Husqvarna K 4000 operation manual

Operator’s manual Manuel d’utilisation

Bedienungsanweisung Gebruiksaanwijzing

Istruzioni per l’uso

K 4000 Cut-n-Break

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine. Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie sich mit dem Inhalt vertraut,bevor Sie das Gerät GB FR DE NL IT benutzen.

Neem de gebruiksaanwijzing grondig door en gebruik de machine niet voor u alles duidelijk heeft begrepen.

Prima di usare la macchina,leggere per intero le istruzioni per l’uso e accertarsi di averne compreso il contenuto.

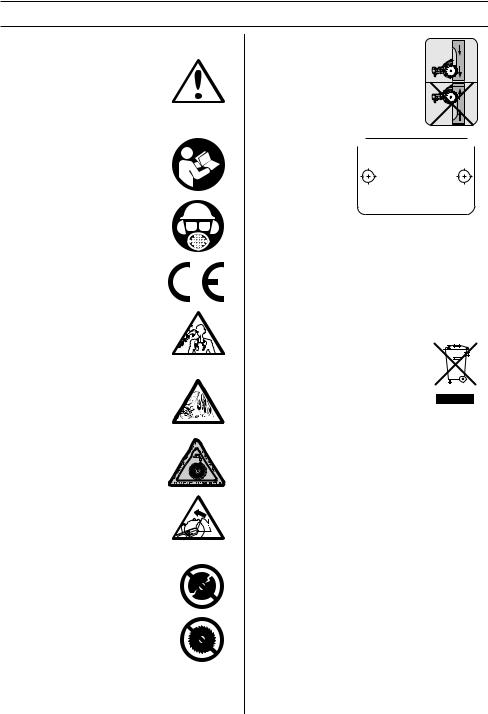

KEY TO SYMBOLS

Symbols on the machine:

WARNING! The machine can be a dangerous tool if used incorrectly or carelessly, which can cause serious or fatal injury to the operator or others.

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Wear personal protective equipment. See instructions under the ”Personal protective equipment” heading.

This product is in accordance with applicable EC directives.

WARNING! Dust forms when cutting, which can cause injuries if inhaled. Use an approved breathing mask. Always provide for good ventilation.

WARNING! Sparks from the cutting blade can cause fire in combustible materials such as: petrol (gas), wood, dry grass etc.

Water cooling must always be used.

WARNING! Kickbacks can be sudden, rapid and violent and can cause life threatening injuries. Read and understand the instructions in the manual before using the machine.

WARNING! Ensure the blades are not cracked or damaged in any other way.

WARNING! Do not use circular saw blades

Always cut in the correct direction. See safety instructions!

Rating plate

Row 1: Brand, Model (X,Y)

Row 2: Serial No. with manufacturing date (Y, W, X): Year, Week, Sequence No.

Row 3: Product No.

(X)

Row 4: Manufacturer

XXXXXXXXX YYYY

XXXXXXXXX YYYY  s / n YYYY WWXXXXX

s / n YYYY WWXXXXX

XXX XX XX-XX

Husqvarna AB

AAAAAA BBBBB CC

DDDD EEEE FFFF

XXXXXXXXXXXXXXX

Row 5: A: Max speed of output shaft, B: Cutting blade diameter, C: Blade bolt diameter

Row 6: D: Input voltage, E: Input current, F: Input frequency

Row 7: Country of origin

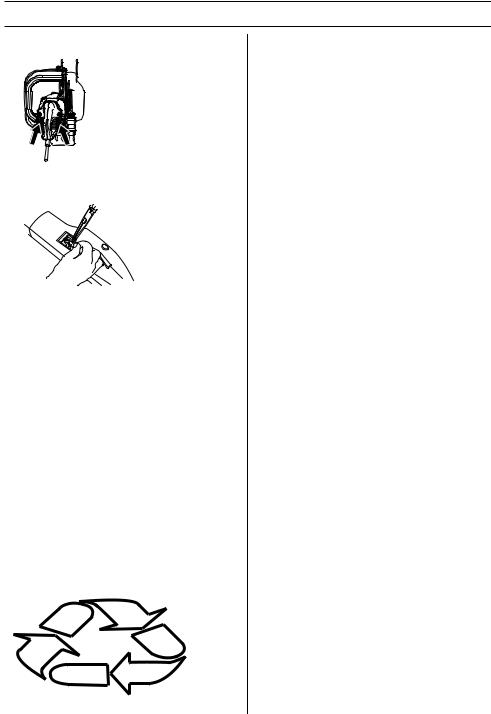

Environmental marking. Symbols on the product or its packaging indicate that this product cannot be handled as domestic waste. It must instead be submitted to an appropriate recycling station for the recovery of electrical and electronic equipment.

By ensuring that this product is taken care of correctly, you can help to counteract the potential negative impact on the environment and people that can otherwise result through the incorrect waste management of this product.

For more detailed information about recycling this product, contact your municipality, your domestic waste service or the shop from where you purchased the product.

Other symbols/decals on the machine refer to special certification requirements for certain markets.

2 – English

KEY TO SYMBOLS

Explanation of warning levels

The warnings are graded in three levels.

WARNING!

! |

WARNING! Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

CAUTION!

! |

CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE!

NOTICE! Is used to address practices not related to personal injury.

English – 3

CONTENTS

Contents |

|

KEY TO SYMBOLS |

|

Symbols on the machine: ...................................... |

2 |

Explanation of warning levels ............................... |

3 |

CONTENTS |

|

Contents ............................................................... |

4 |

PRESENTATION |

|

Dear Customer, ..................................................... |

5 |

WHAT IS WHAT? |

|

What is what on the power cutter? ....................... |

6 |

MACHINE´S SAFETY EQUIPMENT |

|

General ................................................................. |

7 |

CUTTING BLADES |

|

General ................................................................. |

9 |

Diamond blades for different materials ................. |

9 |

Water cooling ........................................................ |

9 |

Sharpening diamond blades ................................. |

9 |

Transport and storage ........................................... |

9 |

ASSEMBLY |

|

Assembly .............................................................. |

10 |

OPERATING |

|

Protective equipment ............................................ |

11 |

General safety warnings ....................................... |

11 |

Basic working techniques ..................................... |

14 |

STARTING AND STOPPING |

|

Before starting ...................................................... |

17 |

Starting ................................................................. |

17 |

Stopping ................................................................ |

17 |

MAINTENANCE |

|

General ................................................................. |

18 |

Maintenance schedule .......................................... |

18 |

Cleaning ................................................................ |

19 |

Functional inspection ............................................ |

19 |

Replacing the carbon brushes .............................. |

20 |

Water tap .............................................................. |

21 |

Disposal, scrapping .............................................. |

21 |

TECHNICAL DATA |

|

Technical data ....................................................... |

22 |

Cutting equipment ................................................. |

22 |

Recommended cable dimensions ......................... |

22 |

EC Declaration of Conformity ............................... |

23 |

4 – English

PRESENTATION

Dear Customer,

Thank you for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. A purchase of one of our products gives you access to professional help with repairs and services. If the retailer who sells your machine is not one of our authorized dealers, ask him for the address of your nearest service workshop.

This operator’s manual is a valuable document. Make sure it is always at hand at the work place. By following its content (operating, service, maintenance etc.) the life span and the second-hand value of the machine can be extended. If you will sell this machine, make sure that the buyer will get the operator´s manual.

More than 300 years of innovation

Husqvarna AB is a Swedish company based on a tradition that dates back to 1689, when the Swedish King Karl XI ordered the construction of a factory for production of muskets. At that time, the foundation was already laid for the engineering skills behind the development of some of the world's leading products in areas such as hunting weapons, bicycles, motorcycles, domestic appliances, sewing machines and outdoor products.

Husqvarna is the global leader in outdoor power products for forestry, park maintenance and lawn and garden care, as well as cutting equipment and diamond tools for the construction and stone industries.

User responsibility

It is the owner’s/employer’s responsibility that the operator has sufficient knowledge about how to use the machine safely. Supervisors and operators must have read and understood the Operator’s Manual. They must be aware of:

•The machine’s safety instructions.

•The machine’s range of applications and limitations.

•How the machine is to be used and maintained.

National legislation could regulate the use of this machine. Find out what legislation is applicable in the place where you work before you start using the machine.

The manufacturer’s reservation

All information and all data in the Operator’s Manual were applicable at the time the Operator’s Manual was sent to print.

Husqvarna AB has a policy of continuous product development and therefore reserves the right to modify the design and appearance of products without prior notice.

