Page 1

Quick Reference Guide

Kurzanleitung

ND 1200 R

Radial

Softwar e Version

2.8.x

2/2011

Page 2

quit

cancel

enter

finish

+/-0

4

1

7

5 6

2 3

8 9

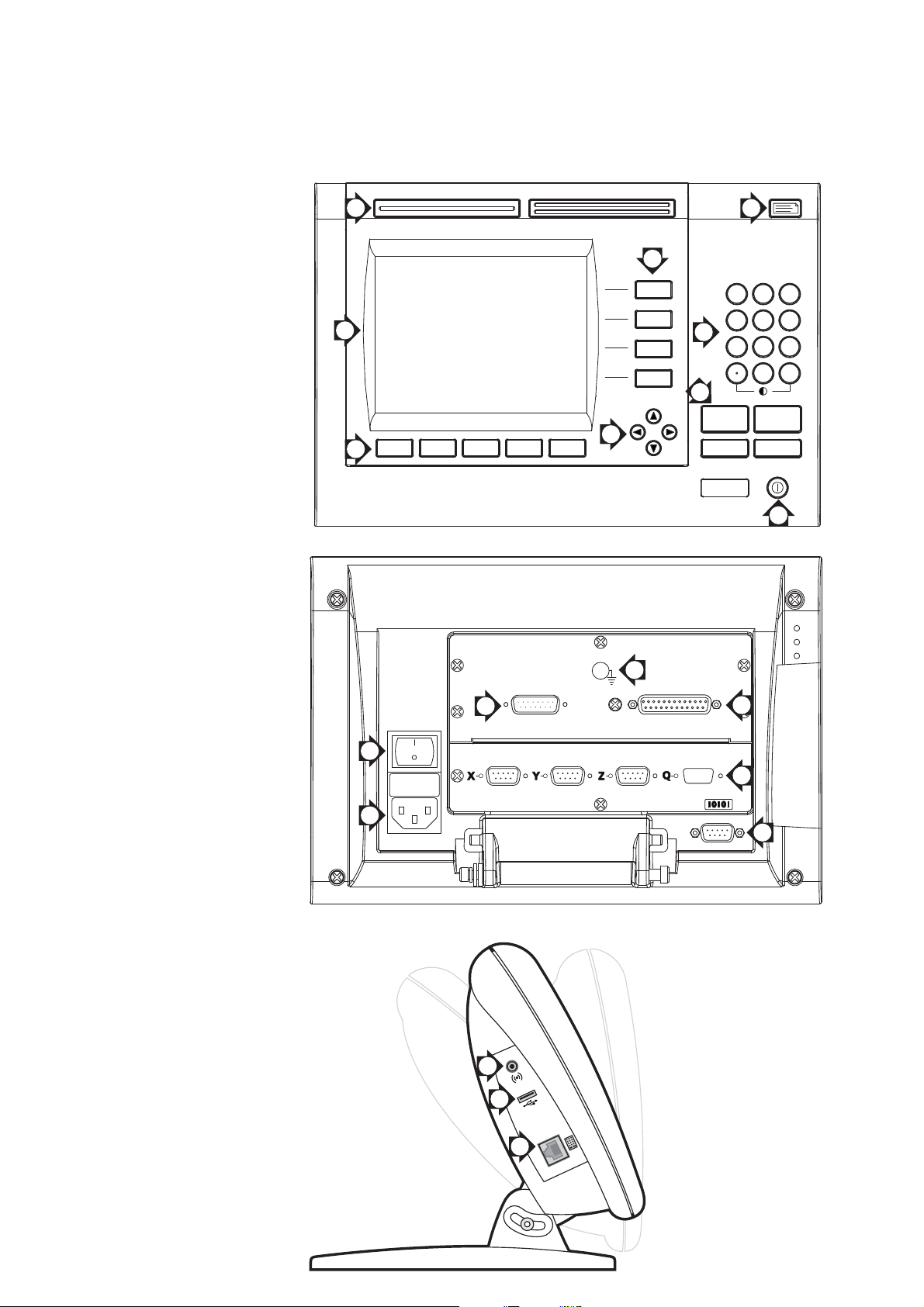

ND 1200 R RADIAL

Front panel

F

C

H

Rear side

A

G

+/-

D

enter

B

E

3

6

1

cancel

finish

quit

I

7

4

Side view

2

5

8

9

10

Page 3

ND 1200 R RADIAL

English

Setup

For detailed description, see www.heidenhain.de

Before Power up

Electrical connection

Line voltage: 100V~ to 240V

(–15 % to +10 %)

