Page 1

ANSI

Operation and Safety Manual

Original Instructions - Keep this manual with the machine at all times.

Model(s)

15/20MVL

15/20MSP

3121230

June 29, 2018 - Rev L

Page 2

WARNING

Operating, servicing and maintaining this vehicle or equipment

can expose you to chemicals including engine exhaust, carbon

monoxide, phthalates, and lead, which are known to the State of

California to cause cancer and birth defects or other

reproductive harm. To minimize exposure, avoid breathing

exhaust, do not idle the engine except as necessary, service your

vehicle or equipment in a well-ventilated area and wear gloves

or wash your hands frequently when servicing. For more

information go to www.P65Warnings.ca.gov.

Page 3

FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and

operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

Other Publications Available:

Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3121231

Illustrated Parts Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3121232

3121230 – JLG Lift – a

Page 4

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED,

WILL HAVE A RED BACKGROUND.

IN DICATES A POTENTIA LIT Y HA Z ARDOUS S ITUATI O N. IF NOT

AVOIDED,

WILL HAVE AN ORANGE BACKGROUND.

b – JLG Lift – 3121230

WILL RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

COULD RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

IN DICATES A POTENTIA LIT Y HA Z ARDOUS S ITUATI O N. IF NOT

AVOIDED,

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL HAVE A

YELLOW BACKGROUND.

INDICATES INFORMATION OR A COMPANY POLICY THAT RELATES

DIRECTLY OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.

MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY

Page 5

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED

JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETY

RELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR THIS

PRODUCT.

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE

OWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES,

INC. TO ENSURE THAT THE CURRENT OWNER RECORDS ARE UPDATED

AND ACCURATE.

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL

INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR

WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG PRODUCT.

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

For :

• Accident Reporting

• Product Safety Publications

• Current Owner

Updates

• Questions Regarding

Product Safety

Contact :

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

or Your Local JLG Office

(See addresses on inside of manual cover)

In USA:

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

Phone: 240-420-2661

E-mail: ProductSafety@JLG.com

• Standards and Regulations Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding

Product Modifications

3121230 – JLG Lift – c

Page 6

REVISION LOG

REVISION LOG

Original Issue A - November 29, 2005

Revised B - April 19, 2006

Revised C - October 4, 2006

Revised D - April 2, 2007

Revised E - November 6, 2007

Revised F - May 12, 2009

Revised G - December 22, 2009

Revised H - November 24, 2010

Revised I - February 24, 2012

Revised J - December 5, 2013

Revised K - December 20, 2013

Revised L - June 29, 2018 - Revised Covers, Prop 65

d – JLG Lift – 3121230

Page 7

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

FOREWORD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL

WORDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

Contact : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

In USA: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

Outside USA: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C

REVISION LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Operator Training And Knowledge . . . . . . . . . . . 1-1

Workplace Inspection. . . . . . . . . . . . . . . . . . . . . . . . 1-2

Machine Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Trip and Fall Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Electrocution Hazards. . . . . . . . . . . . . . . . . . . . . . . . 1-4

Tipping Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Crushing And Collision Hazard . . . . . . . . . . . . . . . 1-7

3121230 – JLG Lift – i

1.4 TOWING, LIFTING, AND HAULING . . . . . . . . . . . . . . . 1-8

SECTION - 2 - PREPARATION AND INSPECTION

2.1 PERSONNEL TRAINING. . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Training Supervision . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Operator Responsibility . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 PREPARATION, INSPECTION, AND MAINTENANCE 2-

2

2.3 PRE-START INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 DAILY WALK-AROUND INSPECTION . . . . . . . . . . . . . 2-5

2.5 FUNCTION CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

SECTION - 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 MACHINE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 MACHINE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 BATTERY CHARGING. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Battery - Low Voltage Warning Indicators . . . . . 3-3

To Charge Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Battery Charging Status Indicators. . . . . . . . . . . . 3-4

Page 8

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

3.5 GROUND CONTROL STATION - OPERATION . . . . . 3-7

Main Power Selector Switch . . . . . . . . . . . . . . . . . . 3-7

Emergency Stop/Shut Down Button . . . . . . . . . . 3-7

Brake Release Button . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Platform Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Platform Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Manual Descent Control Valve . . . . . . . . . . . . . . . . 3-9

Machine Status LCD Display . . . . . . . . . . . . . . . . 3-10

LCD Display Fault Conditions . . . . . . . . . . . . . . . 3-11

3.6 PLATFORM CONTROL CONSOLE OPERATION . . . 3-15

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Platform On/Off Key Switch. . . . . . . . . . . . . . . . . 3-16

Platform Emergency Stop Button . . . . . . . . . . . 3-17

Platform Control Display Panel . . . . . . . . . . . . . 3-17

Drive/Lift Mode Selector Switch . . . . . . . . . . . . 3-19

Horn Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Joystick Function Enable Lever . . . . . . . . . . . . . 3-19

Multifunction Joystick Control . . . . . . . . . . . . . . 3-20

Drive Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Lift Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Drive Speed Setting Controls . . . . . . . . . . . . . . . 3-23

3.7 PARKING MACHINE. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.8 PLATFORM CONFIGURATIONS . . . . . . . . . . . . . . . . .3-24

StockPicking Platform Operation . . . . . . . . . . . 3-28

ii – JLG Lift – 3121230

3.9 FALL PROTECTION - LANYARD ATTACHMENT . . 3-30

3.10 QUICK-CHANGE PLATFORM MOUNTING. . . . . . . 3-31

Platform Removal (see illustration following) 3-31

Platform Installation . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3.11 TRANSPORTING, LIFTING AND

TIE DOWN PROCEDURES . . . . . . . . . . . . . . . . . . . . . . 3-32

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Truck Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Machine Tie-Down . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Crane Hook Accessory (Option). . . . . . . . . . . . . 3-33

Fork-Lift Truck Transport. . . . . . . . . . . . . . . . . . . . 3-34

3.12 PROGAMMABLE SECURITY LOCK (PSL™)

(MVL/MSP - OPTION). . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

PSL™ Box and Ground Control Locations . . . . 3-36

Machine Power Up using the PSL™ . . . . . . . . . . 3-37

Machine Power Down . . . . . . . . . . . . . . . . . . . . . . 3-37

Changing the Operator’s Code . . . . . . . . . . . . . . 3-37

3.13 OBSTRUCTION SENSING SYSTEM -

(MSP OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

System Description . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

OSS Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . 3-39

3.14 RUG CARRIER ACCESSORY

(MSP - OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Page 9

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

Pre-Start Inspection. . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Hanging a Rug using the Rug Carrier

Accessory Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Removing a Rug using Rug Carrier

Accessory Arms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3.15 STOCK-PICKER HANGER ACCESSORY . . . . . . . . . . 3-45

Pre-Start Inspection. . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Loading and Transporting an Item

using the Hanger Accessory. . . . . . . . . . . . . . . . . 3-45

SECTION - 4 - EMERGENCY PROCEDURES

4.1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 EMERGENCY OPERATION. . . . . . . . . . . . . . . . . . . . . . . 4-1

Operator Unable to Control Machine . . . . . . . . . 4-1

Platform Caught Overhead. . . . . . . . . . . . . . . . . . . 4-1

4.3 INCIDENT NOTIFICATION. . . . . . . . . . . . . . . . . . . . . . . 4-1

SECTION - 5 - GENERAL SPECIFICATIONS AND OPERATOR

MAINTENANCE

5.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . 5-2

Machine Specifications . . . . . . . . . . . . . . . . . . . . . . 5-2

Machine Wheel Loads and PSI - Per Wheel . . . . 5-4

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . 5-6

3121230 – JLG Lift – iii

5.3 OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . 5-9

5.4 GROUND CONTROL STATION -

5.5 DRIVE MOTOR BRUSH WEAR -

5.6 SUPPLEMENTAL INFORMATION. . . . . . . . . . . . . . . . 5-21

SECTION - 6 - INSPECTION AND REPAIR LOG

Platform Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Machine Component Weights . . . . . . . . . . . . . . . . 5-8

Serial Number Locations . . . . . . . . . . . . . . . . . . . . . 5-8

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Tires and Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

PROGRAMMING5-14

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Programming Levels . . . . . . . . . . . . . . . . . . . . . . . 5-14

Operator Programming Mode . . . . . . . . . . . . . . 5-14

Activating Programming Mode . . . . . . . . . . . . . 5-17

Entering Password . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Programming Mode Selection . . . . . . . . . . . . . . 5-18

Selecting Programmable Item to Adjust . . . . 5-19

Adjusting Programmable Setting . . . . . . . . . . . 5-19

WARNING INDICATION . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Page 10

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

LIST OF FIGURES

2-1. Daily Walk-Around Inspection for

MVL/MSP Machines.. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-2. Pot-Hole-Protection Bars Lowered. . . . . . . . . . . . . . 2-7

3-1. Ground Control Station. (Machine Rear View) . . . 3-8

3-2. Platform Control Console. . . . . . . . . . . . . . . . . . . . . . 3-15

3-3. Platform Control Display Panel. . . . . . . . . . . . . . . . . 3-17

3-4. Machine Operating Specifications . . . . . . . . . . . . . 3-21

3-5. Crane Hook Accessory. . . . . . . . . . . . . . . . . . . . . . . . . 3-33

3-6. Forklift Truck Lifting Pockets and

Machine Tie Down Loop Locations. . . . . . . . . . . . . 3-35

3-7. PSL™ Switch & Ground Control Station

Locations - At Rear of Machine. . . . . . . . . . . . . . . . . 3-36

3-8. PSL™ Switch Controls & Indicators.. . . . . . . . . . . . . 3-36

3-9. OSS Transducer Sensor Array Location. . . . . . . . .3-39

3-10. OSS - Pre-Start Inspection of Operation. . . . . . . . . 3-40

3-11. MVL Series Decal Installation Chart -

(See Table 3-4 for Installation) . . . . . . . . . . . . . . . . . 3-47

3-12. MSP Decal Installation Chart -

(See Table 3-5. for Installation) . . . . . . . . . . . . . . . . . 3-50

5-1. Wheel Lug Nut Tightening Sequence . . . . . . . . . . 5-10

5-2. Location of Lubrication Points (See Table 5-5) . . 5-12

iv – JLG Lift – 3121230

Minimum Approach Distances (M.A.D.) . . . . . . . . . . . . . . . 1-5

Inspection and Maintenance Table . . . . . . . . . . . . . . . . . . . 2-3

Battery Low Voltage Warning Indicators.. . . . . . . . . . . . . . 3-3

LCD Display - Operation Fault Conditions . . . . . . . . . . . . 3-12

Max. Capacity with Side Entry Platform

w/Folding Material Tray Installed . . . . . . . . . . . . . . . . . . . . 3-26

MVL Series Decal Installation Chart. . . . . . . . . . . . . . . . . . . 3-48

MSP Decal Installation Chart. . . . . . . . . . . . . . . . . . . . . . . . . 3-51

15MVL/MSP - Machine Maximum

Wheel Loads (Lb.) and (PSI) - Per Wheel.. . . . . . . . . . . . . . . 5-4

20MVL/MSP - Machine Maximum

Wheel Loads (Lb.) and (PSI) - Per Wheel.. . . . . . . . . . . . . . . 5-5

Wheel Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Lubrication Intervals for Various Components. . . . . . . . 5-13

Ground Control Module Setting Range and

Default Factory Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Inspection and Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

LIST OF TABLES

Page 11

SECTION 1. SAFETY PRECAUTIONS

SECTION 1 - SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper and

safe machine usage and maintenance. For proper machine use,

it is mandatory that a daily routine is established based on the

content of this manual. A maintenance program, using the

information provided in this manual and the Service and Maintenance Manual, must also be established by a qualified person

and must be followed to ensure that the machine is safe to

operate.

The owner/user/operator/lessor/lessee of the machine should

not accept operating responsibility until this manual has been

read, training is accomplished, and operation of the machine

has been completed under the supervision of an experienced

and qualified operator.

