Husqvarna K 970 User Manual

Operator′s manual

K 970

K 970 Rescue

Please read the operator’s manual carefully and make sure you |

English |

|

understand the instructions before using the machine. |

||

|

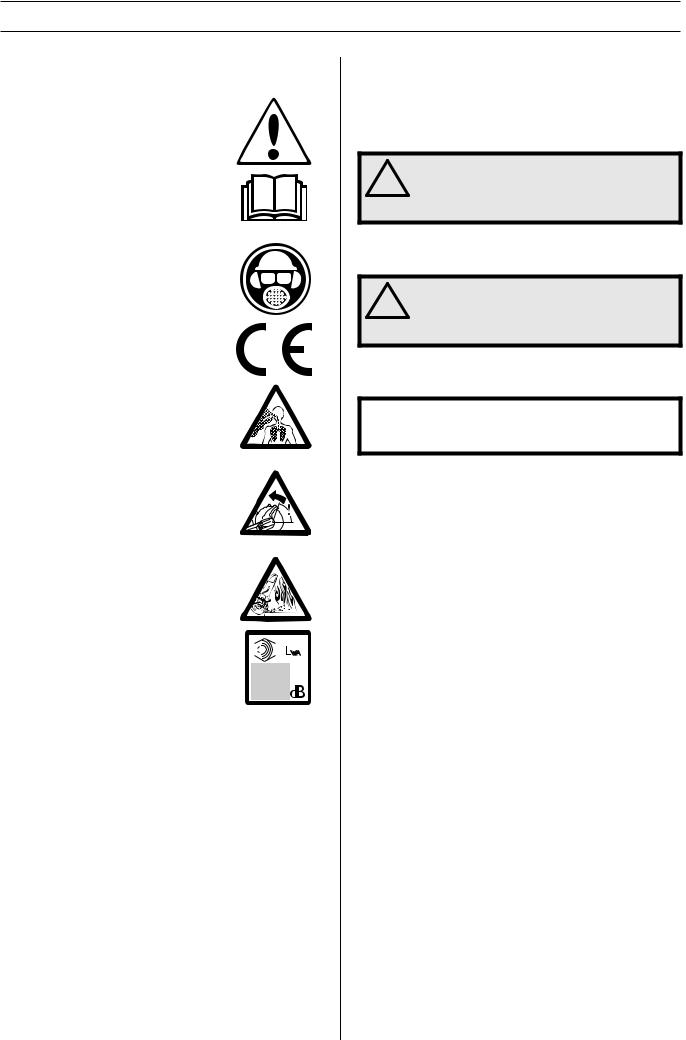

KEY TO SYMBOLS

Symbols on the machine:

WARNING! The machine can be a dangerous tool if used incorrectly or carelessly, which can cause serious or fatal injury to the operator or others.

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Wear personal protective equipment. See instructions under the heading ”Personal protective equipment”.

This product is in accordance with applicable EC directives.

WARNING! Dust forms when cutting, this can cause injuries if inhaled. Use an approved breathing mask. Avoid inhaling petrol fumes and exhaust fumes. Always provide for good ventilation.

WARNING! Kickbacks can be sudden, rapid and violent and can cause life threatening injuries. Read and understand the instructions in the manual before using the machine.

WARNING! Sparks from the cutting blade can cause fire in combustible materials such as: petrol (gas), wood, dry grass etc.

Noise emission to the environment according to the European Community’s Directive. The machine’s emission is specified in chapter Technical data and on label.

Other symbols/decals on the machine

refer to special certification requirements for certain markets.

Explanation of warning levels

The warnings are graded in three levels.

WARNING!

! |

WARNING! Used if there is a risk of serious |

injury or death for the operator or damage to |

|

the surroundings if the instructions in the |

|

|

manual are not followed. |

CAUTION! |

|

! |

CAUTION! Used if there is a risk of injury to |

the operator or damage to the surroundings |

|

if the instructions in the manual are not |

|

|

followed. |

NOTICE!

