MITSUBISHI FR-D700 User Guide

•

Features

•

Standard

specifications

•

Outline

dimension

drawings

•

Terminal connection

diagram

•

Terminal specification

explanation

•

Operation panel

•

Parameter unit

•

Parameter list

•

Protective

functions

•

Option and

peripheral devices

•

Precautions for

operation/selection

•

Precautions for peripheral

device selection

1

5

7

•

FR-D700 Series

Specification

Difference List

32

•

Warranty

•

International

FA Center

33

11

13

16

23

24

27

High reliability is realized!

Safety stop function

Spring clamp terminal (control circuit terminal)

Long-life design

The FR-D700 series is compliant to the EU

Machinery Directive without the addition of

previously required external devices.

Operation of an external Emergency

Stop device results in a highly reliable

immediate shutoff of the D700's output to

the motor.

This safety stop function conforms to the

following standards.

Enhanced function

Equipped with small class highest level of function/performance!!

150%/1Hz high starting torque by general

-purpose magnetic flux vector control

General-purpose magnetic flux vector control and auto

tuning function are available.

It ensures operation that requires high starting torque,

such as transfer machine including conveyer, hoist, lift,

etc., washing machine, and agitators.

•

High torque 150%/1Hz and 200%/3Hz are realized

•

Auto tuning

Many kinds of motors can be optimally controlled with

Mitsubishi original "non-rotation " auto tuning function.

(R1 constants tuning)

Brake resistor can be connected

A brake transistor is built-in to the 0.4K or more.

Connecting an optional brake resistor increases

regeneration capability.

It is useful for deceleration time reduction of a machine

with a large inertia, such as fan, and operation of lift, etc.

Highly reliable and easy wiring is realized by the incorporation of spring clamp terminals.*

•

The design life of the cooling fan has been extended to 10

years

*1

. The life of the fan can be further extended utilizing the

it’s ON/OFF.

•

The longevity of the capacitors has been extended to 10

years by the adoption of a capacitor with a specification of

5000 hours and 105˚C surrounding air temperature

*1,*2

.

Most advanced life check

•

Degrees of deterioration of main circuit capacitor, control

circuit capacitor, and inrush current limit circuit can be

monitored.

•

Trouble can be avoided with the self-diagnostic alarm

*4

that is

output when the life span is near.

Password function

Registering 4-digit password can limit

parameter read/write.

It is effective for parameter setting

protection.

EN954-1 (ISO13849-1) Category 3

IEC60204-1 Stop Categor y 0

*: Main circuit terminal is screw terminal.

Provided by the user (present) FR-D700

Safety function

is equipped

Emergency stop

(example: automobile production line)

(example: hoist)

*1: Surrounding air temperature : annual average 40˚C (free from corrosive gas,

flammable gas, oil mist, dust and dirt) Since the design life is a calculated value, it is

not a guaranteed value.

*2: Output current : 80% of the inverter rated current

*3: Excerpts from "Periodic check of the transistorized inverter" of JEMA (Japan Electrical

Manufacturerís Association)

*4: If any one of main circuit capacitor, control circuit capacitor, inrush current restriction

circuit or cooling fan reaches the output level, an alarm is output. Capacity of the main

circuit capacitor can be measured by setting parameter at a stop and turning the

power from off to on. Measuring the capacity enables alarm to be output.

The cooling fan outputs alarm by using fan speed detection.

•

Life indication of critical components

Components

Cooling fan

Main circuit smoothing capacitor

Printed board smoothing capacitor

Guideline of the FR-D700 Life

10 years

10 years

10 years

Guideline of JEMA

*3

2 to 3 years

5 years

5 years

Emergency stop

Only one MC is enough Only one MC is enough

with safety stop function!with safety stop function!

Only one MC is enough

with safety stop function!

•Cost reduction

•Maintenance of one MC

•Installation space is reduced

For conventional modelFor conventional model...

Two MCs are necessaryTwo MCs are necessary

For conventional model...

Two MCs are necessary

•High cost

•Maintenance of two MCs is

necessary

•Installation space is necessary

•

Magnetic contactor (MC)

•

Emergency stop wiring

(example:

industrial washing machine)

(example: conveyer)

(example: automated storage)

New functions and useful functions from superior models

support all sorts of applications.

•

Regeneration avoidance function

For a pressing machine and

fan rotated faster than the set

speed due to the effect of

another fan, a trip can be

made less likely to occur by

automatically increasing

frequency at regeneration.

•

Optimum excitation control

This control enables the motor

efficiency to its optimum. More

energy saving is possible in

applications with variable load

torque characteristic such as

fan and pump.

•

Power failure-time deceleration-to-stop function

The motor can be decelerated to a stop when a power

failure or undervoltage occurred to prevent the motor

from coasting.

For fail-safe of machine tool, etc., it is effective to stop

the motor when a power failure has occurred.

•

Dancer control

Entering position detection signal of dancer roll to use

PID control enables tension control by dancer roll.

•

Traverse function

Traverse function for wind-up drum of spinning

machine and wiredrawing machine prevents

unevenness and deformation at thread winding.

(example: air-conditioning fan)

(example: pump)

(example: pressing machine)

(example: spindle)

(example: textile machine) (example: wiredrawing machine)

(1) (1)

(3)

(2)

(2)

(3) (4)

(5)

1 2

•

High reliability

Spring structure in terminal contact

section inside prevents contact fault

by vibration.

•

Maintenance is unnecessary

Screw retightening is unnecessary.

•

Easy wiring

Wiring is completed only

by inserting wires treated

with bar terminal (max,

diameter 1.5mm)

Capable of wiring without

a bar terminal.

RoHS Directive compliant

Complies with UL, cUL,EN (LVD) standards

Human and environment-friendly inverter in compliant with

RoHS Directive.

The lineup of EMC filter integrated models.

The lineup of three phase 200V/400V class goes to 15K.

For the FR-D700 series, North American (NA), EU (EC), and Chinese (CHT) specifications also are supported.

Parameter unit FR-PU07 (option)

An optional parameter unit (FR-PU07) can be connected as well.

Enhanced communication function

•

Modbus and Mitsubishi inverter protocol

Supports Modbus RTU

Communication speed of RS-485 has been improved

(communication at 38.4kbps is available)

"Multi command mode" has been added to Mitsubishi inverter protocol

(data processing time of the inverter has been reduced to 1/4)

Setting is easily done from a personal

computer using the FR Configurator

(option) (available soon)

Connecting a personal computer and the inverter via RS-485

communication realizes setting with wizard (interactive) function

of the FR Configurator (inverter setup software).

In addition, a parameter setting can be converted from the FR-

S500 series to the FR-D700 series by "convert" function.

Displays monitor data in waveform. [Graph]

Enclosure surface operation panel

FR-PA07 (option)

Optional enclosure surface operation panel (FR-PA07) can be

connected. In addition, an operation panel for the FR-E500

series can be connected.