If there are any questions with regard to safety, training, inspection, maintenance, application, and operation, please contact

JLG Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED IN THIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

3121230 – JLG Lift – 1-1

1.2 PRE-OPERATION

Operator Training And Knowledge

• Read and understand this manual before operating the

machine.

• Do not operate this machine until complete training is performed by authorized persons.

• Only authorized and qualified personnel can operate the

machine.

• Read, understand, and obey all DANGERS, WARNINGS, CAUTIONS, and operating instructions on the machine and in

this manual.

• Use the machine in a manner which is within the scope of

its intended application set by JLG.

Page 12

SECTION 1 - SAFETY PRECAUTIONS

• All operating personnel must be familiar with the emergency controls and emergency operation of the machine as

specified in this manual.

• Read, understand, and obey all applicable employer, local,

and governmental regulations as they pertain to operation

of the machine.

Workplace Inspection

• The operator is to take safety measures to avoid all hazards

in the work area prior to machine operation.

• Do not operate or raise the platform while on trucks, trailers, railway cars, floating vessels, scaffolds or other equipment unless approved in writing by JLG.

• This machine can be operated in temperatures of 0° F to

104° F (-20° C to 40° C). Consult JLG for operation outside

this range.

Machine Inspection

• Before machine operation, perform inspections and functional checks. Refer to Section 2 of this manual for detailed

instructions.

• Do not operate this machine until it has been serviced and

maintained according to requirements specified in the Service and Maintenance Manual.

• Ensure all safety devices are operating properly. Modification of these devices is a safety violation.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM SHALL BE

MADE ONLY WITH PRIOR WRITTEN PERMISSION FROM THE MANUFACTURER

• Do not operate any machine on which the safety or instruction placards or decals are missing or illegible.

• Avoid any build up of debris on platform floor. Keep mud,

oil, grease, and other slippery substances from footwear

and platform floor.

1-2 – JLG Lift – 3121230

Page 13

SECTION 1 - SAFETY PRECAUTIONS

1.3 OPERATION

General

• The JLG MVL/MSP Model Lifts are electric self-propelled

machines with an aerial work platform mounted to an elevating aluminum mast mechanism. The personnel lift’s

intended purpose is to provide personnel access to areas

above ground level.

The MSP model lift is intended for stock picking purposes in

retail stores or warehouses to allow placing and removing

of stock from storage or display areas.

• Do not use the machine for any purpose other than positioning personnel, their tools and equipment, or for hand

stock picking.

• Never operate a machine that is not working properly. If a

malfunction occurs, shut down the machine.

• Never slam a control switch or lever through neutral to an

opposite direction. Always return switch to neutral and

stop before moving the switch to the next function. Operate controls with slow and even pressure.

• Do not allow personnel to tamper with or operate the

machine from the ground with personnel in the platform,

except in an emergency.

• Do not carry materials directly on platform railing unless

approved by JLG.

• Always ensure that power tools are properly stowed and

never left hanging by their cord from the platform work

area.

• Fully lower mast assembly and shut off all power before

leaving machine.

• When performing welding operations at elevation, precautions must be taken to protect all machine components

from contact with weld splatter or molten metal.

• Battery fluid is highly corrosive. Avoid contact with skin and

clothing at all times.

• Charge batteries on in a well ventilated area.

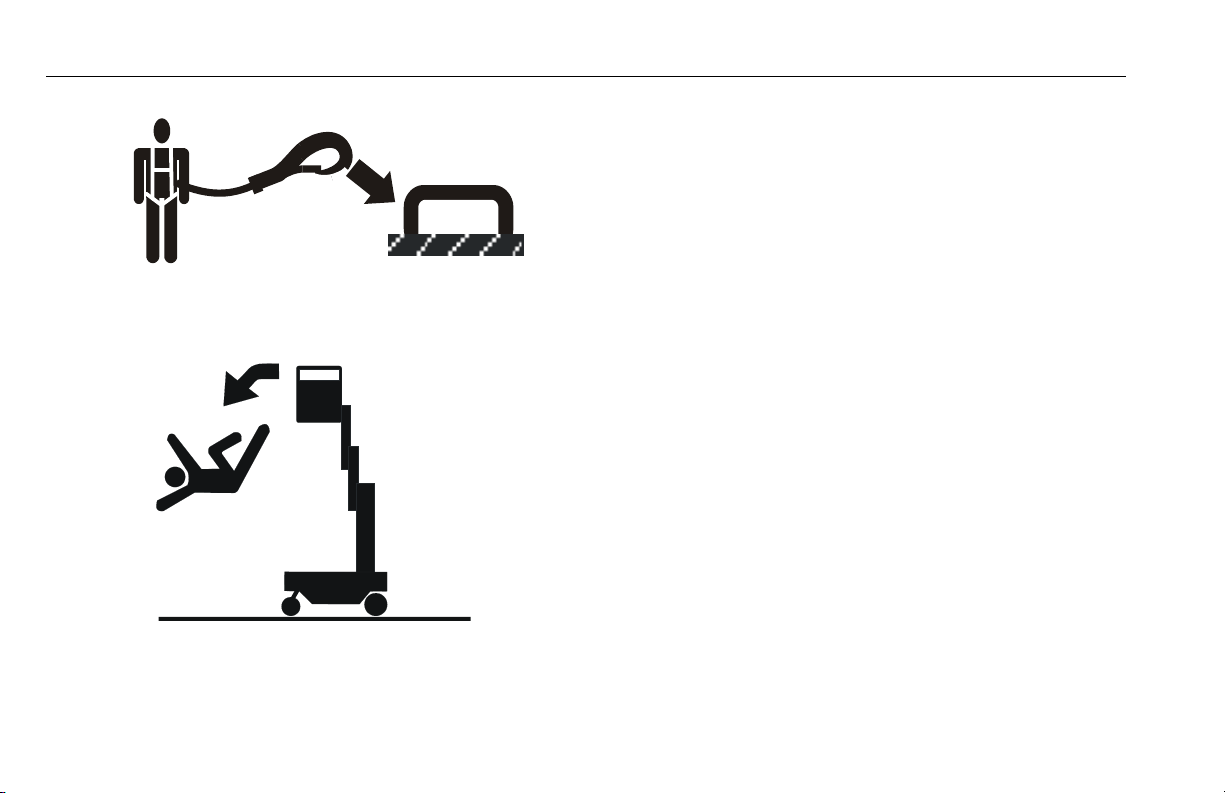

Trip and Fall Hazard

• JLG Industries, Inc. recommends that the operator in the

platform wear approved fall protection attached to an

authorized lanyard anchorage point. Reference “StockPicking Platform Operation” on page 28 for fall protection

requirements applicable to stockpicker platforms operated

with the rails in the open position. For further information

regarding fall protection requirements on JLG products,

contact JLG Industries, Inc.

3121230 – JLG Lift – 1-3

Page 14

SECTION 1 - SAFETY PRECAUTIONS

• Before operating the machine, make sure all railing and

gates are fastened in their proper position.

• Keep both feet firmly positioned on the platform floor at all

times. Never use ladders, boxes, steps, planks, or similar

items on platform to provide additional reach.

• Never use the mast assembly to enter or leave the platform.

• Use extreme caution when entering or leaving platform.

Ensure that the mast assembly is fully lowered. Face the

machine when entering or leaving the platform. Always

maintain “three point contact” with the machine, using two

hands and one foot or two feet and one hand at all times

during entry and exit.

1-4 – JLG Lift – 3121230

Page 15

SECTION 1 - SAFETY PRECAUTIONS

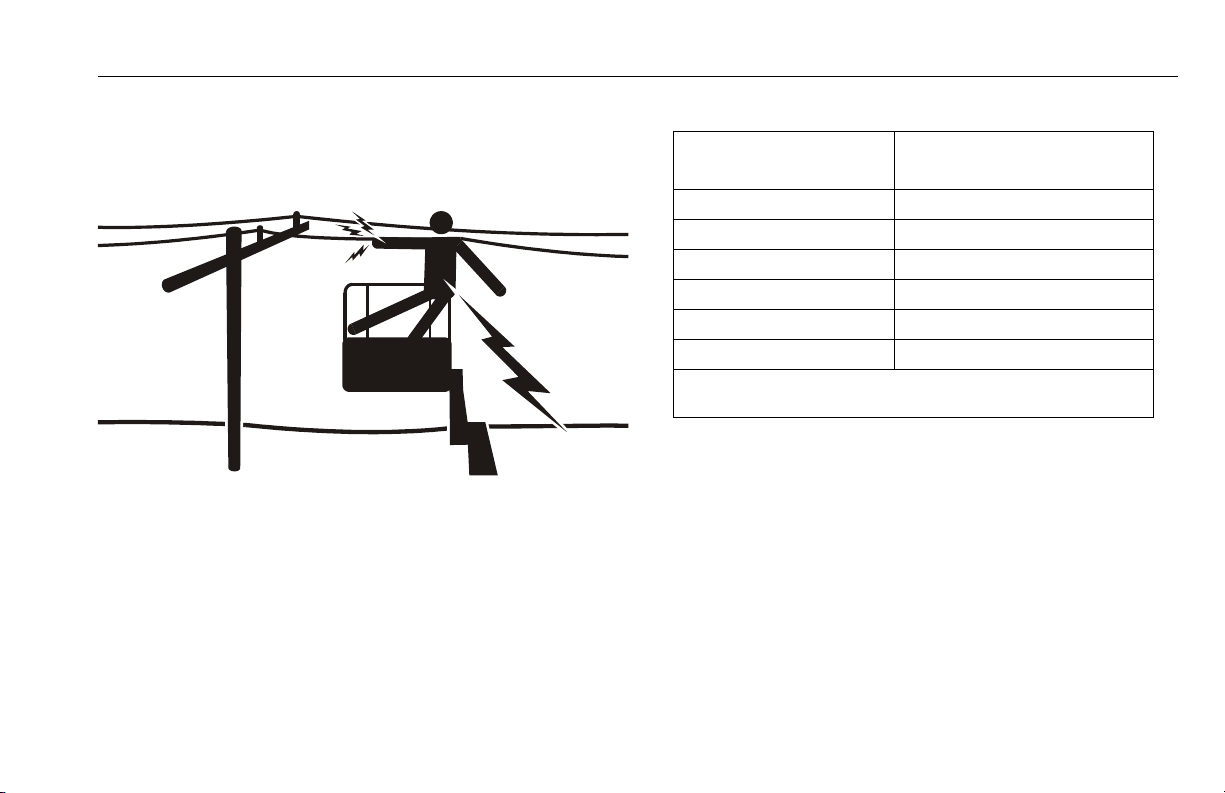

Electrocution Hazards

• This machine is not insulated and does not provide protection from contact or proximity to electrical current.

• Maintain distance from electrical lines, apparatus, or any

energized (exposed or insulated) parts according to the

Minimum Approach Distance (MAD) as shown in Table 1-1.

• Allow for machine movement and electrical line swaying.

Table 1-1. Minimum Approach Distances (M.A.D.)

Voltage Range

(Phase to Phase)

0 to 50 KV 10 (3)

Over 50KV to 200 KV 15 (5)

Over 200 KV to 350 KV 20 (6)

Over 350 KV to 500 KV 25 (8)

Over 500 KV to 750 KV 35 (11)

Over 750 KV to 1000 KV 45 (14)

NOTE: This requirement shall apply except where employer, local or govern-

mental regulations are more stringent.

• Maintain a clearance of at least 10 ft. (3m) between any part

of the machine and its occupants, their tools, and their

equipment from any electrical line or apparatus carrying up

to 50,000 volts. One foot additional clearance is required for

every additional 30,000 volts or less.

• The minimum approach distance may be reduced if insulating barriers are installed to prevent contact, and the barriers are rated for the voltage of the line being guarded.

These barriers shall not be part of (or attached to) the

machine. The minimum approach distance shall be reduced

to a distance within the designed working dimensions of

the insulating barrier. This determination shall be made by

MINIMUM APPROACH DISTANCE

in Feet (Meters)

3121230 – JLG Lift – 1-5

Page 16

SECTION 1 - SAFETY PRECAUTIONS

a qualified person in accordance with the employer, local,

or governmental requirements for work practices near

energized equipment

DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITED ZONE

(MAD). ASSUME ALL ELECTRICAL PARTS AND WIRING ARE ENERGIZED

UNLESS KNOWN OTHERWISE.