English – 5

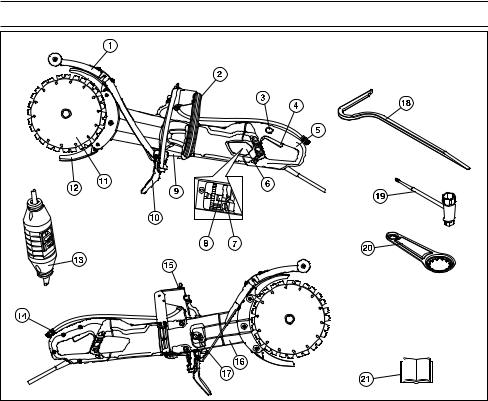

WHAT IS WHAT?

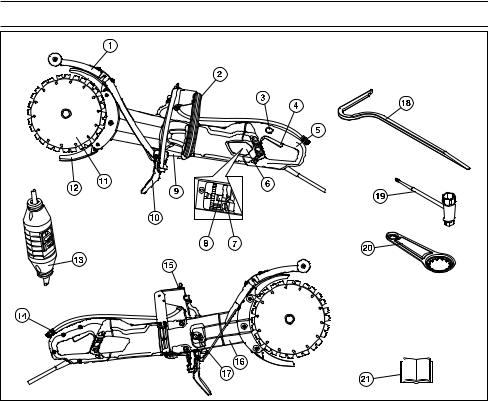

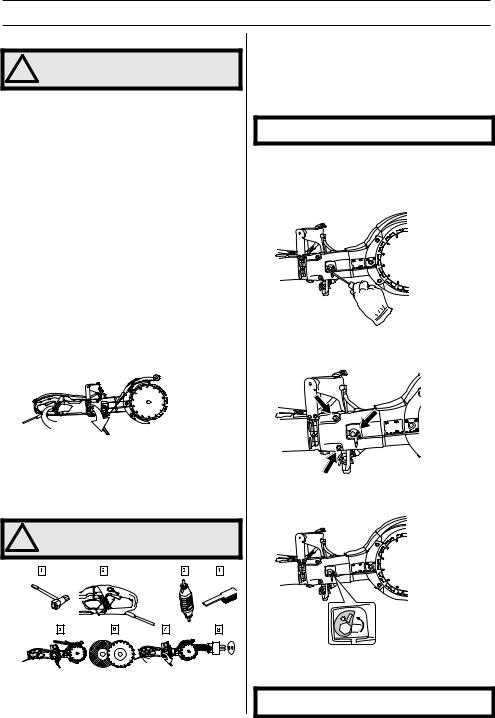

What is what on the power cutter?

1 |

Splash guard |

12 |

Blade guards |

2 |

Front handle |

13 |

Residual-current device (not for UK and Ireland 110V) |

3 |

Power switch lock |

14 |

Water connector |

4 |

Power switch |

15 |

Water tap |

5 |

Rear handle |

16 |

Cutting arm |

6 |

Inspection cover |

17 |

Belt tensioner |

7 |

Carbon brushes |

18 |

Breaking tool |

8 |

Brush retainer |

19 |

Combination spanner |

9 |

Rating plate |

20 |

Bearing tool |

10 |

Spray guard |

21 |

Operator′s manual |

11 |

Blades |

|

|

6 – English

MACHINE´S SAFETY EQUIPMENT

General

This section describes the machine′s safety equipment, its purpose, and how checks and maintenance should be carried out to ensure that it operates correctly. See the ”What is what?” section to locate where this equipment is positioned on your machine.

! |

WARNING! Never use a machine that has |

faulty safety equipment! Carry out the |

|

|

inspection, maintenance and service |

|

routines listed in this section. |

All servicing and repair work on the machine requires special training.This is especially true of the machine′s safety equipment. If your machine fails any of the checks described below you must contact your service agent. When you buy any of our products we guarantee the availability of professional repairs and service. If the retailer who sells your machine is not a servicing dealer, ask him for the address of your nearest service agent.

Power switch

The power switch should be used to start and stop the machine.

Checking the power switch

•Start the machine, release the power switch and check that the engine and the cutting blade stop.

•A defective power switch should be replaced by an authorized service workshop.

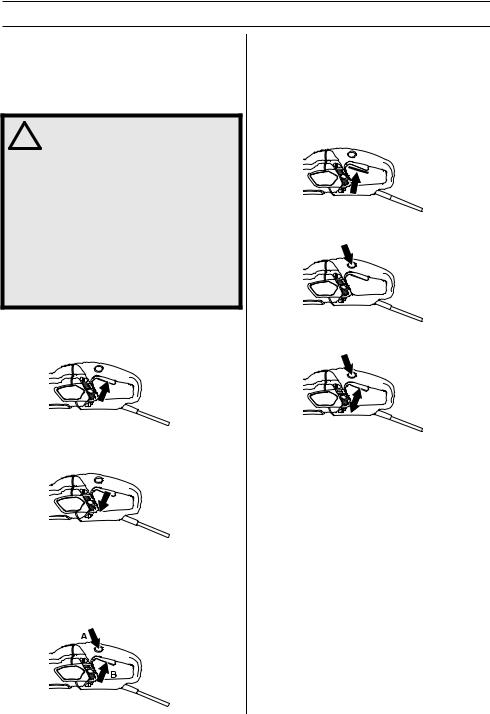

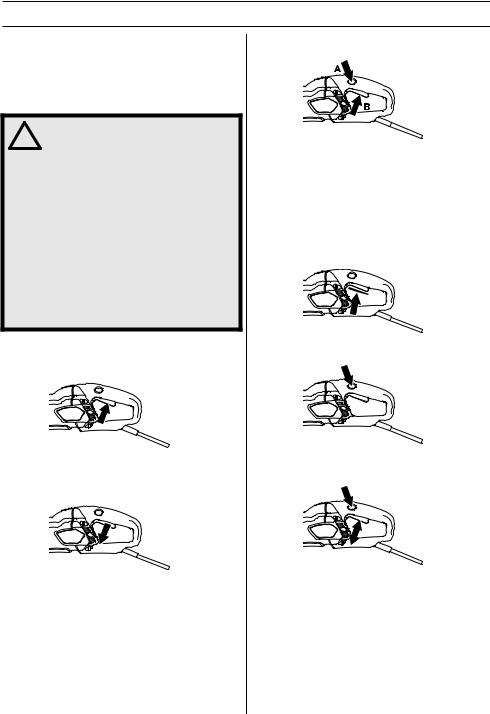

Power switch lock

The power switch lock is designed to prevent accidental operation of the switch. When the lock (A) is pressed in the power switch (B) is released.

The power switch lock remains depressed as long as the power switch is depressed. When the grip on the handle is released both the power switch and power switch lock are reset. This movement is controlled by two independent return springs. This position results in the machine stopping and the power switch being locked.

Checking the power switch lock

•Make sure the power switch is locked when the power switch lock is in its original position.

•Press in the power switch lock and make sure it returns to its original position when you release it.

•Check that the power switch and power switch lock move freely and that the return springs work properly.

•Switch on the machine, release the switch, and check that the engine and blades stop.

Gradual start and overload protection

The machine is equipped with electronically controlled gradual start and overload protection.

The engine starts to pulsate if the machine is loaded above a specific level. If the load is reduced the engine reverts to its normal state and cutting can resume.

The electronics will cut the current after a set time if the machine continues to be run with a pulsating engine. The higher load the faster the shutoff.

The electronics cut the current immediately if the blade jams.

English – 7

MACHINE´S SAFETY EQUIPMENT

Blade guards

This guard is fitted above and below the cutting blade and is designed to prevent parts of the blade or cutting fragments from being thrown towards the user.

Checking the blade guards

WARNING! Always check that all guards ! are correctly fitted before starting the

machine. Check that the cutting blade is fitted correctly and does not show signs of damage. A damaged cutting blade can cause personal injury. See instructions under the heading Assembly.

• Check that the guard is complete and without any cracks or deformations.

• Never use a defective guard or a guard that has not been fitted correctly.

Spray guard

The spray guard provides protection against ejected debris, thrown water and concrete slurry.

Checking the spray guard

Ensure there are no cracks or holes from slurry blasting in the spray guard. Replace guard if damaged.

Residual-current device

(not for UK and Ireland 110V)

Ground fault circuit interrupters are for protection in case an electrical fault should occur.

The LED indicates that the ground fault circuit interrupter is on and that the machine can be switched on. If the LED is not on, push the RESET button (green).

Check the residual-current device

•Connect the machine to the socket. Push the RESET button (green) and the red LED lights up.

•Start the machine.

•Push the TEST button (blue).

•The ground fault circuit interrupter should trip and the machine switch off instantly. If not, contact your dealer.