RoHS Directive requires member nations must guarantee that new electrical and electronic

equipment sold in the market after July 1, 2006 do not contain lead, cadmium, mercury,

hexavalent chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether

(PBDE) flame retardants

<G> mark indicating RoHS Directive compliance is printed on the package.

Easily replaceable compact body

Installation size is the same as that of the FR-S500 series which

is the smallest model of the Mitsubishi inverter.

Side by side installation saves space

Space can be saved by side by side no clearance installation*.

Easy replacement of cooling fan

A cooling fan is provided on top

of the inverter of all capacities

requiring a cooling fan (1.5K or

more).

A cooling fan can be easily

replaced without disconnecting

main circuit wires.

Combed shaped wiring cover

Since a cover can be fitted

after wiring, wiring work is

easily done.

The operation panel of the inverter can not be removed.

A parameter unit connection cable (FR-CB20 ) is

separately necessary.

A parameter unit connection cable (FR-CB20 ) is separately necessary.

Quick setup with the setting dial

Mitsubishi inverter has a setting dial of course.

•

The scrolling speed of the dial was made to variable for more

improved operability.

•

The nonslip setting dial is easier to turn.

Acceleration/deceleration

pattern setting

Acceleration/deceleration

time setting

Parameter list display

Setting wizard function (example: acceleration/deceleration time setting)

128mm

FR-D740-0.4K FR-S540E-0.4K

*: Use the inverter at the surrounding air temperature of 40˚C or less.

*: This catalog explains based on the Japanese specifications.

Consult our sales office for specifications of each country.

FR-D740 -0.4K-

Inverter Type

Inverter Capacity

0.1 0.2 0.4 0.75 1.5 2.2 3.7 5.5 7.5

FR-D720- K

FR-D740- K

FR-D720S- K

FR-D710W- K

Three phase

200V

Three phase

400V

Single phase

200V

*

Single phase

100V *

Enclosed structure (IP20)

Totally-enclosed structure (IP40)

Enclosed structure (IP20)

Totally-enclosed structure (IP40)

Enclosed structure (IP20)

Enclosed structure (IP20)

11 15

*: Output of the single-phase 200V and single-phase 100V input models is three-phase 200V.

:Available models :Models to be released :Not available

Power

Supply

Symbol

1

2

4

Voltage

100V class

200V class

400V class

Symbol

None

C

Protective Structure

Enclosed-type structure IP20

Totally enclosed structure IP40

Symbol

0.1K to 15K

Inverter Capacity

Indicate capacity

"kW".

Symbol

None

S

W

Number of Power Phases

Three-phase input

Single-phase input

Single-phase input

(double voltage output)

(1) (1) (2)

(1)

(3)

(1) (2)

(2) (3)

EMC filter integrated model

(to be released)

(3)

(4)

(5)

3 4

FeaturesOptions

Standard

Specifications

Operation panel

Parameter unit

Parameter

List

Protective

Functions

Terminal Connection

Diagram

Terminal Specification

Explanation

Outline

Dimension

Drawings

Instructions

FR-D700 Series

Specification

Difference List

Warranty

International

FA Center

•

Setting such as direct input method with a numeric

keypad, operation status indication, and help

function are usable.

Eight languages can be displayed.

•

Parameter setting values of maximum of three

inverters can be stored.

•

A battery pack type (FR-PU07BB(-L)) allows

parameter setting and parameter copy without

powering on the inverter. (available soon)

•

To use a parameter unit with battery pack (FR-PU07BB)

outside Japan, order a “FR-PU07BB-L” (parameter unit type

indicated on the package has L at the end).

Since enclosed batteries may conflict with laws in countries to

be used (new EU Directive on batteries and accumulators, etc.),

batteries are not enclosed with an FR-PU07BB except Japan.