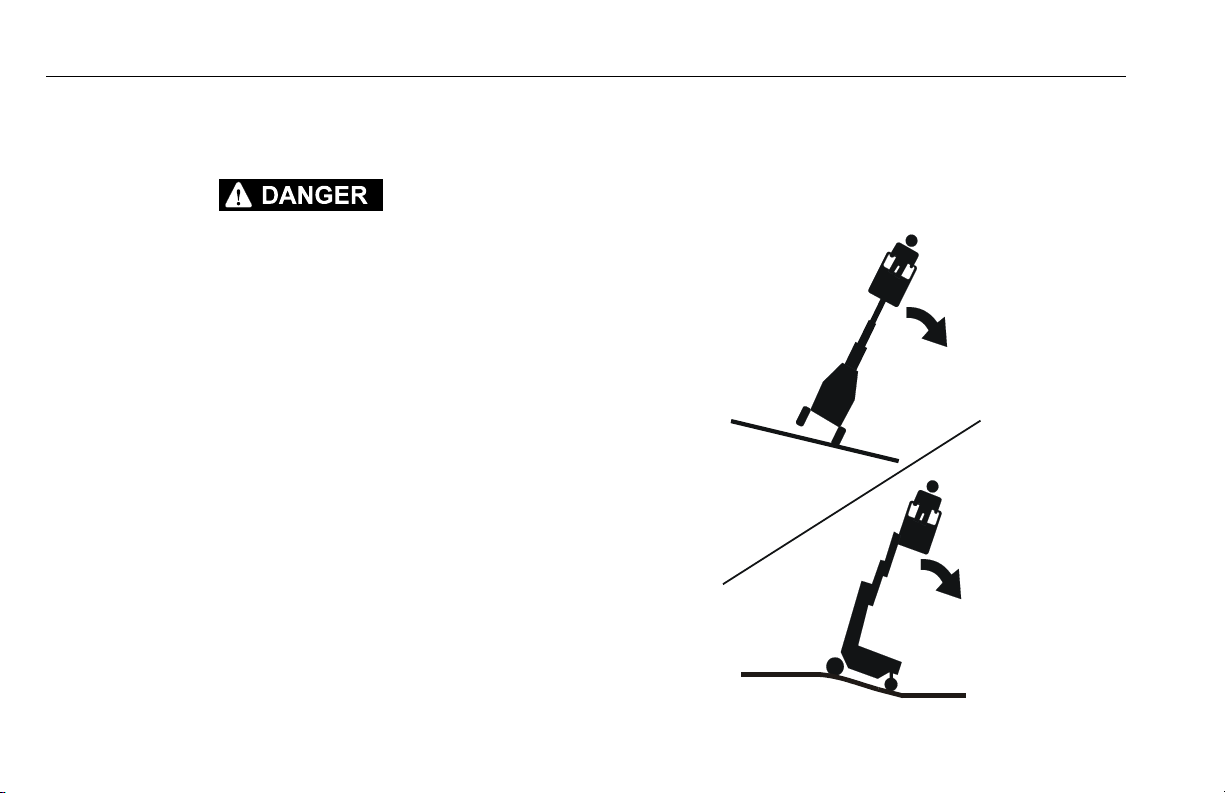

Tipping Hazard

• The user should be familiar with the surface before driving.

Do not exceed the allowable sideslope and grade while

driving.

1-6 – JLG Lift – 3121230

Page 17

SECTION 1 - SAFETY PRECAUTIONS

• Do not elevate platform or drive with platform elevated

while on a slope, or on an uneven or soft surface.

• Before driving on floors, bridges, trucks, and other surfaces,

check allowable capacity of the surfaces.

• Never exceed the maximum platform capacity. Distribute

loads evenly on platform floor.

• Keep the chassis of the machine a minimum of 2 ft. (0.6m)

from holes, bumps, drop-offs, obstructions, debris, concealed holes, and other potential hazards at the ground

level.

• Never attempt to use the machine as a crane. Do not tie-off

machine to any adjacent structure.

• Do not increase the platform size with unauthorized deck

extensions or attachments, increasing the area exposed to

wind will decrease stability.

• If mast assembly or platform is caught so that one or more

wheels are off the ground, the operator must be removed

before attempting to free the machine. Use cranes, forklift

trucks, or other appropriate equipment to stabilize machine

and remove personnel.

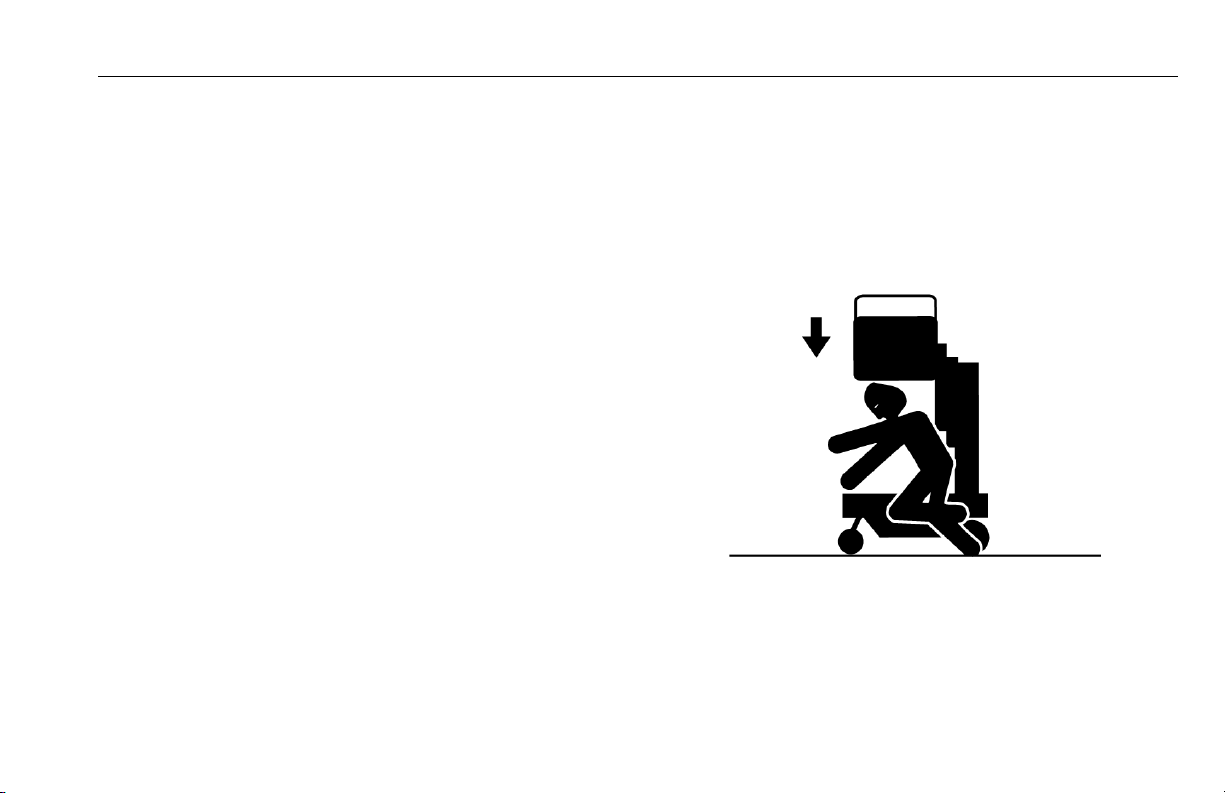

Crushing And Collision Hazard

• Personal protection equipment must be worn by all operating and ground personnel.

• Check work area clearances above, on sides, and bottom of

platform while driving and lifting or lowering platform.

• During operation, keep all body parts inside platform railing.

• Always post a lookout when driving in areas where vision is

obstructed.

3121230 – JLG Lift – 1-7

Page 18

SECTION 1 - SAFETY PRECAUTIONS

• Keep non-operating personnel at least 6 ft. (1.8m) away

from machine during all driving operations.

• Limit travel speed according to conditions of ground surface, congestion, visibility, slope, location of personnel, and

other factors causing hazards of collision or injury to personnel.

• Be aware of stopping distances in all drive speeds.

• Do not drive at high speeds in restricted or close quarters or

when driving in reverse.

• Exercise extreme caution at all times to prevent obstacles

from striking or interfering with operating controls and persons in the platform.

• Ensure that operators of other overhead and floor level

machines are aware of the aerial work platform’s presence.

Disconnect power to overhead cranes.

• Warn personnel not to work, stand, or walk under a raised

platform. Position barricades on floor as necessary.

1.4 TOWING, LIFTING, AND HAULING

• Never allow personnel in platform while towing, lifting, or

hauling.

• This machine should not be towed, except in the event of

emergency, malfunction, power failure, or loading/unloading. Refer to the Emergency Procedures Section of this

manual for emergency towing procedures.

• Ensure platform is fully retracted and completely empty of

tools prior to towing, lifting or hauling.

• Do not assist a stuck or disabled machine by pushing or

pulling except by pulling at the chassis tie-down bars.

• When lifting machine with a forklift, position forks only at

designated areas of the machine. Lift with a forklift of adequate capacity.

• Refer to the Machine Operation section of this manual for

lifting information.

1-8 – JLG Lift – 3121230

Page 19

SECTION 2 - PREPARATION AND INSPECTION

SECTION 2. PREPARATION AND INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it is necessary that it be operated and maintained only by trained personnel.

Persons under the influence of drugs or alcohol or who are subject to seizures, dizziness or loss of physical control must not

operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform and

at the ground, emergency controls and safety systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of

the machine to recognize a malfunction.

6. The safest means to operate the machine where overhead obstructions, other moving equipment, and

obstacles, depressions, holes, drop-offs are present.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified person in an open area free of obstructions until the trainee has

developed the ability to safely control and operate the machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility and authority to shut down the machine in case of a malfunction or other unsafe condition of either the machine or the

job site.

NOTE: The Manufacturer or Distributor will provide qualified peo-

ple for training assistance with the first unit(s) delivered

and from that time forward as requested by the user or

his/her personnel.

3121230 – JLG Lift – 2-1

Page 20

SECTION 2 - PREPARATION AND INSPECTION

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

The following table covers the periodic machine inspections

and maintenance recommended by JLG Industries, Inc. Consult

local regulations for further requirements for aerial work platforms. The frequency of inspections and maintenance must be

increased as necessary when the machine is used in a harsh or

hostile environment, if the machine is used with increased frequency, or if the machine is used in a severe manner.

