Page 1

Operating Instructions

ND 1200 T

TOOL-CHEK

(TC 200)

English (en)

9/2013

Page 2

Page 3

Tool-Chek® 200

User’s Guide

Page 4

Proprietary notice

Disclaimer

All information set forth in this document, all rights to such information, any and all inventions disclosed herein and any patents

that might be granted by employing the materials, methods, techniques or apparatus described herein are the exclusive property

of Metronics Incorporated, Bedford, New Hampshire.

No part of this document may be reproduced, stored in a retrieval

system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the

prior permission of Metronics Incorporated. The information contained herein is designed only for use with the Tool-Chek 200 Tool

Presetter Readout. Metronics Incorporated is not responsible for

any use of this information as applied to any other apparatus.

The information contained in this document is subject to change

without notice. Metronics Incorporated assumes no responsibility

or liability for any errors or inaccuracies contained herein, or for

incidental or consequential damage in connection with the furnishing, performance, or use of this guide.

Metronics Inc. shall not be liable to the purchaser of this product

or third parties for damages, losses, costs, or expenses incurred by

the purchaser or third parties as a result of: accident, misuse, or

abuse of this product or unauthorized modifications, repairs, or

alterations to this product, or failure to strictly comply with

Metronics Incorporated’s operating and maintenance instructions.

Trademarks

Metronics, Tool-Chek, Tool-Chek 200, and TC200 are registered

trademarks of Metronics Incorporated.

Other product names used herein are for identification purposes

only and may be trademarks of their respective owners. Metronics

Incorporated disclaims any and all rights to those marks.

Page 5

Safety and

Maintenance

Considerations

Location and

Mounting

Cleaning

General safety precautions must be followed when operating the

system. Failure to observe these precautions could result in damage to the equipment, or injury to personnel. It is understood

that safety rules within individual companies vary. If a conflict

exists between the material contained in this guide and the rules

of a company using this system, the more stringent rules should

take precedence.

Although Metronics strongly recommends that you read all parts

of this guide, it is essential for reliable and safe operation to read

the first portions up to and including Chapter 2: Operation, prior

to operating the TC200.

The TC200 must be placed or mounted on a stable, reliable surface. If the TC200 should fall, it could become seriously damaged

and more importantly could cause injuries to the user.

Use only a cloth dampened with water and a mild detergent for

cleaning the exterior surfaces. Never use abrasive cleaners, and

never use strong detergents or solvents. Only dampen the cloth,

do not use a cleaning cloth that is dripping wet.

Electrical

Do not allow the power cord to be located such that it can be

Page 6

General maintenance

walked on or create a tripping hazard.

WARNINGWARNING

WARNING

WARNINGWARNING

Unplug the TC200 from the electrical outlet before cleaning.Unplug the TC200 from the electrical outlet before cleaning.

Unplug the TC200 from the electrical outlet before cleaning.

Unplug the TC200 from the electrical outlet before cleaning.Unplug the TC200 from the electrical outlet before cleaning.

WARNINGWARNING

WARNING

WARNINGWARNING

The TC200 is equipped with a 3-prong power plug that includesThe TC200 is equipped with a 3-prong power plug that includes

The TC200 is equipped with a 3-prong power plug that includes

The TC200 is equipped with a 3-prong power plug that includesThe TC200 is equipped with a 3-prong power plug that includes

a separate ground connection. Always connect the power pluga separate ground connection. Always connect the power plug

a separate ground connection. Always connect the power plug

a separate ground connection. Always connect the power pluga separate ground connection. Always connect the power plug

to a 3-prong grounded outlet. The use of 2-prong power plugto a 3-prong grounded outlet. The use of 2-prong power plug

to a 3-prong grounded outlet. The use of 2-prong power plug

to a 3-prong grounded outlet. The use of 2-prong power plugto a 3-prong grounded outlet. The use of 2-prong power plug

adapters or any other connection accessories that remove theadapters or any other connection accessories that remove the

adapters or any other connection accessories that remove the

adapters or any other connection accessories that remove theadapters or any other connection accessories that remove the

third grounded connection create a safety hazard and shouldthird grounded connection create a safety hazard and should

third grounded connection create a safety hazard and should

third grounded connection create a safety hazard and shouldthird grounded connection create a safety hazard and should

not be permitted. If a 3-prong grounded outlet is not available,not be permitted. If a 3-prong grounded outlet is not available,

not be permitted. If a 3-prong grounded outlet is not available,

not be permitted. If a 3-prong grounded outlet is not available,not be permitted. If a 3-prong grounded outlet is not available,

ask your electrician to provide one.ask your electrician to provide one.

ask your electrician to provide one.

ask your electrician to provide one.ask your electrician to provide one.

Unplug the TC200 from the wall outlet and seek the assistance of

a qualified service technician if:

• The power cord is frayed or damaged or the power plug is

damaged

• Liquid is spilled or splashed onto the enclosure

• The TC200 has been dropped or the exterior has been dam aged

• The TC200 exhibits degraded performance or indicates a need

for service some other way

Backup battery

charging

FCC compliance statement

The TC200 utilizes an internal battery to maintain system configuration settings during power interruptions. A battery circuit

charges this backup battery during periods of normal operation.

When the TC200 is used on a daily basis, the backup battery will

be adequately charged to maintain configuration settings during

power outages. However, over extended periods of nonuse, the

battery might lose the charge necessary to maintain configuration settings. To keep the backup battery charged over extended

periods of nonuse, apply power to the TC200 and leave it turned

on for a minimum of 2 days each month.

Page 7

FCC Rule NP15R Rev. 23, June, 1989

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used

in accordance with the instructions in this guide, may cause harmful interference to radio communication. Operation of this equipment in a residential area is likely to cause harmful interference, in

which case the user will be required to correct the interference at

his own expense.

Shielded cables must be used with this unit to ensure compliance

with Class A FCC limits. The connection of a non-shielded equipment interface cable to this equipment will invalidate the FCC Certification of this device and may cause interference levels which

exceed the limits established by the FCC for this equipment. It is

the responsibility of the user to obtain and use a shielded equipment interface cable with this device. Do not leave cables connected to unused interfaces. Changes or modifications not expressly approved by the manufacturer could void the user’s authority to operate the equipment.

For Canadian Users:

This Class “A” digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Declaration of Conformity (EU)

Cet appareil numérique de la classe “A” respecte toutes les exigences

du Reglement sur le matériel brouilleur du Canada.

Page 8

This product conforms to the following product standards:

EN61010-1 Safety

EN61326:1998 EMC

The product therefore conforms with the requirements of the

European Directives on Low Voltage 73/23/EEC and EMC 89/336/

EEC.

Supporting documentation is maintained at Metronics, Inc. USA.

Guide Part Number: 11A10073

Printing History:

September, 2000 First Printing

Revision 1.0

Software Version: 1.00

Printed in the USA

Page 9

Page 10

Page 11

Contents

Introduction ........................................................ i

About this manual ...............................................................................................................i

Who should read this guide ................................................................................................. i

What this guide covers......................................................................................................... i

Conventions and Basic terms ............................................................................................... ii

Measurement polarity ......................................................................................................... ii

Measurementresolution in the guide .................................................................................. ii

Icons ....................................................................................................................................iii

Type styles ...........................................................................................................................iii

Accuracy andprecision......................................................................................................... iii

System configuration ..........................................................................................................iv

and setup ............................................................................................................................iv

Overview .......................................................... 1-1

Proprietary notice ............................................................................................................ 1-4

Disclaimer ......................................................................................................................... 1-4

Trademarks....................................................................................................................... 1-4

Safety and Maintenance Considerations .......................................................................... 1-5

Location and Mounting ................................................................................................... 1-5

Cleaning ........................................................................................................................... 1-5

Electrical ........................................................................................................................... 1-5

General maintenance ....................................................................................................... 1-6

Backup battery charging .................................................................................................. 1-6

FCC compliance statement ............................................................................................... 1-6

For Canadian Users: ......................................................................................................... 1-7

Declaration of Conformity (EU) ........................................................................................ 1-7

Specifications ..................................................................................... 1-5

Input voltage range: ........................................................................................................ 1-5

Fuse:................................................................................................................................. 1-5

Input Frequency: .............................................................................................................. 1-5

Environmental Conditions: ............................................................................................... 1-5

Dimensions: ...................................................................................................................... 1-5

