Trane TCONT803AS32DA, TCONT802AS32DA User Manual

TCONT802AS32DA Touch Screen and TCONT803AS32DA Touch Screen with Dehumidification Control Comfort Controls

18-HD25D19-3

INSTALLATION INSTRUCTIONS

APPLICATION

The TCONT802AS32DA and TCONT803AS32DA Touch Screen Comfort Controls provide electronic control of 24 Vac heating and cooling systems. See Table 1 for a general description.

Table 1. TCONT802AS32DA and TCONT803AS32DA Comfort Control Description.

|

|

|

|

|

Power Method |

Changeover |

System Selection |

Fan Selection |

Comments |

|

|

|

|

|

|

|

|

|

|

24 Vac common |

Automatic or |

Heat-Off-Cool- |

On-Auto-Circ |

System and Fan selection |

wire |

manual selectable |

Auto (Em. Heat |

|

vary based on system type |

|

|

for heat pumps) |

|

|

|

|

|

System and Fan selection |

|

|

|

|

|

|

|

|

|

|

vary based on System type. |

|

|

|

|

Humidity sensor to control |

|

|

|

|

dehumidification. |

|

|

|

|

|

MERCURY NOTICE

MERCURY NOTICE

If this control is replacing a control that contains mercury in a sealed tube, do not place your old control in the trash. Dispose of properly.

Contact your local waste management authority for instructions regarding recycling and the proper disposal of the old control.

INSTALLATION

When Installing this Product...

1.Read these instructions carefully. Failure to follow the instructions can damage the product or cause a hazardous condition.

2.Installer must be a trained, experienced service technician.

3.After completing installation, use these instructions to check out the product operation.

Selecting Location

Install the comfort control about 5 ft. (1.5m) above the floor in an area with good air circulation at average temperature. See Fig. 1.

NO

|

YES |

|

NO |

NO |

5 FEET |

[1.5 METERS]

M19925

Fig. 1. Selecting comfort control location.

U.S. Pat. No. 6595430, D509151, and Other Patents Pending |

69-1790-3 |

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

Do not install the comfort control where it can be affected by:

—Drafts or dead spots behind doors and in corners.

—Hot or cold air from ducts.

—Radiant heat from sun or appliances.

—Concealed pipes and chimneys.

—Unheated (uncooled) areas such as an outside wall behind the comfort control.

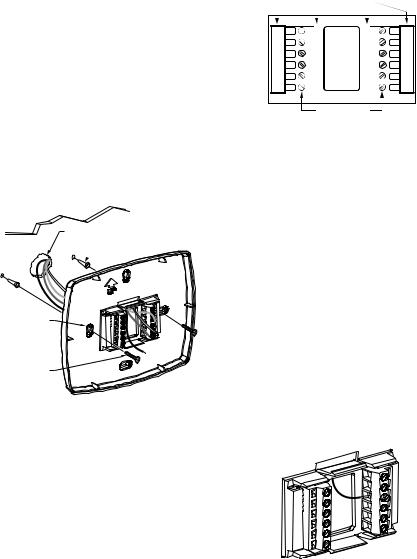

Installing Wallplate

CAUTION

CAUTION

Electrical Hazard.

Can cause electrical shock or equipment damage.

Disconnect power before wiring.

The comfort control can be mounted horizontally on the wall or on a 4 in. x 2 in. (101.6 mm x 50.8 mm) wiring box.

1.Position and level the wallplate (for appearance only).

2.Use a pencil to mark the mounting holes.

WALL

WIRES THROUGH WALL

AND WIRE SLOT

WALL ANCHORS (2)

WALL ANCHORS (2)

MOUNTING

HOLES

MOUNTING

SCREWS (2)

M19916

Fig. 2. Mounting wallplate.

3.Remove the wallplate from the wall and, if drywall, drill two 3/16-in. holes in the wall, as marked. For firmer material such as plaster, drill two 7/32-in. holes. Gently tap anchors (provided) into the drilled holes until flush with the wall.

4.Position the wallplate over the holes, pulling wires through the wiring opening. See Fig. 2.

5.Insert mounting screws into the holes and tighten.

3.Securely tighten each screw.

4.Push excess wire back into the hole.

