Husqvarna K 535i Manual

Husqvarna K 535i

EN |

Operator's manual |

2-24 |

DE |

Bedienungsanweisung |

25-50 |

FR |

Manuel d'utilisation |

51-76 |

NL |

Gebruiksaanwijzing |

77-101 |

Contents

Introduction..................................................................... |

2 |

Safety.............................................................................. |

4 |

Assembly...................................................................... |

10 |

Operation...................................................................... |

14 |

Maintenance................................................................. |

19 |

Troubleshooting............................................................ |

21 |

Transportation, storage and disposal........................... |

22 |

Technical data.............................................................. |

22 |

Accessories.................................................................. |

23 |

EC Declaration of Conformity....................................... |

24 |

Introduction

Product description

Husqvarna K 535i is a portable handheld cut-off machine. The product is energized by a battery.

Work is constantly in progress to increase your safety and efficiency during operation. Speak to your servicing dealer for more information.

Intended use

This product is used to cut roof tiles, garden plates and light concrete.

Note: National regulations can limit the operation of the product.

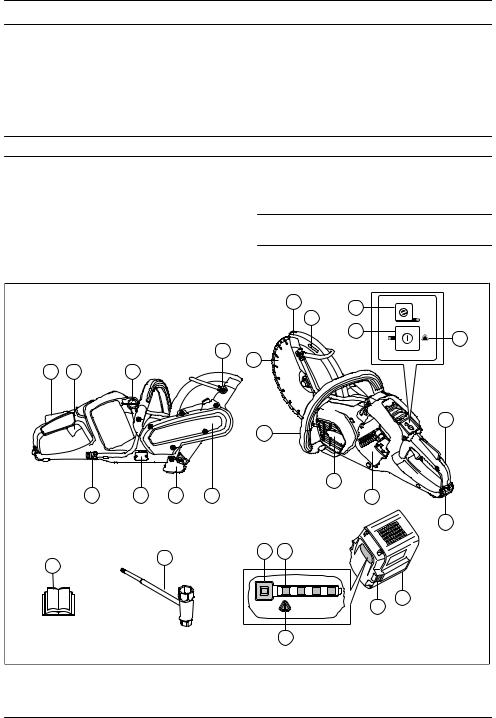

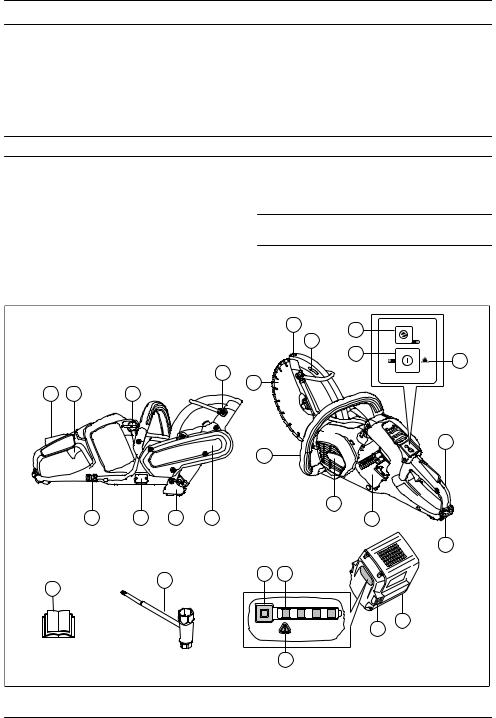

Product overview

|

|

|

|

|

6 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

9 |

|

|

|

|

|

|

10 |

|

|

|

|

4 |

|

|

|

|

|

|

5 |

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

15 |

|

|

|

|

|

|

|

|

14 |

|

19 |

18 |

17 |

16 |

|

13 |

|

|

|

|

|

|

12 |

|

|

|

21 |

22 |

23 |

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

26 |

|

|

|

|

|

|

25 |

|

|

|

|

|

24 |

|

1. |

Power trigger lockout |

3. |

Water valve |

2. |

Power trigger |

4. |

Water nozzle |

2 |

745 - 008 - 12.11.2018 |

5.Cutting blade

6.Blade guard

7.Blade rotation

8.SavE button

9.Start and stop button

10.Warning indicator

11.Rear handle with right hand guard

12.Rear ground support with a rope eyelet

13.Battery slot

14.Fan housing

15.Front handle

16.Belt guard

17.Front ground support

18.Type plate

19.Water connection with filter

20.Operator's manual

21.Combination wrench

22.Button, battery status

23.Battery status

24.Warning indicator

25.Battery release button

26.Battery (not included)

Symbols on the product

Make sure the blade is not cracked or damaged.

Do not use circular saw blades.

Environmental mark. The product or package of the product is not domestic waste. Recycle it at a recycling location for electrical and electronic equipment.

|

Direction of blade rotation |

yyyywwxxxx |

The rating plate shows serial |

|

number. yyyy is the production |

|

year, ww is the production |

|

week. |

ØMaximum outside blade diameter

d.c. |

Direct Current |

nRated speed

Risk of serious injury or death to the operator or others. Be careful and use the product correctly.

Read the manual carefully and make sure you understand the instructions before using the product.

Wear approved protective helmet, breathing

Wear approved protective helmet, breathing

protection, hearing and eye protection.

protection, hearing and eye protection.

This product obey applicable EC Directives.

Fume from cutting can cause injuries if breathed in. Use an approved breathing protection. Prevent breathe exhaust fumes. Make sure that the airflow is sufficient.

Sparks from the cutting blade can cause fire  in flammable materials such as: gasoline,

in flammable materials such as: gasoline,

wood, clothes and dry grass.

wood, clothes and dry grass.

Kickbacks can be sudden, fast and can cause injuries. Read and understand the instructions in the manual before using the product.

Note: Other symbols/decals on the product refer to certification requirements for some markets.

Symbols on the battery and/or on the battery charger

Recycle this product at a recycling station for electrical and electronic equipment. (Applies to Europe only)

Fail-safe transformer.

Use and keep the battery charger indoors only.

Double insulation.

745 - 008 - 12.11.2018 |

3 |

Product liability

As referred to in the product liability laws, we are not liable for damages that our product causes if:

•the product is incorrectly repaired.

•the product is repaired with parts that are not from the manufacturer or not approved by the manufacturer.

•the product has an accessory that is not from the manufacturer or not approved by the manufacturer.

•the product is not repaired at an approved service center or by an approved authority.

Safety

Safety definitions

Warnings, cautions and notes are used to point out specially important parts of the manual.

WARNING: Used if there is a risk of injury or death for the operator or bystanders if the instructions in the manual are not obeyed.

CAUTION: Used if there is a risk of damage to the product, other materials or the adjacent area if the instructions in the manual are not obeyed.

Note: Used to give more information that is necessary in a given situation.

General power tool safety warnings

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Note: Save all warnings and instructions for future reference. The term "power tool" in the warnings refers to your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

Work area safety

•Keep work area clean and well lit. Cluttered or dark areas invite accidents.

•Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

•Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

•Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

•Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

•Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

•Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

•When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

•If operating a power tool in a damp location is unavoidable, use a residual circuit interrupter (RCD) protected supply. Use of a RCD reduces the risk of electric shock

CAUTION: Do not pressure wash the machine, as water can enter the electrical system or the engine and cause damage to the machine or short circuit.

Personal safety

•Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

•Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

•Prevent unintentional starting. Ensure the switch is in the OFF-position before connecting to a power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

4 |

745 - 008 - 12.11.2018 |

•Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

•Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

•Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

•If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

•The vibration emission during actual use of the power tool can differ from the declared total value depending on the ways in which the tool is used. Operators should identify safety measures to protect themselves that are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger).

•Remain at a distance from the blade when the engine is running.

Power tool use and care

•Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

•Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

•Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

•Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

•Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool´s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

•Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

•Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

•Under no circumstances should you modify the original design of the machine without approval from the manufacturer. Always use original spare parts. Unauthorized modifications and/or accessories may lead to serious injury or death to the user or others.

•Make sure that no pipes or electrical cables are routed in the working area or in the material to be cut.

•Always check and mark out where gas pipes are routed. Cutting close to gas pipes always entails danger. Make sure that sparks are not caused when cutting in view of the risk of explosion. Remain concentrated and focused on the task. Carelessness can result in serious personal injury or death.

Battery tool use and care

•Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

•Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

•When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

•Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritations or burns.

Service

•Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Cut-off machine safety warning

•The guard provided with the tool must be securely attached to the power tool and positioned for maximum safety so the least amount of wheel is exposed towards the operator. Position yourself and bystanders away from the plane of the rotating wheel. The guard helps to protect operator from broken wheel fragments and accidental contact with the wheel.

•Use only bonded reinforced or diamond cut-off wheels for your power tool. Just because an accessory can be attached to your power tool, it does not assure safe operation.

745 - 008 - 12.11.2018 |

5 |

•The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories running faster than their rated speed can break and fly apart.

•Wheels must be used only for recommended applications. For example, do not grind with the side of the cut-off wheel. Abrasive cut-off wheels are intended for peripheral grinding, side forces applied to these wheels may cause them to shatter.

•Always use undamaged wheel flanges that are of correct diameter for your selected wheel. Proper wheel flanges support the wheel thus reducing the possibility of wheel breakage.

•Do not use worn down reinforced wheels from larger power tools. Wheels intended for a larger power tool are not suitable for the higher speed of a smaller tool and may burst.

•The outside diameter and the thickness of your accessory must be within the capacity rating of your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

•The arbour size of wheels and flanges must properly fit the spindle of the power tool. Wheels and flanges with arbour holes that do not match the mounting hardware of the power tool will run out of balance, vibrate ecxessively and may cause loss of control.

•Do not use damaged wheels. Before each use, inspect wheels for chips and cracks. If power tool or wheel is dropped, inspect for damage or install an undamaged wheel. After inspecting and installing the wheel, position yourself and bystanders away from the plane of the rotating wheel and run the power tool at maximum no load speed for one minute. Damaged wheels will normally break apart during this test time.

•Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and shop apron capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of stopping flying debris generated by various operations. The dust mask or respirator must be capable of filtrating particles generated by your operation. Prolonged exposure to high intensity noise may cause hearing loss.

•Keep bystanders a safe distance away from work area. Anyone entering the work area must wear personal protective equipment. Fragments of workpiece or a broken wheel may fly away and cause injury beyond immediate area of operation.

•Hold the power tool by insulated gripping surfaces only, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could give the operator an electric shock.

•Never lay the power tool down until the accessory has come to a complete stop. The

spinning wheel may grab the surface and pull the power tool out of your control.

•Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your clothing, pulling the accessory into your body.

•Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

•Do not operate the power tool near flammable materials. Sparks could ignite these materials.

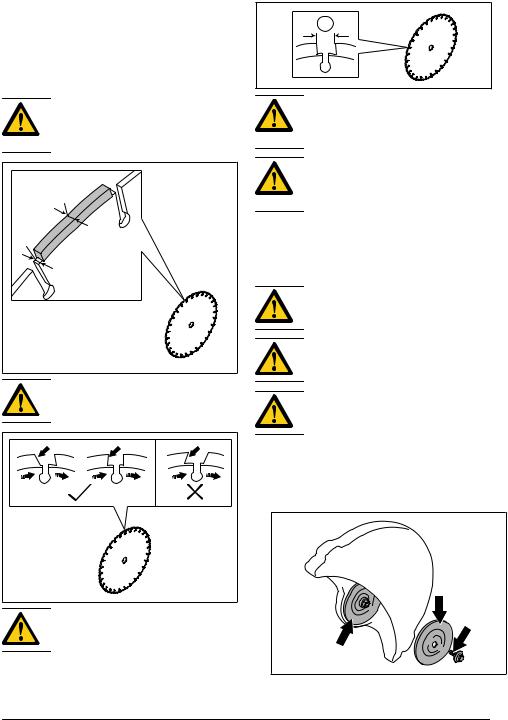

Kickback and related warnings

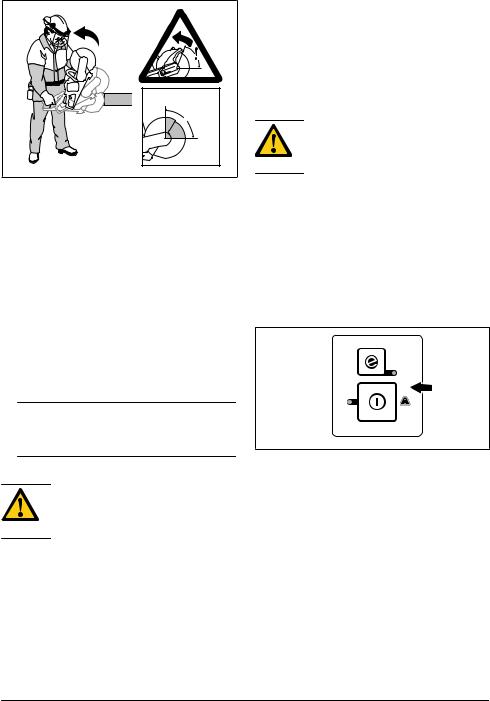

•Kickback is a sudden reaction to a pinched or snagged rotating wheel. Pinching or snagging causes rapid stalling of the rotating wheel which in turn causes the uncontrolled power tool to be forced in the direction opposite of the wheel’s rotation at the point of the binding.

•For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that is entering into the pinch point can dig into the surface of the material causing the wheel to climb out or kick out. The wheel may either jump toward or away from the operator, depending on direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions.

•Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

•Maintain a firm grip on the power tool and position your body and arm to allow you to resist kickback forces. Always use auxiliary handle, if provided, for maximum control over kickback or torque reaction during start-up. The operator can control torque reactions or kickback forces, if proper precautions are taken.

•Never place your hand near the rotating accessory. Accessory may kickback over your hand.

•Do not position your body in line with the rotating wheel. Kickback will propel the tool in direction opposite to the wheel’s movement at the point of snagging.

•Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the accessory. Corners, sharp edges or bouncing have a tendency to snag the rotating accessory and cause loss of control or kickback.

•Do not attach a saw chain, woodcarving blade, segmented diamond wheel with a peripheral gap greater than 10 mm or toothed saw blade. Such blades create frequent kickback and loss of control.

•Do not ”jam” the wheel or apply excessive pressure. Do not attempt to make an excessive depth of cut. Overstressing the wheel increases the

6 |

745 - 008 - 12.11.2018 |

loading and susceptibility to twisting or binding of the wheel in the cut and the possibility of kickback or wheel breakage.

•When wheel is binding or when interrupting a cut for any reason, switch off the power tool and hold the power tool motionless until the wheel comes to a complete stop. Never attempt to remove the wheel from the cut while the wheel is in motion otherwise kickback may occur. Investigate and take corrective action to eliminate the cause of wheel binding.

•Do not restart the cutting operation in the workpiece. Let the wheel reach full speed and carefully re-enter the cut. The wheel may bind, walk up or kickback if the power tool is restarted in the workpiece.

•Support panels or any oversized workpiece to minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their own weight. Supports must be placed under the workpiece near the line of cut and near the edge of the workpiece on both sides of the wheel.

•Use extra caution when making a “pocket cut” into existing walls or other blind areas. The protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause kickback.

General safety instructions

WARNING: Read the warning instructions that follow before you use the product.

•This product is a dangerous tool and can cause serious injury if it is not used careful or if used incorrectly. It is very important that you read and understand the contents of this manual.

•Do not change the product without an approval from the manufacturer. Do not use a product that has been changed by others and always use original accessories. Changes that are not approved from the manufacturer can result in serious injury or death to the operator or others.

•Keep the product clean. Signs and decals must be fully visual.

•This product produces an electromagnetic field during operation. This field may under some circumstances interfere with active or passive medical implants. To decrease the risk of serious injury or death, we recommend persons with medical implants to turn to their physician and the medical implant manufacturer before operating this product.

Safety instructions for operation

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electrical shock, fire and/or serious injury.

•Do not cut asbestos materials.

•When dry cutting, make sure the dust is removed safely.

•The information in this manual is not a replacement for professional knowledge and experience. If you do not feel safe in the situation that you are in, stop the product. Do not use the product in unknown situations.

•Turn to your servicing dealer or Husqvarna if you have questions about the operation of the product. We can give you information about how to operate your product safely with best result.

•Do not use a product, battery or battery charger that is defective.

•Do not touch a rotating cutting blade. It can cause serious injuries or death.

•Do not use the product in bad weather, for example, heavy fog or rain, strong wind and intense cold. Bad weather add risks such as ice on the ground.

•Do not start a product unless all covers and guards are assembled correctly.

•Look around you. Make sure that there is no risk that persons or animals touch or influence on your control of the product.

•Do not let children use or be near the product. The product is easy to start. This can mean a risk of serious injury.

•Remove the battery when you do not have full view of the product. Remove the battery if you will not use the product for a long time.

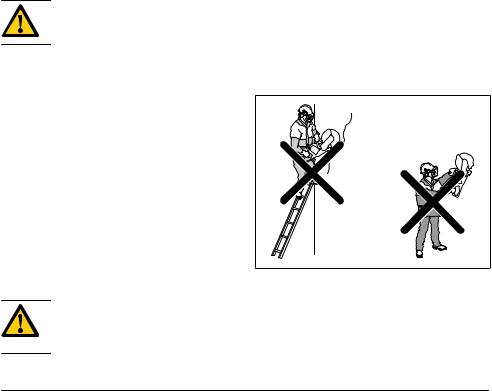

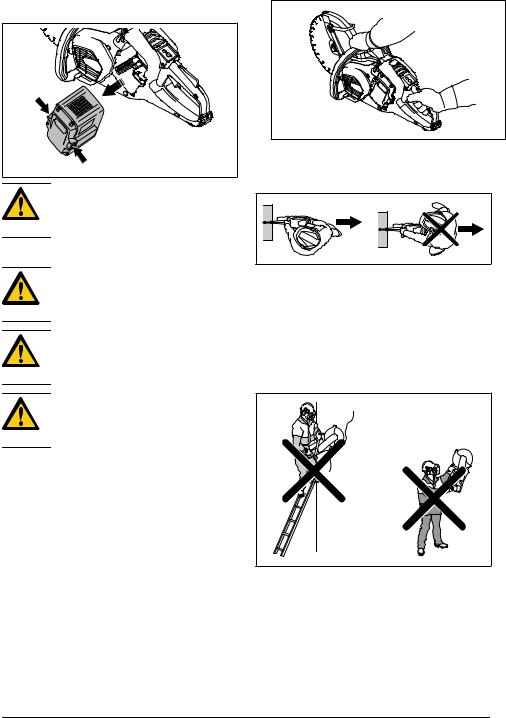

•You must be stable on your feet in order to have full control of the product. Do not use the product if you are on a ladder. Do not use the product if you are not on stable ground.

•Do not use the product above shoulder height.

745 - 008 - 12.11.2018 |

7 |

•If you are not careful, the risk of kickback increases.

•Do not hold the product with one hand. This product is not safely controlled with one hand.

•Do not use a product in a situation where you can not get for support if an accident occurs.

•Make sure that you can move around safely. Examine the conditions and the terrain around you for possible obstacles.

•Overexposure to vibration can lead to circulatory damage or nerve damage in people who have impaired circulation. Contact your doctor if you experience symptoms of overexposure to vibration. Such symptoms include numbness, loss of feeling, tingling, pricking, pain, loss of strength, changes in skin colour or condition. These symptoms normally appear in the fingers, hands or wrists. These symptoms may be increased in cold temperatures.