LCD: ................................................................................................................................. 1-5

Resolution: ....................................................................................................................... 1-5

ENC tests: ......................................................................................................................... 1-6

Page 12

Table of Contents

Operation......................................................... 2-1

Getting ready to operate the TC200 ................................................ 2-1

Location and mounting ................................................................................................... 2-2

Power cord and plug ....................................................................................................... 2-2

Power surge suppressor ................................................................................................... 2-2

Liquids .............................................................................................................................. 2-2

Configuration and system setup ...................................................................................... 2-2

Checking connections ...................................................................................................... 2-2

Applying power ................................................................................. 2-3

Initial system settings ....................................................................... 2-4

Adjusting LCD tilt ............................................................................................................. 2-4

Adjusting LCD brightness ................................................................................................. 2-4

Setting measurement and display parameters ................................................................. 2-4

Diameter/Radius ............................................................................................................... 2-4

Absolute/Incremental ....................................................................................................... 2-4

Unit of measure (Linear)................................................................................................... 2-5

Help ................................................................................................................................. 2-5

Feature selection keys....................................................................... 2-6

Setting gage ....................................................................................................................2-6

Tool .................................................................................................................................. 2-6

Tool Sequence .................................................................................................................. 2-6

Circle ................................................................................................................................ 2-6

Angle ............................................................................................................................... 2-7

Basic operating .................................................................................. 2-8

procedures ......................................................................................... 2-8

To measure and store a setting gage ............................................................................... 2-8

To measure and store a tool........................................................................................... 2-12

Creating a tool sequence ............................................................................................... 2-14

Running a tool sequence ............................................................................................... 2-16

Measuring a circle............................................................................ 2-19

To measure a circle ......................................................................................................... 2-19

Measuring an angle......................................................................... 2-22

To measure an angle ...................................................................................................... 2-22

Zeroing Axes .................................................................................................................. 2-25

Freezing Axes ................................................................................................................. 2-25

Contents-2

Page 13

Tool-Chek® TC200

Setup................................................................ 3-1

Configuring the TC200 ...................................................................... 3-1

Basic setup terms............................................................................... 3-1

Accessing the ..................................................................................... 3-2

Setup menu ........................................................................................ 3-2

Using the ............................................................................................ 3-3

Setup menu ........................................................................................ 3-3

Setup Instructions ............................................................................. 3-3

Command Keys .................................................................................. 3-4

Enter Key .......................................................................................................................... 3-4

Finish Key ......................................................................................................................... 3-4

Cancel Key........................................................................................................................ 3-4

Quit Key ........................................................................................................................... 3-4

Supervisor Password ......................................................................... 3-5

To enter the password ..................................................................................................... 3-5

About .................................................................................................. 3-6

Display ................................................................................................ 3-6

MM Disp Res.....................................................................................................................3-8

Inch Disp Res .................................................................................................................... 3-8

DMS Disp Res ................................................................................................................... 3-9

DD Disp Res .................................................................................................................... 3-10

Startup Linear ................................................................................................................ 3-10

Startup Angular ............................................................................................................. 3-11

Radix .............................................................................................................................. 3-11

Current Angular............................................................................................................. 3-12

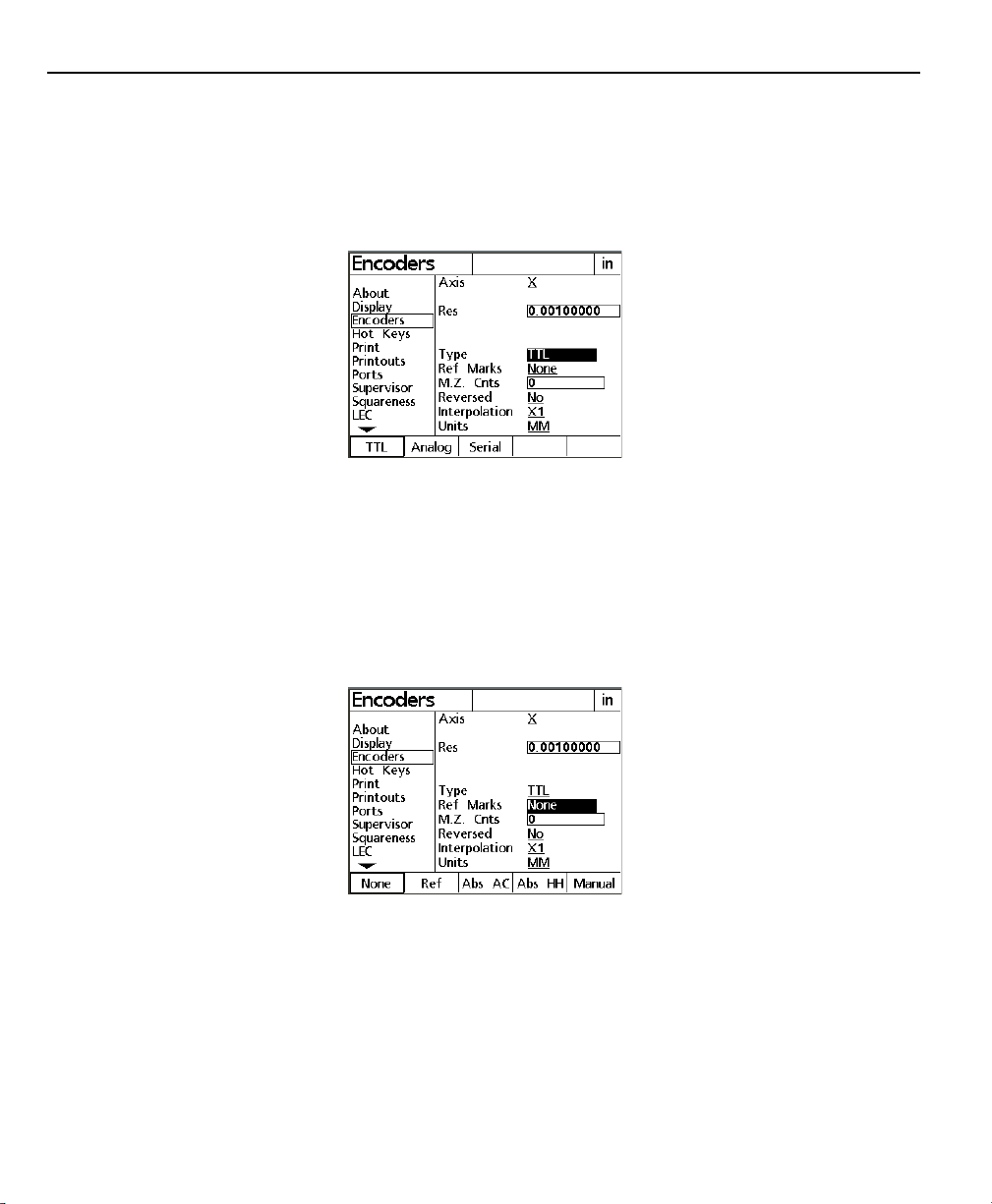

Encoders ........................................................................................... 3-12

Axis ................................................................................................................................3-13

Resolution (Res) .............................................................................................................. 3-13

Type ............................................................................................................................... 3-14

Reference Marks ............................................................................................................ 3-14

MZ Cnts.......................................................................................................................... 3-15

Reversed ......................................................................................................................... 3-15

Interpolation .................................................................................................................. 3-16

Units............................................................................................................................... 3-16

Print .................................................................................................. 3-17

Auto Label ..................................................................................................................... 3-17

Auto Report ................................................................................................................... 3-18

Label Format .................................................................................................................. 3-18

Pre Line .......................................................................................................................... 3-19

Post Line......................................................................................................................... 3-19

Contents-3

Page 14

Table of Contents

Pre Form......................................................................................................................... 3-19

Post Form .......................................................................................................................3-20

Print Report ....................................................................................................................3-20

Label Lines ...................................................................................................................... 3-20

Skip Lines ....................................................................................................................... 3-21

Label Indent ................................................................................................................... 3-21

Ports.................................................................................................. 3-23

Baud ............................................................................................................................... 3-24

Word Len (word length) ................................................................................................ 3-24

Stop Bits......................................................................................................................... 3-24

Parity .............................................................................................................................. 3-25

Handshake ..................................................................................................................... 3-25

Data/ Parallel Data.......................................................................................................... 3-26

