Yokogawa UT55A, UT52A Operating Manual

User’s

Manual

|

|

|

|

|

|

|

|

|

|

|

l |

|

|

|

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

tio |

|

|

|

|

|||

|

|

|

|

|

c |

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

t |

||

|

|

u |

|

|

|

|

|

|

|

|

|

||

|

F |

|

|

|

|

|

|

|

|

|

n |

||

|

|

|

|

|

|

|

|

|

|

|

e |

|

|

UT55A/UT52A |

|

|

|

|

|

|

|

|

m |

|

|

||

|

|

|

|

|

|

|

e |

|

|

|

|

||

|

|

|

|

|

|

|

c |

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

||

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

|

|

h |

|

|

|

|

|

|

|

|

|

|

|

n |

|

|

|

|

|

|

|

|

|

|

||

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

Digital Indicating Controller

User’s Manual

IM 05P01C31-01EN

IM 05P01C31-01EN

8th Edition

Product Registration

Thank you for purchasing YOKOGAWA products.

YOKOGAWA provides registered users with a variety of information and services. Please allow us to serve you best by completing the product registration form accessible from our homepage.

http://www.yokogawa.com/ns/reg/

Introduction

Thank you for purchasing the UT55A/UT52A digital indicating controller (hereinafter referred to as UT55A/UT52A).

This manual describes how to use UT55A/UT52A functions other than UT55A/UT52A’s communication function and ladder sequence function. Please read through this user’s manual carefully before using the product.

Note that the manuals for the UT55A/UT52A comprise the following nine documents:

● Printed manual

Manual Name |

Manual Number |

Description |

|

UT55A/UT52A Operation |

IM 05P01C31-11EN |

This manual describes the basic operation |

|

Guide «Standard Code Model» |

method. |

||

UT55A/UT52A Operation |

IM 05P01C31-15EN |

This manual describes the basic operation |

|

Guide «Detailed Code Model» |

method. |

||

|

|||

UT55A/MDL, UT52A/MDL |

|

This manual describes the basic operation |

|

Operation Guide «Standard |

IM 05P01C81-11EN |

||

method. |

|||

Code Model» |

|

||

|

|

||

Precautions on the Use of |

IM 05P01A01-11EN |

This manual is always delivered even if |

|

the UTAdvanced Series |

‘without manuals’ was selected. |

||

|

● Electronic manuals

Manual Name |

|

Manual Number |

|

Description |

|

UT55A/UT52A Operation Guide |

|

IM 05P01C31-11EN |

|

This is identical to the printed manual. |

|

«Standard Code Model» |

|

|

|

|

|

UT55A/UT52A Operation Guide |

|

IM 05P01C31-15EN |

|

This is identical to the printed manual. |

|

«Detailed Code Model» |

|

|

|

|

|

UT55A/MDL, UT52A/MDL |

|

|

|

This manual describes the basic operation |

|

Operation Guide «Standard |

|

IM 05P01C81-11EN |

|

||

|

|

method. |

|

||

Code Model» |

|

|

|

|

|

|

|

|

|

|

|

UT55A/UT52A |

|

|

|

This manual. It describes the usage of all |

|

|

IM 05P01C31-01EN |

|

functions except the ladder sequence and |

||

User’s Manual |

|

|

|||

|

|

|

communication functions. |

||

|

|

|

|

||

UTAdvanced Series |

|

|

|

This manual describes how to use |

|

Communication Interface |

|

IM 05P07A01-01EN |

|

UT55A/UT52A in Ethernet and serial |

|

(RS-485, Ethernet) |

|

|

communications. For communication wiring, |

||

|

|

|

|||

User’s Manual |

|

|

|

see the Operation Guide or User’s Manual. |

|

UTAdvanced Series |

|

|

|

This manual describes how to use UT55A |

|

Communication Interface |

|

IM 05P07A01-02EN |

|

in PROFIBUS-DP/DeviceNet/CC-Link |

|

(Open Network) |

|

|

communications. For communication wiring, |

||

|

|

|

|||

User’s Manual |

|

|

|

see the Operation Guide or User’s Manual. |

|

LL50A Parameter Setting |

|

IM 05P05A01-01EN |

|

This manual describes how to install and |

|

Software Installation Manual |

|

|

uninstall the LL50A. |

|

|

|

|

|

|

This manual describes how to use the |

|

LL50A Parameter Setting |

|

IM 05P05A01-02EN |

|

LL50A, ladder sequence function, peer-to- |

|

Software User’s Manual |

|

|

peer communication, and network profile |

||

|

|

|

|||

|

|

|

|

creating function. |

|

Precautions on the Use of |

|

IM 05P01A01-11EN |

|

This manual is always delivered even if |

|

the UTAdvanced Series |

|

|

‘without manuals’ was selected. |

||

|

|

|

|||

* User’s Manual can be downloaded from a website. |

|

||||

http://www.yokogawa.com/ns/ut/im/ |

|

||||

● General Specifications |

|

|

|

|

|

General Specification Name |

|

GS Number |

|||

UT55A/UT52A Digital Indicating Controller |

|

GS 05P01C31-01EN |

|||

|

|

||||

UT55A/MDL, UT52A/MDL Digital Indicating Controller (DIN Rail Mounting Type) |

GS 05P01C81-01EN |

||||

|

|

|

|||

LL50A Parameter Setting Software |

|

GS 05P01A01-01EN |

|||

|

|

|

|

|

|

*The last two characters of the manual number and general specification number indicate the language in which the manual is written.

8th Edition : Mar. 2016 (YK)

All Rights Reserved, Copyright © 2009 Yokogawa Electric Corporation

IM 05P01C31-01EN |

i |

● Authorised Representative in the EEA

Authorised Representative in the EEA

Yokogawa Europe BV. (Address: Euroweg 2 , 3825 HD Amersfoort, The Netherlands) is the Authorised Representative of Yokogawa Electric Corporation for this Product in the EEA.

Target Readers

This guide is intended for the following personnel;

●Engineers responsible for installation, wiring, and maintenance of the equipment.

●Personnel responsible for normal daily operation of the equipment.

Notice

●The contents of this manual are subject to change without notice as a result of continuing improvements to the instrument’s performance and functions.

●Every effort has been made to ensure accuracy in the preparation of this manual.

Should any errors or omissions come to your attention, however, please inform

Yokogawa Electric’s sales office or sales representative.

●Under no circumstances may the contents of this manual, in part or in whole, be transcribed or copied without our permission.