5

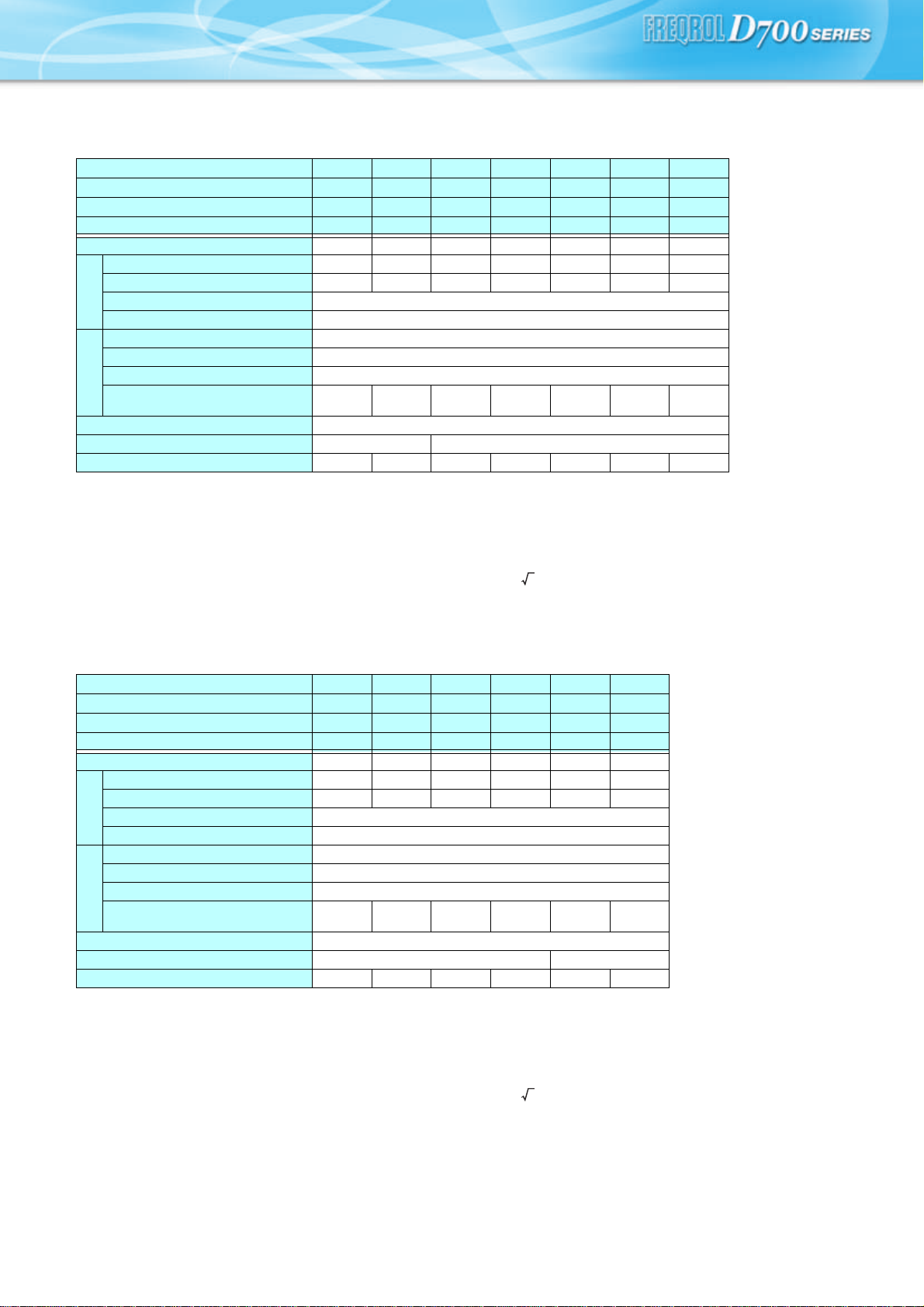

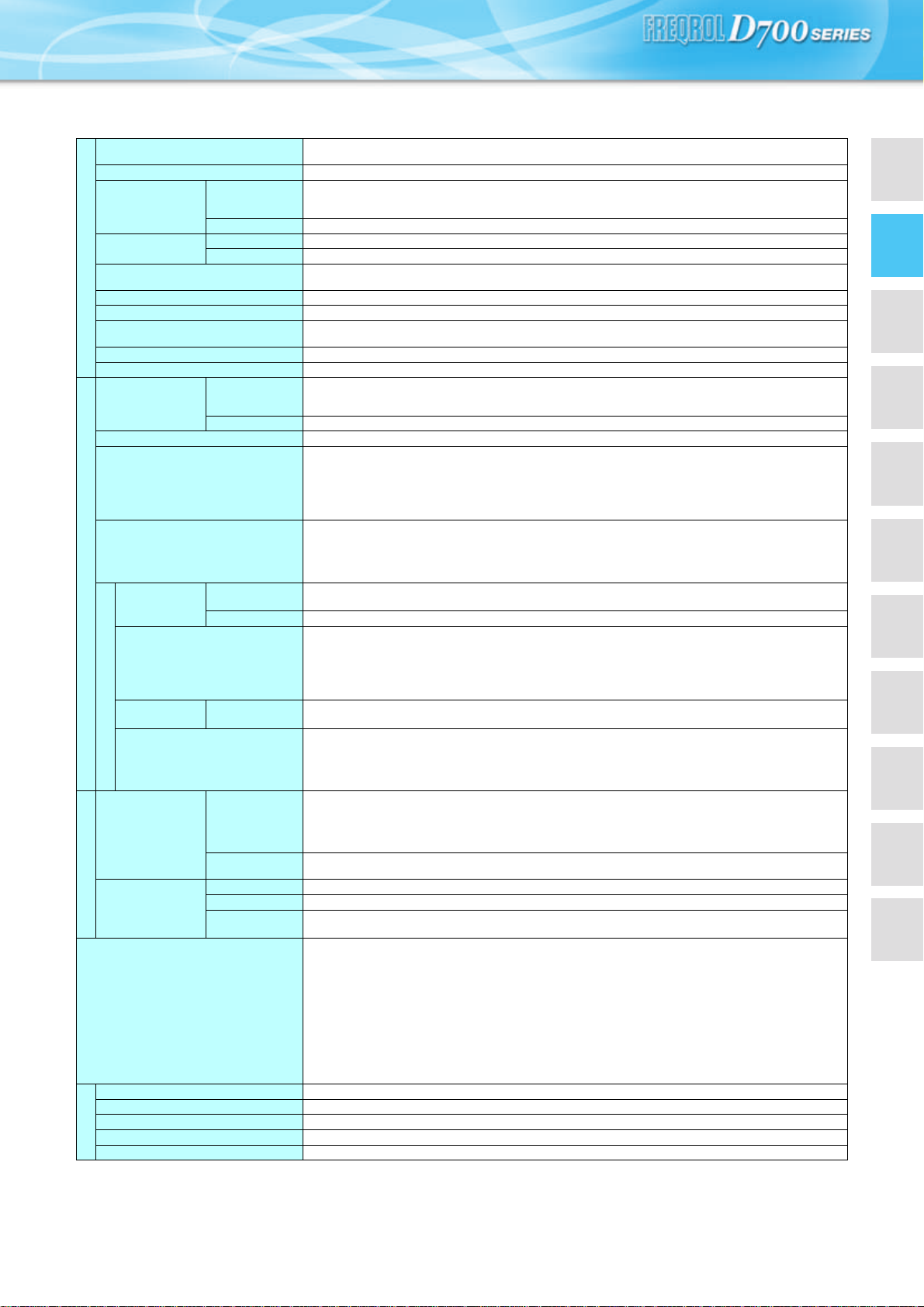

Standard specifications

Rating

z Three-phase 400V power supply

∗1 The applicable motor capacity indicated is the maximum capacity applicable for use of the Mitsubishi 4-pole standard motor.

∗2 The rated output capacity indicated assumes that the output voltage is 440V.

∗3 The % value of the overload current rating indicated is the ratio of the overload current to the inverter's rated output current. For repeated duty, allow time for

the inverter and motor to return to or below the temperatures under 100% load.

∗4 The maximum output voltage does not exceed the power supply voltage. The maximum output voltage can be changed within the setting range. However,

the pulse voltage value of the inverter output side voltage remains unchanged at about that of the power supply.

∗5 The power supply capacity varies with the value of the power supply side inverter impedance (including those of the input reactor and cables).

∗6 Totally enclosed structure series ends with -C.

z Single-phase 200V power supply

∗1 The applicable motor capacity indicated is the maximum capacity applicable for use of the Mitsubishi 4-pole standard motor.

∗2 The rated output capacity indicated assumes that the output voltage is 230V.

∗3 The % value of the overload current rating indicated is the ratio of the overload current to the inverter's rated output current. For repeated duty, allow time for

the inverter and motor to return to or below the temperatures under 100% load.

∗4 The maximum output voltage does not exceed the power supply voltage. The maximum output voltage can be changed within the setting range. However,

the pulse voltage value of the inverter output side voltage remains unchanged at about that of the power supply.

∗5 The power supply capacity varies with the value of the power supply side inverter impedance (including those of the input reactor and cables).

Model FR-D740-K(-C)∗6 0.4 0.75 1.5 2.2 3.7 5.5 7.5

Model FR-D740--NA 012 022 036 050 080 120 160

Model FR-D740--EC 012 022 036 050 080 120 160

Model FR-D740-K-CHT 0.4 0.75 1.5 2.2 3.7 5.5 7.5

Applicable motor capacity (kW)∗1 0.4 0.75 1.5 2.2 3.7 5.5 7.5

Output

Rated capacity (kVA)∗2 1.2 2.0 3.0 4.6 7.2 9.1 13.0

Rated current (A) 1.2 2.2 3.6 5.0 8.0 12.0 16.0

Overload current rating∗3 150% 60s, 200% 0.5s (inverse-time characteristics)

Voltage∗4 Three-phase 380 to 480V

Power supply

Rated input voltage/frequency Three-phase 380 to 480V 50Hz/60Hz

Permissible AC voltage fluctuation 325 to 528V 50Hz/60Hz

Permissible frequency fluctuation ±5%

Power supply capacity (kVA)∗5 1.52.54.55.59.512 17

Protective structure (JEM1030) Enclosed type (IP20). IP40 for totally enclosed structure series.