EOC Delay (end of character delay) ................................................................................ 3-26

EOL Delay (end of line delay).......................................................................................... 3-27

Squareness ....................................................................................... 3-28

Angle ............................................................................................................................. 3-28

Master Axis.....................................................................................................................3-29

Error Correction ............................................................................... 3-30

Linear Error Correction (LEC) .......................................................... 3-31

Segmented Linear Error Correction (SLEC) ................................... 3-33

Misc. (miscellaneous) ...................................................................... 3-35

Key Delay........................................................................................................................ 3-35

Volume ........................................................................................................................... 3-35

Libraries ............................................................................................ 3-35

Use Locations ................................................................................................................. 3-36

Tool Button .................................................................................................................... 3-36

SG 00 master .................................................................................................................. 3-37

SG Edit Lock ................................................................................................................... 3-37

SG Cal Lock .................................................................................................................... 3-38

Tool Sequence Edit Lock ................................................................................................. 3-38

Clock ................................................................................................. 3-39

Year ................................................................................................................................ 3-39

Month ............................................................................................................................ 3-40

Day................................................................................................................................. 3-40

Hours ............................................................................................................................. 3-40

Minutes .......................................................................................................................... 3-41

Seconds.......................................................................................................................... 3-41

Date Format ................................................................................................................... 3-41

Time Format ................................................................................................................... 3-42

Contents-4

Page 15

Tool-Chek® TC200

Communications ............................................. 4-1

RS232 port .......................................................................................... 4-1

Default settings ................................................................................. 4-2

Ports section of Setup menu: ........................................................................................... 4-2

Print section of Setup menu: ........................................................................................... 4-2

Feature print formats ........................................................................ 4-3

Feature Formats................................................................................. 4-4

Print Setup ......................................................................................... 4-4

Pre Line ............................................................................................................................ 4-5

Post Line........................................................................................................................... 4-5

Pre Form........................................................................................................................... 4-5

Post Form ......................................................................................................................... 4-5

Print Report ...................................................................................................................... 4-5

Print Labels....................................................................................................................... 4-6

Print POT .......................................................................................................................... 4-6

Num Label Lines ............................................................................................................... 4-6

Num Skip Lines ................................................................................................................. 4-6

Amt Label Indent ............................................................................................................. 4-6

Glossary .............................................................................................. 1-6

IndexIndex

Index

IndexIndex

......................................................................................................

...................................................

......................................................................................................

Index-1Index-1

Index-1

Index-1Index-1

Contents-5

Page 16

Table of Contents

Contents-6

Page 17

About this manual

Who should read

this guide

What this guide

covers

Introduction

The material in this guide is divided into 4 chapters ranging from

introductory material to advanced topics. If you are an advanced

user of tool presetter readouts, feel free to skim the material contained in this guide, but do not begin to operate the readout

unless you’re confident that you understand the essential information contained in these chapters. Observe all precautions and

safety rules while using this equipment.

After an initial review, this guide will become an invaluable reference source that can be used routinely to answer questions and

ensure smooth continued operation of the Tool-Chek. The comprehensive table of contents and index facilitate rapid access to

specific information contained within the guide.

This user’s guide is intended for operators, technicians, supervisors and dealer representatives.

Chapter 1: Overview

An overview of TC200 system including specifications.

Chapter 2: Operation

Demonstration of TC200 operation for getting started with a minimum of details.

Chapter 3: Setup

Contains an explanation of the various menu functions found on

the TC200.

Chapter 4: Communications

Serial (RS232) and parallel communication with printers and IBMcompatible personal computers.

i

Page 18

Introduction

Conventions and

Basic terms

Measurement polarity

The terms Tool-Chek 200, TC200 and system used in this guide

refer to the Tool-Chek 200 tool presetter readout.

A program is simply a series or sequence of key-presses used to

perform measurements and stored by the system to be repeated

automatically later. The stored sequence (program) can be repeated later simply by pressing one user-defined key.

It is assumed in all discussions of measurements that:

• Moving crosshairs to the right causes measure counts to

increase in a positive direction; 1 to 2 to 3 and so on.

• Moving crosshairs up causes measure counts to increase

in a positive direction; 1 to 2 to 3 and so on.

• Rotating crosshairs counterclockwise causes measure counts

to increase in a positive direction; 1 degree to 2 degrees to

3 degrees and so on.

• This count direction can easily be reversed if necessary.

Reversing the count direction is discussed later in Chapter 6:

Orthogonal axis calibration.

Measurement

resolution in

the guide

ii

In most cases the display resolution shown on screens in this guide

will be one ten-thousandths of an inch (0.0001) or two microns

metric (0.002). The display resolutions shown in this manual are

not meant to suggest resolutions that should be set on your system, they are only examples.

Page 19

Icons

Tool-Chek® TC200

This guide uses the following icons to highlight information:

The raised hand icon indicates a warning regarding a situation or

condition that could lead to personal injury or death. You should

not proceed until you read and thoroughly understand the warning message. Warning messages are shown in bold type.

The exclamation point icon indicates a caution regarding a situation or condition that could lead to equipment malfunction or

damage. You should not proceed until you read and fully understand the caution message. Caution messages are shown in bold

type.

The note icon indicates additional or supplementary information

about an activity or concept. Notes are shown in bold type.

Type styles

Accuracy and

precision

Warnings, cautions, notes and the titles of front panel keys or

system commands and menus shown in instructions are shown in

bold type.

The TC200 is capable of great accuracy and precision and may

surpass the measurement-accuracy capability of the human operator. The system is also capable of displaying higher resolution

and more significant figures than is often needed. These facts

may be important in your interpretation and use of the measurement data provided by the system.

iii

Page 20

Introduction

System configuration

and setup

Metronics, Incorporated assumes that all TC200 systems will be

configured and setup for the end-user by dealer representatives

or OEMs. This setup includes calibration according to the user’s

tool presetter if needed.

When the end-user installs a new tool presetter, it will probably

be necessary to perform configuration and setup again. In that

case, contact their dealer representatives for assistance.

WARNINGWARNING

WARNING

WARNINGWARNING

There is never any reason to open the TC200 enclosure. ThereThere is never any reason to open the TC200 enclosure. There

There is never any reason to open the TC200 enclosure. There

There is never any reason to open the TC200 enclosure. ThereThere is never any reason to open the TC200 enclosure. There

are no user-serviceable components or assemblies inside. Asare no user-serviceable components or assemblies inside. As

are no user-serviceable components or assemblies inside. As

are no user-serviceable components or assemblies inside. Asare no user-serviceable components or assemblies inside. As

with any electronic instrument, there is a danger of electricalwith any electronic instrument, there is a danger of electrical

with any electronic instrument, there is a danger of electrical

with any electronic instrument, there is a danger of electricalwith any electronic instrument, there is a danger of electrical

shock and damage to the instrument if the enclosure is opened.shock and damage to the instrument if the enclosure is opened.

shock and damage to the instrument if the enclosure is opened.

shock and damage to the instrument if the enclosure is opened.shock and damage to the instrument if the enclosure is opened.

Refer all maintenance requirements to your original dealerRefer all maintenance requirements to your original dealer

Refer all maintenance requirements to your original dealer

Refer all maintenance requirements to your original dealerRefer all maintenance requirements to your original dealer

failing that to Metronics Incorporated.failing that to Metronics Incorporated.

failing that to Metronics Incorporated.

failing that to Metronics Incorporated.failing that to Metronics Incorporated.

, or, or

, or

, or, or

iv

Page 21

Chapter 1

Overview

The Tool-Chek 200 is an advanced tool presetter readout system

that allows the user to establish datums using a setting gage and

measure tool offset relative to nominal dimensions. Using the

TC200 you can create a tool sequence to perform a series of commonly repeated tool measurements. Measurement results can be

viewed on the TC200’s LCD display, sent to a printer, or downloaded to a computer. The TC200 supports a variety of reporting

formats for the user to select.

The intuitive interface will be familiar to users of the Tool-Chek

and other Metronics products. Operators will find the TC200 easy

to understand and use thanks to a large LCD display and front

panel keys clearly marked with familiar function and mode symbols.

1-1

Page 22

Chapter 1 Overview

The LCD displays alphanumeric information that enables the user

to perform simple offset measurements or more complex tool presetting and sequencing functions. It’s size allows pertinent information to be clearly displayed and eliminates the need to page or

scroll for information.

