Mitsubishi Electronics FR-E710W, FR-E700, FR-E740, FR-E720S, FR-E720 User Manual

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INVERTER |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

||||||||||

FR-E700 |

|

|

|

||||||||||||

INSTRUCTION MANUAL (BASIC) |

|

|

|

||||||||||||

1 |

|||||||||||||||

FR-E720-0.1K to 15K |

|

|

|

|

|||||||||||

FR-E740-0.4K to 15K |

|

|

|

||||||||||||

FR-E720S-0.1K to 2.2K |

2 |

||||||||||||||

FR-E710W-0.1K to 0.75K |

|

|

|

|

|||||||||||

|

|

|

|

||||||||||||

|

|

|

|

|

|

||||||||||

Thank you for choosing this Mitsubishi Inverter. |

3 |

||||||||||||||

This Instruction Manual (Basic) provides handling information and precautions for use of the equipment. |

|||||||||||||||

Please forward this Instruction Manual (Basic) to the end user. |

|

|

|

||||||||||||

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

CONTENTS |

|

OUTLINE ................................................................................... |

1 |

INSTALLATION AND WIRING ................................................... |

6 |

PRECAUTIONS FOR USE OF THE INVERTER......................... |

18 |

FAILSAFE OF THE SYSTEM WHICH USES THE INVERTER ... |

20 |

DRIVING THE MOTOR............................................................. |

21 |

ENERGY SAVING OPERATION FOR FANS AND PUMPS ........ |

31 |

PARAMETERS ......................................................................... |

32 |

TROUBLESHOOTING .............................................................. |

37 |

PRECAUTIONS FOR MAINTENANCE AND INSPECTION ........ |

42 |

SPECIFICATIONS.................................................................... |

44 |

(Applied) |

|

To obtain the Instruction Manual700 |

|

Contact where you purchased the inverter, your Mitsubishi sales representative, or the nearest Mitsubishi FA Center for the following manual:

y Instruction Manual (Applied) [IB(NA)-0600277ENG]

This manual is required if you are going to utilize functions and performance.

The PDF version of this manual is also available for download at "MELFANS Web," the Mitsubishi Electric FA network service on the world wide web (URL: http://www.MitsubishiElectric.co.jp/melfansweb).

4

4

5

5

6

6

7

7

8

8

9

9

10

This Instruction Manual (Basic) provides handling information and precautions for use of the equipment. Please forward this Instruction Manual (Basic) to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read through the Instruction Manual (Basic) and appended documents carefully and can use the equipment correctly. Do not use this product until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual (Basic), the safety instruction levels are classified into "WARNING" and "CAUTION".

Incorrect handling may cause  WARNING hazardous conditions, resulting in

WARNING hazardous conditions, resulting in

death or severe injury.

CAUTION |

Incorrect handling may cause |

hazardous conditions, resulting in |

|

|

medium or slight injury, or may cause |

|

only material damage. |

The CAUTION |

level may even lead to a serious |

consequence according to conditions. Both instruction levels must be followed because these are important to personal safety.

1. Electric Shock Prevention

WARNING

WARNING

zWhile power is ON or when the inverter is running, do not open the front cover. Otherwise you may get an electric shock.

zDo not run the inverter with the front cover or wiring cover removed. Otherwise you may access the exposed highvoltage terminals or the charging part of the circuitry and get an electric shock.

zEven if power is OFF, do not remove the front cover except for wiring or periodic inspection. You may accidentally touch the charged inverter circuits and get an electric shock.

zBefore wiring or inspection, power must be switched OFF. To confirm that, LED indication of the operation panel must be checked. (It must be OFF.) Any person who is involved in wiring or inspection shall wait for at least 10 minutes after the power supply has been switched OFF and check that there are no residual voltage using a tester or the like. The capacitor is charged with high voltage for some time after power OFF, and it is dangerous.

zThis inverter must be earthed (grounded). Earthing (grounding) must conform to the requirements of national and local safety regulations and electrical code (NEC section 250, IEC 536 class 1 and other applicable standards).

A neutral-point earthed (grounded) power supply for 400V class inverter in compliance with EN standard must be used.

zAny person who is involved in wiring or inspection of this equipment shall be fully competent to do the work.

zThe inverter must be installed before wiring. Otherwise you may get an electric shock or be injured.

zSetting dial and key operations must be performed with dry hands to prevent an electric shock.

zDo not subject the cables to scratches, excessive stress, heavy loads or pinching. Otherwise you may get an electric shock.

zDo not change the cooling fan while power is ON. It is dangerous to change the cooling fan while power is ON.

zDo not touch the printed circuit board or handle the cables with wet hands. Otherwise you may get an electric shock.

zWhen measuring the main circuit capacitor capacity, the DC voltage is applied to the motor for 1s at powering OFF. Never touch the motor terminal, etc. right after powering OFF to prevent an electric shock.

2. Fire Prevention

CAUTION

CAUTION

zInverter must be installed on a nonflammable wall without holes (so that nobody touches the inverter heatsink on the rear side, etc.). Mounting it to or near flammable material can cause a fire.

zIf the inverter has become faulty, the inverter power must be switched OFF. A continuous flow of large current could cause a fire.

zWhen using a brake resistor, a sequence that will turn OFF power when a fault signal is output must be configured. Otherwise the brake resistor may overheat due to damage of the brake transistor and possibly cause a fire.

zDo not connect a resistor directly to the DC terminals P/+ and N/-. Doing so could cause a fire.

3.Injury Prevention

CAUTION

CAUTION

zThe voltage applied to each terminal must be the ones specified in the Instruction Manual. Otherwise burst, damage, etc. may occur.

zThe cables must be connected to the correct terminals. Otherwise burst, damage, etc. may occur.

zPolarity must be correct. Otherwise burst, damage, etc. may occur.

zWhile power is ON or for some time after power-OFF, do not touch the inverter as they will be extremely hot. Doing so can cause burns.

4.Additional Instructions

Also the following points must be noted to prevent an accidental failure, injury, electric shock, etc.

(1) Transportation and Mounting

CAUTION

CAUTION

zThe product must be transported in correct method that corresponds to the weight. Failure to do so may lead to injuries.

zDo not stack the boxes containing inverters higher than the number recommended.

zThe product must be installed to the position where withstands the weight of the product according to the information in the Instruction Manual.

zDo not install or operate the inverter if it is damaged or has parts missing.

zWhen carrying the inverter, do not hold it by the front cover or setting dial; it may fall off or fail.

zDo not stand or rest heavy objects on the product.

zThe inverter mounting orientation must be correct.

zForeign conductive objects must be prevented from entering the inverter. That includes screws and metal fragments or other flammable substance such as oil.

zAs the inverter is a precision instrument, do not drop or subject it to impact.

zThe inverter must be used under the following environment. Otherwise the inverter may be damaged.

|

Surrounding |

-10°C to +50°C (non-freezing) |

|

|

air |

||

Environment |

temperature |

|

|

Ambient |

90%RH or less (non-condensing) |

||

humidity |

|||

|

|||

Storage |

-20°C to +65°C *1 |

||

temperature |

|||

Atmosphere |

Indoors (free from corrosive gas, flammable gas, |

||

|

|

oil mist, dust and dirt) |

|

|

Altitude/ |

Maximum 1,000m above sea level. |

|

|

5.9m/s2 or less at 10 to 55Hz (directions of X, Y, Z |

||

|

vibration |

axes) |

|

|

|

1 Temperature applicable for a short time, e.g. in transit.

A-1

(2) Wiring

CAUTION

CAUTION

zDo not install a power factor correction capacitor or surge suppressor/capacitor type filter on the inverter output side. These devices on the inverter output side may be overheated or burn out.

zThe connection orientation of the output cables U, V, W to the motor affects the rotation direction of the motor.

(3) Trial run

CAUTION

CAUTION

zBefore starting operation, each parameter must be confirmed and adjusted. A failure to do so may cause some machines to make unexpected motions.

