SECTION 5. ACCESSORIES

Table 5-1. 1532R/1932R - Available Accessories

SECTION 5 - ACCESSORIES

ACCESSORY

Inventer

Magnetic Gate Latch

Anti-Vandalism Package

Platform Extension Handles

Footswitch

JLG™ Mobile Control

ACCESSORY

Pipe Rack s

Pane l Car rie r

3121744 5-1

ANSI ANSI Exp CSA CE AUS Japan China

Table 5-2. 1932R Only - Available Accessories

ANSI ANSI Exp CSA CE AUS Japan China

Market

Market

SECTION 5 - ACCESSORIES

Table 5-3. 1532R - Options/Accessories Relationship Table

ACCESSORY

Inverter

Magnetic G ate Latch

Anti-Vandalism Package

Platform Extension Handles

Footswitch

COMPATIBLE WITH

( Note 1)

Anti- Vandalism Package, Fire Extinguisher, Platform Extension Handles, Footswitch, Dual Rails, Magnetic Gate Latch

Inverter, Anti- Vandalism Package, Fire Extinguisher, Platform Extension Handles,

Footswitch, Dual Rails

Inverter, Fire Extinguisher, Platform Extension Handles, Footswitch, Dual Rails,

Magnetic Gate Latch

Inverter, Anti-Vandalism Package, Fire Extinguisher, Footswitch, Magnetic Gate

Latch

Inverter, Anti- Vandalism Package, Fire Extinguisher, Platform Extension Handles,

D ua l R a il s , M ag n et i c G a te La tc h

INCOMPATIBLE WITH

——

——

——

Dual Rails —

——

INTERCHANGEABLE

WITH (Note 2)

JLG™ Mobile Control All — —

Note 1: Any accessory not listed under “COMPATIBLE WITH” is assumed to be incompatible.

Note 2: Can be used on same unit but not simultaneously.

1001218523-G

5-2 3121744

Table 5-4. 1932R - Options/Accessories Relationship Table

SECTION 5 - ACCESSORIES

ACCESSORY

Inverter

Magnetic G ate Latch

Anti-Vandalism Package

(ANSI, ANSI Exp., CSA, JPN)

Anti-Vandalism Package

(CE, AU S, CH N)

Platform Extension Handles

(ANSI, ANSI Exp., CSA, JPN)

Platform Extension Handles

(CE, AU S, CH N)

Pipe Racks

Footswitch (ANSI, ANSI Exp.,

CSA, JPN)

Footswitch (CE, AUS, CHN

(GB)

JLG™ Mobile Control All — —

Note 1: Any accessory not listed under “COMPATIBLE WITH” is assumed to be incompatible.

Pipe Racks, Anti-Vandalism Package, Fire Extinguisher, Platform Extension

Handle s, Footswitch , Dual Ra ils, Magnet ic Gate Latch

Inverter, Pipe Racks, Anti-Vandalism Package, Fire Extinguisher, Platform

Extension Handles, Footswitch, Dual Rails

Inverter, Pipe Racks, Fire Extinguisher, Platform Extension Handles, Footswitch,

Dual Ra ils, Magnet ic Gate Latch

Inverter, Pipe Racks, Platform Extension Handles, Footswitch, Dual Rails, Magnetic

Gate Latch

Pi p e R a ck s, A nt i -Va n da li s m P ac k ag e , R a il Pa dd i ng , F i re Ex t in g ui s he r, In ve r te r,

Footswitch, Magnetic Gate Latch

Inverter, Anti-Vandalism Package, Footswitch, Magnetic Gate Latch Fire Extinguisher, Dual Rails —

Inverter, Anti-Vandalism Package, Fire Extinguisher, Platform Extension Handles,

Footswitch, Dual Rails, Magnetic Gate Latch

All — —

Inverter, Anti-Vandalism, Extension Handles, OH Protection, Dual Rails, Mag. Gate

Latch

COMPATIBLE WITH

( Note 1)

INCOMPATIBLE WITH

——

——

——

Fire Extin guisher —

Dual Rails —

——

Fire Extin guisher —

INTERCHANGEABLE

WITH (Note 2)

3121744 5-3

SECTION 5 - ACCESSORIES

0"%

1

1. Inverter Module

Table 5-4. 1932R - Options/Accessories Relationship Table (Continued)

ACCESSORY

COMPATIBLE WITH

Note 2: Can be used on same unit but not simultaneously.