1-2

Many of the features and symbols from previous Tool-Chek version are retained in the TC200. The feature selection keys and the

features they activate will be familiar to most Tool-Chek users.

Additional ‘softkeys’ expand the functionality of the TC200 and

make the interface more user-friendly. Softkeys are used to access additional groups of related functions. To access softkey functions simply press the softkey beneath the desired group.

User’s can navigate through lists using the arrow keys and enter

numeric information via

the numeric keypad.

Page 23

Tool-Chek® TC200

Commonly executed tasks can be programmed into the TC200

and activated via one of the two Fast keys at the top of the readout.

All front panel keys provide tactile sensory feedback, and many

keypress operations can be configured by supervisors or dealer

representatives to generate an audible sound.

Speaker and external speaker jack outputs are provided that can

be adjusted for quiet or noisy environments. Earphones can be

plugged into the external speaker jack to facilitate silent operation in quiet environments.

The compact ergonomic design and adjustable-tilt front panel of

the TC200 allows users to locate and mount the instrument in a

wide variety of environments. The tilt front panel can be adjusted

and secured in any convenient position. Rubber feet on the bottom prevent slipping when the is not permanently bolted to a

work surface. Bolt holes are provided in the mounting stand that

match the pattern of the TC2000.

1-3

Page 24

Chapter 1 Overview

Measurements viewed on the front panel LCD can be transmitted

to an IBM-compatible personal computer over a standard parallel

port connection, or to a printer over a parallel or serial port.

Sequences of keypresses used to perform measurements can be

recorded and stored as programs. These programs can be replayed later to perform complete measurement sequences. Sequences can be as simple as measuring a line, or can be expanded

to include skew adjustment, the measurement of multiple features and printing reports of measurement results.

An optional foot switch and remote keypad are available for feature-point and numeric data entry when the user is not close to

the front panel.

1-4

Page 25

Specifications

Tool-Chek® TC200

Input voltage range:

85 VAC to 264 VAC. 100 W maximum (Auto switchable)

Fuse:

1.6 Amp 250V Type T

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Fuses provide protection against fire and other damage.Fuses provide protection against fire and other damage.

Fuses provide protection against fire and other damage.

Fuses provide protection against fire and other damage.Fuses provide protection against fire and other damage.

Replacement fuses MUST match the specified voltage and currentReplacement fuses MUST match the specified voltage and current

Replacement fuses MUST match the specified voltage and current

Replacement fuses MUST match the specified voltage and currentReplacement fuses MUST match the specified voltage and current

ratings.ratings.

ratings.

ratings.ratings.

Input Frequency:

47Hz to 63Hz

Environmental Conditions:

Temperature: 0C to 45C (32F to 113F) non-condensing

Humidity: 90%rh

Altitude: 2000 meters

Pollution degree: 2

Installation category: II

Dimensions:

Enclosure: (WxHxD): 11.5" X 7.5" X 2.75"

Base (WxHxD): 10"X 2" X 7.8"

Enclosure weight: 3.5 lbs.

Base weight: 7lbs.

LCD:

Size/color: 6" black and white

Display digit size: 0.5"

Resolution:

1-5

Page 26

Chapter 1 Overview

0.000004" or 0.0001mm

ENC tests:

EN61326:1998

EMC for electrical equipment for measurement, control, and laboratory use

EN61010

Safety requirements for electrical equipment for measurement,

control, and laboratory use

WARNING:WARNING:

WARNING:

WARNING:WARNING:

TT

o reduce the risk of electrical shock, never remove the cover oro reduce the risk of electrical shock, never remove the cover or

T

o reduce the risk of electrical shock, never remove the cover or

TT

o reduce the risk of electrical shock, never remove the cover oro reduce the risk of electrical shock, never remove the cover or

open the enclosure. There are no user-serviceable parts inside.open the enclosure. There are no user-serviceable parts inside.

open the enclosure. There are no user-serviceable parts inside.

open the enclosure. There are no user-serviceable parts inside.open the enclosure. There are no user-serviceable parts inside.

Refer all service requirements to qualified service personnel.Refer all service requirements to qualified service personnel.

Refer all service requirements to qualified service personnel.

Refer all service requirements to qualified service personnel.Refer all service requirements to qualified service personnel.

1-6

Page 27

Chapter 2

Operation

This chapter demonstrates the operation of the Tool-Chek 200.

This demonstration is provided to allow experienced operators to

start using the TC200 immediately. The demonstration will be

most helpful if you perform the indicated steps on your TC200

while reading this material.

NOTENOTE

NOTE

NOTENOTE

Illustrations are included in this manual to indicate the basicIllustrations are included in this manual to indicate the basic

Illustrations are included in this manual to indicate the basic

Illustrations are included in this manual to indicate the basicIllustrations are included in this manual to indicate the basic

types or displays found while operating the TC200. Specifictypes or displays found while operating the TC200. Specific

types or displays found while operating the TC200. Specific

types or displays found while operating the TC200. Specifictypes or displays found while operating the TC200. Specific

data (i.e. measurements) will vary according to user selections.data (i.e. measurements) will vary according to user selections.

data (i.e. measurements) will vary according to user selections.

data (i.e. measurements) will vary according to user selections.data (i.e. measurements) will vary according to user selections.

It is not necessary to match actual measurements to thoseIt is not necessary to match actual measurements to those

It is not necessary to match actual measurements to those

It is not necessary to match actual measurements to thoseIt is not necessary to match actual measurements to those

presented here.presented here.

presented here.

presented here.presented here.

The demonstration will include:

• Getting ready to operate the TC200

• Applying power

• Initial system settings

• Measuring and storing a setting gage

• Measuring and entering a tool

• Creating a tool sequence

• Measuring a circle

• Measuring an angle

Getting ready to operate the TC200

The contents of LCD screens used in this demonstration will reflect a system using X and Z axis encoders configured with factory

default settings.

This demonstration assumes a basic familiarity with the process of

measuring features, TC200 controls and indicators, and the types

of information presented on LCD screens.

2-1

Page 28

Chapter 2 Operation

NOTENOTE

NOTE

NOTENOTE

It is assumed that operators have a basic understanding of toolIt is assumed that operators have a basic understanding of tool

It is assumed that operators have a basic understanding of tool

It is assumed that operators have a basic understanding of toolIt is assumed that operators have a basic understanding of tool

fixturing and the geometric probing techniques required for theirfixturing and the geometric probing techniques required for their

fixturing and the geometric probing techniques required for their

fixturing and the geometric probing techniques required for theirfixturing and the geometric probing techniques required for their

tool presetting devices.tool presetting devices.

tool presetting devices.

tool presetting devices.tool presetting devices.

Location and mounting

Verify that the TC200 is mounted on a stable reliable surface. If it

should fall, it could become seriously damaged or cause injuries to

the user.

Power cord and plug

The power cord should not be located where it can be walked on

or create a tripping hazard. Always connect the 3-prong power

plug to a 3-prong grounded outlet. Use of a 2-prong power plug

adapter or any other connection accessory that removes the third

grounded connection creates a safety hazard and should not be

permitted.

Power surge suppressor

A high-quality power surge suppressor should be used to limit the

amplitude of potentially damaging power line transients caused

by the operation of heavy electrical machinery or lightning.

2-2

Liquids

Do not spill or splash liquids on the TC200 enclosure.

Configuration and system setup

System configuration and setup should be performed only by technically qualified supervisors or dealer representatives. Operators

should not attempt to alter the configuration of the TC200

Checking connections

Perform a routine inspection of all connections to the tool preset

readout system. Connections should be clean and tight. Cables

should be located away from moving objects and should not create tripping hazards.

Cables connected to the parallel and serial (RS232) output ports

should be shielded and should be terminated and firmly connected

on both ends.

Page 29

Applying power

Tool-Chek® TC200

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Never connect electrical cables to the system when the power isNever connect electrical cables to the system when the power is

Never connect electrical cables to the system when the power is

Never connect electrical cables to the system when the power isNever connect electrical cables to the system when the power is

on. Optical edge detector cables may be connected oron. Optical edge detector cables may be connected or

on. Optical edge detector cables may be connected or

on. Optical edge detector cables may be connected oron. Optical edge detector cables may be connected or

disconnected with the power on.disconnected with the power on.

disconnected with the power on.

disconnected with the power on.disconnected with the power on.