(4) Usage

WARNING

WARNING

zAny person must stay away from the equipment when the retry function is set as it will restart suddenly after trip.

zSince pressing  key may not stop output depending on the function setting status, separate circuit and switch that make an emergency stop (power OFF, mechanical brake operation for emergency stop, etc.) must be provided.

key may not stop output depending on the function setting status, separate circuit and switch that make an emergency stop (power OFF, mechanical brake operation for emergency stop, etc.) must be provided.

zOFF status of the start signal must be confirmed before resetting the inverter fault. Resetting inverter alarm with the start signal ON restarts the motor suddenly.

zThe inverter must be used for three-phase induction motors. Connection of any other electrical equipment to the inverter output may damage the equipment.

zDo not modify the equipment.

zDo not perform parts removal which is not instructed in this manual. Doing so may lead to fault or damage of the product.

CAUTION

CAUTION

zThe electronic thermal relay function does not guarantee protection of the motor from overheating. It is recommended to install both an external thermal and PTC thermistor for overheat protection.

zDo not use a magnetic contactor on the inverter input for frequent starting/stopping of the inverter. Otherwise the life of the inverter decreases.

zThe effect of electromagnetic interference must be reduced by using a noise filter or by other means. Otherwise nearby electronic equipment may be affected.

zAppropriate measures must be taken to suppress harmonics. Otherwise power supply harmonics from the inverter may heat/damage the power factor correction capacitor and generator.

zWhen driving a 400V class motor by the inverter, the motor must be an insulation-enhanced motor or measures must be taken to suppress surge voltage. Surge voltage attributable to the wiring constants may occur at the motor terminals, deteriorating the insulation of the motor.

zWhen parameter clear or all parameter clear is performed, the required parameters must be set again before starting operations because all parameters return to the initial value.

zThe inverter can be easily set for high-speed operation. Before changing its setting, the performances of the motor and machine must be fully examined.

zStop status cannot be hold by the inverter's brake function. In addition to the inverter’s brake function, a holding device must be installed to ensure safety.

zBefore running an inverter which had been stored for a long period, inspection and test operation must be performed.

zFor prevention of damage due to static electricity, nearby metal must be touched before touching this product to eliminate static electricity from your body.

(5) Emergency stop

CAUTION

CAUTION

zA safety backup such as an emergency brake must be provided to prevent hazardous condition to the machine and equipment in case of inverter failure.

zWhen the breaker on the inverter input side trips, the wiring must be checked for fault (short circuit), and internal parts of the inverter for a damage, etc. The cause of the trip must be identified and removed before turning ON the power of the breaker.

zWhen any protective function is activated, appropriate corrective action must be taken, and the inverter must be reset before resuming operation.

(6) Maintenance, inspection and parts replacement

CAUTION

CAUTION

zDo not carry out a megger (insulation resistance) test on the control circuit of the inverter. It will cause a failure.

(7) Disposal

CAUTION

CAUTION

z The inverter must be treated as industrial waste.

General instruction

Many of the diagrams and drawings in this Instruction Manual (Basic) show the inverter without a cover or partially open for explanation. Never operate the inverter in this manner. The cover must be always reinstalled and the instruction in this Instruction Manual (Basic) must be followed when operating the inverter.

A-2

<Abbreviation>

yPU: Operation panel and parameter unit (FR-PU04, FR-PU07)

yInverter: Mitsubishi inverter FR-E700 series

yFR-E700: Mitsubishi inverter FR-E700 series

yPr.: Parameter number (Number assigned to function)

yPU operation: Operation using the PU (operation panel/FR-PU04/FR-PU07)

yExternal operation: Operation using the control circuit signals

yCombined operation : Operation using the PU (FR-PU04/FR-PU07) and external operation

yStandard motor : SF-JR

yConstant torque motor : SF-HRCA

<Trademark>

yLONWORKS® is a registered trademark of Echelon Corporation in the U.S.A and other countries.

yCompany and product names herein are the trademarks and registered trademarks of their respective owners.

<Mark>

REMARKS: Additional helpful contents and relations with other functions are written.

REMARKS: Additional helpful contents and relations with other functions are written.

Note: Contents requiring caution or cases when set functions are not activated are written.

POINT: Useful contents and points are written.

POINT: Useful contents and points are written.

<Related document>

Refer to the Instruction Manual (Applied) for further information on the following points.

Refer to the Instruction Manual (Applied) for further information on the following points.

yRemoval and reinstallation of the cover

yConnection of stand-alone option unit

yEMC and leakage currents

yDetailed explanation on parameters

yTroubleshooting

yCheck first when you have a trouble

yInspection items (life diagnosis, cooling fan replacement)

yMeasurement of main circuit voltages, currents and powers

yFor customers who are replacing the conventional model with this inverter

A-3

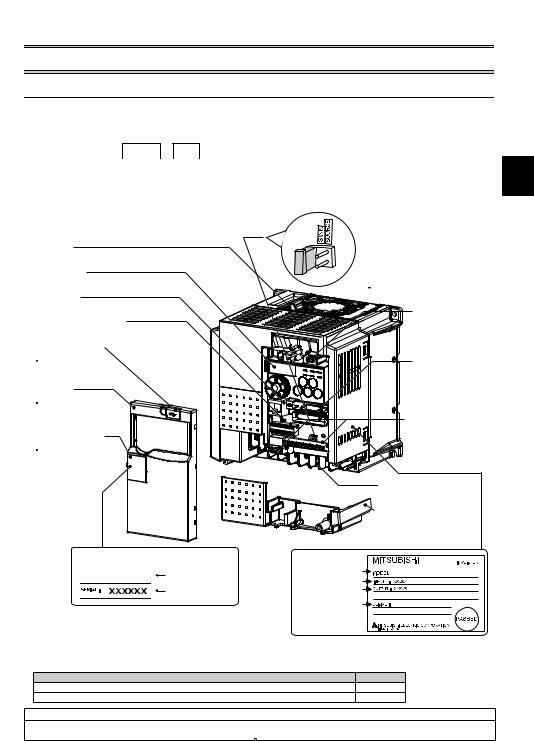

Product checking and parts identification

1 OUTLINE

1.1Product checking and parts identification

Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side face to ensure that the product agrees with your order and the inverter is intact.

zInverter model

FR - E740 - 3.7 K

|

|

|

|

|

|

|

|

|

No. |

Voltage class |

|

Represents the |

|||||

|

|

|

|

|

|

|||

E720 |

Three-phase 200V class |

|

inverter capacity [kW] |

|||||

|

|

|

|

|

|

|

|

|

E740 |

Three-phase 400V class |

|

|

|

|

|||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

E720S |

Single-phase 200V class |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

E710W |

Single-phase 100V class |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Cooling fan

The cooling fan is removable.

Operation panel

1

Control logic switchover jumper connector

The jumper connector is in the sink logic (SINK) when shipped from the factory. Move the jumper connector to change to the source logic (SOURCE). Always fit the jumper connector to the either position.

(Refer to page 2)

PU connector

(Refer to page 9)

Voltage/current input switch

(Refer to page 9)

USB connector cover

Refer to the Instruction Manual (Applied) for how to open the cover.

Refer to the Instruction Manual (Applied) for how to open the cover.

Front cover

Refer to the Instruction Manual (Applied) for installation/removal.

Refer to the Instruction Manual (Applied) for installation/removal.

PU connector cover

Refer to the Instruction Manual (Applied) for how to

Refer to the Instruction Manual (Applied) for how to

(  Refer to the Instruction Manual (Applied))

Refer to the Instruction Manual (Applied))

USB connector (mini-B connector)

(Refer to page 9)

Connector for plug-in option connection

(Refer to the instruction manual of options.)

