HUSQVARNA Rider 111B User Manual

T2® / T2-HP™

Integrated Hydrostatic Transaxle

Service and Repair Manual

BLN-52749

July 2011

TABLE OF CONTENTS

Foreword.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

. .1 |

Description and Operation . . . . . . . . . . . . . . . . . . |

|

. .2 |

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

. .2 |

Hydraulic Schematic. . . . . . . . . . . . . . . . . . . . . . . |

|

. .3 |

External Features. . . . . . . . . . . . . . . . . . . . . . . . . |

. 4-5 |

|

Technical Specifications. . . . . . . . . . . . . . . . . . . . |

|

. .6 |

Product Identification. . . . . . . . . . . . . . . . . . . . . . |

|

. .6 |

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

. .7 |

Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . |

|

. .7 |

Tool Safety.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

. .7 |

|

Work Area Safety . . . . . . . . . . . . . . . . . . . . . . . . . |

|

. .7 |

Servicing Safety . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

. .7 |

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . |

|

. .8 |

Service and Maintenance. . . . . . . . . . . . . . . . . . . |

|

. .9 |

External Maintenance.. . . . . . . . . . . . . . . . . . . . . |

|

. .9 |

Service and Maintenance Procedures . . . . . . . . . |

|

. .9 |

Fluids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

. .9 |

Fluid Volume and Level.. . . . . . . . . . . . . . . . . . . . |

|

. .9 |

Fluid Change Procedure.. . . . . . . . . . . . . . . . . . . |

.10 |

|

Purging Procedures. . . . . . . . . . . . . . . . . . . . . . . |

.11 |

|

Return To Neutral Setting. . . . . . . . . . . . . . . . . . . |

.12 |

|

Brake Maintenance.. . . . . . . . . . . . . . . . . . . . . . . |

.13 |

|

Friction Pack Adjustment. . . . . . . . . . . . . . . . . . . |

.13 |

|

Tear Down and Reassembly.. . . . . . . . . . . . . . . . |

.14 |

|

How to Use This Manual.. . . . . . . . . . . . . . . . . . . |

.14 |

|

General Instructions . . . . . . . . . . . . . . . . . . . . . . . |

.14 |

|

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

.15 |

Torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.15 |

|

Transaxle Removal. . . . . . . . . . . . . . . . . . . . . . . . |

.16 |

|

Fan and Pulley. . . . . . . . . . . . . . . . . . . . . . . . . . . |

.17 |

|

Expansion Tank. . . . . . . . . . . . . . . . . . . . . . . . . . |

.18 |

|

Control Arm Assembly . . . . . . . . . . . . . . . . . . . . . |

. . . |

19 |

Return to Neutral Option.. . . . . . . . . . . . . . . . . . . |

.20 |

|

Return to Neutral/ROS Assembly Option. . . . . . . |

. . |

.21 |

Brake Arm & Brake Assembly. . . . . . . . . . . . . . . |

.22 |

|

Side Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.23 |

|

RH Axle Shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.24 |

Bull Gear Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.25 |

Reduction Gear Set. . . . . . . . . . . . . . . . . . . . . . . |

.26 |

Input Shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.27 |

Swashplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.28 |

Bypass Arm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.29 |

Center Section, Motor Shaft & Motor Block . . . . . |

.30 |

Filter Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . |

.31 |

Cylinder Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . |

.31 |

LH Axle Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.32 |

Expansion Tank Hose and Fitting . . . . . . . . . . . . |

.33 |

Assembly after Teardown. . . . . . . . . . . . . . . . . . . |

.34 |

Side Housing-Screw Sequence . . . . . . . . . . . . . . |

.35 |

T2® Transaxle Exploded View . . . . . . . . . . . . . . . |

.36 |

Glossary of Terms. . . . . . . . . . . . . . . . . . . . . . . . |

38-39 |

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.40 |

T2® |

i |

FOREWORD

Headquartered in Sullivan, Illinois,

Hydro-Gear® is a world leader in the design, manufacture, and service of quality hydrostatic transaxles for the lawn and garden industry. .