To apply power, press the power switch located at the back of the

enclosure to ON (1). The system will initialize and display the powerup screen.

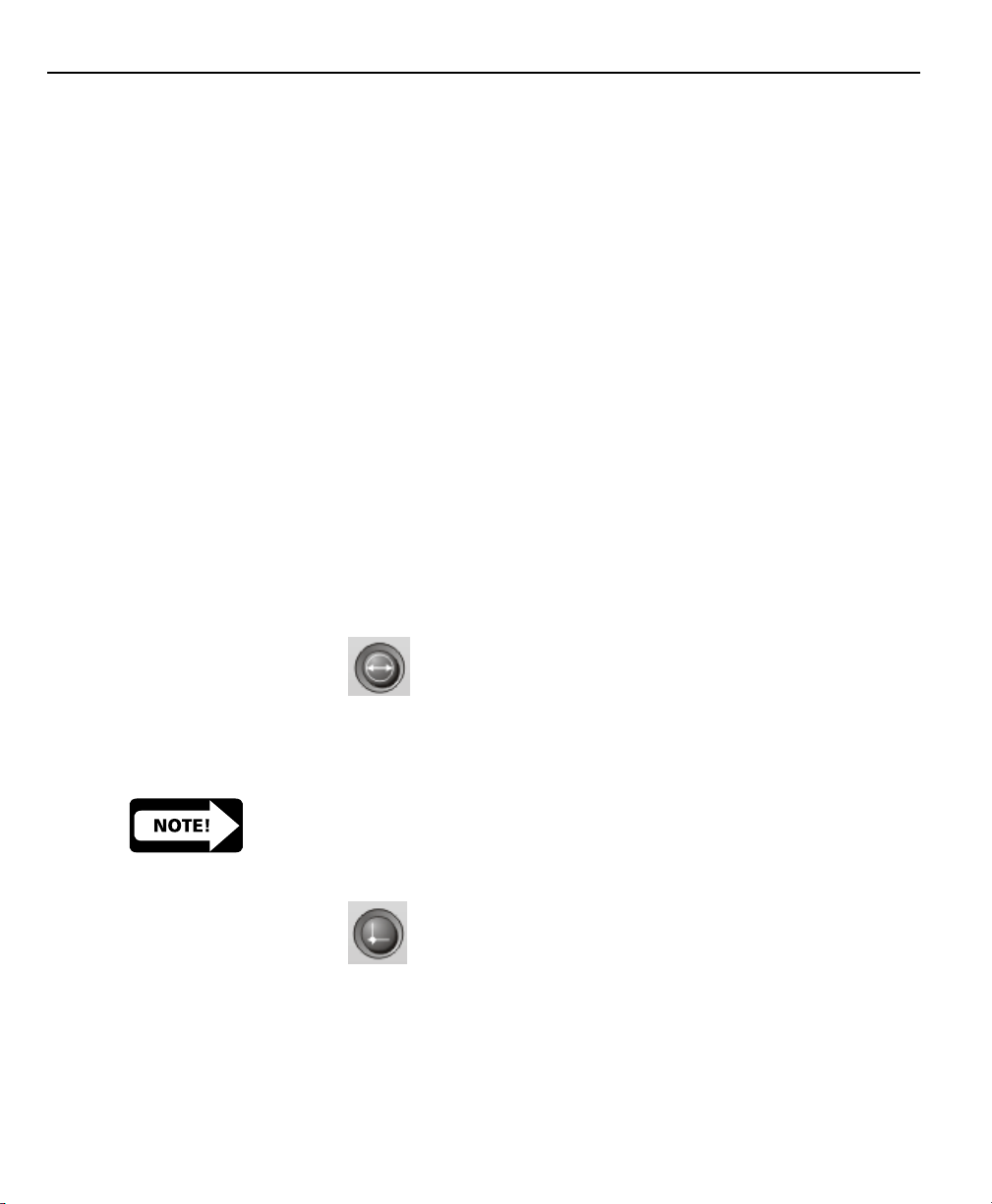

Press any key on the front panel to complete the system initialization. The DRO screen will be displayed showing the current positions of encoders on each axis.

NOTENOTE

NOTE

NOTENOTE

If the encoders used with your system include reference marks,If the encoders used with your system include reference marks,

If the encoders used with your system include reference marks,

If the encoders used with your system include reference marks,If the encoders used with your system include reference marks,

you may be instructed to cross the reference marks on each axisyou may be instructed to cross the reference marks on each axis

you may be instructed to cross the reference marks on each axis

you may be instructed to cross the reference marks on each axisyou may be instructed to cross the reference marks on each axis

before the DRO screen is displayed.before the DRO screen is displayed.

before the DRO screen is displayed.

before the DRO screen is displayed.before the DRO screen is displayed.

2-3

Page 30

Chapter 2 Operation

Initial system settings

The first steps in any measurement session will include adjusting

the LCD viewing angle, contrast and measurement or display settings.

Adjusting LCD tilt

The tilt angle of the TC200 enclosure can usually be adjusted for

optimum viewing by simply swiveling the enclosure on its base to

the desired position. If the enclosure angle is locked in position,

loosen the two Allen screws at the base of the enclosure, move

the enclosure to the desired angle and tighten the Allen screws so

that the enclosure is held firmly in position but can be adjusted

again without loosening the Allen screws.

Adjusting LCD brightness

The LCD contrast can be adjusted for optimum viewing from the

DRO screen. Press the decimal point of the numeric keypad to

decrease contrast or the +/- key to increase contrast.

Setting measurement and display parameters

The measure and display parameters that you establish prior to a

measurement session will depend on the measurement that you

are making and the way you would like to have data and graphics

displayed on the LCD screen and on reports.

2-4

Diameter/Radius

Select diameter or radius measurement by pressing the Diameter/

Radius mode key. This selection can be changed at any time.

NOTENOTE

NOTE

NOTENOTE

When the user changes the mode from diameter or radius theWhen the user changes the mode from diameter or radius the

When the user changes the mode from diameter or radius the

When the user changes the mode from diameter or radius theWhen the user changes the mode from diameter or radius the

value entered remains the same. Be certain to adjust the valuevalue entered remains the same. Be certain to adjust the value

value entered remains the same. Be certain to adjust the value

value entered remains the same. Be certain to adjust the valuevalue entered remains the same. Be certain to adjust the value

entered to obtain accurate presets.entered to obtain accurate presets.

entered to obtain accurate presets.

entered to obtain accurate presets.entered to obtain accurate presets.

Absolute/Incremental

Select absolute or incremental modes for the X and Z axis by pressing the Absolute/Incremental mode key. When the Absolute/Incremental mode key is pressed the user is prompted to select the

axis to be changed to incremental mode. To select either the X or

Z axis press the axis key. To switch both axes to incremental press

Page 31

Tool-Chek® TC200

the zero key. Pressing the Absolute/Incremental mode key a second time will return both axes to absolute. Both axes are can be

changed to incremental by simply pressing the zero button and

following the on-screen instructions.

Unit of measure (Linear)

Features can be displayed in mm or inches. Select the desired unit

of measure if necessary by pressing the mm/inch mode key. The

unit of measure will be displayed at the upper right corner of the

LCD. This selection can be changed at any time.

Help

Displays help text on the screen explaining the current function or

LCD screen.

2-5

Page 32

Chapter 2 Operation

Feature selection keys

The feature selection keys initiate TC200 functions that measure

and calculate setting gage and tool dimensions, store tool sequencing programs, and initiate other automated features.

Setting gage

Setting gages are used to establish a datum on the tool presetter.

Pressing this key brings up the Select Setting Gage screen. The

user can input new, edit existing, and delete unneeded setting

gages with softkey functions on this screen. All tool presetting

operations require at least one setting gage.

Tool

Allows the user to input nominal information for a tool. Pressing

this key brings up the New Tool screen. The user can input information to store a new tool on this screen. New tools can be

saved by pressing the save softkey. Existing tools can be selected

by pressing the select softkey.

2-6

Tool Sequence

Allows the user to program a series of tool measurements required for a specific part. Pressing this key brings up the recording screen. The TC200 will record all keypresses and user selections and store them for later use. Users can retrieve a tool sequence using this key as well.

Circle

Circles can be measured by targeting between 3 and 100 points

around the circumference. Generally, accuracy of the feature is

increased as more points are targeted and the targeted points are

Page 33

Tool-Chek® TC200

distributed at more or less equal arc distances around the circle.