5.1 INVERTER

The DC to AC Power Inverter converts DC voltage from the

onboard system batteries to AC voltage for use at the

platform AC output receptacle.

The inverter module is mounted on the inside of the

battery compartment door.

( Note 1)

INCOMPATIBLE WITH

INTERCHANGEABLE

WITH (Note 2)

1001218523-G

5-4 3121744

SECTION 5 - ACCESSORIES

Specifications

DESCRIPTION SPECIFICATION

Electrical System Voltage (DC) 24V

Power I nvert er:

DC Input:

DC Input Voltage:

Operating Temperature:

AC Ou tput :

Output Power (Continuous):

Output Power (Surge):

Output Power (AC):

Output Voltage (AC):

Output Frequency:

Typ e:

Protection:

Out put Reverse DC Polarity:

Power Bri ght

20 to 30 VDC

-4° F (-20° C) to 113° F (+45° C)

900W

1800W

7.5A

117V +/– 10%

60 Hz

Modified Sine Wave

3 X 25A Replaceable Fuse

Safety Precautions

THIS ACCESSORY MAY CAUSE SHOCK OR ELECTROCUTION IF USED IMPROPERLY.

TREAT INVERTER OUTPUT THE SAME AS COMMERCIAL AC POWER.

• This inverter will only operate from a 24V power

source. Do not attempt to connect the inverter to

any other power source, including any AC power

source.

• Do not allow water or other liquids to contact the

inverter.

• Do not use appliances with damaged or wet cords.

• Route appliance cords and extension cords to

prevent accidental pinching, crushing, abrading, and

tripping hazards.

• Do not use the inverter near flammable materials or

in any locations that may accumulate flammable

fumes or gases. This is an electrical device that can

briefly spark when electrical connections are made

or broken.

Operation

1. Set the inverter ON/OFF switch to the ON position at

the ground control station.

2. Only plug in tools or appliances rated within the maximum output wattage at the platform AC receptacle

mounted on the platform.

3121744 5-5

SECTION 5 - ACCESSORIES

1

1.Magnetic Gate Latch Assembly

5.2 MAGNETIC GATE LATCH

The Magnetic Gate Latch ensures the platform gate latches

securely when closed.

Operation

Grasp handle and swing gate open.

The Anti-Vandalism Package consists of two lockable covers for the Platform and Ground Control Stations that prevent unauthorized use of the machine. Locks are not provided with this kit.

5-6 3121744

SECTION 5 - ACCESSORIES

0"%

1. Lock Position (Covers Closed) 2. Covers Open

Platform Control Station

1

2

0"%

Ground Control Station

1. Lock Position (Cover Closed) 2. Cover Open

1

2

3121744 5-7

SECTION 5 - ACCESSORIES

0"%

1. Extension Handle in the Stowed

Posi tion

2. Extension Handle in the Extension

Posi tion

5.4 PLATFORM EXTENSION HANDLES

The Platform Extension Handles are mounted to the top

rails of the extension platform at the roller tabs. When

rotated up 90°, the handles provide the operator an

optional grip to push the extension platform out from its

stowed position.

Operation

1. Swing both extension handles up 90° to the extend

position.

2. While standing on the main platform, release the

extension platform lock mechanism with one foot.

3. Grasp both handles and push platform extension out

until locked in either of the two other locked extension positions.