The mission of our company is to be recognized by our customers and the industry as a world-class supplier and the quality leader in everything we do..

This Service and Repair Manual is designed to provide information useful in servicing and troubleshooting the Hydro-Gear T2® Integrated

Hydrostatic Transaxle..

Also included is a glossary of terms that are frequently used throughout the industry and in

Hydro-Gear service publications.. Understanding terminology is very important!

It is necessary, and a good shop practice, that your service area be equipped with the proper tools and the mechanics be supplied the latest information available. . All repair procedures illustrated in this guide are suggested, but preferred methods of repair..

Internal repair procedures require that the transaxle unit be removed from the vehicle..

This is not a certification, test or study guide for a certification test. If a technician is interested in certification, they should contact an agent representing the EETC (Equipment and Engine Training Council) at (262) 367-6700 or their Hydro-Gear Central Service Distributor.. Many distributors will be hosting certification testing.

These study guides will cover most of the products and manufacturers in our industry..

For more information about Hydro-Gear or our products, please contact your Central Service

Distributor, or visit our Customer Service Department website at www..hydro-gear..com..

T2® |

1 |

DESCRIPTION AND OPERATION INTRODUCTION

The purpose of this manual is to provide information useful in servicing the Hydro-Gear® T2®

Integrated Hydrostatic Transaxle.. This manual includes the T2’s general description, hydraulic schematic, technical specifications, servicing and troubleshooting procedures..

The transaxle normally will not require servicing during the life of the vehicle in which it is installed.. Should other servicing be required, the exterior of the transaxle will need to be thoroughly cleaned before beginning most procedures.. Do not wash the transaxle while it is hot.. Do not use a pressure washer to clean the unit..

GENERAL DESCRIPTION

The T2 is a self contained unit designed for the transfer and control of power.. It provides an infinitely variable speed range between zero and maximum in both forward and reverse modes of operation..

This transaxle uses a variable displacement pump with a maximum displacement of 8cc per revolution, and motor with a fixed displacement of 10..2cc per revolution.. The variable displacement pump features a trunnion mounted swashplate with a direct-proportional displacement control.. Reversing the direction of the swashplate reverses the flow of oil from the pump and thus reverses the direction of the motor output rotation.. The pump and motor are of the axial piston design and utilize spherical nosed pistons which are held against a thrust race by internal compression springs..

The T2 has a self contained fluid supply and an internal filter. The fluid is forced through the filter by a positive “head” on the fluid in the housing/expansion tank with an assist by the negative pressure created in the pump pistons as they operate..

The check valves in the center section are used to control the makeup flow of the fluid to the low pressure side of the loop..

A block lifting bypass is utilized in the T2 to permit moving the vehicle for a short distance at a maximum of 2 m..p..h.. (3..2 Km/h) without starting the engine.. The T2 utilizes an in-line floating disc brake controlled by a “cam” style actuating arm..

2 |

T2® |

DESCRIPTION AND OPERATION (CONTINUED)

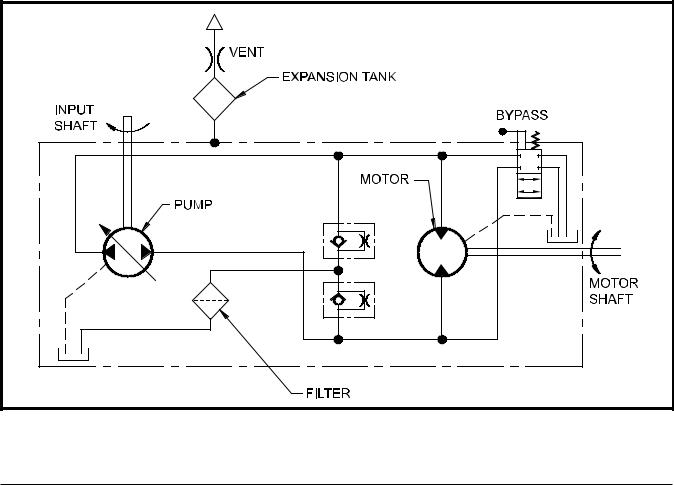

HYDRAULIC SCHEMATIC

Figure 1 is a schematic of the hydraulic oil circuit.. The oil supply for the hydraulic system of the T2® is also utilized for lubricating the components of the final drive assembly.