NOTICE! Used if there is a risk of damage to materials or the machine if the instructions in the manual are not followed.

2 – English

CONTENTS

Contents |

|

KEY TO SYMBOLS |

|

Symbols on the machine: ............................................. |

2 |

Explanation of warning levels ...................................... |

2 |

CONTENTS |

|

Contents ...................................................................... |

3 |

PRESENTATION |

|

Dear Customer, ............................................................ |

4 |

Features ....................................................................... |

4 |

PRESENTATION |

|

What is what on the power cutter - K 970? .................. |

5 |

PRESENTATION |

|

What is what on the power cutter - K 970 Rescue? ..... |

6 |

MACHINE´S SAFETY EQUIPMENT |

|

General ........................................................................ |

7 |

CUTTING BLADES |

|

General ........................................................................ |

9 |

Abrasive blades ........................................................... |

9 |

Diamond blades ........................................................... |

10 |

Toothed blades, carbide tipped blades and emergency |

|

situations ...................................................................... |

10 |

Transport and storage .................................................. |

10 |

ASSEMBLING AND ADJUSTMENTS |

|

General ........................................................................ |

11 |

Checking the drive shaft and flange washers .............. |

11 |

Fitting the cutting blade ................................................ |

11 |

Guard for the blade ...................................................... |

11 |

FUEL HANDLING |

|

General ........................................................................ |

12 |

Fuel .............................................................................. |

12 |

Fuelling ........................................................................ |

12 |

Transport and storage .................................................. |

12 |

OPERATING |

|

Protective equipment ................................................... |

13 |

General safety precautions .......................................... |

13 |

Transport and storage .................................................. |

16 |

STARTING AND STOPPING |

|

Before starting ............................................................. |

17 |

Starting ........................................................................ |

17 |

Stopping ....................................................................... |

18 |

MAINTENANCE |

|

General ........................................................................ |

19 |

Maintenance schedule ................................................. |

19 |

Cleaning ....................................................................... |

20 |

Functional inspection ................................................... |

20 |

TECHNICAL DATA |

|

Technical data .............................................................. |

24 |

Cutting equipment ........................................................ |

24 |

EC-declaration of conformity ........................................ |

25 |

English – 3

PRESENTATION

Dear Customer,

Thank you for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. A purchase of one of our products gives you access to professional help with repairs and services. If the retailer who sells your machine is not one of our authorised dealers, ask him for the address of your nearest service workshop.

This operator’s manual is a valuable document. Make sure it is always at hand at the work place. By following its´ content (using, service, maintenance etc) the life span and the second-hand value of the machine can be extended. If you will sell this machine, make sure that the buyer will get the operator´s manual.

More than 300 years of innovation

Husqvarna AB is a Swedish company based on a tradition that dates back to 1689, when the Swedish King Charles XI ordered the construction of a factory for production of muskets. At that time, the foundation was already laid for the engineering skills behind the development of some of the world's leading products in areas such as hunting weapons, bicycles, motorcycles, domestic appliances, sewing machines and outdoor products.

Husqvarna is the global leader in outdoor power products for forestry, park maintenance and lawn and garden care, as well as cutting equipment and diamond tools for the construction and stone industries.

User responsibility

It is the owner’s/employer’s responsibility that the operator has sufficient knowledge about how to use the machine safely. Supervisors and operators must have read and understood the Operator’s Manual. They must be aware of:

•The machine’s safety instructions.

•The machine’s range of applications and limitations.

•How the machine is to be used and maintained.

National legislation could regulate the use of this machine. Find out what legislation is applicable in the place where you work before you start using the machine.

The manufacturer’s reservation

All information and all data in the Operator’s Manual were applicable at the time the Operator’s Manual was sent to print.

Husqvarna AB has a policy of continuous product development and therefore reserves the right to modify the design and appearance of products without prior notice.