5-8 3121744

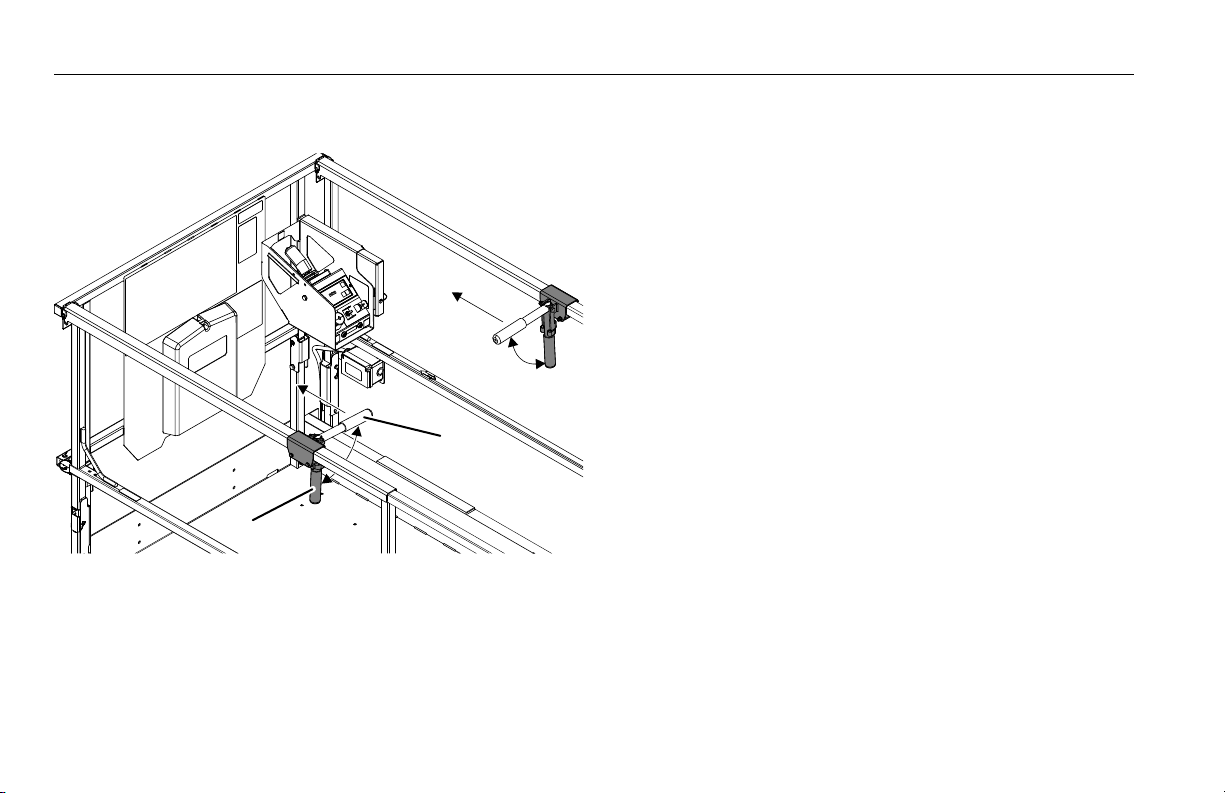

5.5 PIPE RACKS

OAD00100

1. Pipe Racks

(Working Position)

2. Capacity Decals

1

1

2

2

OAD00110

3

4

3. Tie-Down Strap 4. Locking Pins

Pipe Racks store pipe or conduit inside the platform in

order to prevent rail damage and optimize platform utility.

The accessory consists of two racks attached to the lower

platform handrail with adjustable straps that secure the

load in place.

SECTION 5 - ACCESSORIES

NOTE: This accessory is available for the 1932R in CE and Austra-

lian markets only.

3121744 5-9

SECTION 5 - ACCESSORIES

Safety Precautions

THIS ACCESSORY AFFECTS OVERALL PLATFORM CAPACITY. REFER TO CAPACITY DECALS AND ADJUST ACCORDINGLY. WEIGHT IN RACKS PLUS WEIGHT IN

PLATFORM MUST NOT EXCEED RATED CAPACITY.

RETRACT PLATFORM EXTENSION BEFORE ATTACHING PIPE RACKS AND LOADING

MATERIAL.

MAXIMUM WEIGHT IN RACKS IS 45 KG (100 LB) EVENLY DISTRIBUTED BETWEEN

RACKS. MAX LENGTH IS 6 M (20 FT). MAX CIRCUMFERENCE OF MATERIAL IS 180 MM

PER PIPE.

• Do not exit platform over rails or stand on rails.

• Do not drive the machine without material secured.

• Use this accessory on approved models only.

• Return racks to the stowed position when not in use.

Preparation and Inspection

• Ensure both racks are mounted and securely

fastened to inside of platform rails.

• Check for missing or damaged components. Replace

if necessary.

Operation

1. To prepare racks for loading, remove locking pins,

rotate each rack 90 degrees from stowed to working

position, then secure with locking pins.

2. Place material onto racks with weight evenly

distributed between both racks. Do not exceed the

rated capacity stated on the decal.

3. Route the tie-down straps at each end across loaded

material and tighten.

4. To remove material, loosen and remove tie-down

straps, then carefully remove material from racks.