2-2 – JLG Lift – 3121230

Page 21

SECTION 2 - PREPARATION AND INSPECTION

NOTICE

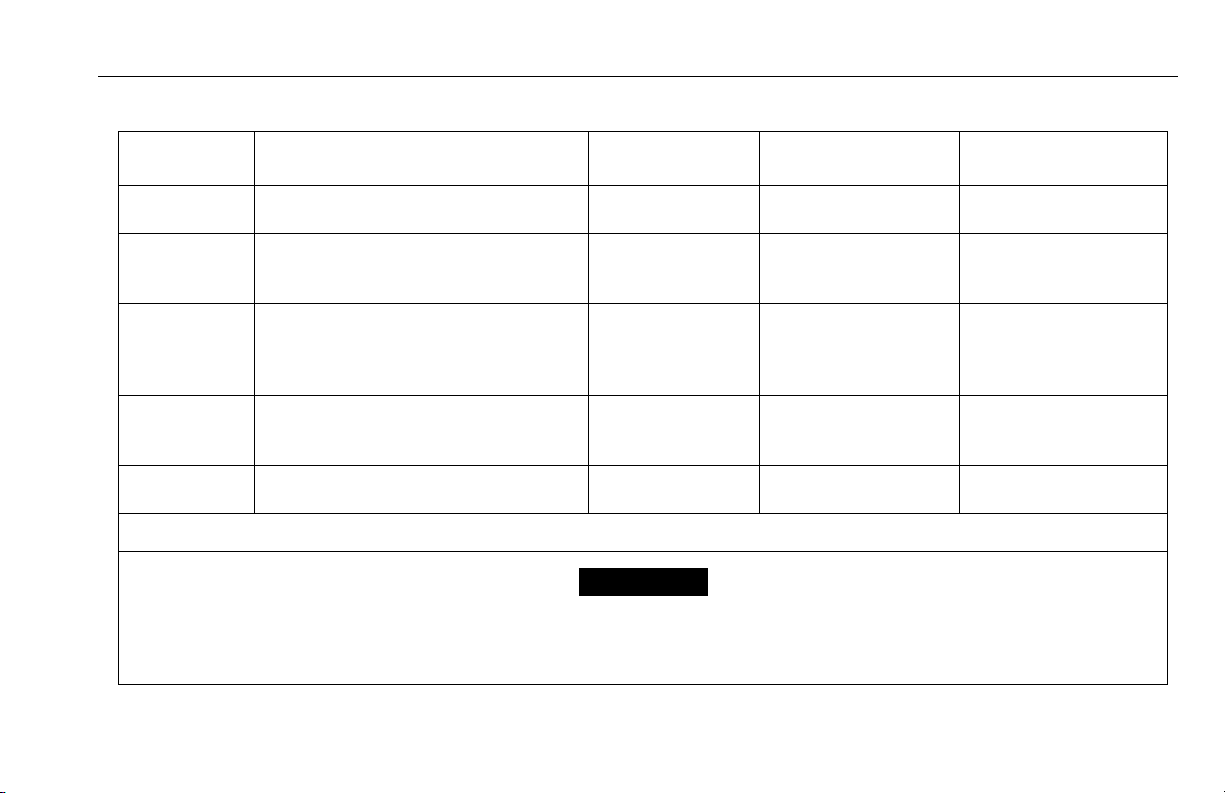

Table 2-1. Inspection and Maintenance Table

TYPE FREQUENCY

Pre-Star t

Inspection

Pre-Delivery

Inspection

(See Note)

Frequent

Inspection

Annual Machine

Inspection

Preventative

Maintenance

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

JLG INDUSTRIES, INC. RECOGNIZES A QUALIFIED JLG MECHANIC AS A PERSON WHO HAS SUCCESSFULLY COMPLETED THE JLG SERVICE TRAINING SCHOOL FOR THE SPECIFIC JLG

PRODUCT MODEL.

Before using each day; or

whenever there’s an Operator change.

Before each sale, lease, or rental delivery. Owner, Dealer, or User Qualified JLG Mechanic Service and Maintenance Man-

In service for 3 months or 150 hours, whichever

comes first; or;

Out of service for a period of more than 3 months; or

Purchased used.

Annually, no later than 13 months from the date of

prior inspection.

At intervals as specified in the Service and Maintenance Manual.

PRIMARY

RESPONSIBILITY

User or Operator User or Operator Operator and Safety Manual

Owner, Dealer, or User Qualified JLG Mechanic Service and Maintenance Man-

Owner, Dealer, or User Qualified JLG Mechanic

(Recommended)

Owner, Dealer, or User Qualified JLG Mechanic Service and Maintenance Man-

SERVICE

QUALIFICATION

REFERENCE

ual and applicable JLG inspection form

ual and applicable JLG inspection form

Service and Maintenance Manual and applicable JLG inspection form

ual

3121230 – JLG Lift – 2-3

Page 22

SECTION 2 - PREPARATION AND INSPECTION

2.3 PRE-START INSPECTION

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil, fuel,

or battery fluid) or foreign objects. Report any leakage

to the proper maintenance personnel.

2. Decals and Placards – Check all for cleanliness and

legibility. Make sure no decals or placards are missing.

Make sure all illegible decals and placards are cleaned

or replaced. (Reference "Decal Installations" in Section

3).

3. Operators and Safety Manuals – Make sure a copy of

the Operator and Safety Manual, EMI Safety Manual

(Domestic only), and ANSI Manual of Responsibilities

(Domestic only) is enclosed in the weather resistant

storage container.

4. Daily Walk-Around Inspection – (See Section 2.4)

5. Battery – Charge as required.

6. Hydraulic Oil – Check the hydraulic oil level.

NOTE: Check Service Manual for instructions and hydraulic oil

specification before adding. DO NOT OVERFILL.

FILL TO LINE

on Hydraulic

Reservoir

indicates the

proper level for

hydraulic oil.

7. Function Check – Check all machine controls for

operation per Section 2.5, Function Check.

If optional equipment is installed on this machine refer to Section 3 for specific Pre-Start Inspection and Operation instructions.

2-4 – JLG Lift – 3121230

Page 23

SECTION 2 - PREPARATION AND INSPECTION

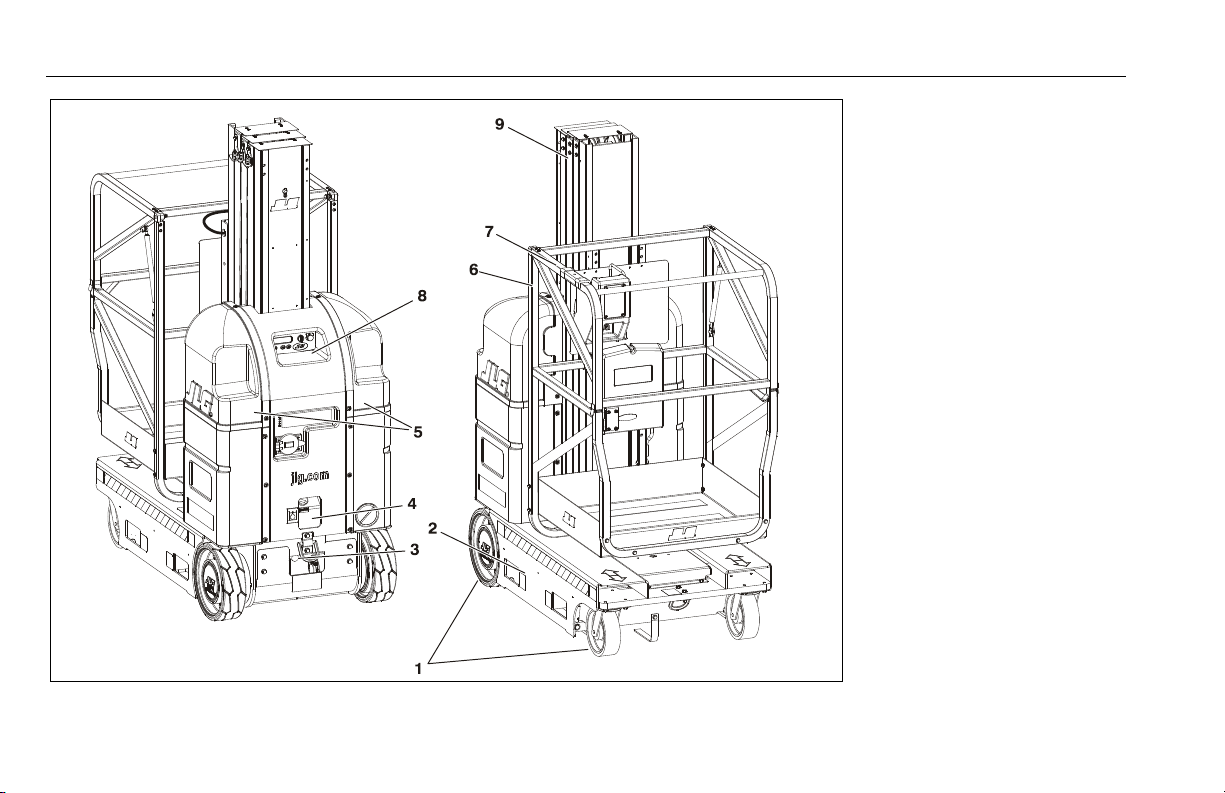

2.4 DAILY WALK-AROUND INSPECTION

Begin the “Walk-Around Inspection” at item one (1) as noted on

the diagram. Continue around machine check each item in

sequence for the conditions listed in the following check list.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS “OFF” DURING

“WALK-AROUND INSPECTION”.

DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE BEEN CORRECTED.

DO NOT OVERLOOK VISUAL INSPECTION OF THE BASE FRAME UNDERSIDE.

CHECK THIS AREA FOR OBJECTS OR DEBRIS WHICH COULD CAUSE EXTENSIVE

MACHINE DAMAGE.

INSPECTION NOTE: On all components, make sure there are no

loose or missing parts, that they are securely fastened, and that no

visible damage, leaks or excessive wear exists in addition to any

other criteria mentioned.

1. Drive and Caster Wheels - Check for any debris stuck

to or around wheels.

2. Base Frame - Check pot-hole-protection system components; check for loose wires or cables dangling

below the base.

3. Manual Descent Control Valve - See inspection note

above.

4. Motor/Pump/Reservoir Unit - No evidence of

hydraulic leaks. Hydraulic oil level should be filled level

with the full line.

5. Batteries - Charge if necessary.

6. Platform Assembly and Gate - Quick-Change plat-

form mounting and mounting pins; platform railings;

entry bar or gate in proper working order; MSP - platform fasteners.

7. Platform Control Console - Platform control; placards

secure and legible; emergency stop switch reset for

operation; Control markings legible.

8. Ground Control Station - Main Power Selector Switch

operable; placards secure and legible; emergency stop

switch operates properly.

9. Mast Assembly - Mast sections; slide pads; mast

chains; sequencing cables; platform control and

power cables (on side of mast); power cables properly

tensioned and seated in sheaves; cable sheaves rotat-

ing freely.

3121230 – JLG Lift – 2-5

Page 24

SECTION 2 - PREPARATION AND INSPECTION

1. Drive and Caster Wheels

2. Base Frame

3. Manual Descent Control Valve

4. Motor/Pump/Reservoir Unit

5. Batteries - (Inside Cover)

6. Platform Assembly

7. Platform Control Console

8. Ground Control Station

9. Mast Assembly

Figure 2-1. Daily Walk-Around Inspection for MVL/MSP Machines.

2-6 – JLG Lift – 3121230

Page 25

SECTION 2 - PREPARATION AND INSPECTION

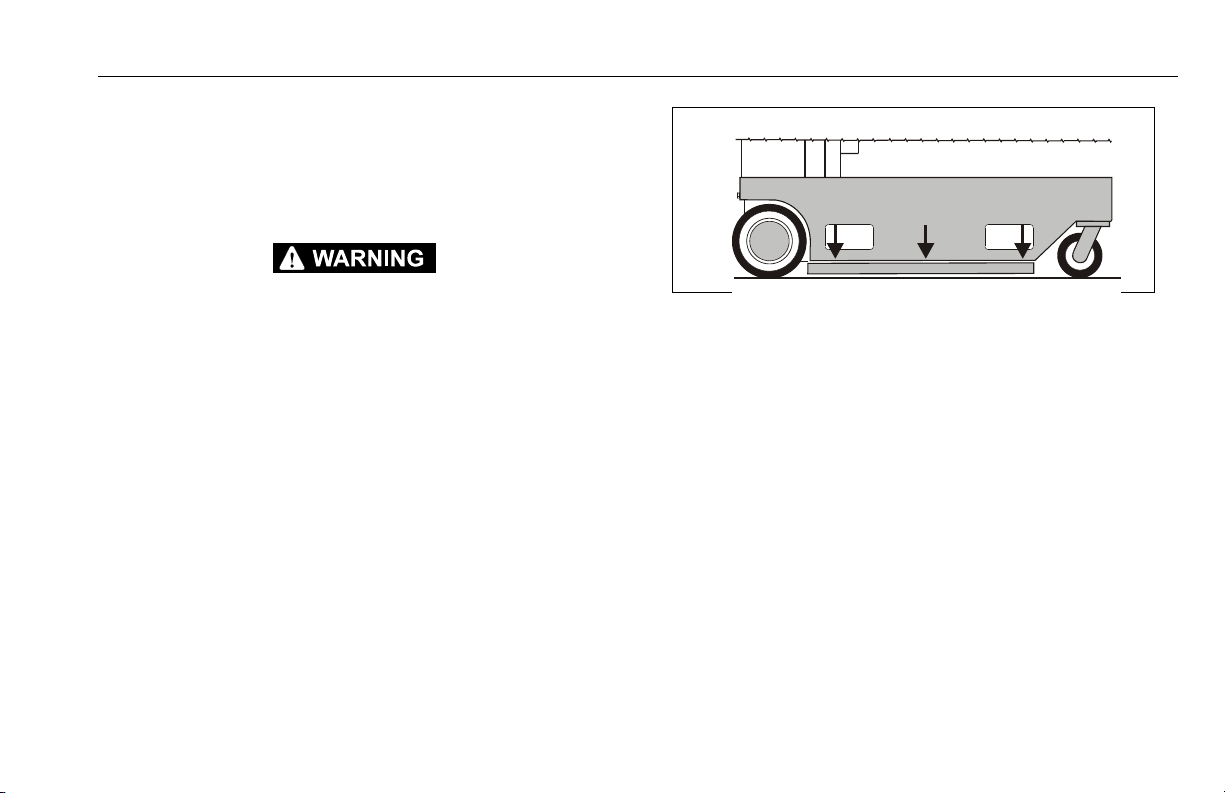

2.5 FUNCTION CHECK

Once the “Walk-Around” Inspection is complete, perform a

function check of all systems in an area free of overhead and

ground level obstructions. Refer to Section 3 for more specific

operating instructions.