When more than 3 points are targeted, a best-fit algorithm will be

used to create the circle feature and an F (Form) value will be

included in the circle feature data.

Angle

Angles can be measured by targeting between 2 and 100 points

on each of the vertices of the angle. Generally, accuracy of the

feature is increased as more points are targeted and the targeted

points are distributed at more or less equal distances along the

line.

2-7

Page 34

Chapter 2 Operation

Basic operating

procedures

To measure and store a setting gage

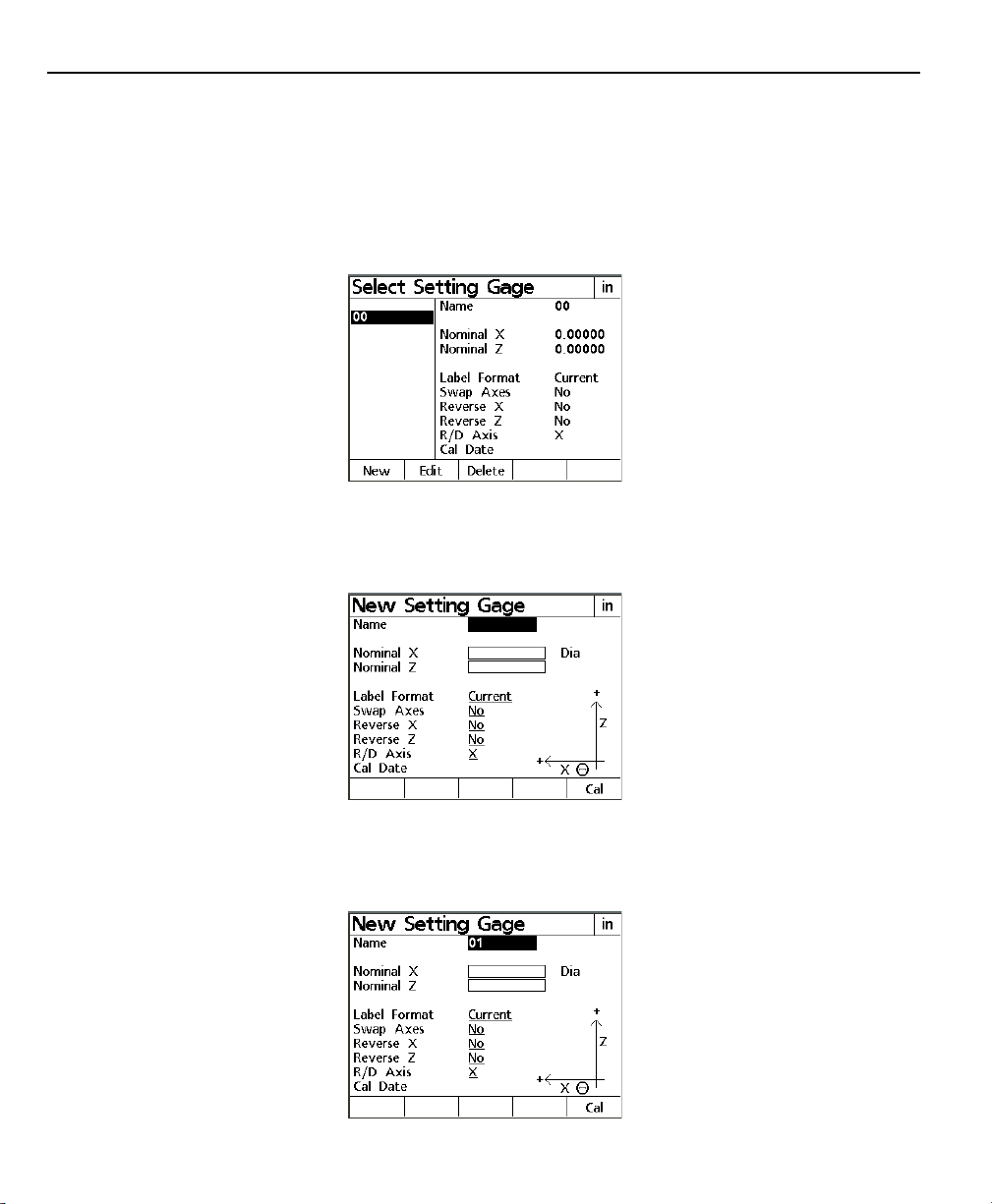

Step 1

From the feature selection keys press setting gage. The LCD displays the select setting gage screen.

Step 2

Press the new softkey. The LCD displays the new setting gage

screen.

2-8

Step 3

Use the numerical keypad to enter a name for the setting gage

and then press enter.

Page 35

Tool-Chek® TC200

Step 4

Enter the value for Nominal X. Nominal X is the diameter or radius

of the setting gage. Press enter.

NOTENOTE

NOTE

NOTENOTE

The TC200 displays either ‘Dia’ or ‘Rad’ next to input field forThe TC200 displays either ‘Dia’ or ‘Rad’ next to input field for

The TC200 displays either ‘Dia’ or ‘Rad’ next to input field for

The TC200 displays either ‘Dia’ or ‘Rad’ next to input field forThe TC200 displays either ‘Dia’ or ‘Rad’ next to input field for

Nominal X to indicate whether the value is a diameter or radius.Nominal X to indicate whether the value is a diameter or radius.

Nominal X to indicate whether the value is a diameter or radius.

Nominal X to indicate whether the value is a diameter or radius.Nominal X to indicate whether the value is a diameter or radius.

This indication can be changed by pressing the Diameter/RadiusThis indication can be changed by pressing the Diameter/Radius

This indication can be changed by pressing the Diameter/Radius

This indication can be changed by pressing the Diameter/RadiusThis indication can be changed by pressing the Diameter/Radius

mode selection keymode selection key

mode selection key

mode selection keymode selection key

NOTENOTE

NOTE

NOTENOTE

When the user changes the mode from diameter or radius theWhen the user changes the mode from diameter or radius the

When the user changes the mode from diameter or radius the

When the user changes the mode from diameter or radius theWhen the user changes the mode from diameter or radius the

value entered remains the same. Be certain to adjust the valuevalue entered remains the same. Be certain to adjust the value

value entered remains the same. Be certain to adjust the value

value entered remains the same. Be certain to adjust the valuevalue entered remains the same. Be certain to adjust the value

entered to obtain accurate presets.entered to obtain accurate presets.

entered to obtain accurate presets.

entered to obtain accurate presets.entered to obtain accurate presets.

..

.

..

NOTENOTE

NOTE

NOTENOTE

Be certain to use the correct units of measurement to avoidBe certain to use the correct units of measurement to avoid

Be certain to use the correct units of measurement to avoid

Be certain to use the correct units of measurement to avoidBe certain to use the correct units of measurement to avoid

errors. The units of measure are displayed at the top right cornererrors. The units of measure are displayed at the top right corner

errors. The units of measure are displayed at the top right corner

errors. The units of measure are displayed at the top right cornererrors. The units of measure are displayed at the top right corner

of the screen. Tof the screen. T

of the screen. T

of the screen. Tof the screen. T

inches mode selection keyinches mode selection key

inches mode selection key

inches mode selection keyinches mode selection key

Step 5

Enter the value for Nominal Z. Nominal Z via the distance from

the datum to the tip of the setting gage. Press enter.

o change the units of measure press the mm/o change the units of measure press the mm/

o change the units of measure press the mm/

o change the units of measure press the mm/o change the units of measure press the mm/

..

.

..

2-9

Page 36

Chapter 2 Operation

Step 6

Press the list softkey and use the up or down arrow keys to choose

label formats and press enter.

Step 7

The swap axes feature allows the user to swap the X and Z axis.

Use the softkeys to select yes or no and press enter.

2-10

Step 8

The reverse X feature allows the user to reverse the positive and

negative ends of the X axis. Use the softkeys to select yes or no

and press enter.

Page 37

Tool-Chek® TC200

NOTENOTE

NOTE

NOTENOTE

It may be necessary to reverse axes when presetting lathe toolsIt may be necessary to reverse axes when presetting lathe tools

It may be necessary to reverse axes when presetting lathe tools

It may be necessary to reverse axes when presetting lathe toolsIt may be necessary to reverse axes when presetting lathe tools

to achieve positive offset values.to achieve positive offset values.

to achieve positive offset values.

to achieve positive offset values.to achieve positive offset values.