Trademarks

●Our product names or brand names mentioned in this manual are the trademarks or registered trademarks of Yokogawa Electric Corporation (hereinafter referred to as YOKOGAWA).

●Microsoft, MS-DOS, Windows, Windows XP, Windows Vista, and Windows 7 are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries.

●Adobe, Acrobat, and Postscript are either registered trademarks or trademarks of

Adobe Systems Incorporated.

●Ethernet is a registered trademark of XEROX Corporation in the United States.

●Modbus is a registered trademark of Schneider Electric.

●PROFIBUS-DP is a registered trademark of PROFIBUS User Organization.

●DeviceNet is a registered trademark of Open DeviceNet Vender Association, Inc.

●CC-Link is a registered trademark of CC-Link Partner Association (CLPA.)

●We do not use the TM or ® mark to indicate these trademarks or registered trademarks in this user’s manual.

●All other product names mentioned in this user’s manual are trademarks or registered trademarks of their respective companies.

Safety Precautions

This instrument is a product of Installation Category II of IEC/EN/CSA/UL61010-1, IEC/ EN61010-2-201, IEC/EN61010-2-030 Safety Standards and Class A of EN61326-1, EN55011 (EMC Standards).

CAUTION

This instrument is an EMC class A product. In a domestic environment, this product may cause radio interference in which case the user needs to take adequate measures.

The instrument is a product rated Measurement Category O (other). * Measurement Category O (other)

This category applies to electric equipment that measures a circuit connected to a low-voltage facility and receives power from stationary equipment such as electric switchboards.

ii

IM 05P01C31-01EN

To use the instrument properly and safely, observe the safety precautions described in this user’s manual when operating it. Use of the instrument in a manner not prescribed herein may compromise protection features inherent in the device. We assume no liability for or warranty on a fault caused by users’ failure to observe these instructions.

This instrument is designed to be used within the scope of Measurement Category O (other) and is dedicated for indoor use.

Notes on the User’s Manual

•This user’s manual should be readily accessible to the end users so it can be referred to easily. It should be kept in a safe place.

•Read the information contained in this manual thoroughly before operating the product.

•The purpose of this user’s manual is not to warrant that the product is well suited to any particular purpose, but rather to describe the functional details of the product.

Safety, Protection, and Modification of the Product

The following symbols are used in the product and user’s manuals to indicate safety precautions:

“Handle with Care” (This symbol is attached to the part(s) of the product to indicate that the user’s manual should be referred to in order to protect the operator and the instrument from harm.)

AC

AC/DC

The equipment wholly protected by double insulation or reinforced insulation.

Functional grounding terminal (Do not use this terminal as a protective grounding terminal.)

•In order to protect the system controlled by this product and the product itself, and to ensure safe operation, observe the safety precautions described in this user’s

manual. Use of the instrument in a manner not prescribed herein may compromise the product’s functions and the protection features inherent in the device. We assume no liability for safety, or responsibility for the product’s quality, performance or functionality should users fail to observe these instructions when operating the product.

•Installation of protection and/or safety circuits with respect to a lightning protector; protective equipment for the system controlled by the product and the product itself; foolproof or failsafe design of a process or line using the system controlled by the product or the product itself; and/or the design and installation of other protective and safety circuits are to be appropriately implemented as the customer deems necessary.

•Be sure to use the spare parts approved by YOKOGAWA when replacing parts or consumables.

•This product is not designed or manufactured to be used in critical applications that directly affect or threaten human lives. Such applications include nuclear power equipment, devices using radioactivity, railway facilities, aviation equipment, air navigation facilities, aviation facilities, and medical equipment. If so used, it is the user’s responsibility to include in the system additional equipment and devices that ensure personnel safety.

•Modification of the product is strictly prohibited.

•This product is intended to be handled by skilled/trained personnel for electric devices.

•This product is UL Recognized Component. In order to comply with UL standards, end-products are necessary to be designed by those who have knowledge of the requirements.

IM 05P01C31-01EN |

iii |

WARNING

●Power Supply

Ensure that the instrument’s supply voltage matches the voltage of the power supply before turning ON the power.

●Do Not Use in an Explosive Atmosphere

Do not operate the instrument in locations with combustible or explosive gases or steam. Operation in such environments constitutes an extreme safety hazard.

Use of the instrument in environments with high concentrations of corrosive gas (H2S, SOX, etc.) for extended periods of time may cause a failure.

●Do Not Remove Internal Unit

The internal unit should not be removed by anyone other than YOKOGAWA’s service personnel. There are dangerous high voltage parts inside. Additionally, do not replace the fuse by yourself.

●Damage to the Protective Construction

Operation of the instrument in a manner not specified in this user’s manual may damage its protective construction.

Warning and Disclaimer

•YOKOGAWA makes no warranties regarding the product except those stated in the WARRANTY that is provided separately.

•The product is provided on an “as is” basis. YOKOGAWA assumes no liability to any person or entity for any loss or damage, direct or indirect, arising from the use of the product or from any unpredictable defect of the product.

Notes on Software

•YOKOGAWA makes no warranties, either expressed or implied, with respect to the software’s merchantability or suitability for any particular purpose, except as specified in the terms of the separately provided warranty.

•This software may be used on one specific machine only.

•To use the software on another machine, the software must be purchased again separately.

•It is strictly prohibited to reproduce the product except for backup purposes.

•Store the software CD-ROM (the original medium) in a safe place.

•All reverse-engineering operations, such as reverse compilation or the reverse assembly of the product are strictly prohibited.

•No part of the product’s software may be transferred, converted, or sublet for use by any third party, without prior written consent from YOKOGAWA.

Handling Precautions for the Main Unit

•The instrument comprises many plastic components. To clean it, wipe it with a soft, dry cloth. Do not use organic solvents such as benzene or thinner for cleaning, as discoloration or deformation may result.

•Keep electrically charged objects away from the signal terminals. Not doing so may cause the instrument to fail.

•Do not apply volatile chemicals to the display area, operation keys, etc. Do not leave the instrument in contact with rubber or PVC products for extended periods. Doing so may result in failure.

•If the equipment emits smoke or abnormal smells or makes unusual noises, turn OFF the instrument’s power immediately and unplug the device. In such an event, contact your sales representative.

iv

IM 05P01C31-01EN

Checking the Contents of the Package

Unpack the box and check the contents before using the product. If the product is different from that which you have ordered, if any parts or accessories are missing, or if the product appears to be damaged, contact your sales representative.

UT55A/UT52A Main Unit

The UT55A/UT52A main units have nameplates affixed to the side of the case.