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF THE MACHINE

IMMEDIATELY! REPORT THE PROBLEM TO THE PROPER MAINTENANCE PERSONNEL. DO NOT OPERATE THE MACHINE UNTIL IT IS DECLARED SAFE FOR

OPERATION.

Perform a Function Check as follows:

1. From the ground controls with no load in the platform:

a. Operate ground control functions, platform lift up and

lift down.

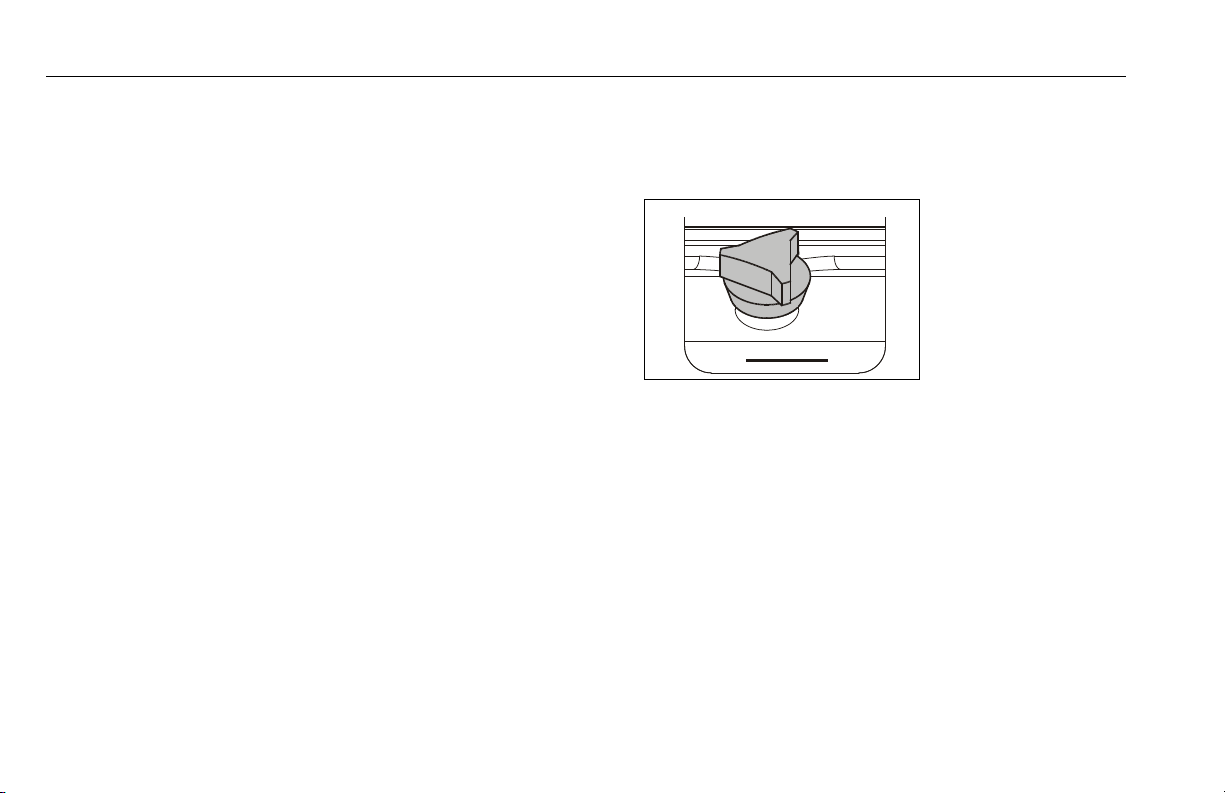

b. Ensure Pot-Hole-Protection device is fully engaged

(bars down on sides) when the platform is elevated (See

Figure 2-2.).

c. Ensure that all machine functions are disabled when

the Emergency Stop Button is activated.

d. Check Manual Descent Control valve is operating prop-

erly.

Figure 2-2. Pot-Hole-Protection Bars Lowered.

2. From the platform control console:

a. Ensure that the control console is properly mounted

and secure.

b. Raise and lower platform 2 ft. to 3 ft. (.61m to .92 m) sev-

eral times. Check for smooth elevation and lowering of

platform.

c. Operate all functions, check all limit, cut-out, and

enable switches are functioning properly:

• Machine Brakes - Drive the machine on a grade,

(do not exceed the rated gradeability), and stop

to ensure the brakes hold.

• Tilt Warning Limit - With the platform completely

lowered, drive the machine onto a surface with a tilt

of more than 1.5° in any direction (do not exceed

rated gradeability). The machine will indicate a tilt

3121230 – JLG Lift – 2-7

Page 26

SECTION 2 - PREPARATION AND INSPECTION

condition if any attempt is made to elevate the platform.

• Drive Speed Reduction Limit - When platform is

elevated more than 1.5 to 2 ft. (.5m) drive speed is

cut to 1/4 of platform lowered drive speed.

• Platform Joystick Enable Trigger - The machine

will not operate (drive or lift) unless this switch is

pressed and held during drive or lift operation.

d. Ensure all machine functions are disabled when the

Emergency Stop Button is activated (pressed in).

2-8 – JLG Lift – 3121230

Page 27

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

SECTION 3. MACHINE CONTROLS, INDICATORS AND OPERATION

3.1 GENERAL

THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE APPLICATION AND OPERATION. THE USER AND OPERATOR ARE RESPONSIBLE FOR

CONFORMING WITH GOOD SAFETY PRACTICES.

This section provides the necessary information needed to

understand control function and operation.

3121230 – JLG Lift – 3-1

3.2 MACHINE DESCRIPTION

The JLG MVL/MSP Model Lifts are electric self-propelled

machines with an aerial work platform mounted to an elevating

aluminum mast mechanism. The personnel lift’s intended purpose is to provide personnel access to areas above ground level.

The MSP model lift is intended for stock picking purposes in

retail stores or warehouses to allow placing and removing of

stock from storage or display areas.

The primary control station is located in the platform. From the

Platform Control Console the operator can drive the machine

and raise or lower the platform.

The controls of the programmable Ground Control Station are

to be used during machine power-up, machine maintenance or

in case of emergency should the operator in the platform be

unable to lower the platform.

Vibrations emitted by these machines are not hazardous to an

operator working in the platform.

The continuous A-Weighted sound pressure level at the work

platform is less than 70db (A).

Page 28

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.3 MACHINE OPERATION

Getting Started

The following control conditions must be met before the

machine can be operated from either the Ground or Platform

Controls.

• The batteries contain enough voltage to operate the

machine.

• The Main Power Selector Switch on the Ground Control Station must be set for either Ground Control Mode or Platform Control Mode.

• Both Emergency Stop Switches, one on the Ground Control

Station the other on the Platform Control Console must be

in the RESET position.

• If equipped, the On/Off Key Switch on the Platform Console

must be set to the ON position.

3.4 BATTERY CHARGING

This machine is equipped with an AC voltage input/DC voltage

output battery charger. The charger automatically terminates

charging when the batteries reach full capacity.

NOTE: The platform drive function is disabled when the battery

charger is plugged into an AC receptacle.

LEAD ACID BATTERIES MAY GENERATE EXPLOSIVE HYDROGEN GAS DURING

NORMAL OPERATION. KEEP SPARKS, FLAMES, AND SMOKING MATERIALS

AWAY FROM BATTERIES. PROVIDE ADEQUATE VENTILATION DURING CHARGING. NEVER CHARGE A FROZEN BATTERY. STUDY ALL BATTERY MANUFACTURERS’ SPECIFIC PRECAUTIONS SUCH AS RECOMMENDED RATES OF CHARGE

AND REMOVING OR NOT REMOVING CELL CAPS WHILE CHARGING.

3-2 – JLG Lift – 3121230

Page 29

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

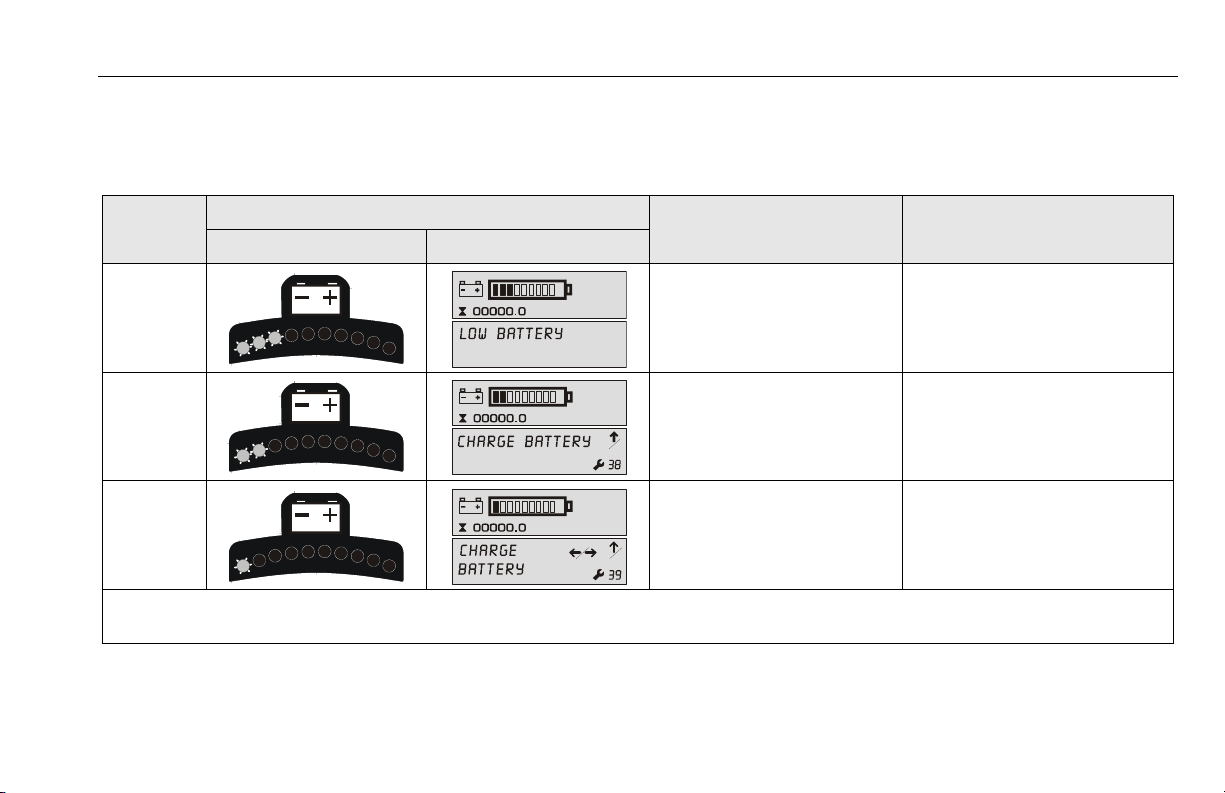

Battery - Low Voltage Warning Indicators

The MVL/MSP Platform Control Console and Ground Control Station indicate battery low voltage at three (3) Warning Levels.