NOTE: Reinstall tie-down straps across any remaining material

before continuing machine operations.

5. When not in use, remove locking pins, rotate racks 90

degrees to the stowed position, then secure locking

pins.

5-10 3121744

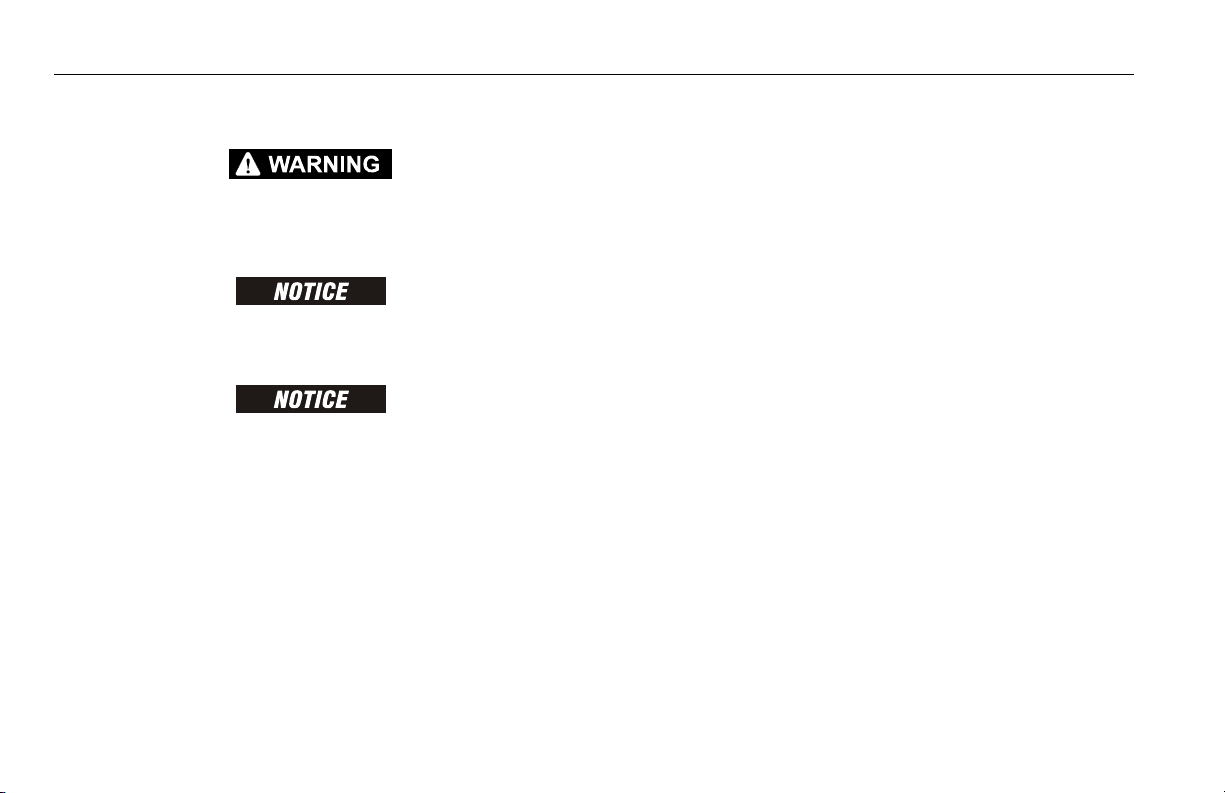

5.6 FOOTSWITCH

OAD00120

1

1.Footswitch Assembly

The Footswitch serves as another enable switch in the

function control circuit. It must be depressed in sequence

with the platform control joystick trigger switch to enable

operation of machine functions when using the platform

controls. Power is removed from the platform controls

when the footswitch is released.

NOTE: This accessory is only available in Japanese and Korean

markets .

Operation

To operate a function, engage the footswitch and joystick

trigger in any sequence before operating a function.

