Bosch RA1054 Operating/safety Instructions Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Version Version française Versión en español

See page 2 Voir page 6 Ver la página 10

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

RA1054

BM 2610998756 09-11:BM 2610998756 09-11 9/22/11 8:03 AM Page 1

-2-

Read and und e r s t a n d

these instructions and tool

manual for use of these accessories.

Disconnect the plug from

the power source before

making any adjustm e n t s , ch a n g i n g

accessories, or storing the tool. Such

preventive safety measures reduce the risk

of starting the tool accidentally.

ASSEMBLING FOR USE AS AN

EDGE GUIDE

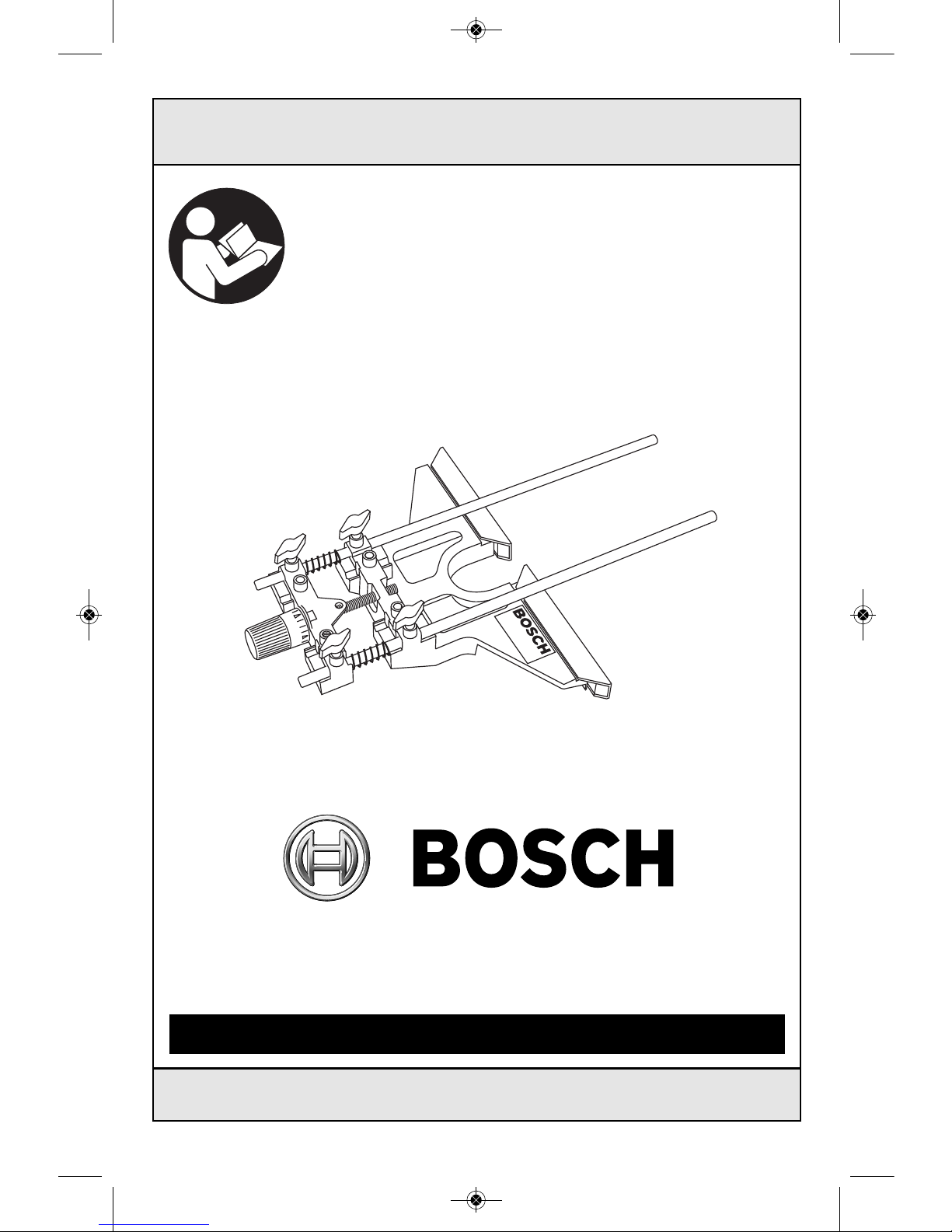

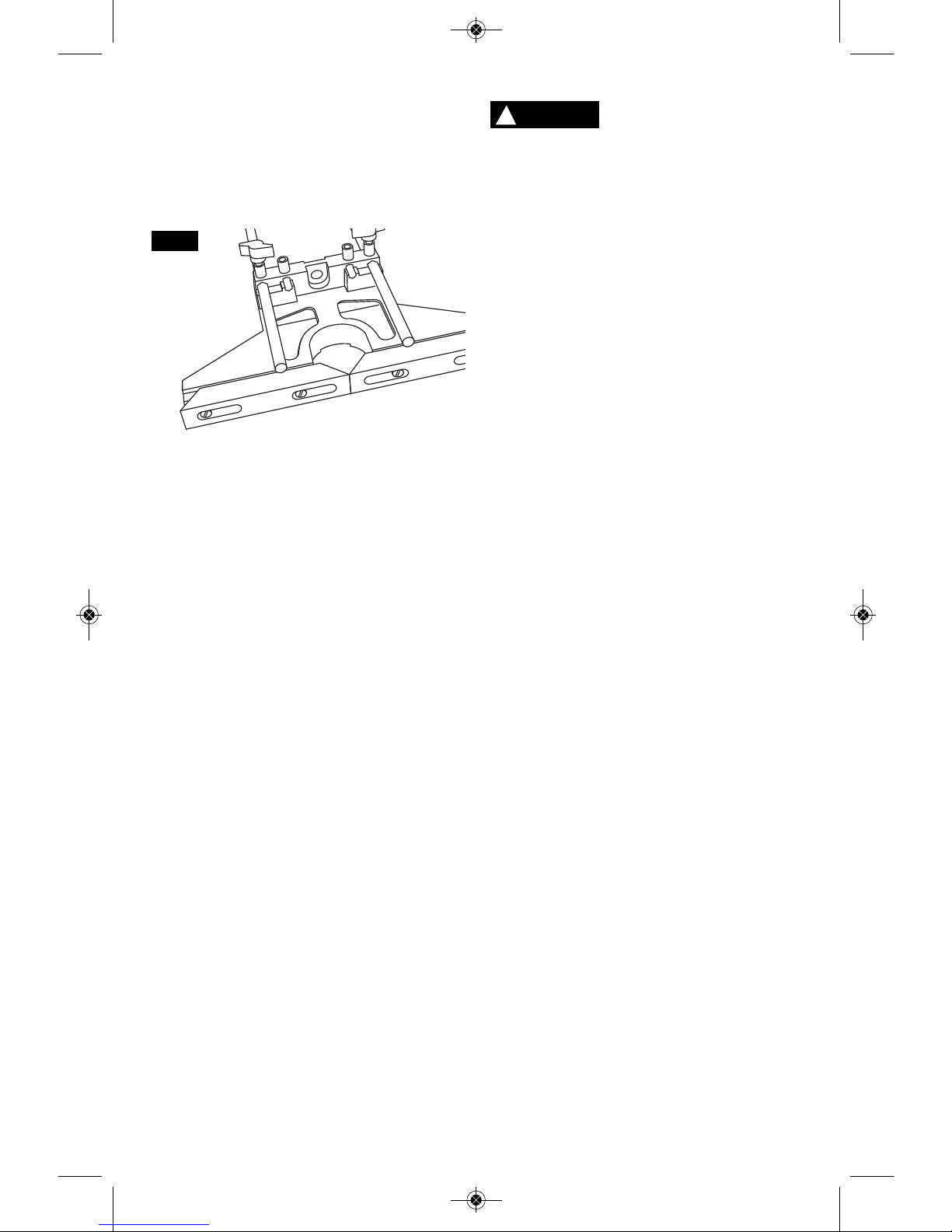

To assemble the Deluxe Router Guide: (Fig. 1)