Table 3-1. Battery Low Voltage Warning Indicators.

WARNING

LEVEL

PLATFORM CONTROL LED GROUND CONTROL LCD

LEVEL-1

LEVEL-2

LEVEL-3

NOTE: (a) To maximize battery life, it is recommended that the factory supplied batteries be charged continuously for a minimum of 4 hours or until 8 bars are lit on the ground station LCD Display

before operating the machine. When drained to Warning Level 2 or 3, batteries must be charged until 8 bars are lit on the ground station LCD display to clear the fault code.

INDICATOR LOCATION

RESULT ACTION REQUIRED TO CLEAR FAULT

• 3 LEDs/BARS Flashing with an audible

beep.

• Machine will Operate - No Control

Functions Locked Out.

• 2 LEDs/BARS Flashing with an audible

beep.

• Platform Lift-UP Function is Locked

Out.

• 1 LED/BAR Flashing with an audible

beep.

• Drive and Platform Lift-UP Functions

Locked Out.

Charge batteries to a level of four (4)

LEDs/BARS or more before operating.

Charge batteries for a minimum of four

(4) continuous hours or eight (8) LEDs/

BARS lit before operating. (a)

Charge batteries for a minimum of four

(4) continuous hours or eight (8) LEDs/

BARS lit before operating. (a)

3121230 – JLG Lift – 3-3

Page 30

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

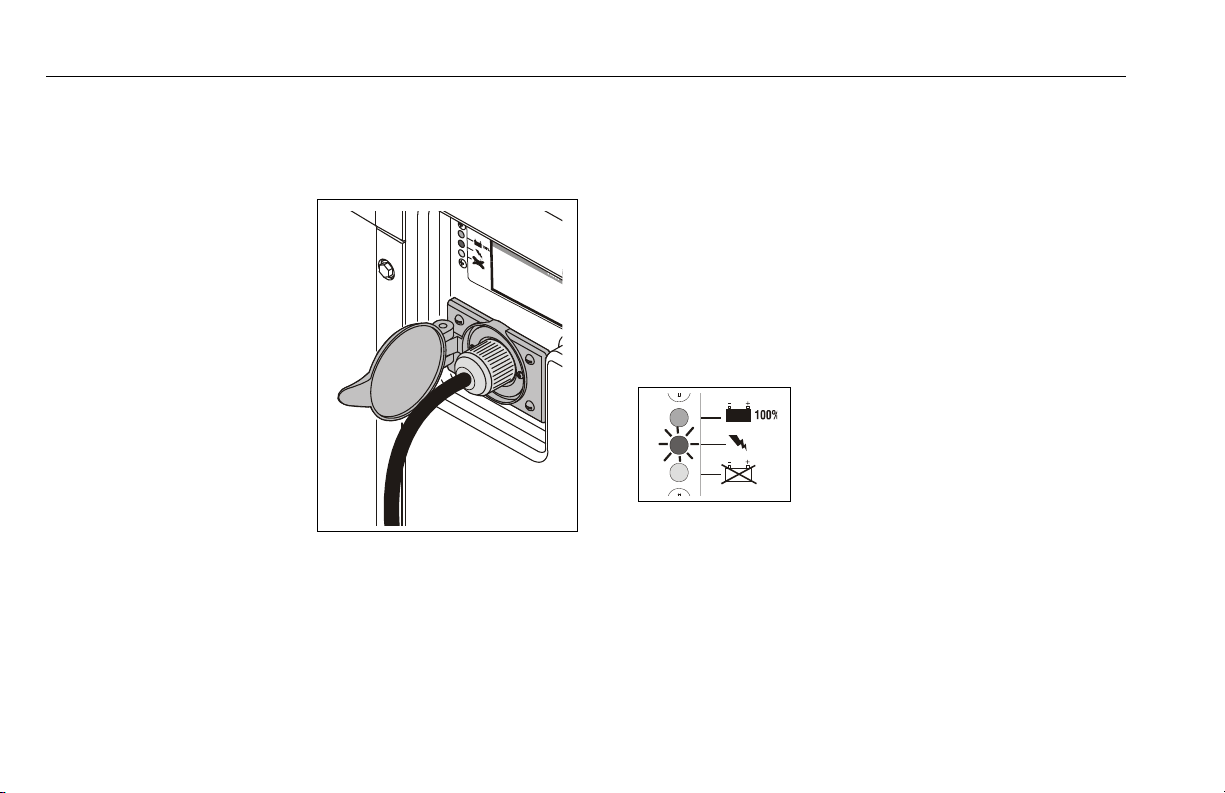

To Charge Batteries

1. Park machine in a well ventilated area near an AC voltage electrical outlet.

2. Always use a

grounded AC outlet.

Connect charger to

an outlet that has

been properly

installed and

grounded in accordance with all local

codes and ordinances. A grounded

outlet is required to

reduce risk of electric shock – do not

use ground adapters or modify plug.

When using an

extension cord,

avoid excessive voltage drops by using a

grounded 3-wire 12

AWG cord.

Battery Charging Status Indicators

The battery charging status indicators are located just above the

Charger AC input receptacle on the center cover section at the

rear of the machine. (See Figure 3-1. on page 3-8)

1. When plugged in the charger will automatically turn

on and run through a short LED indicator self-test (all

LED’s will flash in an up-down sequence for two seconds).

2. The YELLOW ‘CHARGING’ LED will turn on and a trickle

current will be applied until a minimum voltage is

reached.

CHARGING

YELLOW (MIDDLE) LED ON

Charge Incomplete

Once a minimum battery voltage of 2 volts per cell is

detected, the charger will enter the bulk charging constant-current stage and the YELLOW ‘CHARGING’ LED

will remain on. The length of charge time will vary by

how large and how depleted the battery pack is, the

input voltage (the higher, the better), and ambient

temperatures (the lower, the better). If the input AC

voltage is low (below 104VAC), then the charging

3-4 – JLG Lift – 3121230

Page 31

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

power will be reduced to avoid high input currents. If

the ambient temperature is too high, then the charging power will also be reduced to maintain a maximum internal temperature.

3. When the GREEN ‘CHARGED’ LED turns on, the batteries are completely charged.

CHARGE COMPLETE

GREEN (TOP) LED ON

100% Complete

The charger may now be unplugged from AC power

(always pull on plug and not cord to reduce risk of damage to the cord). If left plugged in, the charger will

automatically restart a complete charge cycle if the

battery pack voltage drops below a minimum voltage

or 30 days has elapsed.

4. If a fault occurred anytime during charging, a fault

indication is given by flashing the RED ‘FAULT’ LED

with a code corresponding to the error.

CHARGING PROBLEM

RED (BOTTOM) LED ON

See Flash Codes following

There are several possible conditions that generate

errors. Some errors are serious and require human

intervention to first resolve the problem and then to

reset the charger by interrupting AC power for at least

10 seconds. Others may be simply transient and will

automatically recover when the fault condition is eliminated. To indicate which error occurred, the RED

‘FAULT’ LED will flash a number of times, pause, and

then repeat.

[1 FLASH] Battery Voltage High: auto-recover. Indicates a high battery pack voltage.

[2 FLASH] Battery Voltage Low: auto-recover. Indicates either a battery pack failure, battery pack is not

connected to charger, or battery volts per cell is less

than 0.5 VDC. Check the battery pack and battery pack

connections.

3121230 – JLG Lift – 3-5

Page 32

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

[3 FLASH] Charge Timeout: Indicates the battery did

not charge within the allowed time. This could occur if

the battery is of a larger capacity than the algorithm is

intended for. It can also occur if the battery pack is

damaged, old, or in poor condition. In unusual cases it

could mean charger output is reduced due to high

ambient temperature.

[4 FLASH] Check Battery: Indicates the battery pack

could not be trickle charged up to the minimum 2

volts per cell level required for the charge to be

started. This may also indicate that one or more cells in

the battery pack are shorted or damaged.

[5 FLASH] Over-Temperature: auto-recover. Indicates

charger has shutdown due to high internal temperature which typically indicates there is not sufficient airflow for cooling – see step 1 of Installation

Instructions. Charger will restart and charge to completion if temperature is within accepted limits.

[6 FLASH] QuikQ Fault: Indicates that the batteries will

not accept charge current, or an internal fault has

been detected in the charger. This fault will nearly

always be set within the first 30 seconds of operation.

Once it has been determined that the batteries and

connections are not faulty and Fault 6 is again displayed after interrupting AC power for at least 10 seconds, the charger must be brought to a qualified

service depot.

3-6 – JLG Lift – 3121230

Page 33

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.5 GROUND CONTROL STATION - OPERATION

(See Figure 3-1.)

NOTE: If equipped with optional Programmable Security Lock

(PSL) see Section 3.12 for additional instructions.

Main Power Selector Switch

Set the Main Power Selector

Switch to Ground Control Mode

for Ground Control operation or

Platform Control Mode for Platform Operation.

Emergency Stop/Shut Down Button

POWER OFF

PUSH IN -

To Engage

Emergency Stop

POWER ON

TURN CLOCKWISE

and RELEASE -

To Reset

Emergency Stop

Brake Release Button

DO NOT MANUALLY DISENGAGE THE BRAKES UNLESS MACHINE IS SETTING

ON A LEVEL SURFACE OR MACHINE IS FULLY RESTRAINED.

PUSH and RELEASE TO DISENGAGE Brakes

PUSH and RELEASE AGAIN TO ENGAGE Brakes

NOTE: The brakes only DISENGAGE (electrically) when the joy-

stick control is moved off center during driving or are

manually DISENGAGED (electrically) using the the Brake

Release Button.

If the machine’s batteries are completely depleted of electrical charge the brakes cannot be released manually.

3121230 – JLG Lift – 3-7

Page 34

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Ground Control Module

1.Machine Status LCD Display

2.Main Power Selector Switch

3.Emergency Stop

4.Brake Release

5.Platform Up

6.Platform Down

Battery Charging Station

7.Battery Charging Status Indicators

8.Charger A/C Input Receptacle

Hydraulic System

9. Hydraulic Oil Reservoir

10. Manual Descent Control Valve

NOTE: The Ground Control Station Module is fully programmable. For

operator level programmability see Section 5.4, GROUND CONTROL STATION - PROGRA MMING.

NOTE: If equipped with optional Programmable Security Lock (PSL) see

Section 3.12 on page 3-36 for additional machine power-up

instructions.

Figure 3-1. Ground Control Station. (Machine Rear View)

3-8 – JLG Lift – 3121230

Page 35

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Platform Up

Platform Down

PUSH IN TO ELEVATE Platform

RELEASE TO STOP ELEVATING

PUSH IN TO LOWER Platform

RELEASE TO STOP LOWERING

Manual Descent Control Valve

PUSH-IN TO

LOWER Platform

RELEASE TO STOP Platform

Descent

3121230 – JLG Lift – 3-9

Page 36

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3

5

4

1

2

00

00

00000.0

Machine Status LCD Display

At power-up and during operation the LCD display on the

Ground Control Module displays the current machine operating

status. The following illustration explains the symbol indications.

Note: (a) When an Fault Code is indicated the LCD screen will

LCD Display Symbols

1. Battery Charge Indicator (BCI)

2. Function Display or Function Disabled Indicators

3. Hour Meter Display

4. Fault Code Indicator

5. Fault Text Message Display (a)

alternate between the text and symbol display modes.