•Reset with the RESET button (green).

8 – English

CUTTING BLADES

General |

||

! |

WARNING! A cutting blade may burst and |

|

cause injury to the operator. |

||

|

||

A cutting blade should be checked before it is assembled on the saw and frequently during use. Look for cracks, lost segments (diamond blades) or pieces broken off. Do not use a damaged cutting blade.

Test the integrity of each new cutting blade by running it at full throttle for about 1 minute.

Only use original cutting blades designed by Husqvarna for use on this machine.

Husqvarna issues warnings and recommendations for the use and proper care of the cutting blades.Those warnings come with the cutting blades. Read and follow all instructions from Husqvarna.

•This machine is only to be used with Husqvarna´s specially developed diamond blades intended for Cut- n-Break. The blades have an integrated belt pulley and are approved for freehand cutting.

•Diamond blades consist of a steel core provided with segments that contain industrial diamonds.

•Always use a sharp diamond blade.

•Ensure the blades are not cracked or damaged in any other way. Replace blades if necessary.

Diamond blades for different materials

! |

WARNING! Never use a cutting blade for |

any other materials than what it was |

|

|

intended to cut. |

Never use a diamond blade to cut plastic material.The heat produced during cutting may melt the plastic and it can stick to the cutting blade and cause a kickback.

Cutting metal generates sparks that may cause fire. Do not use the machine near ignitable substances or gases.

•Diamond blades are ideal for masonry and reinforced concrete. Ask your dealer for help in choosing the right product.

•Diamond blades are available in several hardness classes. A "soft" diamond blade has a relatively short service life and large cutting capacity. It is used for

hard materials such as granite and hard concrete. A "hard" diamond blade has a longer service life and reduced cutting capacity, and should be used for soft materials such as brick and asphalt.

Water cooling

! |

WARNING! Cool diamond blades |

|

designed for wet cutting continuously |

||

|

||

|

with water to prevent heating, which can |

|

|

deform the diamond blade resulting in |

|

|

damage to the machine and personal |

|

|

injury. |

•Water cooling must always be used.

•Using wet cutting blades without water can cause excessive heat build-up, resulting in poor performance, severe blade damage and is a safety hazard.

•Water cools the blade and increases its service life while also reducing the formation of dust.

Sharpening diamond blades

Diamond blades can become dull when the wrong feeding pressure is used or when cutting certain materials such as heavily reinforced concrete. Working with a dull diamond blade causes overheating, which can result in the diamond segments coming loose.

Sharpen the blades by cutting a soft material such as sandstone or brick.

Transport and storage

•Make sure the machine is secured and that the cutting blades are properly protected during the transport and storage of the machine.

•Before use inspect all blades for transport or storage damage.

English – 9

ASSEMBLY

Assembly |

||

! |

WARNING! Always pull out the plug from |

|

the outlet socket before cleaning, |

||

|

||

|

maintenance or assembly. |

|

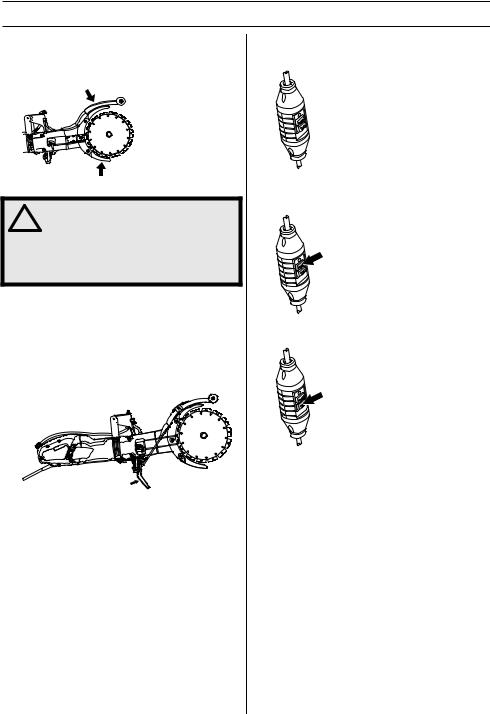

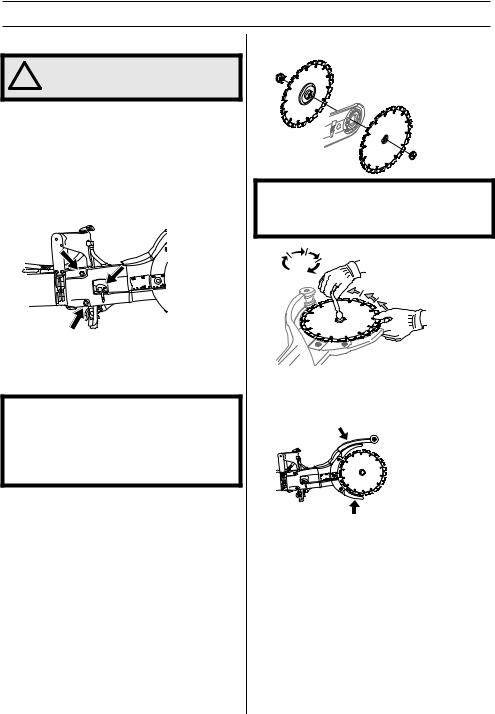

Assembling the blades

•Husqvarna blades are especially manufactured and approved for freehand cutting with the K 3000 Cut-n- Break. The blades have integrated belt pulley halves and are to be changed in pairs.

•Loosen the nuts and clamping bolt which release the bar. This will position the drive belt in a more favourable position with regard to assembling the new blades. The drive belt is not clamped so easily.

•Dismantle the old blades by loosening the centre nut. Check the drive belt for wear when the blades are dismantled. When changing the drive belt see the instructions under the heading ”Replacing the drive belt”.

NOTICE! It is very important that the blades rotate when the nut is tightened. This is to ensure that the belt is not clamped between the integrated drive belt halves on the blades when the blades/drive belt are pulled together with the nut. Ideally this is done alternately, i.e. tighten a little, rotate a little and repeat until the blades are secured.

•Position the blades on each side of the cutting arm. Make sure that the holes for both guide pins in the drive belt halves are aligned so that they correspond with the holes in the washer, and the nut too. Now fit the bolt and washer unit with guide pins. Tightening

torque for the bolt holding the blade is: 15 Nm (130 in.lb).

NOTICE! Do not forget to tighten the belt and check the belt adjustment before cutting. See the instructions under the heading ”Inspecting and adjusting the drive belt”.

Protection for the blades

•The guards should always be fitted on the machine. Check that the guards are properly secured and work before starting to cut.

10 – English

OPERATING

Protective equipment

General

Do not use the machine unless you are able to call for help in the event of an accident.

Personal protective equipment

You must use approved personal protective equipment whenever you use the machine. Personal protective equipment cannot eliminate the risk of injury but it will reduce the degree of injury if an accident does happen. Ask your dealer for help in choosing the right equipment.

! |

WARNING! The use of products such as |

|

cutters, grinders, drills, saws that sand |

||

|

||

|

or form material can generate dust and |

|

|

vapours which may contain hazardous |

|

|

chemicals. Check the nature of the |

|

|

material you intend to process and use |

|

|

an appropriate breathing mask. |

Long-term exposure to noise can result in permanent hearing impairment. Always use approved hearing protection. Listen out for warning signals or shouts when you are wearing hearing protection. Always remove your hearing protection as soon as the motor stops.

Always wear:

•Approved protecting helmet.

•Hearing protection.

•Approved eye protection. If you use a face shield then you must also wear approved protective goggles. Approved protective goggles must comply with standard ANSI Z87.1 in the USA or EN 166 in EU countries. Visors must comply with standard EN 1731.

•Approved respiratory protection.

•Protective gloves.

•Heavy-duty, firm grip gloves.

•Tight-fitting, heavy-duty and comfortable clothing that permits full freedom of movement. Cutting generates sparks that can ignite clothing. Husqvarna recommends that you wear flame-retardant cotton or heavy denim. Do not wear clothing made of material such as nylon, polyester or rayon. If ignited such material can melt and cling to the skin. Do not wear shorts

•Boots with steel toe-caps and non-slip sole.

Other protective equipment |

|

! |

CAUTION! Sparks may appear and start a |

fire when you work with the machine. |

|

|

Always keep fire fighting equipment |

|

handy. |

•Fire Extinguisher

•First aid kit

General safety warnings

This section describes basic safety directions for using the machine. This information is never a substitute for professional skills and experience. If you get into a situation where you feel unsafe, stop and seek expert advice. Contact your dealer, service agent or an experienced user. Do not attempt any task that you feel unsure of!