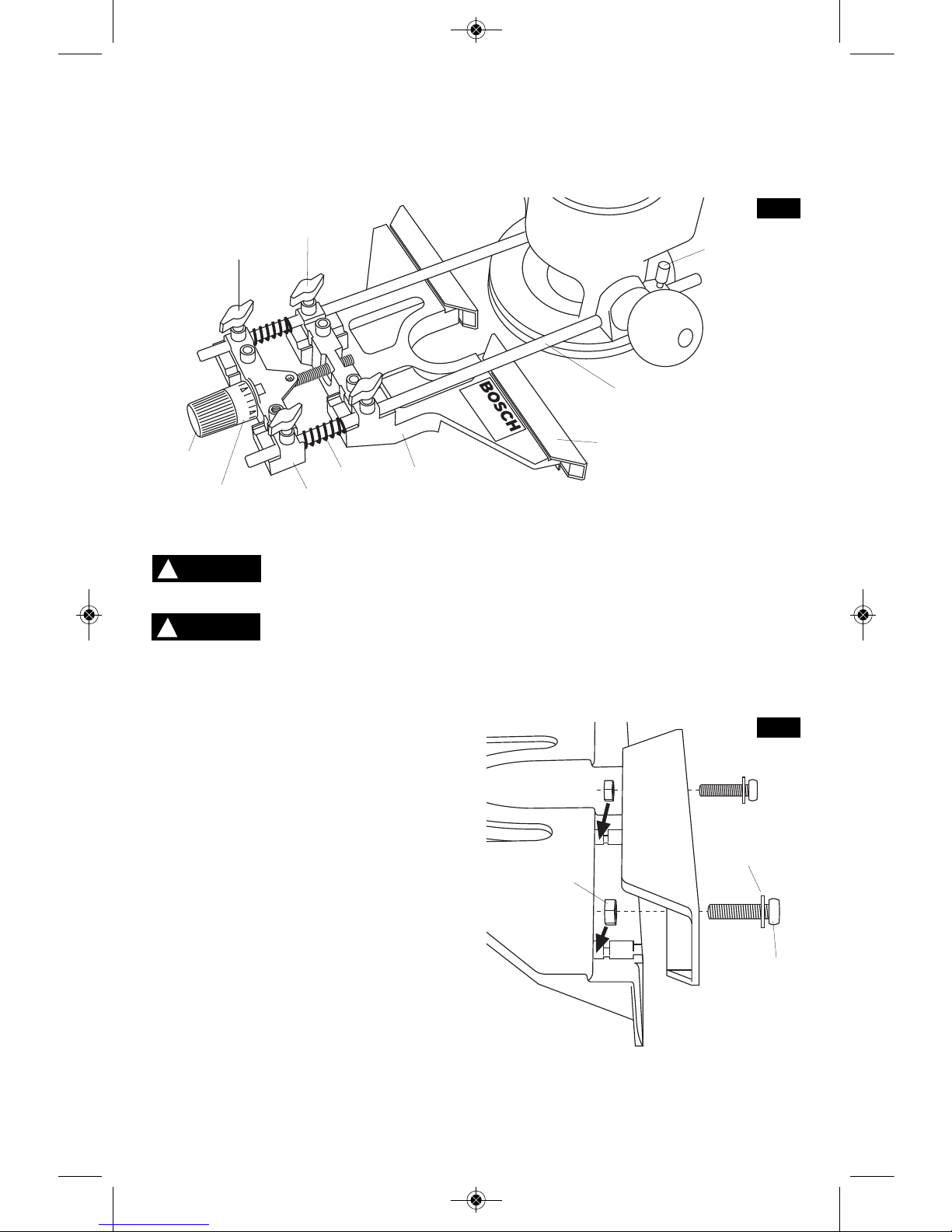

1. Attach the screws (A), washers (B) and nuts

(C) to the guide plates (D) as shown (Fig. 2).

