Page 1

Operating Instructions

ND 1200R

Radial

Software Version

2.8.x

English (en)

6/2013

Page 2

Page 3

ND 1200R Introduction

quit

cancel

enter

finish

+/-0

4

1

7

5 6

2 3

8 9

12345

678

9

quit

cancel

enter

finish

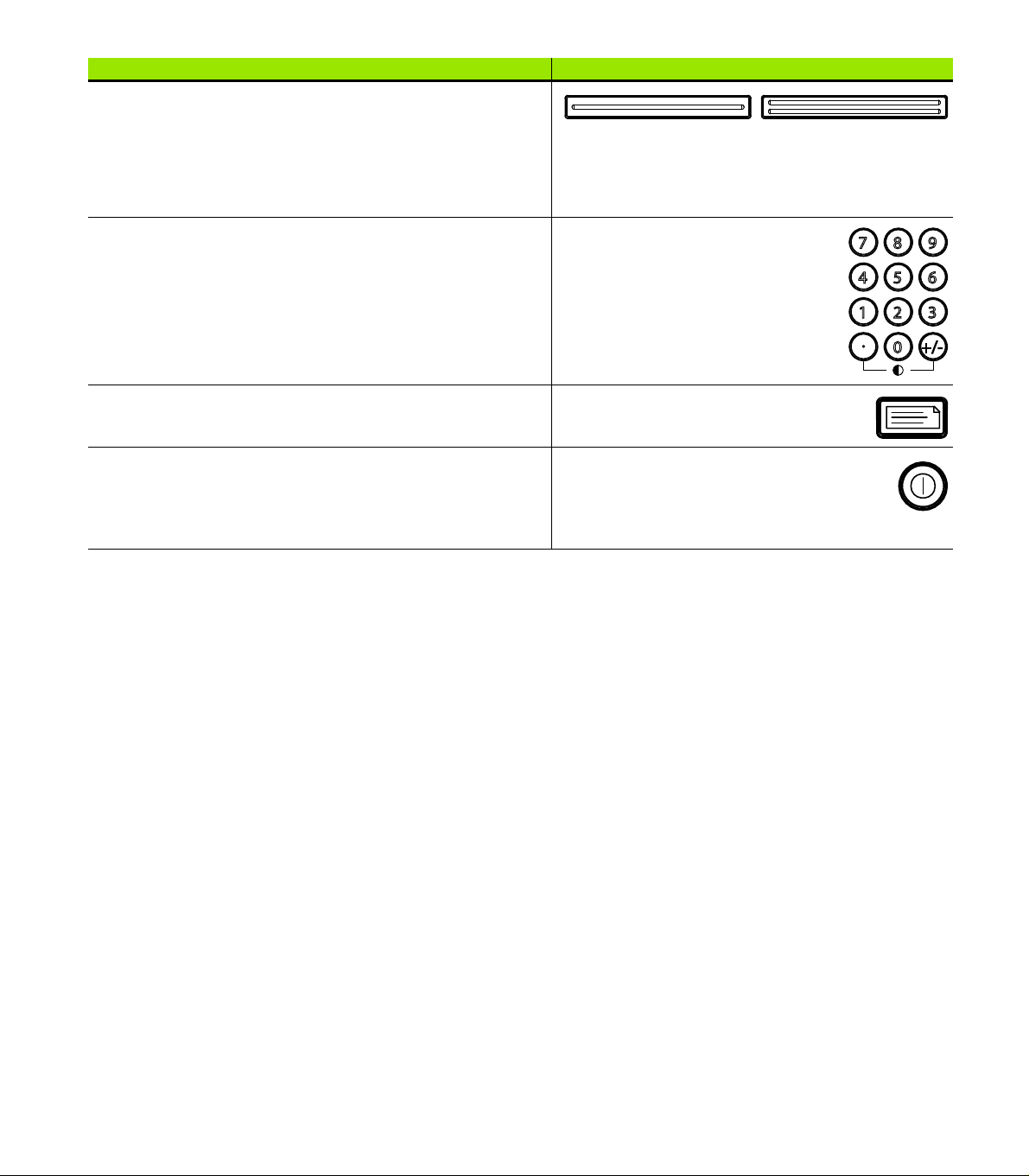

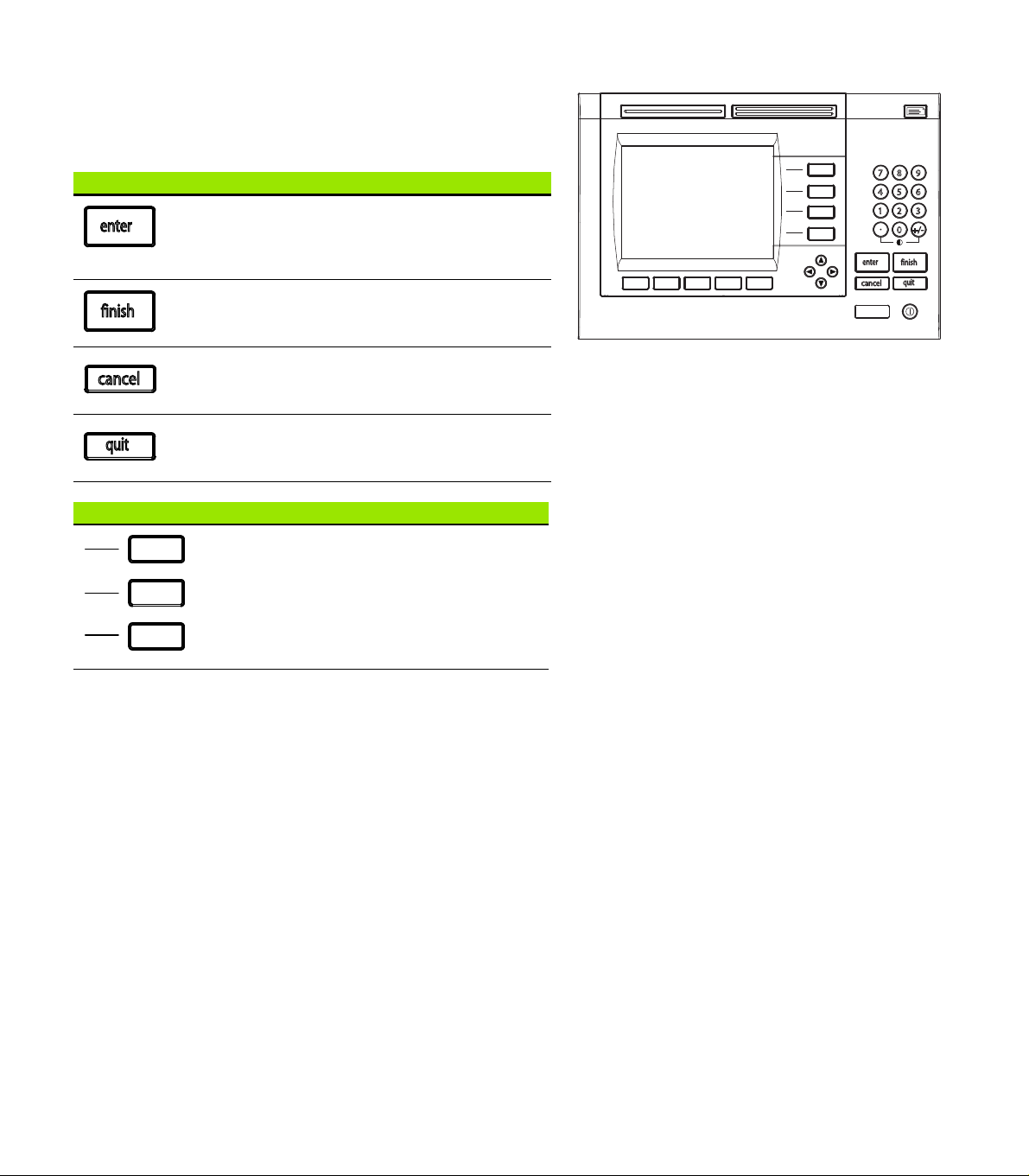

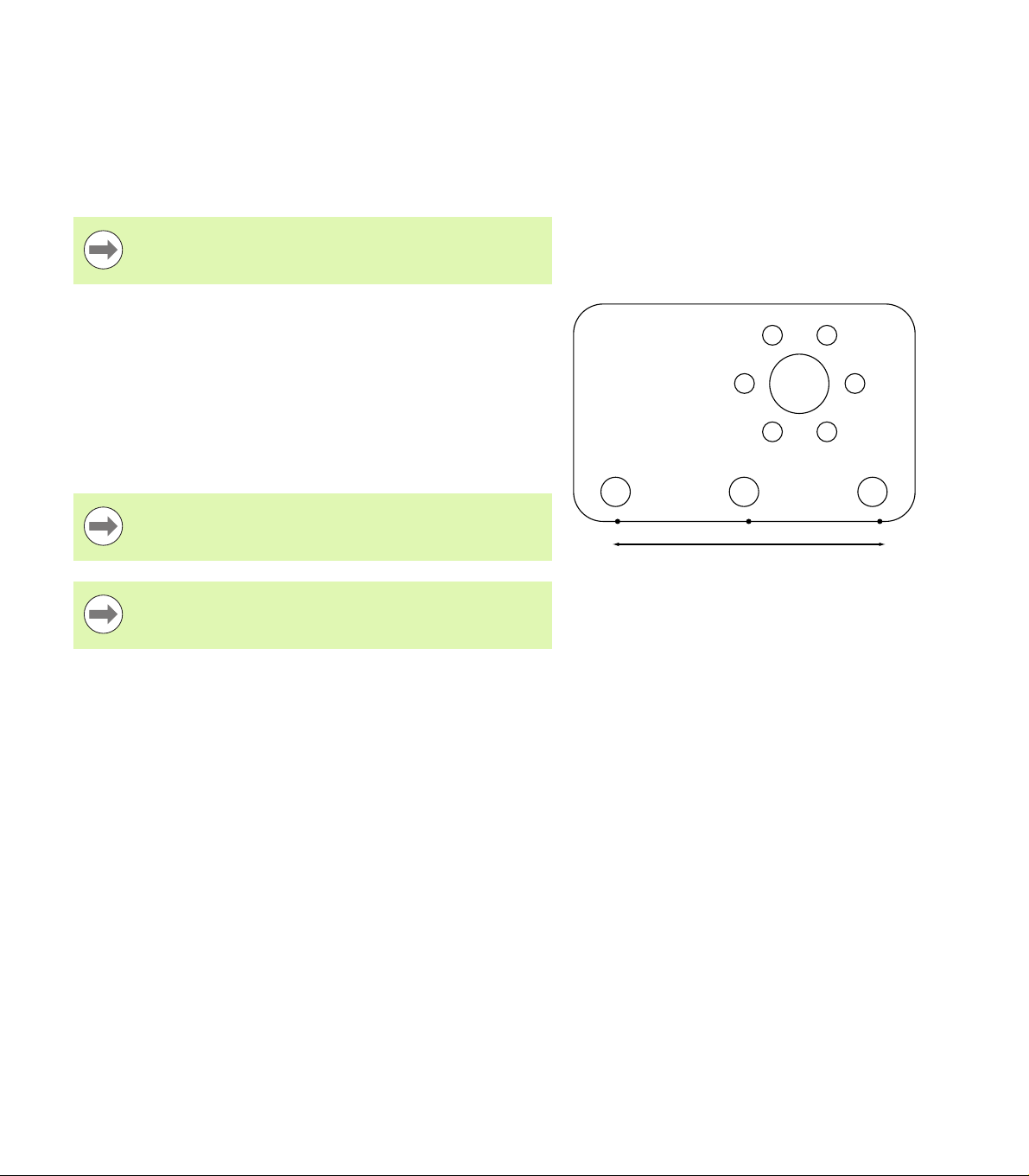

1 LCD screen

2 Soft keys

3 Axis keys

4 Command keys

5 Arrow keys

6 Wide keys

7 Numeric keypad

8 Send key

9 LCD On/Off key

ND 1200R panel keys

Panel keys are used to enter target position coordinates, send data via

RS-232 and USB ports and configure operational parameters.

Panel function key Panel key

Soft keys: Functions change in support of the activities displayed

on the LCD.

Axis keys: used to enter target positions.

Command keys: Control target and data entry processes.

Arrow keys: Used to scroll through lists and navigate menus and

setup screen data fields.

ND 1200R Radial 3

Page 4

Panel function key Panel key

+/-0

4

1

7

5 6

2 3

8 9

Wide keys: Two programmable Wide keys are used to perform

frequently used functions. These keys can easily be located by

touch without taking your eyes off the part. By default the left

fast track key is assigned the SEND2 function and the right is

assigned the ZERO2 function. Users can program either wide

key as described later in the Hotkeys portion of Chapter 2:

Installation, Setup and Specifications.

Numeric keypad: Used to enter numeric data. Additionally, the

decimal point key and +/- key are used to adjust the contrast

of the LCD display.

Send key: Used to transmit target data to a computer or USB

printer.

LCD On/Off key: Press the LCD on/off button to turn the LCD

display off without removing power from the ND 1200R. Press

the button a second time to restore the LCD display. Additionally,

the LCD On/Off key can be used to clear target data, datums and

skews.