The input shaft and pump cylinder block are turned in one direction only by the engine/drive belt/pulley combination. Output of the oil flow is controlled by the direction and amount that the variable swashplate is angled.. As the pump pistons compress they force the oil to flow through one of two passageways (forward or reverse) in the center section to the motor cylinder block and motor shaft. Since the motor has a fixed displacement angle it is forced to turn with the flow of oil.As the angle of the pump swashplate is increased the amount of oil being pumped will increase and cause a higher speed output of the

motor.. Reversing the angle of the swashplate will reverse the direction of oil flow.

During the operation of the transaxle, fluid is “lost” from the hydraulic loop through leak paths designed into the product for lubrication purposes (around pistons, under the rotating cylinder blocks, etc.). This “lost” fluid returns to the transaxle housing, then is pulled back into one of the check valves depending upon the direction of vehicle operation.. All of this oil must pass through an internal filter.

The motor cylinder block mounts onto a splined motor shaft which drives the gear train..

The bypass feature in the T2 has a mechanical lever which lifts the motor block off the center section running surface. This allows oil flow from the cylinder blocks to be discharged..

Figure 1, T2 Hydraulic Schematic

T2® |

3 |

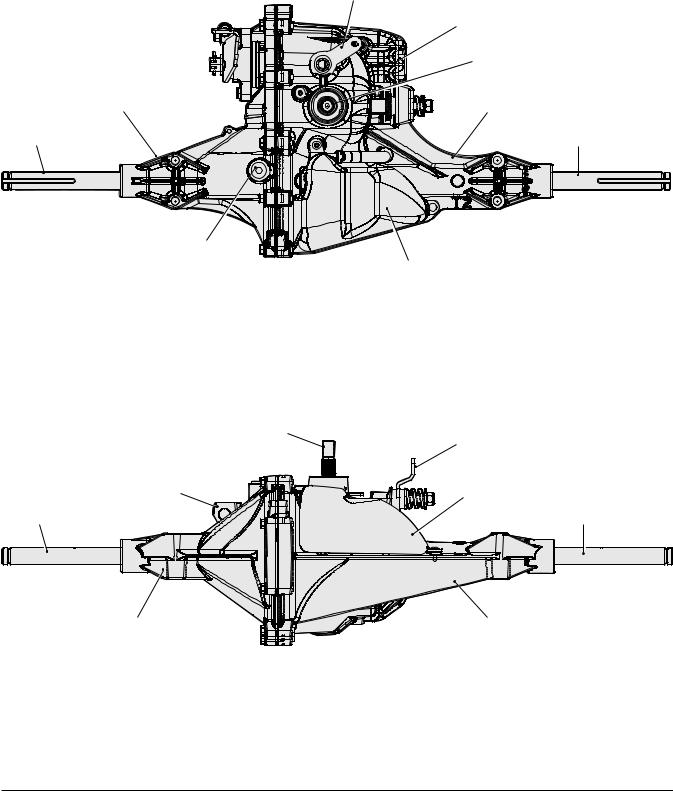

EXTERNAL FEATURES T2®

Side Housing

RH Axle

Bypass Arm

Control Arm |

Input Shaft |

Main Housing |

LH Axle

Oil Fill Plug

Expansion Tank