Check the model and suffix codes inscribed on the nameplate to confirm that the product received is that which was ordered.

No. (Instrument number)

When contacting your sales representative, inform them of this number, too.

IM 05P01C31-01EN |

v |

Model and Suffix Codes of UT55A (for Standard Code Model)

|

|

|

|

|

|

|

Optional |

|

Model |

|

Suffix code |

|

suffix |

Description |

|||

|

|

|

|

|

|

|

code |

|

UT55A |

|

|

|

|

|

|

|

Digital Indicating Controller (Power supply: 100-240 V AC) (provided with |

|

|

|

|

|

|

|

retransmission output or 15 V DC loop power supply, 3 DIs, and 3 DOs) |

|

|

|

|

|

|

|

|

|

|

Type 1: |

-0 |

|

|

|

|

|

|

Standard type |

Basic |

-1 |

|

|

|

|

|

|

Position proportional type |

control |

-2 |

|

|

|

|

|

|

Heating/cooling type |

|

|

0 |

|

|

|

|

|

None |

|

|

1 |

|

|

|

|

|

Remote (1 additional aux. analog) input, 6 additional DIs, 5 additional DOs, |

|

|

|

|

|

|

|

and RS-485 communication (Max.19.2 kbps, 2-wire/4-wire) (*1) (*2) |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

Remote (1 additional aux. analog) input, 1 additional DI, and RS-485 |

Type 2: |

|

|

|

|

|

|

communication (Max.19.2 kpbs, 2-wire/4-wire) (*2) |

|

|

|

|

|

|

|

|

||

|

3 |

|

|

|

|

|

5 additional DIs and 5 additional DOs |

|

Functions |

|

|

|

|

|

|

||

|

4 |

|

|

|

|

|

Remote (1 additional aux. analog) input and 1 additional DI |

|

|

|

|

|

|

|

|

||

|

|

5 |

|

|

|

|

|

Remote (1 additional aux. analog) input, 6 additional DIs, and 5 additional |

|

|

|

|

|

|

|

DOs |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

5 additional DIs and 15 additional DOs |

|

|

7 |

|

|

|

|

|

3 additional aux. analog inputs and 3 additional DIs |

|

|

|

0 |

|

|

|

|

None |

Type 3: |

|

|

1 |

|

|

|

|

RS-485 communication (Max.38.4 kbps, 2-wire/4-wire) |

|

|

2 |

|

|

|

|

Ethernet communication (with serial gateway function) |

|

Open networks |

|

3 |

|

|

|

|

CC-Link communication (with Modbus master function) |

|

|

|

|

4 |

|

|

|

|

PROFIBUS-DP communication (with Modbus master function) |

|

|

|

5 |

|

|

|

|

DeviceNet communication (with Modbus master function) |

|

|

|

|

-1 |

|

|

|

English (Default. Can be switched to other language by the setting.) |

Display language (*3) |

-2 |

|

|

|

German (Default. Can be switched to other language by the setting.) |

|||

-3 |

|

|

|

French (Default. Can be switched to other language by the setting.) |

||||

|

|

|

|

|

|

|

||

|

|

|

|

-4 |

|

|

|

Spanish (Default. Can be switched to other language by the setting.) |

Case color |

|

|

|

|

0 |

|

|

White (Light gray) |

|

|

|

|

1 |

|

|

Black (Light charcoal gray) |

|

|

|

|

|

|

|

|

||

Fixed code |

|

|

|

|

|

-00 |

|

Always "-00" (for Standard Code Model) |

|

|

|

|

|

|

|

/DR |

Additional direct input (TC and 3-wire/4-wire RTD) and current input to |

|

|

|

|

|

|

|

Remote (1 additional aux. analog) input, 1 DI to be deleted (*4) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/LP |

24 V DC loop power supply (*5) |

Optional suffix codes |

|

|

|

/HA |

Heater break alarm (*6) |

|||

|

|

|

/DC |

Power supply 24 V AC/DC |

||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

/CT |

Coating (*7) |

|

|

|

|

|

|

|

/MDL |

Mount on DIN rail (please see the General Specifications GS 05P01C81- |

|

|

|

|

|

|

|

01EN.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*1: |

When the Type 2 code is “1” or “6”, only “0” can be specified for the Type 3 code. |

|||

|

|

|

|

*2: |

When the /LP option is specified, the RS-485 communication of the Type 2 code “1” or “2” is |

|||

|

|

|

|

|

|

2-wire system. |

||

|

|

|

|

*3: |

English, German, French, and Spanish are available for the guide display. |

|||

|

|

|

|

*4: |

The /DR option can be specified when the Type 2 code is any of “1”, “2”, “4”, “5”, or “7.” |

|||

|

|

|

|

*5: |

The /LP option can be specified in the combination of Type 2 code (any of “0”, “2”, “3”, or |

|||

|

|

|

|

|

|

“4”) and Type 3 code (any of “0” or “1”). Additionally the /LP option can be specified in the |

||

|

|

|

|

|

|

combination of Type 2 code “1” and Type 3 code “0”. |

||

|

|

|

|

*6: |

The /HA option can be specified only when the Type 1 code is “-0.” |

|||

|

|

|

|

*7: |

When the /CT option is specified, the UT55A does not conform to the safety standards (UL |

|||

|

|

|

|

|

|

and CSA) and CE marking (Products with /CT option are not intended for EEA-market). |

||

vi

IM 05P01C31-01EN

Model and Suffix Codes of UT52A (for Standard Code Model)

