the Mechanical part comprising a Frame, Feeding, Developing, Driving, Transferring, Fusing, and Cabinet and the Electrical part comprising a SMPS, a HVPS, a LSU, and some facilities in the Main Controller to control the Engine part for printing.

2.2.1.1 Main Parts of System

Stacking Area

Fuser |

|

|

|

|

DEVE Y |

|

|

DEVE M |

|

OPC |

DEVE C |

|

|

|

T2 Roller |

|

DEVE K |

|

|

Regi.

Roller

LSU

Pick

Cassette

Service Manual |

2-11 |

Samsung Electronics |

|

Product spec and feature

Cassette

•Feeding Method : Cassette Type

•Feeding Standard : Center Loading

•Feeding Capacity : Cassette 150 Sheets(75g/ , 20lb Pa per Standard)

•No Manual Feeder

•Paper Detecting Sensor : Photo Sensor (Empty, Registration, Exit)

•Paper Size Sensor : None

LSU(Laser Scan Unit)

The LSU unit is controlled by video controller. It scans the video data received from video controller with laser beam by using the rotation principle of the polygon mirror to create the latent image on the OPC drum. It is the core part of LBP.

The OPC drum rotates as the same speed as the paper feeding speed. It creates the /HSYNC signal and sends it to the engine when the laser beam of the LSU reaches the end of the polygon mirror, and the engine detects the /HSYNC signal to arrange the vertical line of the image on the paper. After detecting the /HSYNC signal, the image data is sent to the LSU to arrange the its margin on the paper.

•Consisted of LD(Laser Diode) and Polygon Motor Control.

Error |

Phenomenon |

||

Polygon Motor Error |

The Rotation of Polygon Motor can not reach stable |

||

|

|

|

|

Hsync Error |

Though the rotation of Polygon Motor reach stable, the signal of Hsync is |

||

|

|

not occurred |

|

|

|

|

|

|

|

|

|

Service Manual |

2-12 |

Samsung Electronics |

|

Product spec and feature

2nd Transfer Ass’y

•The life span: Print over 100,000 sheets (in 15~30 )

•Specification: Similar to CLP-300 Series

Fuser Ass’y

This unit consists of Heat Roller, a Thermostat and a Thermistor. It melts and fuses the toner, transferred by the transfer roller onto the paper, by applying pressure and high temperature to complete printing job.

* Heat Lamp : Kunckle Type

*Fusing system : 3-Roll Fusing type

-Heat roller : Pipe type (Lamp inside)

-Pressure roller

-Pressure roller Shaft

*Thermistor - Temperature-Measuring Device

*Thermostat - Critical Temperature-Detecting Device

*The life span – 100k(black)/color(25k)

Thermostat

When a heat lamp is overheated, a Thermostat cuts off the main power to prevent over-heating. - Non-Cotact type Thermostat

Heat roller

The heat roller transfers the heat from the lamp to apply a heat on the paper. The surface of a heat roller is coated with Teflon, so toner does not stick to the surface.

Pressure roller

A pressure roller mounted under a heat roller is made of a silicon resin, and the surface also is coated with Teflon. When a paper passes between a heat roller and a pressure roller, toner adheres to the surface of a paper permanently.

Service Manual |

2-13 |

Samsung Electronics |

|

Product spec and feature

& ITB(Intermediate Transfer Belt) & 1st Transfer Roller

•The life span: Print over Approx. 50,000 pages(B&W) / 12,500 pages (Color)

•The ITB unit includes 1st Transfer Roller

& OPC(Organic Photo-Conductor) & Developer

•The life span: Print over 50,000 Images (Both)

•Imagine Unit consists of 4 kinds of Developer , OPC, and Deve. Main Frame

Toner Kits

•The life span: Color -> 1000 images (Std. ISO 19798 Print-Out) Black -> 1500 images (Std. ISO 19798 Print-Out)

Driver Ass’y

•It is a power delivery unit by gearing

•By driving the motor, it supplies the power to the feeding unit, the fusing unit, and the distributing unit.

•The Main Motor is similar to CLP-310 Series Main Motor.

Wireless PBA (Only CLP-325W)

•CLP-325W model has a Wireless PBA to use wireless network.

