Miele WS 5071 MOP-PROFI Operating instructions

Operating instructions

Washer-Extractor

WS 5071 MOP-PROFI

To avoid the risk of accidents or damage to the machine it is |

en - GB |

essential to read these instructions before installing, |

M.-Nr. 07 076 772 |

commissioning and using it for the first time. |

2 |

M.-Nr. 07 076 772 |

Contents

Warning and Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Setting the local language (if necessary). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Setting current time and date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Washing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Before using for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Preparing the wash load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Programme end - to open the drum door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Maximum load / Detergent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Bleaching agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Detergent dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Additional functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 With Pre-wash. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Starch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Without spin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Skipping programme stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Programme interruption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Programme cancellation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Delayed Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 PCPrinter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 PCPrinter connection: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Liquid dispensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Amount to be dispensed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Commissioning the dispensing pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Cleaning and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Problem solving guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Power cut during a wash programme - Emergency door release . . . . . . . . . . . . . . . . . . . . . . . 27 Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Possible reasons for increased levels of foaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Explanation of symbols on the data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Notes for the installer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Transit fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Connection to water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

The washer-extractor must be installed and commissioned by an approved Service technician or authorised Service Dealer.

M.-Nr. 07 076 772 |

3 |

Warning and Safety Instructions

Please read the operating instructions before using this machine for the first time. They contain important information about the safety, use and maintenance of the machine. This will avoid the risk of accidents and damage to the machine.

Appropriate use of the machine

This washer extractor is only intended for items of laundry which have not been

impregnated with dangerous or inflammable substances.

Only machine wash articles which possess a care label stating they are

suitable for machine washing.

It is the operator’s responsibility to ensure that the standard of disinfection

in thermal as well as chemo thermal procedures is maintained (in accordance with § 18 IFSG) by carrying out suitable validation tests. These procedures should be checked on a regular basis, either thermo-electrically using loggers, or bacteriologically with bio indicators. The operator must pay particular attention to maintaining the correct parameters in the procedure, including temperature and with chemo thermal programmes the chemical concentration used. Disinfection programmes must not be interrupted, as this can have a limiting effect on the disinfection result.

On no account must solvents of the kind used for dry cleaning be used in this

machine. There may be the danger of fire or explosion.

Never use or store petrol or petroleum based substances or any easily

inflammable substances near the machine. Do not use the machine lid as a resting place.

Danger of fire or explosion

Technical and electrical safety

The electrical safety of this machine can only be guaranteed when continuity is

complete between it and an effective earthing system which complies with local and national safety regulations.

It is most important that this basic safety requirement is regularly tested by a qualified electrician. The manufacturer cannot be held liable for the consequences of an inadequate earthing system.

Do not damage, remove or bypass the safety features and controls on the

machine.

Where there is any damage to the machine or to the cable insulation the

machine must not be used until it has been repaired.

Any removable outer panels must be in place, and all moving or electrical parts

shielded before the machine is operated.

The machine is only completely isolated from the electricity supply either when

switched off at the wall isolator, or the mains fuse is withdrawn from the socket.

Repairs should only be undertaken by a suitably qualified service engineer to

ensure safety. Unauthorised repairs could be dangerous.

Faulty components should only be exchanged for Miele original spare parts.

Only when these parts are fitted can the safety standards of the machine be guaranteed.

The very best materials are used in the manufacture of this machine, and every

care is taken in its manufacture. However, with time, deterioration of parts can occur, especially with rubber components such as hoses. Check the inlet hoses regularly for signs of deterioration and replace in good time, to avoid leaks and subsequent damage.

4 |

M.-Nr. 07 076 772 |

Warning and Safety Instructions

Use of the machine

This washer extractor is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience or knowledge, unless they have been given supervision or instruction concerning its use by a person responsible for their safety.

Never allow children to play in, on or near the washer extractor, or to operate it

themselves. Please supervise its use by the elderly or infirm.