SECTION 5 - ACCESSORIES

3121744 5-11

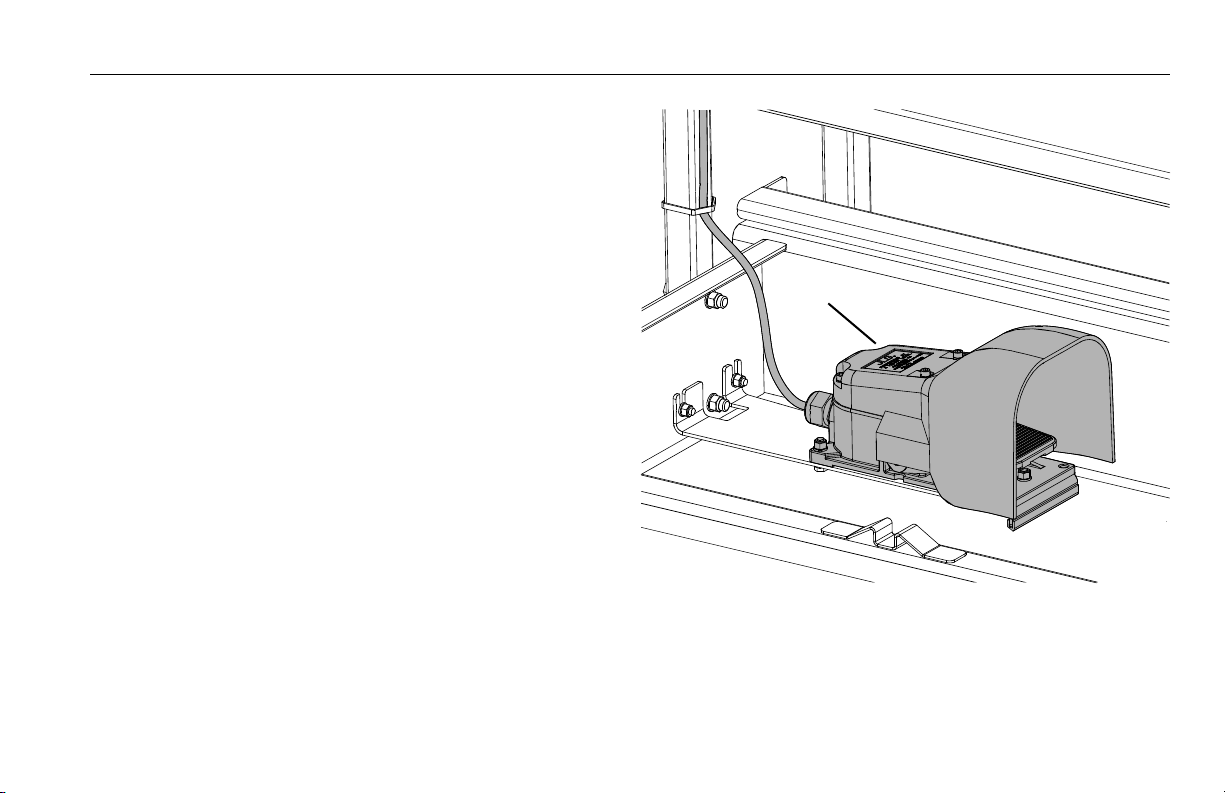

SECTION 5 - ACCESSORIES

0"%

1

2

3

1. Adjustable Bracket

2. Capacity Decal (on back)

3. Carrier Tray

5.7 PANEL CARRIER

The Panel Carrier can transport flat sheets or panels to an

elevated site by positioning them in a channel on the outside of the platform. It consists of a carrier tray that runs

parallel to the length of the platform and an adjustable

bracket mounted to the handrail to hold material in place.

The panels can measure up to 4 ft x 8 ft (1.22 m x 2.4 m), or

approximately 32 ft sq. (3 m sq.).

This accessory is unavailable for model 1930ES except in

CE and AUS markets.

5-12 3121744

SECTION 5 - ACCESSORIES

Safety Precautions

MULTIPLE MATERIAL-HANDLING ACCESSORIES CAN BE INSTALLED BUT ONLY

ONE MAY BE LOADED AT A TIME UNLESS APPROVED BY JLG INDUSTRIES, INC.

THIS ACCESSORY AFFECTS THE OVERALL PLATFORM CAPACITY. REFER TO THE

CAPACITY DECAL AND ADJUST ACCORDINGLY.

WHEN THE CARRIER TRAY IS LOADED, THE INCREASE OF AREA EXPOSED TO

WIND WILL DECREASE STABILITY. REFER TO THE DECAL FOR MAXIMUM

PANEL SIZE AND WIND SPEED.

• Ensure no personnel are beneath the platform.