Line frequency: 43 Hz to 63 Hz

Line fuse: T1600 mA, 250 V

5 x 20 mm

Power connector wiring

L: Line voltage (brown)

N: Neutral (blue)

Earth ground (yellow/green)

Danger of electr ical shoc k!

Do not open the enclosure•

Never use 3-wire to 2-wire adapters •

or allow the ground connection to

the ND 1200 R to be interrupted or

disconnected.

Caution

Changes to the power cable may be

made only by an electrical technician.

Caution

Do not connect encoders or other

equipment to the ND 1200 R when the

power is on.

Safety Considerations

General accepted safety precautions

must be followed when operating the

ND 1200 R. Failure to observe these

precautions could result in damage to

the equipment, or injury to personnel.

It is understood that safety rules within

individual companies vary. If a confl ict

exists between the material contained

in this guide and the rules of a company

using this system, the more stringent

rules should take precedence.

Controls and Displays

A LCD scr een

B

Soft ke ys: Change to support

functions

C

Axis keys: Enter target

information

D

Command keys: Control

operations

E

Arro w cursor keys: Menu

navigation

F

Fast trac k keys: Programmable

for frequently used functions

G

Numeric k e ypad: Enter numeric

data

H

Send key: Transmit data to PC,

USB printer or USB drive

I

LCD on/off ke y: Turn LCD on or

off and clear data

Connections rear side

1 Pow er switc h

2 Pow er connection with fuse

3

Ground (protective ground)

4

Encoder inputs, X, Y and Z axis.

5

RS-232-C interface f or PC

connection. RS-232 cable must

not include crossovers.

6

Probe connector for

HEIDENHAIN 15 pin universal

touch probe sensor.

7 Unused

Connections side view

8

Audio out, for 3.5 mm

headphone / speaker jack,

monaural, 8 Ohm

9

USB type A int erface for printer

or data storage

10

Remote accessory interf ace

RJ-45 for optional foot switc h or

keypad accessory . Two optional

remote accessories can be used

simultaneously using an RJ-45

splitter.

Mounting

The ND 1200 R is secured to the swivel

slots of the mounting stand or arm

mount by a shoulder screw, a cap

screw mount as shown and associated

washers.

Very important

Please note

For your information

Initial power up

Press the power• switch to power

the ND 1200 R. The startup screen is

displayed. Press the FINISH key to

display the current axis positions on

the DRO screen.

Software setup

The operating parameters of the

ND 1200 R must be confi gured prior

to using it for the fi rst time, and any

time part measurement, reporting or

communication requirements change.

Settings will be retained until:

The data-backup battery is changed•

The data and settings are cleared•

Caution

Setup parameters control the operation

of the ND 1200 R and are passwordprotected. Only qualifi ed personnel

should be given password access to

setup screens.

Access setup menu1.

Press the MENU soft k e y and then the

SETUP sof t k e y. The setup menu is

displayed.

Select the language2.

Use the arrow cursor• keys to highlight

the desired language fi eld.

Press the • YES soft key.

Press the • FINISH key.

Enter password3.

Use the arrow cursor• keys to navigate

to the SUPERVISOR setup screen.

Highlight the • PASSWORD fi eld and

enter the password.

Enable • STARTUP ZERO if a machine

zero will be used for error correction.

Press the • FINISH key.

1

Page 4

ND 1200 R RADIAL

Setup

Operation

Encoder setup4.

Use the arrow cursor• keys to navigate

to the ENCODERS setup screen.