•Please read the operator’s manual carefully and make sure you understand the instructions before using the machine. It is recommended that first time operators also obtain practical instruction before using the machine.

•Keep in mind that it is you, the operator that is responsible for not exposing people or their property to accidents or hazards.

•The machine must be kept clean. Signs and stickers must be fully legible.

! |

WARNING! Read all safety warnings and |

|

all instructions. Failure to follow the |

||

|

||

|

warnings and instructions may result in |

|

|

electric shock, fire and/or serious injury. |

Save all warnings and instructions for future reference.

The term ”power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

•Keep work area clean and well lit. Cluttered or dark areas invite accidents.

•Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

•Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

•Do not use the machine in bad weather, such as dense fog, rain, strong wind, intense cold, etc. Working in bad weather is tiring and can lead to dangerous conditions, e.g. slippery surfaces.

•Never start to work with the machine before the working area is clear and you have a firm foothold. Look out for any obstacles with unexpected

English – 11

OPERATING

movement. Ensure when cutting that no material can become loose and fall, causing injury to the operator.Take great care when working on sloping ground.

WARNING! The safety distance for the

!power cutter is 15 metres (50 foot). You are responsible to ensure that animals and onlookers are not within the working area. Do not start cutting until the working area is clear and you are standing firmly.

Electrical safety

•Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

•Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

•Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

•Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

•When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

•If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected device. Use of an RCD reduces the risk of electric shock.

•Check that the cord and extension cord are intact and in good condition. Never use the machine if the cord is damaged, hand it in to an authorized service workshop for repair. An undersized cable means a risk of reduced machine capacity and overheating.

•The machine should be connected to an earthed outlet socket. Check that the mains voltage corresponds with that stated on the rating plate on the machine.

•Ensure the cord is behind you when you start to use the machine so that the cord will not be damaged.

WARNING! Do not pressure wash the ! machine, as water can enter the

electrical system or the engine and cause damage to the machine or short circuit.

|

! |

WARNING! The machine (United |

|

Kingdom 110V) is not equipped with a |

|

|

|

|

|

|

ground fault circuit interrupter. The |

|

|

machine must always be used with an |

|

|

isolating transformer for protection in |

|

|

case an electrical fault should occur. |

|

|

|

Personal safety

•Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

•Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

•Prevent unintentional starting. Ensure the switch is in the OFF-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

•Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

•Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

•Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

•If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

•Remain at a distance from the blades when the engine is running.

WARNING! Overexposure to vibration ! can lead to circulatory damage or nerve

damage in people who have impaired circulation. Contact your doctor if you experience symptoms of overexposure to vibration. These symptoms include numbness, loss of feeling, tingling, pricking, pain, loss of strength, changes in skin colour or condition. These symptoms normally appear in the fingers, hands or wrists.

12 – English

OPERATING

Power tool use and care

•Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

•The machine is only designed for cutting hard materials, such as concrete, brick, masonry as well as cast iron and cement pipes.

! |

WARNING! A power cutter is a |

|

dangerous tool if used carelessly or |

||

|

||

|

incorrectly and can cause serious, even |

|

|

fatal injuries. It is extremely important |

|

|

that you read and understand the |

|

|

contents of this Operator’s Manual. |

•Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

•Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

•Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

•Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

•Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool´s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

•Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

•Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

! |

WARNING! Under no circumstances may |

|

the design of the machine be modified |

||

|

||

|

without the permission of the |

|

|

manufacturer. Always use original |

|

|

accessories. Non-authorized |

|

|

modifications and/or accessories can |

|

|

result in serious personal injury or the |

|

|

death of the operator or others. |

•Make sure that no pipes or electrical cables are routed in the working area or in the material to be cut.

•Always check and mark out where gas pipes are routed. Cutting close to gas pipes always entails danger. Make sure that sparks are not caused when cutting in view of the risk of explosion. Remain concentrated and focused on the task. Carelessness can result in serious personal injury or death.

•Inspect new blades for transport or storage damage.

•The guard for the cutting equipment must always be on when the machine is running.

Service

•Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Always use common sense

It is not possible to cover every conceivable situation you can face. Always exercise care and use your common sense. If you get into a situation where you feel unsafe, stop and seek expert advice. Contact your dealer, service agent or an experienced user. Do not attempt any task that you feel unsure of!

! |

WARNING! The machine can be a |

|

dangerous tool if used incorrectly or |

||

|

||

|

carelessly, which can cause serious or |

|

|

fatal injury to the operator or others. |

Never allow children or other persons not trained in the use of the machine to use or service it.

Never allow anyone else to use the machine without first ensuring that they have read and understood the contents of the operator’s manual.

Never use a machine that is faulty. Carry out the safety checks, maintenance and service instructions described in this manual. Some maintenance and service measures must be carried out by trained and qualified specialists. See instructions under the Maintenance heading.

English – 13

OPERATING

Basic working techniques

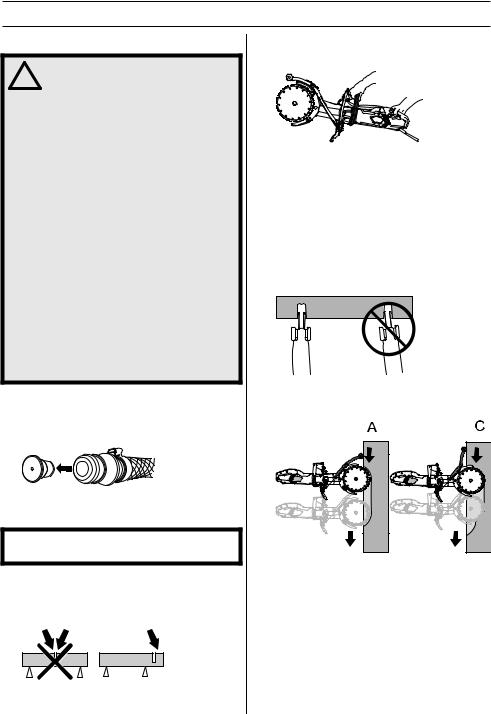

! |

WARNING! This section describes basic |

|

safety directions for using a power |

||

|

||

|

cutter. This information is never a |

|

|

substitute for professional skills and |

|

|

experience. If you get into a situation |

|

|

where you feel unsafe, stop and seek |

|

|

expert advice. Contact your dealer, |

|

|

service agent or an experienced power |

|

|

cutter user. Do not attempt any task that |

|

|

you feel unsure of! |

Do not pull the power cutter to one side, this can cause the blade to jam or break resulting in injury to people.

Under all circumstances avoid grinding using the side of the blade; it will almost certainly be damaged, break and can cause immense damage. Only use the cutting section.

Cutting plastics with a diamond blade can cause kickback when the material melts due to the heat produced when cutting and sticks to the blade. Never cut plastic materials with a diamond blade!

Cutting metal generates sparks that may cause fire. Do not use the machine near ignitable substances or gases.

Water cooling

Water cooling must always be used. Dry cutting causes immediate overheating and machine and cutting blade failure with a risk of personal injury.

At a low water pressure, for example when the water tank is used, the restrictor can be dismantled to give the correct water flow.

NOTICE! It is important not to use a too high water flow without throttling as the belt can then slip.

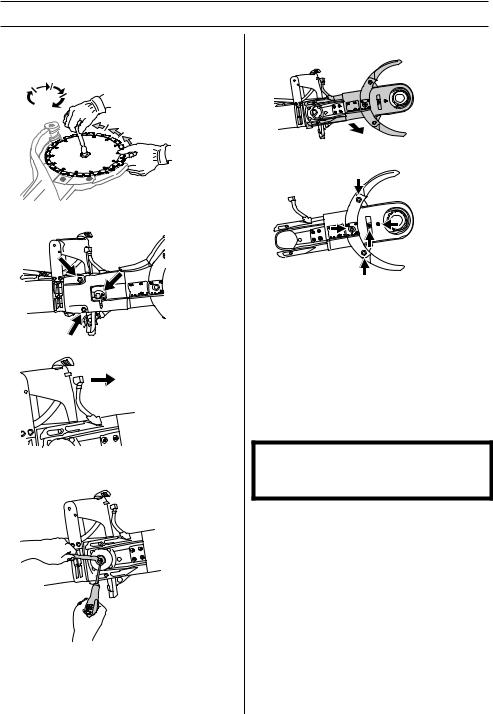

Cutting technique

•Support the work piece in such a way that it is possible to predict what will happen, and so that the cut remains open while cutting.

•Always hold the machine in a firm grip with both hands. Hold it so that the thumbs and fingers grip round the handles.

•Check that the blade is not in contact with anything when the machine is started

•Start cutting with the machine running at maximum speed.