Cooling system Self-cooling Forced air cooling

Approximate mass (kg) 1.2 1.2 1.3 1.4 1.5 3.1 3.1

Model FR-D720S-K 0.1 0.2 0.4 0.75 1.5 2.2

Model FR-D720S--NA 008 014 025 042 070 100

Model FR-D720S--EC 008 014 025 042 070 100

Model FR-D720S-K-CHT 0.1 0.2 0.4 0.75 1.5 2.2

Applicable motor capacity (kW)∗1 0.1 0.2 0.4 0.75 1.5 2.2

Output

Rated capacity (kVA)∗2 0.3 0.5 1.0 1.6 2.8 3.8

Rated current (A) 0.8 1.4 2.5 4.2 7.0 10.0

Overload current rating∗3 150% 60s, 200% 0.5s (inverse-time characteristics)

Voltage∗4 Three-phase 200 to 240V

Power supply

Rated input voltage/frequency Single-phase 200 to 240V 50Hz/60Hz

Permissible AC voltage fluctuation 170 to 264V 50Hz/60Hz

Permissible frequency fluctuation ±5%

Power supply capacity (kVA)∗5 0.5 0.9 1.5 2.3 4.0 5.2

Protective structure (JEM1030) Enclosed type (IP20).

Cooling system Self-cooling Forced air cooling

Approximate mass (kg) 0.5 0.6 0.9 1.1 1.5 1.9

2

2

FeaturesOptions

Standard

Specifications

Operation panel

Parameter unit

Parameter

List

Protective

Functions

Terminal Connection

Diagram

Terminal Specification

Explanation

Outline

Dimension

Drawings

Instructions

FR-D700 Series

Specification

Difference List

Warranty

International

FA Center

6

Common specifications

Control specifications

Control method

Soft-PWM control/high carrier frequency PWM control (V/F control, general-purpose magnetic flux vector control,

optimum excitation control can be selected)

Output frequency range

0.2 to 400Hz

Frequency setting

resolution

Analog input

0.06Hz/60Hz (terminal2, 4: 0 to 10V/10bit)

0.12Hz/60Hz (terminal2, 4: 0 to 5V/9bit)

0.06Hz/60Hz (terminal4: 0 to 20mA/10bit)

Digital input

0.01Hz

Frequency

accuracy

Analog input

Within ±1% of the max. output frequency (25°C ±10°C)

Digital input

Within 0.01% of the set output frequency

Voltage/frequency characteristics

Base frequency can be set from 0 to 400Hz

Constant torque/variable torque pattern can be selected

Starting torque

150% or more (at 1Hz)...when general-purpose magnetic flux vector control and slip compensation is set

Torque boost

Manual torque boost

Acceleration/deceleration time setting

0.1 to 3600s (acceleration and deceleration can be set individually), linear or S-pattern acceleration/deceleration

mode can be selected.

DC injection brake

Operation frequency (0 to 120Hz), operation time (0 to 10s), operation voltage (0 to 30%) variable

Stall prevention operation level

Operation current level can be set (0 to 200% adjustable), whether to use the function or not can be selected

Operation specifications

Frequency setting

signal

Analog input

Two po in ts

Terminal 2: 0 to 10V, 0 to 5V can be selected

Terminal 4: 0 to 10V, 0 to 5V, 4 to 20mA can be selected

Digital input

Entered from operation panel and parameter unit. Frequency setting increments is selectable

Start signal

Forward and reverse rotation or start signal automatic self-holding input (3-wire input) can be selected.

Input signal

Five points

You can select from among multi-speed selection, remote setting, second function selection, terminal 4 input

selection, JOG operation selection, PID control valid terminal, external thermal input, PU-external operation

switchover, V/F switchover, output stop, start self-holding selection, traverse function selectiom, forward rotation,

reverse rotation command, inverter reset, PU-NET operation switchover, external-NET operation switchover,

command source switchover, inverter operation enable signal, and PU operation external interlock

Operational functions

Maximum/minimum frequency setting, frequency jump operation, external thermal relay input selection, automatic

restart after instantaneous power failure operation, forward/reverse rotation prevention, remote setting, second

function, multi-speed operation, regeneration avoidance, slip compensation, operation mode selection, offline

auto tuning function, PID control, computer link operation (RS-485), optimum excitation control, power failure

stop, speed smoothing control, Modbus-RTU

Output signal

Output signal

points

Open collector

output

One point

Relay output

One point

Operating status

You can select from among inverter operation, up-to-frequency, overload alarm, output frequency detection,

regenerative brake prealarm, electronic thermal relay function prealarm, inverter operation ready, output current

detection, zero current detection, PID lower limit, PID upper limit, PID forward/reverse rotation output, fan

alarm∗2, heatsink overheat pre-alarm, deceleration at an instantaneous power failure, PID control activated, PID

output interruption, during retry, life alarm, current average value monitor, remote output, alarm output, fault

output, fault output 3, and maintenance timer alarm

For meter

Output points

Pulse output

MAX 2.4kHz: one point

For meter

You can select from among output frequency, motor current (steady), output voltage, frequency setting, converter

output voltage, regenerative brake duty, electronic thermal relay function load factor, output current peak value,

converter output voltage peak value, reference voltage output, motor load factor, PID set point, PID measured

value, output power, PID deviation, Motor thermal load factor, Inverter thermal load factor

Pulse train output (1440 pulses/s/full scale)

Indication

Operation panel

Parameter unit

(FR-PU07)

Operating status

You can select from among output frequency, motor current (steady), output voltage, frequency setting,

cumulative energization time, actual operation time, converter output voltage, regenerative brake duty, electronic

thermal relay function load factor, output current peak value, converter output voltage peak value, motor load

factor, PID set point, PID measured value, PID deviation, inverter I/O terminal monitor, output power, cumulative

power, motor thermal load factor, inverter thermal load factor, PTC thermistor resistance.