Select an axis and enter the required •

encoder parameters.

Repeat setup for all axes.•

Press the • FINISH key.

Radial Drill setup5.

Use the arrow cursor keys to navigate •

to the RADIAL DRILL setup screen.

Enter the desired parameters and •

press the FINISH key.

Error correction6.

Linear error correction (LEC) methods

can be used to compensate for encoder

and machine measurement errors.

Refer to the ND 1200 R User Guide f or

instructions.

Display formatting7.

Use the arrow cursor keys to navigate •

to the DISPLAY screen.

Enter the desired display resolutions •

and other parameters.

Press the • FINISH key.

Note:

Refer to the ND 1200 R User Guide f or

additional setup functions.

Preparation

Power up the ND 1200 R1.

Check connections to the ND 1200 R.•

Press the • POWER switch to power

the ND 1200 R.

Press the • FINISH key to display the

DRO screen.

Find machine zero2.

Move the stage to cross reference

marks if the system was setup to

establish machine zero at startup.

Select a unit of measure3.

Press the MM (IN) soft k e y to toggle

between mm and inches.

Select coordinates4.

Press the X/Y (R/A) soft k e y to toggle

between rectangular and polar

coordinates

Replacement5.

The ND 1200 R must be parameterized

in accordance with the machine

settings. Transfer the correct parameters

or have a (re)calibration performed.

2

Probing a position

A position can be probed with a hard

probe or a touch probe.

Probing with a hard probe1.

Touch the probe to the edge of the •

workpiece.

Press • ENTER.

Enter the probe diameter.•

Press the arrow cursor key that •

indicates the probe compensation

direction.

Probing with a touch probe2.

Touch the edge of the workpiece with •

the probe.

Aligning the part

Perf orm a sk e w alignment to eliminate

cosine errors resulting from misaligned

parts.

Align the part on the stage1.

Align the reference edge of the part to a

measurement axis.

Perform a skew alignment2.

Press the • DATUM soft key.

Press the • SKEW soft key.

Probe points along the part edge •

aligned to the reference axis.

Press the • FINISH key to complete the

alignment.

Set zero point

The fi rst point of the skew will be used

as the zero point. Use ZERO to c hange

the zero point along the reference axis.

Press the • ZERO soft key.

Press the soft key for the axis to zero •

along (skew edge).

Probe the part edge perpendicular to •

the skew edge.

Note:

The center of a hole can be used as a

point for a skew alignment or setting a

zero point. Ref er to the ND 1200 R User

Guide for detailed instructions.

Move zero point

If the zero point of a part is not reachable

by a probe the zero point can be mov ed.

Press the • DATUM soft key

Press the • MOVE 0 soft key.

Enter the X and Y coordinates to •

move the zero point to.

Press • FINISH.

Target entry

Press the • X or Y axis key.

Enter the desired position to target.•

Press the • ENTER key.

Repeat for the opposite axis.•

Press the • FINISH key. The distance

from the target is displayed.

Hole patterns

Press the • MENU soft key.

Press the • PATTERN soft key.

Press the soft key to select the •

desired pattern.

Enter the desired parameters.•

Press • FINISH.

Programs

Save a program1.

Create a target sequence.•

Press the • MENU soft key.

Press the • PROG soft key.

Press the • SAVE soft key.

Use the numeric keypad to enter a •

name for the program.

Press the • ENTER key.

Run a program2.

Press the • MENU soft key.

Press the • PROG soft key.

Use the arrow cursor keys to highlight •

a program.

Press the • RUN soft key.

Delete a program3.

Press the • MENU soft key.

Press the • PROG soft key.

Use the arrow cursor keys to highlight •

a program.

Press the • DELETE soft key.

Press the • YES soft key.

Note:

Refer to the ND 1200 R User Guide f or

detailed instructions.