4 Preface

Page 5

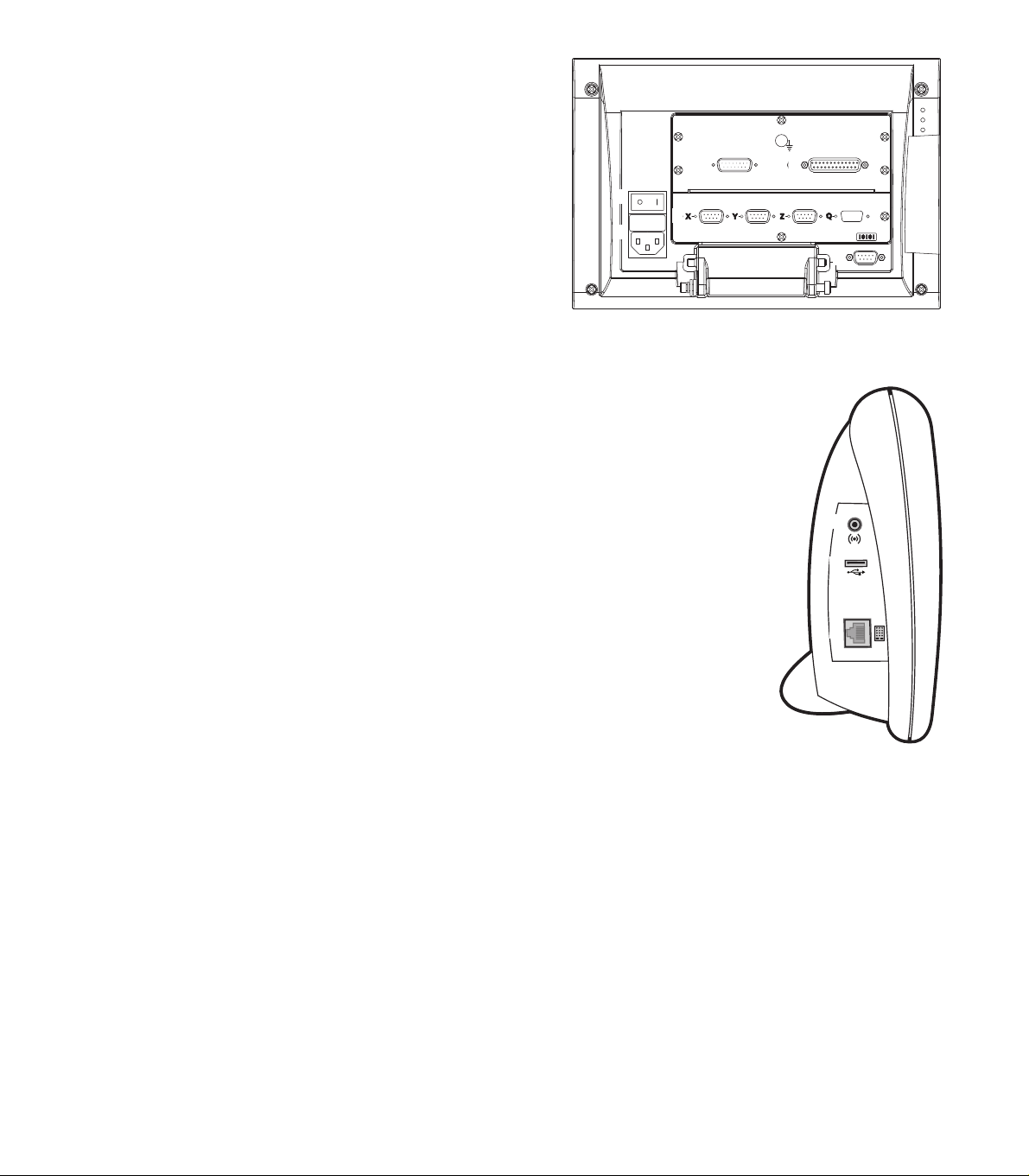

ND 1200R rear panel

1

2

3

5

4

678

123

1 Power switch

2 Power cord connector and fuse holder

3 Power ground access

4 HEIDENHAIN 15 pin universal touch probe sensor

5 Measurement axis connectors

6 RS-232 serial port connector

7 Not supported in the ND 1200R

8 Tilt base mechanical tightness adjustment

ND 1200R side panel

1 Speaker/headset jack

2 USB Type A connector

3 RJ-45 Foot switch/hand switch/keypad connector

ND 1200R Radial 5

Page 6

Information contained in this manual

This User's manual covers the operation, installation, setup and

specifications of the ND 1200R. Operating information is contained in

chapter 1. Installation, setup instructions and specifications are

contained in chapter 2.

Fonts used in this manual

The following fonts are used to indicate operator controls or to show

emphasis:

Operator controls - SOFT KEYS and other PANEL KEYS are shown

in upper case.

Emphasis - Items of special interest or concepts that are

emphasized to the user are shown in bold type.

Showing sequences of key presses

The ND 1200R user performs sequences of soft key and panel key

presses to complete tasks. These sequences are indicated using text

as shown in the following example:

Press the MENU soft key, press the DATUM soft key and then

press the ZERO soft key is sometimes abbreviated as:

Press MENU>DATUM>ZERO

Symbols within notes

Notes are marked with symbols on the left indicating the type, or

potential severity of the information.

General Information

This is additional or supplementary information about an

activity or concept.

Warning

This warns of a situation or condition that could lead to

measurement errors, equipment malfunction or

equipment damage. Do not proceed until the message is

read and understood.

Caution - Risk of electric shock

This warns of a situation or condition that could lead to

electrical shock and to personal injury or death. Do not

proceed until the message is read and understood.

6 Preface

Page 7

Safety considerations

General accepted safety precautions must be followed when

operating the system. Failure to observe these precautions could

result in damage to the equipment, or injury to personnel. It is

understood that safety rules within individual companies vary. If a

conflict exists between the material contained in this manual and the

rules of a company using this system, the more stringent rules should

take precedence.

The ND 1200R is equipped with a 3-wire power plug that

includes a separate ground connection. Always connect

the power plug to a 3-wire grounded outlet. Use of 2-wire

power plug adapters or any other connection accessories

that remove the third grounded connection create a safety

hazard and should not be permitted.

Unplug the ND 1200R from the power outlet and seek the

assistance of a qualified service technician if:

The power cord is frayed or damaged or the power plug

is damaged

Liquid is spilled or splashed onto the enclosure

The ND 1200R has been dropped or the exterior has

been damaged

The ND 1200R exhibits degraded performance or

indicates a need for service some other way

ND 1200R measurement axes

The ND 1200R DRO can display 2 or 3 axes depending on the model

purchased. DRO screen images used throughout this manual show

different numbers of axes and are for illustration only.

Software version

The software version is shown in the About setup screen discussed

later in chapter 2.

Cleaning

Use only a cloth dampened with water and a mild detergent for

cleaning the exterior surfaces. Never use abrasive cleaners, and never

use strong detergents or solvents. Only dampen the cloth, do not use

a cleaning cloth that is dripping wet.

ND 1200R Radial 7

Page 8

8 Preface

Page 9

1 Operation

1.1 ND 1200R Overview ......................................................................................................................................... 12

1.2 Basic Functions of the ND 1200R..................................................................................................................... 13

Switching on the ND 1200R ........................................................................................................................ 13

Establishing a repeatable machine zero....................................................................................................... 14

Switching off the ND 1200R........................................................................................................................ 14

Panel key descriptions................................................................................................................................. 15

LCD screen and soft key layout................................................................................................................... 17

DRO mode screen and soft keys ......................................................................................................17

Distance from target mode screen and soft keys.............................................................................18

ND 1200R Menus ........................................................................................................................................ 19

1.3 Preparing to drill ................................................................................................................................................ 23

Power-up the ND 1200R.............................................................................................................................. 23

Establish machine zero................................................................................................................................ 23

Adjust LCD screen contrast......................................................................................................................... 24

Select unit of linear measure....................................................................................................................... 24

Select a coordinate system ......................................................................................................................... 24

Probing a position ........................................................................................................................................ 25

Select a probe diameter............................................................................................................................... 26

Aligning the part to an axis .......................................................................................................................... 27

Establish a datum ........................................................................................................................................ 29

Setting a datum from a probed point ................................................................................................29

Setting a datum from a skew line .....................................................................................................29

Setting a datum on the center of a hole............................................................................................29

Moving a datum........................................................................................................................................... 30

1.4 Targets .............................................................................................................................................................. 31

Entering a target .......................................................................................................................................... 31

Entering an absolute target position..................................................................................................31

Entering an incremental target position ............................................................................................33

Editing and clearing targets ......................................................................................................................... 35

Editing a target ..................................................................................................................................35

Deleting a target................................................................................................................................35

Clearing the target list .......................................................................................................................35

Marking a target........................................................................................................................................... 36

1.5 Target patterns.................................................................................................................................................. 37

Frame pattern .............................................................................................................................................. 38

Rectangle pattern ........................................................................................................................................ 39

Line pattern.................................................................................................................................................. 40

Circle pattern ............................................................................................................................................... 41

1.6 Target programs................................................................................................................................................ 42

Saving a program......................................................................................................................................... 42

Running a program ...................................................................................................................................... 43

Mirroring a program..................................................................................................................................... 44

Deleting a program .............................................................................................................

1.7 Navigating to a target........................................................................................................................................ 46

......................... 45

ND 1200R Radial 9

Page 10

2 Installation, Setup and Specifications

2.1 ND 1200R Shipment Contents ..........................................................................................................................48

Items included with the ND 1200R ..............................................................................................................48

Optional items possibly included..................................................................................................................48

Repackaging the ND 1200R .........................................................................................................................49

2.2 Hardware Installation.........................................................................................................................................50

Assembling the mounting stand ..................................................................................................................50

Benchtop location and mounting ......................................................................................................50

Arm mounting (optional) ...................................................................................................................51

Connecting power........................................................................................................................................52

Connecting encoders and probes.................................................................................................................53

Connecting a computer................................................................................................................................54

Connecting a headphone..............................................................................................................................55

Connecting a USB printer.............................................................................................................................55

Connecting an optional foot switch or remote keypad.................................................................................56

2.3 Software setup ..................................................................................................................................................57

Setup menu..................................................................................................................................................58

Setup example: entering the supervisor password......................................................................................59

Order of setup..............................................................................................................................................61

Language selection and product version......................................................................................................62

Supervisor password....................................................................................................................................63

Encoder configuration ..................................................................................................................................65

Encoders screen ...............................................................................................................................65

Misc screen ......................................................................................................................................68

Probe configuration ......................................................................................................................................69

Radial screen.....................................................................................................................................69

Error correction.............................................................................................................................................71

Linear error correction (LEC).............................................................................................................71

Display formatting ........................................................................................................................................74

Display screen...................................................................................................................................74

Hot key assignments....................................................................................................................................76

Hot keys screen................................................................................................................................76

Print formatting ............................................................................................................................................79

Print screen.......................................................................................................................................79

Port configuration.........................................................................................................................................81

Ports screen......................................................................................................................................81

Audio volume ...............................................................................................................................................85

Misc screen ......................................................................................................................................85

Key repeat rate adjustment..........................................................................................................................86

Misc screen ......................................................................................................................................86

Screen saver activation ................................................................................................................................87

Misc screen ......................................................................................................................................87

Time and date settings.................................................................................................................................88

Clock screen .....................................................................................................................................88

2.4 Specifications.....................................................................................................................................................89

Dimensions ..................................................................................................................................................90

Arm mount bracket ...........................................................................................................................91

10

Page 11

Operation

Page 12

1.1 ND 1200R Overview

quit

cancel

enter

finish

+/-0

4

1

7

5 6

2 3

8 9

The ND 1200R is an advanced digital readout (DRO) system for radial

drilling machines using analog or TTL encoders. The system allows the

operator to directly enter either cartesian or polar coordinates for

target positions. This alleviates the requirement of either pre-drilling

holes or a previous operation of marking out the holes on an expensive

machine elsewhere. The system defaults to cartesian coordinates

when entering target positions and polar coordinates when navigating

to a target.

The following functions are available in the ND 1200R:

Reference mark evaluations for distance-coded and single reference

encoders

Linear error correction

1.1 ND 1200R Overview

Multilingual LCD user interface: language is selected by the user

Soft key functions under LCD change to support different user

activities

Arrow keys for easy navigation of lists and menus

Skew compensation for part alignment, eliminating the need for

time-consuming fixturing

Absolute and incremental targeting

Axis zero for establishing a datum

Number keypad with:

Number keys for data entry

Decimal point and +/- keys for data entry and LCD screen contrast

adjustment

User-defined hot keys that program panel and optional remote keys

to initiate commonly used functions.