Control circuit terminal block

(Refer to page 10)

open the cover. |

|

|

Main circuit terminal block |

|

|

|

|

|

|

|

(Refer to page 10) |

|

|

|

Combed shaped wiring cover |

|

|

|

Refer to the Instruction Manual |

|

|

|

(Applied) for installation/removal. |

|

|

Example of FR-E740-3.7K |

|

Capacity plate |

|

Rating plate |

|

FR-E740-3.7K |

Inverter model |

Inverter model |

FR-E740-3.7K |

Input rating |

|

||

|

|

|

|

|

Serial number |

Output rating |

|

|

|

Serial number |

|

•Accessory

·Fan cover fixing screws (M3 × 35mm)

These screws are necessary for compliance with the EU Directive (Refer to page 47)

Capacity |

Quantity |

FR-E720-1.5K to 3.7K, FR-E740-1.5K to 3.7K, FR-E720S-0.75K to 2.2K |

1 |

FR-E720-5.5K to 15K, FR-E740-5.5K to 15K |

2 |

Harmonic suppression guideline (when inverters are used in Japan)

All models of general-purpose inverters used by specific consumers are covered by "Harmonic suppression guideline for consumers who receive high voltage or special high voltage". (For further details,  refer to Chapter 3 of the Instruction Manual (Applied).)

refer to Chapter 3 of the Instruction Manual (Applied).)

1

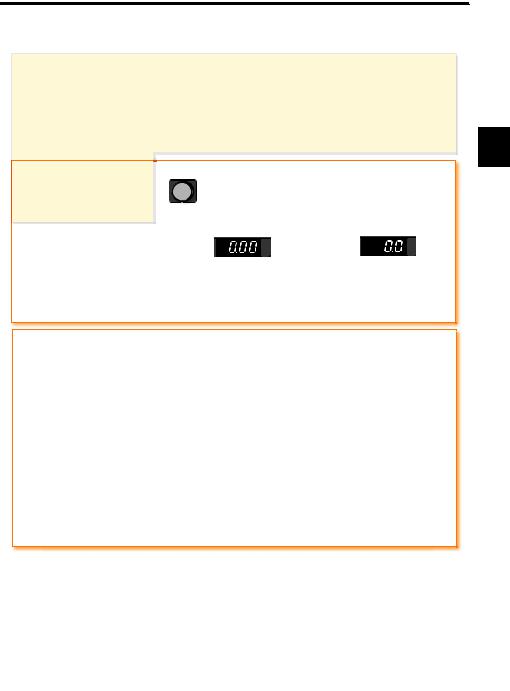

Operation panel

Operation panel

1.2Operation panel

1.2.1Names and functions of the operation panel

The operation panel cannot be removed from the inverter.

Operation mode indicator

PU: Lit to indicate PU operation mode. EXT: Lit to indicate External operation mode.

(Lit at power-ON at initial setting.) NET: Lit to indicate Network operation

mode.

PU, EXT: Lit to indicate External/PU combined operation mode 1, 2.

These turn OFF when command source is not on operation panel.

Unit indicator

Hz: Lit to indicate frequency. (Flickers when the set frequency monitor is displayed.)

A: Lit to indicate current.

(Both "Hz" and "A" turn OFF when other than the above is displayed.)

Monitor (4-digit LED)

Shows the frequency, parameter number, etc.

Setting dial

(Setting dial: Mitsubishi inverter dial) Used to change the frequency setting and parameter settings.

Press to display the following.

yDisplays the set frequency in the monitor mode

yPresent set value is displayed during calibration

yDisplays the order in the faults history mode

Mode switchover

Used to change each setting mode. Pressing  simultaneously changes

simultaneously changes

the operation mode.

Pressing for a while (2s) can lock operation. (  Refer to the Instruction Manual (Applied))

Refer to the Instruction Manual (Applied))

Determination of each setting

If pressed during operation, monitor changes as below:

Running frequency

Operating status indicator

Operating status indicator

Lit or flicker during inverter operation.

* Lit: When the forward rotation operation is being performed.

Slow flickering (1.4s cycle):

When the reverse operation is being performed.

Fast flickering (0.2s cycle):

When  was pressed or the

was pressed or the

start command was given, but the operation cannot be made.

yWhen the frequency command is less than the starting frequency.

yWhen the MRS signal is input.

Parameter setting mode

Parameter setting mode

Lit to indicate parameter setting mode.

Monitor indicator

Lit to indicate monitoring mode.

Stop operation

Stop operation

Used to stop Run command. Fault can be reset when protective function is activated (fault).

Operation mode switchover

Operation mode switchover

Used to switch between the PU and External operation mode.

When using the External operation mode (operation using a separately connected frequency setting potentiometer and start signal), press this key to light up the EXT indication.

(Press  simultaneously (0.5s) or

simultaneously (0.5s) or

change Pr. 79 setting to change to combined mode .) (  Refer to the Instruction Manual (Applied))

Refer to the Instruction Manual (Applied))

PU: PU operation mode EXT: External operation mode Cancels PU stop also.

Start command

Start command

The rotation direction can be selected by setting Pr. 40.

Output current

Output voltage

2

Operation panel

1.2.2Basic operation (factory setting)

Monitor/frequency setting

Operation mode switchover

At power-ON (External operation mode)

|

PU Jog operation mode |

1 |

|

|

|

(Example) |

|

PU operation mode |

Value change |

and frequency flicker. |

|

(output frequency monitor) |

|||

|

|

||

|

|

Frequency setting has been |

|

|

|

written and completed!! |

|

|

Output current monitor STOP |

Output voltage monitor |

|

|

|

Parameter setting

Faults history

|

|

Display the |

Parameter setting mode |

|

present setting |

|

|

(Example) |

Value change |

|

Parameter and a setting value |

|

|

flicker alternately. |

|

|

Parameter write is completed!! |

Parameter clear |

All parameter |

Faults history clear |

|

clear |

|

Initial value change list

[Operation for displaying faults history] (Refer to page 38)

Past eight faults can be displayed. (The latest fault is ended by ".".)

When no fault history exists,

is displayed.

is displayed.

While a fault is displayed:

The display shifts as follows by pressing

: Output frequency at the fault

: Output frequency at the fault Output current

Output current Output voltage

Output voltage Energization time.

Energization time.

(After Energization time, it goes back to a fault display.)

Pressing the setting dial shows the fault history number.

3

Operation panel

Operation panel

1.2.3Changing the parameter setting value

Changing |

Change the Pr. 1 Maximum frequency setting. |

|

example |

||

|

|

Operation |

Display |

|

1. Screen at power-ON |

|

|

|

The monitor display appears. |

|

||

2. Press |

to choose the PU operation mode. |

PU indicator is lit. |

|

|

|||

3. Press |

to choose the parameter setting |

PRM indicator is lit. |

|

|

|||

mode. |

|

|

(The parameter number read previously appears.) |

|

|

|

|

4. Turn |

until |

(Pr. 1) appears. |

|

5. Press  to read the currently set value. "

to read the currently set value. "

"(120.0Hz (initial value)) appears.

"(120.0Hz (initial value)) appears.

6. Turn  to change the set value to "

to change the set value to "

" (60.00Hz).

" (60.00Hz).

7. Press  to set.

to set.

Flicker...Parameter setting complete!!

yTurn  to read another parameter.

to read another parameter.

yPress  to show the setting again.

to show the setting again.

yPress  twice to show the next parameter.

twice to show the next parameter.

yPress  twice to return the monitor to frequency monitor.

twice to return the monitor to frequency monitor.

REMARKS

REMARKS

|

to |

is displayed...Why? |

|

appears |

....................Write disable error |

|

appears .................... |

Write error during operation |

|

appears .................... |

Calibration error |

|

appears .................... |

Mode designation error |

(For details, |

Refer to the Instruction Manual (Applied).) |

|

yThe number of digits displayed on the operation panel is four. Only the upper four digits of values can be displayed and set. If the values to be displayed have five digits or more including decimal places, the fifth or later numerals can not be displayed nor set. (Example) For Pr. 1

When 60Hz is set, 60.00 is displayed.

When 120Hz is set, 120.0 is displayed and second decimal place is not displayed nor set.