— Top View —

|

Input Shaft |

Control Arm |

|

|

|

Brake Arm |

|

Expansion Tank |

RH Axle |

|

LH Axle |

Side Housing |

Main Housing |

— Inboard View —

4 |

T2® |

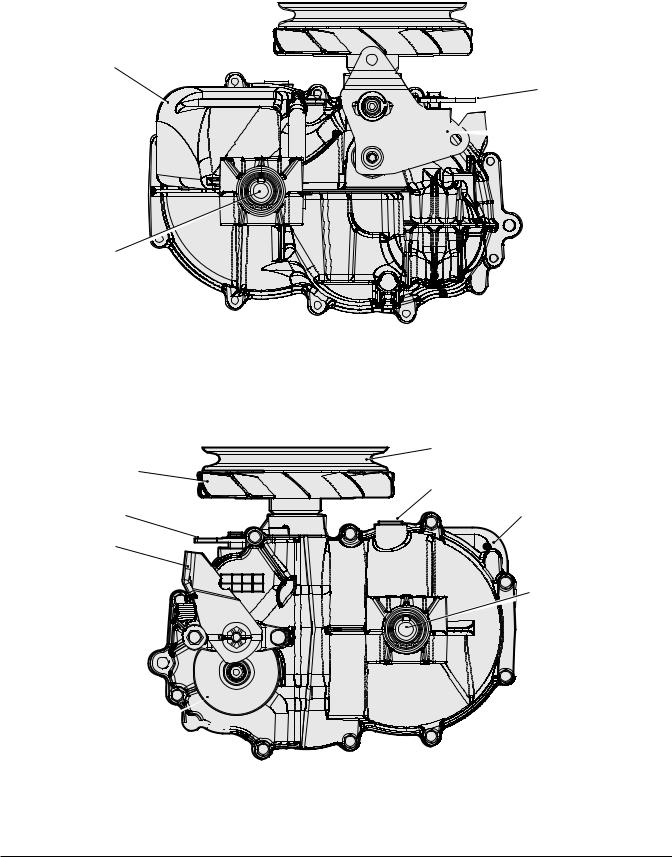

EXTERNAL FEATURES T2®

Expansion Tank

LH Axle

Fan

Bypass Arm

Brake Arm

Bypass Arm

Control Arm

Control Arm

— Outboard View—Left —

Pulley

Oil Fill Plug

Expansion Tank

RH Axle

Brake Rotor

— Outboard View—Right —

T2® |

5 |

TECHNICAL SPECIFICATIONS

T2® TECHNICAL SPECIFICATIONS

|

T2 |

|

T2-HP |

||

Overall Transaxle Reduction |

20..6 |

22..7 |

|

25..3 |

|

Input Speeds |

|

|

|

|

|

|

|

|

|

|

|

Maximum Hi-Idle (No Load) |

|

|

3000 rpm |

|

|

Minimum |

|

|

1800 rpm |

|

|

Output Torque |

|

|

|

|

|

|

|

|

|

|

|

Peak |

395 lb-ft (536 N-m) |

|

425 lb-ft (576 N-m) |

|

500 lb-ft (678 N-m) |

Continuous |

105 lb-ft (142 N-m) |

|

115 lb-ft (156 N-m) |

|

145 lb-ft (196 N-m) |

Weight on Tires (per unit) |

|

|

|

|

|

Maximum with 16” tires |

540 lb (245 kg) |

|

— |

|

— |

Maximum with 18” tires |

— |

|

500 lb (227 kg) |

|

— |

Maximum with 20” tires |

— |

|

— |

|

540 lb (245 kg) |

Axle Shaft Diameter |

|

|

..75 in (19..05 mm) |

|

|

|

|

|

|

||

Axle Shaft End Options |

|

|

Keyed or Two Flats |

|

|

Parking Brake Type |

|

|

Disc |

|

|

Weight of Unit |

|

|

28 lb (12..7) kg |

|

|

Maximum Tire Diameter |

16 in (406 mm) |

|

18 in (457 mm) |

|

20 in (508 mm) |

|

|

||||

|

|

|

|

|

|

PRODUCT IDENTIFICATION

The model and configuration of the T2 can be determined from the label shown below.