User-defined programs to save target sequences

Direct entry of cartesian or polar target coordinates

User-defined drilling patterns for:

Frame pattern

Rectangular pattern

Line pattern

Circle pattern

Speaker jack outputs for quiet or noisy environments

Optional remote foot switch and keypad facilitate measurement

when the user is not close to the front panel

ND 1200R Front panel

12 1 Operation

Page 13

1.2 Basic Functions of

finish

the ND 1200R

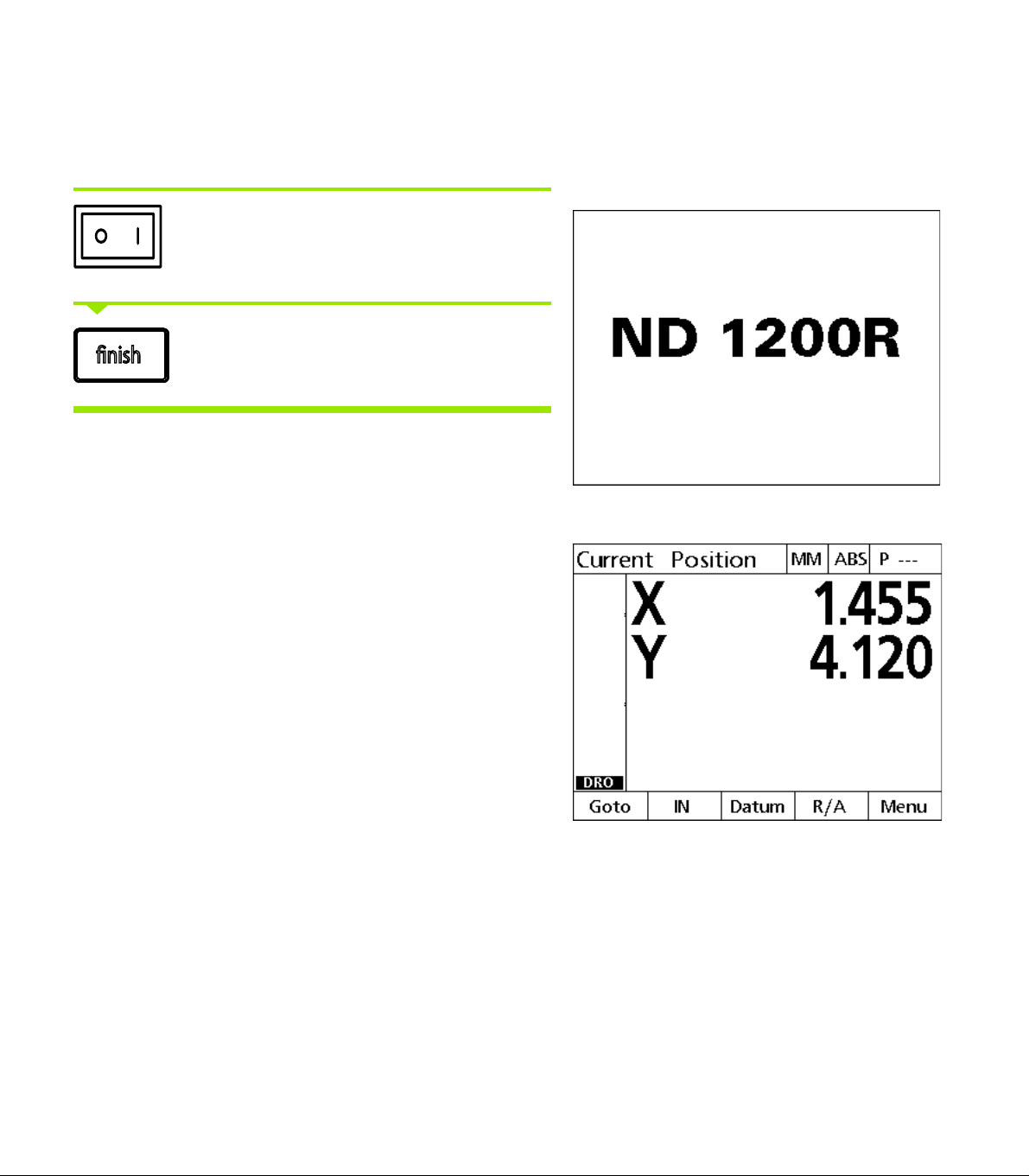

Switching on the ND 1200R

Switch on the ND 1200R. The POWER switch is

located on the rear of the enclosure. After switching

the power on, or after a power failure, the power-up

screen will be displayed.

Press the FINISH key to advance from the power-up

screen to the DRO.

Your ND 1200R is now ready for operation and is in the Current

Position operating mode. Encoder position values will be displayed for

all axes.

Power-up screen

DRO screen

1.2 Basic Functions of the ND 1200R

ND 1200R Radial 13

Page 14

Establishing a repeatable machine zero

If your ND 1200R was configured to establish a machine zero upon

power-up, a message will be displayed asking you to cross reference

marks or enter hard-stop axis reference positions. The machine zero is

used by the ND 1200R to apply error correction data. To establish a

repeatable machine zero you must either:

Move the stage to have encoder reference mark crossings

recognized on each axis or

move the stage to the hard-stop reference position and press

ENTER on each axis when no encoder reference marks are present.

If the requirement to cross reference marks is bypassed

by pressing the CANCEL soft key, error correction data

that might be stored in your ND 1200R will not be

applied.

Switching off the ND 1200R

Switch the ND 1200R off. The parameter settings,

error compensation tables and recorded programs

that have been saved during operation will be

1.2 Basic Functions of the ND 1200R

retained in memory.

14 1 Operation

Page 15

Panel key descriptions

quit

cancel

enter

finish

+/-0

4

1

7

5 6

2 3

8 9

enter

finish

cancel

quit

Descriptions of panel key functions are provided in the following

pages for COMMAND, AXIS, WIDE, SEND, LCD ON/OFF and

ARROW keys. Soft key functions are also described later in the next

section as part of screen and soft key layout descriptions.

Command keys Function

Enter data: Press the enter key to enter

values into configuration fields. Pressing the

enter key indicates that data in a field is ready

for use.

Finish a target entry: Press the finish key to

complete a target entry or select the next

target in a program.

Delete data or target: Press the cancel key

to delete data in configuration fields or any

highlighted target from the target list.

Quit current activity: Press the quit key to

abandon the current task and return to the

DRO screen or to exit the target list.

ND 1200R Panel keys

AXIS keys Function

Enter a target: Press an Axis key to enter

target position coordinates.

ND 1200R Radial 15

1.2 Basic Functions of the ND 1200R

Page 16

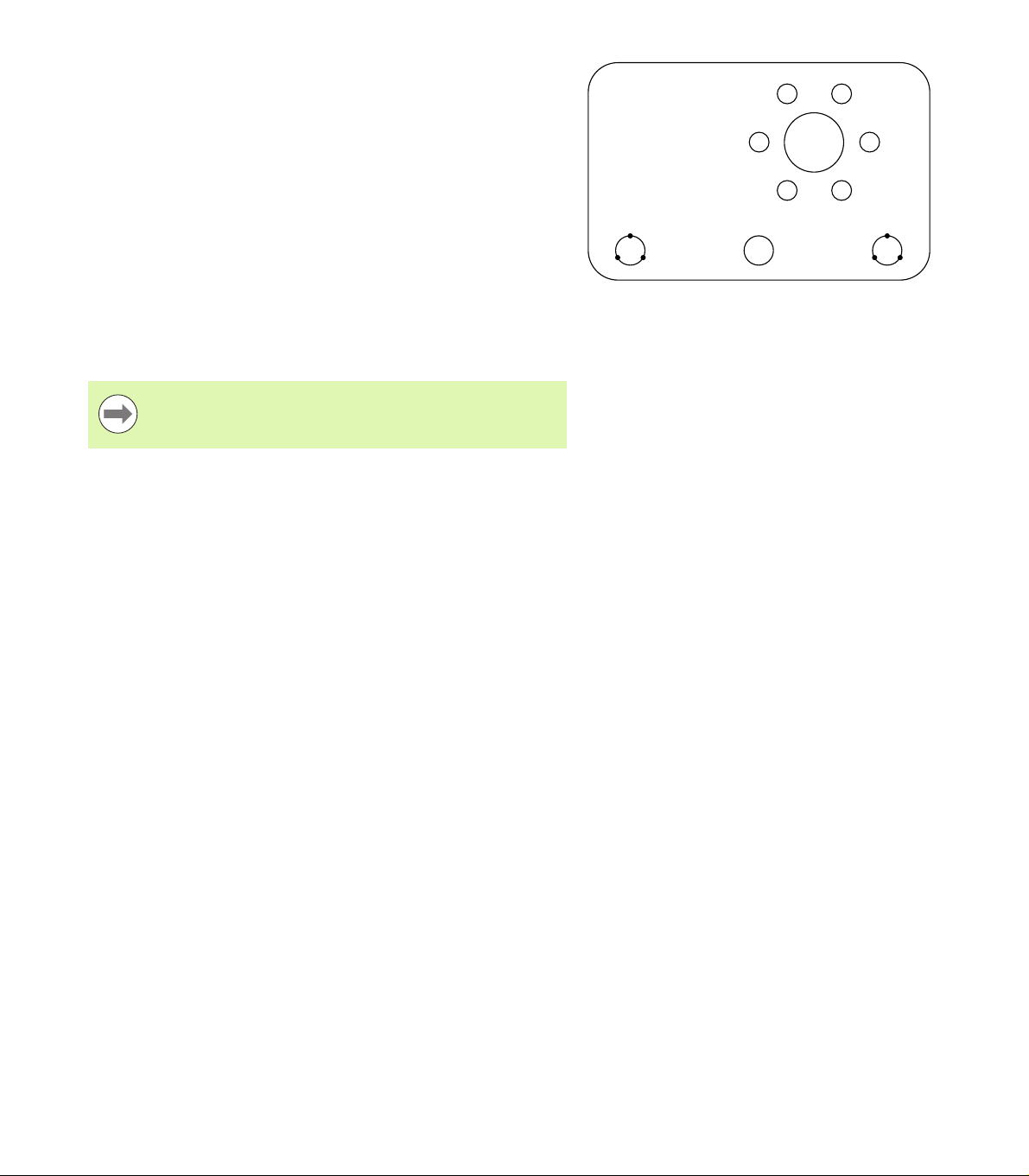

WIDE keys Function

SEND key Function

Transmit target data: Press the SEND key

to transmit target data to a computer or a

USB printer.

LCD ON/OFF key Function

1.2 Basic Functions of the ND 1200R

Turn the LCD off or clear data: Press the

LCD ON/OFF key to toggle between LCD on

and LCD off, or to clear target data, datums

and part alignments (skews).

Left frequently used function:

Press the left WIDE key to initiate

the function programmed for this

key. The factory default function for

this key is SEND2. Refer to "Hot key

assignments” on page 76 for

additional information.

Right frequently used function:

Press the right WIDE key to initiate

the function programmed for this

key. The factory default function for

this key is ZERO2. Refer to "Hot key

assignments” on page 76 for

additional information.

ARROW keys Function

Navigate menus and setup screen

data fields.

16 1 Operation

Page 17

LCD screen and soft key layout

ND 1200R LCD screens display information in one of three operating

modes:

DRO mode displays current positions of axes

Distance from target mode displays the distance from a target

position

Setup mode displays ND 1200R setup screens

Soft keys change to support activities shown on the screens.

Setup screens and soft keys are described in Chapter 2:

Installation, Setup and Specifications.

DRO mode screen and soft keys

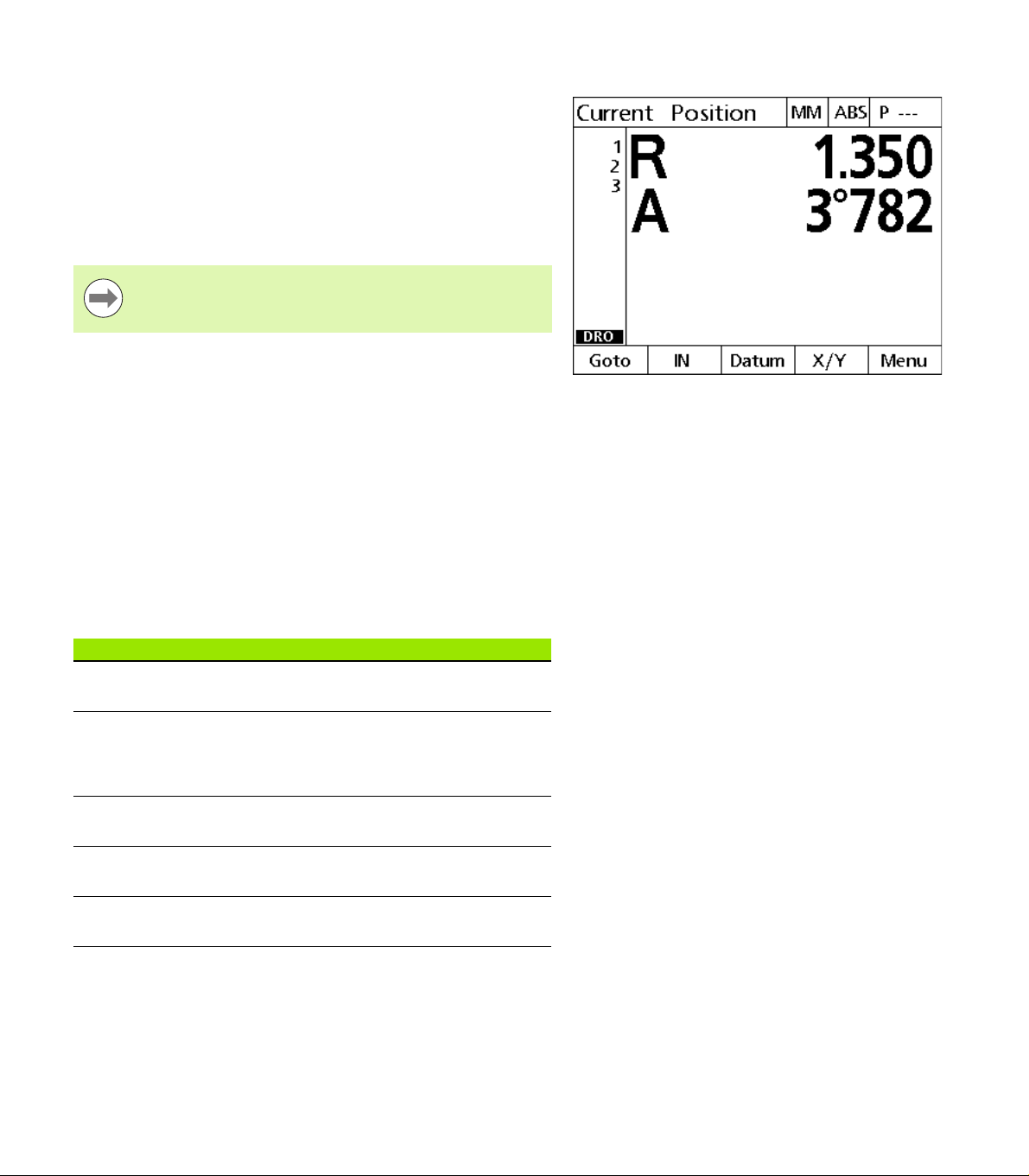

The DRO screen shows:

List of targets on the left side

Unit of measure, current datum and program number in the upper

right corner

The current positions of all axes

Part alignment status: a small rectangle over the axis letter indicates

that the part is aligned to a measurement axis (a skew was

performed)

Soft key functions for target selection, unit of measure, datuming,

cartesian or polar coordinates and menus

DRO screen showing current axis positions

1.2 Basic Functions of the ND 1200R

DRO soft keys Function

Goto Press the GOTO soft key to select a target to

navigate to.