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 8669 31-0

| +49 8669 5061

E-mail: info@heidenhain.de

www.heidenhain.de

Page 5

ND 1200 R RADIAL

Deutsch

Einric hten

Eine genaue Beschreibung fi nden Sie unter www.heidenhain.de

Vor der Inbetriebnahme

Elektrischer Anschluss

Netzspannung: 1 00 V~ bis 240 V

(–15 % bis +10 %)

Netzfrequenz: 43 Hz bis 63 Hz

Netzsicherung: T1600 mA, 250 V

5 x 20 mm

Anschluss des Netzsteckers

L: Phase (braun)

N: Nullleiter (blau)

Schutzleiter (gelb/grün)

Stromschlaggefahr!

Gerät nicht öffnen!•

Schutzleiter der ND 1200 R darf nie •

unterbrochen sein, auch nicht bei

Anschluss über Adapter.

Achtung

Änderungen am Netzkabel nur durc h

Elektrotechniker!

Achtung

Keine Messgeräte oder anderen Geräte

anschließen, während die ND 1200 R

eingeschaltet ist.

Sicherheitsvorkehrungen

Für den B etrieb der ND 1200 R

gelten die allgemein anerkannten

Sicherheitsvorschriften. Nichtbeachtung

dieser Sicherheitsvorschriften kann zu

Sach- oder Personenschäden führen.

Die Sicherheitsvorschriften können je

nach Unternehmen variieren. Im F alle

eines Konfl ikts zwischen dem Inhalt

dieser Kurzanleitung und den internen

Regelungen eines Unternehmens, in

dem dieses Gerät verwendet wird,

sollten die strengeren Regelungen

gelten.

Anzeige- und Bedienelemente

A LCD-Bildschirm

B

Softke ys: funktionsabhängig

C

Achstasten: Eingabe v on

Zielinformationen

D

Befehlstasten: B estätigung v on

Aktionen

E

Pfeiltasten: Na vigation durch die

Menüs

F

Schnellzugrif fstast en: pro-

grammierbar für häufi g genutzte

Funktionen

G

Zahlenblock: Eingabe von Zahlen

H

Taste SENDEN: Daten an

PC, USB-Druc k er oder USBSpeichermedium senden

I

Taste LCD Ein/Aus: LCD-Anzeige

ein-/ausschalten oder Daten

löschen

Anschlüsse auf der Rückseite

1 Netzschalter

2 Netzanschluss mit Sicherung

3 Erdungsanschluss

(Schutzerdung)

4

Messgerät-Eingänge, X-, Y- und

Z-Achse

5

Schnittstelle V .24/RS-232-C

für PC-Anschluss. Kabel für V.24/

RS-232 darf keine gekreuzten

Adern haben.

6

Anschluss für 15-poliges univ ersel-

les Tastsy stem von HEIDENHAIN

7 Nicht belegt

Anschlüsse auf der Seite

8

Audio-Ausgang für Kopfhörer

3,5 mm / Lautsprecherbuchse,

Einohr , 8 Ohm

9

USB-Schnittstelle, Typ A, für

Druc k er oder Speichermedien

10 Schnittstelle RJ-45 für Fernbe-

dienung über optionalen Fuß-

schalter oder externes B edienfeld.

Mithilfe eines RJ-45-Split ters können zwei Fernbedienungsoptionen gleichzeitig genutzt w erden.

Montage

Die ND 1200 R wird mit einer

Passsc hraube, einer K opfschraube und

passenden Unterlegscheiben in den

Schwenkschlitzen des Montagefußes

oder -arms befestigt (s. Abb.)

unbedingt beachten

wichtig

informativ

Erstinbetriebnahme

Zum Einschalten der ND 1200 R •

den Netzschalter drücken. Der

Startbildschirm erscheint. Zur Anzeige

der aktuellen Achspositionen (ISTPOSITION) Taste FINISH drücken.

Software-Setup

Die Betriebsparameter der ND 1200 R

müssen vor der Erstinbetriebnahme und

immer , w enn sich die Anforderungen an

die Vermessung von T eilen, B erichterstellung oder Kommunikation ändern,

konfi guriert werden.

Einstellungen werden beibehalten bis:

Batterie für Daten-Backup gewechselt •

wird.

Daten und Einstellungen gelöscht •

werden.