Note: See “Attaching the Dust Extraction

Hood”, on page 2, if you want to attach the

dust extraction hood.

2. Insert the assembled guide plates (D) into

the top of the guide base (E) and tighten.

3. Insert guide rods (F) into the outer holes of

guide base (E).

4. Tighten rods in place with front wing knobs

(G).

5. Place springs (H) over the ends of the rods.

6. Attach rear wing knobs (I) to fine adjustment

guide (J) and slide it over the rods.

7. Screw fine adjustment knob (K), spacer (not

shown) and indicator (L) through fine adjust

guide (J) and into guide base (E). While

assembling, the fine adjustment knob (K)

should be tightened to the point that the

springs H are slightly compressed between the

fine adjust base (J) and the guide base (E).

8. Tighten rear wing knobs (I).

RA1054 BOSCH DELUXE ROUTER GUIDE

For use with Bosch 1613, 1615, 1617/18, 1619, and MR23EVS Series routers

J

F

A

B

D

E

C

K

L

H

E

G

I

FIG. 1

D

N

WARNING

!

FIG. 2

WARNING

!

BM 2610998756 09-11:BM 2610998756 09-11 9/22/11 8:03 AM Page 2

-3-

Do not overreach. Keep

proper footing and balance

at all times. This enables better control of the

power tool in unexpected situations.

Always maintain control of

tool power switch. Some

cutting applications require repositioning of

your hands. Always ensure that one hand is

in control of the power switch.