•It is not possible to include each possible situation you can face when you use this product. Always be careful and use your common sense.

•Note: After operating the tool, hearing protection must be lifted immediately when sawing is completed to hear sounds and warning signals can be heard.

Personal protective equipment

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electrical shock, fire and/or serious injury.

•You must use approved personal protective equipment during operation. Personal protective equipment does not give you full protection from injuries but it decreases the degree of injury if an accident occurs. Speak to your servicing dealer for recommendations about which equipment to use.

•Your clothing must be close-fitting but not limit your movements. Regularly do a check of the condition of the personal protective equipment.

•Use an approved protective helmet.

•Use approved respiratiory protection.

•Use approved hearing protection. Long-term exposure to noise can result in permanent damage to the hearing.

•Use protective glasses or a face visor to decrease the risk of injury from particles and dust. This can result in serious injury, especially to the eyes.

•Use heavy duty protective gloves.

•Use boots with steel toe-cap and non-slip sole.

•Always have a first aid kit kit with you.

Safety devices on the product

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electrical shock, fire and/or serious injury.

•Do not use a product with damaged safety components. The safety equipment must go through inspection and maintenance regularly. Turn to your servicing dealer for repair if an inspection of a safety device is not approved.

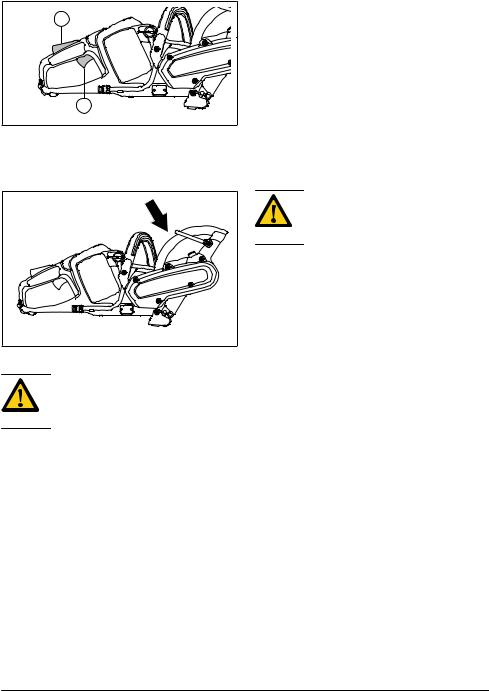

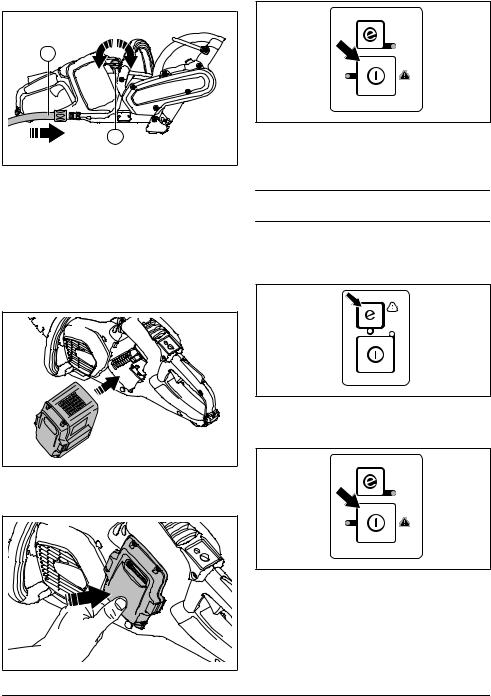

Keypad

The warning indicator flashes if there is a risk of overload. The overload protection temporarily stops the product and you can not use the product until the temperature restores. If the indicator shows a solid light, turn to your servicing dealer.

The automatic stop function

The product has an automatic stop function that stops the product if you do not use it for one minute.

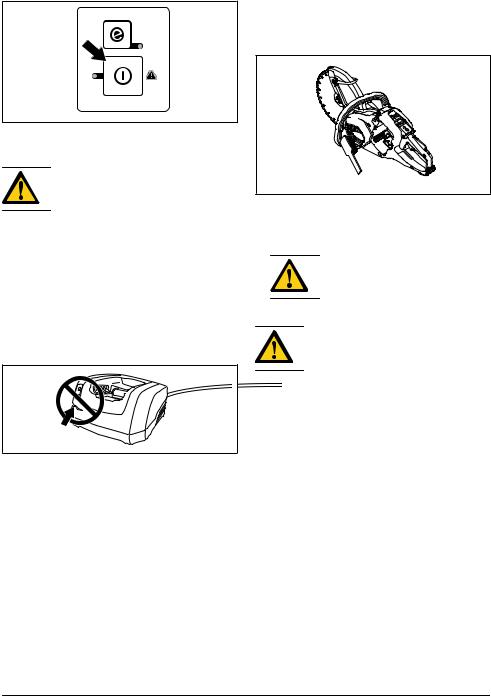

Power trigger lockout

The power trigger lockout prevents accidental operation of the power trigger. If you put your hand around the handle and press the power trigger lockout (A), it releases the power trigger (B). If you release the handle,

8 |

745 - 008 - 12.11.2018 |

the power trigger and the power trigger lockout move back to their initial positions.

A |

B |

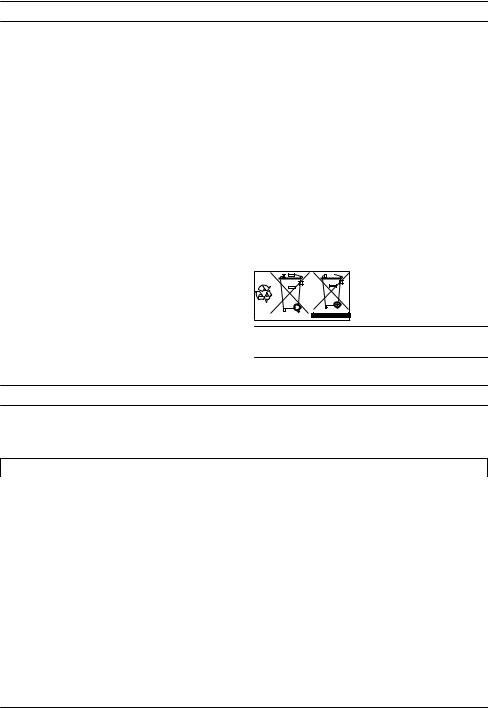

Blade guard

The blade guard protects the cutting particles to damage the user. The protection prevents parts from loosening and damaging the user

Battery safety

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electrical shock, fire and/or serious injury.

•Only use the Husqvarna BLi batteries that we recommend for your product. The batteries are software encrypted.

•Use the Husqvarna BLi batteries that are rechargable as a power supply for the related Husqvarna products only. To prevent injury, do not use the battery as a power supply for other devices.

•Risk of electrical shock. Do not connect the battery terminals to keys, screws or other metal. This can cause a short circuit of the battery.

•Do not use batteries that are non-rechargable.

•Do not put objects into the air slots of the battery.

•Keep the battery away from sunlight, heat or open flame. The battery can blow up and cause burns and/or chemical burns.

•Keep the battery away from rain and wet conditions.

•Keep the battery away from microwaves and high pressure.

•Do not try to disassemble or break the battery.

•Do not let battery acid touch your skin. Battery acid causes injuries to the skin, corrosion and burns. If you get battery acid in your eyes, do not rub but flush with water for minimum 15 minutes. If battery acid has touched your skin, you must clean the skin with a large quantity of water and soap. Get medical aid.

•Use the battery in temperatures between -10 °C (14 °F) and 40 °C (104 °F).

•Do not clean the battery or the battery charger with water. See To clean the battery and the battery charger on page 20.

•Do not use a defective or damaged battery.

•Keep batteries in storage away from metal objects such as nails, screws or jewelry.

•Keep the battery away from children.

Battery charger safety

WARNING: Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electrical shock, fire and/or serious injury.

•Risk of electrical shock or short circuit if the safety instructions are not obeyed.

•Do not use other battery chargers than the one supplied for your product. Only use Husqvarna QC chargers when you charge Husqvarna replacement batteries BLi.

•Do not try to disassemble the battery charger.

•Do not use a defective or damaged battery charger.

•Do not lift the battery charger by the power cord. To disconnect the battery charger from a mains socket, pull out the plug. Do not pull the power cord.

•Keep all cables and extension leads away from water, oil and sharp edges. Make sure that the cable is not caught between doors, fences or equivalent.

•Do not use the battery charger near flammable materials or materials that can cause corrosion. Make sure that the battery charger is not covered. Pull out the plug to the battery charger if there is smoke or fire.

•Only charge the battery indoors in a location with good airflow and away from sunlight. Do not charge the battery outdoors. Do not charge the battery in wet conditions.

•Only use the battery charger where the temperature is between 5 °C (41 °F) and 40 °C (104 °F). Use the charger in an environment which has a good airflow, dry and free from dust.

•Do not put objects into the air slots of the battery charger.

•Do not connect the battery charger terminals to metal objects as this can short circuit the battery charger.

•Do not charge non-rechargeable batteries in the battery charger or use them in the machine.

•Use approved mains sockets that are not damaged.

745 - 008 - 12.11.2018 |

9 |

Safety instructions for maintenance

WARNING: Read the warning instructions that follow before you do maintenance on the product.

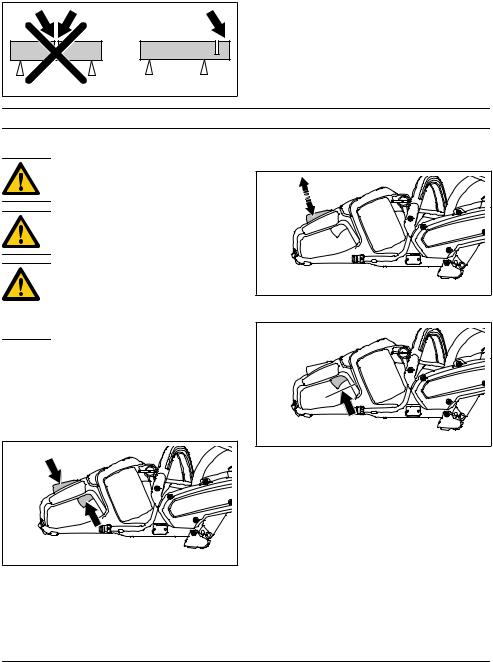

•Remove the battery before you do maintenance, other checks or assemble the product.