4

Operation panel

1.2.4Parameter clear/all parameter clear

POINT

y Set "1" in Pr.CL Parameter clear, ALLC all parameter clear to initialize all parameters. (Parameters are not cleared when "1" is set in Pr. 77 Parameter write selection.)

yRefer to the extended parameter list of  the Instruction Manual (Applied) for parameters cleared with this operation.

the Instruction Manual (Applied) for parameters cleared with this operation.

|

Operation |

Display |

||

1. Screen at power-ON |

|

1 |

||

The monitor display appears. |

||||

|

||||

2. Press |

|

|

PU indicator is lit. |

|

to choose the PU operation mode. |

||||

3. Press |

|

|

PRM indicator is lit. |

|

to choose the parameter setting |

||||

mode. |

|

|

(The parameter number read previously appears.) |

|

|

|

|

||

4. Turn |

until |

( |

Parameter clear |

|

) appears. |

||||

All parameter clear

5. Press  to read the currently set value. "

to read the currently set value. "

"(initial value) appears.

"(initial value) appears.

6. Turn  to change it to the set value "

to change it to the set value "  ".

".

7. Press |

Parameter clear |

to set. |

|

|

All parameter clear |

Flicker ··· Parameter setting complete!!

yTurn  to read another parameter.

to read another parameter.

yPress  to show the setting again.

to show the setting again.

yPress  twice to show the next parameter.

twice to show the next parameter.

Setting |

Description |

0Not executed.

Sets parameters back to the initial values. (Parameter clear sets back all parameters except

1 |

calibration parameters and terminal function selection parameters to the initial values.) Refer to the |

||

parameter list of |

the Instruction Manual (Applied) for availability of parameter clear and all |

||

|

|||

|

parameter clear. |

|

|

REMARKS

REMARKS

and

and

are displayed alternately ... Why?

are displayed alternately ... Why?

The inverter is not in the PU operation mode.

The inverter is not in the PU operation mode.

PU connector or USB connector is used.

PU connector or USB connector is used.

1.Press  . [PU] is lit and the monitor (4-digit LED) displays "1". (When Pr. 79 = "0" (initial value))

. [PU] is lit and the monitor (4-digit LED) displays "1". (When Pr. 79 = "0" (initial value))

2.Carry out operation from step 6 again.

5

2 INSTALLATION AND WIRING

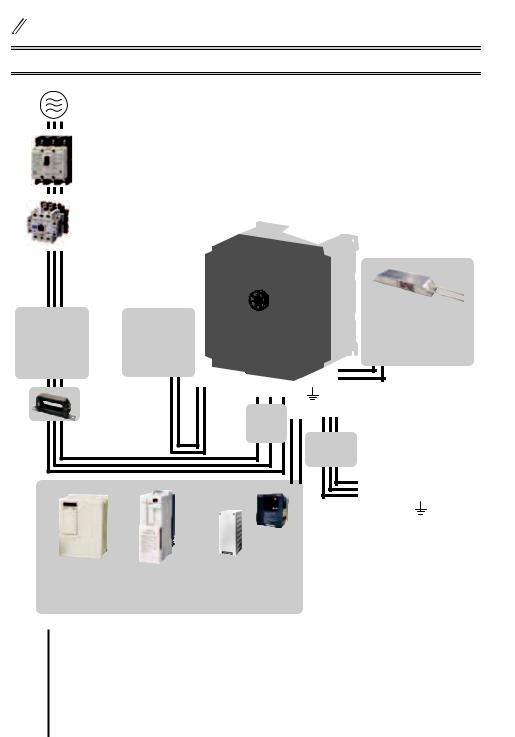

AC power supply

Use within the permissible power supply specifications of the inverter. To ensure safety, use a moulded case circuit breaker, earth leakage circuit breaker or magnetic

contactor to switch power ON/OFF.

(Refer to page 44)

Moulded case circuit breaker (MCCB) or earth leakage circuit breaker (ELB), fuse

The breaker must be selected carefully since an in-rush current flows in the

inverter at power ON.

(Refer to page 7)

Magnetic contactor (MC)

Parameter unit (FR-PU07)

Enclosure surface operation panel (FR-PA07)

By connecting the connection cable (FR-CB2) to the PU connector, operation can be performed from FR-PU07, FR-PA07.

USB connector

A personal computer and an inverter can be connected with a

USB (Ver1. 1) cable.

(  Refer to Chapter 3 of the Instruction Manual (Applied))

Refer to Chapter 3 of the Instruction Manual (Applied))

Install the magnetic contactor to ensure safety. Do not use this magnetic contactor to start and stop the inverter. Doing so will cause the inverter life to be shorten.

(Refer to page 7) |

|

|

|

|

|

|

|

Reactor (FR-HAL, FR-HEL option) |

|

|

|

|

|

|

|

Reactors (option) must be used when |

|

|

|

|

|

|

|

power harmonics measures are taken, |

|

|

|

|

|

|

|

the power factor is to be improved or the |

|

|

|

|

|

|

|

inverter is installed near a large power |

|

|

|

|

|

|

|

supply system (500kVA or more). The |

|

|

|

|

|

|

|

inverter may be damaged if you do not |

|

|

|

|

|

|

|

use reactors. Select the reactor according |

|

|

|

|

|

|

|

to the model. Remove the jumpers across |

|

|

|

|

|

Brake resistor |

|

terminals P/+ and P1 to connect the DC reactor. |

|

|

|

|

|||

|

|

|

|

(FR-ABR, MRS type, MYS type) |

|||

|

|

|

|

|

|

|

|

AC reactor (FR-HAL) |

DC reactor (FR-HEL) * |

|

|

|

|

|

Braking capability can be improved. (0.4K |

|

|

|

|

|

|

|

or higher) |

|

|

|

|

|

|

|

Always install a thermal relay when using |

|

|

|

|

|

|

|

a brake resistor whose capacity is 11K or |

|

|

|

|

|

|

|

higher. (Refer to page 17) |

|

|

|

|

|

|

P/+ |

|

|

EMC filter (ferrite core) * |

P/+P1 |

Inverter (FR-E700) |

|

PR |

|

|

|

|

|

|

||||

|

(FR-BSF01, FR-BLF) |

|

|

EMC filter (ferrite core) |

|||

|

|

|

R/L1 S/L2 T/L3 |

|

|

||

|

Install an EMC filter (ferrite core) |

|

|

|

|

(FR-BSF01, FR-BLF) |

|

|

|

|

|

|

|

||

|

to reduce the electromagnetic |

EMC filter |

Earth (Ground) |

Install an EMC filter (ferrite core) |

|||

|

noise generated from the |

|

|

|

to reduce the electromagnetic |

||

|

(capacitor) * |

P/+ N/- |

U |

V W |

|||

|

inverter. Effective in the range |

||||||

|

|

|

noise generated from the inverter. |

||||

|

(FR-BIF) |

|

|

|

|||

|

from about 1MHz to 10MHz. |

|

|

|

|||

|

|

|

|

Effective in the range from about |

|||

|

|

|

|

|

|

||

|

When more wires are passed |

Reduces the |

|

|

|

||

|

|

|

|

1MHz to 10MHz. A wire should be |

|||

|

through, a more effective result |

radio noise. |

|

|

|

||

|

|

|

|

wound four turns at a maximum. |

|||

|

can be obtained. A wire should |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

be wound four turns or more. |

|

|

|

|

|

|

* Filterpack (FR-BFP2), which contains DC reactor and EMC filter in one package, is also available.