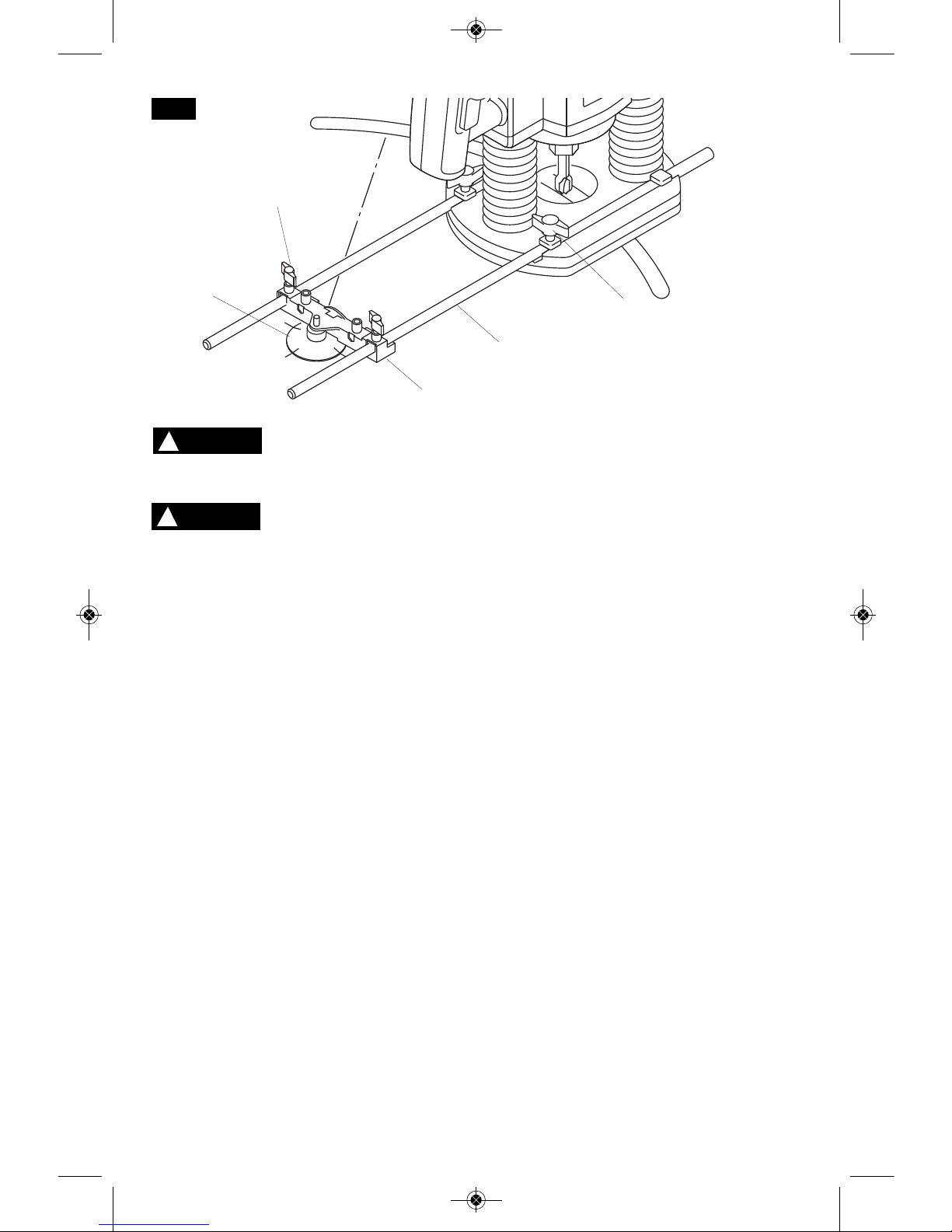

ASSEMBLY FOR USE AS

A CIRCLE GUIDE

To reassemble the deluxe router guide for use

as a circle guide (or arc guide), follow these

steps: (Fig. 3)

1. Loosen rear w i n g knobs (I) and fine

adjustment knob (K), spacer, and indicator

(L) and remove these parts from guide rods

(F).

2. Remove springs (H) from guide rods.

3. Loosen front wing knobs (G) and guide

base (E) and remove from the guide rods.

4. Reinstall fine adjustment guide (J) onto

guide rods (F) rotated 180 degrees from

normal position so that circle guide hole

faces away from the router.

5. Insert guide rods (F) into router base. For

maximum stability, make sure each rod

goes through both holes and protrudes out

the other side of the router base. (At a

minimum, the rods must be inserted far

enough into the router base that they are

both su pported from below at a point

beyond the fastener on the router.)

6. Securely fasten the router to the rods by

tigh t e n i n g the thumbscrews (N).

(Depending on the router model, another

set of wing knobs (O) may be used instead

of the knurled thumbscrews.) The largest

circles and arcs can be made when the

guide rods enter the side of the router

where the thumbscrews (or wing knobs)

are located.

7. Mark the workpiece at the center of the

desired circle.

8. Using the centering slots on the edge of the

pivot plate (P), center the pivot plate on the

center mark and attach to the workpiece

with several strips of strong tape placed

over the pivot plate in a crisscross pattern.

9. Place fine adjustment guide (J) on pivot

plate (P) so that the hole in guide (J) fits

over the steel pin.

10.Adjust the position of the rods and router as

necessary to achieve the desired radius of

the circle or arc, then securely tighten wing

knobs (I).

ATTACHING THE DUST

EXTRACTION HOOD

To attach the dust extraction hood (M): (Fig. 4)

1. Remove the two guide pl a t e s (D) by

loosening the four screws and lifting the two

guide plate assemblies off the top of the

guide base.

2. Remove the nuts (C) from the two center

screws.

3. Reattach the guide plates using only their

outside screws.

4. Insert the nuts (C) into the hex cavities in the

dust extraction hood.

F

IG. 3

J

P

I

F

O

WARNING

!

WARNING

!

BM 2610998756 09-11:BM 2610998756 09-11 9/22/11 8:03 AM Page 3

-4-

5

. Move the hood into place beneath the guide

assembly.