Step 9

The reverse Z feature allows the user to reverse the positive and

negative ends of the Z axis. Use the softkeys to select yes or no

and press enter.

NOTENOTE

NOTE

NOTENOTE

It may be necessary to swap axes when presetting lathe tools toIt may be necessary to swap axes when presetting lathe tools to

It may be necessary to swap axes when presetting lathe tools to

It may be necessary to swap axes when presetting lathe tools toIt may be necessary to swap axes when presetting lathe tools to

achieve positive offset values.achieve positive offset values.

achieve positive offset values.

achieve positive offset values.achieve positive offset values.

Step 10

The R/D Axis feature allows the user to designate the X or Z axis as

the diameter/radius of the setting gage. Use the softkeys to select X or Z and press finish.

2-11

Page 38

Chapter 2 Operation

Step 11

Align the setting gage with the crosshairs on the tool presetter

and press enter. The TC200 will store the setting gage in its

memory.

To measure and store a tool

Step 1

From the feature selection keys press tool. The LCD displays the

New Tool screen.

2-12

Step 2

Use the numeric keypad to enter a number for the tool and press

enter.

Step 3

Position of tool (POT) refers to a tools location in a tool changer

mechanism. Use the numeric keypad to enter a value between 1

and 99 then press enter.

Step 4

Nominal X is the diameter or radius of the tool. Use the numeric

keypad to enter a value for nominal X and press enter.

Page 39

Tool-Chek® TC200

NOTENOTE

NOTE

NOTENOTE

The TC200 displays either ‘Dia’ or ‘Rad’ next to input field forThe TC200 displays either ‘Dia’ or ‘Rad’ next to input field for

The TC200 displays either ‘Dia’ or ‘Rad’ next to input field for

The TC200 displays either ‘Dia’ or ‘Rad’ next to input field forThe TC200 displays either ‘Dia’ or ‘Rad’ next to input field for

Nominal X to indicate whether the value is a diameter or radius.Nominal X to indicate whether the value is a diameter or radius.

Nominal X to indicate whether the value is a diameter or radius.

Nominal X to indicate whether the value is a diameter or radius.Nominal X to indicate whether the value is a diameter or radius.

This indication can be changed by pressing the Diameter/RadiusThis indication can be changed by pressing the Diameter/Radius

This indication can be changed by pressing the Diameter/Radius

This indication can be changed by pressing the Diameter/RadiusThis indication can be changed by pressing the Diameter/Radius

mode selection keymode selection key

mode selection key

mode selection keymode selection key

NOTENOTE

NOTE

NOTENOTE

Be certain to use the correct units of measurement to avoidBe certain to use the correct units of measurement to avoid

Be certain to use the correct units of measurement to avoid

Be certain to use the correct units of measurement to avoidBe certain to use the correct units of measurement to avoid

errors. The units of measure are displayed at the top right cornererrors. The units of measure are displayed at the top right corner

errors. The units of measure are displayed at the top right corner

errors. The units of measure are displayed at the top right cornererrors. The units of measure are displayed at the top right corner

of the screen. Tof the screen. T

of the screen. T

of the screen. Tof the screen. T

inches mode selection keyinches mode selection key

inches mode selection key

inches mode selection keyinches mode selection key

Step 5

Nominal Z is the length of the tool. Use the numeric keypad to

enter a value for nominal Z and press enter.

Step 6

Enter the name of the setting gage to be used with this tool. The

setting gage name may be entered with the numeric keypad or by

pressing the list softkey. When using the list softkey, use the up or

down arrow keys to scroll through the list. Highlight the setting

gage to be used and press enter. If the setting gage has not been

entered the user will be unable to save the tool data.

..

.

..

o change the units of measure press the mm/o change the units of measure press the mm/

o change the units of measure press the mm/

o change the units of measure press the mm/o change the units of measure press the mm/

..

.

..

Step 7

The TC200 allows the user to store the location of tools in the

location field. Location refers to the physical storage location of

the tool and not the position of the tool (POT) in the automated

tool changer. Entries in this field are optional. Use the numerical

keypad to enter the tool location and press enter. To continue

without entering a location simply press enter.

2-13

Page 40

Chapter 2 Operation

Step 8

The TC200 includes additional inputs for radius and angle for specialized cutting tools. For conventional milling procedures these

fields are left blank.

Step 9

Press the save softkey to save the tool. The TC200 displays the

tool just created.

Creating a tool sequence

The TC200 records user input and store it as a tool sequence. Tool

sequences can be saved for repeated use or modified for slightly

different tasks. For more on modifying tool sequences see Chapter 3: operation.

NOTENOTE

NOTE

NOTENOTE

While recording a tool sequence, use the cancel key to return toWhile recording a tool sequence, use the cancel key to return to

While recording a tool sequence, use the cancel key to return to

While recording a tool sequence, use the cancel key to return toWhile recording a tool sequence, use the cancel key to return to

a previously recorded tool. Pressing cancel once brings up thea previously recorded tool. Pressing cancel once brings up the

a previously recorded tool. Pressing cancel once brings up the

a previously recorded tool. Pressing cancel once brings up thea previously recorded tool. Pressing cancel once brings up the

previous tool; to go back three tools press cancel three times,previous tool; to go back three tools press cancel three times,

previous tool; to go back three tools press cancel three times,

previous tool; to go back three tools press cancel three times,previous tool; to go back three tools press cancel three times,

and so forth. Tand so forth. T

and so forth. T

and so forth. Tand so forth. T

pressing the tool sequence key then using the up or down arrowpressing the tool sequence key then using the up or down arrow

pressing the tool sequence key then using the up or down arrow

pressing the tool sequence key then using the up or down arrowpressing the tool sequence key then using the up or down arrow

keys to select the desired tool and pressing finish.keys to select the desired tool and pressing finish.

keys to select the desired tool and pressing finish.

keys to select the desired tool and pressing finish.keys to select the desired tool and pressing finish.

ools can also be re-measured after recording byools can also be re-measured after recording by

ools can also be re-measured after recording by

ools can also be re-measured after recording byools can also be re-measured after recording by

2-14

Step 1

Press the tool sequence feature selection key. The LCD displays

the Recording Temp screen.

Page 41

Tool-Chek® TC200

Step 2

Press the save softkey. Use the numerical keypad to enter a tool

sequence name and press OK. The DRO screen is displayed.

NOTENOTE

NOTE

NOTENOTE

In the running temp or running sequence screen, use the leftIn the running temp or running sequence screen, use the left

In the running temp or running sequence screen, use the left

In the running temp or running sequence screen, use the leftIn the running temp or running sequence screen, use the left

and right arrow keys to view the entire tool report.and right arrow keys to view the entire tool report.

and right arrow keys to view the entire tool report.

and right arrow keys to view the entire tool report.and right arrow keys to view the entire tool report.

2-15

Page 42

Chapter 2 Operation

Running a tool sequence

Step 1

Press the tool sequence feature selection key. Press the select

softkey and use the cursor keys to highlight the desired sequence.

Press the enter key.

Step 2

Press the run softkey. The name of the first tool in the sequence

appears in the upper left corner of the screen.

2-16

Page 43

Tool-Chek® TC200

Step 3

Align the tool on the tool presetter. When the tool is aligned

press finish. The next tool in the sequence is displayed in the

upper left corner of the screen. Repeat this process for each of

the tools in the sequence.

2-17

Page 44

Chapter 2 Operation

Step 4

After the last tool in the sequence press finish. The TC200 prompts

‘Print tool sequence report?’

Press the yes softkey to print a report, otherwise press the no

softkey. The tool sequence has been successfully completed.

2-18

Page 45

Measuring a circle

Tool-Chek® TC200

Circles can be measured by targeting between 3 and 100 points

around the circumference. Generally, accuracy of the feature is

increased as more points are targeted and the targeted points are

distributed at more or less equal arc distances around the circle.

When more than 3 points are targeted, a best-fit algorithm will be

used to create the circle feature and an F (Form) value will be

included in the circle feature data.