Features

Values such as high performance, reliability, innovative technology, advanced technical solutions and environmental considerations distinguish Husqvarna's products.

Some of the unique features of your product are described below.

Active Air Filtration™

Centrifugal air cleaning in three steps for longer service life and longer service intervals.

SmartCarb™

Built-in automatic filter compensation maintains high power and reduces fuel consumption.

Dura Starter™

Dust sealed starter unit, where the return spring and the pulley bearing are sealed which makes the starter virtually maintenance free and even more reliable.

X-Torq®

The X-Torq® engine provides a more accessible torque for a wider range of speeds which results in maximum cutting capacity. X-Torq® reduces the fuel consumption with up to 20% and the emissions with up to 60%.

EasyStart

The engine and starter are designed to ensure quick and easy starting of the machine. Reduces the pull resistance in the starter cord with up to 40%. (Reduces the compression during starting.)

Air purge

When you push the air purge diaphragm, fuel is pumped through to the carburettor. Fewer pulls are required for starting, meaning the machine becomes easier to start.

DEX

Low flushing wet cutting kit for effective dust handling.

Efficient vibration damping system

Efficient vibration dampers spare arms and hands.

Specially designed starter handle (K 970 Rescue)

Specially designed starter handle, with room for heavy gloves.

Adjustable carry strap (K 970 Rescue)

Adjustable carry strap for full freedom of movement.

Chromium-plated blade guard (K 970 Rescue)

Chromium-plated blade guard, visible in smoke and water spray, enhances control of the cutter.

4 – English

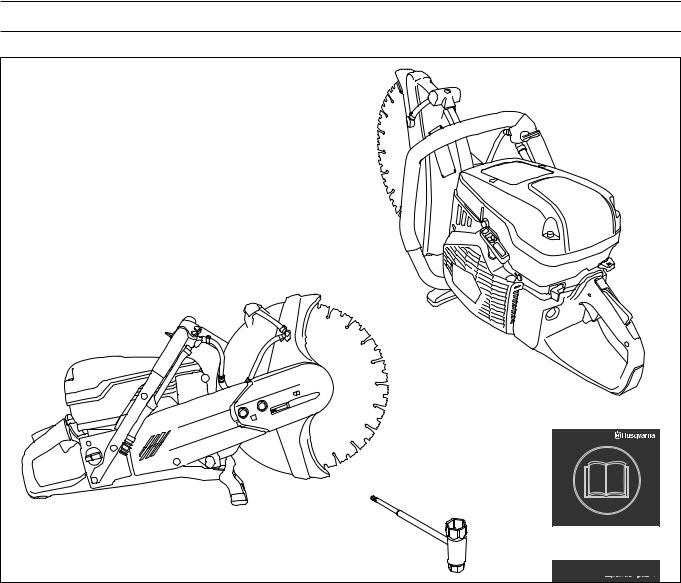

PRESENTATION |

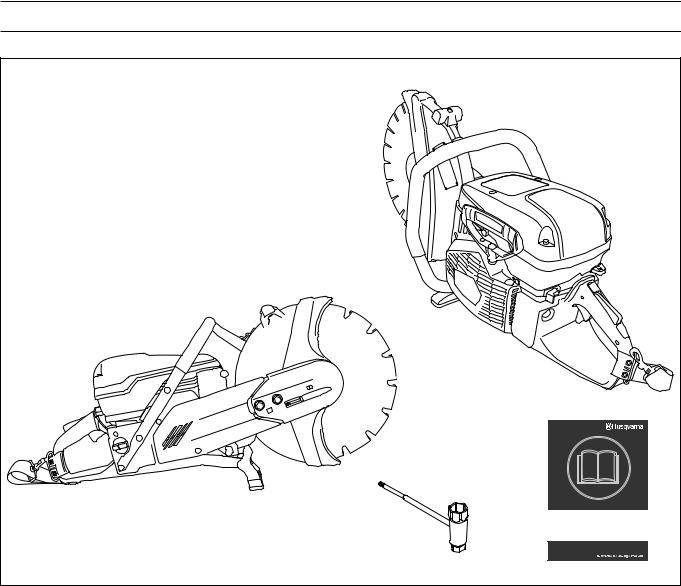

What is what on the power cutter - K 970?