Remember that the door porthole glass can become hot during the operation of

the machine. Do not let children touch it.

When washing with high temperatures steam can be emitted from the venting

slot behind the machine.

Do not grip between the suspended drum unit and the seal of the front panel

cut-out during spin.

Always make sure the drum is stationary before reaching in to remove washing.

Reaching into a moving drum is extremely dangerous.

Water used for washing and rinsing must not be used as drinking water. It must be

discharged into a proper drainage system.

The machine should only be operated unsupervised when there is a floor drain

(gully) in the direct vicinity of the machine.

To avoid flooding:

If hooking the hose into a sink make sure that the water can flow away freely to avoid flooding.

Secure the hose against slipping. The pressure of the water flowing out can push an unsecured hose out of the sink.

Disinfecting and cleaning agents often have compounds containing chlorides in

them. If these agents dry on to stainless steel surfaces, the residual chlorides will attack the steel and can cause rusting.

To protect your machine from rust damage, we recommend only using chloride free disinfecting and cleaning agents for washing and disinfecting programmes and for cleaning stainless steel surfaces of the machine itself.

If you are not sure about a particular agent, contact the manufacturer of that agent for advice.

If you accidentally spill an agent containing chlorides on the machine it should be rinsed off with water and dried using a soft cloth.

Proprietary dyes, dye removers and descaling agents may only be used in

this machine if the manufacturer expressly states that they are suitable for use in a washing machine. Follow the instructions on the packaging.

Laundry that was soiled with biological oils or fat should be washed using a

suitable detergent and/or wash programme. It must also be inspected after washing. If oils or fat are not sufficiently removed they could cause the laundry to self ignite during the drying process.

Always follow the instructions of the chemical manufacturer when using a combination of cleaning agents and special

application chemicals. Only use such chemicals for the purpose and in the situation specified by the manufacturer in order to avoid the danger of adverse chemical reactions and material damage. If in doubt check the suitability of the product for use in this machine with the manufacturer before using it.

M.-Nr. 07 076 772 |

5 |

Warning and Safety Instructions

Where a chemical cleaning agent is recommended on technical application

grounds, this does not imply that the manufacturer of the machine takes responsibility for the effect of the chemical on the material of the items being cleaned or on the machine.

Please be aware that changes in formulation, storage conditions etc., which may not be publicised by the chemical producer, can have a negative effect on the cleaning result.

On no account use pressure washers or hose down the machine to clean it.

Use of accessories

Accessory parts may only be fitted when expressly approved by Miele. If other

parts are used, guarantee, performance and product liability claims may be invalidated.

Chlorine and component damage

Notes on using chlorine bleach and perchlorethylene

Frequent use of chlorine increases the risk of component damage.

The use of agents containing chlorine, such as sodium hypochlorite and chlorine bleach in powder form, can damage the protective surface of stainless steel and cause corrosion. Factors affecting this are chlorine concentration levels, contact time and temperature. It is therefore advisable to avoid the use of such agents. Oxygen based bleaching agents should be used instead.

If, however, chlorine based bleaching agents have to be used for particular types of soiling, then anti-chlorine measures must also be carried out. If this is not done irreparable damage can occur to components in the machine and to laundry.

Anti-chlorine treatment

Anti-chlorine treatment has to be carried out immediately after chlorine bleach has been used. Hydrogen peroxide and oxygen based cleaning and bleaching agents must only be used in programmes specified for their use. Any wash performance problems should be discussed with the manufacturer of the cleaning / bleaching product in the first instance.

With thiosulfate, especially when used with hard water, gypsum can form, which can lead to incrustations on laundry or deposits in the machine.

The exact quantity of additives and the treatment temperatures required must be set and tested on site in accordance with the dosage recommendations of the detergent and additive manufacturers. The laundry must also be tested to make sure it contains no active chlorine residues after processing.

Disposal of old machines

When disposing of an old washerextractor first make it unusable.