6. Insert the two center screws into the guide

assembly and screw into the nuts in the

hood.

The dust extraction hood is sized to accept

35mm vacuum hoses. Also included is an

adapter that will connect the hood to 1-1/4” and

1-1/2” vacuum hoses. Do not use this hood at

the same time you are using any other dust

extraction hood with the router.

ATTACHING THE GUIDE

TO THE ROUTER

1. Insert guide rods F into router base. For

maximum stability, make sure each rod goes

through both holes and protrudes out the

other side of the router base. (At a minimum,

the rods must be inserted far enough into

the router base that they are both supported

fro m below at a po i n t beyond the tw o

knurled thumbscrews (N).)

2. Securely fasten the router to the rods by

tightening the thumbscrews N. (Depending on

the router model, another set of wing knobs

(O) may be used instead of the knurled

thumbscrews.) (Fig. 1 or 3.)

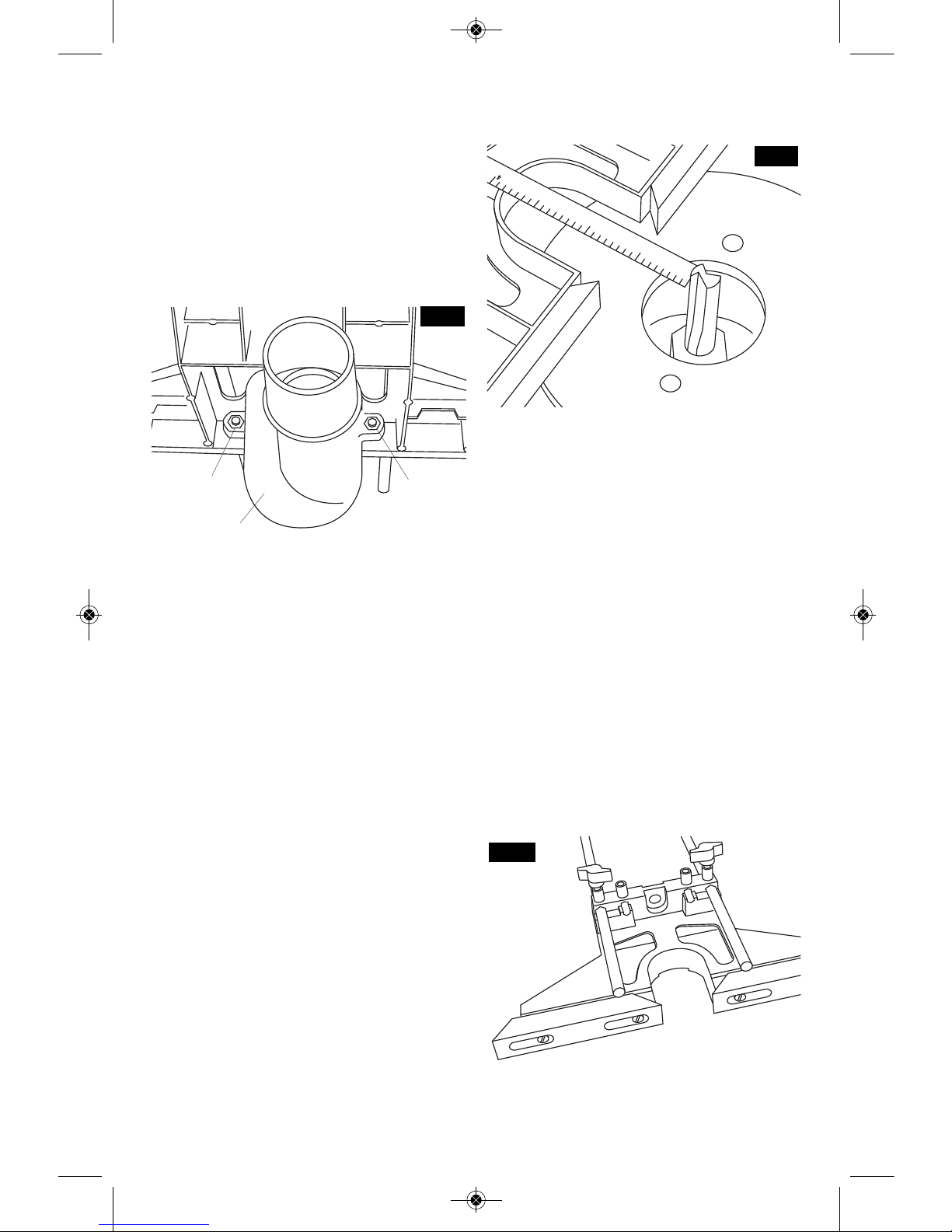

ADJUSTING THE ROUTER

GUIDE POSITION

The router may be positioned either directly

over the guide plates for edge forming

operations or for the creation of slots near the

workpiece edge or beyond the guide plates for

creating slots away from the workpiece edge.

For initial adjustment, slide the router guide

assembly along the rods to the approximate

desired position and securely tighten the rear

set of wing knobs (I). (Fig. 1)

To determine the distance between the bit and

the face plates, place a ruler in the recess in

the bottom of the guide, and measure the

d

istance from the face of the guide plates to

the outermost edge of the router bit. (Fig. 5)

For fine adjustment:

1. Without moving the fine adjustment knob,

move the fine adjustment indicator (L) so

that the ‘0’ position aligns with the indicator

on the fine adjustment guide (J). This

makes it easier to precisely move the guide

in or out by the desired amount.

2. Loosen the front wing knobs (G).

3. To move the router in towards router guide,

turn fine adjustment knob (K) clockwise

(when viewed from back of the router guide)

To move router away from router guide, turn

it counterclockwise. The total travel per

revolution of the knob is 5/64" or 2 mm.