Brake unit (FR-BU2)

|

|

|

|

|

|

Devices connected to the output |

Earth (Ground) |

|

|

|

|

|

|

|

|

|

|

P/+ PR |

Do not install a power factor correction capacitor, |

||||

|

|

surge suppressor or capacitor type filter on the output |

|||||

|

|

P/+ |

|

|

|

||

|

|

|

|

|

side of the inverter. When installing a moulded case |

||

|

|

PR |

|

|

|

||

|

|

|

|

|

circuit breaker on the output side of the inverter, |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

contact each manufacturer for selection of the |

|

High power factor |

Power regeneration |

Resistor unit (FR-BR) |

moulded case circuit breaker. |

|

|||

Earth (Ground) |

|

||||||

converter (FR-HC) |

common converter |

Discharging resistor (GZG, GRZG) |

|

||||

|

(FR-CV) |

|

|

|

|

To prevent an electric shock, always earth (ground) |

|

Power supply harmonics |

Great braking capability |

The regenerative braking capability |

the motor and inverter. For reduction of induction noise |

||||

can be greatly suppressed. |

is obtained. |

of the inverter can be exhibited fully. |

from the power line of the inverter, it is recommended |

||||

Install this as required. |

Install this as required. |

Install this as required. |

to wire the earthing cable by returning it to the earth |

||||

|

|

|

|

|

|

(ground) terminal of the inverter. |

|

NOTE

y The life of the inverter is influenced by surrounding air temperature. The surrounding air temperature should be as low as possible within the permissible range. This must be noted especially when the inverter is installed in an enclosure. (Refer to page 8)

yWrong wiring might lead to damage of the inverter. The control signal lines must be kept fully away from the main circuit to protect them from noise. (Refer to page 9)

yDo not install a power factor correction capacitor, surge suppressor or capacitor type filter on the inverter output side. This will cause the inverter to trip or the capacitor and surge suppressor to be damaged. If any of the above devices are connected, immediately remove them.

yElectromagnetic wave interference

The input/output (main circuit) of the inverter includes high frequency components, which may interfere with the communication devices (such as AM radios) used near the inverter. In this case, install options among the capacitor type EMC filter FR-BIF (for use in the input side only), the ferrite core type EMC filter FR-BSF01/FR-BLF, filterpack, and EMC filter to minimize the interference. (  Refer to Chapter 3 of the Instruction Manual (Applied)).

Refer to Chapter 3 of the Instruction Manual (Applied)).

yRefer to the instruction manual of each option and peripheral devices for details of peripheral devices.

6

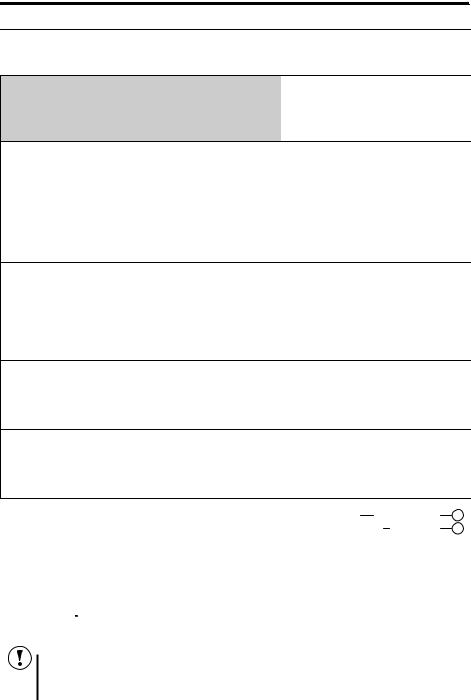

Peripheral devices

2.1Peripheral devices

Check the inverter model of the inverter you purchased. Appropriate peripheral devices must be selected according to the capacity. Refer to the following list and prepare appropriate peripheral devices.

Single-Phase 100V Single-Phase 200V Three-Phase 400V Three-Phase 200V

1

2

3

4

5

6

|

|

|

Moulded Case Circuit Breaker |

Magnetic Contactor (MC) |

|

|

|

|

|

|||

|

|

Motor |

|

(MCCB) 1 |

Reactor |

|

|

|||||

Applicable Inverter |

or Earth Leakage Circuit Breaker |

3 |

|

|

||||||||

Output |

|

|

|

|

|

|||||||

|

Model |

|

(ELB) 2 |

|

|

|

|

|

|

|

||

|

(kW) |

|

|

|

|

|

|

|

|

|||

|

|

Reactor connection |

Reactor connection |

FR-HAL |

FR-HEL |

|

|

|||||

|

|

|

|

|

||||||||

|

|

|

without |

|

with |

without |

with |

|

|

|

|

|

|

FR-E720-0.1K |

0.1 |

5A |

|

5A |

S-N10 |

S-N10 |

0.4K 5 |

0.4K 5 |

|

|

|

|

FR-E720-0.2K |

0.2 |

5A |

|

5A |

S-N10 |

S-N10 |

0.4K 5 |

0.4K 5 |

|

|

|

|

FR-E720-0.4K |

0.4 |

5A |

|

5A |

S-N10 |

S-N10 |

0.4K |

|

0.4K |

|

|

|

FR-E720-0.75K |

0.75 |

10A |

|

10A |

S-N10 |

S-N10 |

0.75K |

|

0.75K |

|

|

|

FR-E720-1.5K |

1.5 |

15A |

|

15A |

S-N10 |

S-N10 |

1.5K |

|

1.5K |

|

|

|

|

|||||||||||

|

FR-E720-2.2K |

2.2 |

20A |

|

15A |

S-N10 |

S-N10 |

2.2K |

|

2.2K |

|

2 |

|

FR-E720-3.7K |

3.7 |

30A |

|

30A |

S-N20, S-N21 |

S-N10 |

3.7K |

|

3.7K |

|

|

|

|

|

|

|

||||||||

|

FR-E720-5.5K |

5.5 |

50A |

|

40A |

S-N25 |

S-N20, S-N21 |

5.5K |

|

5.5K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FR-E720-7.5K |

7.5 |

60A |

|

50A |

S-N25 |

S-N25 |

7.5K |

|

7.5K |

|

|

|

FR-E720-11K |

11 |

75A |

|

75A |

S-N35 |

S-N35 |

11K |

|

11K |

|

|

|

FR-E720-15K |

15 |

125A |

|

100A |

S-N50 |

S-N50 |

15K |

|

15K |

|

|

|

FR-E740-0.4K |

0.4 |

5A |

|

5A |

S-N10 |

S-N10 |

H0.4K |

|

H0.4K |

|

|

|

FR-E740-0.75K |

0.75 |

5A |

|

5A |

S-N10 |

S-N10 |

H0.75K |

H0.75K |

|

|

|

|

FR-E740-1.5K |

1.5 |

10A |

|

10A |

S-N10 |

S-N10 |

H1.5K |

|

H1.5K |

|

|

|

FR-E740-2.2K |

2.2 |

15A |

|

10A |

S-N10 |

S-N10 |

H2.2K |

|

H2.2K |

|

|

|

FR-E740-3.7K |

3.7 |

20A |

|

15A |

S-N10 |

S-N10 |

H3.7K |

|

H3.7K |

|

|

|

FR-E740-5.5K |

5.5 |

30A |

|

20A |

S-N20, S-N21 |

S-N11, S-N12 |

H5.5K |

|

H5.5K |

|

|

|

FR-E740-7.5K |

7.5 |

30A |

|

30A |

S-N20, S-N21 |

S-N20, S-N21 |

H7.5K |

|

H7.5K |

|

|

|

FR-E740-11K |

11 |

50A |

|

40A |

S-N20, S-N21 |

S-N20, S-N21 |

H11K |

|

H11K |

|

|

|

FR-E740-15K |

15 |

60A |

|

50A |

S-N25 |

S-N20, S-N21 |

H15K |

|

H15K |

|

|

|

FR-E720S-0.1K |

0.1 |

5A |

|

5A |

S-N10 |

S-N10 |

0.4K 5 |

0.4K 5 |

|

|

|

|

FR-E720S-0.2K |

0.2 |

5A |

|

5A |

S-N10 |

S-N10 |

0.4K 5 |

0.4K 5 |

|

|

|

|

FR-E720S-0.4K |

0.4 |

10A |

|

10A |

S-N10 |

S-N10 |

0.75K 5 |

0.75K 5 |

|

|

|

|

FR-E720S-0.75K |

0.75 |

15A |

|

10A |

S-N10 |

S-N10 |

1.5K 5 |

1.5K 5 |

|

|

|

|

FR-E720S-1.5K |

1.5 |

20A |

|

20A |

S-N10 |

S-N10 |

2.2K 5 |

2.2K 5 |

|

|

|

|

FR-E720S-2.2K |

2.2 |

40A |

|

30A |

S-N20, S-N21 |

S-N10 |

3.7K 5 |

3.7K 5 |

|

|

|

|

FR-E710W-0.1K |

0.1 |

10A |

|

5A |

S-N10 |

S-N10 |

0.75K 4, 5 |

−−− 6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FR-E710W-0.2K |

0.2 |

10A |

|

10A |

S-N10 |

S-N10 |

1.5K 4, |

5 |

−−− 6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FR-E710W-0.4K |

0.4 |

15A |

|

15A |

S-N10 |

S-N10 |

2.2K 4, |

5 |

−−− 6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FR-E710W-0.75K |

0.75 |

30A |

|

20A |

S-N10 |

S-N10 |

3.7K 4, |

5 |

−−− 6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ySelect an MCCB according to the power supply capacity. |