•The operator must only do the maintenance and servicing shown in this operator's manual. Turn to your servicing dealer for maintenance and servicing of a larger extension.

•Do not clean the battery or the battery charger with water. Strong detergent can cause damage to the plastic.

•If you do not do maintenance, it decreases the life cycle of the product and increases the risk of accidents.

•Special training is necessary for all servicing and repair work, especially for the safety devices on the product. If not all checks in this operator's manual are approved after you have done maintenance, turn to your servicing dealer. We guarantee that there are professional repairs and servicing available for your product.

•Only use original spare parts.

Assembly

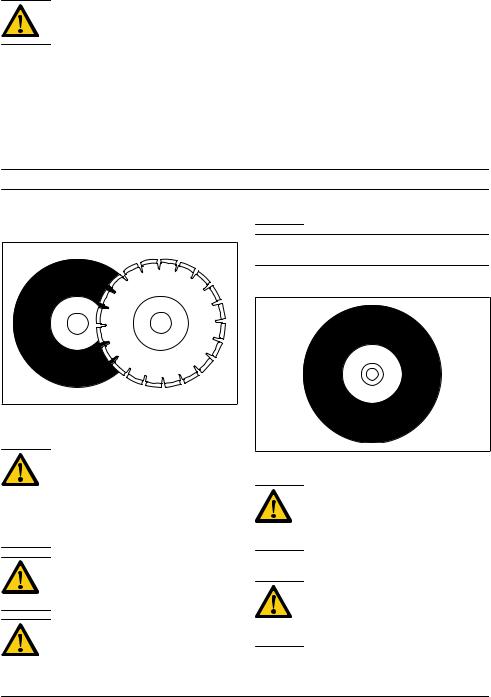

Applicable cutting blades

Cutting blades for Husqvarna K 535i are available in two basic models: abrasive blades and diamond blades.

are in compliance with national or regional standards.

Note: Only cut materials approved in the instruction supplied with the blade.

Check that the blade is approved for the same or higher speed written on the type plate of the power cutter.

Cutting blades for handheld high speed power cutters

WARNING: Only use diamond blades and abrasive blades for concrete. Do not use blades with serrations such as circular wood cutting blades or blades with carbide tips. The risk of kickback is increased and carbide tips can come off and be thrown at high speed. This can result in injury or death.

WARNING: Incorrect use can cause the blade to become too hot. A blade that is too hot can cause malfunction, which can cause damage and injury.

WARNING: Do not use a cutting blade with a lower maximum speed than that of the power cutter. Only use cutting blades that

100 M/S

XXXX RPM

Blade vibration

CAUTION: If you use the product with too much force, the blade can get too hot, bend and cause vibrations. Use the product with less force. If the vibrations continues, replace the blade.

Abrasive blades

WARNING: Do not use abrasive blades with water. The strength is impaired when abrasive blades are exposed to water or moisture, which results in an increased risk of the blade breaking.

10 |

745 - 008 - 12.11.2018 |

CAUTION: Cutting with abrasive blade is not allowed with the Vac attachment. Use of abrasive blades causes unnatural wear on the Vac attachment.

CAUTION: Do not use abrasive blades with thickess exceeding maximum recommended thickness, refer to Technical data on page 22

•Do not use worn reinforced wheels from larger power tools. Wheels intended for a larger power tool are not suitable for the higher speed of a smaller tool and may burst.

•The cutting material on abrasive blades consists of a grit bonded agent using an organic binder. Reinforced blades are made up of a fabric or fibre base that prevents total breakage at maximum working speed if the blade should be cracked or damaged.

•A cutting blade’s performance is determined by the type and size of abrasive corn, and the type and hardness of the bonding agent.

•Ensure the cutting blade is not cracked or damaged.

•Test the abrasive blade by hanging it on your finger and tapping it lightly with a screwdriver or the like. If the blade does not produce a resonant, ringing sound it is damaged.

Diamond blades

WARNING: Never use a diamond blade to cut plastic material. The heat produced during cutting may melt the plastic and it can stick to the cutting blade and cause a kickback.

WARNING: Diamond blades become very hot when used. An overheated blade is a result of improper use, and may cause deformation of the blade, resulting in damage and injuries.

Note: Sharpen the blade by cutting soft material such as sandstone or block.

•Always use a sharp diamond blade.

•Diamond blades can become dull when the wrong feeding pressure is used or when cutting certain materials such as heavily reinforced concrete.

Working with a dull diamond blade causes overheating, which can result in the diamond segments coming loose.

•Diamond blades consist of a steel core provided with segments that contain industrial diamonds.

•Diamond blades are ideal for masonry, concrete and other composite materials.

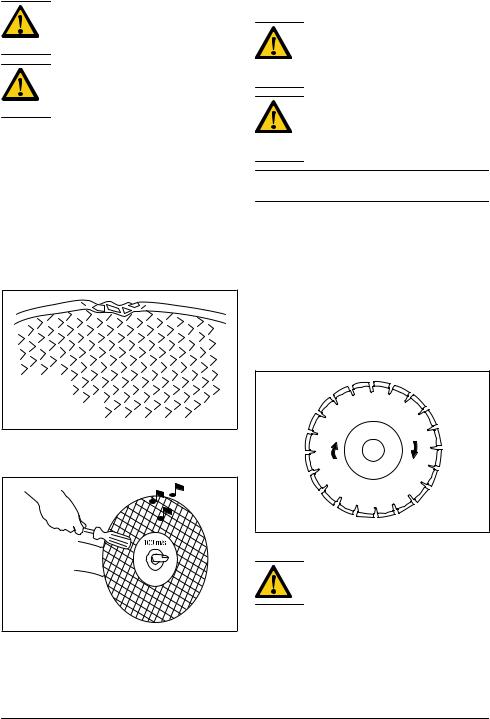

•When using diamond blade make sure that it rotates in the direction indicated by the arrow on the blade.

XXXX

•Ensure that correct abrasive blade is used on the intended material.

Wet cutting

CAUTION: Do not use Vac equipment together with the wet system.

•Diamond blades for wet cutting must be used with the wet system.

•Water cool the blade and increases its service life while also decrease the dust.

•When wet cutting, make sure to collect the waste water safely.

745 - 008 - 12.11.2018 |

11 |

Dry cutting

•When dry cutting, lift the blade out from the cut each 30–60 seconds and let it rotate in the air for 10 seconds to let it cool.

•Use Vac equipment if possible.

Diamond blade - requirements

WARNING: Make sure the diamond segment (T1) is wider than the blade (T2). This is to prevent pinching in the cutting slot and a kickback.

T1 |

T2 |

CAUTION: Do not use diamond blades with positive rake angles.

CAUTION: Do not use diamond blades with greater gap between segments than max 10 mm (A).

A

CAUTION: Do not use diamond blades with greater blade thickness than recommended maximum, refer to Technical data on page 22.

CAUTION: Some cutting situations and worn blades may cause increased wear on the side of the segments. Replace the blade before it is worn out.

To examine the spindle shaft and flange washers

Examine the flange washers and the spindle shaft when the blade is replaced.

CAUTION: Use only flange washers supplied by Husqvarna with minimum diameter 60 mm/2.4 in.

CAUTION: Do not use damaged, defective or dirty flange washers.

CAUTION: Do not use different dimensions of flange washers.

•Make sure that the threads on the spindle shaft are not damaged.

•Make sure that the surfaces on the blade and the flange washers are not damaged, of the correct dimension, clean, and that they run correctly on the spindle shaft.

12 |

745 - 008 - 12.11.2018 |

To examine the arbor bushing

•Use only Husqvarna arbor bushings.

•Make sure that the arbor bushing has the correct dimension for the cutting blade. The correct dimension is printed on the cutting blade.

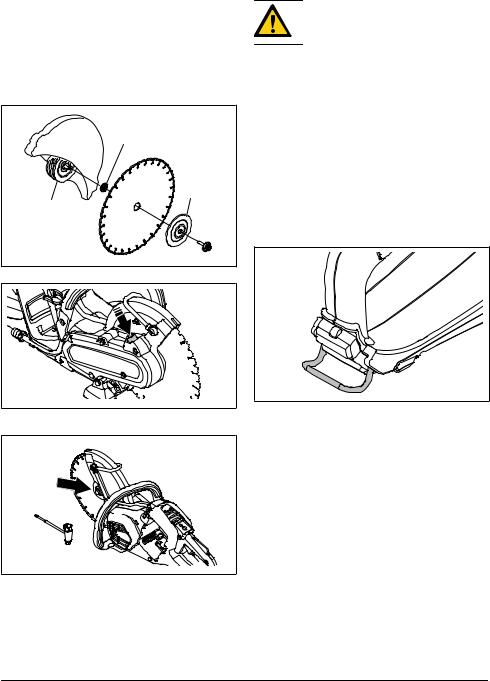

To attach the cutting blade

1.The cutting blade is put on the bushing (A) between the inner flange washer (B) and the flange washer

(C). The flange washer is turned to attach to the axle.

A

C

B

2. Lock the shaft.

To examine the blade and the blade guard

WARNING: A damaged cutting blade can cause injury.

1.Make sure that the cutting blade is attached correctly and does not show signs of damage.

2.Make sure that the blade guard has no cracks or is damaged.