Disconnect from all services.

Make the door lock inoperative, so that children cannot accidentally shut themselves in. Make appropriate arrangements for the safe disposal of the machine.

All personnel working with this machine must be fully trained in all aspects of its use and safety.

Keep these instructions in a safe place

6 |

M.-Nr. 07 076 772 |

Caring for the environment

Disposal of the packing material

The transport and protective packing has been selected from materials which are environmentally friendly for disposal and can normally be recycled. Packaging e.g. cling film, polystyrene and plastic wrappings must be kept out of the reach of babies and young children. Danger of suffocation.

Rather than just throwing these materials away, please ensure that they are recycled.

Disposal of your old machine

Electrical and electronic machines often contain materials which, if handled or disposed of incorrectly, could be potentially hazardous to human health and to the environment. They are, however, essential for the correct functioning of your machine. Please do not therefore dispose of it with your household waste.

Please dispose of it at your local community waste collection/recycling centre, and ensure that it presents no danger to children while being stored for disposal.

It should be unplugged or disconnected from the mains electricity supply by a competent person.

M.-Nr. 07 076 772 |

7 |

Guide to the machine

WS 5071 MOP-PROFI

This machine is constructed in accordance with IEC 60204-1:2005

a Detergent dispenser box

b Control panel

c Drum door

d Front wall panel

eAccess panel to suds filter/drainage system and emergency door release

f Four adjustable screw feet

g Cold water connection

h Hot water connection

iCold water connection for liquid dispensing

j Venting socket

k Cable entry for power supply

l Liquid dispenser box

m Cable entry for dispenser pumps

n Cable entry for 3 dispenser pumps

o Serial interface for printer

p Cable entry for add-on appliances

q Vent screw for drain valve

r Back wall

s Cold water connection for drain valve

t Drainage

8 |

M.-Nr. 07 076 772 |

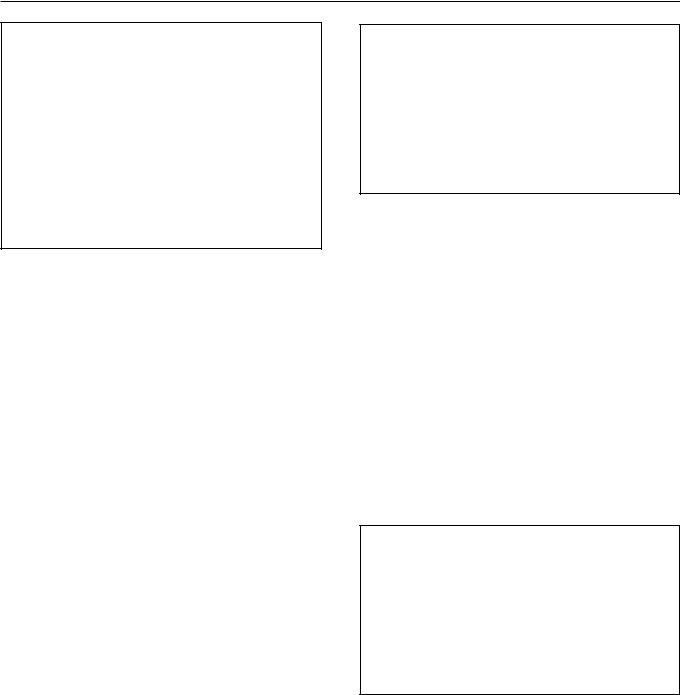

Guide to the machine

Control panel

a

a Key switch b Display

c Programme selector

9 Optical interface

Switches

Y Mains on

Z Mains off

Buttons

5 Door

T Block + / (pre-wash)

U Starch hold

V Without spin

12 Cursor

3Minus

4Plus

W Delay start

X Start

7 End

b |

c |

|

|

|

|

|

|

|

PROGRAMME 1 |

COTTONS |

|

|

>90° C< Main wash 1 |

|

|

|

Rinses |

3 |

1200 RPM -> |

Display

The Display content shows after the machine is switched on. It has up to four lines, each 40 digits long, showing which programme has been selected.