•Start cutting smoothly, allowing the machine to work without forcing or pressing in the blade. Always cut at maximum speed.

•Cut in the same direction when cutting into an existing cut. Avoid cutting at an angle to the previous cut, otherwise there is a risk of the blade jamming or that the machine can ”climb in the cut” and cause a kickback.

•Always cut from top to bottom (A).

•Remove the cutter and use a crowbar to remove the material that remains between the cut (B).

14 – English

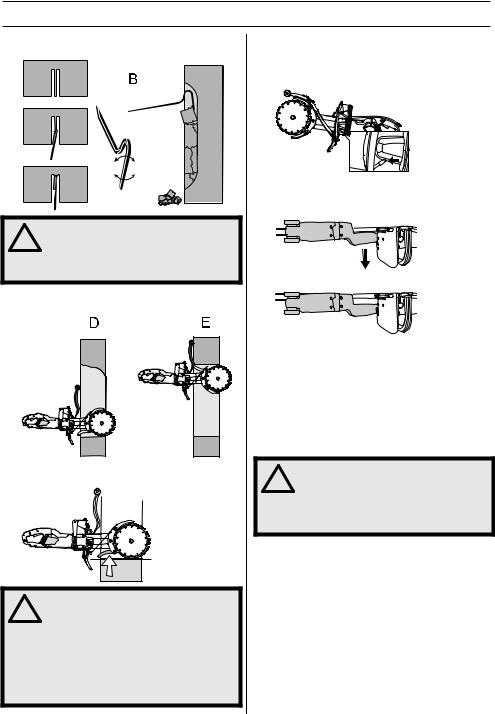

OPERATING

•Follow the same saw cut, but further in the work piece (C), and repeat the work with the crowbar.

! |

WARNING! When cutting vertically, |

|

always cut from the top of the cut and |

||

|

||

|

down. Never cut from the bottom of the |

|

|

cut and up. This can cause a kickback |

|

|

and result in personal injury. |

•Repeat this working method until the required cutting depth is achieved (D, E).

•The blade guards are designed to easily adapt to how deep in the work piece the power cutter is moved.

! |

WARNING! Under all circumstances |

|

avoid grinding using the side of the |

||

|

||

|

blade; it will almost certainly be |

|

|

damaged or break and can cause |

|

|

immense damage. Only use the cutting |

|

|

section. |

Do not pull the power cutter to one side, this can cause the blade to jam or break resulting in injury to people.

Smooth cutting

To enable smooth cutting, the splash guard must be adjusted.

•Release the latch.

•Slide the splash guard sideways.

•Lock the latch.

Kickback

Kickback is a sudden, rearward motion of the saw that can occur if the blades are stalled (pinched, jammed, twisted) in the so called kickback zone. Most kickbacks are small and felt as small ”jerks” in the front handle. However, kickback can be very powerful. If you are not paying attention or have a poor grip the saw can be thrown all the way back at you.

! |

WARNING! Kickback can be very sudden |

|

and viloent, throwing the saw back at |

||

|

||

|

you. It can cause serious or even fatal |

|

|

injuries. It is vital you understand what |

|

|

causes kickback and how to aviod it |

|

|

using proper cutting techique. |

English – 15

OPERATING

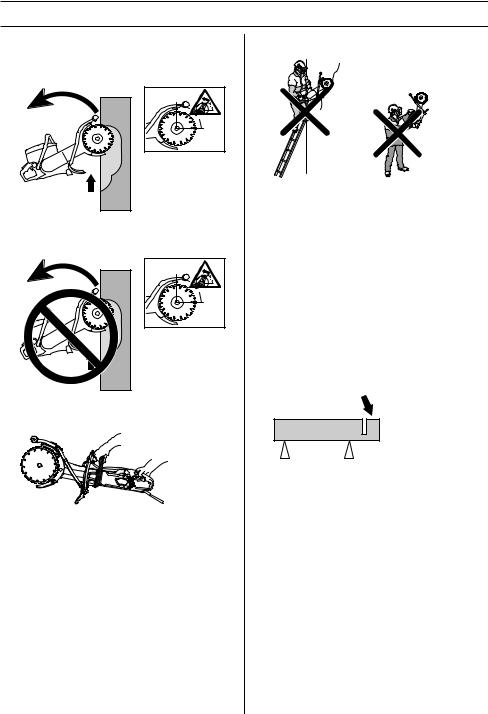

Cause of kickback

Kickback is caused if you are cutting with the kickback zone of the blade for example when cutting ”upwards” or towards you.

General rules

•Never cut upwards or towards you so that the kickback zone becomes actively cutting.

•Always hold the machine in a firm grip with both hands. Hold it so that the thumbs and fingers grip round the handles.

•Keep a good balance and a firm foothold.

•When cutting vertically, always cut from the top of the cut and down.

•Always cut at maximum speed.

•Do not cut with the upper quadrant (kickback zone) of the blade. Avoid twisting or pushing the blades sideways in the cut. This can cause kickback.

•Take care when inserting the blade in an existing cut. Make certain that the cut is wide enough and that the blades are not angled in the cut. This can cause kickback.

•Stand at a comfortable distance from the work piece.

•Never cut above shoulder height.

•Never cut from a ladder. Use a platform or scaffold if the cut is above shoulder height.

•Be alert to movement of the work piece or anything else that can occur, which could cause the cut to close and pinch the blade.

Pull in

Pull in occurs when the blades’ lower sections suddenly stop or when the cut closes. (To avoid, see the instructions under the heading ”General rules” and ”Pinching/rotation”, here below.).

Pinching/rotation

If the cut is pressed together this can lead to jamming. The machine can be pulled down suddenly with a very powerful jerk.

How to avoid pinching

Support the work piece in such a way that the cut remains open during the cutting operation and when the cut is finished.

Check the engine speed

Use a revolution counter regularly to check the engine speed at the working temperature, at full throttle and without a load.

16 – English

STARTING AND STOPPING

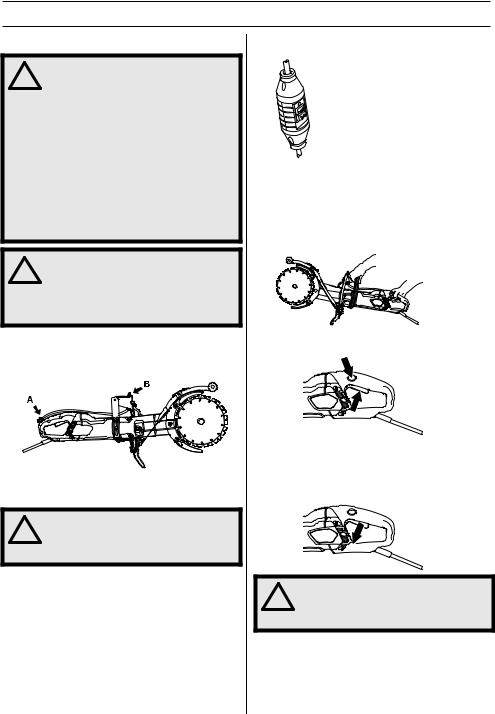

Before starting

WARNING! Note the following before ! starting:

The machine should be connected to an earthed outlet socket.

Check that the mains voltage corresponds with that stated on the rating plate on the machine.

Make sure you have a secure footing and that the cutting blade cannot touch anything.

Keep people and animals well away from the working area.

! |

WARNING! The machine (UK and Ireland |

110V) is not equipped with a ground fault |

|

|

circuit interrupter. The machine must |

|

always be used with an isolating |

|

transformer for protection in case an |

|

electrical fault should occur. |

Water connector

•Connect the water hose to the water supply (A). The water flow is regulated using the water tap (B).

Residual-current device |

||

(not for UK and Ireland 110V) |

||

! |

WARNING! Never use the tool without the |

|

ground fault circuit interrupter delivered |

||

|

||

|

with the tool. Carelessness can result in |

|

|

serious personal injury or even death. |

|

•Make sure the ground fault circuit interrupter is switched on. The LED indicates that the ground fault circuit interrupter is on and that the machine can be

switched on. If the LED is not on, push the RESET button (green).

•Check the ground fault circuit interrupter. See instructions under the heading Checking, maintaining and servicing the machine’s safety equipment.

Starting

•Grip the front handle with the left hand.

•Grip the rear handle with your right hand.

•Press in the power switch lock with your right-hand thumb and press in the power switch.

•Run the machine unloaded and in a safe manner for at least 30 seconds.

Stopping

•Stop the motor by releasing the power switch.

