Bosch Rexroth HAB10-330-4X/2G09G-2E111-CE, Rexroth HAB, Rexroth HAB6-350-4X/2G07G-2N111-CE, Rexroth HAB10-330-4X/2G09G-2N111-CE, Rexroth HAB20-330-4X/2G09G-2E111-CE Operating Instructions Manual

...

Bladder-type accumulator

Type HAB

Component series 4X

Nominal volume 1 to 50 liters

Maximum operating pressure 350 bar

RE 50170/12.10

Replaces: 01.09

1/18

Table of contents

Contents Page

Features 1

Ordering code 2

Operating instructions and declarations of conformity 2

Function, section, symbol 3

Technical data 4

Application, mode of operation 5

Calculation 5 to 10

Unit dimensions, standard types 11

Accessories 12 to 16

Intended use 17

Safety instructions for hydraulic accumulators 17

Legal provisions 17

Safety devices 17

Information on available spare parts:

www.boschrexroth.com/spc

Features

– Hydraulic accumulator as per Pressure Equipment Directive

97/23/EC

– Bladder material for different applications

Use:

– Energy storage in systems with intermittent operation

– Energy reserve for emergencies

– Compensation of leakage losses

– Shock and vibration absorption

– Volume compensation in case of pressure and tempera-

ture changes

Note

The Pressure Equipment Directive 97/23/EC of the European

Parliament and the Council of 29 May 1997 on the approximation of the laws of the Member States has been in effect since