MM or IN Toggles between millimeters and inches units

of measure. The current unit of measure is

displayed in the upper right corner of the

screen.

Datum Press the datum soft key to probe, zero, move

or skew a datum.

R/A or X/Y Toggles between cartesian and polar

coordinates displayed on the LCD screen.

Menu Press the MENU soft key to access program,

ND 1200R Radial 17

datum, pattern and setup menus.

Page 18

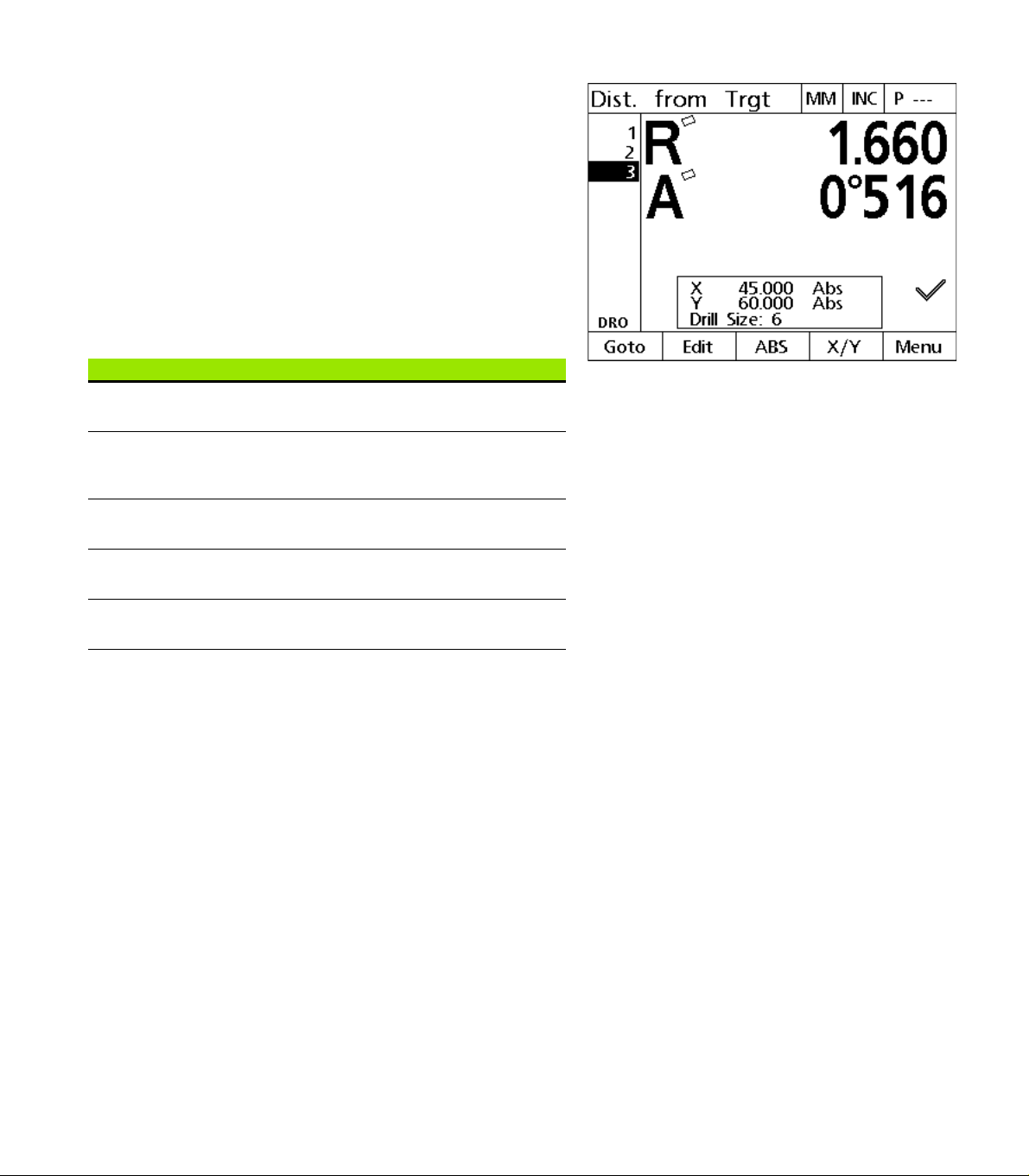

Distance from target mode screen and soft keys

The Distance from target screen shows:

List of targets on the left side

Unit of measure, current datum and program in the upper right

corner

The the distance from a target position

Part alignment status: a small rectangle over the axis letter indicates

that the part is aligned to a measurement axis (a skew was

performed)

Soft key functions for target selection, editing a target, absolute or

incremental distance selection, cartesian or polar coordinates

selection and menu access

DRO soft keys Function

Goto Press the GOTO soft key to select a target to

Edit Press the EDIT soft key to access the target

INC or ABS Toggles between incremental and absolute

1.2 Basic Functions of the ND 1200R

R/A or X/Y Toggles between cartesian and polar

Menu Press the MENU soft key to access program,

navigate to.

editing screen and edit the coordinates of the

selected target.

distances.

coordinates.

datum, pattern and setup menus.

Distance from target screen showing the distance

from the current position to the target position

18 1 Operation

Page 19

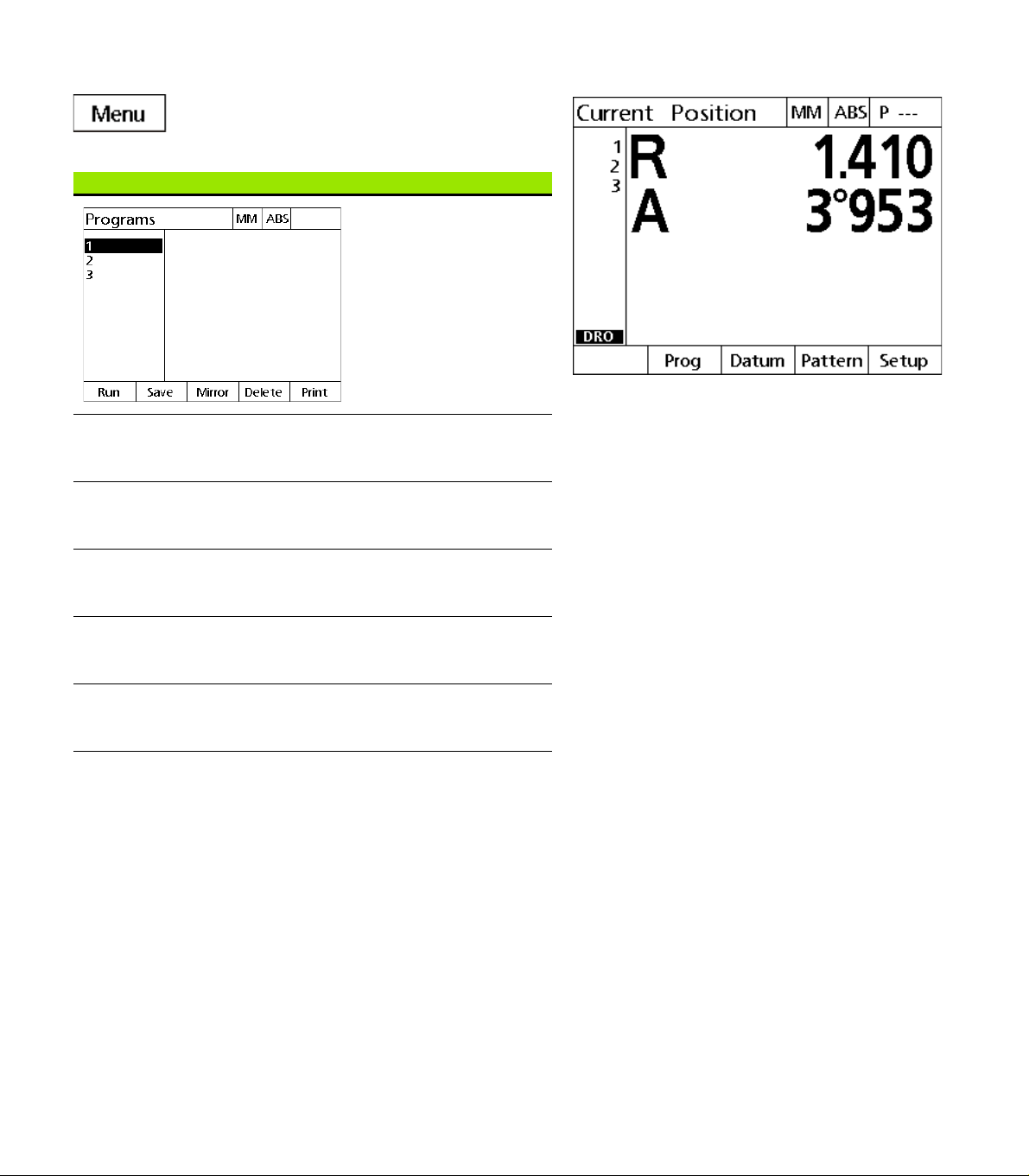

ND 1200R Menus

Press the MENU soft key to display menu titles over

the soft keys at the bottom of the LCD screen. Press

a menu soft key to display the corresponding menu

screen. Menus include:

PROGRAMS menu PROGRAMS functions

Press the PROG soft key to

display the PROGRAMS

screen and soft keys for

program functions. Soft

keys include:

Run Press the RUN soft key to

play a program of recorded

target positions.

Save Press the SAVE soft key to

save a program that can be

played back later.

Menu titles are displayed over soft keys at the bottom

of the LCD screen

1.2 Basic Functions of the ND 1200R

Mirror Press the MIRROR soft key

Delete Press the DELETE soft key

Print Press the PRINT soft key to

to mirror and run a

program.

to delete the selected

program.

transmit a program to a

computer or a USB printer.

ND 1200R Radial 19

Page 20

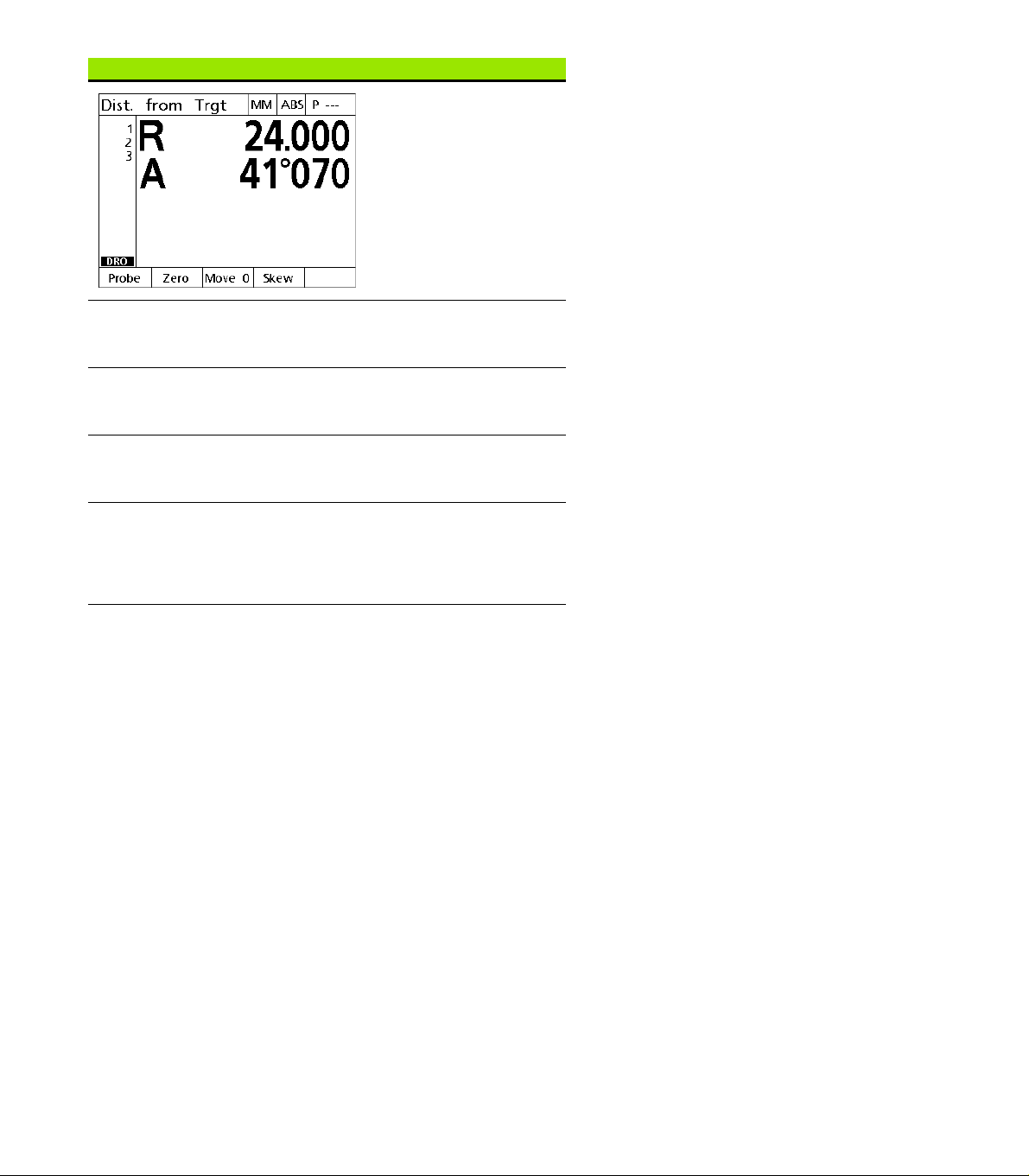

DATUM menu DATUM functions

Press the DATUM soft key

to display soft key

selections for zeroing,

moving and skewing the

datum. Soft keys include:

Probe Press the PROBE soft key

to enter the probe diameter

using the numeric keypad.