5.Plug the hole with nonflammable insulation to prevent drafts from affecting the comfort control.

HEAT PUMP

HEAT/COOL

Y2 |

Y2 |

RC |

RC |

F |

|

R |

R |

X2 |

|

W1 |

O |

W1 |

W2 |

Y |

Y |

S1 |

S1 |

G |

G |

S2 |

S2 |

B |

B |

|

SCREW TERMINALS |

M22636 |

|

Fig. 3. Selecting terminal identifications for system type.

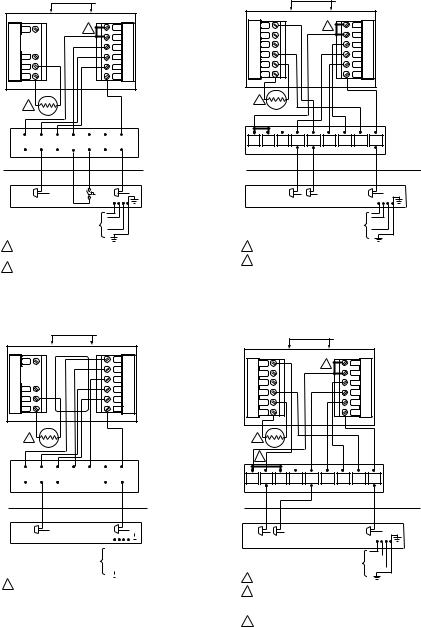

Table 2. Selecting Terminal Identifications for System Type.

|

|

|

|

Wallplate |

Wiring |

System Type |

Terminal |

Diagram |

Identifications |

Reference |

|

|

|

|

Standard Heat/Cool |

Heat/Cool |

Fig. 5, |

|

|

Fig. 6 |

|

|

|

Standard Multistage |

Heat/Cool |

Fig. 7, |

up to 2 Heat/2 Cool |

|

Fig. 8 |

|

|

|

Heat Pump with |

Heat Pump |

Fig. 9, |

Electric Auxiliary |

|

Fig. 10, |

(Backup) Heat |

|

Fig. 11 |

|

|

|

Heat Pump with |

Heat Pump |

Fig. 12, |

Fossil Fuel Auxiliary |

|

Fig. 13, |

(Dual Fuel) Heat |

|

Fig. 14, |

|

|

Fig. 15 |

|

|

|

NOTE: The factory default setting is configured for a 1 Heat/1 Cool System with a gas furnace.

WIRING (FIG. 5-15)

All wiring must comply with local electrical codes and ordinances.

1.Select set of terminal identifications (Table 2) that corresponds with system type (heat/cool or heat pump in Fig. 3).

2.Loosen the screws for the appropriate system type selected; see Table 2. Insert wires in the terminal block under the loosened screw. See Fig. 4.

M19917

Fig. 4. Inserting wires in terminal block.

IMPORTANT

Use 18 gauge comfort control wire.

Pub. No. 18-HD25D19-3 |

|

69-1790—3 |

2 |

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

|

|

HEAT/COOL |

Y2 |

1 |

RC |

|

|

R |

|

|

W1 |

W2 |

|

Y |

S1 |

|

G |

S2 |

|

B |

|

T |

|

|

2 |

|

R |

|

Y |

|

G |

|

|

|

W2 |

|

W3 |

|

B/C |

AIR |

|

|

|

W1 |

|

|

|

|||||||

|

|

|

|

|

|

HANDLER |

INDOOR

OUTDOOR

|

ODT |

|

COOLING UNIT |

Y |

B |

O.D. SECTION |

|

|

(SINGLE STAGE) |

||

|

|

|

|

TO POWER SUPPLY |

(3 PH |

|

|

PER LOCAL CODES |

ONLY) |

|

|

|

|

||

1FACTORY INSTALLED JUMPER.

OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE

2ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE. |

M22637 |

|

|

|

HEAT/COOL |

Y2 |

1 |

RC |

|

|

R |

|

|

W1 |

W2 |

|

Y |

S1 |

|

G |

S2 |

|

B |

2 |

T |

|

|

|

R |

BK |

O |

YLO |

Y |

G |

W1 |

W2 |

B/C |

INDOOR

OUTDOOR

VARIABLE SPEED

TWO-STAGE

FURNACE/VARIABLE SPEED AIR HANDLER

Y1 Y2 |

B |

COOLING UNIT |

O.D. SECTION |

||

|

|

(TWO STAGE) |

TO POWER SUPPLY |

(3 PH |

|

PER LOCAL CODES |

ONLY) |

|

|

|

1FACTORY INSTALLED JUMPER.

2OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE. |

M22640 |

|

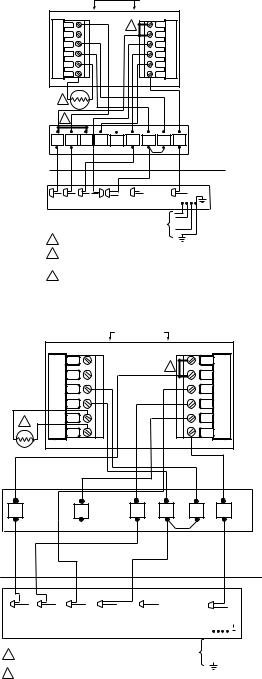

Fig. 5. Typical hookup of single-stage heat and cool system with single transformer (1H/1C).

|

HEAT/COOL |

Y2 |

RC |

|

R |

|

W1 |

W2 |

Y |

S1 |

G |

S2 |

B |

|

T |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OIL |

R |

|

Y |

|

G |

T |

|

T |

W |

B/C |

|

|

FURNACE |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

OIL BURNER PRIMARY |

|

|

|

|

|

|

|||||||

|

|

|

|

INDOOR |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

OUTDOOR |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COOLING UNIT |

|

|

Y |

|

|

|

|

B |

|

|

O.D. SECTION |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(SINGLE STAGE) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

TO POWER SUPPLY |

|

(3 PH |

|

|

|

|

||||||||

|

|

PER LOCAL CODES |

|

ONLY) |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE

FROM THE THERMOSTAT CABLE.

M22638

Fig. 6. Typical hookup of single-stage heat and cool system with two transformers (1H/1C).

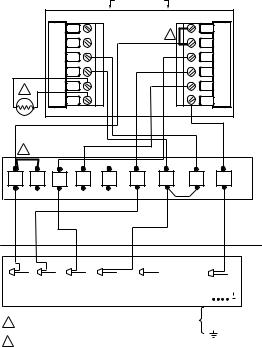

Fig. 7. Typical hookup of two-stage indoor and two-stage cooling unit in a single transformer system (2H/2C or 2H/1C or 1H/2C).

|

|

|

|

|

|

HEAT/COOL |

|

||

Y2 |

|

|

|

|

1 |

|

RC |

|

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

W1 |

|

|

W2 |

|

|

|

|

|

|

Y |

|

|

S1 |

|

|

|

|

|

|

G |

|

|

S2 |

|

|

|

|

|

|

B |

|

|

2 |

|

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

R |

BK |

O |

YLO |

Y |

G |

W1 |

W2 |

B/C |

VARIABLE SPEED |

TWO STAGE |

|||||||||

|

|

|

|

|

|

|

|

|

FURNACE |

|

|

|

|

|

|

|

|

|

INDOOR |

|

|

|

|

|

|

|

|

|

OUTDOOR |

|

|

|

|

|

|

|

|

|

16 SEER |

|

Y2 |

Y1 |

|

|

|

|

|

B |

COOLING UNIT |

|

|

|

|

|

|

O.D. SECTION |

|||

|

|

|

|

|

|

|

|

|

(TWO STEP) |

TO POWER SUPPLY |

(3 PH |

|

PER LOCAL CODES |

ONLY) |

|

|

|

|

1 FACTORY INSTALLED JUMPER.

2OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE FROM THE THERMOSTAT CABLE.