29 November 1999. Since 29 May 2002, the marketing of hydraulic accumulators must exclusively satisfy this directive.

2/18 Bosch Rexroth AG Hydraulics HAB RE 50170/12.10

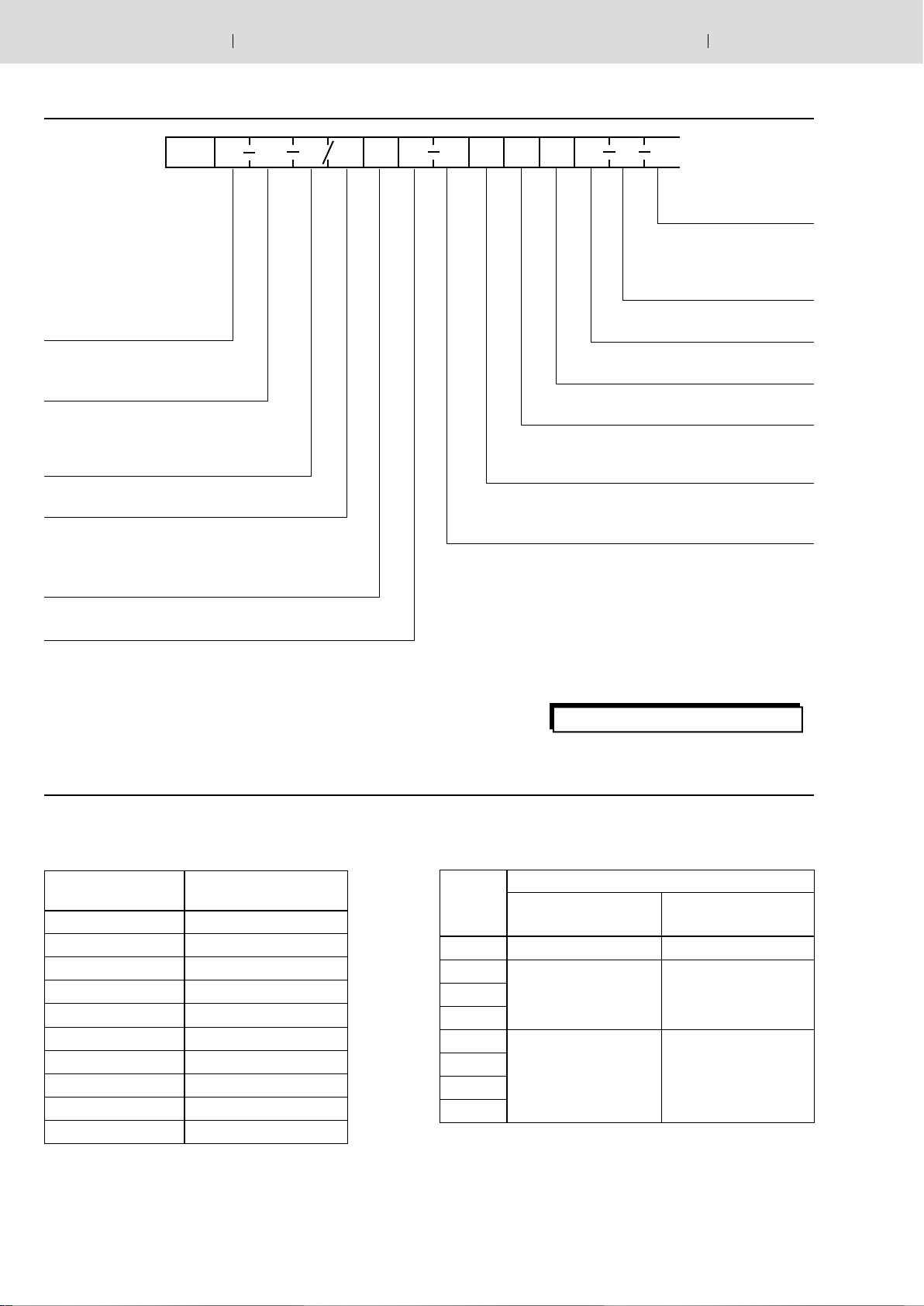

Ordering code

HAB 4X 2 G 2 1 1 1

Nominal volume

1 liter = 1

2.5 liters = 2,5

4 liters = 4

6 liters = 6

10 liters = 10

20 liters = 20

35 liters = 35

50 liters = 50

Max. admissible operating pressure

350 bar (1 to 6 liters) = 350

330 bar (10 to 50 liters) = 330

Component series

Component series 40 to 49 = 4X

(identical installation and connection

dimensions)

Gas filling pressure

2 bar = 2

Connection size for hydraulic fluid

G 3/4 = G05

G 1 1/4 = G07

G 2 = G09

Mounting type (oil port form)

Thread with sealing surface, radial on the inside = G

1)

*

Further details in the

plain text

e.g. special versions

Certification (acceptance)

CE = Acceptance according

to 97/23/EC

BA = Instructions for use

Surface of the connection side

1 = Steel

Surface of the tank inside

1 = Steel

Tank material

1 = Steel

Bladder material

N = NBR

E = ECO

Gas port form

2 = Gas valve for filling and testing device

(see page 14)

Order example:

HAB10-330-4X/2G09G-2N111-CE

1)

1)

1)

1)

1)

Other variants upon request

Operating instructions and declarations of conformity

Operating instructions

applicable to HAB1 to HAB50

Language

Operating instructions

German R901200925

English R901200926

French R901200927

Spanish R901200928

Italian R901200929

Chinese R901200930

Russian R901200931

Norwegian R901200932

Polish R901278729

Czech R901278730

Material no.

Declarations of conformity

Language: German, English, French

Nominal

volume

1 l – –

2.5 l

4 l

6 l

10 l

20 l

35 l

50 l

Standard types see page 11

Declaration of conformity

Bladder material NBR

Material no.

Bladder material ECO

Material no.

R901200940 R901200942

R901200941 R901200943

Function, section, symbol

Hydraulics Bosch Rexroth AGRE 50170/12.10 HAB 3/18

General

Hydraulic accumulators are hydrostatic devices that are able

to save a certain amount of energy and release it to the hydraulic system, if necessary.

Liquids are only compressible to a very small extent; gases,

however, are very compressible. The working principle of all

gas-filled hydraulic accumulators is based on that difference.