|

|

|

|

|

|

yInstall one MCCB per inverter. |

|

|

MCCB |

|

INV |

IM |

|

|

|

|

|

|

|

|

|

|

MCCB |

|

INV |

IM |

For the use in the United States or Canada, select a UL and cUL certified fuse with Class T fuse equivalent cut-off

speed or faster with the appropriate rating for branch circuit protection. Alternatively, select a UL489 molded case circuit breaker (MCCB). (Refer to page 50) Magnetic contactor is selected based on the AC-1 class. The electrical durability of magnetic contactor is 500,000 times. When the magnetic contactor is used for emergency stop during motor driving, the electrical durability is 25 times.

When using the MC for emergency stop during motor driving or using on the motor side during commercial-power supply operation, select the MC with class AC-3 rated current for the motor rated current.

When connecting a single-phase 100V power input inverter to a power transformer (50kVA or more), install a AC reactor (FR-HAL) so that the performance is more reliable. (  Refer to Chapter 3 of the Instruction Manual (Applied))

Refer to Chapter 3 of the Instruction Manual (Applied))

The power factor may be slightly lower.

Single-phase 100V power input model is not compatible with DC reactor.

NOTE

yWhen the inverter capacity is larger than the motor capacity, select an MCCB and a magnetic contactor according to the inverter model and cable and reactor according to the motor output.

yWhen the breaker on the inverter input side trips, check for the wiring fault (short circuit), damage to internal parts of the inverter, etc. Identify the cause of the trip, then remove the cause and power ON the breaker.

7

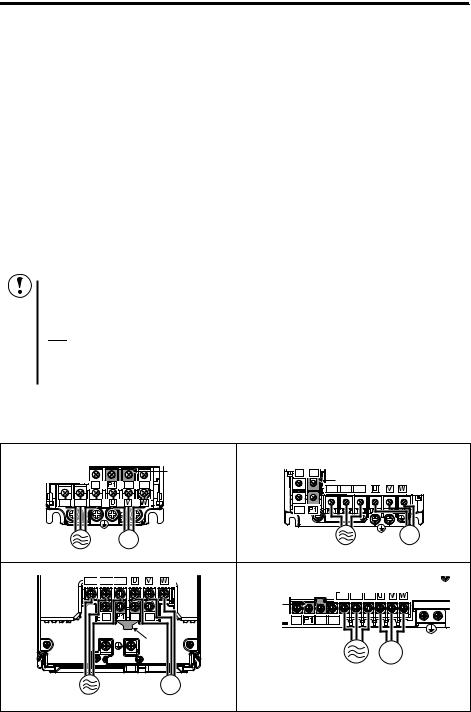

Installation of the inverter and instructions

Installation of the inverter and instructions

2.2Installation of the inverter and instructions

(1)Installation of the inverter

Enclosure surface mounting

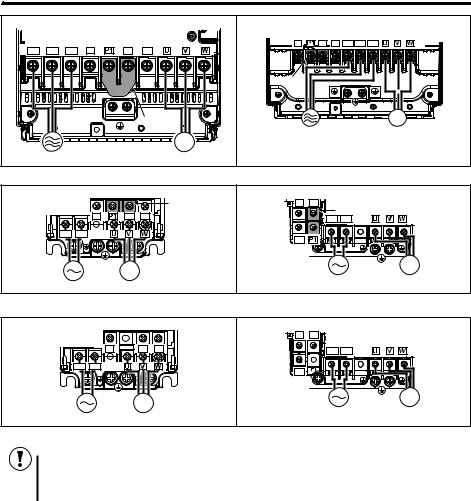

Remove the front cover and wiring cover to fix the inverter to the surface. (Remove the covers in the directions of the arrows.)

FR-E720-0.1K to 0.75K |

FR-E720-1.5K to 3.7K |

FR-E720-5.5K to 15K |

FR-E720S-0.1K to 0.4K |

FR-E740-0.4K to 7.5K |

FR-E740-11K, 15K |

FR-E710W-0.1K to 0.4K |

FR-E720S-0.75K or higher |

|

|

FR-E710W-0.75K |

|

Front cover |

|

|

|

Front cover |

|

|

Front cover 1 |

|

Wiring cover |

Wiring cover |

|

|

Wiring cover |

|

|

|

Note

yWhen encasing multiple inverters, install them in parallel as a cooling measure.

yInstall the inverter vertically.

yFor heat dissipation and maintenance, take at least the clearances shown in the table below from the inverter to the other devices and to the enclosure surface.

|

Measurement |

10cm or more |

|

||

|

position |

|

|

||

5cm |

5cm |

|

|

|

|

|

|

1cm or |

1cm or |

1cm or |

|

|

5cm |

more 1, 2 |

more 1, 2 |

||

Measurement |

more 1 |

||||

|

|

|

|||

position |

|

|

10cm or more |

|

|

Refer to the clearances

shown on the left.

shown on the left.

Vertical

-10 C to 50 C (non-freezing)

1 Take 5cm or more clearances for 5.5K or higher.

2 When using the inverters at the surrounding air temperature of 40°C or less, the inverters can be installed without any clearance between them (0cm clearance).

(2)Environment

Before installation, check that the environment meets the specifications on page 45.

Note

yInstall the inverter on a strong surface securely and vertically with bolts.

yLeave enough clearances and take cooling measures.

yAvoid places where the inverter is subjected to direct sunlight, high temperature and high humidity.

yInstall the inverter on a nonflammable wall surface.

8

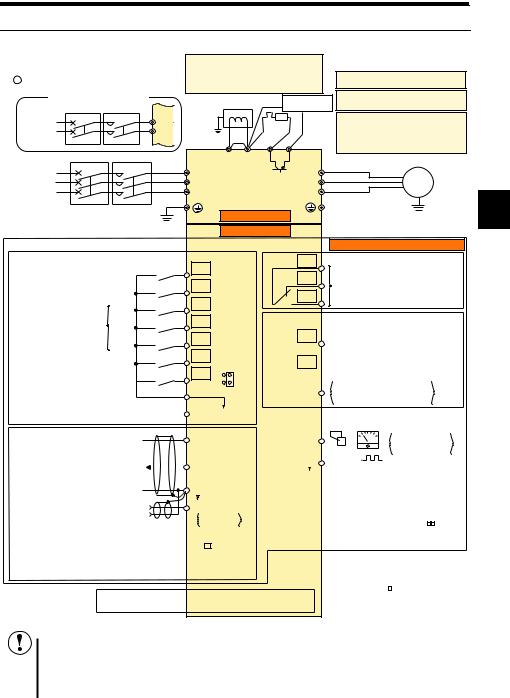

Wiring

2.3Wiring

2.3.1Terminal connection diagram

Sink logic

Main circuit terminal

Main circuit terminal

Control circuit terminal

Single-phase power input

MCCB |

MC |

|

Single-phase |

R/L1 |

|

AC power |

S/L2 |

|

supply |

||

|

MCCB MC

Three-phase AC power supply

Earth (Ground)

*1. DC reactor (FR-HEL)

When connecting a DC reactor, remove the jumper across P1 and P/+.