1 |

Front handle |

14 |

Muffler |

2 |

Water tap |

15 |

Adjustment handle for guard |

3 |

Warning decal |

16 |

Guard for the blade |

4 |

Air filter cover |

17 |

Fuel tank |

5 |

Cylinder cover |

18 |

Water connection with filter |

6 |

Choke |

19 |

Belt guard |

7 |

Throttle lockout |

20 |

Rating plate |

8 |

Throttle control |

21 |

Cutting arm |

9 |

Air purge |

22 |

Belt tensioner |

10 |

Stop switch |

23 |

Cutting head |

11 |

Starter handle |

24 |

Cutting blade |

12 |

Starter |

25 |

Combination spanner |

13 |

Decompression valve |

26 |

Operator′s manual |

English – 5

PRESENTATION |

What is what on the power cutter - K 970 Rescue?

1 |

Front handle |

14 |

Muffler |

2 |

Water tap |

15 |

Adjustment handle for guard |

3 |

Warning decal |

16 |

Guard for the blade |

4 |

Air filter cover |

17 |

Fuel tank |

5 |

Cylinder cover |

18 |

Harness |

6 |

Choke |

19 |

Belt guard |

7 |

Throttle lockout |

20 |

Rating plate |

8 |

Throttle control |

21 |

Cutting arm |

9 |

Air purge |

22 |

Belt tensioner |

10 |

Stop switch |

23 |

Cutting head |

11 |

Starter handle |

24 |

Cutting blade |

12 |

Decompression valve |

25 |

Combination spanner |

13 |

Starter |

26 |

Operator′s manual |

6 – English

MACHINE´S SAFETY EQUIPMENT

General |

|

! |

WARNING! Never use a machine that has |

faulty safety equipment! If your machine |

|

fails any of these checks contact your |

|

|

service agent to get it repaired. |

The engine should be switched off, and the stop switch in STOP position.

This section describes the machine´s safety equipment, its purpose, and how checks and maintenance should be carried out to ensure that it operates correctly.