Service Manual |

2-14 |

Samsung Electronics |

|

Product spec and feature

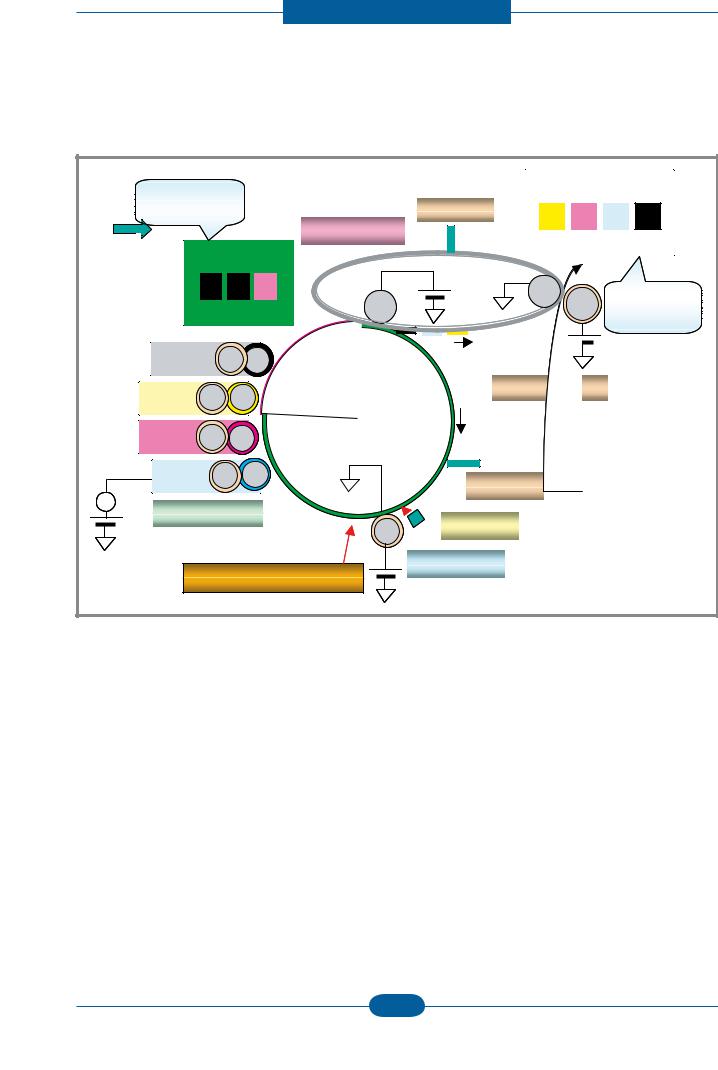

2.2.1.2 EP Process

- Structure of EP Process

|

P1: Image |

Blade |

|

on OPC |

|

|

ITB Unit |

|

|

|

P2: Image |

|

|

on Media |

|

|

Media Path |

|

OPC |

|

~ |

|

Blade |

Developer |

|

|

|

Eraser |

|

|

|

|

|

Laser Scanning Unit |

Charger |

|

|

Service Manual |

2-15 |

Samsung Electronics |

|

Product spec and feature

Charging

•Conductive Roller charging

•Applied voltage : -1.1kV

•Charge acceptance : -520V

•OPC coating thickness : 21um

•OPC diameter : Φ60mm

•Eraser system

1.Organic Photoconductor is charged to uniform voltage by conductive roll charging method

2.No ozone is produced because corona is not used

3.Charger roll is cleaned with cleaning roll

4.Toner remained on OPC after T1 process is cleaned by cleaning blade and retrieved into waste toner box by auger and belt driving mechanism

Exposing

•One polygon motor ( 6 facet )

•Single beam LD (1ea)

•LD wavelength : 785nm

•Polygon motor rpm : 29685

•LSU energy : 0.25uJ/cm^2

•OPC exposed potential : -50V

1.Exposing is implemented by laser striking on to OPC with uniform potential

2.Laser beam is modulated according to image to be printed that is from PC

3.Latent Image is formed on OPC, which is developed with toner

Developing

•Non-magnetic, mono component

•Non-contact development

•Developing bias : DC + AC

•AC peak to peak : 1.5 ~ 2.0kV

•Roller diameter : Φ10mm

•Process speed ratio : 1.2 (OPC=1.0)

•Color order : Y -> M -> C -> K

1.Only latent image formed by exposing process is developed with toner

2.AC + DC Voltage is being used to develop toner into latent image on OPC because non-contact developing method is adopted

3.Y, M, C, and K Images are sequentially developed onto OPC and transferred onto Intermediate Transfer Belt (hereafter ITB) to form a color image on ITB

4.Toner Bottles are used to supply toner into developer compartment

5.Toner level is being sensed to control toner supply from toner bottle to developer

Service Manual |

2-16 |

Samsung Electronics |

|

Product spec and feature

Transfer 1

•Multi-pass transfer

•Indirect transfer

•Transfer voltage : 0.5 ~ 2.0kV (controllable)