4

7

1

If a certain pressurized gas quantity is pressurized with a

higher liquid pressure, the gas volume decreases with increasing liquid pressure whereas the gas pressure increases

with the liquid pressure.

If the liquid pressure decreases, the extending gas presses

the liquid back into the hydraulic system until the pressure is

equalized again.

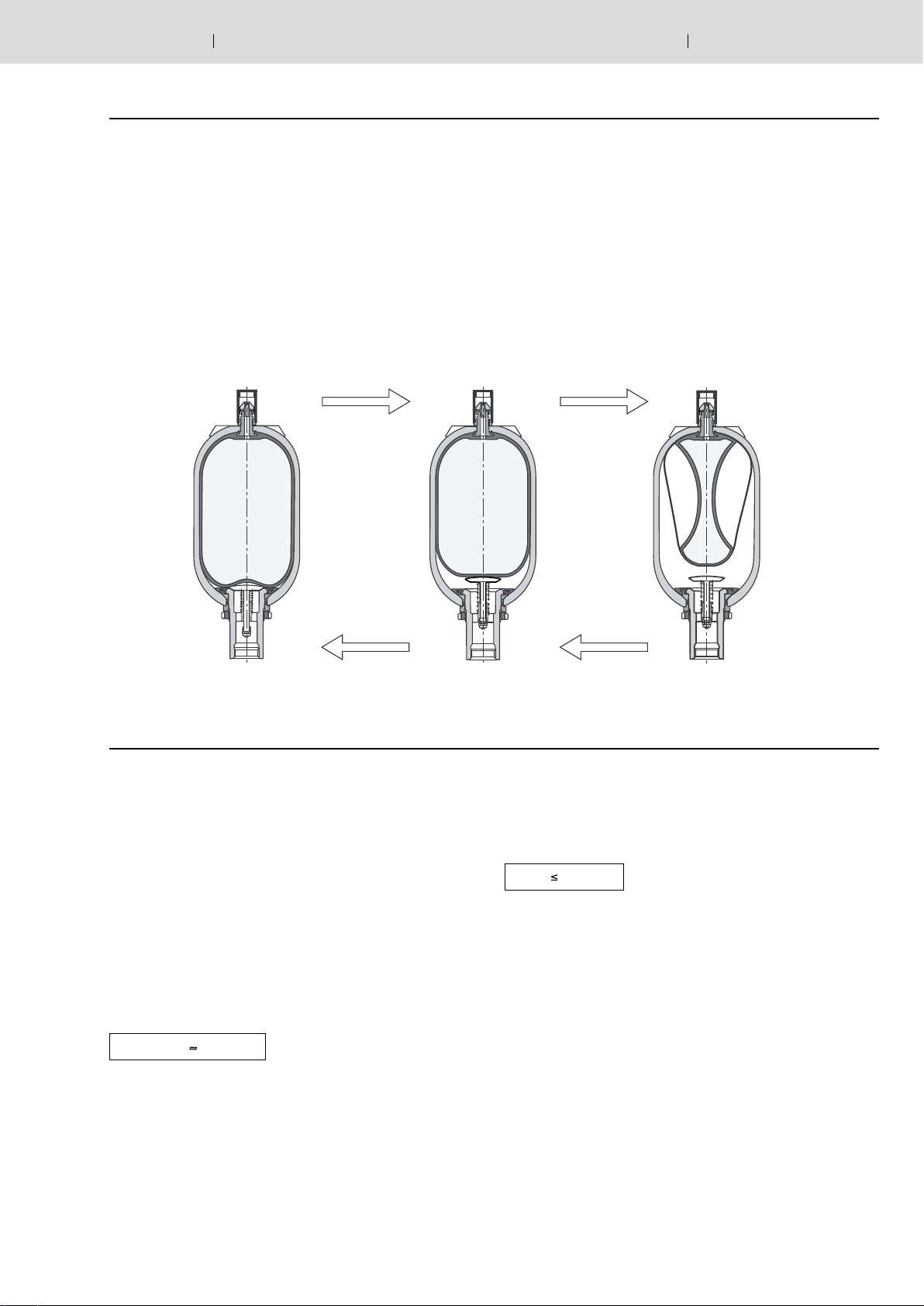

Bladder-type accumulators

Bladder-type accumulators consist of a seamlessly produced

cylindrical pressure vessel (1) made of high-tensile steel.