Zero Press the ZERO soft key to

select an axis, axes or hole

for zeroing the datum.

Move 0 Press the MOVE 0 soft key

to move the datum to a

new location.

Skew Press the SKEW soft key to

1.2 Basic Functions of the ND 1200R

compensate electronically

for non-square part

alignment on the primary

axis.

20 1 Operation

Page 21

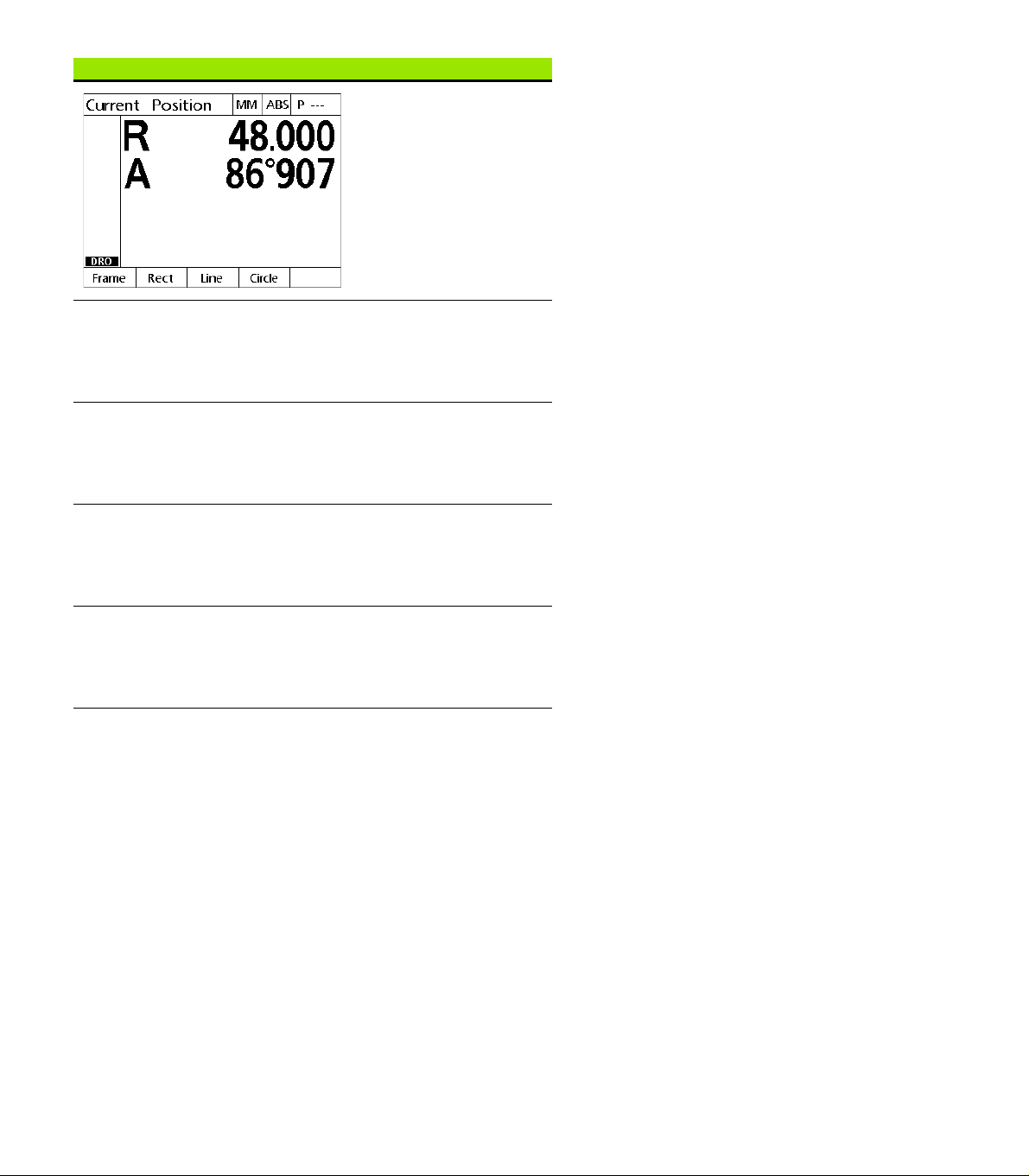

PATTERN menu PATTERN functions

Press the PATTERN soft

key to select a drilling

pattern. Soft keys include:

Frame Press the FRAME soft key

to enter the parameters to

define a frame drilling

pattern. Refer to "Frame

pattern” on page 38

Rect Press the RECT soft key to

enter the parameters to

define a rectangle drilling

pattern. Refer to "Rectangle

pattern” on page 39

Line Press the LINE soft key to

enter the parameters to

define a line drilling pattern.

Refer to "Line pattern” on

page 40

Circle Press the CIRCLE soft key

to enter parameters to

define a circle drilling

pattern. Refer to "Circle

pattern” on page 41

1.2 Basic Functions of the ND 1200R

ND 1200R Radial 21

Page 22

SETUP menu SETUP functions

Press the SETUP menu

soft key to display the

collection of SETUP

screens used to configure

the ND 1200R. Use of the

setup menu is explained in

Chapter 2: Installation,

Setup and Specifications.

Access to setup menu configuration data fields is

password restricted to supervisors and other technically

qualified personnel. Configuration mistakes can result in

serious measurement errors.

1.2 Basic Functions of the ND 1200R

22 1 Operation

Page 23

1.3 Preparing to drill

Power-up the ND 1200R

Switch on the ND 1200R. The POWER switch is located on the rear

of the enclosure. After switching the power on, or after a power

failure, the power-up screen will be displayed. See "Switching on the

ND 1200R" on page 13.

Press the FINISH key to advance from the power-up screen to the

DRO.

If your ND 1200R was configured to establish a machine zero upon

powering up, a message will be displayed asking you to cross

reference marks or specify axis references manually.

Establish machine zero

A repeatable machine zero is required for the DRO to apply the

calibration chart to the machine geometry correctly.

It is not recommended to use the machine without active

calibration. This would lead to unknown position errors.

Usually the calibration is based on referencing via reference marks on

the encoders. To establish the machine zero after power-up:

Move the stage to have the reference mark crossings recognized on

each axis.

If the machine zero is determined via hard stops:

Move the stage to the hard-stop reference position and press

ENTER on each axis.

1.3 Preparing to drill

ND 1200R Radial 23

Page 24

Adjust LCD screen contrast

+/-0

If necessary, adjust the LCD screen contrast using the decimal point

and +/- keys located on the numeric keypad.

Press the DECIMAL POINT key to increase the

contrast.

Press the +/- key to decrease the contrast.

Select unit of linear measure

Press the MM or IN soft key to toggle between

millimeters and inches.

1.3 Preparing to drill

Select a coordinate system

Press the X/Y or R/A key to toggle between cartesian

and polar coordinate systems.

24 1 Operation

Page 25

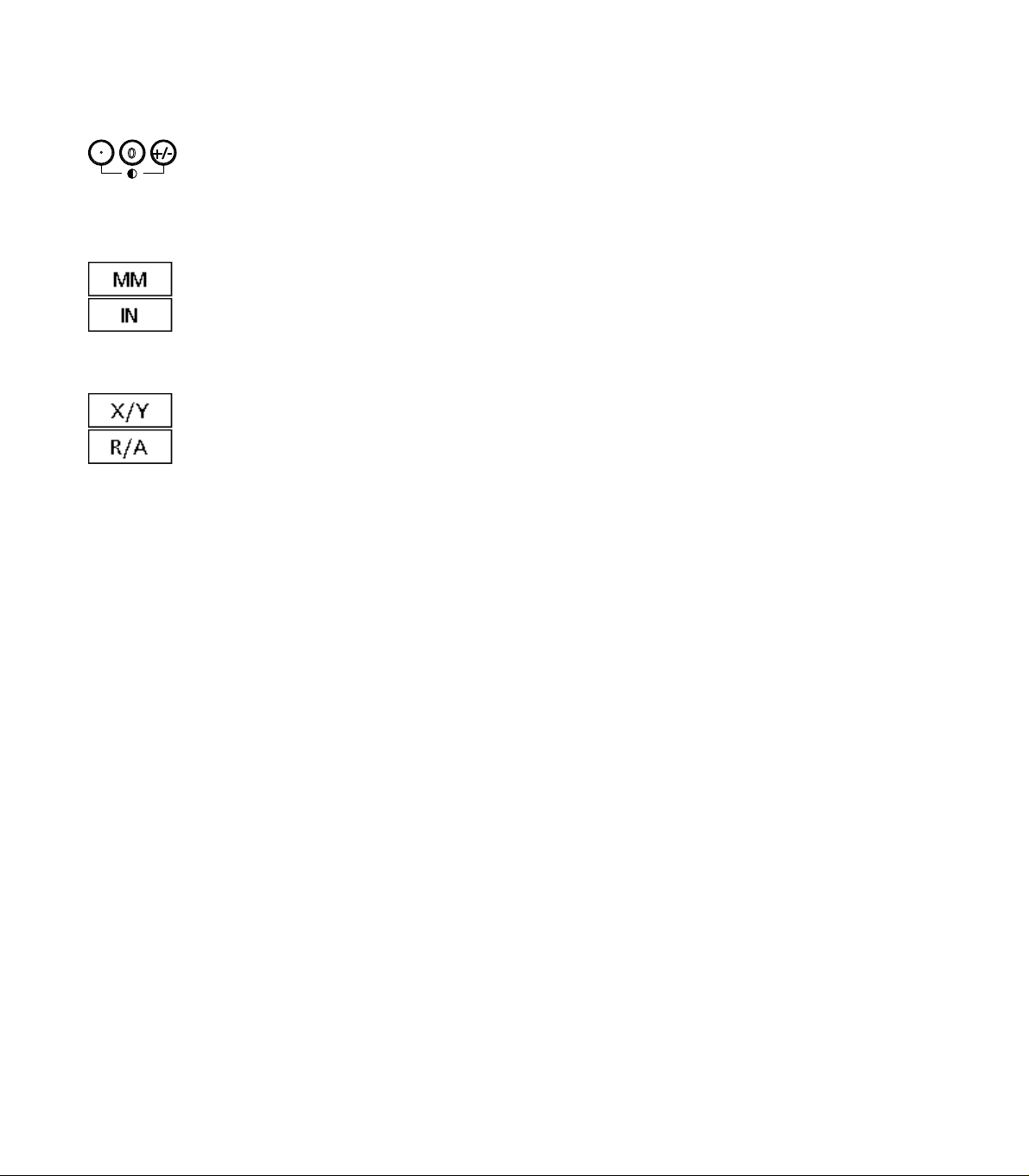

Probing a position

A position can be probed with a hard probe or a touch probe.

To probe a point with a hard probe:

Touch the edge of the workpiece with the probe.

Press the ENTER key.

Enter the probe diameter.

Press the ARROW key that indicates the probe compensation

direction.

To probe a point with a touch probe:

Touch the edge of the workpiece with the probe. The point and the

direction of probing will be entered automatically.

1.3 Preparing to drill

Probing a position with a hard probe

Probing a position with a touch probe

ND 1200R Radial 25

Page 26

Select a probe diameter

A probe is required to zero the axes on a workpiece. The diameter of

the probe can be adjusted. This is needed to compensate for the

offset of the part from the edge of the probe being used.This diameter

is either the diameter of the touch probe or hard probe being used.

To assign a probe diameter:

Press the DATUM soft key.

Press the PROBE soft key.

Enter the probe size.

Press the FINISH key.

1.3 Preparing to drill

26 1 Operation

Page 27

Aligning the part to an axis

1

2

3

Accurate drilling requires the part to be perfectly aligned along an axis.

Misaligned parts result in targeting errors. Use the SKEW function to

convert machine coordinates to part coordinates and compensate for

part misalignment. Perform a skew each time a new part is mounted.