3 THE INSTALLER MUST JUMPER AT THE LVTB “R” TO “O”. M24231

Fig. 8. Typical hookup of two-stage indoor and two-step scroll cooling unit in a single transformer system (2H/2C or 2H/1C or 1H/2C).

|

Pub. No. 18-HD25D19-3 |

3 |

69-1790—3 |

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

HEAT PUMP

Y2 |

1 |

RC |

|

F |

|

R |

|

X2 |

|

O |

|

W1 |

|

Y |

|

S1 |

|

G |

|

S2 |

|

B |

|

2 |

T |

|

|

|

|

|

|

|

|

I-PF |

PM-A |

|

|

|

|

SUPPL. HTR. |

|

R |

Y |

O |

G W1 W2 |

W3 CONTROL BOX |

B/C T |

|

|

|

|

REQ. |

|

|

|

|

ODT-1 |

FOR |

|

|

|

|

TO POWER 3 PH |

|

|

|

|

|

|

|

|

|

|

|

ODT-2 |

SUPPLY PER |

|

|

|

|

LOCAL |

|

|

|

|

|

|

CODES AND |

|

|

|

|

|

AS DEFINED |

|

|

|

|

|

IN FIELD |

|

|

|

|

INDOOR |

WIRING TABLE |

|

|

|

|

OUTDOOR |

|

|

R |

Y |

O |

X2/BK |

BR(T) |

B |

|

|

|

|

TO POWER SUPPLY |

(3 PH |

|

|

|

|

PER LOCAL CODES |

ONLY) |

|

|

|

|

|

1FACTORY INSTALLED JUMPER.

2OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE ON SELECT MODELS. WIRES MUST HAVE A CABLE SEPARATE FROM THE THERMOSTAT CABLE.

AIR

HANDLER

HEAT PUMP

O.D. SECTION (SINGLE STAGE)

M22641

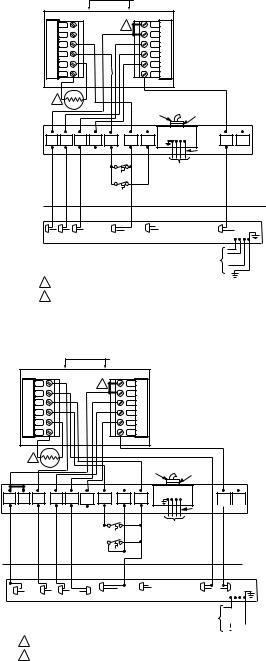

Fig. 9. Typical hookup of single-stage heat pump with auxiliary/backup heat (2H/1C heat pump).

HEAT PUMP

Y2 |

1 |

RC |

|

F |

|

R |

|

X2 |

|

O |

|

W1 |

|

Y |

|

S1 |

|

G |

|

S2 |

|

B |

|

2 |

T |

|

|

|

|

|

|

|

|

I-PF |

PM-A |

|

|

|

|

|

|

|

|

|

SUPPL. HTR. |

|

R |

BK |

Y |

YLO |

O |

G |

W1 |

W2 |

W3 |

CONTROL BOX |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

REQ. |

|

|

|

|

|

|

ODT-1 |

|

|

FOR |

|

|

|

|

|

|

|

|

TO POWER |

3 PH |

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

ODT-2 |

|

SUPPLY PER |

||

|

|

|

|

|

|

|

LOCAL |

|

||

|

|

|

|

|

|

|

|

|

CODES AND |

|

|

|

|

|

|

|

|

|

|

AS DEFINED |

|

|

|

|

|

|

|

|

|

|

IN FIELD |

|

|

|

|

|

|

INDOOR |

|

|

WIRING TABLE |

||

|

|

|

|

|

OUTDOOR |

|

|

|

|

|

B/C T VARIABLE SPEED AIR

HANDLER

HANDLER

R |

Y2 |

Y1 |

O |

X2/BK |

BR(T) |

F |

B |

|

|

|

|

|

|

|

|

|

TO POWER SUPPLY |

(3 PH |

|

|

|

ONLY) |

|

|||

PER LOCAL CODES |

|

|

|

|

|

|

|

|

|

HEAT PUMP O.D. SECTION (TWO STAGE)

1FACTORY INSTALLED JUMPER.

2OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. AVAILABLE ON SELECT MODELS.

WIRES MUST HAVE A CABLE SEPARATE FROM THE THERMOSTAT CABLE. |

M22642 |

Fig. 10. Typical hookup of multistage heat pump with auxiliary/backup heat (3H/2C heat pump).