•Roller diameter : Φ14mm

•Transfer unit life : 100K images

1.Developed Image on OPC is transferred onto ITB by T1 Process

2.T1 Voltage is positive which attract toner to ITB

3.4 times of T1 process is required to make a color image on ITB, which means multi-pass process

4.ITB has a hole as a fiducial mark for timing. Engine control for color image is synchronous with it, ITB Home Sensing Signal

Transfer 2

•Indirect transfer

•Transfer voltage : 1 ~ 4.0kV (controllable)

•Roller diameter : Φ18.6mm

•Transfer unit life : 100 K images

1.Color image formed on ITB is transferred onto media by T2 process

2.T2 voltage is also positive to get color image moved onto media

3.Toner remained on ITB after T2 process is cleaning by ITB cleaning blade and collected and

4.Transported and retrieved into waste toner box by auger and belt driving system

5.T2 Roll is engaged when color image is being transferred onto media. Otherwise it is disengaged. Clutch is used for driving T2 Roll engagement and disengagement

Fusing

•3 Roll system

-> short warm-up time (35sec)

•Post Pressure Roll

1. Color Image on media is melted down and fixed into media by fusing process

Service Manual |

2-17 |

Samsung Electronics |

|

Product spec and feature

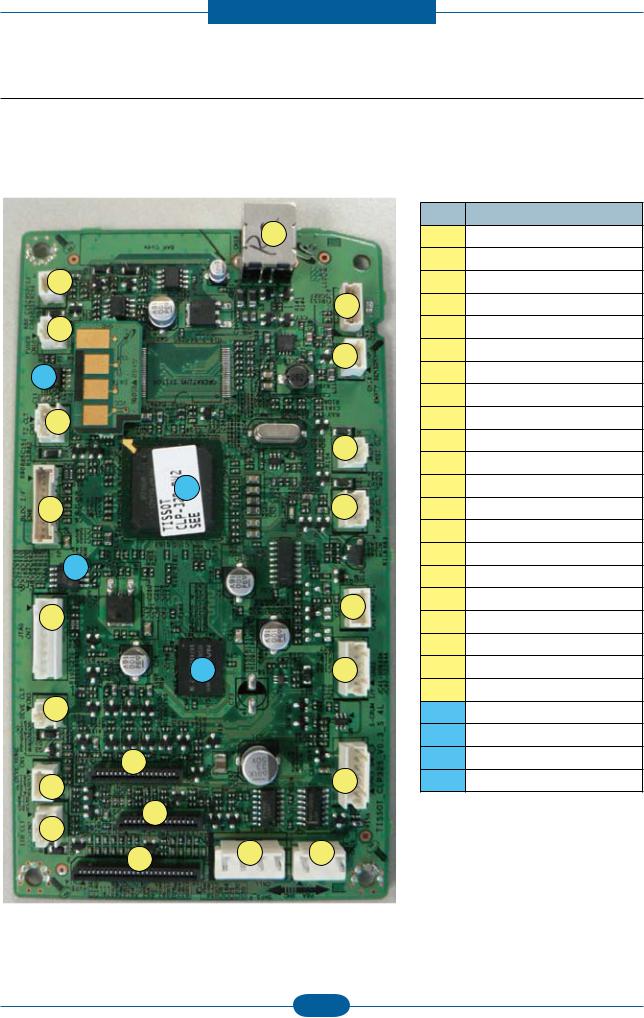

2.2.2 Main PBA Description

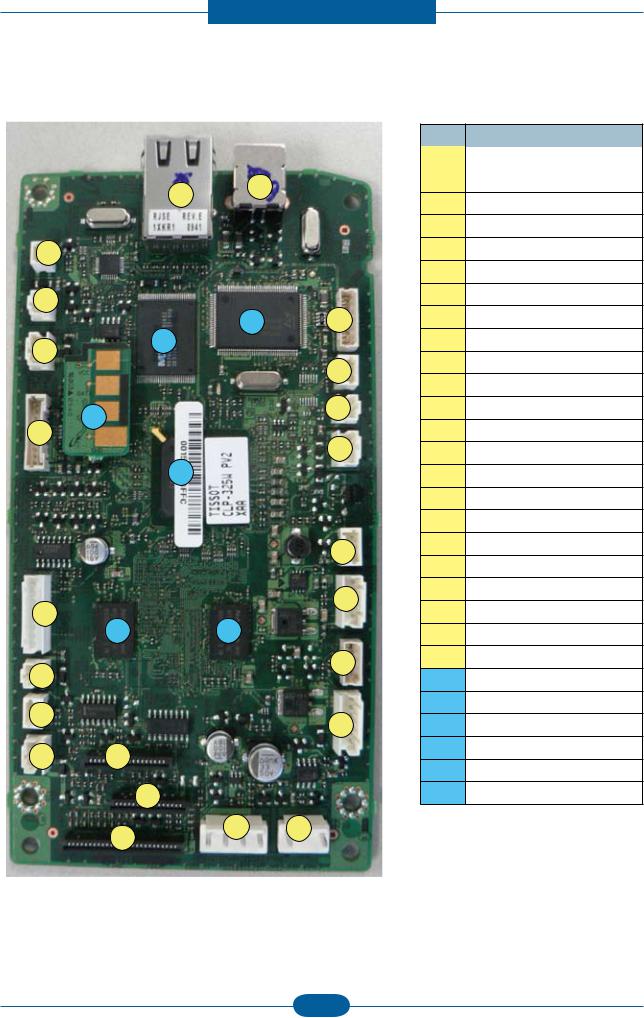

2.2.2.1 Main Controller PBA

- CLP-320/325

19

9

4