Measure a skew line by probing a straight edge of the part on a major

measurement axis or by probing two or more pre-drilled holes.

The skew alignment edge or line must be oriented within

45 degrees of the measurement axis.

Aligning a part edge to an axis

To align a part edge to an axis:

Align the part on the stage.

Press DATUM>SKEW.

Probe a minimum of two points along a part edge. In the example

shown here, the part is aligned to the X-axis by probing three points

along the bottom edge of the part.

Press the FINISH key.

The part could alternately have been aligned along a

vertical edge to the Y-axis.

The orientation of the cartesian coordinate system

depends on the type of machine. It can be changed by the

supervisor (password required).

1.3 Preparing to drill

Three points are probed to align the bottom edge of a

part to the X-axis

ND 1200R Radial 27

Page 28

Aligning a pair of holes to an axis

1

2

3

4

5

6

There are certain times when the part needs to be aligned on the

center of two pre-drilled holes.

To align a pair of holes to an axis:

Align the part on the stage.

Press DATUM>SKEW>HOLE.

Probe a minimum of three points around the edge of the first hole

to be used in the skew.

Press the FINISH key to complete the first hole measurement.

Press the HOLE soft key.

Probe a minimum of three points around the edge of the second

hole to be used in the skew.

1.3 Preparing to drill

Press the FINISH key to complete the second hole measurement.

Press the FINISH key to complete the skew.

Distributing the probed points evenly around the

circumference of the hole will provide a more accurate

placement for the center of the hole.

Three points are probed for each hole to align the

center of the holes with the X-axis

28 1 Operation

Page 29

Establish a datum

1

2

3

4

1

2

3

A datum can be created from a probed point, the center point of a

probed hole or a point created from the intersection of the skew

alignment line and another line perpendicular to the skew alignment

line.

Setting a datum from a probed point

To set the datum from a probed point:

Press DATUM>ZERO>XY.

Probe the desired location of the datum.

Setting a datum from a skew line

The first point of a skew line is automatically set as the datum. The

datum is most commonly created from a point that is the intersection

of the skew alignment line and a second part edge line.

To set the datum from a skew line:

Perform a skew alignment.

Press DATUM>ZERO.

Press the soft key for the axis to zero along (the same axis used for

the skew line).

Probe a point on the part edge perpendicular to the skew line. The

datum is now set to the intersection of the skew alignment line and

the probed part edge.

Setting a datum on the center of a hole

The center of a hole is found by probing a minimum of three points on

the edge of the hole.

To set the datum from the center of a hole:

Press DATUM>ZERO>HOLE.

Probe a minimum of three points around the edge of the hole.

Press the FINISH key.

1.3 Preparing to drill

A skew is performed along the bottom and a point is

probed on the side perpendicular to the skew line

Distributing the probed points evenly around the

circumference of the hole will provide a more accurate

placement for the center of the hole.

A minimum of three points is probed around the edge

of a hole

ND 1200R Radial 29

Page 30

Moving a datum

If the datum of the part is not reachable by a probe it can be moved by

entering the coordinates from a point that has been probed.

To move the datum:

Press DATUM>MOVE 0.

Enter the X distance in relationship to the probed datum point.

Press the ENTER key.

Enter the Y distance in relationship to the probed datum point.

Press the FINISH key.

1.3 Preparing to drill

30 1 Operation

Page 31

1.4 Targets

Entering a target

The ND 1200R allows simple entry of target position coordinates. As

target position coordinates are entered a target list is created. The

target list is shown on the left side of the LCD screen.

Entering an absolute target position

To enter an absolute target position:

Press the X axis key.

Enter the X coordinate for the target.

Press the ENTER key.

Enter the Y coordinate for the target.

Press the FINISH key.

1.4 Targets

Target list shown on left side of screen

Enter the X coordinate for the target Enter the Y coordinate for the target

ND 1200R Radial 31

Page 32

Optional: Prior to pressing the FINISH key a drill diameter may be

entered. The diameter is for user reference only and does not effect

target position calculation.

Press the ENTER key.

Enter the drill diameter.

Press the FINISH key.

1.4 Targets

Optional: Enter the drill bit diameter The new target is added to the target list

and the Dist from Trgt screen is

displayed

32 1 Operation

Page 33

Entering an incremental target position

To enter an incremental target position:

Press the X axis key.

Enter the X coordinate for a new target relative to a previously

entered target.

Press the ABS/INC soft key to toggle to incremental mode.

Enter the number of the previously entered target.

Press the ENTER key.

1.4 Targets

Enter the X coordinate for the new target

relative to a previously entered target

Press the ABS/INC soft key to toggle to

incremental mode

Enter the number of the previously

entered target

ND 1200R Radial 33

Page 34

Enter the Y coordinate for the new target relative to a previously

entered target.

Press the ABS/INC soft key to toggle to incremental mode.

Enter the number of the previously entered target.

Press the FINISH key.

Optional: Prior to pressing the FINISH key a drill diameter may be

entered. The diameter is for user reference only and does not effect

1.4 Targets

target position calculation.

Press the ENTER key.

Enter the drill diameter.

Press the FINISH key.

Enter the Y coordinate for the new target

relative to a previously entered target

Press the ABS/INC soft key to toggle to

incremental mode

Enter the number of the previously

entered target

34 1 Operation

Page 35

Editing and clearing targets

Editing a target

To edit a target:

Use the UP and DOWN ARROW keys to select a target in the target

list.

Press the EDIT soft key. The Target Edit screen is displayed.

To edit target position coordinates, follow the previous instructions

for entering a target position.

Deleting a target

To delete a target:

Use the UP and DOWN ARROW keys to select a target in the target

list.

Press the CANCEL key. A message on the LCD screen will ask “Are

you sure you would like to delete this target?”.

Press the YES soft key.

1.4 Targets

Target Edit screen

Clearing the target list

To clear the target list:

Press the LCD ON/OFF key. A message on the LCD screen will

advise “The display will be turned of in 15 seconds or you may press

one of the below soft keys to clear targets and datums.”

Press the CLEAR soft key.

Deleting a target from the target list

ND 1200R Radial 35

Page 36

Marking a target

Positions in the target list can be marked with a checkmark in order to

identify the target for a future machining operation.

To mark a target:

Use the UP and DOWN ARROW keys to select a target in the target

list.

1.4 Targets

Press the AXIS key next to the checkmark symbol to mark a target.

Target marked for future machining operation

36 1 Operation

Page 37

1.5 Target patterns

Target patterns allow a way to quickly create targets by entering

parameters for target coordinates arranged in one of four patterns.

Available patterns are:

Frame

Rectangle

Line

Circle

1.5 Target patterns

ND 1200R Radial 37

Page 38

Frame pattern

Y

X

A

XD

YD

To create a Frame pattern:

Press MENU>PATTERN>FRAME.

Use the UP and DOWN ARROW keys to navigate between

parameter data fields and enter the parameter values required for

the pattern.

Press the FINISH key. The targets in the pattern are added to the

Target list and the Current Position screen is shown.

Press the FINISH key again to navigate to the first target in the

pattern.

1.5 Target patterns

Parameter Description

Start X X axis coordinate for the center of the

first hole in the pattern.

Start Y Y axis coordinate for the center of the

first hole in the pattern.

Num of Col Number of columns in the pattern.

Num of Row Number of rows in the pattern.

X Distance Distance between the center of each

hole along the X axis prior to an angle

being applied to the pattern.

Y Distance Distance between the center of each

hole along the Y axis prior to an angle

being applied to the pattern.

Angle of Array Angle applied to the pattern in relation to

the X axis.

Drill Diameter Diameter of the drill.

Frame pattern screen

Frame pattern

38 1 Operation

Page 39

Rectangle pattern

Y

X

A

XD

YD

To create a Rectangle pattern:

Press MENU>PATTERN>RECT.

Use the UP and DOWN ARROW keys to navigate between

parameter data fields and enter the parameter values required for

the pattern.

Press the FINISH key. The targets in the pattern are added to the

Target list and the Current Position screen is shown.

Press the FINISH key again to navigate to the first target in the

pattern.

Parameter Description

Start X X axis coordinate for the center of the

first hole in the pattern.

Start Y Y axis coordinate for the center of the

first hole in the pattern.

Num of Col Number of columns in the pattern.

Num of Row Number of rows in the pattern.

X Distance Distance between the center of each

hole along the X axis prior to an angle

being applied to the pattern.

Y Distance Distance between the center of each

hole along the Y axis prior to an angle

being applied to the pattern.

Angle of Array Angle applied to the pattern in relation to

the X axis.

Drill Diameter Diameter of the drill.

1.5 Target patterns

Rectangular pattern screen

Rectangular pattern

ND 1200R Radial 39

Page 40

Line pattern

Y

X

A

HD

To create a Line drill pattern:

Press MENU>PATTERN>LINE.

Use the UP and DOWN ARROW keys to navigate between

parameter data fields and enter the parameter values required for

the pattern.

Press the FINISH key. The targets in the pattern are added to the

Target list and the Current Position screen is shown.

Press the FINISH key again to navigate to the first target in the

pattern.

1.5 Target patterns

Parameter Description

Start X X axis coordinate for the center of the

first hole in the pattern.

Start Y Y axis coordinate for the center of the

first hole in the pattern.

Num of Holes Number of holes in the pattern.

Hole Dist. Distance between the center of each

hole along the X axis prior to an angle

being applied to the pattern.

Angle of Line Angle applied to the pattern in relation

to the X axis.

Drill Diameter Diameter of the drill.

Line pattern screen

Line pattern

40 1 Operation

Page 41

Circle pattern

Y

X

A

D

To create a Circle pattern:

Press MENU>PATTERN>CIRCLE.

Use the UP and DOWN ARROW keys to navigate between

parameter data fields and enter the parameter values required for

the pattern.

Press the FINISH key. The targets in the pattern are added to the

Target list and the Current Position screen is shown.

Press the FINISH key again to navigate to the first target in the

pattern.

Parameter Description

Center X X axis coordinate for the center of the

pattern.

Center Y Y axis coordinate for the center of the

pattern.

Diameter Diameter of the circle for the pattern.

Num of Holes Number of holes in the pattern.

Angle of 1st Hole Angle applied to the first hole in the

pattern in relation to the X axis.

Drill Diameter Diameter of the drill bit.

1.5 Target patterns

Circle pattern screen

Circle pattern

ND 1200R Radial 41

Page 42

1.6 Target programs

Target programs permit the user to save and run target list sequences

for later use. This allows the user to switch between workpieces and

programs without having to re-enter target coordinates.

Target programs can be:

Saved

Run

Mirrored

Printed

1.6 Target programs

Deleted

Saving a program

To save a target program:

Create a target sequence.

Press MENU>PROG>SAVE.

Enter a number for the program. A maximum of 12 digits may be

used for the number.

Press the OK soft key.

Create a target list Press MENU>PROG>SAVE Enter a program number and press the

OK soft key

42 1 Operation

Page 43

Running a program

To run a target program:

Press MENU>PROG.

Use the UP and DOWN ARROW keys to select a program.

Press the RUN soft key. The Distance to Target screen is displayed

and the program number is displayed in the upper right corner of the

screen.

1.6 Target programs

Press MENU>PROG, select a program

and press the RUN soft key

The Distance from Target screen is

displayed

ND 1200R Radial 43

Page 44

Mirroring a program

To mirror a target program:

Press MENU>PROG.

Use the UP and DOWN ARROW keys to select a program.

Press the MIRROR soft key.

Press the AXIS key for the axis to mirror the program along. The

DIstance from Target screen is displayed.

1.6 Target programs

Press MENU>PROG and select a

program

Press the MIRROR soft key Press an axis key to select an axis to

mirror along

44 1 Operation

Page 45

Deleting a program

To delete a target program:

Press MENU>PROG>.

Use the UP and DOWN ARROW keys to select a program.

Press the DELETE soft key.

Press the YES soft key to confirm program deletion.

1.6 Target programs

Press MENU>PROG and select a

program

Press the DELETE soft key and the YES

soft key to confirm program deletion

ND 1200R Radial 45

Page 46

1.7 Navigating to a target

The ND 1200R displays all entered target positions as an R (radius) and

A (angle) distance from the current position. Navigating to a target is

accomplished by moving the drill head to zero directly above the

desired target position. This is for either direct targeting or from the

Pattern function.

To navigate to a target:

Select a target. The Distance from Target screen is displayed.

Move the tool in or out along the R axis until the R display reads zero.

Rotate the radial arm until the A display reads zero. The tool is now

positioned above the center of the target.

Lock the drill head and drill the hole.

1.7 Navigating to a target

Move the tool in or out until the R axis

reads zero

It is important to zero the R axis first. If the A axis is zeroed

first and the tool is moved in or out along the R axis, the

zero on the A axis will be lost.

Move the radial arm until the A axis reads

zero

46 1 Operation

Page 47

Installation, Setup and Specifications

Page 48

2.1 ND 1200R Shipment Contents

The contents of your ND 1200R shipment are described below.

Repackaging instructions are also included for return shipments for

distributors and OEM customers that are configuring a ND 1200R and

shipping it to an end-user.

Save the ND 1200R packaging materials for possible

return shipment or shipment to an end-user.