3-10 – JLG Lift – 3121230

Page 37

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

In the LCD Display Symbols illustration item (2), the Function

Display or Function Disabled Indicators will vary as shown following:

DRIVE Disabled

LIFT UP Disabled

LIFT DOWN Disabled

Both LIFT UP and LIFT DOWN

Disabled

Drive Speed Cut-Back Turtle) Mode Engaged

(When Platform is Elevated)

Battery Charger (AC) Plugged In

LCD Display Fault Conditions

Table 3-2, LCD Display - Operation Fault Conditions show common LCD display Fault indications which may occur during

operation and are usually caused by either an error in machine

operation or a work area condition. These fault conditions can

usually be corrected by the operator and do not require a qualified mechanic to repair.

AFTER A FAULT CONDITION IS CORRECTED THE MACHINE POWER MAY NEED

TO BE RECYCLED TO RESET THE GROUND CONTROL STATION.

3121230 – JLG Lift – 3-11

Page 38

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

00000.0

00000.0

00000.0

00000.0

02

02

00000.0

03

03

00000.0

Table 3-2. LCD Display - Operation Fault Conditions

FAULT

CODE

——

— — NONE

——

——

PLATFORM

LEDS

FLASHING

22

32

LCD SYMBOL SCREEN LCD TEXT SCREEN

FAULT DESCRIPTION/

MACHINE CONDITION

Brakes Released

(DRIVE Disabled)

Charger AC Plugged In

DRIVE Disabled

Obstruction Sensor System

(Platform Elevated)

LIFT DOWN Disabled

Programmable Security

Lock Password

Left PHP Bar UP

(Platform Elevated)

DRIVE and Lift UP Disabled

Right PHP Bar UP

(Platform Elevated)

DRIVE and Lift UP Disabled

LOOK FOR THIS

To Engage Brakes - Press Brake

Release Button on Ground Control

Station

Unplug Charger AC Power Cord

Obstruction Under Platform or

Sensor Defective

Enter Code on PSL Keypad to

Power-Up Machine

Lower Platform and Check the Left

Pot Hole Protection Bar

Lower the Platform and Check the

Right Pot Hole Protection Bar

3-12 – JLG Lift – 3121230

Page 39

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

04

04

00000.0

13

13

00000.0

17

17

00000.0

32

32

00000.0

33

33

00000.0

Table 3-2. LCD Display - Operation Fault Conditions (Continued)

FAULT

CODE

PLATFORM

LEDS

FLASHING

43

68

13 6

17 7

32 7

33 2

LCD SYMBOL SCREEN LCD TEXT SCREEN

FAULT DE SCRIPTIO N/

MACHINE CONDITION

Tilt Condition

(Platform Elevated)

DRIVE and Lift UP Disabled

Drive Motor Brush Wear Warning (

25 hrs. of DRIVE operation remaining to a 10 sec. shut down mode)

Tra cti on Mo dul e

Over Temperature

(DRIVE Disabled)

Ground Control Module

Over Temperature

(Machine Stopped)

Pump Motor Over Current

(LIFT UP Disabled)

Both PHP Bars UP

DRIVE and Lift UP Disabled

LOOK FOR THIS

Lower the Platform and Drive off

the Tilt Condition

Drive Motor Brushes Require Service Replacement -

(See Section 5.5 on page 5-20 for

further Instructions)

Allow Drive System Traction Module to Cool Before

Operating

Allow Ground Control

Module to Cool Before

Operating

Platform Load Over Capacity

Check for Object Blocking Both the

Left and Right PHP Bars

3121230 – JLG Lift – 3-13

Page 40

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

Table 3-2. LCD Display - Operation Fault Conditions (Continued)

FAULT

CODE

34 —

35 —

NOTE: The fault conditions shown above are fault conditions which the Operator may be able to resolve. Should a fault occur and be displayed on the LCD screen which cannot be corrected at the Oper-

PLATFORM

LEDS

FLASHING

ator’s level, the problem must be referred to a qualified JLG mechanic. A complete table of Fault Codes is listed in the TroubleShooting Section of the Service and Maintenance Manual.

LCD SYMBOL SCREEN LCD TEXT SCREEN

FAULT DESCRIPTION/

MACHINE CONDITION

Aux . #1 - P latfor m Gate Open o r No

Pressure on the Platform Enable

switch.

Aux. #1 - Platform Enable switch

depressed during Machine Powerup.

LOOK FOR THIS

Close Platform Gate or Depress

Platform Enable switch during

machine operation.

Do Not Press on Platform Enable

switch during Machine Power-Up.

3-14 – JLG Lift – 3121230

Page 41

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

2

4

5

6

7

8

3

3.6 PLATFORM CONTROL CONSOLE OPERATION

1. On/Off Key Switch (See page 3-16)

2. Emergency Stop/Shut Down Button (See page 3-17)

3. Function Enable Lever - (on front of joystick) (See

page 3-19)

4. Multifunction Joystick Control (See page 3-20)

5. Drive Speed Setting Selector Switch (See page 3-23)

6. Platform Control Display Panel (See page 3-17)

7. Horn Button - (See page 3-19)

8. Drive/Lift Mode Selector Switch -

(See page 3-19)

Figure 3-2. Platform Control Console

3121230 – JLG Lift – 3-15

Page 42

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

2

General

The following conditions must be met before the machine can

be operated from the platform control console:

• Ground Control Station - Main Power Selector Switch must

be set to PLATFORM CONTROL MODE.

• Ground Control Station - Emergency Stop/Shut Down Button must be in the RESET position (POWER ON).

NOTE: See Section 3.5 on page 3-7, for Ground Control Station

operation.

• Platform Console - On/Off Key Switch must be set to the ON

position.

• Platform Console - Emergency Stop/Shut Down Button

must be in the RESET position (POWER ON).

• If equipped with the OPTIONAL - PSL (Programmable Secu-

rity Lock - Section 3.12 on page 3-36) it must be set to the ON

position.

NOTE: SLEEP MODE - During operation if no control functions

have been activated for 10 minutes (default programmable setting), the ground control module will power the

machine down to conserve battery power. Cycle power

back on using either the main power selector switch (key)

or the emergency stop/power down button on either the

platform controller or the ground control station.

Platform On/Off Key Switch

At the Platform Control Console - Set

the On/Off Key Switch to the ON

position (2) to operate machine.

1. OFF Position

2. ON Position

Set the ON/OFF Key Switch to the OFF position to power

machine down.

NOTE: If necessary, when machine is not in use, remove key from

platform key switch to disable machine from unauthorized use.

NOTE: During operation the operator in the platform can prevent

unauthorized control of the machine (from the Ground

Control Station) by either switching the On/Off Key to the

OFF position, or activating the Emergency Stop Button on

the platform control console.

3-16 – JLG Lift – 3121230

Page 43

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3

142

Platform Emergency Stop Button

NOTE: The Platform and Ground Control Station Emergency Stop

Buttons must both be in the RESET position to operate

machine.

POWER OFF

PUSH IN TO ENGAGE

Emergency Stop

POWER ON

TURN CLOCKWISE

and RELEASE to

RESET Emergency Stop

Platform Control Display Panel

Figure 3-3. Platform Control Display Panel.

1. Battery Charge/Flash Code

LEDS

2. Drive Mode Indicator

3. Lift Mode Indicator

4. Drive Speed Setting

Indicator

3121230 – JLG Lift – 3-17

Page 44

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1. Battery Charge/Flash Code Indicator LEDS

On normal power-up and operation this series of ten (10)

LEDs visually indicates the amount of charge remaining in

the batteries.

The number of LEDs lit will change depending on the level

of charge in the batteries.

• (+) All Three (3) GREEN LEDs lit up indicate maximum

battery charge.

• Four (4) YELLOW LEDs indicate a two thirds to one third

battery charge remaining.

• (–) Three (3) RED LED’s lit indicate minimum battery

charge remaining. The machine will continue to operate at

this charge level but will begin to indicate low battery voltage warning indicators.

NOTE: For more information on Battery Warning Level Indicators

See “Battery - Low Voltage Warning Indicators” on page 3-

3.

This set of ten (10) LEDs will also indicate a flash (fault) code

if operating problems are detected by the Ground Control

Station. Fault codes are also accompanied by a beeping alert

from the platform control console.

NOTE: LED Flash (Fault) Code indications that can be corrected

by the operator are shown on Table 3-2 on page 3-12, this

section of the manual.

2. Drive Mode Indicator

When the Drive/Lift Mode Selector Switch is set to DRIVE

MODE the round LED indicator on that portion of the display

panel will light up indicating the DRIVE Mode active.

3. Lift Mode Indicator

When the Drive/Lift Mode Selector Switch is set to LIFT

MODE the round LED indicator on that portion of the display

panel will light up indicating the LIFT Mode active.

4. Drive Speed Setting Indicator

The five (5) GREEN LEDs on the top of this indicator display

the drive speed setting with the TURTLE (on the left) representing the MINIMUM speed setting and the RABBIT (on the

right) representing the MAXIMUM speed setting.

3-18 – JLG Lift – 3121230

Page 45

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1 2

Drive/Lift Mode Selector Switch Horn Button

Drive/Lift Mode Selector Switch

1. LIFT Mode

2. DRIVE Mode

PUSH the rocker switch

to select mode of operation.

Whichever mode is

selected the appropriate

LED indicator on the display panel below will

light up showing which

mode has been activated

for joystick operation.

IMPORTANT:

The selected

mode will only

remain active for

5 seconds if the

function is not

operated.

When the machine is

powered on, pressing this

button will sound the

Horn.

Joystick Function Enable Lever

The Function Enable lever on the

front of the joystick control,

must be engaged and held in

during any joystick operation.

3121230 – JLG Lift – 3-19

Page 46

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

Multifunction Joystick Control

The joystick will operate the following machine functions:

• Drive/Steer

• Platform Lift Up and Down

NOTE: Use the Drive/Lift Mode Selector Switch to select which

function the joystick will operate.

The selected operating mode will only remain active for 5

seconds if the function is not operated.

Remember to press and hold the joystick function enable

lever to operate any joystick functions.

SEE FIGURE 3-4. ON PAGE 3-21 FOR GRADE AND SIDESLOPE DRIVING

DESCRIPTION WHEN DRIVING WITH THE PLATFORM LOWERED (STOWED).

WHEN THE PLATFORM IS ELEVATED DRIVE ONLY ON A SMOOTH, FIRM, AND

LEVEL SURFACE.

Drive Mode

1. Activate the Drive Mode

using the Drive/Lift Mode

Selector switch.

Within 5 seconds of activation - ENGAGE and HOLD

the JOYSTICK ENABLE LEVER

then move the joystick in

the desired direction of

travel. Drive power is

applied proportionally the

further the joystick is

moved off center.

3-20 – JLG Lift – 3121230

Page 47

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

G

R

A

D

E

SMOOTH, FIRM AND LEVEL

DO NOT DRIVE MACHINE ON A GRADE OR SIDESLOPE EXCEEDING

THOSE SPECIFIED IN SECTION 5 - MACHINE SPECIFICATIONS

SIDESLOPE

3121230 – JLG Lift – 3-21

Figure 3-4. Machine Operating Specifications

Page 48

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

2

3

Lift Mode

1. Activate the Lift Mode using

the Drive/Lift Mode Selector

switch.

2. Platform LIFT DOWN Direction

3. Platform LIFT UP

Direction

Within 5 seconds of activation - ENGAGE and HOLD the

JOYSTICK ENABLE LEVER

then move the joystick in

the direction of LIFT (3) OR

LOWER (2).

IF THE TILT ALARM WARNING HAS BEEN ACTIVATED WHILE DRIVING WITH

THE PLATFORM ELEVATED, LOWER PLATFORM COMPLETELY AND DRIVE TO A

FIRM LEVEL SURFACE.

ENSURE THE AREA BENEATH THE PLATFORM IS FREE OF PERSONNEL PRIOR

TO LOWERING THE PLATFORM.