After the Programme start:

a PROGRAMME 1 COTTONS

b 60 °C Pre-wash |

25 °C |

|

|

c 95 °C Main wash

d - ->

a Programme number / Prog.name

bRequired temperature of the current prog.block. / Name of the current prog. block. / Current temperature / Time line for the current Prog. block

cRequired temperature of the following prog. block. / Name of the following Programme block

d Indicates more lines in the display

M.-Nr. 07 076 772 |

9 |

Guide to the machine

Mains on Y Switch

Mains off Z Switch

Door 5 button

Key switch

Position A - Free access

At this operating level only those programmes can be started which have been allocated free access.

See Programming Instructions for allocation of free access.

Position B - Operation

All programmes can be started at this operating level. The display will show the programme the selector has been turned to.

Position C - Programming

In this position programming can be carried out, e.g. copying, deleting, printing out, altering, giving or barring free access and creating new programme sequences. See Programming Instructions.

Position D - Unlocking

At this operating level barred programmes can be unlocked. Locked Programmes (e.g. Disinfection programmes) can not be cancelled 1 minute after they have been started. If the key switch is turned to position D in such a programme, the programme running is unlocked and can be cancelled. See Programming Instructions.

Keys for the key switch

Key 1 (2 supplied) for operating levels A and B.

Key 2 for operating levels

A, B, C.

Key 3 for operating levels

A, B, C, D.

10 |

M.-Nr. 07 076 772 |

Guide to the machine

Programme selector switch

Programme numbers 1 - 24 can be selected directly.

Programme numbers 25 - 99 can be selected using selector position 24 together with the 4 Plus button.

The name of the selected programme and its corresponding number appear in the display. Programme positions 1 - 10 are filled with standard programmes.

The subsequent programme positions vary according to the model, and are listed in the Programme Survey. If the programme selector switch is turned to another position after the start of a programme, the first line of the display flashes. The programme does not however change.

Standard programmes:

1 Cottons 90°C

2 Cottons 60°C

3 Cottons 40°C

4 Short programme

5 Minimum iron

6 Delicates / Synthetics

7 Woollens

8 Separate rinse and spin

9 Separate spin

10 Separate drain

Block + button T with indicator light

When the button is pressed the light above it comes on. The corresponding programme block (e.g. Pre-wash) is added to the programme. Pressing the button a second time de-selects the function.

Starch hold button U with indicator light

Press this button if the washing is to be starched. The light comes on.

Spin-stop button V with indicator light

Press this button if a final spin is not required after the final rinse. The light comes on.

Start button X

Press to start the selected programme.

End button 7

Pressing this button halts a programme (Stop mode). Pressing the button again immediately terminates a programme. A halted programme can be continued in the relevant programme stage by pressing the Start button.

M.-Nr. 07 076 772 |

11 |

Guide to the machine

Cursor buttons 12

The cursor buttons are used to navigate backwards or forwards into the input fields or into the next display, (this appears as > < flashing in the display). After the start of the programme it is possible in Stop mode to scroll block by block backwards or forwards in the programme. Pressing continuously on the button scrolls quickly through the blocks.

Plus-/-Minus buttons 43

Once an input field has been selected it is possible to make a modification. Pressing continuously on the button scrolls quickly through the options.

Delay start button W

If this button is pressed before the start of a programme, the display indicates that a start time can be selected. If the button is pressed again the Delay start option is cancelled.

If the button is pressed after the start of a programme the current time of day and date are shown.

Optical interface

Optical interface

Data transfer to and from the machine’s controls and a PC can take place using the relevant software. The optical interface on the machine’s control panel provides the connection point.

12 |

M.-Nr. 07 076 772 |

Loading...

Loading...