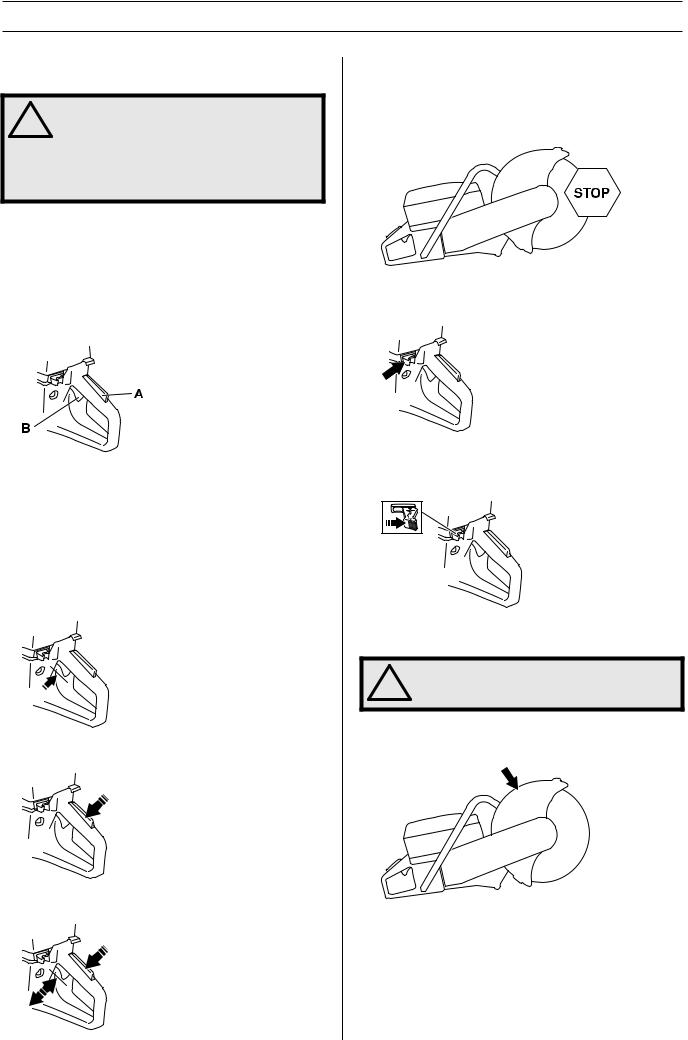

Throttle lockout

The throttle trigger lock is designed to prevent accidental operation of the throttle. When the lock (A) is pressed in this releases the throttle (B).

The trigger lock remains pressed in as long as the throttle is pressed. When the grip on the handle is released the throttle trigger and the throttle trigger lock both return to their original positions. This is controlled by two independent return spring systems. This means that the throttle trigger is automatically locked in the idle position.

Checking the throttle lockout

•Make sure the throttle control is locked at the idle setting when the throttle lockout is released.

•Press the throttle lockout and make sure it returns to its original position when you release it.

•Check that the throttle control and throttle lockout move freely and that the return springs work properly.

•Start the power cutter and apply full throttle. Release the throttle control and check that the cutting blade stops and remains stationary. If the cutting blade rotates when the throttle is in the idle position you should check the carburettor’s idle adjustment. See instructions in the section "Maintenance".

Stop switch

Use the stop switch to switch off the engine.

Checking the stop switch

•Start the engine and make sure the engine stops when you move the stop switch to the stop setting.

Guard for the blade |

||

! |

WARNING! Always check that the guard is |

|

correctly fitted before starting the machine. |

||

|

||

This guard is fitted above the cutting blade and is designed to prevent parts of the blade or cutting fragments from being thrown towards the user.

Checking the blade guard

•Check that the guard over the cutting blade is not cracked or damaged in any other way. Replace when damaged.

•Check that the cutting blade is fitted correctly and does not show signs of damage. A damaged cutting blade can cause personal injury.