Fault definition

Fault definition is displayed when the fault occurs and the past 8 fault definitions (output voltage/current/

frequency/cumulative energization time right before the fault occurs) are stored

Additional display

by the parameter

unit (FR-PU04/FR-

PU07) only

Operating status

Not used

Fault definition

Output voltage/current/frequency/cumulative energization time immediately before the fault occurs

Interactive

guidance

Function (help) for operation guide

Protective/warning function

<Protective functions>

Overcurrent during acceleration, overcurrent during constant speed, overcurrent during deceleration, overvoltage

during acceleration, overvoltage during constant speed, overvoltage during deceleration, inverter protection

thermal operation, motor protection thermal operation, heatsink overheat, input phase failure ∗4 ∗5, output side

earth (ground) fault overcurrent at start∗4, output phase failure, external thermal relay operation ∗4, PTC

thermistor operation∗4, parameter error, PU disconnection, retry count excess ∗4, CPU fault, brake transistor

alarm, inrush resistance overheat, analog input error, stall prevention operation, output current detection value

exceeded

<Warning functions>

Fan alarm∗2, overcurrent stall prevention, overvoltage stall prevention, PU stop, parameter write error,

regenerative brake prealarm ∗4, electronic thermal relay function prealarm, maintenance output ∗4, undervoltage,

operation panel lock, password locked, inverter reset

Environment

Surrounding air temperature

-10°C to +50°C (non-freezing) (-10°C to +40°C for totally-enclosed structure feature) ∗3

Ambient humidity

90%RH maximum (non-condensing)

Storage temperature∗1

-20°C to +65°C

Atmosphere

Indoors (without corrosive gas, flammable gas, oil mist, dust and dirt etc.)

Altitude/vibration

Maximum 1000m above sea level, 5.9m/s

2

or less

∗1 Temperatures applicable for a short time, e.g. in transit.

∗2 As the 0.75K or less is not provided with the cooling fan, this alarm does not function.

∗3 When using the inverters at the surrounding air temperature of 40°C or less, the inverters can be installed closely attached (0cm clearance).

∗4 This protective function does not function in the initial status.

∗5 This protective function is available with the three-phase power input specification model only.

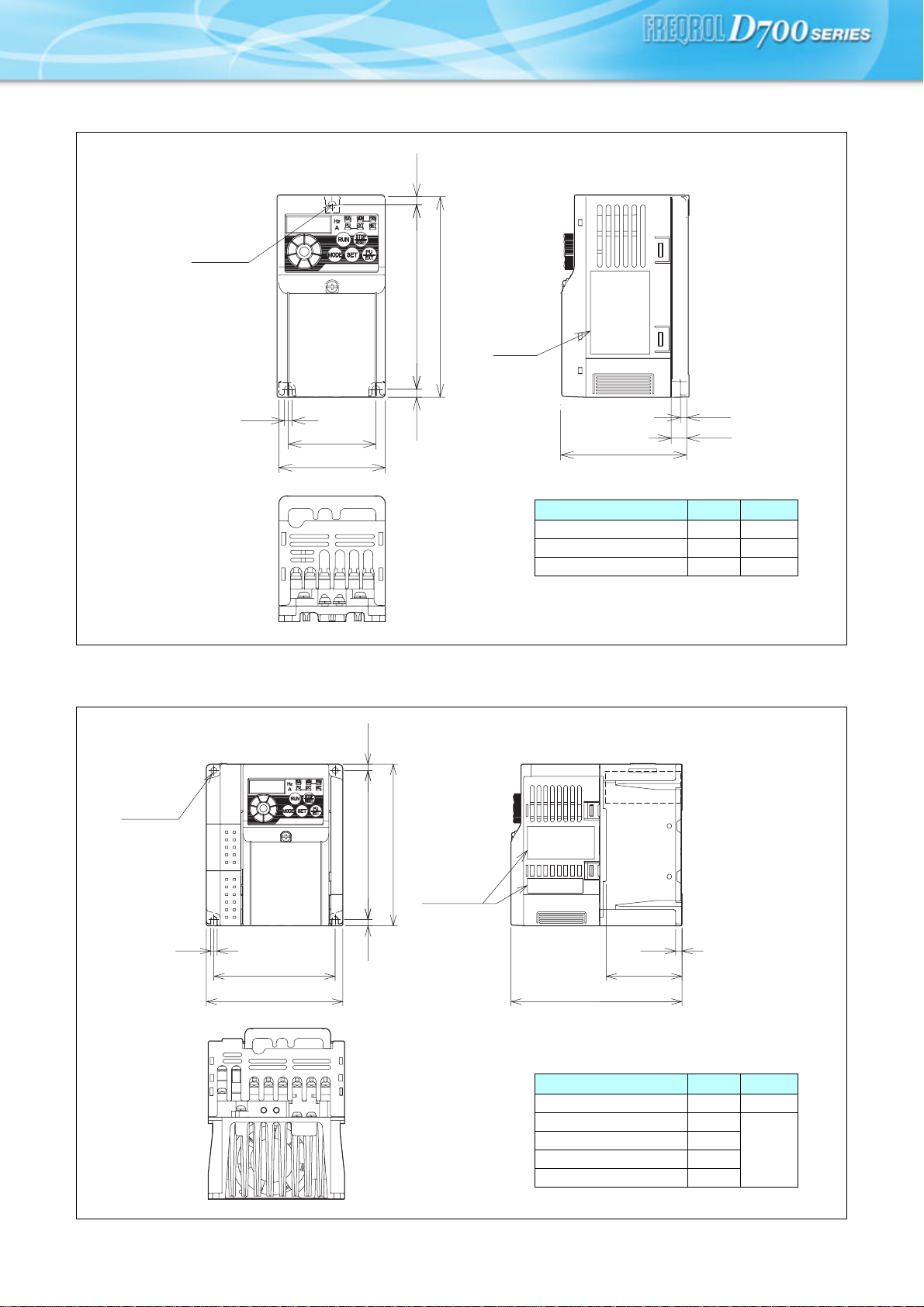

7

zFR-D720S-0.1K to 0.75K

zFR-D740-0.4K to 3.7K

zFR-D720S-1.5K

(Unit: mm)

(Unit: mm)

1-φ5 hole

5

68

56

5 118 5

128

Rating

plate

D

4

D1

Inverter Type

D D1

FR-D720S-0.1K, 0.2K 80.5 10

FR-D720S-0.4K 142.5 42

FR-D720S-0.75K 162.5 62

Rating

plate

2-φ5 hole

*

FAN

5

96

108

5 5

128

118

5

D1

D

Inverter Type

D D1

FR-D740-0.4K, 0.75K 129.5 54

FR-D740-1.5K 135.5

60

FR-D740-2.2K 155.5

FR-D740-3.7K 165.5

FR-D720S-1.5K 155.5

∗ FR-D740-0.4K, 0.75K are not provided with the cooling fan.