Not available for single-phase 100V power input model.

Brake unit (Option)

*1

R

Earth |

*8 |

|

(Ground) |

||

|

Jumper |

|

PR |

N/- |

P1 |

P/+ |

*7 |

|

*6 |

|

|

U |

R/L1 |

|

|

|

|

|

|

|

S/L2 |

|

|

V |

T/L3 |

|

|

W |

Main circuit

Control circuit

*6 Terminal P1 is not available for singlephase 100V power input model.

*7 A brake transistor is not built-in to the 0.1K and 0.2K.

*8 Brake resistor (FR-ABR, MRS, MYS type) Install a thermal relay to prevent an overheat and burnout of the brake resistor. (The brake resistor can not be connected to the 0.1K and 0.2K.)

Motor

IM

2

Earth (Ground)

Standard control terminal block

Control input signals (No voltage input allowed)

|

Terminal functions vary |

|

Forward |

|

|

|

rotation start |

||

|

with the input terminal |

|

Reverse |

|

|

assignment (Pr. 178 to |

|

||

|

|

rotation start |

||

|

Pr. 184) |

|

||

|

|

|

High |

|

|

|

|

|

speed |

|

Multi-speed selection Middle |

|||

|

|

|

|

speed |

|

*2 When using terminals PC |

|

Low |

|

|

and SD as a 24VDC |

|

||

|

|

speed |

||

|

power supply, take care |

|

||

|

|

|

||

|

not to short across |

|

Output |

|

|

terminals PC and SD. |

|

stop |

|

Reset

Contact input common

STF

STR

RH

RM

RL

MRS

RES

SD

SOURCE |

SINK |

C

B

A

RUN

FU

SE

Relay output

|

Terminal functions vary |

Relay output |

by Pr. 192 A,B,C terminal |

(Fault output) |

function selection |

|

|

|

Open collector output |

|

|

|

Terminal functions vary with |

Running |

the output terminal assignment |

|

|

|

(Pr. 190 and Pr. 191) |

Frequency detection

Frequency detection

Open collector output common

Sink/source common

|

24VDC power supply |

|

|

|

PC *2 |

|

|

|

|

|

|

Calibration resistor |

|

||||||||||||||||||

|

(Common for external power supply transistor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicator |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency setting signals (Analog) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

|

- |

(Frequency meter, etc.) |

||||

|

3 |

|

|

|

|

10(+5V) |

|

|

|

FM |

|

|

|

|

|

|

|

|

Moving-coil type |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

*3 Terminal input specifications |

Frequency |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*9 |

|

|

|

|

|

|

1mA full-scale |

||

|

can be changed by analog |

setting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

input specifications |

|

|

|

|

|

2 |

|

|

2 |

|

0 to 5VDC |

*3 |

|

|

SD |

|

|

|

|

|

|

|

|

|

|

|||||

|

potentiometer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

switchover (Pr. 73). |

|

|

|

|

(0 to 10VDC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

1/2W1kΩ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*9 |

It is not necessary when calibrating the |

|||||||

|

|

|

*4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PU |

|

|

|

|

|

indicator from the operation panel. |

||||||

|

*4 It is recommended to use 2W1kΩ |

1 |

|

|

|

|

5(Analog common) |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

when the frequency setting signal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

connector |

|

|

|

*10 |

Operation and parameter setting can be |

||||||||||

|

is changed frequently. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

done from the parameter unit (FR-PU07) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*10 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Terminal 4 input (+) |

|

|

|

4 |

|

4 to 20mADC |

|

|

|

|

|

|

|

and the enclosure surface operation panel |

||||||||||||||||

|

(Current input) |

(-) |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

0 to 5VDC |

|

*5 |

|

|

|

|

|

|

|

(FR-PA07). |

|

|

|

||||||||||

|

*5 Terminal input specifications can be changed by analog |

|

|

|

|

|

|

0 to 10VDC |

|

|

|

|

|

|

|

|

(Use the option cable (FR-CB2 ).) |

||||||||||||||

|

input specifications switchover (Pr. 267). Set the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RS-485 communication can be utilized from |

|||||||||||

|

voltage/current input switch in the "V" position to select |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a personal computer and other devices. |

|||||||||||

|

voltage input (0 to 5V/0 to10V) and "I" (initial value) to |

|

|

|

I |

|

|

V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

select current input (4 to 20mA). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

To use terminal 4 (initial setting is current input), set "4" |

|

|

Voltage/current |

|

USB |

|

|

|

*11 |

A personal computer and an inverter can be |

||||||||||||||||||||

|

in any of Pr.178 to Pr.184 (input terminal function selection) |

|

|

input switch |

*5 |

|

|

|

|

|

|

connected with a USB (Ver1.1) cable. |

|||||||||||||||||||

|

to assign the function, and turn ON AU signal. |

|

|

|

|

|

|

|

|

|

|

|

|

connector |

|

|

|

|

You can perform parameter setting and |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*11 |

|

|

|

|

|

|

monitoring with the FR Configurator (FR- |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SW3-SETUP-W |

). |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

Connector for |

|

|

|

|

|

|

|

|

|

Option connector |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

plug-in option connection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

NOTE

yTo prevent a malfunction caused by noise, separate the signal cables more than 10cm from the power cables. Also separate the main circuit wire of the input side and the output side.

yAfter wiring, wire offcuts must not be left in the inverter.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean. When drilling mounting holes in an enclosure etc., take care not to allow chips and other foreign matter to enter the inverter.

yThe output of the single-phase power input model is three-phase 200V.

9

Wiring

Wiring

2.3.2Terminal specifications

Type

Main circuit

Contact input

Control circuit/input signal

Frequency setting

Terminal |

Terminal Name |

|

|

|

|

|

|

Description |

|

|||||

Symbol |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

||||||

R/L1, S/L2, |

AC power input |

Connect to the commercial power supply. Keep these terminals open when using the high |

||||||||||||

power factor converter (FR-HC) or power regeneration common converter (FR-CV). |

||||||||||||||

T/L3 * |

||||||||||||||

|

When using single-phase power input, terminals are R/L1 and S/L2. |

|||||||||||||

|

|

|

|

|

|

|||||||||

U, V, W |

Inverter output |

Connect a three-phase squirrel-cage motor. |

|

|||||||||||

P/+, PR |

Brake resistor connection |

Connect a brake resistor (MRS type, MYS type, FR-ABR) across terminals P/+ and PR. |

||||||||||||

|

|

|

|

|

|

(The brake resistor can not be connected to the 0.1K or 0.2K) |

|

|||||||

|

|

|

|

|

Brake unit connection |

Connect the brake unit (FR-BU2), power regeneration common converter (FR-CV) or high |

||||||||

P/+, N/- |

power factor converter (FR-HC). |

|

||||||||||||

|

|

|||||||||||||

|

|

|

|

|

DC power input |

Connect the plus side of the power supply to terminal P/+ and minus side to terminal N/-. |

||||||||

P/+, P1 * |

DC reactor connection |

Remove the jumper across terminals P/+ and P1 and connect a DC reactor. Single-phase |

||||||||||||

100V power input model is not compatible with DC reactor. |

|

|||||||||||||

|

|

|

|

|

|

Terminal P1 is not available for single-phase 100V power input model. |

||||||||

|

|

|

|

|

Earth (Ground) |

For earthing (grounding) the inverter chassis. Must be earthed (grounded). |

||||||||

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STF |

Forward rotation start |

Turn ON the STF signal to start forward rotation and turn it OFF |

When the STF and STR |

|||||||||||

to stop. |

signals are turned ON |

|||||||||||||

|

|

|

|

|

|

|||||||||

STR |

Reverse rotation start |

Turn ON the STR signal to start reverse rotation and turn it OFF |

simultaneously, the stop |

|||||||||||

to stop. |

command is given. |

|||||||||||||

|

|

|

|

|

|

|||||||||

RH, RM, RL |

Multi-speed selection |

Multi-speed can be selected according to the combination of RH, RM and RL signals. |