Model Number

H Y D R O - G E A R

T2-AABC-2X1A-1CXX

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 352 K1 476 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Assembled in USA |

||||||||||||||||||||||

Year |

Built |

|

Date (JulianDay of year) |

Serial Number (unique for that model - for that day) |

Type of Product and Build Information

Figure 2, Configuration Label

6 |

T2® |

SAFETY

This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others.. Read and follow all instructions in this manual before attempting maintenance on your transaxle.. When you see this symbol - HEED ITS WARNING.

This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others.. Read and follow all instructions in this manual before attempting maintenance on your transaxle.. When you see this symbol - HEED ITS WARNING.

Wear appropriate clothing.. Loose or hanging clothing or jewelry can be hazardous.. Use the appropriate safety equipment, such as eye and hearing protection, and safety-toe and slip-proof shoes..

Never use compressed air to clean debris from yourself or your clothing..

WARNING

POTENTIAL FOR SERIOUS INJURY

Inattention to proper safety, operation, or maintenance procedures could result in personal injury, or damage to the equipment. Before servicing or repairing the T2® transaxle, fully read and understand the safety precautions described in this section.

PERSONAL SAFETY

Certain safety precautions must be observed while servicing or repairing the T2.. This section addresses some of these precautions but must not be considered an all-inclusive source on safety information.. This section is to be used in conjunction with all other safety material which may apply, such as:

1.Other manuals pertaining to this machine,

2.Local and shop safety rules and codes,

3.Governmental safety laws and regulations..

Be sure that you know and understand the equipment and the hazards associated with it..

Do not place speed above safety..

Notify your supervisor whenever you feel there is any hazard involving the equipment or the performance of your job..

Never allow untrained or unauthorized personnel to service or repair the equipment..

TOOL SAFETY

Use the proper tools and equipment for the task..

Inspect each tool before use and replace any tool that may be damaged or defective..

WORK AREA SAFETY

Keep the work area neat and orderly.. Be sure it is well lit, that extra tools are put away, trash and refuse are in the proper containers, and dirt or debris have been removed from the working areas of the machine..

The floor should be clean and dry, and all extension cords or similar trip hazards should be removed..

SERVICING SAFETY

Certain procedures may require the vehicle to be disabled in order to prevent possible injury to the servicing technician and/or bystanders..

The loss of hydrostatic drive line power may result in the loss of hydrostatic braking capability..

Some cleaning solvents are flammable. Use only approved cleaning materials: Do not use explosive or flammable liquids to clean the equipment..

To avoid possible fire, do not use cleaning solvents in an area where a source of ignition may be present..

Discard used cleaning material in the appropriate containers..

T2® |

7 |

TROUBLESHOOTING

WARNING

Do not attempt any servicing or adjustments with the engine running. Use extreme caution while inspecting the drive belt assembly and all vehicle linkage!

Follow all safety procedures outlined in the vehicle owner’s manual.

In many cases, problems with the T2® are not related to a defective transaxle, but are caused by slipping drive belts, partially engaged bypass valves, and loose or damaged control linkages. . Be sure to perform all operational checks and adjustments outlined in Service and

Maintenance, before assuming the transaxle is malfunctioning.. The table below provides a troubleshooting checklist to help determine the cause of operational problems..