NOTENOTE

NOTE

NOTENOTE

The procedure below assumes that circle data is required for aThe procedure below assumes that circle data is required for a

The procedure below assumes that circle data is required for a

The procedure below assumes that circle data is required for aThe procedure below assumes that circle data is required for a

saved tool. If circle data is required for simple verification orsaved tool. If circle data is required for simple verification or

saved tool. If circle data is required for simple verification or

saved tool. If circle data is required for simple verification orsaved tool. If circle data is required for simple verification or

other purposes, press the circle feature selection key and proceedother purposes, press the circle feature selection key and proceed

other purposes, press the circle feature selection key and proceed

other purposes, press the circle feature selection key and proceedother purposes, press the circle feature selection key and proceed

from step 3.from step 3.

from step 3.

from step 3.from step 3.

To measure a circle

Step 1

Press the Circle feature selection key. Be certain there is not a tool

selected. If a tool name appears at the top of the screen press the

Quit command key followed by Circle feature selection key. The

Probe Circle screen will be displayed.

2-19

Page 46

Chapter 2 Operation

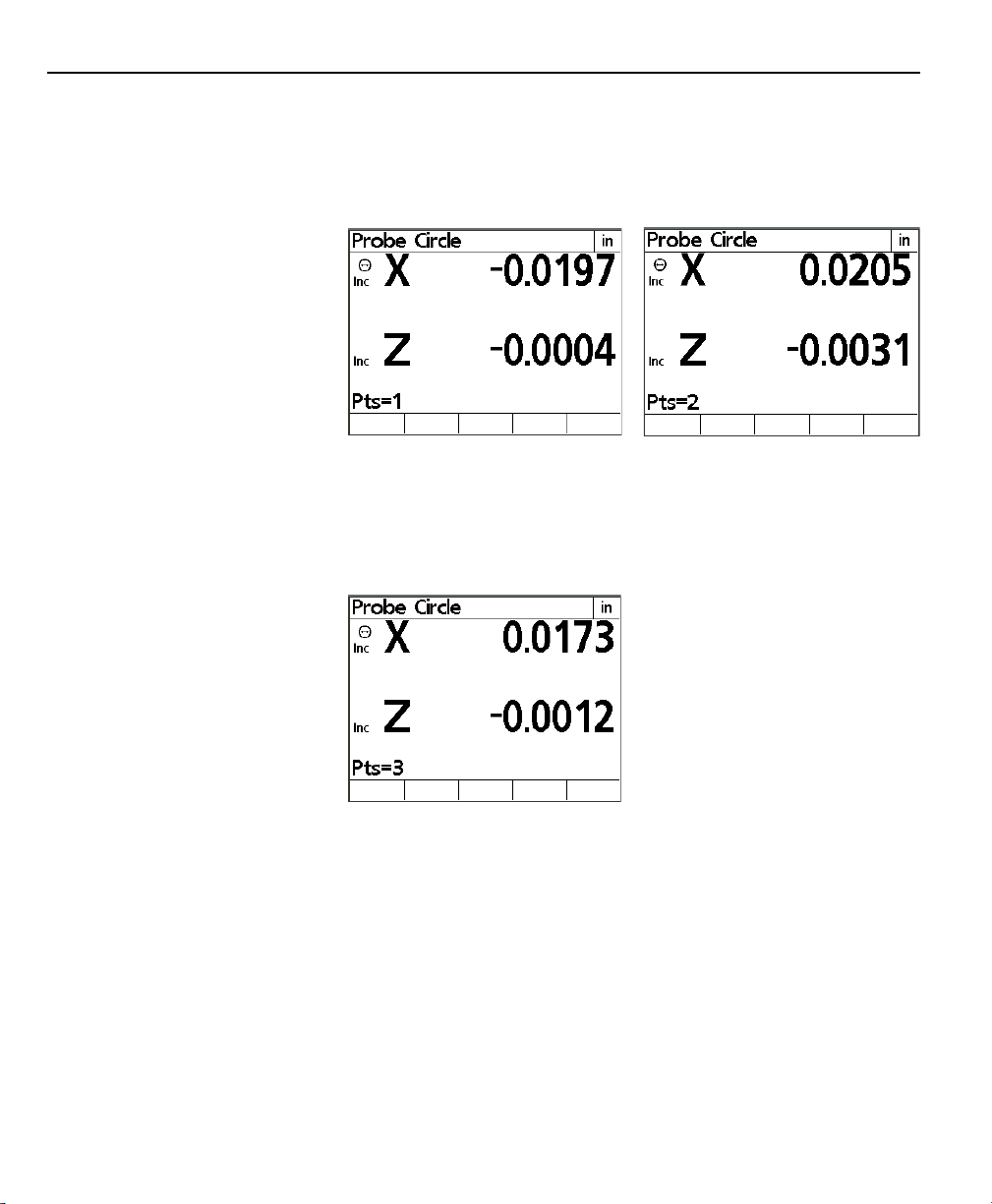

Step 2

Align the tool with the crosshairs on the tool presetter and press

enter. The location of the targeted point will be shown on the

Probe Circle screen and the number of points indicated on the

lower left part of the display will increase.

Step 3

Align the tool with the crosshairs on the tool presetter on the

second point and press enter. The new location will be shown

and the number of points will increase again. The Tool-Chek requires a minimum of 3 points to measure a circle.

2-20

Page 47

Tool-Chek® TC200

Step 4

Continue this process until all of the points have been targeted

and entered. When all of the required points on the perimeter of

the circle have been entered, press the Finish key.

Step 5

Press the Tool feature selection key. Enter the tool information

and press the save softkey.

2-21

Page 48

Chapter 2 Operation

Measuring an angle

Angles can be measured by targeting between 2 and 100 points

on each of the vertices of the angle. Generally, accuracy of the

feature is increased as more points are targeted and the targeted

points are distributed at more or less equal distances along the

line.

NOTENOTE

NOTE

NOTENOTE

The procedure below assumes that angle data is required for aThe procedure below assumes that angle data is required for a

The procedure below assumes that angle data is required for a

The procedure below assumes that angle data is required for aThe procedure below assumes that angle data is required for a

saved tool. If angle data is required for simple verification orsaved tool. If angle data is required for simple verification or

saved tool. If angle data is required for simple verification or

saved tool. If angle data is required for simple verification orsaved tool. If angle data is required for simple verification or

other purposes, press the angle feature selection key and proceedother purposes, press the angle feature selection key and proceed

other purposes, press the angle feature selection key and proceed

other purposes, press the angle feature selection key and proceedother purposes, press the angle feature selection key and proceed

from step 2.from step 2.

from step 2.

from step 2.from step 2.

To measure an angle

Step 1

Press the Angle feature selection key. Be certain there is not a

tool selected. If a tool name appears at the top of the screen

press the Quit command key followed by Angle feature selection

key. The Probe Line 1 screen will be displayed.

2-22

Page 49

Tool-Chek® TC200

Step 2

Align the first line of the angle with the crosshairs on the tool

presetter and press enter. The location of the targeted point will

be shown on the Probe Line 1 screen and the number of points

indicated on the lower left part of the display will increase. A

minimum of 2 points is needed for a line. When all points are

entered press the Finish command key.

Step 3

Align the second line of the angle with the crosshairs on the tool

presetter and press enter. The location of the targeted point will

be shown on the Probe Line 2 screen and the number of points

indicated on the lower left part of the display will increase. A

minimum of 2 points is needed for a line. When all points are

entered press the Finish command key.

2-23

Page 50

Chapter 2 Operation

Step 4

Press the Tool feature selection key. Enter the tool information

and press the save softkey.

2-24

Page 51

Tool-Chek® TC200

Zeroing Axes

Press the zero key to zero one or both axes on the TC200. The

TC200 will prompt: press axis to zero, or press zero again to zero

both axes.

Freezing Axes

Occasionally a tool is to large to fit entirely on the tool presetter.

When this happens it is sometimes necessary to measure one axis

at a time. The TC200 allows users to freeze axes in order to measure along only one axis at a time.

To freeze an axis, press the freeze/zero axis key adjacent the axis

to be froze. In this example the X axis is frozen. When an axis is

frozen it appears in a hollow font.

2-25

Page 52

Chapter 2 Operation

2-26

Page 53

Configuring the TC200

Basic setup terms

Chapter 3

Setup

Configure the TC200 prior to using it the first time and when tool

measurement, reporting, or data communication requirements

change. System configurations are entered using the arrow keys,

command keys, softkeys, and numeric keypad. The setup menu

structure allows easy navigation and quick setup of the TC200.

The following is a list of terms used in this chapter and their definitions.