||||||||||||

MRS |

Output stop |

Turn ON the MRS signal (20ms or more) to stop the inverter output. |

||||||||||||

Use to shut off the inverter output when stopping the motor by electromagnetic brake. |

||||||||||||||

|

|

|

|

|

|

|||||||||

RES |

Reset |

Used to reset alarm output provided when protective circuit is activated. Turn ON the RES |

||||||||||||

signal for more than 0.1s, then turn it OFF. Initial setting is for reset always. By setting Pr. 75, |

||||||||||||||

|

|

|

|

|

|

reset can be set to enabled only at fault occurrence. Recover about 1s after reset is cancelled. |

||||||||

|

|

|

|

|

Contact input common |

Common terminal for contact input terminal (sink logic) and terminal FM. |

||||||||

|

|

|

|

|

(sink) (initial setting) |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

SD |

External transistor |

Connect this terminal to the power supply common terminal of a transistor output (open |

|||||||||||

|

collector output) device, such as a programmable controller, in the source logic to avoid |

|||||||||||||

|

common (source) |

|||||||||||||

|

|

|

|

|

malfunction by undesirable current. |

|

||||||||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

24VDC power supply |

Common output terminal for 24VDC 0.1A power supply (PC terminal). |

||||||||

|

|

|

|

|

common |

Isolated from terminals 5 and SE. |

|

|||||||

|

|

|

|

|

External transistor |

Connect this terminal to the power supply common terminal of a transistor output (open |

||||||||

|

|

|

|

|

common |

collector output) device, such as a programmable controller, in the sink logic to avoid |

||||||||

|

PC |

(sink) (initial setting) |

malfunction by undesirable current. |

|

||||||||||

|

Contact input common |

Common terminal for contact input terminal (source logic). |

|

|||||||||||

|

|

|

|

|

|

|||||||||

|

|

|

|

|

(source) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

24VDC power supply |

Can be used as 24VDC 0.1A power supply. |

|

|||||||

10 |

|

Frequency setting power |

Used as power supply when connecting potentiometer for |

5VDC |

||||||||||

|

supply |

frequency setting (speed setting) from outside of the inverter. |

permissible load current 10mA |

|||||||||||

|

|

|

|

|

||||||||||

|

|

|

|

|

Frequency setting |

Inputting 0 to 5VDC (or 0 to 10V) provides the maximum output |

Input resistance 10kΩ ± 1kΩ |

|||||||

2 |

|

|

frequency at 5V (10V) and makes input and output |

Permissible maximum voltage |

||||||||||

|

|

(voltage) |

proportional. Use Pr. 73 to switch between input 0 to 5VDC |

|||||||||||

|

|

|

|

|

20VDC |

|||||||||

|

|

|

|

|

|

(initial setting) and 0 to 10VDC input. |

||||||||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

Inputting 0 to 20mADC (or 0 to 5V / 0 to 10V) provides the |

|

|||||||

|

|

|

|

|

|

maximum output frequency at 20mA and makes input and |

|

|||||||

|

|

|

|

|

|

output proportional. This input signal is valid only when the AU |

Voltage input: |

|||||||

|

|

|

|

|

|

signal is ON (terminal 2 input is invalid). To use terminal 4 |

||||||||

|

|

|

|

|

|

(initial setting is current input), set "4" to any of Pr.178 to Pr.184 |

Input resistance 10kΩ ± 1kΩ |

|||||||

|

|

|

|

|

Frequency setting |

(input terminal function selection), and turn AU signal ON. Use |

Permissible maximum voltage |

|||||||

4 |

|

|

Pr. 267 to switch among input 4 to 20mA (initial setting), 0 to |

20VDC |

||||||||||

|

|

|

|

|

(current) |

5VDC, and 0 to 10VDC. Set the voltage/current input switch in |

Current input: |

|||||||

|

|

|

|

|

|

the "V" position to select voltage input (0 to 5V/0 to 10V). |

Input resistance 233Ω ± 5Ω |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum permissible current |

|

|

|

|

|

|

|

Current input |

30mA. |

|||||||

|

|

|

|

|

|

(initial status) Voltage input |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

Frequency setting |

Common terminal for the frequency setting signals (terminals 2 and 4). Do not earth (ground). |

||||||||||

|

|

common |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

10

Wiring

Type |

Terminal |

Terminal Name |

Description |

|

|

|

|

||

Symbol |

|

|

|

|

|||||

|

Relay |

A, B, C |

Relay output |

1 changeover contact output indicates that the inverter fault occurs. |

|

|

|

||

|

Fault: discontinuity across B-C (continuity across A-C), Normal: continuity across B-C |

|

|

|

|||||

|

(fault output) |

|

|

|

|||||

|

|

(discontinuity across A-C) Contact capacity 230VAC 0.3A (power factor = 0.4) 30VDC 0.3A |

|

|

|

||||

circuit/outputsignal |

|

RUN |

Inverter running |

Switched Low when the inverter output frequency is equal to or |

Permissible load 24VDC |

|

|

|

|

|

higher than the starting frequency (initial value 0.5Hz). |

(Maximum 27VDC) 0.1A |

|

|

|

||||

Opencollector |

|

|

Switched High during stop or DC injection brake operation. |

(a voltage drop is 3.4V |

|

|

|

||

|

|

|

|

maximum when the signal is |

|

|

|

||

|

|

|

|

the transistor is OFF (does |

|

||||

|

|

|

|

Switched Low when the inverter output frequency is equal to or |

on) |

|

|

|

|

|

|

FU |

Frequency detection |

higher than the preset detected frequency and High when less |

collector output transistor |

is |

|

||

|

|

|

|

than the preset detected frequency. |

|

ON (conducts). High is when |

|

||

Control |

|

|

|

|

|

not conduct). |

|

|

|

|

SE |

output common |

Common terminal of terminal RUN and FU. |

|

|

|

|

|

|

|

|

|

Open collector |

|

|

|

|

|

|

|

Pulse |

|

|

Used to output a selected monitored item (such as Output |

|

|

|

|

|

|

FM |

For meter |

frequency) among several monitored items. (Not output during |

Permissible load current 1mA |

|

||||

|

inverter reset.) The output signal is proportional to the |

1440 pulses/s at 60Hz |

|

|

|

||||

|

|

|

|||||||

|

|

|

|

magnitude of the corresponding monitoring item. |

|

|

|

2 |

|

Communication |

— |

PU connector |

With the PU connector, RS-485 communication can be established. |

|

|

||||

· Connector: USB mini B connector (receptacle mini B type) |

|

|

|

|

|||||

|

|

· Conforming standard: EIA-485 (RS-485) |

· Transmission format: Multi-drop link |

|

|

|

|||

|

|

|

|

· Communication speed: 4800 to 38400bps |

· Overall extension: 500m |

|

|

|

|

|

|

— |

USB connector |

FR Configurator can be operated by connecting the inverter to the personal computer through USB. |

|

|

|||

|

|

· Interface: conforms to USB1.1 |

· Transmission Speed: 12Mbps |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Note

ySet Pr. 267 and a voltage/current input switch correctly, then input an analog signal in accordance with the setting. Applying a voltage with voltage/current input switch in "I" position (current input is selected) or a current with switch in "V" position (voltage input is selected) could cause component damage of the inverter or analog circuit of output devices.

yThe inverter will be damaged if power is applied to the inverter output terminals (U, V, W). Never perform such wiring.

y

indicates that terminal functions can be selected using Pr. 178 to Pr. 184 and Pr. 190 to Pr. 192 (I/O terminal function selection).

indicates that terminal functions can be selected using Pr. 178 to Pr. 184 and Pr. 190 to Pr. 192 (I/O terminal function selection).

yTerminal names and terminal functions are those of the factory set.

yWhen connecting the DC power supply, be sure to connect the plus side of the power supply to terminal P/+ and minus side to terminal N/-. Opposite polarity will damage the inverter.