TROUBLESHOOTING CHECKLIST

Possible Cause |

Corrective Action |

Unit Operates In One Direction Only |

|

Control linkage bent or out of adjustment |

Repair or replace linkage, Page 9 |

Drive belt slipping or pulley damaged |

Repair or replace drive belt or pulley, Page 9 |

Vehicle Does Not Drive/Track Straight |

|

Vehicle tires improperly inflated |

Refer to vehicle manufacturer suggested pressure |

Control linkage bent or out of adjustment |

Repair or replace linkage, Pages 9 and 12 |

Bypass assembly sticking |

Repair or replace bypass, Page 29 |

Brake Partially Engage |

Disengage Brake, Replace Broken or Missing Brake Return Spring |

|

Unit Is Noisy |

Oil level low or contaminated oil |

Fill to proper level or change oil, Page 10 |

Excessive loading |

Reduce vehicle loading, Page 9 |

Loose parts |

Repair or replace loose parts |

Bypass assembly sticking |

Repair or replace linkage, Page 9 |

Air trapped in hydraulic system |

Purge hydraulic system, Page 11 |

Brake Partially Engage |

Disengage Brake, Replace Broken or Missing Brake Return Spring |

|

Unit Has No/Low Power |

Engine speed low |

Adjust to correct setting |

Control linkage bent or out of adjustment |

Repair or replace linkage, Page 9 |

Drive belt slipping or pulley damaged |

Repair or replace drive belt or pulley, Page 9 |

Oil level low or contaminated oil |

Fill to proper level or change oil, Page 10 |

Excessive loading |

Reduce vehicle loading, Page 9 |

Bypass assembly sticking |

Repair or replace linkage, Page 9 |

Air trapped in hydraulic system |

Purge hydraulic system, Page 11 |

Brake Partially Engage |

Disengage Brake, Replace Broken or Missing Brake Return Spring |

|

Unit Is Operating Hot |

Debris buildup around transaxle |

Clean off debris, Page 9 |

Cooling fan damaged |

Repair or replace cooling fan, Pages 17 |

Oil level low or contaminated oil |

Fill to proper level or change oil, Page 10 |

Excessive loading |

Reduce vehicle loading, Page 9 |

Air trapped in hydraulic system |

Purge hydraulic system, Page 11 |

Brake Partially Engage |

Disengage Brake, Replace Broken or Missing Brake Return Spring |

|

|

|

Transaxle Leaks Oil |

Damaged seals, housing, or gaskets |

Replace damaged components |

Air trapped in hydraulic system |

Purge hydraulic system, Page 11 |

|

|

8 |

T2® |

SERVICE AND MAINTENANCE

NOTE: Any servicing dealer attempting a warranty repair must have prior approval before conducting maintenance of a Hydro-Gear® product unless the servicing dealer is a current Authorized Hydro-Gear Service Center.

EXTERNAL MAINTENANCE

Regular external maintenance of the T2® should include the following:

1.Check the vehicle operator’s manual for the recommended load ratings. . Insure the current application does not exceed load rating..

2.Check oil level in accordance with Figure 3 Page 10..

3..Inspect the vehicle drive belt, idler pulley(s), and idler spring(s). . Insure that no belt slippage can occur.. Slippage can cause low input speed to the transmission..

4. . Inspect the transmission cooling fan for broken or distorted blades and remove any obstructions (grass clippings, leaves, dirt, etc..)..

5..Inspect the axle parking brake and vehicle linkage to insure proper actuation and adjustment of the parking brake..

6.Inspect the vehicle control linkage to the directional control arm on transaxle.. Also, insure the control arm is securely fastened to the trunnion arm of the transaxle..

7. . Inspect the bypass mechanism on the transaxle and vehicle linkage to insure it actuates and releases fully..

SERVICE AND MAINTENANCE PROCEDURES

All the service and maintenance procedures presented on the following pages can be performed while the T2 is mounted on the vehicle.. Any repair procedures as mentioned in the repair section of this manual must be performed after the unit has been removed from the vehicle..

FLUIDS

The fluids used in Hydro-Gear products have been carefully selected, and only equivalent, or better products should be substituted..

Typically, an engine oil with a minimum rating of 9.0 cSt (55 SUS) at 230°F (110° C) and anAPI classification of SLis recommended.A20W-50 engine oil has been selected for use by the factory and is recommended for normal operating temperatures..