• Do not exit the platform over the rails, or stand on

the rails.

• Remove the tray when not in use.

Preparation and Inspection

• Ensure all components are secured to the platform.

• Check for any missing or damaged components.

Replace if necessary.

• Check for loose nuts and bolts. If necessary, torque

according to the Torque Chart specifications in the

Service Manual.

• Replace any missing or illegible decals.

• Replace any torn or frayed straps.

Operation

1. Attach the carrier tray to the outside of the platform.

2. Load the Panel Carrier with material and secure with

the adjustable bracket.

3. Position the panel to its desired location.

4. Remove the carrier tray when finished.

3121744 5-13

SECTION 5 - ACCESSORIES

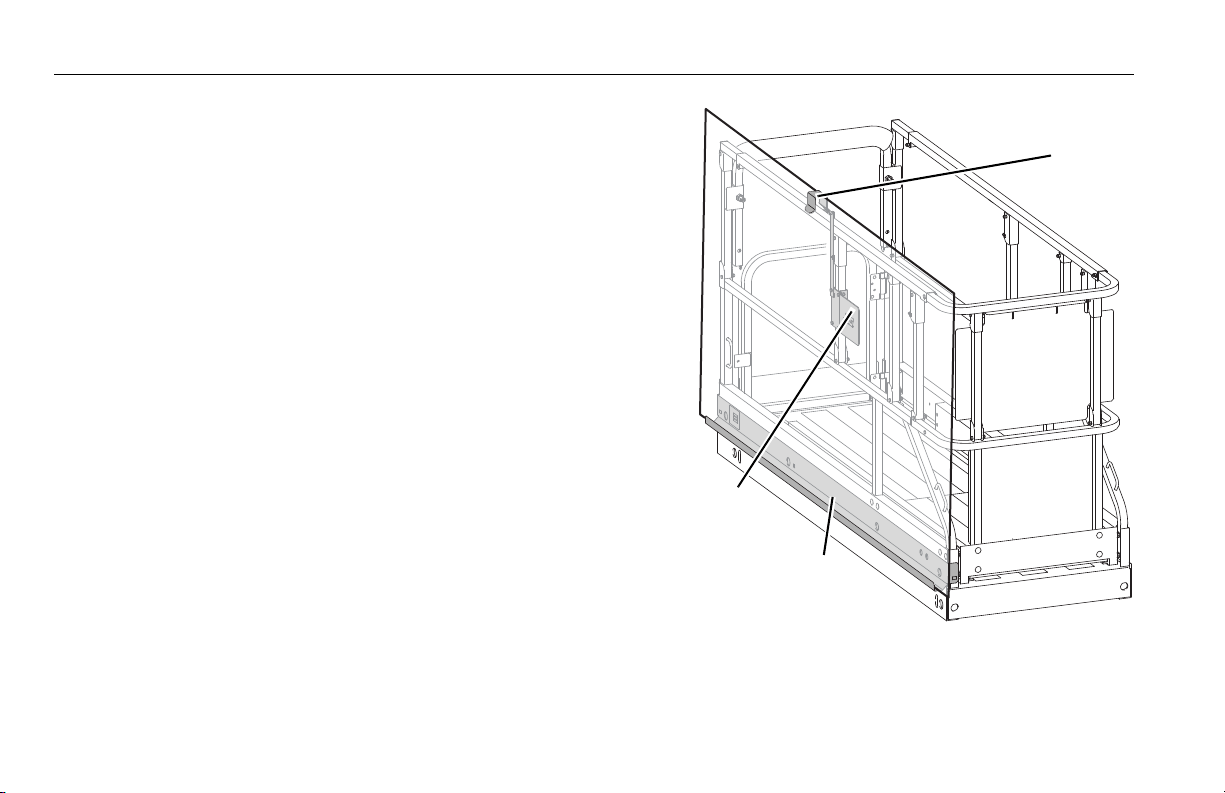

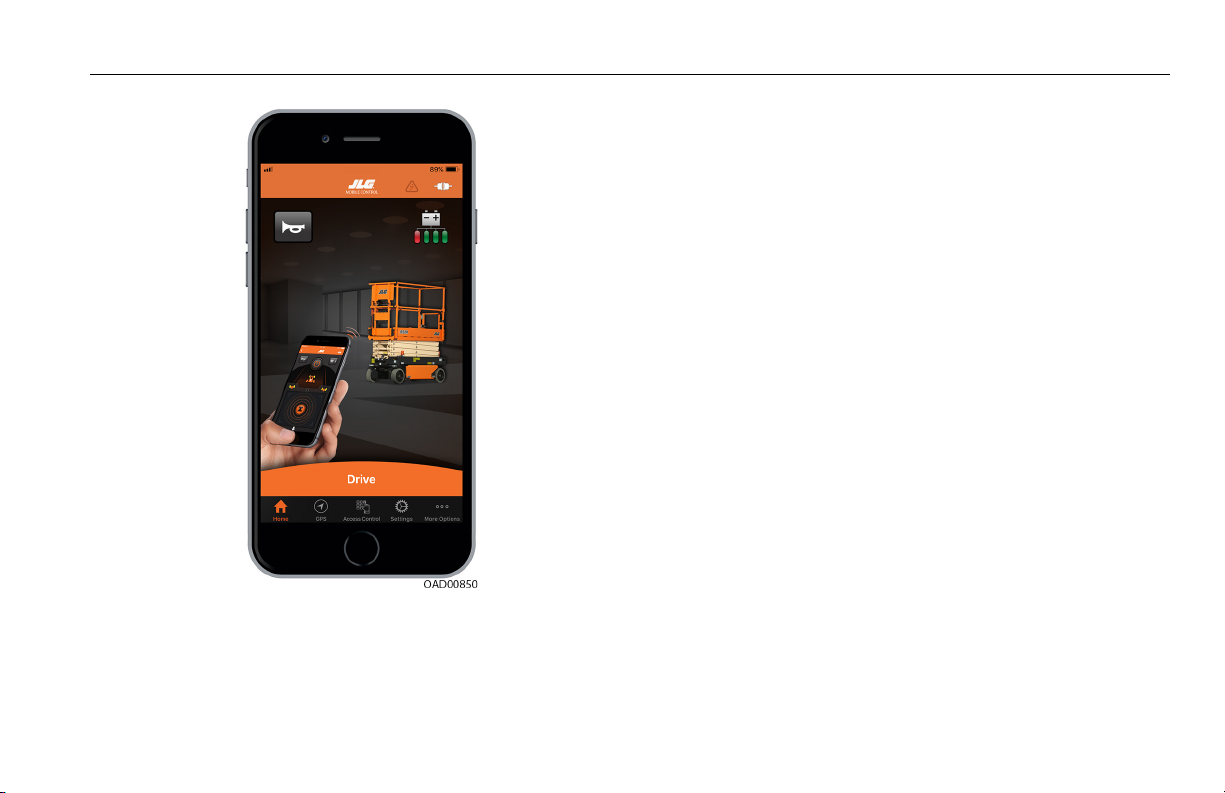

5.8 JLG™ MOBILE CONTROL

The JLG Mobile Control application allows machine

operators to drive remotely from a Bluetooth® equipped

handheld iOS mobile device.

Prior to operation, the machine operator first pairs a

Mobile Control Module equipped machine with a

JLG Mobile Control loaded mobile device by scanning a QR

Code on the machine.

Operation

Download, read, and understand the JLG Mobile Control

Manual from www.JLG.com prior to using the JLG Mobile

Control.

WARNING

NEVER drive the machine using JLG Mobile Control while

standing in the platform, or without clear line-of-sight

between the machine and the destination, as serious

injury could occur to operator or bystander.

Download

Download the JLG Mobile Control on a Bluetooth® equipped

iOS handheld mobile device by visiting

www.JLG.com/mobilecontrol, the Apple Store®

or Google Play®.

5-14 3121744

SECTION 5 - ACCESSORIES

1. JLG Mobile Control

3121744 5-15

SECTION 5 - ACCESSORIES

b

a

c

d

Document Resources

Access to application related documentation.

1. Select Settings (a) from the Home Screen

2. Select either:

b. JLG Mobile Control manual

c. Legal Statements

d. Regulatory Statements

The Bluetooth™ word mark and logos are registered

trademarks owned by Bluetooth SIG, Inc. and any use of

such marks by JLG is under license. Other trademarks and

trade names are those of their respective owners.

5-16 3121744

SECTION 5 - ACCESSORIES

3121744 5-17

SECTION 5 - ACCESSORIES

5-18 3121744

Loading...

Loading...