Achtung

Die Setup-Parameter steuern die

Bedienung der ND 1200 R und sind

passwortgeschützt. Das Passwort für

die Setup-Menüs sollte nur an gesc hulte

Personen w eitergegeben w erden.

Menü „Setup“ öffnen1.

MENÜ-Softke y und dann Softkey SETUP

drücken. Das Menü „Setup“ wird

angezeigt.

Sprache wählen2.

Mit den Pfeiltasten• das gewünschte

Sprachfeld markieren.

Softkey • JA drücken.

Taste • FINISH drücken.

Passwort eingeben3.

Mit den Pfeiltasten• zum Untermenü

PASSWORT navigieren.

Das • PASSWORT-Datenfeld markieren

und Passwort eingeben.

NULLEN AM START• aktivieren, wenn

ein Maschinen-Bezugspunkt für die

Fehlerkompensation verwendet

werden soll.

Taste • FINISH drücken.

1

Page 6

ND 1200 R RADIAL

Einric hten

Bedienung

Setup für Messgerät4.

Mit den Pfeiltasten• zum Untermenü

MESSGERÄT navigieren.

Achse auswählen und erforderliche •

Messgerät-Parameter eingeben.

Setup für alle Achsen wiederholen.•

Taste • FINISH drücken.

Setup für Radial Drill5.

Mit den Pfeiltasten zum Untermenü •

RADIAL DRILL navigieren.

Gewünschte Parameter eingeben und •

mit Taste FINISH bestätigen.

Fehlerkompensation6.

Messgerät- und Maschinenmessf ehler

können mit der linearen

Fehlerkompensation (LEC) k orrigiert

werden. Siehe auch Geräte-Handbuch

ND 1200 R.

Anzeigeformat7.

Mit den Pfeiltasten zum Untermenü •

ANZEIGE navigieren.

Anzeigeaufl ösungen und weitere •

Parameter eingeben.

Taste • FINISH drücken.

Hinweis:

Für w eitere Einrichtefunktionen, siehe

auch Geräte-Handbuch ND 1200 R.

Vorbereitung

ND 1200 R einschalten1.

Anschlüsse der ND 1200 R •

überprüfen.

Zum Einschalten der ND 1200 R den •

NETZSCHALTER drücken.

Taste • FINISH drücken, um die

Anzeige „IST-Position“ zu öffnen.

Maschinen-Nullpunkt ermitteln2.

Zum Überfahren der Ref erenzmark en

Tisch verschieben, wenn beim

Systemstart ein Masc hinenBezugspunkt festgelegt w erden soll.

Maßeinheit wählen3.

Softke y MM (IN) drücken, um zwischen

Millimeter und Zoll umzuschalten.

Koordinatensystem auswählen4.

Softke y X/Y (R/A) drücken, um

zwischen kartesischem und polarem

Koordinatensystem umzusc halten.

Gerät austauschen5.

Die Parametrierung der ND 1200 R muss

auf die Maschine abgestimmt sein.

Übertragen Sie die korrekten Parameter

oder lassen Sie eine Kalibrierung

durchführen.

2

Position erfassen

Eine Position kann mittels Taststift oder

Kantentaster erfasst werden.

Erfassung mittels Taststift1.

Werkstückkante mit dem Taststift •

antasten.

ENTER• drücken.

Taststift-Durchmesser eingeben.•

Pfeiltaste für die Richtung der •

Taststiftkorrektur drücken.

Erfassung mittels Kantentaster2.

Werkstückkante mit dem •

Kantentaster antasten.

Teileausrichtung

Mit der T eileausrichtung werden

Kosinus-Messfehler aufgr und f alsch

ausgerichteter T eile beseitigt.

Werkstück auf dem Tisch 1.

ausrichten

Bezugskante des Werkstücks an einer

Messachse ausrichten.

Ausrichtung durchführen2.

Softkey • BEZUGSPUNKT drücken.

Softkey • AUSRICHTUNG drücken.

Punkte entlang der an der Messachse •

ausgerichteten Werkstückkante

erfassen.