Items included with the ND 1200R

The following items are shipped with the ND 1200R:

ND 1200R instrument

Mounting stand hardware

Power cord

ND 1200R Quick reference guide

Warranty registration card

2.1 ND 1200R Shipment Contents

Optional items possibly included

The following items might be shipped with your ND 1200R, depending

on the options and accessories ordered at the time of purchase:

Remote foot switch

Remote keypad

ND 1200R Protective cover

QC-Wedge communication software

If any components were damaged in shipment, save the

packaging materials for inspection and contact your

shipping agent for mediation. Contact your Heidenhain

distributor or OEM for replacement parts.

48 2 Installation and Specifications

Page 49

Repackaging the ND 1200R

When shipping the ND 1200R on to an end-user, repackage all

ND 1200R components in the original packaging as received from the

factory.

The original packaging must be duplicated and the LCD

must be inserted face-up to prevent damage to the

screen.

It is not necessary to ship the mounting stand and

hardware with the instrument when returning the

ND 1200R for service.

Connect the mounting screws and washer to the ND 1200R

instrument.

Replace the contents of the cardboard box insert if shipping the

ND 1200R on to an end-user. The cardboard box can be empty if

returning the ND 1200R to the factory for service.

Repackage the instrument, foam and cardboard box insert as

originally shipped from the factory. The instrument should be

oriented face-up in the carton.

Replace the warranty card and slip sheets originally found at the top

of the carton when shipping on to an end-user. The “Before you

begin” slip sheet should be inserted last.

2.1 ND 1200R Shipment Contents

ND 1200R Radial 49

Page 50

2.2 Hardware Installation

5

4

3

2

1

The ND 1200R is easy to install. This section describes how to install

the ND 1200R hardware.

Assembling the mounting stand

The ND 1200R is secured to the swivel slots of the mounting stand by

a shoulder screw, a cap screw and associated washers.

Assemble the ND 1200R to the mounting stand as shown on the

right

Tighten the shoulder screw (1).

Tighten the cap screw (5) and washers (3 & 4) enough so that the

ND 1200R will be secure when adjusted to the desired tilt position.

Adjust the ND 1200R to the desired tilt position.

2.2 Hardware Installation

Complete tightening the cap screw (5) to secure the ND 1200R.

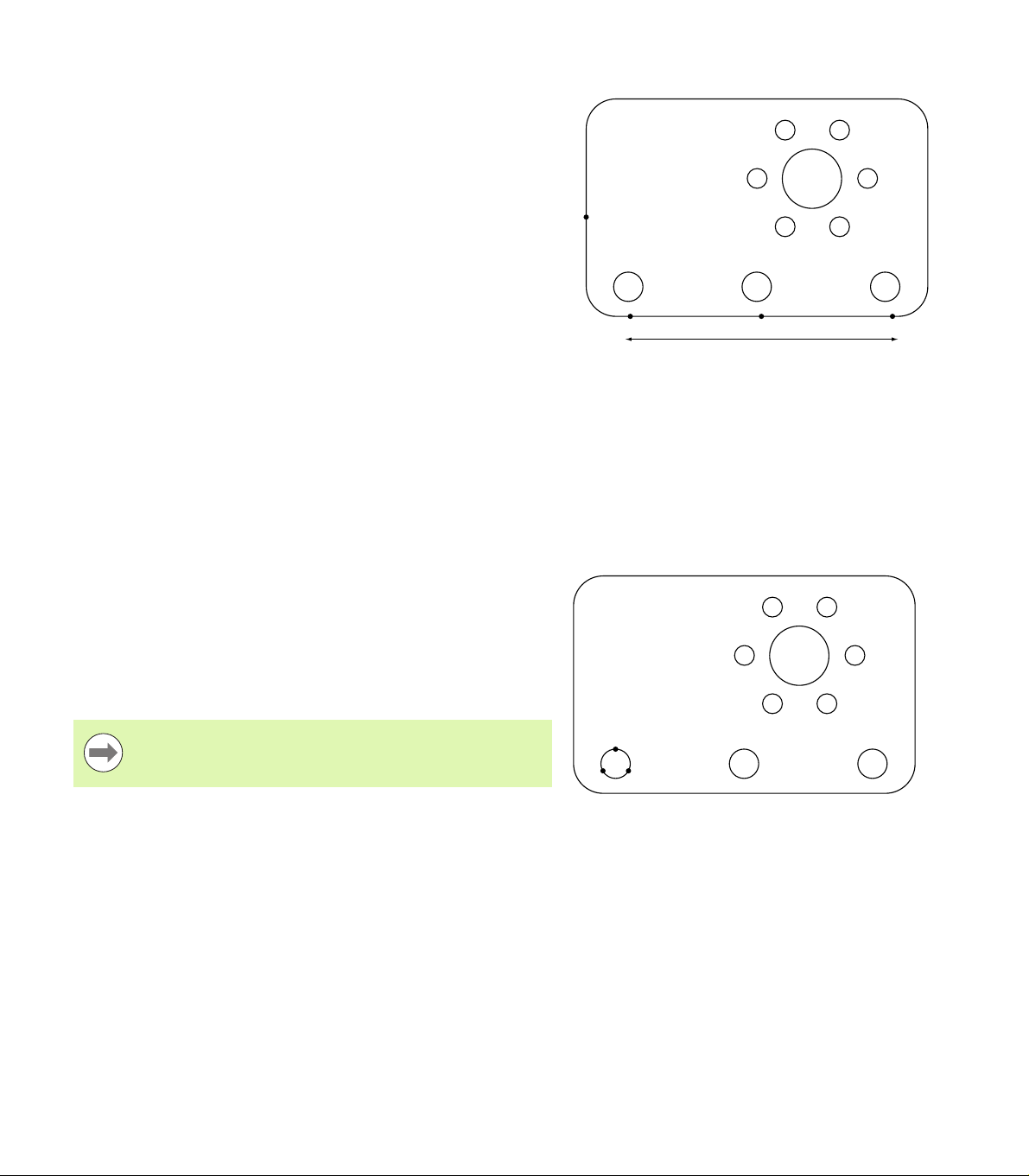

Benchtop location and mounting

Rest the ND 1200R on a flat, stable surface, or bolt it to a stable

surface from the bottom using four 10/32 screws fastened in the

pattern shown at the right.

The dimensions are shown in millimeters.

Mounting stand assembly

Mounting hole pattern

50 2 Installation and Specifications

Page 51

Arm mounting (optional)

Secure the arm mount adapter to the ND 1200R and bolt the adapter

and ND 1200R to the arm as shown at the right.

2.2 Hardware Installation

Optional arm mounting

ND 1200R Radial 51

Page 52

Connecting power

1

2

1

3

Connect the ND 1200R to power through a high-quality power surge

suppressor. Surge suppressors limit the amplitude of potentially

damaging power line transients caused by electrical machinery or

lightning, and protect the ND 1200R from most power line transients

that can corrupt system memory or damage circuits.

Do not locate the power cord where it can be walked on or will create

a tripping hazard. Connect the 3-wire power plug to only a 3-wire

grounded power outlet.

Never connect 2-wire to 3-wire adapters to the power cord

or remove the third ground wire to fit the plug into a 2-wire

electrical outlet. Modifying or overriding the third-wire

ground creates a safety hazard and should not be

permitted.

The power connector assembly includes:

2.2 Hardware Installation

1 Power switch

2 Fuse compartment

3 Power cord connector

Always disconnect the power cord from the source of AC

power before unplugging it from the ND 1200R power

connector. The AC voltage available at electrical outlets is

extremely dangerous and can cause serious injury or

death.

Power switch, fuse and connector

52 2 Installation and Specifications

Page 53

Connecting encoders and probes

142

3

Axis encoders and probes are attached to interface connectors on the

rear of the ND 1200R. Many encoder interfaces are available to match

the wide variety of encoders that can be used with the ND 1200R. The

type and number of axis encoder connectors will vary depending on

the application. The ND 1200R shown in this photo includes

connectors for the X, Y and Z axes and a touch probe. Encoder inputs

are specified as analog or TTL at the time of purchase and cannot be

changed in the field.

Do not locate encoder cables where they can be walked

on or will create a tripping hazard.

The encoder connector locations are:

1 X-axis

2 Y-axis

3 Z-axis

4 Touch probe

To connect the encoder cables and probe:

Verify that the ND 1200R is off.

Connect the axis encoders tightly to their connectors. An axis label

is provided near each connector. If the connectors include mounting

screws, do not overtighten them.

Encoder axis connectors

2.2 Hardware Installation

ND 1200R Radial 53

Page 54

Connecting a computer

1

Measurement result data can be sent to a computer over the RS-232

port (1) using a serial cable that does not include crossed wires. To

connect a computer:

Verify that the ND 1200R and the computer power are off.

Connect a computer COM port to the ND 1200R RS-232 serial port

(1) using a standard straight-through serial cable. Make sure the

cable connectors are tight, but do not overtighten the connector

screws.

Apply power to the computer, and then the ND 1200R. The

ND 1200R default settings for communication over the RS-232

serial port (1) are:

Baud rate 115,200

Word length 8 bits

2.2 Hardware Installation

Stop bits 1 bit

Parity None

Launch the computer application that will be used to communicate

with the ND 1200R, and configure the communication properties of

the COM port to match those of the ND 1200R.

RS-232 connector

54 2 Installation and Specifications

Page 55

Connecting a headphone

1

2

Audio alerts can be sent to headphones in areas that are noisy and

make it difficult to hear, or are quiet where audio alerts might create a

disturbance.

The speaker jack (1) is located on the side of the ND 1200R.

To connect headphones:

Verify that the ND 1200R power is off. Plug the headphones into the

speaker jack (1) on the side of the enclosure.

Make sure the headphone plug is fully inserted.

Connecting a USB printer

The ND 1200R supports certain USB printers. Printer models are

specified by Heidenhain at the time of purchase, or approved by

Heidenhain later.

The USB port (2) is located on the side of the ND 1200R.

To connect a USB printer:

Verify that the ND 1200R and printer power are off. Connect the

USB printer to the USB Type A port (2) on the side of the enclosure.

Make sure the USB cable plug is fully inserted.

Headphone, USB connectors

2.2 Hardware Installation

ND 1200R Radial 55

Page 56

Connecting an optional foot switch or remote

1

2

keypad

The optional foot switch and remote keypad are connected to the

RJ-45 connector on the side of the ND 1200R.

Often, only the optional foot switch or remote keypad is used.

However, two options can be connected simultaneously using a RJ-45

splitter.

The RJ-45 connector and splitter are shown here:

1 RJ-45 connector

2 RJ-45 splitter

RJ-45 splitters are available from most retail electronics

stores.

2.2 Hardware Installation

The foot switch and remote keypad can be used individually or in

combination:

foot switch

remote keypad

foot switch and remote keypad

When the foot switch and remote keypad are connected using the

RJ-45 splitter, all operating functions of each device are retained.

However, the switch shares Hot Key mapping with the number keys

7 and 8 of the remote keypad. As a result, functions assigned to the

two switch contacts will also be mapped to remote keypad numbers

7 and 8.

RJ-45 connector and RJ-45 splitter

Hot keys are discussed later in this chapter under

Software setup/Hotkeys. See "Hot key assignments" on

page 76.

To connect the foot switch or remote keypad:

Verify that the ND 1200R is off.

Plug an RJ-45 splitter into the ND 1200R RJ-45 connector if multiple

devices will be used.

Connect the RJ-45 plug of the devices into the RJ-45 splitter if

multiple devices will be used, or directly into the ND 1200R RJ-45

connector if only a single device will be used.

56 2 Installation and Specifications

Optional foot switch and remote keypad

Page 57

2.3 Software setup

The operating parameters of the ND 1200R must be configured prior

to using it for the first time, and any time drilling or communication

requirements change. Day to day use of the ND 1200R does not

require reconfiguration of software settings.

Parameter changes made in any of the setup screens can

change the operation of the ND 1200R. For this reason,

setup parameters are password-protected. Only qualified

personnel should be given password access to setup

screens. The unlocking of password-protected setup

functions is described on page 63.

Software is configured manually using the setup menu screens.

Parameters configured in setup screens will be retained until:

The data-backup battery is changed

The data and settings are cleared by maintenance personnel

Parameters are changed using the setup menu screens

Certain software upgrades are performed

2.3 Software setup

ND 1200R Radial 57

Page 58

Setup menu

1

2

3

Most operating parameters of the ND 1200R are configured using

screens and data fields accessed from the setup menu. Highlighting

setup menu items on the left side of the setup screen displays the

corresponding setup parameter data fields and choice fields on the

right side of the screen.

1 Setup menu item: Setup screen name

2 Setup data field: Setup data are entered

3 Setup choice field: Setup choices are made

The setup menu is easy to use:

2.3 Software setup

Press the MENU soft key and then press the SETUP soft key.

Navigate up or down in the menu to highlight the desired menu item

using the UP/DOWN ARROW keys.

Navigate from the menu (left side) to the setup fields (right side)

using the LEFT/RIGHT ARROW keys.

Navigate up or down to highlight the desired data or choice field

using the UP/DOWN ARROW keys.

Enter setup data using the NUMERIC KEYPAD, or choose a setup

parameter choice from soft key selections or list shown when the

field is highlighted.

Press the FINISH key to save the entry and return to the setup

menu.

Press the FINISH key again to return to the DRO.

An example of using the setup menu to enter the supervisor password

is shown on the next page.

Setup screen menu items, data fields and choice

fields

58 2 Installation and Specifications

Page 59

Setup example: entering the supervisor password

Critical setup parameters are password-protected. Only qualified

personnel should be given password access to setup screen

parameters. In this example, the setup menu is navigated to the

Supervisor screen and the supervisor password is entered.