10

16

D

5

|

|

8 |

6 |

A |

20 |

|

||

C |

|

|

7 |

|

17 |

|

|

|

|

B |

22 |

3 |

|

|

13 |

|

23 |

1 |

|

|

|

|

|

15 |

|

|

2 |

|

|

14 |

11 |

18 |

|

|

NO. NAME

1Deve home CON.(3P)

2ITB CLT(3P)

3Deve CLT(2P)

4 Debug(4P)

5 T2 CLT(3P)

7 BLDC I/F(10P)

8JTAG (8P)

9 Regi CLT.(2P)

10 Fuser CLT(2P)

12Fuser(2P)

13SMPS_P(4P)

14OPE & ITB (18P)

15HVPS(26P)

16LSU Con.(16P)

17Empty Sensor (3P)

18Key PTL(4P)

19Cover OPEN (2P)

20USB (4P)

21Pickup CLT. (3P)

22S-CRUM I/F (5P)

23SMPS_S (6P)

A CPU(Jupiter5)

BDDR2 (32MB)

CSerial FLASH(2MB) D EEPROM

Service Manual |

2-18 |

Samsung Electronics |

|

Product spec and feature

- CLP-320N/325W

4 15

24

10

F 3

18 E

16

27

D 19

26

A

|

|

|

29 |

8 |

|

|

5 |

B |

B |

|

|

|

|

||

20 |

|

|

6 |

|

|

|

|

12 |

|

|

9 |

|

|

|

|

22 |

1 |

|

|

|

|

7 |

|

|

28 |

11 |

30 |

|

|

|

NO. |

NAME |

|

|

1 |

OPE & ITB (18P) |

|

|

3 |

W-LAN (6P) (W Only) |

4Ethernet (8P)

5 S-CRUM I/F (5P)

6Debug(4P)

7 LSU Con.(16P)

8JTAG (8P)

9 SMPS_S (6P)

10Fuser(2P)

11SMPS_P(4P)

12Deve home CON.(3P)

15USB (4P)

16Empty (3P)

18T2 CLT(3P)

19Regi CLT.(2P)

20Deve CLT(2P)

22ITB CLT(3P)

24Fuser CLT(2P)

26Pickup CLT. (3P)

27BLDC I/F(10P)

28HVPS(26P)

29Key PTL(4P)

30Cover OPEN (2P)

ACPU(Jupiter5)

BDDR2 (64MB X 2)

CNor FLASH(32MB)

D EEPROM (Under PBA)

E PHY Chip

FUSB IC(W Only)