Taste • FINISH drücken, um die

Ausrichtung abzuschließen.

Nullpunkt setzen

Der erste Punkt der Ausrichtung dient

als Nullpunkt. Mit NULLEN kann der

Nullpunkt entlang der Bezugsachse

verschoben w erden.

Softkey • NULLEN drücken.

Softkey für die Achse, an der der •

Nullpunkt verschoben werden soll,

drücken (Ausrichtungskante).

Werkstückkante senkrecht zur •

Ausrichtkante antasten.

Hinweis:

Ein Loch-Mittelpunkt kann als

Ausric ht ungspunkt dienen oder zum

Nullpunkt-Setzen verwendet werden.

Eine genaue Anleitung fi nden Sie im

Geräte-Handbuch ND 1200 R.

Nullpunkt verschieben

Wenn der Nullpunkt eines Teils mit dem

Tastsystem nicht zu erreic hen ist, kann

er verschoben w erden.

Softkey • BEZUGSPUNKT drücken.

Softkey • NULL VER. drücken.

Die X- und Y-Koordinaten für die •

Nullpunktverschiebung eingeben.

FINISH• drücken.

Zieleingabe

Taste für die • X- oder Y-Achse drücken.

Gewünschte Zielposition eingeben.•

Mit • ENTER bestätigen.

Für die gegenüberliegende Achse •

wiederholen.

Taste • FINISH drücken. Die Entfernung

zum Ziel wird angezeigt.

Lochmuster

Softkey • MENÜ drücken.

Softkey • LÖCHER drücken.

Mittels Softkey das gewünschte •

Lochmuster auswählen.

Die gewünschten Parameter •

eingeben.

FINISH• drücken.

Programme

Programm speichern1.

Zielsequenz erstellen.•

Softkey • MENÜ drücken.

Softkey • PROG drücken.

Softkey • SPEICHERN drücken.

Mittels Zahlenblock einen •

Programmnamen eingeben.

Mit • ENTER bestätigen.

Programm ausführen2.

Softkey • MENÜ drücken.

Softkey • PROG drücken.

Mit den Pfeiltasten ein Programm •

markieren.

Softkey • AUSF. drücken.

Programm löschen3.

Softkey • MENÜ drücken.

Softkey • PROG drücken.

Mit den Pfeiltasten ein Programm •

markieren.

Softkey • LÖSCH. drücken.

Softkey • JA drücken.

Hinweis:

Eine genaue Anleitung fi nden Sie im

Geräte-Handbuch ND 1200 R.

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 8669 31-0

| +49 8669 5061

E-mail: info@heidenhain.de

www.heidenhain.de

Page 7

ND 1200 R RADIAL

Tilting base

Mounting base

158.75

A

203.2

260

B

M6.3 - 1.3 x 16.5

(1/4 - 20" x 0.65")