Outline Dimension Drawings

FeaturesOptions

Standard

Specifications

Operation panel

Parameter unit

Parameter

List

Protective

Functions

Terminal Connection

Diagram

Terminal Specification

Explanation

Outline

Dimension

Drawings

Instructions

FR-D700 Series

Specification

Difference List

Warranty

International

FA Center

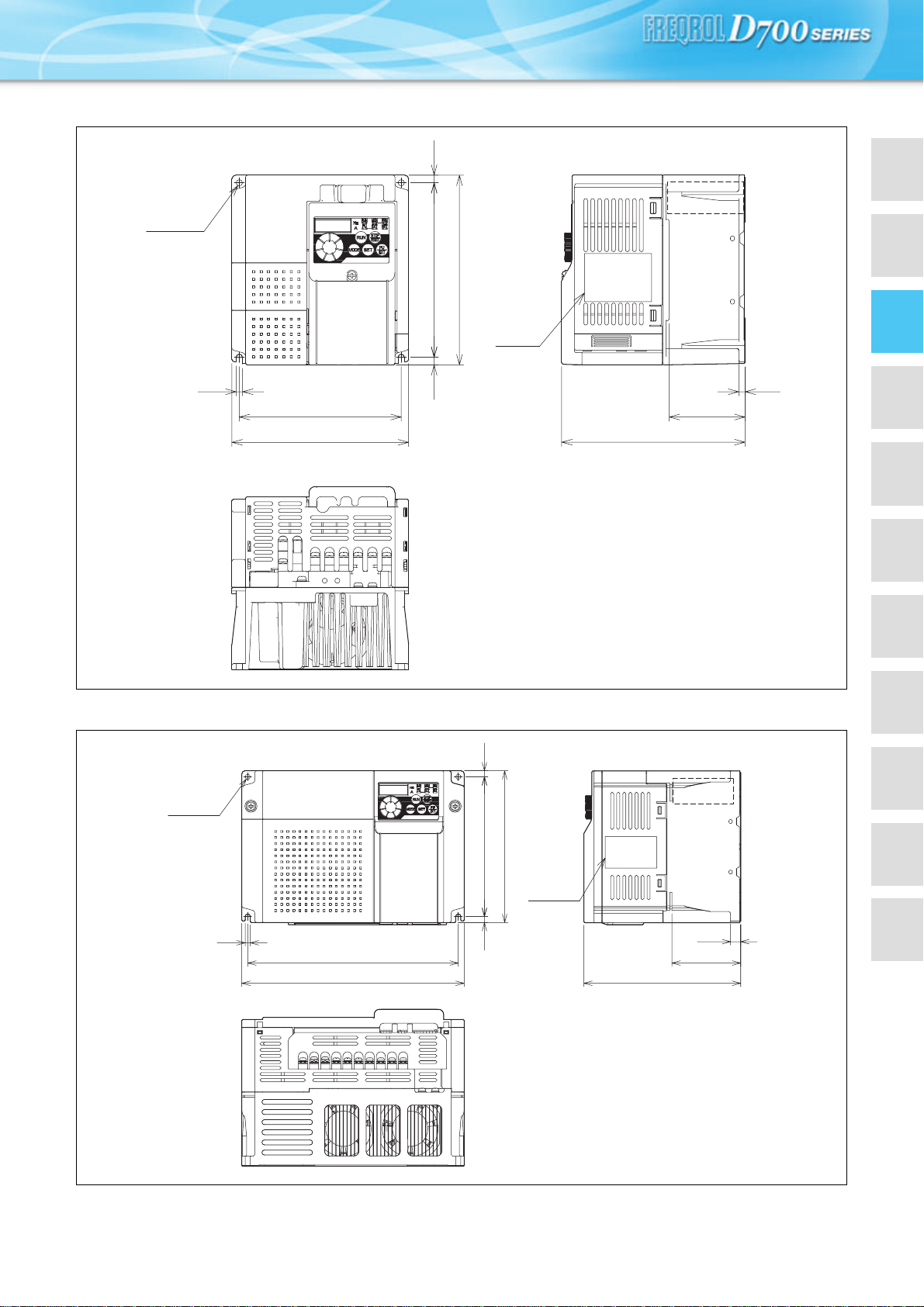

8

zFR-D720S-2.2K

zFR-D740-5.5K, 7.5K

(Unit: mm)

(Unit: mm)