4. When the guide is in the desired location,

securely tighten wing knobs (G).

ADJUSTING THE GUIDE PLATES

Moving the guide plates (D) to their outermost

position extends the overall length of the guide

surface and provides added stability on long

workpieces. (Fig. 6)

FIG. 6

GUIDE PLATES OPENED

1

2

3

FIG. 5

FIG. 4

M

C

C

BM 2610998756 09-11:BM 2610998756 09-11 9/22/11 8:03 AM Page 4

Moving the guide plates (D) inward for edgeforming reduces the gap between the guide

plates and the router bit and provides close-in

support. This is especially helpful when routing

very short workpieces and at the end of any

workpiece. It also reduces the possibility of

t

ear out on the workpiece. (Fig. 7)

The RA1054 can also be used to guide a

router along convex curves. When used in this

way, it is best to fasten the guide plates at their

outer-most positions, then adjust the location

of the router on the rods so that the bit is

positioned to make the desired cut.

The guide plate screws should be tightened to

secure guide plates in the desired location.

Guide plates (D) (and dust

extraction hood, if used)

must clear the router bit by at least 1/8" (3

mm) in all directions.

O

PERATING INSTRUCTIONS

Once the router guide is assembled, attached

and adjusted, it is ready for use.

The router should be fed from left to right with

steady feed pressure

When guiding along straight edges, the guide

plates should be kept in contact with the edge

of the workpiece at all times.

When guiding along convex curves, the two

inner edges of the guide plates should be held

against the workpiece at all times.

USE OF CIRCLE CUIDE

Follow the normal procedure for using the

router.

• When a clean round opening in the

workpiece is desired, the smoothest surface

for the opening will be achieved by moving the

router in a clockwise direction.

• When making a round workpiece such as a

small tabletop, the smoothest surface for the

round workpiece will be achieved by moving

the router in a counter-clockwise direction.

-5-

GUIDE PLATES CLOSED

WARNING

!

FIG. 7

BM 2610998756 09-11:BM 2610998756 09-11 9/22/11 8:03 AM Page 5

Loading...

Loading...