|

|

|

|

|

|

|

Optional |

|

Model |

|

Suffix code |

|

suffix |

Description |

|||

|

|

|

|

|

|

|

code |

|

UT52A |

|

|

|

|

|

|

|

Digital Indicating Controller (Power supply: 100-240 V AC) (provided with |

|

|

|

|

|

|

|

retransmission output or 15 V DC loop power supply, 3 DIs, and 3 DOs) |

|

|

|

|

|

|

|

|

|

|

Type 1: |

-0 |

|

|

|

|

|

|

Standard type |

Basic |

-1 |

|

|

|

|

|

|

Position proportional type |

control |

-2 |

|

|

|

|

|

|

Heating/cooling type |

|

|

0 |

|

|

|

|

|

None |

Type 2: |

|

1 |

|

|

|

|

|

Remote (1 additional aux. analog) input, 1 additional DI, and RS-485 |

|

|

|

|

|

|

communication (Max. 38.4 kbps, 2-wire) |

||

Functions |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

Remote (1 additional aux. analog) input and 1 additional DI |

|

|

|

|

|

|

|

|

||

|

|

3 |

|

|

|

|

|

2 additional DIs and 2 additional DOs |

Type 3: |

|

|

0 |

|

|

|

|

None |

Open networks |

|

|

|

|

|

CC-Link communication (with Modbus master function) (*1) |

||

|

|

|

|

-1 |

|

|

|

English (Default. Can be switched to other language by the setting.) |

Display language (*2) |

-2 |

|

|

|

German (Default. Can be switched to other language by the setting.) |

|||

-3 |

|

|

|

French (Default. Can be switched to other language by the setting.) |

||||

|

|

|

|

|

|

|

||

|

|

|

|

-4 |

|

|

|

Spanish (Default. Can be switched to other language by the setting.) |

Case color |

|

|

|

|

0 |

|

|

White (Light gray) |

|

|

|

|

1 |

|

|

Black (Light charcoal gray) |

|

|

|

|

|

|

|

|

||

Fixed code |

|

|

|

|

|

-00 |

|

Always "-00" (for Standard Code Model) |

|

|

|

|

|

|

|

/DR |

Additional direct input (TC and 3-wire/4-wire RTD) and current input to |

|

|

|

|

|

|

|

Remote (1 additional aux. analog) input, 1 DI to be deleted (*3) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/LP |

24 V DC loop power supply (*4) |

Optional suffix codes |

|

|

|

/HA |

Heater break alarm (*5) |

|||

|

|

|

/DC |

Power supply 24 V AC/DC |

||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

/CT |

Coating (*6) |

|

|

|

|

|

|

|

/MDL |

Mount on DIN rail (please see the General Specifications GS 05P01C81- |

|

|

|

|

|

|

|

01EN.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*1: |

The Type 3 code “3” can be specified only when the Type 1 code is “-0” and the Type 2 code |

|||

|

|

|

|

|

|

is “0.” |

|

|

|

|

|

|

*2: |

English, German, French, and Spanish are available for the guide display. |

|||

|

|

|

|

*3: |

The /DR option can be specified only when the Type 2 code is “2” and the Type 3 code is “0.” |

|||

|

|

|

|

*4: |

The /LP option can be specified only when the Type 1 code is “-0” or “-1.” Furthermore both |

|||

|

|

|

|

|

|

Type 2 and Type 3 codes should be “0.” |

||

|

|

|

|

*5: |

The /HA option can be specified only when the Type 1 code is “-0” and the Type 3 code is “0.” |

|||

|

|

|

|

*6: |

When the /CT option is specified, the UT52A does not conform to the safety standards (UL |

|||

|

|

|

|

|

|

and CSA) and CE marking (Products with /CT option are not intended for EEA-market). |

||

IM 05P01C31-01EN |

vii |

Model and Suffix Codes of UT55A/MDL (for Standard Code Model)

|

|

|

|

|

|

|

Optional |

|

Model |

|

Suffix code |

|

suffix |

Description |

|||

|

|

|

|

|

|

|

code |

|

UT55A |

|

|

|

|

|

|

/MDL |

Controller (Power supply: 100-240 V AC) (provided with retransmission |

|

|

|

|

|

|

(Required) |

output or 15 V DC loop power supply, 3 DIs, and 3 DOs) |

|

|

|

|

|

|

|

|

||

Type 1: |

-0 |

|

|

|

|

|

|

Standard type |

Basic |

-2 |

|

|

|

|

|

|

Heating/cooling type |

control |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

None |

|

|

2 |

|

|

|

|

|

Remote (1 additional aux. analog) input, 1 additional DI, and RS-485 |

Type 2: |

|

|

|

|

|

|

communication (Max.19.2 kpbs, 2-wire/4-wire) (*1) |

|

|

|

|

|

|

|

|

||

|

3 |

|

|

|

|

|

5 additional DIs and 5 additional DOs |

|

Functions |

|

|

|

|

|

|

||

|

4 |

|

|

|

|

|

Remote (1 additional aux. analog) input and 1 additional DI |

|

|

|

|

|

|

|

|

||

|

|

5 |

|

|

|

|

|

Remote (1 additional aux. analog) input, 6 additional DIs, and 5 additional DOs |

|

|

7 |

|

|

|

|

|

3 additional aux. analog inputs and 3 additional DIs |

|

|

|

0 |

|

|

|

|

None |

Type 3: |

|

|

1 |

|

|

|

|

RS-485 communication (Max.38.4 kbps, 2-wire/4-wire) |

|

|

2 |

|

|

|

|

Ethernet communication (with serial gateway function) |

|

Open networks |

|

3 |

|

|

|

|

CC-Link communication (with Modbus master function) |

|

|

|

|

4 |

|

|

|

|

PROFIBUS-DP communication (with Modbus master function) |

|

|

|

5 |

|

|

|

|

DeviceNet communication (with Modbus master function) |

Fixed code |

|

|

|

-1 |

|

|

|

Temperature unit: deg C & deg F |

Case color |

|

|

|

1 |

|

|

Black (Light charcoal gray) |

|

Fixed code |

|

|

|

|

|

-00 |

|

Always "-00" (for Standard Code Model) |

|

|

|

|

|

|

|

/MDL |

Mount on DIN rail |

Optional suffix codes |

|

(Required) |

||||||

|

/LP |

24 V DC loop power supply (*2) |

||||||

|

|

|

|

|

|

|

/DC |

Power supply 24 V AC/DC |

|

|

|

|

|

|

|

/CT |

Coating (*3) |

|

|

*1: |

When the /LP option is specified, the RS-485 communication of the Type 2 code “2” is 2-wire |

|||||

|

|

|

|

|

|

system. |

|

|

|

|

*2: |

The /MDL option and /LP option can be specified in the combination of Type 2 code (any of |

|||||

|

|

|

|

|

|

“0”, “2”, “3”, or “4”) and Type 3 code “1”. |

||

|

|

*3: |

When the /CT option is specified, the UT55A does not conform to the safety standards (UL |

|||||

|

|

|

|

|

|

and CSA) and CE marking (Products with /CT option are not intended for EEA-market). |

||

viii

IM 05P01C31-01EN

Model and Suffix Codes of UT52A/MDL (for Standard Code Model)