To enter the supervisor password:

Press the MENU soft key to display the menu soft keys.

Press the SETUP soft key to display the setup menu.

Navigate up or down in the menu to highlight the Supervisor menu

item using the UP/DOWN ARROW keys.

2.3 Software setup

The MENU soft key is pressed to display

the menu soft keys

The SETUP soft key is pressed to display

the setup menu

The UP/DOWN ARROW keys are used

to highlight the Supervisor menu item

ND 1200R Radial 59

Page 60

Navigate from the menu to the Password setup field using the

RIGHT ARROW key.

Enter the supervisor password using the NUMERIC KEYPAD.

2.3 Software setup

The RIGHT ARROW key is used to

highlight the Password data field

Press the FINISH key to save the password and return to the setup

The supervisor password is entered

using the NUMERIC KEYPAD

menu.

Press the FINISH key to return to the DRO.

The FINISH key is pressed to save the

password and return to the setup menu

60 2 Installation and Specifications

Page 61

Order of setup

The ND 1200R setup software is contained on up to 12 screens,

depending on the hardware configuration. It is possible that not all the

setup screens described in this chapter are active in your system.

Disregard screen descriptions that do not apply to your ND 1200R.

The initial ND 1200R setup tasks should be performed in the order

listed here. Instructions are presented in this order on subsequent

pages.

Initial setup tasks Setup screens

1: Language selection and product version information About

2: Supervisor password entry and program unlocking Supervisor

3: Encoder configuration Encoders and Misc

4. Touch probe configuration Radial

5: Error correction LEC

6: Display formatting Display

The additional setup tasks can be performed in any order.

Remaining setup tasks Setup screens

Hot key assignments Hot keys

2.3 Software setup

Print formatting Print and Form characters screens

RS-232 and USB port configuration Ports

Audio volume Misc

Key repeat delay Misc

Screen saver activation Misc.

Time and date Clock

ND 1200R Radial 61

Page 62

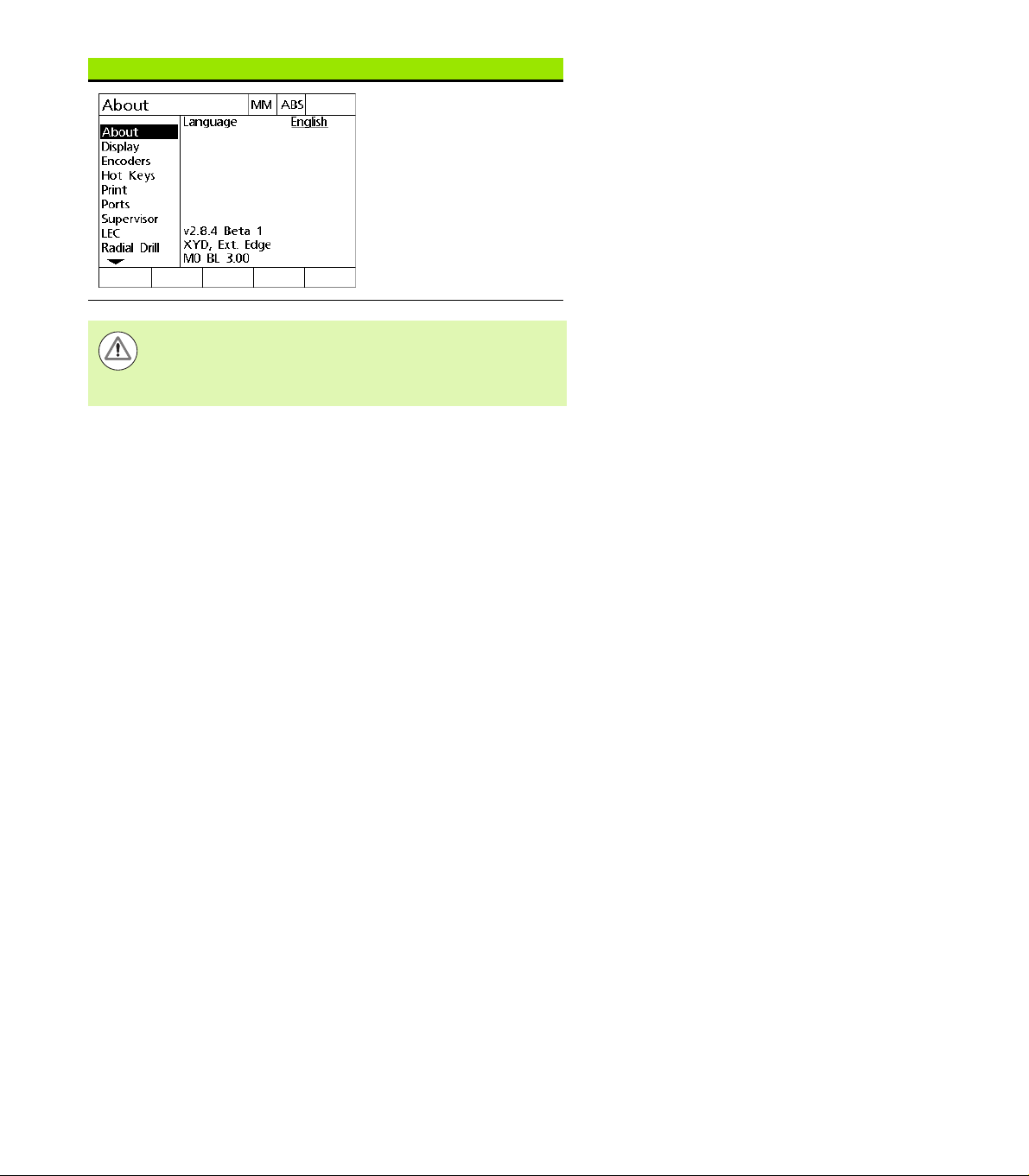

Language selection and product version

The About screen contains selections for changing the language of

text displayed on the screen and included in transmitted or printed

data. Product software and hardware information is also provided on

the About screen.

The product software and hardware version information

will be required if technical support is needed.

To select a language:

Press MENU>SETUP to display the setup menu and highlight the

2.3 Software setup

About menu item.

Press the RIGHT ARROW key to highlight the first language

selection field.

Use the UP/DOWN ARROW keys to select the desired language.

Press the YES soft key.

Highlight the About menu item Highlight the first language selection

field

Press the FINISH key to save the language and return to the setup

Highlight a language and press the YES

soft key

menu.

62 2 Installation and Specifications

Page 63

Supervisor password

The Supervisor screen contains the Password data field and Startup

Zero choice field.

Most setup parameters are password-protected and setup can only be

performed after the password is entered. To enter the supervisor

password:

Press MENU>SETUP to display the setup menu and then highlight

the Supervisor menu item.

Highlight the Password data field.

Enter the supervisor password.

Highlight the Supervisor menu item Highlight the Password data field Enter the password

2.3 Software setup

ND 1200R Radial 63

Page 64

To enable Startup Zero:

Highlight the Startup Zero choice field.

Press the YES soft key.

2.3 Software setup

Highlight the Startup Zero choice field Press the YES soft key

Press the FINISH key to save parameters and return to the setup

menu.

64 2 Installation and Specifications

Page 65

Encoder configuration

The Encoders and Misc screens contain data and choice fields for

configuring the encoders.

Encoders screen

The Encoders screen configuration fields include:

Axis selection

Encoder resolution

Encoder type (TTL, analog or serial)

Reference mark selection

Machine zero offset (MZ Cnts)

Reversing encoder count direction

To configure encoder settings in the Encoders screen:

Press MENU>SETUP to display the setup menu and then highlight

the Encoders menu item.

Highlight the Axis choice field and then press a soft key to select the

desired axis.

The setup process for all axes is identical.

Highlight the Res data field and then enter the encoder resolution in

the units shown in the Units choice field.

2.3 Software setup

Encoders menu item is highlighted Press an axis soft key Enter the encoder resolution

ND 1200R Radial 65

Page 66

Highlight the Type choice field and then press a soft key to select

the encoder type.

Highlight the Ref Marks choice field and then press a soft key to

select the encoder reference mark type.

The M.Z. Cnts (Machine zero counts) data field is rarely used to specify

an offset from the machine zero position created by crossing encoder

reference marks.

Custom machine zeroes are rarely used because datums are always

established before performing measurements.

To specify a custom machine zero, highlight the M.Z. Cnts data field

and enter the machine zero offset in machine counts as determined

by: Machine counts = DRO value/encoder resolution.

2.3 Software setup

Select the encoder type Select an encoder reference mark type Enter machine zero offset counts if

required

66 2 Installation and Specifications

Page 67

Highlight the Reversed choice field and then press the YES soft key

to reverse the encoder count direction.

Choose a count direction

Press the FINISH key to save parameters and return to the setup

menu.

2.3 Software setup

ND 1200R Radial 67

Page 68

Misc screen

The Misc screen encoder configuration fields include:

Auto DRO counts: The number of least significant DRO counts

required to refresh the DRO with new axis values.

Slew limit for the axes: High input slew rates resulting from rapid

input encoder motion can result in erroneous measurements.

Erroneous measurements are avoided by displaying encoder error

warnings when encoder values change at very high rates.

To configure encoder settings in the Misc screen:

Press MENU>SETUP to display the setup menu and then highlight

the Misc menu item.

2.3 Software setup

Highlight the Auto DRO Cnts data field and enter the number of

DRO counts (axis motion) in the least significant digit position

required to automatically refresh the DRO axis values.

Highlight the Slew Limit data field and enter the slew rate limit

(increments of resolution per second). For example, at a channel

resolution of 0.001 mm, a slew rate limit of 50,000 will result in

warning messages at encoder motion rates higher than 50 mm per

second.

Enter Auto DRO counts Enter the slew rate limit in encoder

counts per second

Press the FINISH key to save parameters and return to the setup

menu.

68 2 Installation and Specifications

Page 69

Probe configuration

The Radial screen contains data and choice fields for configuring a

probe.

Radial screen

The Radial screen configuration fields include:

Touch probe type

Probe size

Prompts for drilling

Side operation

Probe level

Probe debounce

To configure probe settings in the Radial screen:

Press MENU>SETUP to display the setup menu and then highlight

the Radial menu item.

Highlight the Touch Probe choice field and then press a soft key to

select the probe type.

Highlight the Probe Size data field and then enter the diameter of the

probe.

Highlight the Drill Prompts choice field and then press a soft key to

select prompting for drill changes.

2.3 Software setup

Select a touch probe type Enter a probe size Select display of drill prompts

ND 1200R Radial 69

Page 70

Highlight the Side Oper choice field and then press a soft key to

select side operation.

Highlight the Probe Level choice field and then press a soft key to

select High or Low probe level.

Highlight the Prb Debounce data field and then enter the minimum

time the probe must be stable in seconds.

2.3 Software setup

Select side operation Select probe level Enter the probe debounce time in

seconds

Press the FINISH key to save parameters and return to the setup

menu.

70 2 Installation and Specifications

Page 71

Error correction

The ND 1200R provides Linear Error Correction for the R axis. LEC

compensates for encoder and machine travel variations with error

correction coefficients. Coefficients are determined by comparing

actual measurements of a standard to the nominal values

imprintedonit.

Linear error correction (LEC)

Linear Error Correction is performed in the LEC setup screen and

compensates for variations along the R axis using one correction

coefficient for the entire range of motion on the axis. For example, an

LEC coefficient of 0.0002 per inch applied to a 6 inch measurement

along an axis produces a result of 6.0012 inches. To apply LEC to the

R axis:

Press MENU>SETUP to display the setup menu.

Highlight the LEC menu item and make sure that all correction

values are 1.0.

2.3 Software setup

Press MENU>SETUP to display the

Setup menu

ND 1200R Radial 71

Highlight the LEC menu item and make

sure that all correction values are 1.0

Page 72

Position the standard artifact along the R axis.

0

0

+0.02

+0.01

0.00

-0.01

-0.02

8.0

7.98

123

4

Align the artifact as closely as possible to the axis and then perform

a skew alignment as described in chapter 1 (see "Aligning the part

to an axis" on page 27).

Perform a single measurement of the entire range of motion using

the standard artifact and make a note of the result.

Use an artifact that allows measurements of as much of

the axis range of motion as possible.

In this example of applying LEC, one point at end of the axis

measurement range is measured using an 8 inch standard.

2.3 Software setup

Arrow number Descriptions

1: Standard length Entire 8 inch length is measured

2: Standard values The certified length of the standard

3: Observed values The measured length of the standard

4: Deviation graph Difference between standard and observed

values (not entered into any screen)

LEC example using an 8 inch standard

72 2 Installation and Specifications

Page 73

To perform the linear error correction in the LEC screen:

Highlight the LEC menu item.

Enter the Standard value of the artifact and the Observed value

measured by the ND 1200R for the R axis.

The standard and observed values for axes should be

1.000 when no LEC correction is applied.

Highlight the LEC screen Enter the standard and observed values

for the R axis

Press the FINISH key to save parameters and return to the setup

menu.

2.3 Software setup

ND 1200R Radial 73

Page 74

Display formatting

The Display screen contains data and choice fields for configuring

display resolution and other display parameters.

Display screen

The Display screen configuration fields include:

Startup linear units of measure

Selection of a comma or decimal point radix

Resolutions for linear and angular measurements

To configure display settings:

2.3 Software setup

Press MENU>SETUP to display the setup menu and then highlight

the Display menu item.

Highlight the Startup Linear choice field and press a soft key to