M5

200

203.5

mm

Tolerancing ISO 8015

ISO 2768 - m H

< 6 mm: ±0.2 mm

125

27.5

38

43.5

55

B

Page 8

4

XYZQ » 1 V

PP

4 12 2 10 1 9 3 11 14 7 5/6/8/

13/15

» 1 V

pp

U

Sensor

P

U

P

0 V Sensor

0 V

A+ A– B+ B– R+ R– /

4

XYZQ « TTL

762345981

« TTL U

P

0 V U

a1

U

a2

£

U

a0

¤

/

5

V.24/RS-232-C

123456789

/ TXD RXD DTR Signal

DSR RTS CTS /

GND

6

HEIDENHAIN

Universal T ouch Probe

1 2 4 5 6 8 10 11 13 15 3/7/9/

12/14

GND LED+ 12 Vdc 15 Vdc 5 Vdc GND In S+ I(2) S+ I(1) LED- /

7

Parallel Input/Output Port

23456789114161718

Data

Out 1

Data

Out 2

Data

Out 3

Data

Out 4

Data

Out 5

Data

Out 6

Data

Out 7

Data

Out 8

Data

Out 9

Data

Out 10

Data

Out 11

Data

Out 12

Signal

GND

15 13 12 11 1 0 19 20 21 22 23 24 25 –

Data

In 1

Data

In 2

Data

In 3

Data

In 4

Data

In 5

Signal

GND

Signal

GND

Signal

GND

Signal

GND

Signal

GND

Signal

GND

Signal

GND

/

Page 9

8

Audio out

9

USB T ype A

Data I/O

12 3 4

/ Data (-) Data (+) Data

10

RJ-45

Remote Footswitch

12

Out Signal GND

GND

12345678

Signal

GND

S-2

NO

S-1

NO

/ S-1 and S-2

CO

///

Page 10

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 8669 31-0

| +49 8669 5061

E-mail: info@heidenhain.de

Technical support | +49 8669 32 -1000

Measuring systems { +49 8669 31-3104

E-mail: service.ms-support@heidenhain.de

TNC support { +49 8669 31-3101

E-mail: service.nc-support@heidenhain.de

NC programming { +49 8669 31-3103

E-mail: service.nc-pgm@heidenhain.de

PLC programming { +49 8669 31-3102

E-mail: service.plc@heidenhain.de

Lathe controls { +49 8669 31-3105

E-mail: service.lathe-support@heidenhain.de

www.heidenhain.de

Page 11

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 8669 31-0

| +49 8669 5061

E-mail: info@heidenhain.de

www.heidenhain.de

Vollständige und weitere Adressen siehe www.heidenhain.de

For complete and further addr esses see www.heidenhain.de

DE HEIDENHAIN T ec hnisches Bür o Nor d

12681 Berlin, Deutschland

{ 030 54705-240

HEIDENHAIN T ec hnisches Bür o Mit t e

08468 Heinsdorfergrund, Deutschland

{ 03765 69544

HEIDENHAIN Technisches Büro West

44379 Dortmund, Deutschland

{ 0231 618083-0

HEIDENHAIN T ec hnisches Bür o Südw est

70771 Leinfelden-Ec hterdingen, Deutschland

{ 0711 993395-0

HEIDENHAIN T ec hnisches Bür o Südost

83301 T raunreut, Deutschland

{ 08669 31-1345

AR NAKASE SRL.

B1653AO X Villa Ballester, Argentina

www.heidenhain.com.ar

AT HEIDENHAIN Techn. Büro Öster r eic h

83301 T raunreut, Germany

www.heidenhain.de

AU FCR Motion Technology Pty. Ltd

Laverton North 3026, A ustralia

E-mail: vicsales@fcrmotion.com

BA Bosnia and Herzegovina − SL

BE HEIDENHAIN NV/SA

1760 Roosdaal, Belgium

www.heidenhain.be

BG ESD Bulgaria Ltd.

Sofi a 1172, Bulgaria

www.esd.bg

BR DIADUR Indústria e Comércio Ltda.

04763-070 – São Paulo – SP, Brazil

www.heidenhain.com.br

BY Belarus

GERTNER Service GmbH

50354 Huerth, Germany

www.gertner.biz

CA HEIDENHAIN CORPORATION

Mississauga, OntarioL5T2N2, Canada

www.heidenhain.com

CH HEIDENHAIN (SCHWEIZ) AG

8603 Schwerzenbach, Switzerland

www.heidenhain.ch

CN DR. JOHANNES HEIDENHAIN

(CHINA) Co., Ltd.

Beijing 1 01312, China

www.heidenhain.com.cn

CZ HEIDENHAIN s.r.o.

102 00 Praha 10, Czech Republic

www.heidenhain.cz

DK TP TEKNIK A/S

2670 Greve, Denmark

www.tp-gr uppen.dk

ES F ARRESA ELECTRONICA S .A.