3.Replace the blade guard if it is damaged. See To attach the cutting blade on page 13

Rope eyelet

The product has a rope eyelet. The rope eyelet can be used to lift and lowering the product. Attach an applicable strop to the rope eyelet to use it for lift and lowering.

The rope eyelet can be used to attach the product to a solid object to prevent it from fall and damage persons or equipment.

3.Tighten the bolt. The tightening torque for the bolt holding the cutting blade is 30 Nm (18,5 ft-Ibs).

745 - 008 - 12.11.2018 |

13 |

Operation

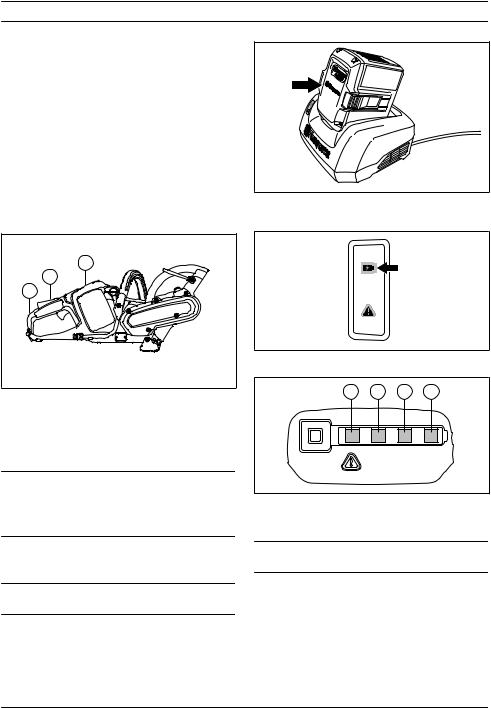

To do a function check before you use the product

1.Do a check of the rear right hand guard (A) to make sure that it is not damaged.

2.Do a check of the power trigger lockout (B) to make sure that it operates correctly and that it is not damaged.

3.Do a check of the keypad (C) to make sure that it operates correctly.

4.Do a check to make sure that all parts and guards are correctly attached and not damaged or missing.

5.Charge the battery and make sure that it is correctly attached to the product.

6.Make sure that the power cutter stops when you release the power trigger.

C |

B |

A |

To connect the battery charger

1.Connect the battery charger to the voltage and frequency that is specified on the rating plate.

2.Put the plug in a grounded socket outlet. The LED on the battery charger flashes green one time.

Note: The battery does not charge if the battery temperature is more than 50 °C/122 °F. If the temperature is more than 50 °C/122 °F, the battery charger makes the battery become cool before the battery charges.

To connect the battery to the battery charger

Note: Charge the battery if it is the first time that you use it. A new battery is only 30% charged.

1. Make sure that the battery is dry.

2. Put the battery in the battery charger.

3.Make sure that the green charging light on the battery charger comes on. That means that the battery is connected correctly to the battery charger.

4.When all LEDs on the battery come on, the battery is fully charged.

A |

B |

C |

D |

5.To disconnect the battery charger from the mains socket, pull the plug. Do not pull the cable.

6.Remove the battery from the battery charger.

Note: Refer to the battery and battery charger manuals for more information.

14 |

745 - 008 - 12.11.2018 |

To connect coolant water

1. Connect the water hose to the water supply (A).

A |

B |

2.Turn the water tap (B) to let the water go or stop.

3.Examine if leakage occurs in the water connection or the hose.

4.Make sure water pressure do not go by maximum permitted water pressure, refer to Technical data.

To start the product

1.Do a check of the power trigger and power trigger lockout. See To do a check of the power trigger lockout on page 19.

2.Put the battery in the battery holder.

4.Press and hold the start/stop button until the green LED light comes on.

To use the SavE function

This product has a power saving function, SavE. The SavE function decreases the blade speed and gives the longest operation time from the battery.

Note: The SavE function does not decrease the cutting power of the product.

1.Press the SavE button on the keypad.

2.Make sure that the green LED comes on.

3.Press the SavE button again to disconnect the function. The green LED goes out.

To stop the product

1. Press and hold the start/stop button on the keypad until the green LED light goes out.

3. Press on the lower part of the battery until you hear a click sound. If the battery does not move into the battery holder easily, it is not attached correctly into the battery holder.

745 - 008 - 12.11.2018 |

15 |

2.Press the battery release buttons and remove the battery from the battery holder.

WARNING: Remove the battery when you do not use or when you do not have full vision of the product. This is to prevent accidental start.

Basic working techniques

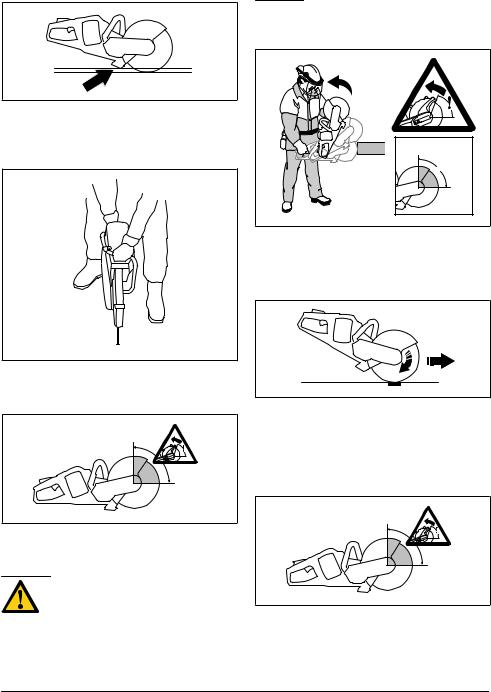

WARNING: Do not move the power cutter to the side. This can prevent the free movement of the blade and cause the blade to break, which can cause an injury.

WARNING: Do not use the side of the blade. The blade can become damaged and broken, which can cause an injury. Use only the cutting edge.

WARNING: Do not use a diamond blade to cut plastic material. The heat that occurs can melt the plastic. Melted plastic can attach to the cutting blade and cause a kickback.

•The product is made for high speed diamond blades approved for handheld power cutters.

•The product is made to cut in to tiles, light concrete and stone. Use only for this type of operation.

•Make sure that the cutting blade does not show signs of damage and that it is attached correctly, see

Abrasive blades on page 10 and To attach the cutting blade on page 13.

•Make sure to use the correct cutting blade for the type of operation, see Cutting blades for handheld high speed power cutters on page 10.

•Do not cut asbestos material.

•Always hold the power cutter with 2 hands. Always hold the product tightly with thumbs and fingers around the handles. Always hold the rear handle with the right hand and the front handle with the left hand.

•Always be parallel to the cutting blade. Do not be linearly behind the cutting blade. If there is a kickback, the power cutter moves in the plane of the cutting blade.

•Keep a safe distance to the cutting blade when the engine operates.

•Make sure that you are in a stable position during operation.

•Keep applicable distance from the object you are cutting.

•Do not operate above shoulder height. Use a platform or scaffold if the cutting operation is above shoulder height. Do not overreach.

•Do not operate from a ladder.

•Make sure that the cutting blade is free when the engine is started.

•Always monitor the product when the engine operates.

•Do not move the product when the cutting blade rotates.The product has a electrical retarder to decrease the blade stop time.

•Make sure that the front ground support is flush with the work piece at the rear. The blade guard collects

16 |

745 - 008 - 12.11.2018 |

spray and dust and moves them away from the operator.

•Cut with full throttle. Keep full rotating speed until the cutting operation is completed.

•Push the cutting blade lightly against the object you are cutting. Do not use force.

•Align the cutting blade with the cut.

kickbacks and how to prevent them before you use the product.

A kickback occurs when the blade is pinched in the kickback zone. Usually they are not dangerous but a strong kickback can cause injury or death.

Reactive force

•A reactive force pulls the product in the opposite direction of the blade movement. Most of the time this force is not strong. If the blade is pinched the strength of the reactive force can cause a kickback.

•Move the cutting blade slowly forward and rearward to decrease the area between the cutting blade and the material. This decreases the temperature of the cutting blade.

•Do not cut with the kickback zone of the blade, see

Kickback on page 17.

Kickback

WARNING: Kickbacks are sudden and can be very dangerous. The product can be moved up and rearward in the direction of the operator in a rotating movement. Injury or death is a possible result of a kickback. Make sure you understand the causes of

•Do not tilt the product when the cutting equipment rotates. Centrifugal forces can decrease movement.

Kickback zone

•Do not cut with the kickback zone of the cutting blade. If the blade is pinched in the kickback zone, the reactive force rotates the product up and back. It can hit the operator and can result in injury or death.

Climbing kickback,

•Do not use the kickback zone. When the kickback zone is used for cutting, the reactive force moves the

745 - 008 - 12.11.2018 |

17 |

blade up into the cut. Use the lower part of the blade to prevent climbing kickback.

Pinching kickback

•A blade is pinched when the cut closes and stops the turning of the blade. If the blade is pinched, the strength of the reactive force can cause loss a kickback.

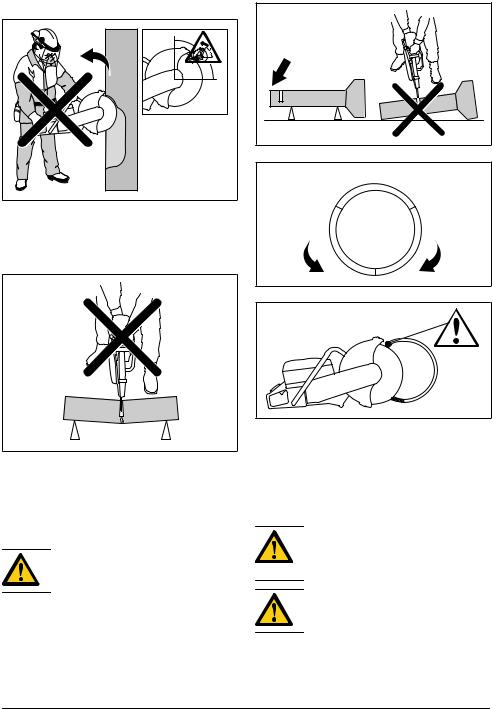

•Make sure that the work piece is held to keep the cut open during a cutting operation. Make an estimate of the possible movement of the work piece during last phase of the cutting operation. Make sure that the cut opens during the cutting operation. A cut that closes can cause a pinching kickback.