! |

WARNING! Make sure that the cutting |

|

blade can rotate freely until it completely |

||

|

||

|

stops. Carelessness can cause serious |

|

|

personal injury. |

English – 17

MAINTENANCE

General

! |

WARNING! The user must only carry out the maintenance and service work described in this Operator's Manual. More extensive work must be carried out by an authorized service workshop.

Inspection and/or maintenance should be carried out with the motor switched off and the plug disconnected.

Wear personal protective equipment. See instructions under the ”Personal protective equipment” heading.

The life span or the runtime of the machine can be reduced and the risk of accidents can increase if machine maintenance is not carried out correctly and if service and/or repairs are not carried out professionally. If you need further information please contact your nearest service workshop.

Maintenance schedule

In the maintenance schedule you can see which parts of your machine that require maintenance, and with which intervals it should take place. The intervals are calculated based on daily use of the machine, and may differ depending on the rate of usage.

|

Daily maintenance |

Weekly maintenance/40 hours |

Monthly maintenance |

|

|

|

|

Cleaning |

Clean the machine. |

|

|

|

|

|

|

Cooling air intake |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

General inspection |

Carbon brushes |

Drive wheel |

|

|

|

|

|

Water system |

Drive belt |

|

|

|

|

|

Functional inspection |

Power switch* |

|

|

|

|

|

|

Power switch lock* |

|

|

|

|

|

|

|

|

|

|

|

|

Blade guard* |

|

|

|

|

|

|

|

Cutting blade** |

|

|

|

|

|

|

18 – English

MAINTENANCE

Cleaning |

|

! |

WARNING! Do not use a high pressure |

washer when rinsing the inside of the |

|

|

machine. |

The machine can withstand taking in damp air and splashes during the cutting process. Clean water does not affect the machine’s function.

When cutting materials such as concrete or brick, which can contain salt, you must rinse the machine after the work is finished. The cleaning reduces the risk for accretions building up inside the engine, which can cause leakage current between electric components, which in turn can cause the ground fault circuit interrupter to turn off without intention.

•Clean the machine daily by rinsing it with clean water after the work is finished.

•Place the machine with the rear handle facing upwards. Rinse the air intakes at the rear handle with clean water.The water will run out through the front air outlets.

•Connect the plug and run the engine dry for approx. 30 sec in order to speed up the drying of the engine.

Cooling system

•The machine is equipped with an efficient fan to cool the motor. Cooling air which is drawn in through the grille by the machines rear handle passes over the stator and rotor and out through the front of the motor housing.

•In order for the machine to always be cooled sufficiently the cooling air openings must be kept clear and clean. Blow down the machine regularly with compressed air.

Functional inspection

General inspection

! |

WARNING! Never use damaged cables. |

|

They can cause serious, even fatal, |

||

|

||

|

personal injuries. |

1Check that nuts and screws are tightened.

2Check that the power switch unit works smoothly.

3Check the residual-current device

4Clean the outside of the machine.

5Checking the blade guard

6Check the condition of the cutting blade.

7Check and clean the cooling air openings.

8Check that the cord and extension cord are intact and in good condition. Never use the machine if the cord is damaged, hand it in to an authorized service workshop for repair.

Drive belt

NOTICE! The drive belt is fully enclosed and well-protected from dust, dirt and mechanical damage when cutting.

Tensioning the drive belt

•Check the tension of the drive belt. Stick a screwdriver in the notch.

•A correctly adjusted drive belt should have about 5 mm of movement.

•Tighten the drive belt.

•Loosen the two nuts.

•Loosen the clamping bolt.

•Turn the eccentric plate anti-clockwise with a screwdriver or a torx driver.This tightens the drive belt by pushing the bar forwards.

•Tighten the nuts.

•Screw the bolt tight. Hold still the eccentric plate so that it doesn’t move along when you tighten the screws.

NOTICE! A new drive belt shall be tightened once after 30-60 minutes operation.

English – 19

MAINTENANCE

Replacing the drive belt

•Release the belt tension.

•Remove the blades.

•Remove the belt cover by loosening the nuts, the clamping bolt and the eccentric cam.

•Loosen water hose.

•Loosen the drive gear. Use a spanner as a counterhold. (The combination spanner or bearing tool can be used as a counterhold.)

•Remove the cutting arm by pulling it straight out from the machine.

•Loosen the five screws holding the guards on the cutting arm.

•Remove the old drive belt and put in a new one.

•Refit the guards on the cutting arm.

•Fit the cutting arm on the machine while fastening the drive wheel.

•Replace the water hose.

•Refit the belt cover, the nuts, the clamping bolt and the eccentric cam.

•Refit the blades and tighten the nut. See instructions under Heading ”Assembling the blades”.

•Tighten the drive belt and the nuts and bolt. See the instructions under the heading ”Inspecting and adjusting the drive belt”.

IMPORTANT! Do not forget to tighten the belt and check the belt adjustment before cutting. See the instructions under the heading ”Inspecting and adjusting the drive belt”.

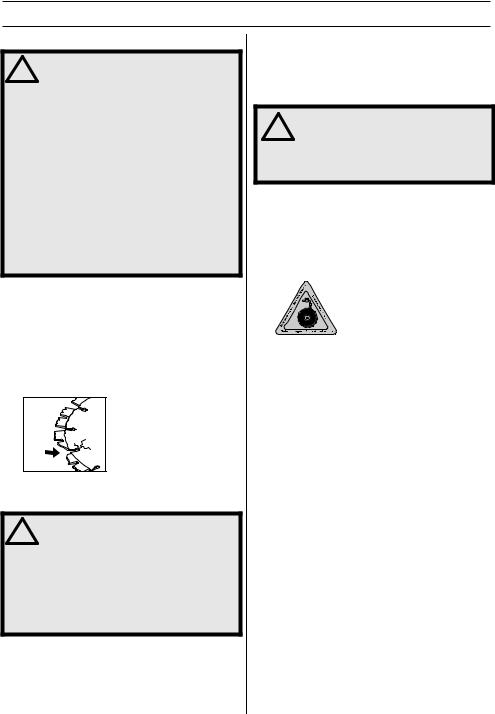

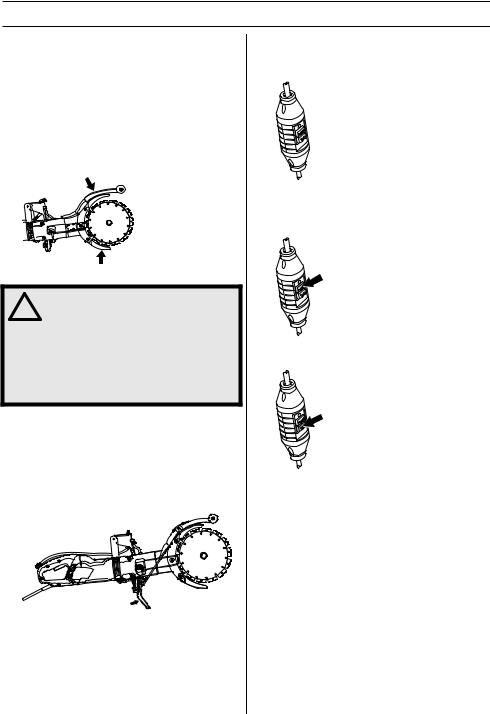

Replacing the carbon brushes

•Check the carbon brushes at least once a month. The carbon brushes should be replaced with new brushes if they are worn, cracked or in any other way deformed.

•All carbon brushes must be replaced when the brushes are replaced.

20 – English

MAINTENANCE

•Remove the inspection cover by loosening both screws.

•Unscrew the cable holding the carbon brush. Now lift up the spring and then lift out the carbon brush from the brush retainer.

•Clean the brush retainers with a dry brush.

•Carefully blow away the dust.

•Fit the new carbon brushes and, at the same time, check that they slide easily in the brush retainers.

•Fold down the springs and tighten the cable.

•New carbon brushes must be run in for approximately 40 minutes while idling.

Water tap

•Check and clean the restrictor if necessary. Do not use hoses that are distorted, worn or damaged.

Disposal, scrapping

This product should be submitted to an appropriate recycling station in accordance with local requirements.

By ensuring that this product is taken care of correctly, you can help to counteract the potential negative impact on the environment and people that can otherwise result through the incorrect waste management of this product.

For more detailed information about recycling this product, contact your municipality, your domestic waste service or the shop from where you purchased the product.