English – 7

MACHINE´S SAFETY EQUIPMENT

Vibration damping system |

|

! |

WARNING! Overexposure to vibration can |

lead to circulatory damage or nerve damage |

|

in people who have impaired circulation. |

|

|

Contact your doctor if you experience |

|

symptoms of overexposure to vibration. |

|

Such symptoms include numbness, loss of |

|

feeling, tingling, pricking, pain, loss of |

|

strength, changes in skin colour or |

|

condition.These symptoms normally appear |

|

in the fingers, hands or wrists. These |

|

symptoms may be increased in cold |

|

temperatures. |

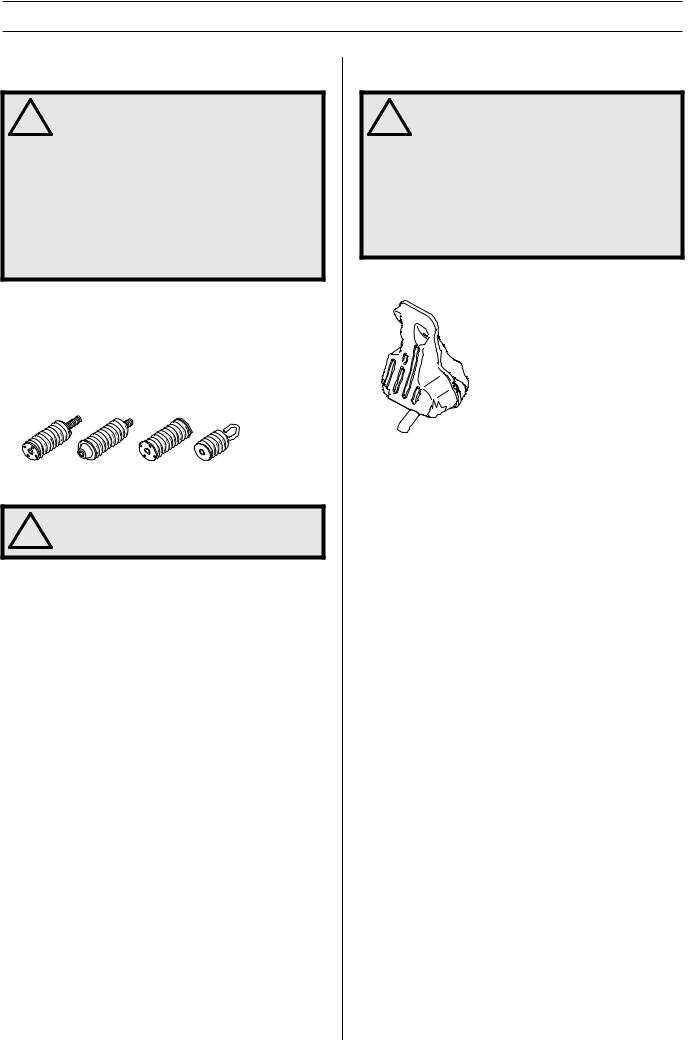

•Your machine is equipped with a vibration damping system that is designed to minimize vibration and make operation easier.

•The machine′s vibration damping system reduces the transfer of vibration between the engine unit/cutting equipment and the machine′s handle unit. The engine body, including the cutting equipment, is insulated from the handles by vibration damping units.

Checking the vibration damping system

WARNING! The engine should be switched

!off, and the stop switch in STOP position.

•Check the vibration damping units regularly for cracks or deformation. Replace them if damaged.

•Check that the vibration damping element is securely attached between the engine unit and handle unit.

Muffler |

|

! |

WARNING! Never use a machine without a |

muffler, or with a faulty muffler. A damaged |

|

muffler may substantially increase the noise |

|

|

level and the fire hazard. Keep fire fighting |

|

equipment handy. |

The muffler gets very hot during and after use. This also applies during idling. Be aware of the fire hazard, especially when working near flammable substances and/or vapours.

The muffler is designed to keep noise levels to a minimum and to direct exhaust fumes away from the user.

Inspecting the muffler

Check regularly that the muffler is complete and secured correctly.