FLUID VOLUME AND LEVEL

Fluid volume information is provided in the

Table below..

Certain situations may require additional fluid to be added or even replaced.. Refer to Page

10, Figure 3 and pages 4 and 5 for the proper fill port location.

Fill the T2 to the bottom of the oil fill port threads..

Recheck the fluid level once the unit has been operated for approximately 1 minute..

Purging may be required.. Refer to the purging procedures on page 11..

Fluid Description

Type: 20W50 motor oil

Fluid Volume (per transaxle)

10 Bolt Housing: 69.3 - 65.9 fl.oz. (2050 - 1950 ml)

14 Bolt Housing: 72.8 - 69.4 fl. oz. (2155 - 2055 ml)

T2® |

9 |

FLUID CHANGE PROCEDURE

This transaxle is factory filled, sealed and does not require oil maintenance.. However, in the event of oil contamination or degradation, oil addition or change may alleviate certain performance problems..

1.. Remove the transaxle from the vehicle..

2.Clean the expansion tank and oil fill port areas of any debris..

3.Remove the oil fill port fitting.

4.Position the transaxle so the oil will drain completely out of the housing..

5..After all the oil is drained from the transaxle, remove the expansion tank by removing the self tapping bolt (10-32 x ½) and ratchet fastener that holds the tank to the housing..

6.Remove the tank and drain the oil from the tank.. DO NOT remove the vent cap from the tank. . DO NOT remove the tank hose or o-ring unless a replacement is needed..

7.Install the tank by first inserting the hose into the opening in the expansion tank. .

Push the tank opening over the o-ring to

ensure a proper seal..

8.Install the tank and self tapping bolt making sure not to cross thread the bolt.. Torque the bolt to the lower value of the torque specification listed in the Table on page 15.

9.Fill the transaxle at the oil fill port according to Figure 3..

10.Install the oil fill port fitting.

EXPANSION TANK FUNCTION

The expansion tank allows the T2™ to operate free of air entrainment and provides maximum lubrication to the mechanical and hydraulic components in the transaxle..

As the T2 transaxle is operated, oil in the transaxle housing heats up which causes the oil to expand. The oil flows through an internal hose to the bottom of the vented expansion tank.. As the oil cools, the oil in the transaxle housing contracts, causing the oil level to go down in the housing. . This creates a negative pressure in the housing causing the oil to be drawn back into the case. . This keeps the transaxle housing full of oil at specified operating temperatures..

1.25” |

|

Top of Fill Port |

Oil Level |

Expansion Tank |

|

.50” |

|

|

Oil Volume:

2050 ml (69

1950 ml (65

Figure 3, Expansion Tank

10 |

T2® |

PURGING PROCEDURES

Due to the effects air has on efficiency in hydrostatic drive applications, it is critical that it be purged from the system..

These purge procedures should be implemented any time a hydrostatic system has been opened to facilitate maintenance or any additional oil has been added to the system..

Air creates inefficiency because its compression and expansion rate is higher than that of the oil approved for use in hydrostatic drive systems..

The resulting symptoms in hydrostatic systems may be:

1.Noisy operation..

2.Lack of power or drive after short term operation..

3.High operation temperature and excessive expansion of oil..

Before starting, make sure the transaxle/transmission is at the proper oil level. If it is not, fill to the specifications outlined on page 9.

The following procedures should be performed with the vehicle drive wheels off the ground, then repeated under normal operating conditions..

1.With the bypass valve open and the engine running, slowly move the directional control in both forward and reverse directions (5 to 6 times), as air is purged from the unit, the oil level will drop..

2.With the bypass valve closed and the engine running, slowly move the directional control in both forward and reverse directions (5 to 6 times).. Check the oil level, and add oil as required after stopping engine..

3.It may be necessary to repeat Steps 1 and 2 until all the air is completely purged from the system.. When the transaxle moves forward and reverse at normal speed purging is complete..

T2® |

11 |

Loading...

Loading...