|

|

|

|

|

|

|

Optional |

|

Model |

|

Suffix code |

|

suffix |

Description |

|||

|

|

|

|

|

|

|

code |

|

UT52A |

|

|

|

|

|

|

/MDL |

Controller (Power supply: 100-240 V AC) (provided with retransmission |

|

|

|

|

|

|

(Required) |

output or 15 V DC loop power supply, 3 DIs, and 3 DOs) |

|

|

|

|

|

|

|

|

||

Type 1: |

-0 |

|

|

|

|

|

|

|

Basic |

|

|

|

|

|

|

Standard type |

|

control |

|

|

|

|

|

|

|

|

Type 2: |

|

0 |

|

|

|

|

|

None |

|

1 |

|

|

|

|

|

Remote (1 additional aux. analog) input, 1 additional DI, and RS-485 |

|

Functions |

|

|

|

|

|

|

||

|

|

|

|

|

|

communication (Max. 38.4 kbps, 2-wire) |

||

|

|

|

|

|

|

|

|

|

Type 3: |

|

|

0 |

|

|

|

|

None |

Open networks |

|

|

|

|

|

CC-Link communication (with Modbus master function) |

||

Fixed code |

|

|

|

-1 |

|

|

|

Temperature unit: deg C & deg F |

Case color |

|

|

|

1 |

|

|

Black (Light charcoal gray) |

|

Fixed code |

|

|

|

|

|

-00 |

|

Always "-00" (for Standard Code Model) |

|

|

|

|

|

|

|

/MDL |

Mount on DIN rail (*1) |

Optional suffix codes |

|

(Required) |

||||||

|

/DC |

Power supply 24 V AC/DC |

||||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

/CT |

Coating (*2) |

|

*1: |

When the /MDL option is specified, the model and the suffix codes are as follows: |

||||||

|

|

|

|

|

|

UT52A-010-11-00/x/MDL |

||

|

|

|

|

|

|

UT52A-003-11-00/x/MDL |

||

|

*2: |

When the /CT option is specified, the UT52A does not conform to the safety standards (UL |

||||||

|

|

|

|

|

|

and CSA) and CE marking (Products with /CT option are not intended for EEA-market). |

||

IM 05P01C31-01EN |

ix |

Model and Suffix Codes of UT55A (for Detailed Code Model)

|

|

|

|

|

|

Optional |

|

Model |

Suffix code |

|

|

suffix |

Description |

||

|

|

|

|

|

|

code |

|

UT55A |

|

|

|

|

|

|

Digital Indicating Controller (Power supply: 100-240 V AC) (provided with 3 |

|

|

|

|

|

|

DIs, and 3 DOs) |

|

|

|

|

|

|

|

|

|

Fixed code |

-NNN |

|

|

|

|

|

Always "-NNN” (for detailed code model) |

|

|

-1 |

|

|

|

|

English (Default. Can be switched to other language by the setting.) |

Display language (*1) |

-2 |

|

|

|

|

German (Default. Can be switched to other language by the setting.) |

|

-3 |

|

|

|

|

French (Default. Can be switched to other language by the setting.) |

||

|

|

|

|

|

|

||

|

|

-4 |

|

|

|

|

Spanish (Default. Can be switched to other language by the setting.) |

Case color |

|

|

0 |

|

|

|

White (Light gray) |

|

|

1 |

|

|

|

Black (Light charcoal gray) |

|

|

|

|

|

|

|

||

|

|

|

|

-A |

|

|

Analog output (current/voltage pulse) |

Output 1 (*2) (*3) |

|

|

-R |

|

|

Relay output (c-contact) |

|

|

|

-U |

|

|

Universal output (current/voltage pulse/relay) |

||

|

|

|

|

-T |

|

|

Triac output |

|

|

|

|

-P |

|

|

Position proportional output |

|

|

|

|

|

A |

|

Analog output (current/voltage pulse) |

Output 2 (*2) (*3) |

|

|

|

R |

|

Relay output (c-contact) |

|

|

|

|

U |

|

Universal output (current/voltage pulse/relay) |

||

|

|

|

|

|

T |

|

Triac output |

|

|

|

|

|

N |

|

None |

Retransmission output |

|

|

|

|

/RT |

Retransmission output or 15 V DC power supply |

|

Heater break alarm (*3) |

|

|

|

|

/HA |

Heater break alarm |

|

|

|

|

|

|

|

/R1 |

Remote (1 additional aux. analog) input and 1 additional DI |

E1 terminal area (*4) |

|

|

|

|

/U1 |

1 additional universal input (TC/RTD/DCV/mA) |

|

|

|

|

|

/X1 |

5 additional DIs |

||

|

|

|

|

|

|

/Y1 |

5 additional DOs |

|

|

|

|

|

|

/W1 |

2 additional DIs and 2 additional DOs |

|

|

|

|

|

|

/A2 |

1 additional aux. analog input and 1 additional DI |

E2 terminal area (*4) |

|

|

|

|

/X2 |

5 additional DIs |

|

|

|

|

|

/Y2 |

5 additional DOs |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

/W2 |

2 additional DIs and 2 additional DOs |

|

|

|

|

|

|

/CH3 |

RS485 communication (Max. 38.4 kbps, 2-wire/4-wire) |

|

|

|

|

|

|

/CC3 |

CC-Link communication |

|

|

|

|

|

|

/PD3 |

PROFIBUS-DP communication |

E3 terminal area (*4) (*5) |

|

|

/DN3 |

DeviceNet communication |

|||

|

|

/ET3 |

Ethernet communication (with serial gateway function) |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

/X3 |

5 additional DIs |

|

|

|

|

|

|

/Y3 |

5 additional DOs |

|

|

|

|

|

|

/W3 |

2 additional DIs and 2 additional DOs |

|

|

|

|

|

|

/A4 |

1 additional aux. analog input and 1 additional DI |

|

|

|

|

|

|

/C4 |

RS485 communication (Max. 19.2 kbps, 2-wire/4-wire) |

|

|

|

|

|

|

/L4 |

24 V DC loop power supply |

|

|

|

|

|

|

/AC4 |

1 additional aux. analog input, 1 additional DI, and RS485 communication |

E4 terminal area (*4) (*5) |

|

|

(Max.19.2 kbps, 2-wire) |

||||

|

|

|

|||||

|

|

/LC4 |

24 V DC loop power supply and RS485 communication (Max.19.2 kbps, |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

2-wire) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/X4 |

5 additional DIs |

|

|

|

|

|

|

/Y4 |

5 additional DOs |

|

|

|

|

|

|

/W4 |

2 additional DIs and 2 additional DOs |

Power supply |

|

|

|

|

|

/DC |

Power supply 24 V AC/DC |

Additional treatment (*6) |

|

|

|

|

/CT |

Coating |

|

*1: |

English, German, French, and Spanish are available for the guide display. |

*2: |

For heating/cooling output, both Output 1 and Output 2 should be specified. Not available when Output 2 is “N.” For |

|

position proportional output, specify “-P” for Output 1 and “N” for Output 2. |

*3: |

The /HA option can be specified only when the code for Output 1 and 2 is “-AN”, “-RN”, “-UN” or “-TN.” |