To cut into pipes

WARNING: If the blade is pinched in the kickback zone it will cause a kickback.

Be careful when cutting in pipes. The pipe is must kept in place correctly and the cut kept open through out the cutting. If not, the blade can be pinched. Be especially careful when cutting a pipe with a bell end or a pipe in a ditch. If it does not have correct support the blade can be pinched.

1. Make sure the pipe does not move during cutting.

2. Cut with section "I".

I

IIIII

3.Make sure that the cut opens to prevent pinching.

4.Move to side II and cut from section I to the bottom of the pipe.

5.Move to side III and cut the remaining part of the pipe.

6.Make sure the pipe is kept in place correctly. The end of the pipe must move down during the cutting.

To prevent pinching

WARNING: Do not let the cut close during a cutting operation. A cut that closes can cause pinching, which can cause a kickback or damage to the cutting blade.

WARNING: Be careful when the cutting blade is put in a cut that was there before.

•Make sure that the work piece cannot move during a cutting operation.

•Make sure that the work piece is held to keep the cut open during a cutting operation.

18 |

745 - 008 - 12.11.2018 |

• Make an estimate of the possible movement of the |

To manage dust |

work piece during the last phase of the cutting |

• The product has a low flushing water kit. Use wet |

operation. |

|

• Make sure that the cut opens during the cutting |

cutting when possible. See instructions in To |

operation. |

connect coolant water on page 15. The correct flow |

|

is different for different types of tasks. If the water |

|

hose comes off at the supply source, the supplied |

|

water pressure can be too high. See Technical data |

|

on page 22 for recommended water pressure. |

|

• Adjust the water flow with the valve. |

Maintenance

Introduction

WARNING: Read and understand the safety chapter before you do maintenance work on the product.

WARNING: Remove the battery before you do maintenance on the product.

WARNING: Failure to do maintenance correctly can decrease the product life cycle and increase the risk of accidents. All servicing and/or repair work must also be done by a professional. Turn to your servicing dealer for more information.

Maintenance and checks of the safety devices on the product

To do a check of the power trigger lockout

1.Make sure that the power trigger and power trigger lockout move freely and that the return spring works correctly.

2.Press down the power trigger lockout and make sure that it goes back to its initial position when you release it.

3.Make sure that the power trigger is locked at the idle position when the power trigger lockout is released.

4.Start the product and apply full power.

5.Release the power trigger and make sure that the cutting blade stops. If the cutting blade rotates when the power trigger is in the idle position, turn to your servicing dealer.

To do a check of the keypad

1.Start the product. See To do a check of the power trigger lockout on page 19

2.Press the start/stop button again.

745 - 008 - 12.11.2018 |

19 |

3.Make sure that the product stops when you press and hold the button. The green LED will go off.

To clean the battery and the battery charger

CAUTION: Do not clean the battery or the battery charger with water.

•Make sure that the battery and the battery charger are clean and dry before you put the battery into the battery charger.

•Clean the battery terminals with compressed air or use a soft and dry cloth.

•Clean the surfaces of the battery and the battery charger with a soft and dry cloth.

To clean the cooling system

The product has a cooling system that keeps the temperature of the product as low as possible.

The cooling system includes an air intake on the left side of the product and a fan on the motor.

1.Clean the cooling system with a brush weekly or more frequently if necessary.

2.Make sure that the cooling system is not dirty or blocked.

CAUTION: A dirty or blocked cooling system can cause the product to become too hot.

To do a check of the battery charger

1.Make sure that the battery charger and the power supply cord are not damaged. Look for cracks and other defects.

Maintenance schedule

WARNING: Remove the battery before you do maintenance.

The following is a list of the maintenance steps that you must do on the product.

Maintenance |

Before |

Weekly |

Monthly |

|

use |

|

|

Clean the external parts of the product. |

X |

|

|

|

|

|

|

Make sure that the power trigger and the power trigger lockout function correctly |

X |

|

|

from a safety point of view. |

|

|

|

|

|

|

|

|

|

|

|

Do a check of the cutting blade. Look for cracks and make sure that the cutting |

X |

|

|

blade is not unusually worn. Replace if necessary. |

|

|

|

|

|

|

|

|

|

|

|

Clean the fan housing on the product. |

X |

|

|

|

|

|

|

Make sure that the screws and nuts are tight. |

X |

|

|

|

|

|

|

Make sure that the keypad works correctly and that it is not damaged. |

X |

|

|

|

|

|

|

Do a check of the connections between the battery and the product. Do a check |

|

|

X |

of the connection between the battery and the battery charger. |

|

|

|

|

|

|

|

|

|

|

|

20 |

745 - 008 - 12.11.2018 |

Maintenance |

Before |

Weekly |

Monthly |

|

use |

|

|

Blow through the product and battery soft with compressed air. |

|

|

X |

|

|

|

|

|

|

|

Troubleshooting |

|

Keypad |

|

|

|

|

Problem |

Cause |

Solution |

|

|

|

|

|

|

|

Warning indica- |

Temperature |

Let the product to cool down. |

|

|

tor flashing. |

deviation. |

|

|

|

|

|

|

|

|

|

Overload. Cut- |

Clean the cutting attachment. |

|

|

|

ting attachment |

|

|

|

|

is clogged. |

|

|

|

|

|

|

|

|

|

The power trig- |

Release the power trigger. |

|

|

|

ger and the |

|

|

|

|

start button are |

|

|

|

|

pressed at the |

|

|

|

|

same time. |

|

|

|

|

|

|

|

|

Green LED |

Low battery |

Charge the battery. |

|

|

flashing. |

voltage. |

|

|

|

|

|

|

|

|

Warning indica- |

Service. |

Turn to your servicing dealer. |

|

|

tor is on. |

|

|

|

|

|

|

|

|

|

Battery |

|

|

|

|

Problem |

Cause |

Solution |

|

|

|

|

|

|

|

Warning indica- |

The battery is |

Charge the battery. |

|

|

tor flashing. |

not charged. |

|

|

|

|

|

|

|

|

|

Temperature |

Use the battery in an environment where temperature are between -10 °C/14°F |

||

|

deviation. |

and 40°C/104°F. |

|

|

|

|

|

|

|

|

To high volt- |

Check that the voltage on the battery is the same as the voltage on the rating |

||

|

age. |

plate on the product. Remove the battery from the battery charger. |

||

|

|

|

|

|

Warning indica- |

Battery cells |

Turn to your servicing dealer. |

|

|

tor is on. |

difference is |

|

|

|

|

too much (1V). |

|

|

|

|

|

|

|

|

Battery charger |

|

|

|

|

Problem |

|

|

Casue |

Solution |

|

|

|

|

|

Warning indicator flashing. |

|

Temperature deviation. |

Use the battery an environment |

|

|

|

|

|

where temperatures are between |

|

|

|

|

5°C/41°F and 40°C/104°F. |

|

|

|

|

|

Warning indicator is on. |

|

|

Turn to your servicing dealer. |

|

|

|

|

|

|

745 - 008 - 12.11.2018 |

21 |

Transportation, storage and disposal

Transportation and storage

•The supplied Li-ion batteries obey the Dangerous Goods Legislation requirements.

•Obey the special requirement on package and labels for commercial transportation, including by third parties and forwarding agents.

•Speak to a person with special training in dangerous material before you send the product. Obey all applicable national regulations.

•Use tape on open contacts when you put the battery in a package. Put the battery in the package tightly to prevent movement.

•Remove the battery for storage or transportation.

•Put the battery and the battery charger in a space that is dry and free from moisture and frost.

•Do not keep the battery in an area where static electricity can occur. Do not keep the battery in a metal box.

•Put the battery in storage where the temperature is between 5 °C (41 °F) and 25 °C (77 °F) and away from open sunlight.

•Put the battery charger in storage where the temperature is between 5 °C (41 °F) and 45 °C (113 °F) and away from open sunlight.

•Charge the battery 30% to 50% before you put it in storage for long periods.

•Put the battery charger in storage in a space that is closed and dry.

•Keep the battery away from the battery charger during storage. Do not let children and other not approved persons to touch the equipment. Keep the equipment in a space that you can lock.

•Clean the product and do a full servicing before you put the product in storage for a long time.

•Use the transportation guard on the product to prevent injuries or damage on the product during transportation and storage.

•Attach the product safely during transportation.

Disposal of the battery, battery charger and product

The symbol below means that the product is not domestic waste. Recycle it at a recycling station for electrical and electronic equipment. This helps to prevent damage to the environment and to persons.

Speak to local authorities, domestic waste service or your dealer for more information.

Note: The symbol shows on the product or package of the product.