English – 21

TECHNICAL DATA

Technical data

Technical data |

K 4000 Cut-n-Break |

||

|

|

|

|

Protection class |

|

|

I |

|

|

|

|

Max. blade speed, rpm |

230V, 50Hz |

|

4200 |

|

|

|

|

120V, 60Hz |

|

3900 |

|

|

|

||

|

|

|

|

Rated voltage, V |

|

|

|

|

|

|

|

Europe |

|

230 |

|

|

|

|

|

United Kingdom |

|

110 |

|

|

|

|

|

Rated output, W |

|

|

|

|

|

|

|

Europe |

230V, 50Hz |

|

2700/12 A |

|

|

|

|

United Kingdom |

110V, 50Hz |

|

2200/20 A |

|

|

|

|

Weight |

|

|

|

|

|

|

|

Power cutter without cable package (excluding cutting blades), kg / Lbs |

|

8.4 / 18.5 |

|

|

|

|

|

Power cutter without cable package (including cutting blades), kg / Lbs |

|

8.9 / 19.6 |

|

|

|

|

|

Water cooling |

|

|

|

|

|

|

|

Water cooling |

|

Yes |

|

|

|

||

Water connector |

Type ”Gardena” |

||

|

|

||

Recommended water pressure, bar / PSI |

0.5-8 / 7.3-116 |

||

|

|

|

|

|

|

|

|

Noise emissions (see note 1) |

|

|

|

|

|

|

|

Sound power level, measured dB(A) |

|

115 |

|

|

|

|

|

Sound levels (see note 2) |

|

|

|

|

|

|

|

Sound pressure level at the operators ear, dB(A) |

|

104 |

|

|

|

|

|

Equivalent vibration levels, a hveq (see note 3) |

|

|

|

Front handle, m/s2 |

|

3.6 |

|

Rear handle, m/s2 |

|

3.8 |

|

Note 1: Noise emissions in the environment measured as sound power (LWA) conforming to EN 60745-1. Reported data for noise power level has an uncertainty of 3 dB(A).

Note 2: Noise pressure level according to EN 60745-1. Reported data for noise pressure level has an uncertainty of 3 dB(A).

Note 3: Equivalent vibration level, according to EN 60745-2-22, is calculated as the time-weighted energy total for vibration levels under various working conditions. Reported data for vibration level has a typical statistical dispersion (standard deviation) of 1,5 m/s2.

Cutting equipment

Cutting blade, mm/inches |

Gear ratio |

Max. peripheral speed, m/s |

Cutting depth, mm/inches |

|

|

|

|

|

|

230 / 9 |

45 / 79 |

60 |

|

400 / 16 |

|

|

|

|

|

Recommended cable dimensions |

|

|||

|

|

|

|

|

Cable area |

1,5 mm2 |

2,5 mm2 |

|

|

Input voltage 100-120 V |

20 m |

40 m |

|

|

|

|

|

|

|

Input voltage 220-240 V |

30 m |

50 m |

|

|

|

|

|

|

|

22 – English

TECHNICAL DATA

EC Declaration of Conformity

(Applies to Europe only)

Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46-36-146500, declares under sole responsibility that the portable cut-off machine Husqvarna K 4000 Cut-n-Break dating from 2018 serial numbers and onwards (the year is clearly stated on the rating plate, followed by the serial number), complies with the requirements of the COUNCIL’S DIRECTIVE:

•of May 17, 2006 ”relating to machinery” 2006/42/EC.

•of February 26, 2014 ”relating to electromagnetic compatibility” 2014/30/EU.

•of June 8, 2011 on the ”restriction of use of certain hazardous substances” 2011/65/EU.

The following standards have been applied: EN ISO 12100:2010, EN 55014-1:2006+A1:2009+A2:2011, EN 55014- 2:1997+A1:2001+A2:2008, EN 61000-3-2:2014, EN 61000-3-3:2013, EN 60745-1:2009, EN 60745-2- 22:2011+A11:2013.

Partille, 1 January 2018

Joakim Ed

Global R & D Director

Construction Equipment Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

English – 23

EXPLICATION DES SYMBOLES

Symboles sur la machine:

AVERTISSEMENT! La machine utilisée de manière imprudente ou inadéquate peut devenir un outil dangereux, pouvant causer des blessures graves voire mortelles à l’utilisateur et aux autres personnes présentes.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

Utiliser les équipements de protection personnelle. Voir au chapitre ”Équipement de protection personnelle”.

Ce produit est conforme aux directives CE en vigueur.

AVERTISSEMENT! Au cours de la découpe, la poussière générée peut occasionner des blessures si elle est aspirée. Utiliser une protection respiratoire approuvée. Veiller à disposer d'une bonne ventilation.

AVERTISSEMENT! Les étincelles du disque de coupe peuvent provoquer un incendie en cas de contact avec des matières inflammables tels que l’essence, le bois, l’herbe sèche.

Toujours utiliser le refroidissement par eau.

AVERTISSEMENT! Les rebonds peuvent être soudains, rapides et violents et peuvent générer des blessures pouvant être mortelles. Lire et assimiler les instructions du manuel avant d'utiliser la machine.

AVERTISSEMENT! Vérifier que les lames ne comportent ni fissures ni autre dommage.

AVERTISSEMENT! N’utilisez pas de lames de scie circulaire.

Toujours couper dans la direction adéquate. Voir les consignes de sécurité !

Plaque signalétique

Rangée 1 : Marque, modèle (X, Y)

Rangée 2 : N° de série avec date de fabrication (Y, W, X) : Année, semaine, n° de séquence

XXXXXXXXX YYYY

XXXXXXXXX YYYY  s / n YYYY WWXXXXX

s / n YYYY WWXXXXX

XXX XX XX-XX

Husqvarna AB

AAAAAA BBBBB CC

DDDD EEEE FFFF

XXXXXXXXXXXXXXX

Rangée 3 : N° de produit (X)

Rangée 4 : Fabricant

Rangée 5 : A : Vitesse max. de l’arbre de sortie, B : Diamètre de la lame de coupe, C : Diamètre du boulon de lame

Rangée 6 : D : Tension d’entrée, E : Courant d’entrée, F : Fréquence d’entrée

Rangée 7 : Pays d’origine

Marquage environnemental. Ce symbole figurant sur le produit ou sur son emballage indique que ce produit ne peut pas être traité comme déchet ménager. Il doit être collecté et amené à une installation de récupération appropriée de déchets d’équipements électriques et électroniques.

En veillant à ce que ce produit soit correctement éliminé, vous pouvez contribuer à prévenir les conséquences négatives potentielles sur l’environnement et les hommes, qui pourraient sinon être le résultat d’un traitement incorrect des déchets de ce produit.

Pour des informations plus détaillées sur le recyclage de ce produit, contactez votre commune ou le magasin où vous avez acheté le produit.

Les autres symboles/autocollants présents sur la machine concernent des exigences de certification spécifiques à certains marchés.

24 – French

EXPLICATION DES SYMBOLES

Explication des niveaux d'avertissement

Il existe trois niveaux d'avertissement.

AVERTISSEMENT!

! |

AVERTISSEMENT! Désigne une situation dangereuse qui, si elle n’est pas évitée, peut entraîner des blessures graves, voire mortelles.

REMARQUE !

! |

REMARQUE ! Désigne une situation dangereuse qui, si elle n’est pas évitée, peut entraîner des blessures mineures ou modérées.

REMARQUE !

REMARQUE ! Sert à désigner des pratiques sans risque de blessures corporelles.

French – 25

SOMMAIRE

Sommaire |

|

EXPLICATION DES SYMBOLES |

|

Symboles sur la machine: ..................................... |

24 |

Explication des niveaux d'avertissement .............. |

25 |

SOMMAIRE |

|

Sommaire ............................................................. |

26 |

PRÉSENTATION |

|

Cher client, ............................................................ |

27 |

QUELS SONT LES COMPOSANTS? |

|

Quels sont les composants de la découpeuse? ... |

28 |

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE |

|

Généralités ........................................................... |

29 |

DISQUES DÉCOUPEURS |

|

Généralités ........................................................... |

31 |

Lames diamant pour matériaux divers .................. |

31 |

Refroidissement par eau ....................................... |

31 |

Affûtage des lames diamant ................................. |

31 |

Transport et rangement ......................................... |

31 |

MONTAGE |

|

Montage ................................................................ |

32 |

COMMANDE |

|

Équipement de protection ..................................... |

33 |

Consignes générales de sécurité ......................... |

33 |

Techniques de travail de base .............................. |

36 |

DÉMARRAGE ET ARRÊT |

|

Avant de démarrer la machine .............................. |

40 |

Démarrage ............................................................ |

40 |

Arrêt ...................................................................... |

40 |

ENTRETIEN |

|

Généralités ........................................................... |

41 |

Schéma d’entretien ............................................... |

41 |

Nettoyage .............................................................. |

42 |

Contrôle fonctionnel .............................................. |

42 |

Remplacement des balais de charbon ................. |

44 |

Robinet d’eau ........................................................ |

44 |

Mise au rebut ........................................................ |

44 |

CARACTÉRISTIQUES TECHNIQUES |

|

Caractéristiques techniques ................................. |

45 |

Équipement de découpe ....................................... |

45 |

Dimensions de câble recommandées ................... |

45 |

Déclaration CE de conformité ............................... |

46 |

26 – French

PRÉSENTATION

Cher client,

Nous vous remercions d'avoir choisi un produit Husqvarna !