Service Manual |

2-19 |

Samsung Electronics |

|

Product spec and feature

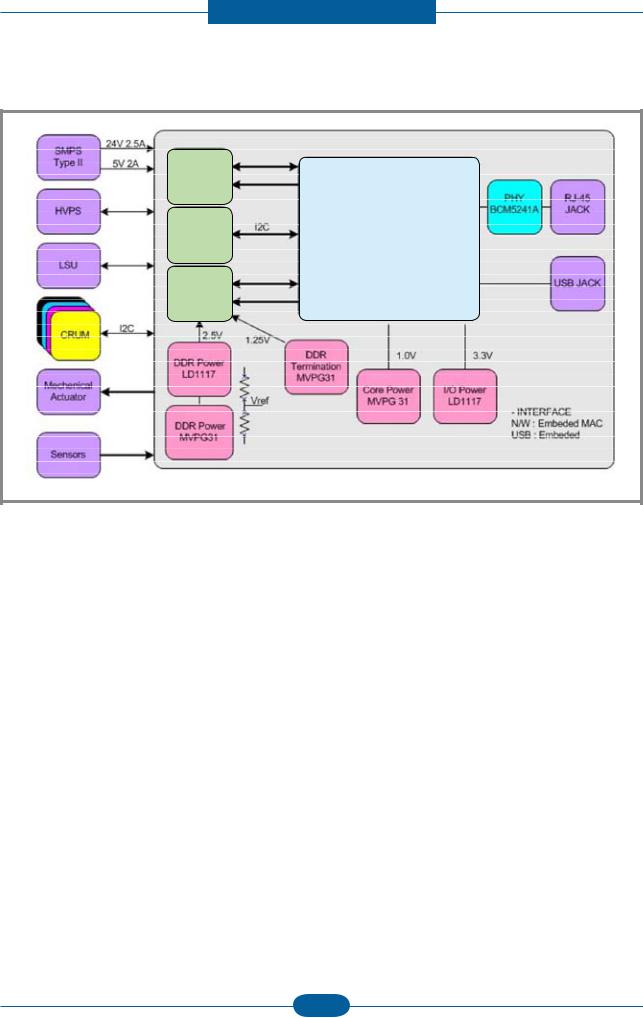

2.2.2.3 Main PBA Description

FLASH

CPU

EEPROM

24C64 Jupiter5(360MHz)

DDR2 SDRAM

Jupiter5

A Proprietary SoC, Jupiter5, executes and controls all jobs and functions to be required for printing. To do these all jobs, the Jupiter5 incorporates all H/W blocks as follows.

▪CPU Core ARM 926ESJ, I/D-Cache 16/16KB , Up to 400MHz

▪System Bus Internally 32-bit width, Up to 120MHz

▪MEM Controller DDR1/2, 16-bit width, 166MHz, 4-Bank, 128MB Space/bank

▪ROM Controller 16-bit width, 4-bank, 16MB Space/bank

▪CODEC Controller JBIG 4-ch Decoder and 2-ch Encoder, 1-ch JPEG

▪Image Processor Processing Scan Image

▪MAC Controller 10/100Mbps Full IEEE 802.3 Compatibility

▪USB Controller USB2.0, Device or Host

▪UART Controller

▪I2C Controller

▪Interrupt Controller

▪Misc. Controller ADC, DAC, PWM, Step Motor Control and so on

▪Voltage Core 1.0V, I/O 3.3V

▪Package 416PBGA

Flash Memory

Used to store System Programs including the Operating System.

▪Type NOR Flash

▪Bus 16-bit width

▪Size : 2MB (CLP-320/325) 32MB (CLP-320N/325W)

Service Manual |

2-20 |

Samsung Electronics |

|

Product spec and feature

System Memory

Used as a Printing buffer for printing, a Scan buffer for scanning, a ECM Buffer for System Working Area.

▪Type DDR2 SDRAM

▪Bus 16-bit 166MHz

▪Size 32MB (320/325) / 256MB(320N/325W)

CRU Control

Used to store the printing and operating information into a Security EEPROM in 4 CRUs, Y,M,C and K Imaging Cartridge, respectively by the CHORUS3.

▪Access I2C Bus Ch.2 400KHz

▪Security Size 2K-bit

System Information Control

Used to store the system operating information needed at printing into a EEPROM in the Main Controller by the CHORUS3.

▪Access I2C Bus Ch.1 400KHz

▪EEPROM Size 64Kbit

OPE Interface

Used to control the OPE by the CHORUS3. Through CHORUS3’s GPIO pins, all LEDs and Keys in the OPE are controlled.

I/O Port

Used to receive or transmit some data from/to the Host.

▪USB Device USB2.0 High speed 480Mbps

▪Network Ethernet 10/100-Base Tx

(note) The Network only equipped at CLP-320N/325N, not CLP-320/325.

Engine Control

Used to control all parts to be required at printing by the CHORUS 3. ▪ Sensors Paper Empty

Paper Registration

Waste Toner Bottle Paper Exit

|

Temperature sensors |

|

Etc. |

▪ Clutches(Solenoid) Paper Pick Up |

|

|

Paper Registration |

|

Etc. |

▪ Motor |

1 BLDC |

▪ LSU |

|

▪ Fuser |

Control the Fuser’s temperature |

▪ HVPS |

Control the high voltage outputs |

▪ ADC |

Reading the Fuser’s temperature and the high voltage outputs’ feedback |

▪ Cover Open Sensing

Service Manual |

2-21 |

Samsung Electronics |

|

Loading...

Loading...