Technical data

Technical data

Husqvarna K 535i

Voltage |

|

36V |

|

|

|

|

|

Weight, kg (lbs) |

|

3.5 |

(7.7) |

|

|

|

|

Blade diameter, mm (in.) |

230 (9) |

||

|

|

|

|

Max blade thickness, |

Abrasive blades |

3.0 |

(0.1) |

mm (in.) |

Diamond blades |

1.8 |

(0.07) |

|

|||

|

|

|

|

Unit rated speed |

|

5940 rpm |

|

|

|

|

|

Water cooling |

|

|

|

|

|

|

|

Water cooling of blade |

|

Yes |

|

|

|

|

|

Connecting nipple |

|

Type ”Gardena” |

|

|

|

|

|

Recommended water pressure, bar (psi) |

0.5 |

- 6 (7.3 - 87) |

|

|

|

|

|

22 |

745 - 008 - 12.11.2018 |

Husqvarna K 535i

Maximum water pressure, bar (psi) |

|

|

6 (87) |

|||

|

|

|

|

|

|

|

|

|

Vibration levels, ahveq 1 |

|

Noise emissions 2 |

||

|

Front/Left |

|

Rear Right |

LpA |

|

LwA |

|

|

|

|

|

|

|

|

m/s2 |

|

m/s2 |

dB(A) |

|

dB(A) |

BLi200 |

1.9 |

|

2.3 |

|

|

|

|

|

|

|

|

|

|

BLi300 |

2.1 |

|

2.5 |

100.5 |

|

111.5 |

|

|

|

|

|

|

|

1 The declared vibration total value has been measured in accordance with EN 60745-2-22 and may be used for comparing one tool with another. The declared vibration total value may also be used in a preliminary assessment of exposure.

2 The noise emission are measured in accordance with EN 60745-2-22.

• Uncertainty for the A-weighted sound power level KpA is 3 dB(A).

• Uncertainty for the A-weighted sound pressure level KpA is 3 dB(A).

|

Accessories |

|

Approved batteries for the product |

|

|

|

|

|

Battery |

BLi200 |

BLi300 |

|

|

|

Type |

Lithium-ion |

Lithium-ion |

|

|

|

Battery capacity, Ah |

5.2 |

9.4 |

|

|

|

Nominal voltage, V |

36 |

36 |

|

|

|

Weight, kg / lb |

1.3 / 2.9 |

1.9 / 4.2 |

|

|

|

Approved battery chargers for the product

Battery charger |

QC330 |

|

|

Mains voltage, V |

100-240 |

|

|

Frequency, Hz |

50-60 |

|

|

Power, W |

330 |

|

|

745 - 008 - 12.11.2018 |

23 |

EC Declaration of Conformity

EC Declaration of Conformity

We, Husqvarna AB, SE-561 82 Huskvarna, SWEDEN, tel: +46-36-146500, declare on our sole responsibility that the product:

Description |

Portable cut-off machine |

Brand |

HUSQVARNA |

|

|

|

|

Type / Model |

K 535i |

|

|

|

|

Identification |

Serial numbers dating from 2018 and onwards |

|

|

|

|

complies fully with the following EU directives and |

|

regulations: |

|

|

|

Directive / Regulation |

Description |

2006/42/EC |

"relating to machinery" |

|

|

2011/65/EU |

"relating to restriction of hazardous substances" |

|

|

and that harmonized standards and/or technical specifications are applied as follows;

•EN ISO 12100:2010

•EN 60745-1:2009

•EN 60745-2-22:2011/A11:2013

Partille, 2018-08-24

Edvard Gulis

Global R&D Director

Responsible for technical documentation

24 |

745 - 008 - 12.11.2018 |

Inhalt

Einleitung...................................................................... |

25 |

Sicherheit...................................................................... |

27 |

Montage........................................................................ |

34 |

Betrieb.......................................................................... |

38 |

Wartung........................................................................ |

44 |

Fehlerbehebung............................................................ |

46 |

Transport, Lagerung und Entsorgung........................... |

47 |

Technische Angaben.................................................... |

48 |

Zubehör........................................................................ |

49 |

EG-Konformitätserklärung............................................ |

50 |

Einleitung

Produktbeschreibung

Husqvarna K 535i ist eine tragbare, handgeführte Schneidmaschine. Das Produkt wird durch einen Akku betrieben.

Wir arbeiten laufend daran, Ihre Sicherheit und die Effektivität während des Betriebs zu verbessern. Ihr Servicehändler steht Ihnen gern für weitere Informationen zur Verfügung.

Verwendungszweck

Dieses Produkt wird verwendet, um Dachziegel, Gartenplatten und Leichtbeton zu schneiden.

Hinweis: Der Betrieb des Geräts kann durch nationale Vorschriften eingeschränkt sein.

Produktübersicht |

|

|

|

|

|

|

|

|

|

|

|

6 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

9 |

|

|

|

|

|

|

10 |

|

|

|

|

4 |

|

|

|

|

|

|

5 |

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

15 |

|

|

|

|

|

|

|

|

14 |

|

19 |

18 |

17 |

16 |

|

13 |

|

|

|

|

|

|

12 |

|

|

|

21 |

22 |

23 |

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

26 |

|

|

|

|

|

|

25 |

|

|

|

|

|

24 |

|

745 - 008 - 12.11.2018 |

|

|

|

|

25 |

|

1.Gashebelsperre

2.Gashebel

3.Wasserventil

4.Wasserdüse

5.Schneidmesser

6.Klingenschutz

7.Trennscheibenrotation

8.SavE-Taste (Energiespartaste)

9.Startund Stopptaste

10.Warnanzeige

11.Hinterer Handgriff mit Rechtshandschutz

12.Bodenstütze hinten mit Seilöse

13.Akkufach

14.Lüftergehäuse

15.Vorderer Handgriff

16.Riemenschutz

17.Bodenstütze vorne

18.Typenschild

19.Wasseranschluss mit Filter

20.Bedienungsanleitung

21.Gabel-Ringschlüssel

22.Taste, Akkuladezustand

23.Akkuladezustand

24.Warnanzeige

25.Akkuentriegelungstaste

26.Akku (nicht enthalten)

Symbole auf dem Gerät

Gefahr von schweren oder tödlichen Verletzungen des Bedieners oder anderer Personen. Gehen Sie vorsichtig vor, und verwenden Sie das Gerät ordnungsgemäß.

Lesen Sie das Handbuch sorgfältig durch und stellen Sie sicher, dass Sie die Anweisungen verstehen, bevor Sie das Produkt benutzen.

Tragen Sie einen zugelassenen Schutzhelm, Atemschutz, Gehörschutz und eine Schutzbrille.

Dieses Produkt stimmt mit den geltenden

CE-Richtlinien überein.

Rauch vom Schneiden kann beim Einatmen Verletzungen verursachen. Verwenden Sie einen zugelassenen Atemschutz. Vermeiden Sie es, die Abgase einzuatmen. Achten Sie auf ausreichende Belüftung.

Von der Trennscheibe erzeugte Funken

Von der Trennscheibe erzeugte Funken  können brennbare Materialien wie z. B.

können brennbare Materialien wie z. B.

Benzin, Holz, Kleidung und trockenes Gras entzünden.

Rückschläge können unvermittelt und schnell passieren und Verletzungen verursachen. Lesen Sie die Anweisungen durch und stellen Sie sicher, dass Sie sie verstehen, bevor Sie das Produkt benutzen.

Vergewissern Sie sich, dass die

Trennscheibe keine Beschädigungen und

Risse aufweist.

Verwenden Sie keine kreisrunden

Sägeklingen.

Umweltkennzeichen. Das Gerät oder die Verpackung des Geräts dürfen nicht über den Hausmüll entsorgt werden. Recyceln Sie es an einer Recyclingstation für elektrische und elektronische Geräte.

|

Drehrichtung der Klinge |

yyyywwxxxx |

Das Typenschild zeigt die Ser- |

|

iennummer. JJJJ ist das Pro- |

|

duktionsjahr, ww ist die Produk- |

|

tionswoche. |

ØMaximaler Klingenaußendurchmesser.

DC Gleichstrom

nNenndrehzahl

Hinweis: Sonstige Symbole/Aufkleber am Gerät beziehen sich auf Zertifizierungsanforderungen, die in bestimmten Ländern gelten.

Symbole auf dem Akku und/oder auf dem Ladegerät

Recyceln Sie dieses Gerät an einer Recyclingstation für elektrische und elektronische Geräte. (nur für Europa)

Störungsfreier Transformator.

26 |

745 - 008 - 12.11.2018 |

Das Akkuladegerät darf nur in geschlossenen Räumen benutzt und aufbewahrt werden.

•das Gerät nicht ordnungsgemäß repariert wurde.

•das Gerät mit Teilen repariert wurde, die nicht vom Hersteller stammen oder vom Hersteller zugelassen sind.

Doppelt isoliert

Produkthaftung

Im Sinne der Produkthaftungsgesetze übernehmen wir keine Haftung für Schäden, die unser Gerät verursacht, wenn...

•ein Zubehörteil mit dem Gerät verwendet wird, das nicht vom Hersteller stammt oder vom Hersteller zugelassen ist.

•das Gerät nicht bei einem zugelassenen Service Center oder von einer zugelassenen offiziellen Stelle repariert wurde.

Sicherheit

Sicherheitsdefinitionen

Warnungen, Vorsichtsmaßnahmen und Hinweise werden verwendet, um auf besonders wichtige Teile der Bedienungsanleitung hinzuweisen.

WARNUNG: Wird verwendet, wenn bei Nichtbeachtung der Anweisungen in diesem Handbuch die Gefahr von Verletzung oder Tod des Bedieners oder anderer Personen besteht.

ACHTUNG: Wird verwendet, wenn bei Nichtbeachtung der Anweisungen in diesem Handbuch die Gefahr von Schäden am Gerät, an anderen Materialien oder in der Umgebung besteht.

Hinweis: Für weitere Informationen, die in bestimmten Situationen nötig sind.

Allgemeine Sicherheitshinweise für Elektrowerkzeuge

WARNUNG: Lesen Sie sämtliche Sicherheitshinweise und Anweisungen durch. Wenn Sie die Warnund Sicherheitshinweise nicht befolgen, kann dies zu Elektroschock, Brand und/oder schweren Verletzungen führen.

Hinweis: Bewahren Sie alle Warnhinweise und Anweisungen für spätere Referenzzwecke auf. Der Begriff „Elektrowerkzeug“ in den Warnhinweisen bezieht sich auf ein Elektrowerkzeug mit Netzbetrieb (über ein Kabel) oder mit Akkubetrieb (kabellos).