3-22 – JLG Lift – 3121230

Page 49

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

Drive Speed Setting Controls

NOTE: When the platform is elevated the maximum drive speed

is automatically cut-back to 1/4th the speed when the

platform is fully lowered. The Ground Control Module-LCD

screen will display a turtle when in this mode, See page 311 - Ground Control - LCD Status Display in this section of

the manual.

Drive Speed Setting

Selector Switch

1. Selector Switch -

(on top of joystick)

Each PRESS on this side of

the switch will DECREASE

maximum drive speed.

(FEWER LEDs Lit up on

the Drive Speed Indicator.)

Each PRESS on this side of

the switch will INCREASE

maximum drive speed.

(MORE LEDs Lit up on the

Drive Speed Indicator.)

3121230 – JLG Lift – 3-23

Page 50

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.7 PARKING MACHINE

1. Drive machine to a well-protected and well-ventilated

area.

2. Ensure the platform is fully lowered, turn the main

power selector switch to the OFF position (centered).

NOTE: If required, charge batteries in preparation for next work

day.

3.8 PLATFORM CONFIGURATIONS

The platforms in the following illustrations show the entry

points as well as the direction of the platform gates for opening

and closing when entering the platform. The maximum loading

capacities per model are shown in the tables below each platform as well as the various components of the platform.

3-24 – JLG Lift – 3121230

Page 51

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

2

3

1

FRONT GULL-WING ENTRY PLATFORM (NON-CE and AUS)

Model Max. Capacity

1. Front Gull-Wing Entry Gate 3. Lanyard Attach Point -

2. Entry Gate Latch (Left side on mast)

15MVL 500 lb. (230kg)

20MVL 350 lb. (160kg)

1. Sliding Side Entry Gate 3. Lanyard Attach Point -

2. Platform Control Console (Left side on mast)

FRONT SLIDE BAR ENTRY PLATFORM

Model Max. Capacity

15MVL 500 lb. (230kg)

20MVL 350 lb. (160kg)

3121230 – JLG Lift – 3-25

Page 52

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

2

1

3

4

2

Side Entry Platform w/Folding Material Tray Installed

Table 3-3. Max. Capacity with

SPEC

(1)

Model

15MSP 300 lb.

ANSI/

CSA

20MSP 300 lb.

CE

AUS

(1)

This platform is only available on models shown for the applicable specification.

NOTE: Australian Specification Machines ONLY - The SIDE

20MVL 250 lb.

15MVL 350 lb.

20MVL 250 lb.

ENTRY PLATFORM w/FOLDING MATERIAL TRAY includes

Platform

Capacity

(136 kg)

(136 kg)

(115 kg)

(160 kg)

(115 kg)

Tray C apacity

150 lb.

(70 kg)

150 lb

(70 kg)

100 lb.

(45 kg)

150 lb.

(70 kg)

100 lb.

(45 kg)

Combined

Capacity

450 lb.

(206 kg)

450 lb.

(206 kg)

350 lb.

(160 kg)

500 lb.

(230 kg)

350 lb.

(160 kg)

a gate release/latch mechanism which is released by

SIDE ENTRY PLATFORM - w/ FOLDING MATERIAL TRAY

1. Swing Side Entry Gates 3. Platform Control Console

2. Lanyard Attach Point - (on side of 4. Material Tray

mast or lug at right rear upper rail)

pressing down on the handles mounted to the top rail of

both entry gates. Releasing the handles will latch the

gates when closed.

3-26 – JLG Lift – 3121230

Page 53

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

EXTENDIBLE PLATFORM (GULL-WING ENTRY - NON CE and AUS)

Model Max. Capacity

15MVL/15MSP 500 lb. (230 kg)

20MVL/20MSP 350 lb. (160kg)

1. Gullwing Entry Gate 4. Extension Slide/Lock Handle

2. Entry Gate Latch 5. Platform Control Console

3. Lanyard Attach Point (on mast) 6. Sliding Extendible Section

EXTENDIBLE PLATFORM (FRONT SLIDE BAR ENTRY - CE ONLY)

Model Max. Capacity

15MVL/15MSP 500 lb. (230 kg)

20MVL/20MSP 350 lb. (160kg)

1. Sliding Bar Entry Gate 4. Platform Control Console

2. Lanyard Attach Point (on mast) 5. Sliding Extendible Section

3. Extension Slide/Lock Handle

3121230 – JLG Lift – 3-27

Page 54

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

StockPicking Platform Operation

The stockpicking platform is available in two (2) versions.

• Fixed side-rail version

• Folding side-rail version

THE STOCKPICKER PLATFORM ALLOWS THE MACHINE TO BE OPERATED IN AN

OPEN RAIL CONFIGURATION (SEE ILLUSTRATION).

CE SPECIFICATION MACHINES:

THE OPERATOR MUST WEAR A FULL BODY HARNESS EQUIPPED WITH A LANYARD SHORT ENOUGH TO PREVENT A FALL FROM THE PLATFORM. THE LANYARD MUST BE ATTACHED TO THE AUTHORIZED LANYARD POINT. ALSO, JLG

RECOMMENDS THAT CE SPECIFICATION MACHINES EQUIPPED WITH THE

STOCKPICKER PLATFORM ARE ONLY TO BE USED FOR STOCKPICKING APPLICATIONS.

NON-CE UNITS:

THE OPERATOR MUST WEAR A FULL BODY HARNESS WITH A LANYARD (MAX.

6 FT. (1.82M) ATTACHED TO THE AUTHORIZED LANYARD POINT OR A BODY

BELT EQUIPPED WITH A LANYARD SHORT ENOUGH TO PREVENT A FALL FROM

THE PLATFORM.

WHILE OPERATING THE MACHINE IN THE OPEN RAIL CONFIGURATION,

ALWAYS OPERATE THE MACHINE FROM THE REAR OF THE PLATFORM WITH

THE MID-GATE CLOSED AND THE PLATFORM CONTROL CONSOLE ATTACHED

TO THE FIXED PORTION OF THE GUARDRAIL.

1. Primary Entrance/Exit Gate 4. Platform Control Console

2. Primary Entrance Latch 5. Mid-Gate

3. Lanyard Attach Point - 6. Gate Release/Lock Pins

(on mast and platform rail) 7. Secondary Exit Gate

STOCKPICKER PLATFORM

(WITH FOLDING SIDE-RAILS) (MSP)

Model Max. Capacity

15MSP 500 lb. (230 kg)

20MSP 400 lb. (180 kg)

3-28 – JLG Lift – 3121230

Page 55

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

STOCKPICKER PLATFORM

(OPEN RAIL CONFIGURATION) (MSP)

1. Platform Mid-Gate (enter platform behind mid-gate and close

the mid-gate when driving with front rails open).

2. Open Rail Configuration work area. (See Caution on previous

page about fall protection requirements).

3. Platform Control Console attached to fixed side-rail in the rear

of the platform.

3121230 – JLG Lift – 3-29

Page 56

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.9 FALL PROTECTION - LANYARD ATTACHMENT

JLG INDUSTRIES, INC. RECOMMENDS THE OPERATOR IN THE PLATFORM

WEAR A FULL BODY HARNESS WITH A LANYARD ATTACHED TO AN AUTHORIZED LANYARD ANCHORAGE POINT.

The lanyard attach point for MVL/MSP machines depends on

the type of platform attached to the machine.

• Quick Change (removable) platforms use a lanyard attach

point located on the lower left side of the mast header, just

behind the platform (see illustration).

• Fixed platforms (bolted permanently to the mast), have lanyard attach points located on the mid or upper platform rail

at the rear of the platform. See specific platform illustration

starting at “PLATFORM CONFIGURATIONS” on page 3-24.

AFTER ENTERING THE PLATFORM, BEFORE BEGINNING OPERATION ALWAYS

CLOSE THE PLATFORM ENTRY GATE(S).

3-30 – JLG Lift – 3121230

Page 57

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

3

2

4

3.10 QUICK-CHANGE PLATFORM MOUNTING

MVL Model Lifts are equipped with quick-change platform

mounts which allow quick removal and installation of currently

available quick-change platforms.

NOTE: MSP Models require the installation of the Quick-Change

mount kit to use Quick-Change Platforms.

Platform Removal (see illustra tion following)

1. Remove the platform control console from the platform and lay aside.

2. Remove both upper and lower mount attach pins

securing the platform support rails to the mast

mounting channels.

3. Swing and lift the platform out of the mounts and lay

aside.

Platform Installation

1. Set platform in upper and lower mounts.

2. Install attach pins in upper and lower mounts.

3. Attach platform control console to platform rail.

ENSURE ALL PINS AND FASTENERS ARE INSTALLED AND SECURE PRIOR TO

OPERATION.

3121230 – JLG Lift – 3-31

Quick-Change Platform Mounting

1. Upper Platform Mount 3. Lower Platform Mount

2. Upper Mount Attach Pins 4. Lower Mount Pins

Page 58

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

3.11 TRANSPORTING, LIFTING AND TIE DOWN PROCEDURES

General

All MVL and MSP Model Personnel Lifts may be transported to a

work site using the following methods:

• Driving the machine around on its base wheels if travel surface area permits.

• Loaded, IN AN UPRIGHT POSITION ONLY onto a heavy-duty

vehicle with the payload capacity capable of supporting

the full weight of the machine (Check machine gross weights

in the Operating Spec Chart at the beginning of this Section).

• Moved with a fork-lift truck using the fork-lift pockets in the

base frame.

Truck Transport

DO NOT TRANSPORT THE MACHINE IN A HORIZONTAL POSITION DUE TO

LEAKAGE OF BATTERY ACID FROM THE BATTERIES OR HYDRAULIC FLUID

FROM THE HYDRAULIC RESERVOIR.

The machine may be winched onto a tilted roll-back truck bed

(see important note following) which has been rolled back to

ground level. Disengage the brakes and always winch (pull)

from the mast (rear) end of the machine, using the rear tie-down

loop attached to the base frame.

DO NOT ATTEMPT TO DRIVE MACHINE ONTO, OFF OF, OR PUSH MACHINE

ONTO A TILTED ROLL-BACK TRUCK BED.

THE MVL AND MSP MACHINES POWER MODULE COULD SUSTAIN SERIOUS DAMAGE

WHEN THE UNIT IS PUSHED, OR TOWED AT SPEEDS GREATER THAN 2 MPH.

WHEN TOWING OR WINCHING, THE MACHINE’S BRAKES MUST BE DISENGAGED.

RE-ENGAGE THE BRAKES ONCE MACHINE IS IN PLACE WITH TRUCK BED LEVEL AND

READY FOR TIE DOWN.

TIE DOWN LOOPS ARE PROVIDED ON BOTH ENDS OF THE BASE FRAME TO SECURE

MACHINE TO BED OF TRANSPORT VEHICLE.

3-32 – JLG Lift – 3121230

Page 59

SECTION 3 - MACHINE CONTROLS, INDICATORS AND OPERATION

1

2

Machine Tie-Down

With machine in position to be tied down and brakes engaged,

use the following guidelines for restraining the machine during

transport.

USE OF EXCESSIVE FORCE WHEN SECURING MACHINE (DRIVE WHEEL LOAD),

CAN CAUSE DAMAGE TO THE MACHINES DRIVE WHEEL COMPONENTS.

1. Secure machine with an adequate chain attached

through the tie down loops located at the front and

rear of machine. (See Figure 3-6.)

2. The chain should be securely tightened with a force of

approximately 100 lb. applied two feet from the pivot

handle.

Crane Hook Accessory (Option)

The crane hook accessory provides an attachment point for a

lifting device to lift the machine. The lifting device must be

capable of handling the gross weight of the machine, see the

machine specifications Section 5 of this manual.

DO NOT ATTEMPT TO USE THE CRANE HOOK ACCESSORY AS AN ATTACH POINT

TO LIFT ITEMS WITH THE MAST ASSEMBLY. THIS WILL RESULT IN DAMAGE TO

THE MAST AND POSSIBLE MACHINE TIPPING.

Figure 3-5. Crane Hook Accessory

1. Crane Hook Attachment 2. Back of Mast

3121230 – JLG Lift – 3-33

Page 60