*4: |

Only one option is available for each terminal area of E1 to E4. |

*5: |

The /L4 and /LC4 options for E4 terminal area can be specified only when the E3 terminal area option is not specified |

|

or specified any of /CH3, /X3, /Y3 or /W3. |

*6: |

When the /CT option is specified, the UT55A does not conform to the safety standards (UL and CSA) and CE marking |

|

(Products with /CT option are not intended for EEA-market). |

x

IM 05P01C31-01EN

Model and Suffix Codes of UT52A (for Detailed Code Model)

|

|

|

|

|

|

|

Optional |

|

Model |

Suffix code |

|

suffix |

Description |

||||

|

|

|

|

|

|

|

code |

|

UT52A |

|

|

|

|

|

|

|

Digital Indicating Controller (Power supply: 100-240 V AC) (provided with 3 DIs, |

|

|

|

|

|

|

|

and 3 DOs) |

|

|

|

|

|

|

|

|

|

|

Fixed code |

-NNN |

|

|

|

|

|

|

Always "-NNN” (for detailed code model) |

|

|

|

-1 |

|

|

|

|

English (Default. Can be switched to other language by the setting.) |

Display language (*1) |

-2 |

|

|

|

|

German (Default. Can be switched to other language by the setting.) |

||

-3 |

|

|

|

|

French (Default. Can be switched to other language by the setting.) |

|||

|

|

|

|

|

|

|

||

|

|

|

-4 |

|

|

|

|

Spanish (Default. Can be switched to other language by the setting.) |

Case color |

|

|

|

0 |

|

|

|

White (Lithg gray) |

|

|

|

1 |

|

|

|

Black (Light charcoal gray) |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

-A |

|

|

Analog output (current/voltage pulse) |

Output 1 (*2) (*3) (*4) |

|

|

-R |

|

|

Relay output (c-contact) |

||

|

|

-U |

|

|

Universal output (current/voltage pulse/relay) |

|||

|

|

|

|

|

-T |

|

|

Triac output |

|

|

|

|

|

-P |

|

|

Position proportional output |

|

|

|

|

|

|

A |

|

Analog output (current/voltage pulse) |

Output 2 (*2) (*3) (*4) (*5) |

R |

|

Relay output (a-contact) |

|||||

U |

|

Universal output (current/voltage pulse/relay) |

||||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

N |

|

None |

Retransmission output |

|

|

|

|

/RT |

Retransmission output or 15 V DC power supply |

||

Heater break alarm (*3) |

|

|

|

|

/HA |

Heater break alarm |

||

|

|

|

|

|

|

|

/R1 |

Remote (1 additional aux. analog) input and 1 additional DI |

|

|

|

|

|

|

|

/U1 |

1 additional universal input (TC/RTD/DCV/mA) |

|

|

|

|

|

|

|

/L1 |

24 V DC loop power supply |

|

|

|

|

|

|

|

/CH1 |

RS485 communication (Max. 38.4 kbps, 2-wire/4-wire) |

E1 terminal area (*5) (*6) |

|

/RCH1 |

Remote (1 additional aux. analog) input, 1 additional DI, and RS485 |

|||||

|

communication (Max.38.4 kbps, 2-wire) |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/LCH1 |

24 V DC loop power supply and RS485 communication (Max. 38.4 kbps, 2-wire) |

|

|

|

|

|

|

|

/X1 |

5 additional DIs |

|

|

|

|

|

|

|

/Y1 |

5 additional DOs |

|

|

|

|

|

|

|

/W1 |

2 additional DIs and 2 additional DOs |

Power supply |

|

|

|

|

|

|

/DC |

Power supply 24 V AC/DC |

Additional treatment (*7) |

|

/CT |

Coating |

|||||

*1: |

English, German, French, and Spanish are available for the guide display. |

|||||||

*2: |

For heating/cooling output, both Output 1 and Output 2 should be specified. Not available when Output 2 is “N.” For |

|||||||

|

position proportional output, specify “-P” for Output 1 and “N” for Output 2. |

|||||||

*3: |

The /HA option can be specified only when the code for Output 1 and 2 is “-AN”, “-RN”, “-UN” or “-TN.” |

|||||||

*4: |

When the code for Output 1 is "-R" or "-U" and Output 2 is "R" or "U", Output 1 is changed from the contact point c to |

|||||||

|

the contact point a. When the code for Output 1 is specified to "-T", only "A" or "N" is available for Output 2. |

|||||||

*5: |

The /L1 or /LCH option can be specified only when the code for Output 2 is “N.” |

|||||||

*6: |

Only one option is available for E1 terminal area. |

|||||||

*7: |

When the /CT option is specified, the UT52A does not conform to the safety standards (UL and CSA) and CE marking |

|||||||

|

(Products with /CT option are not intended for EEA-market). |

|||||||

Coating Treatment

(1)HumiSeal coating treatment

Apply HumiSeal coating to the printed circuit board assembly.

Do not apply HumiSeal coating to the following parts: connector, gold-plated contact area, relay part, RJC device, and in the vicinity of the push switch/LED lamp.

(2)Apply terminal coating to the gold-plated contact area on the printed circuit board.

Notes

▪There are two treatments as described above, but we do not guarantee their effectiveness.

We do not supply any test data on these treatments.

▪Do not apply any treatment to the screw terminal area on the back side of the instrument.