Sicherheit im Arbeitsbereich

•Sorgen Sie für einen sauberen und gut ausgeleuchteten Arbeitsbereich. Durch zugestellte

oder dunkle Arbeitsbereiche steigt die Unfallgefahr stark an.

•Betreiben Sie Elektrowerkzeuge niemals an Orten, an denen Explosionsgefahr besteht, z. B. in der Nähe von leicht entzündlichen Flüssigkeiten, Gasen oder Staubansammlungen.

Bei der Arbeit mit Elektrowerkzeugen kann es zu Funkenbildung kommen, wodurch sich Staub oder Dämpfe entzünden können.

•Sorgen Sie bei der Arbeit mit Elektrowerkzeugen dafür, dass sich keine Kinder oder unbefugte Personen in der Nähe befinden. Durch Ablenkungen können Sie die Kontrolle über das Werkzeug verlieren.

Elektrische Sicherheit

•Die Netzstecker von Elektrowerkzeugen müssen zur Steckdose passen. Der Netzstecker darf in keiner Weise verändert werden. Verwenden Sie bei Elektrowerkzeugen mit Schutzkontakt (geerdet) niemals Adapterstecker. Nicht modifizierte Stecker und Steckdosen reduzieren das Risiko eines Elektroschocks.

•Vermeiden Sie Körperkontakt mit geerdeten Gegenständen wie Rohrleitungen, Heizungen, Herden oder Kühlschränken. Bei Körperkontakt mit geerdeten Gegenständen besteht ein erhöhtes Stromschlagrisiko.

•Setzen Sie Elektrowerkzeuge niemals Regen oder sonstiger Feuchtigkeit aus. Wenn Wasser in ein Elektrowerkzeug eindringt, erhöht sich das Stromschlagrisiko.

•Verwenden Sie das Anschlusskabel nicht missbräuchlich. Verwenden Sie das Anschlusskabel niemals zum Tragen oder Heranziehen des Elektrowerkzeugs, und ziehen Sie den Stecker nicht am Anschlusskabel aus der Steckdose. Halten Sie das Kabel fern von Hitzequellen, Öl, scharfen Kanten und beweglichen Teilen. Beschädigte oder verdrehte Anschlusskabel erhöhen das Stromschlagrisiko.

•Wenn Sie ein Elektrowerkzeug im Freien benutzen, verwenden Sie ein für den

745 - 008 - 12.11.2018 |

27 |

Außeneinsatz geeignetes Verlängerungskabel.

Die Verwendung eines für den Außeneinsatz geeigneten Kabels verringert das Risiko eines Stromschlags.

•Falls der Einsatz eines Elektrowerkzeugs in einer feuchten Umgebung nicht zu vermeiden ist, benutzen Sie eine Stromversorgung mit Fehlerstrom-Schutzeinrichtung (RCD). Die Verwendung einer Fehlerstrom-Schutzeinrichtung (RCD) verringert das Risiko eines elektrischen Schlags

ACHTUNG: Die Maschine nicht mit dem Hochdruckreiniger waschen, da Wasser in das elektrische System oder den Motor eindringen und so Maschinenschäden oder einen Kurzschluss auslösen kann.

Persönliche Sicherheit

•Bleiben Sie aufmerksam, achten Sie auf das, was Sie tun, und setzen Sie gesunden Menschenverstand ein, wenn Sie mit Elektrowerkzeugen arbeiten. Benutzen Sie keine Elektrowerkzeuge, wenn Sie müde sind oder unter dem Einfluss von Drogen, Alkohol oder Medikamenten stehen. Bei der Arbeit mit Elektrowerkzeugen können bereits kurze Phasen der Unaufmerksamkeit zu schweren Verletzungen führen.

•Benutzen Sie eine persönliche Schutzausrüstung. Tragen Sie stets einen Augenschutz. Schutzausrüstung wie Atemschutzmaske, rutschsichere Sicherheitsschuhe, Schutzhelm und Gehörschutz senkt bei angemessenem Einsatz das Verletzungsrisiko.

•Vermeiden Sie ein versehentliches Starten. Achten Sie darauf, dass sich der Schalter in der Aus-Stellung befindet, bevor Sie das Elektrowerkzeug an die Stromversorgung und/ oder den Akku anschließen oder es hochheben oder herumtragen. Durch Herumtragen von Elektrowerkzeugen mit dem Finger am Schalter und das Einstecken des Steckers bei betätigtem Schalter steigt das Unfallrisiko stark an.

•Entfernen Sie sämtliche Einstellschlüssel, bevor Sie das Elektrowerkzeug einschalten. Ein an einem beweglichen Teil des Elektrowerkzeugs angebrachter Schlüssel kann zu Verletzungen führen.

•Sorgen Sie für einen festen Stand. Achten Sie jederzeit darauf, sicher zu stehen und das Gleichgewicht zu bewahren. Dadurch haben Sie das Elektrowerkzeug in unerwarteten Situationen besser im Griff.

•Kleiden Sie sich richtig. Tragen Sie niemals lose sitzende Kleidung oder Schmuck. Halten Sie Haar, Kleidung und Handschuhe von beweglichen Teilen fern. Lose Kleidung, Schmuck oder langes Haar kann von beweglichen Teilen erfasst werden.

•Wenn Anschlüsse für Staubabsaugund Staubsammelvorrichtungen vorhanden sind, sorgen Sie dafür, dass diese richtig angeschlossen und eingesetzt werden. Die Verwendung von Staubsammelvorrichtungen vermindert durch Staub verursachte Gefahren.

•Die Vibrationsemissionen während der tatsächlichen Verwendung des Elektrowerkzeugs können abhängig von der Verwendungsart des Werkzeugs vom angegebenen Gesamtwert abweichen. Bediener sollten Sicherheitsmaßnahmen für den eigenen Schutz ergreifen, die auf einer Beurteilung der Exposition unter tatsächlichen Nutzungsbedingungen beruht. Dabei sind alle Teile des Betriebszyklus zu berücksichtigen, z. B. abgesehen vom Gashebelbetrieb, die Zeiten, wenn das Werkzeug ausgeschaltet ist und wenn es im Leerlauf betrieben wird.

•Stets Abstand zur Trennscheibe halten, wenn der Motor läuft.

Verwendung und Pflege von Elektrowerkzeugen

•Überbeanspruchen Sie Elektrowerkzeuge nicht. Benutzen Sie das richtige Elektrowerkzeug für Ihren Einsatzzweck. Das richtige Elektrowerkzeug erledigt seine Arbeit bei bestimmungsgemäßem Einsatz besser und sicherer.

•Benutzen Sie das Elektrowerkzeug nicht, wenn es sich nicht am Schalter einund ausschalten lässt. Jedes Elektrowerkzeug, das nicht mit dem Schalter betätigt werden kann, stellt eine Gefahr dar und muss repariert werden.

•Trennen Sie das Elektrowerkzeug von der Stromversorgung bzw. vom Akku, bevor Sie Einstellarbeiten vornehmen, Zubehörteile austauschen oder das Elektrowerkzeug verstauen. Solche präventiven Sicherheitsmaßnahmen verhindern den unbeabsichtigten Start des Elektrowerkzeugs.

•Lagern Sie nicht benutzte Elektrowerkzeuge außerhalb der Reichweite von Kindern, und lassen Sie nicht zu, dass Personen das Elektrowerkzeug bedienen, die nicht mit dem Werkzeug selbst und/oder diesen Anweisungen vertraut sind. Elektrowerkzeuge stellen in ungeschulten Händen eine Gefahr dar.

•Halten Sie Elektrowerkzeuge in Stand. Prüfen Sie auf Fehlausrichtungen, sicheren Halt und Leichtgängigkeit beweglicher Teile, Beschädigungen von Teilen sowie auf jegliche andere Zustände, die sich auf den Betrieb des Elektrowerkzeugs auswirken können. Bei Beschädigungen lassen Sie das Elektrowerkzeug reparieren, bevor Sie es benutzen. Viele Unfälle mit Elektrowerkzeugen sind auf schlechte Wartung zurückzuführen.

•Halten Sie Schneidwerkzeuge scharf und sauber.

Ordnungsgemäß gewartete Schneidwerkzeuge mit

28 |

745 - 008 - 12.11.2018 |

scharfen Schneidkanten bleiben seltener hängen und sind einfacher zu bedienen.

•Benutzen Sie Elektrowerkzeuge, Zubehör, Werkzeugspitzen und Ähnliches in Übereinstimmung mit diesen Anweisungen und auf die für das jeweilige Elektrowerkzeug bestimmungsgemäße Weise, und beachten Sie dabei die jeweiligen Arbeitsbedingungen und die Art der auszuführenden Arbeiten. Der Einsatz eines Elektrowerkzeugs für Zwecke, die von den hier angegebenen abweichen, kann zu Gefahrensituationen führen.

•An der Bauweise des Geräts dürfen ohne vorherige Genehmigung des Herstellers keine Veränderungen vorgenommen werden.

Verwenden Sie stets Originalersatzteile. Unzulässige Änderungen und/oder Zubehör können zu schweren oder tödlichen Verletzungen des Benutzers oder anderer Personen führen.

•Stellen Sie außerdem sicher, dass weder unter dem Arbeitsbereich noch im Schneidegut Versorgungsleitungen verlegt sind.

•Überprüfen und markieren Sie immer den Verlauf von Gasleitungen. Schneiden in der Nähe von Gasleitungen bringt immer Gefahren mit sich. Stellen Sie sicher, dass beim Schneiden keine Funken fliegen, wenn Explosionsgefahr besteht. Bleiben Sie konzentriert und widmen Sie der Aufgabe Ihre ganze Aufmerksamkeit. Unachtsamkeit kann zu schweren Verletzungen bis hin zum Tod führen.

Verwendung und Pflege von akkubetriebenen Werkzeugen