The elastic bladder (2) mounted in the interior divides the accumulator into a gas and a fluid side.

Via the gas valve (4), the bladder is filled with nitrogen to the

provided gas filling pressure p

8

6

.

0

4.1

4

4.2

4.3

5

2

3

1 Tank

2 Bladder

3 Oil valve

4 Gas valve

5 Gas valve

support

6 Nut

7 Type cap

8 Cover cap

Depending on the design of the separating element, you distinguish between bladder-type and diaphragm-type accumulators. Hydraulic accumulators basically consist of a liquid and

a gas part with a gas-tight separating element. The liquid part

is connected to the hydraulic circuit.

If the fluid is now pressed into the accumulator, the gas in the

bladder is compressed and in this way, a pressure increase

is achieved. The gas volume decreases and on the fluid side,

the fluid can flow into the accumulator. As soon as the pressure on the fluid side decreases under the gas pressure, the

accumulator is emptied.

In the bladder-type accumulator oil port, there is the oil

valve (3) which closes if the pressure on the gas side exceeds the pressure on the fluid side. In this way, exit of the

bladder into the oil channel and destruction of the bladder are

avoided.

If the minimum operating pressure is reached, a small fluid

volume (approx. 10 % of the hydraulic accumulator nominal

volume) is to remain between bladder and oil valve so that

the bladder does not hit the valve in every expansion process.

The gas valve (4) consists of sealing cap (4.1), gas valve insert (4.2) and gas filling valve body (4.3). These parts can be

exchanged individually.

The type cap (7) contains the technical data and features of

the hydraulic accumulator.

Symbol

4/18 Bosch Rexroth AG Hydraulics HAB RE 50170/12.10

Technical Data (For applications outside these parameters, please consult us!)

general

Weight kg See table page 11

Design Bladder-type accumulator

Installation position Fluid connection socket at the bottom, others on request

Mounting type with clamps and console

Ambient temperature range °C –15 to +65

Line connection Screw-in thread

hydraulic

Nominal volume V

Effective gas volume V

Max. adm. flow q

Max. admissible operating

pressure

nom

eff

max

p

bar 350 350 350 350 330 330 330 330

max

l 1 2.5 4 6 10 20 35 50

l 1.0 2.4 3.7 5.9 9.2 18.1 33.4 48.7

l/min 240 600 600 600 900 900 900 900

1)

Max. adm. pressure

fluctuation range

Δp

bar 200 200 200 200 200 200 200 200

dyn

Operating pressures and useful volumes See calculation page 5 to 10

Hydraulic fluid Hydraulic oil according to DIN 51524; other liquids on request!

Hydraulic fluid temperature range

Others on request

°C –15 to +80 (NBR)

–35 to +80 (ECO)

pneumatic

Charging gas Nitrogen, purity class 4.0, N2 = 99.99 vol. %

Gas filling pressure p

Hydraulic fluids that can be used

Hydraulic fluids Temperature range Material

Mineral oils –15 to +80 °C

–35 to +80 °C

HFC –10 to +60 °C NBR

bar 2

0

NBR Acrylonitrile-butadiene rubber (Perbunan)

NBR

ECO Epichlorhydrin rubber

ECO

For other hydraulic fluids and temperatures, please contact us.

Application, mode of operation

Hydraulics Bosch Rexroth AGRE 50170/12.10 HAB 5/18

Applications

Hydro-pneumatic accumulators offer versatile applications:

– Energy storage for saving pump drive power in systems

with intermittent operation.

– Energy reserve for emergencies, e.g. in case of hydraulic

pump failure.

– Compensation of leakage losses.