2-φ5 hole

Rating

plate

128

140

5

138 66

150

FAN

5

60

145

2-φ5 hole

Rating

plate

6

1386

150

208

5

220

10

68

155

FAN

9

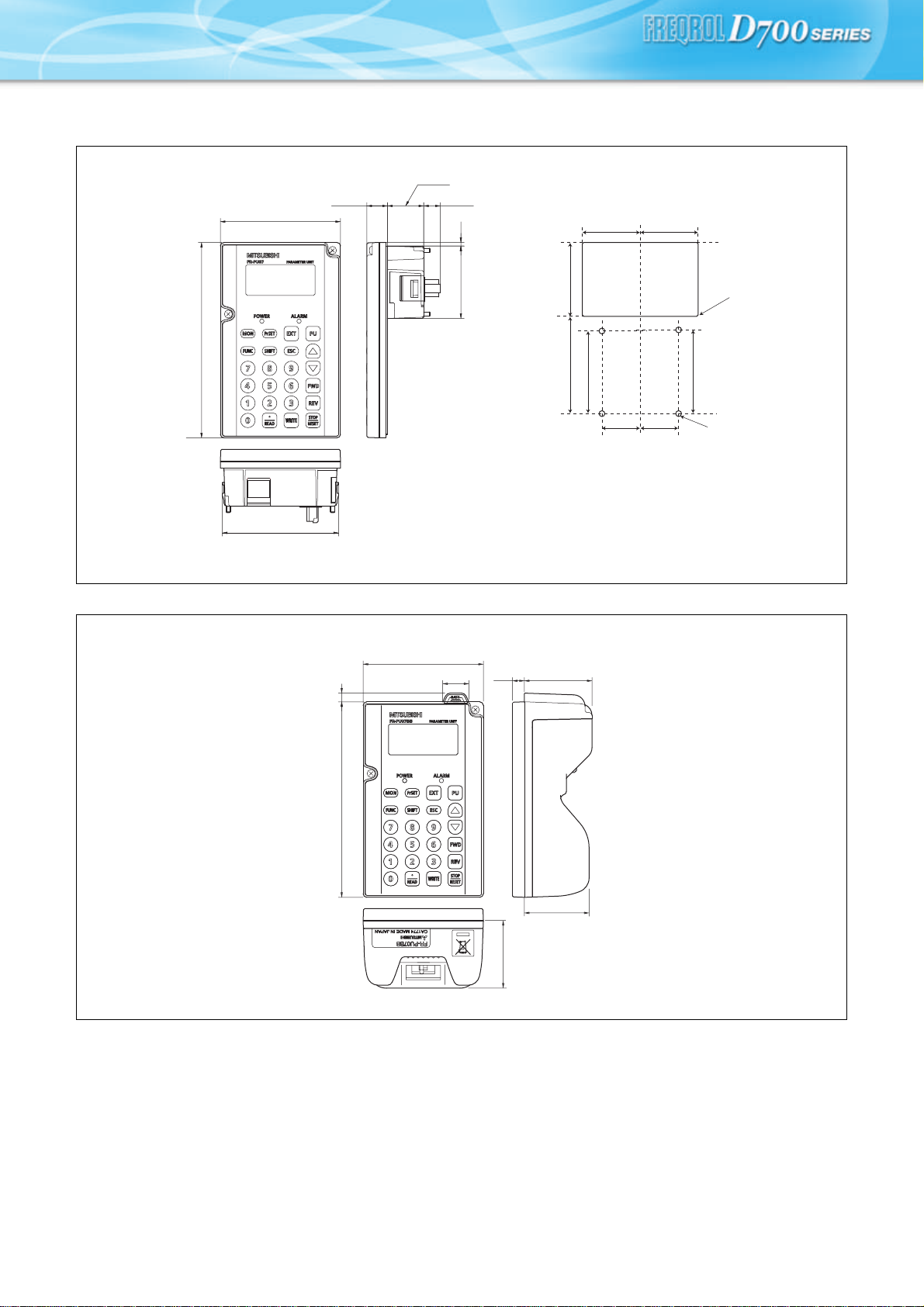

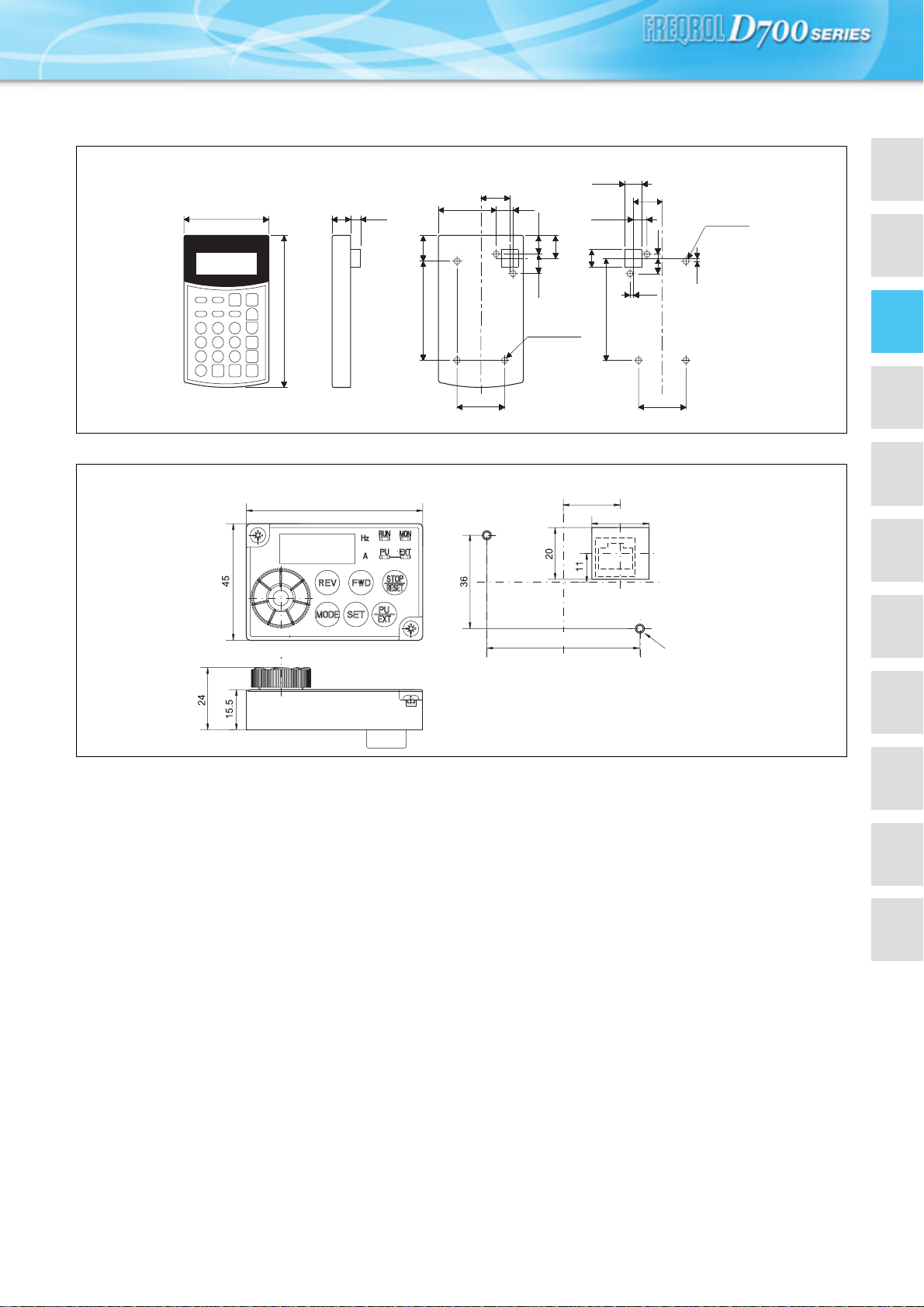

zParameter unit (option) (FR-PU07)

<Outline drawing> <Panel cut dimension drawing>

z

Parameter unit (option) (FR-PU07BB (-L))

<

Outline drawing>

67

51

40

56.8

57.8

26.5

4-R1

26.5

40

4-φ4 hole

(

Effective depth of the

installation screw hole 5.0)

M3 screw *2

Air-bleeding

hole

80.3

(14.2)

2.5

50

(11.45)

25.05

135

83

*1

*1

*1

*1

∗1 When installing the FR-PU07 on the enclosure, etc., remove screws or fix the screws to the FR-PU07 with M3 nuts.

∗2 Select the installation screw whose length will not exceed the effective depth of the installation screw hole.

(Unit: mm)

46.7

135

83

18

6

8.2

46.7

44.7

∗ Select the installation screw whose length will not exceed the effective depth of the installation screw hole.

(Unit: mm)

FeaturesOptions

Standard

Specifications

Operation panel

Parameter unit

Parameter

List

Protective

Functions

Terminal Connection

Diagram

Terminal Specification

Explanation

Outline

Dimension

Drawings

Instructions

FR-D700 Series

Specification

Difference List

Warranty

International

FA Center

10

zParameter unit (option) (FR-PU04)

<

Outline drawing><Panel cut dimension drawing>

zEnclosure surface operation panel (option) (FR-PA07)

<

Outline drawing><Panel cut dimension drawing>

40

5-φ4 hole

23.75

11.75

81.5

1.25

1.5

13

17

16.5

1.5

125

72 15 10.5

18.5

40

80

48

5-M3 screw

24

13

20

21.5

14.5

Effective

depth

of the

installation

screw hole

4.5

Select the installation screws whose length will not exceed the effective depth of the installation screw hole.