IM 05P01C31-01EN |

xi |

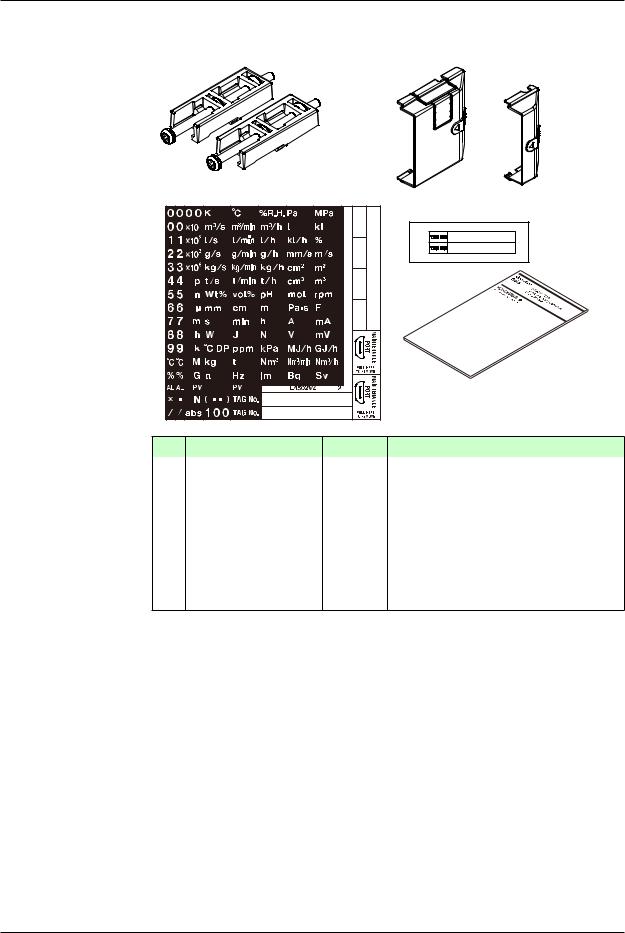

Accessories

The product is provided with the following accessories according to the model and suffix codes. Check that none of them are missing or damaged.

1 |

2 |

For UT55A |

For UT52A |

3 |

|

|

|

|

|

|

4 |

|

|

|

5 |

No. |

Product Name |

Quantity |

Remark |

|

|

|

Part number: L4502TP (For fixing the upper |

|

1 |

Brackets |

2 |

and lower parts) |

|

This does not apply to models with the /MDL |

||||

|

|

|

||

|

|

|

option. |

|

2 |

Terminal cover |

1 |

For UT55A: L4502XP |

|

For UT52A: L4502XQ |

||||

|

|

|

||

3 |

Unit label |

1 |

Part number: L4502VZ |

|

|

|

|

|

|

4 |

Tag label |

1 |

Part number: L4502VE (Only when ordered.) |

|

|

|

|

|

|

5 |

Operation Guide |

1 |

Single-loop control (A3 size, x6) (Standard |

|

model only) |

||||

|

|

|

How to use the unit label

•Affixing the unit label

Affix the unit label to the front panel. If necessary, combine with unit prefixes. Affix it so that the LCD area is not blocked.

•Maintenance port seals

Maintenance port seals (two spares) are available. Use them if the seal affixed to the UTAdvanced controller loses its adhesiveness.

•TAG No. labels

TAG No. labels (two pieces) are available. Use them if necessary.

xii

IM 05P01C31-01EN

Accessory (sold separately)

The following lists an accessory sold separately.

• LL50A Parameter Setting Software

Model |

Suffix code |

|

Description |

|

|

|

|

LL50A |

-00 |

Parameter Setting Software |

|

|

|

|

|

• External Precision Resistor |

|

|

|

Model |

Suffix code |

Description |

|

|

|

|

|

X010 |

See the General Specifications (*) |

Resistance Module |

|

|

|

|

|

*: Necessary to input the current signal to the voltage input terminal.

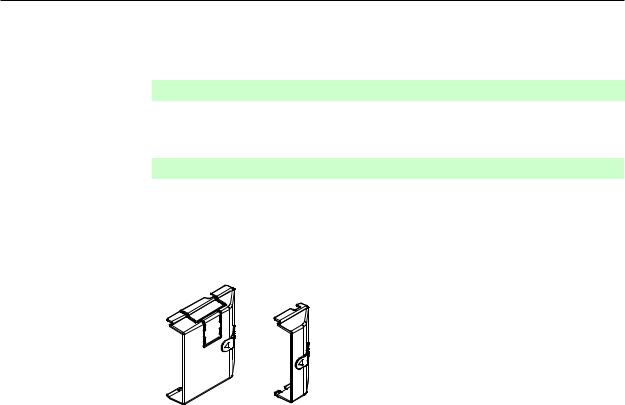

• Terminal cover

For UT55A, Model: UTAP001 For UT52A, Model: UTAP002

For UT55A |

For UT52A |

•Brackets (except for the controller with optional suffix code /MDL) Part number L4502TP (2 pieces for fixing the upper and lower parts)

•User’s Manual (A4 size)

*User’s Manual can be downloaded from a website.

IM 05P01C31-01EN |

xiii |

Symbols Used in This Manual

This symbol is used on the instrument. It indicates the possibility of injury to the user or damage to the instrument, and signifies that the user must refer to the user’s manual for special instructions. The same symbol is used in the user’s manual on pages that the user needs to refer to, together with the term “WARNING” or “CAUTION.”

WARNING

Calls attention to actions or conditions that could cause serious or fatal injury to the user, and indicates precautions that should be taken to prevent such occurrences.

CAUTION

Calls attention to actions or conditions that could cause injury to the user or damage to the instrument or property and indicates precautions that should be taken to prevent such occurrences.

Note

Identifies important information required to operate the instrument.

Indicates related operations or explanations for the user’s reference.

[ ] Indicates a character string displayed on the display.

Setting Display

Indicates a setting display and describes the keystrokes required to display the relevant setting display.

Setting Details

Provides the descriptions of settings.

Description

Describes restrictions etc. regarding a relevant operation.

xiv

IM 05P01C31-01EN

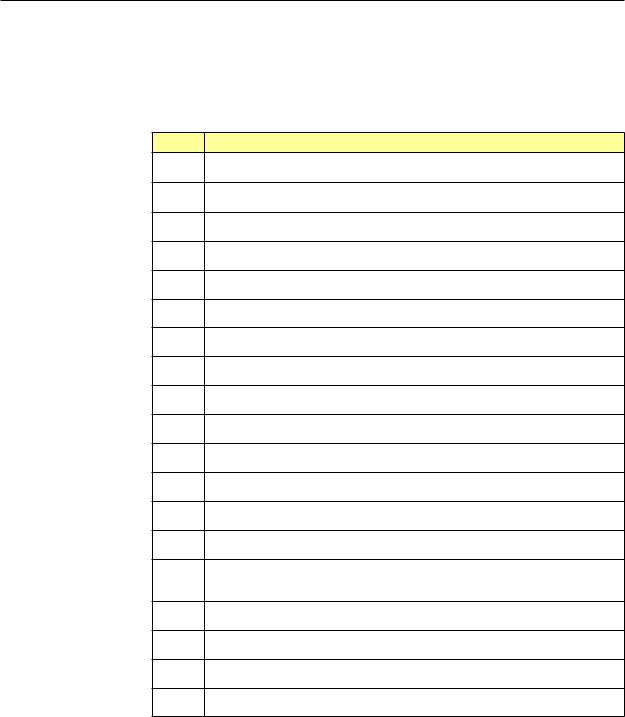

How to Use This Manual

For the ladder sequence and communication functions, see the respective manuals. This user’s manual is organized into Chapters 1 to 18 as shown below. This manual mainly uses the illustrations of the UT55A for describing the operations and functions. The basic operations are the same for the UT52A, so please read them in the same way.