– Shock and vibration absorption in periodic vibrations.

– Volume compensation in case of pressure and tempera-

ture changes.

Charge

V

0

p

0

V

p

Mode of operation

Liquids are almost incompressible and are therefore not able

to store pressure energy. In hydro-pneumatic Rexroth accumulators, the compressibility of a gas is used for the fluid storage. You may only use nitrogen of cleanliness class 4.0!

N

= 99.99 vol. %

2

Charge

1

1

V

2

p

2

Discharge Discharge

Calculation

Pressures

In the accumulator calculation, the following pressures are of

vital importance:

p0 = Gas filling pressure at room temperature

and drained fluid chamber

p

(t ) = Gas filling pressure at operating temperature

0

p0 (t

) = Gas filling pressure at max. operating temperature

max

p

= Minimum operating pressure

1

p

= Maximum operating pressure

2

In order to achieve the best utilization of the accumulator volume possible as well as long service life, compliance with the

following values is recommended:

p0 (t

) 0.9 p

max

1

(1)

The largest hydraulic pressure is not to exceed four times the

filling pressure as otherwise, the bladder elasticity is greatly

strained and excessive compression changes with considerable gas heating result:

p2 4 • p

0

(2)

The accumulator bladder service life is the longer the smaller

the difference between p

and p2. This, however, results in

1

the reduction in the corresponding degree of utilization of the

maximum storage capacity.

0

6/18 Bosch Rexroth AG Hydraulics HAB RE 50170/12.10

Calculation

Oil volume

According to the pressures p

V

… V2 result.

0

… p2, the gas volumes

0

In this connection, V0 is also the accumulator's nominal volume.

The available oil volume V corresponds to the difference of

the gas volumes V

V V1 – V

and V2:

1

2

(3)

The gas volume that can be changed within one pressure difference is determined by the following equations:

a) To isothermal changes of condition of gases, i.e. if the

gas cushion changes so slowly that there is enough time

for the complete heat exchange between the nitrogen and

its environment and the temperature therefore remains

constant, the following applies:

p0 • V0 = p1 • V1 = p2 • V

(4.1)

2

Calculation diagram

For the graphical determination, the formulas (4.1) and (4.2)

in diagrams on pages 7 to 10 are implemented. Depending

on the task, the available oil volume, the accumulator size or

the pressures can be determined.

Available oil

volume

Correction factor K

and K

i

a

The equation (4.1) or (4.2) is only true for ideal gases. In

the behavior of real gases, considerable deviations result at

operating pressures of more than 200 bar, which have to be

considered by correction factors. They can be seen from the

following diagrams. The correction factors by which the ideal

sampling volume

V is to be multiplied lie within the range

from 0.6 … 1.

b) To adiabatic changes of condition, i.e. if the gas cushion

changes quickly with the nitrogen temperature changing as

well, the following applies:

p0 • V

χ

= p1 • V

0

χ

= p2 • V

1

(4.2)

χ

2

χ = Ratio of the specific heats of the gases

(adiabatic exponent), for nitrogen = 1.4

In practice, the changes of condition rather follow adiabatic

laws. The charging is often isothermal, the discharge adiabatic.

Considering the equations (1) and (2), V lies at 50 % to

70 % of the nominal accumulator volume. As reference

point, the following applies:

V0 = 1.5 … 3 x V

(5)

Application of the calculation diagrams

(see page 7 to 10)

Gas filling pressure

V

V in l →

2

V

1

s

2

po

s

1

p in bar →

P

P

1

2

Working pressure range

→

K

i

i

K

Isothermal

1,0

0,9

0,8

0,7

0,6

0,1

0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,

V

p1 / p2 →

real

= V

ideal

• K

V

= V

i

Adiabatic

real

ideal

• K

a

1,0

→

K

0,9

0,8

a

p

2

= 200 bar

p

2

= 300 bar

0,7

0,6

0,1

0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0

p

/ p2 →

1

Loading...

Loading...