(Unit: mm)

68

59

22

22

2-M3 scre

w

(Unit: mm)

11

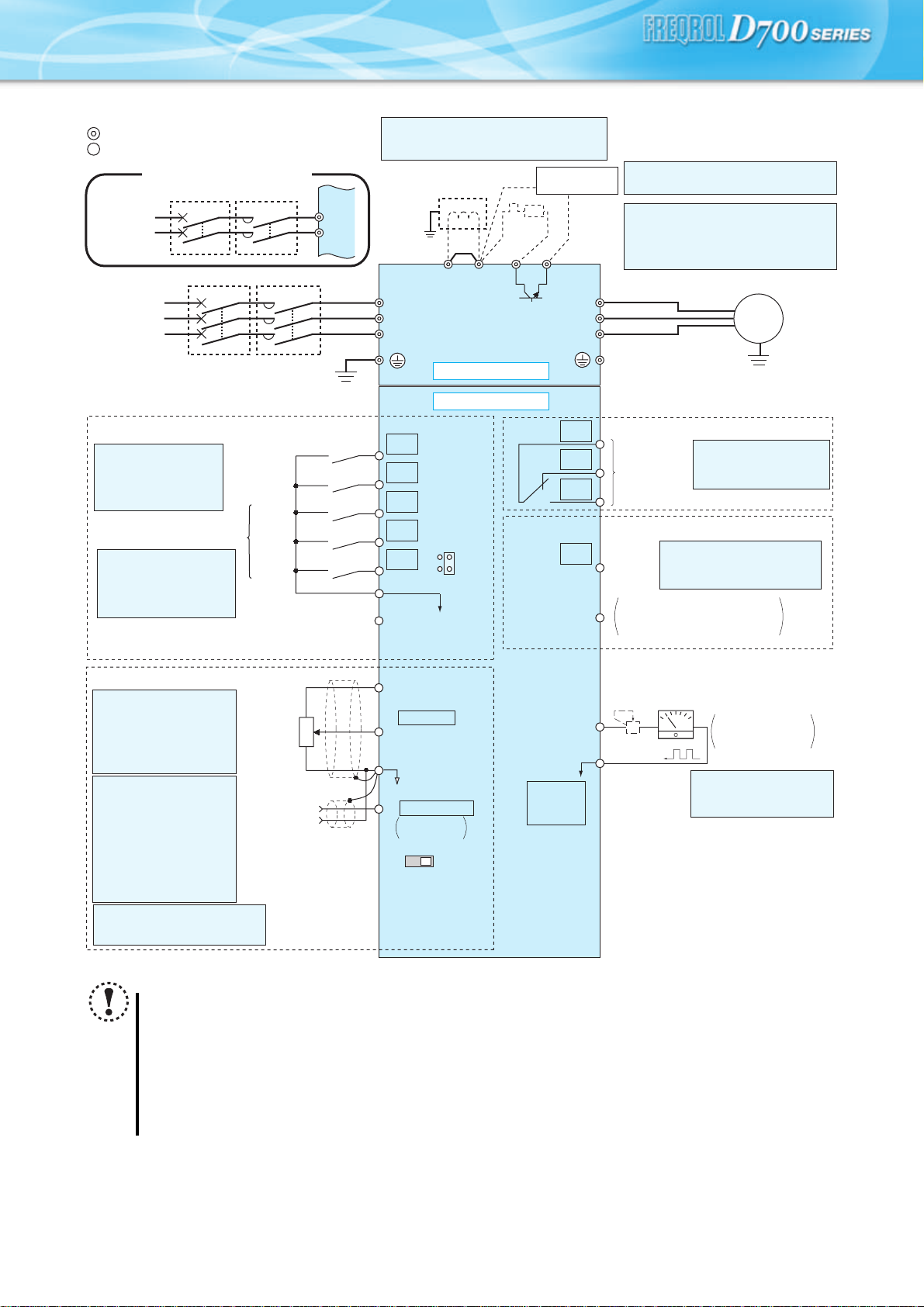

Terminal Connection Diagram

Note

y To prevent a malfunction caused by noise, separate the signal cables more than 10cm from the power cables.

y After wiring, wire offcuts must not be left in the inverter.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean. When drilling mounting holes

in an enclosure etc., take care not to allow chips and other foreign matter to enter the inverter.

y To ensure safety, for single-phase power input specification model, connect the power input to the inverter via a

magnetic contactor and earth leakage circuit breaker or moulded case circuit breaker, and use the magnetic

contactor to switch power on-off.

y The output of the single-phase power input specification is three-phase 200V.

Earth

(Ground)

Motor

IM

Earth (Ground)

Three-phase

AC power

supply

MCCB MC

R/L1

P1 P/+

PR

N/-

S/L2

T/L3

U

V

W

Earth

(Ground)

*7 Brake resistor (FR-ABR, MRS)

Install a thermal relay to prevent an

overheat and burnout of the brake resistor.

(The brake resistor can not be connected

to the FR-D720S-0.1K and 0.2K.)

Forward

rotation start

Reverse

rotation start

Middle

speed

High

speed

Low

speed

Control input signals (No voltage input allowed)

Contact input common

24VDC power supply

Contact input common

(Common for external power supply transistor)

STR

STF

RH

RM

RL

SD

PC

Relay output

Running

Open collector output

Open collector output common

Sink/source common

RUN

SE

A

B

C

Frequency setting signals (Analog)

2 0 to 5VDC

10(+5V)

2

3

1

4 4 to 20mADC

Frequency

setting

potentiometer

1/2W1kΩ

Terminal 4

input

(Current

input)

(+)

(-)

5(Analog common)

*5 It is recommended to use 2W1kΩ

when the frequency setting signal

is changed frequently.

*5

*2 When using terminals PC-

SD as a 24VDC power

supply, take care not to

short across terminals

PC-SD.

PU

connector

*1. DC reactor (FR-HEL)

When connecting a DC reactor, remove the

jumper across P1-P/+

Control circuit terminal

Main circuit terminal

Source logic

Jumper

*1

*7

*6

*2

*3

*4

Terminal functions vary

with the input terminal

assignment (Pr. 178 to

Pr. 182)

Multi-speed selection

Terminal functions vary by

Pr. 190 RUN terminal function

selection

Terminal functions vary

by Pr. 192 A,B,C terminal

function selection

SINK

SOURCE

VI

*4

0 to 5VDC

(0 to 10VDC)

0 to 10VDC

*4 Terminal input

specifications can be

changed by analog input

specifications switchover

(Pr. 267). Set the

voltage/current input

switch in the "V" position

to select voltage input (0

to 5V/0 to10V) and "I"

(initial value) to select

current input (4 to 20mA).

Voltage/current

input switch

Main circuit

Control circuit

R

Relay output

(Fault output)

Brake unit

(Option)

FM

SD

Indicator

(Frequency meter, etc.)

+

-

Moving-coil type

1mA full-scale

Calibration resistor

*8 It is not necessary when

calibrating the indicator

from the operation panel.

*8

Single-phase

AC power

supply

MCCB MC

R/L1

S/L2

Single-phase power input

*6 A brake transistor is not built-in to the

FR-D720S-0.1K and 0.2K.

*3 Terminal input specifications

can be changed by analog

input specifications

switchover (Pr. 73).

Terminal 10 and terminal 2

are used as PTC input

terminal (Pr. 561).

Loading...

Loading...