Nous espérons que cette machine vous donnera toute satisfaction et qu’elle vous accompagnera pendant de longues années. L’achat de l’un des nos produits garantit une assistance professionnelle pour l’entretien et les réparations. Si la machine n’a pas été achetée chez l’un de nos revendeurs autorisés, demandez l’adresse de l’atelier d’entretien le plus proche.

Ce mode d’emploi est précieux. Veillez à ce qu'il soit toujours à portée de main sur le lieu de travail. En suivant les instructions qu’il contient (utilisation, révision, entretien etc.), il est possible d’allonger considérablement la durée de vie de la machine et d’augmenter sa valeur sur le marché de l’occasion. En cas de vente de la machine, ne pas oublier de remettre le manuel d’utilisation au nouveau propriétaire.

Plus de 300 ans d'innovation

Husqvarna AB est une entreprise suédoise qui a vu le jour en 1689 lorsque le roi Karl XI décida de construire un arsenal pour la fabrication des mousquets. À l'époque, les compétences en ingénierie à la base du développement de certains des produits leaders du marché mondial dans des domaines tels que les armes de chasse, les vélos, les motocycles, l'électroménager, les machines à coudre et les produits d'extérieur, étaient déjà solides.

Husqvarna est le premier fournisseur mondial de produits motorisés pour utilisation en extérieur dans la foresterie, l'entretien de parcs, de pelouses et de jardins, ainsi que d'équipements de coupe et d'outils diamant destinés aux industries de la construction et de la pierre.

Responsabilité de l'utilisateur

Il est de la responsabilité du propriétaire/de l’employeur de s’assurer que l’utilisateur possède les connaissances nécessaires pour manipuler la machine en toute sécurité. Les responsables et les utilisateurs doivent avoir lu et compris le Manuel d’utilisation. Ils doivent avoir conscience :

•Des instructions de sécurité de la machine.

•Des diverses applications de la machine et de ses limites.

•De la façon dont la machine doit être utilisée et entretenue.

La législation nationale peut réglementer l'utilisation de cette machine. Recherchez la législation applicable dans le lieu où vous travaillez avant d'utiliser la machine.

Droit de réserve du fabricant

Toutes les informations et toutes les données indiquées dans ce manuel d'utilisation étaient valables à la date à laquelle ce manuel a été porté à l'impression.

Husqvarna AB travaille continuellement au développement de ses produits et se réserve le droit d’en

modifier, entre autres, la conception et l’aspect sans préavis.

French – 27

QUELS SONT LES COMPOSANTS?

Quels sont les composants de la découpeuse?

1 |

Protection anti-éclaboussures |

12 |

Protège-lame |

2 |

Poignée avant |

13 |

Disjoncteur de fuite à la terre |

3 |

Blocage de l'interrupteur |

14 |

Raccord de l’eau |

4 |

Interrupteur |

15 |

Robinet d’eau |

5 |

Poignée arrière |

16 |

Bras de coupe |

6 |

Capot de contrôle |

17 |

Tendeur de courroie |

7 |

Balais de charbon |

18 |

Outil d'arrachage |

8 |

Support de balais |

19 |

Clé universelle |

9 |

Plaque signalétique |

20 |

Dispositif de roulement |

10 |

Protection anti-éclaboussures |

21 |

Manuel d’utilisation |

11 |

Lames |

|

|

28 – French

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Généralités

Ce chapitre présente les équipements de sécurité de la machine, leur fonction, comment les utiliser et les maintenir en bon état. Voir au chapitre Quels sont les composants? pour trouver leur emplacement sur la machine.

! |

AVERTISSEMENT! Ne jamais utiliser une |

machine dont les équipements de |

|

|

sécurité sont défectueux. Suivre les |

|

directives de maintenance, d’entretien et |

|

les instructions de réparation indiquées |

|

dans ce chapitre. |

L’entretien et la réparation de la machine exigent une formation spéciale. Ceci concerne particulièrement l’équipement de sécurité de la machine. Si les contrôles suivants ne donnent pas un résultat positif, s’adresser à un atelier spécialisé. L’achat de l’un de nos produits offre à l’acheteur la garantie d’un service et de réparations qualifiés. Si le point de vente n’assure pas ce service, s’adresser à l’atelier spécialisé le plus proche.

Interrupteur

L'interrupteur est utilisé pour démarrer et arrêter la machine.

Contrôle de l'interrupteur

•Démarrer la machine, relâcher l'interrupteur et contrôler que le moteur et le disque découpeur s'arrête.

•Un interrupteur défectueux doit être remplacé par une atelier d’entretien agréé.

Blocage de l'interrupteur

Le blocage de l'interrupteur a pour fonction d'empêcher toute activation involontaire de l'interrupteur. Quand le

bouton de blocage ((A)) est enfoncé, l'interrupteur (B) est libéré.

Le blocage de l'interrupteur reste enfoncé tant que l'interrupteur est enfoncé. Quand la poignée est relachée, l'interrupteur et le blocage de l'interrupteur reviennent en position initiale. Ce retour s'effectue grâce à deux systèmes de ressorts de rappel indépendants l'un de l'autre. Dans cette position, la machine s'arrête et l'interrupteur se bloque.

Contrôle du blocage de l'interrupteur

•Contrôler que l’interrupteur est bloqué quand le blocage de l’interrupteur est en position de repos.

•Appuyer sur le blocage de líinterrupteur et vérifier quíil revient en position initiale quand il est relâché.

•Vérifier que l'interrupteur, le blocage de l'interrupteur et le système de ressorts de rappel fonctionne correctement.

•Allumez la machine, relâchez l'interrupteur et vérifiez que le moteur et les disques s'arrêtent.

Démarrage en douceur et protection contre les surcharges

La machine est équipée d'un dispositif électronique de démarrage en douceur et d'une protection contre la surcharge.

Si la charge sur la machine dépasse un certain niveau, le moteur se met à pulser. Si la charge est allégée, le moteur retourne à la normale et la découpe peut continuer.

French – 29

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Si l'on continue à utiliser la machine avec le moteur qui pulse, le système électronique coupe le courant après un certain temps. Plus la charge est élevée, plus la coupure est rapide.

Si le disque de coupe se coince, le système électronique coupe immédiatement le courant.

Protège-lame

Cette protection est placée au-dessus et en dessous du disque de découpe et a pour fonction d’empêcher que des éclats de disque ou de matériau ne soient projetés en direction de l’utilisateur.

Contrôle de la protection des lames

AVERTISSEMENT! Vérifiez toujours que ! toutes les protections sont montées

correctement avant de démarrer la machine. Contrôler également si le disque découpeur est correctement monté et qu’il ne présente aucun dommage. Un disque découpeur endommagé peut causer des blessures. Voir les instructions au chapitre Montage.

• Contrôler que la protection est entière et qu’elle n’est ni fissurée, ni déformée.

• Ne jamais utiliser un protège-lame défectueux ou monté de manière incorrecte.

Protection anti-éclaboussures

La protection anti-projections fournit une protection contre les projections de débris, d’eau et de béton.

Vérification de la protection anti-projections

Assurez-vous qu’il n’y a aucune fissure ni aucun trou dans la protection causé(e) par les projections de béton. Remplacez la protection si elle est endommagée.

Disjoncteur de fuite à la terre

Les disjoncteurs de fuite à la terre constituent une protection si un défaut d'origine électrique survient.

Le voyant lumineux indique que le disjoncteur de fuite à la terre est activé et que la machine peut être allumée. Si le voyant lumineux est éteint, appuyez sur le bouton RESET (vert).

Vérifiez le disjoncteur de fuite à la terre

•Branchez la machine à la prise électrique. Appuyez sur le bouton RESET (vert) et le voyant lumineux rouge s'allume.

•Démarrer la machine.

•Appuyez sur le bouton TEST (bleu).

•Le disjoncteur de fuite à la terre devrait s'enclencher et la machine s'éteint instantanément. Dans le cas contraire, veuillez contacter votre revendeur.

•Initialisez l'appareil à l'aide du bouton RESET (vert).

30 – French

Loading...

Loading...