Pub. No. 18-HD25D19-3 |

|

69-1790—3 |

4 |

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

HEAT PUMP

Y2 |

|

|

|

|

1 |

|

RC |

|

F |

|

|

|

|

|

|

R |

|

X2 |

|

|

|

|

|

|

O |

|

W1 |

|

|

|

|

|

|

Y |

|

S1 |

|

|

|

|

|

|

G |

|

S2 |

|

|

|

|

|

|

B |

|

2 |

|

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

R |

BK |

O |

G |

YLO |

Y |

W1 |

W2 |

B/C |

VARIABLE SPEED AIR HANDLER

|

|

INDOOR |

|

|

OUTDOOR |

|

|

16 SEER |

R Y2 Y1 O X2/BK BR(T) |

B |

HEAT PUMP |

O.D. SECTION |

||

|

|

(TWO STEP) |

TO POWER SUPPLY |

(3 PH |

|

PER LOCAL CODES |

ONLY) |

|

|

|

1 FACTORY INSTALLED JUMPER.

2OUTDOOR REMOTE SENSOR. WIRES MUST HAVE A CABLE SEPARATE FROM THE THERMOSTAT CABLE.

3 |

THE INSTALLER MUST JUMPER AT THE LVTB “R” TO “O”. |

M24230 |

|

|

Fig. 11. Typical hookup of multistage two-step scroll heat pump with auxiliary/backup heat (3H/2C heat pump).

HEAT PUMP

|

Y2 |

RC |

|

|

1 |

|

F |

R |

|

X2 |

O |

|

W1 |

Y |

2 |

S1 |

G |

|

|

|

T |

S2 |

B |

|

|

|

|

|

|

|

|

NON-V.S. |

R |

G |

Y |

W1 |

W2 |

B/C |

ONE OR TWO |

|

|

|

|

|

|

STAGE GAS |

|

|

|

|

|

|

FURNACE |

|

|

|

INDOOR |

|

|

|

|

|

OUTDOOR |

|

|

|

|

1

2

R |

Y |

O |

X2/BK |

BR(T) |

|

B |

|

|

|

|

HEAT PUMP |

|

|

|

|

|

|

O.D. SECTION |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(SINGLE STAGE) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TO POWER SUPPLY |

(3 PH |

|

|

|

|

|

|

|

|

FACTORY INSTALLED JUMPER. |

PER LOCAL CODES |

ONLY) |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOOR REMOTE SENSOR. WIRES MUST HAVE A

CABLE SEPARATE FROM THE THERMOSTAT CABLE.

M24200

Fig. 12. Typical hookup of singe-stage heat pump with non-variable speed gas furnace.

|

Pub. No. 18-HD25D19-3 |

5 |

69-1790—3 |

TCONT802AS32DA TOUCH SCREEN AND TCONT803AS32DA TOUCH SCREEN WITH DEHUMIDIFICATION

|

|

|

|

|

HEAT PUMP |

|

|

|

|

|

|

|

Y2 |

|

|

|

1 |

|

RC |

|

|

|

|

F |

|

|

|

|

R |

|

||

|

|

|

|

|

|

|

|

|||

|

|

X2 |

|

|

|

|

|

O |

|

|

|

|

W1 |

|

|

|

|

|

Y |

|

|

|

2 |

S1 |

|

|

|

|

|

G |

|

|

|

|

|

|

|

|

|

|

|

||

|

T |

S2 |

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

||

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VARIABLE |

|

R |

BK |

O |

G |

YLO |

Y |

W1 |

W2 |

B/C |

SPEED |

|

TWO STAGE |

||||||||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

FURNACE |

INDOOR

OUTDOOR

1

2

R |

Y |

O |

BR/X2 |

BR(T) |

|

B |

|

|

|

HEAT PUMP |

|

|

|

|

|

O.D. SECTION |

|||||||

|

|

|

OR BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(SINGLE STAGE) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TO POWER SUPPLY |

(3 PH |

|

|

|

|

|

|

|

FACTORY INSTALLED JUMPER. |

PER LOCAL CODES |

ONLY) |

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

OUTDOOR REMOTE SENSOR. WIRES MUST HAVE A

CABLE SEPARATE FROM THE THERMOSTAT CABLE.

M24201

Fig. 13. Typical hookup of single-stage heat pump with two stage variable speed gas furnace (2H/1C heat pump).

Pub. No. 18-HD25D19-3 |

|

69-1790—3 |

6 |

Loading...

Loading...