8 – English

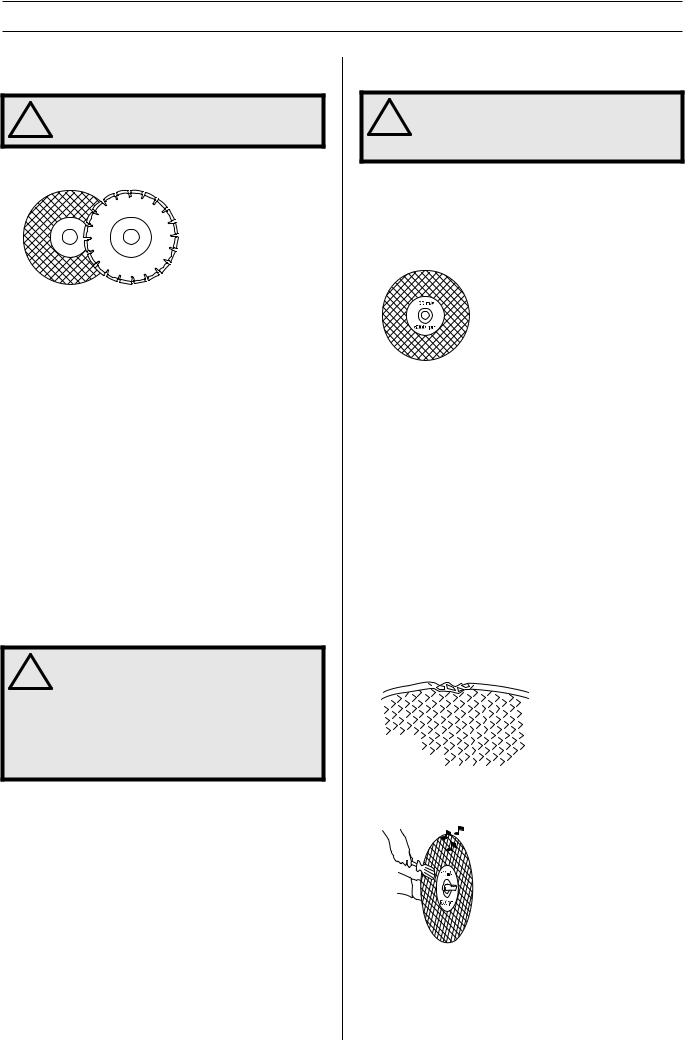

CUTTING BLADES

General |

||

! |

WARNING! A cutting blade may burst and |

|

cause injury to the operator. |

||

|

||

•Cutting blades are available in two basic designs; abrasive baldes and diamond blades.

•High-quality blades are often most economical. Lower quality blades often have inferior cutting capacity and a shorter service life, which results in a higher cost in relation to the quantity of material that is cut.

•Make sure that the right bushing is used for the cutting blade to be fitted on the machine. See the instructions under the heading Assembling the cutting blade.

Suitable cutting blades

Cutting blades |

K 970 |

K 970 Rescue |

|

|

|

Abrasive blades |

Yes* |

Yes* |

|

|

|

Diamond blades |

Yes |

Yes |

|

|

|

Toothed blads |

No |

Yes** |

|

|

|

*Without water

**See instructions under the heading "Toothed blades, carbide tipped blades and emergency situations".

Cutting blades for different materials

WARNING! Never use a cutting blade for any

!other materials than that it was intended for.

Cutting plastics with a diamond blade can cause kickback when the material melts due to the heat produced when cutting and sticks to the blade. Never cut plastic materials with a diamond blade!

Follow the instructions supplied with the cutting blade concerning the suitability of the blade for various applications, or consult your dealer in case of doubts.

|

Concrete |

Metal |

Plastic |

Cast iron |

|

|

|

|

|

Abrasive |

X |

X |

X |

X |

blades |

|

|

|

|

Diamond |

X |

X* |

|

X* |

blades |

|

|

|

|

* CAUTION! Only specialty blades.

Hand-held, high-speed machines

! |

WARNING! Never use a cutting blade at a |

lower speed rating than that of the power |

|

cutter. Only use cutting blades intended for |

|

|

high speed handheld power cutters. |

•Our cutting blades are manufactured for high-speed, portable power cutters.

•Check that the blade is approved for the same or higher speed according to the aproval plate of the engine. Never use a cutting blade with a lower speed rating than that of the power cutter.

Blade vibration

•The blade can become out-of-round and vibrate if an excessive feed pressure is used.

•A lower feed pressure can stop the vibration. Otherwise replace the blade.

Abrasive blades

•The cutting material on abrasive blades consists of grit bonded using an organic binder. ”Reinforced blades” are made up of a fabric or fibre base that prevents total breakage at maximum working speed if the blade should be cracked or damaged.

•A cutting blade’s performance is determined by the type and size of abrasive corn, and the type and hardness of the bonding agent.

•Ensure the blade it not cracked or damaged in any other way.

•Test the abrasive blade by hanging it on your finger and tapping it lightly with a screwdriver or the like. If the blade does not produce a resonant, ringing sound it is damaged.

English – 9

Loading...

Loading...