08028 Barcelona, Spain

www.f ar resa.es

FI HEIDENHAIN Scandinavia AB

02770 Espoo, Finland

www.heidenhain.fi

FR HEIDENHAIN FRANCE sarl

92310 Sèvres, France

www.heidenhain.fr

GB HEIDENHAIN (G.B.) Limit ed

Burgess Hill RH15 9RD , United Kingdom

www.heidenhain.co.uk

GR MB Milionis Vassilis

17341 Athens, Greece

www.heidenhain.gr

HK HEIDENHAIN LTD

Kowloon, Hong Kong

E-mail: sales@heidenhain.com.hk

HR Croatia − SL

HU HEIDENHAIN Kereskedelmi Képviselet

1239 Budapest, Hungary

www.heidenhain.hu

ID PT Servitama Era Toolsindo

Jakarta 13930, Indonesia

E-mail: ptset@group.gts.co.id

IL NEUMO VARGUS MARKETING LTD.

Tel Aviv 61570, Israel

E-mail: neumo@neumo-vargus.co.il

IN HEIDENHAIN Optics & Electronics

India Privat e Limit ed

Chetpet, Chennai 600 031, India

www.heidenhain.in

IT HEIDENHAIN ITALIANA S.r.l.

20128 Milano, Italy

www.heidenhain.it

JP HEIDENHAIN K.K.

Tokyo 102-0083, Japan

www.heidenhain.co.jp

KR HEIDENHAIN Korea L TD .

Gasan-Dong, Seoul, Korea 153-782

www.heidenhain.co.kr

ME Montenegro − SL

MK Macedonia − BG

MX HEIDENHAIN CORPORA TION MEXICO

20235 Aguascalientes, Ags., Mexico

E-mail: info@heidenhain.com

MY ISOSERVE Sdn. Bhd

56100 Kuala Lumpur, Malaysia

E-mail: isoserve@po.jaring.my

NL HEIDENHAIN NEDERLAND B.V.

6716 BM Ede, Netherlands

www.heidenhain.nl

NO HEIDENHAIN Scandinavia AB

7300 Orkanger, Norway

www.heidenhain.no

PH Machinebanks` Corporation

Quezon City, Philippines 1113

E-mail: info@machinebanks.com

PL APS

02-489 Warszawa, Poland

www.apserwis.com.pl

PT FARRESA ELECTRÓNICA, LD A.

4470 - 177 Maia, Portugal

www.f ar resa.pt

RO HEIDENHAIN Reprezentant¸a˘ Romania

Bras¸ov, 500338, Romania

www.heidenhain.ro

RS Serbia − BG

RU OOO HEIDENHAIN

12531 5 Mosco w, Russia

www.heidenhain.r u

SE HEIDENHAIN Scandinavia AB

12739 Skärholmen, Sw eden

www.heidenhain.se

SG HEIDENHAIN PACIFIC PTE LTD.

Singapore 408593

www.heidenhain.com.sg

SK KOPRETINA TN s.r.o.

91 10 1 T rencin, Slovakia

www.k opretina.sk

SL Posredništvo HEIDENHAIN

NA VO d.o.o.

2000 Maribor, Slovenia

www.heidenhain-hubl.si

TH HEIDENHAIN (THAILAND) LTD

Bangkok 10250, T hailand

www.heidenhain.co.th

TR T&M Mühendislik San. ve Tic. LTD. S¸TI·.

34728 Ümraniye-Istanbul, Turk e y

www.heidenhain.com.tr

TW HEIDENHAIN Co., Ltd.

T aichung 40768, Taiw an R.O .C.

www.heidenhain.com.tw

UA Gertner Service GmbH Büro Kiev

01133 Kie v, Ukraine

www.gertner.biz

US HEIDENHAIN CORPORATION

Schaumburg, IL 60173-5337, USA

www.heidenhain.com

VE Maquinaria Diekmann S.A.

Caracas, 1040-A, Venezuela

E-mail: purchase@diekmann.com.ve

VN AMS Co. Ltd

HCM City, Vietnam

E-mail: davidgoh@amsvn.com

ZA MAFEMA SALES SERVICES C.C.

Midrand 1685, South Africa

www.heidenhain.co.za

Zum Abhef t en hier falzen! / Fold here for fi ling!

732 602-90 · Ver00 · 0.5 · 2/2011 · Printed in USA

Loading...

Loading...