On models with the /MDL option, there are no display areas or key operation areas.

Chapter |

Title and Description |

1Introduction to Functions

Describes the main functions of the UT55A/UT52A.

2UT55A/UT52A Operating Procedures

Describes the flow from unpacking to regular operations.

3Part Names

Describes part names and functions on the front panel.

4Basic Operation

Describes basic operation of the UT55A/UT52A.

5Quick Setting Function

Describes the minimum necessary settings for operation.

6Monitoring and Control of Regular Operations

Describes monitoring displays of regular operations and operation.

7Input (PV, Remote, and Auxiliary Analog) Functions

Describes PV input, remote input, and advanced secondary control input.

8Control Functions

Describes basic control and advanced control.

9Auxiliary Control Functions

Describes auxiliary control functions

10Output (Control and Retransmission) Functions

Describes output functions.

11Alarm Functions

Describes alarm output and status output.

12Contact Input/Output Functions

Describes contact input/output functions.

13Display, Key, and Security Functions

Describes display, user function key and security functions.

14Parameter Initialization

Describes the initialization to factory default values and to user default values.

Power Failure Recovery Processing/Power Frequency Setting/Other Settings

15Describes operations performed after momentary power interruption and power failures.

16Troubleshooting, Maintenance, and Inspections

Describes troubleshooting, maintenance, periodic inspections, and disposal.

17Installation and Wiring

Describes installation and wiring.

18Parameters

Provides parameter maps.

GS |

Specifications |

|

Provides the UT55A/UT52A specifications. |

||

|

IM 05P01C31-01EN |

xv |

Blank Page

Contents

|

Introduction............................................................................................................................ |

i |

|

Target Readers..................................................................................................................... |

ii |

|

Notice ................................................................................................................................ |

ii |

|

Trademarks........................................................................................................................... |

ii |

|

Safety Precautions................................................................................................................ |

ii |

|

Handling Precautions for the Main Unit............................................................................... |

iv |

|

Checking the Contents of the Package................................................................................. |

v |

|

Model and Suffix Codes of UT55A (for Standard Code Model)........................................... |

vi |

|

Model and Suffix Codes of UT52A (for Standard Code Model).......................................... |

vii |

|

Model and Suffix Codes of UT55A/MDL (for Standard Code Model)................................. |

viii |

|

Model and Suffix Codes of UT52A/MDL (for Standard Code Model)................................... |

ix |

|

Model and Suffix Codes of UT55A (for Detailed Code Model).............................................. |

x |

|

Model and Suffix Codes of UT52A (for Detailed Code Model)............................................. |

xi |

|

Symbols Used in This Manual............................................................................................ |

xiv |

|

How to Use This Manual..................................................................................................... |

xv |

Chapter 1 Introduction to Functions |

|

|

1.1 |

Quick Setting Function...................................................................................................... |

1-1 |

1.2 |

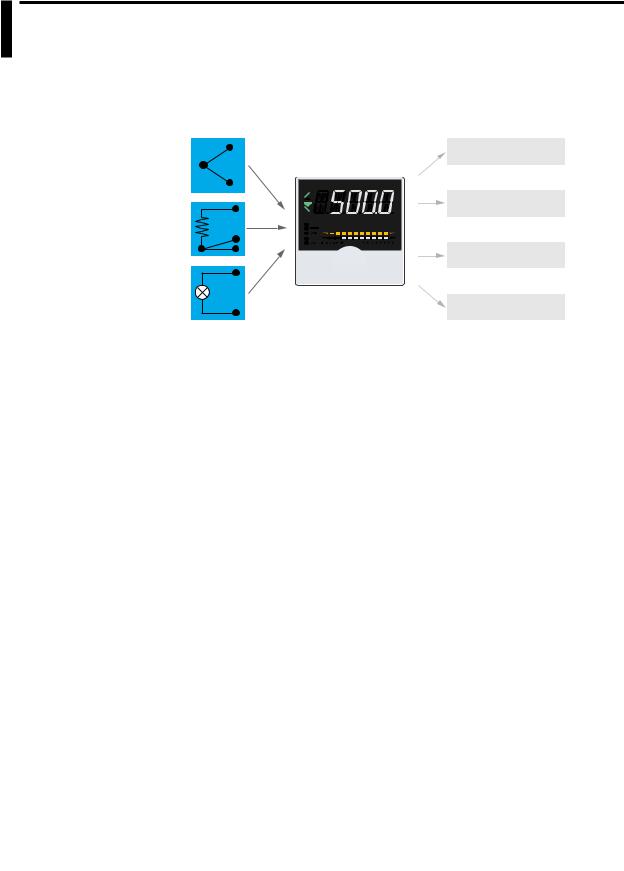

Input/Output Function....................................................................................................... |

1-2 |

1.3 |

Control Functions.............................................................................................................. |

1-4 |

1.4 |

Display and Key Functions............................................................................................... |

1-8 |

1.5 |

Ladder Sequence Function............................................................................................... |

1-9 |

1.6 |

Communication Functions.............................................................................................. |

1-10 |

1.7 |

Definition of Main Symbols and Terms............................................................................ |

1-15 |

Chapter 2 UT55A/UT52A Operating Procedures |

|

|

2.1 |

UT55A/UT52A Operating Procedures............................................................................... |

2-1 |

Chapter 3 Part Names |

|

|

3.1 |

Names and Functions of Display Parts............................................................................. |

3-1 |

3.2 |

Names and Functions of Keys.......................................................................................... |

3-5 |

3.3 |

List of Display Symbols..................................................................................................... |

3-8 |

3.4 |

Brief Description of Setting Details (Parameters)............................................................. |

3-10 |

Chapter 4 Basic Operation |

|

|

4.1 |

Overview of Display Switch and Operation Keys.................................................................... |

4-1 |

4.2 |

How to Set Parameters..................................................................................................... |

4-4 |

Chapter 5 Quick Setting Function |

|

|

5.1 |

Setting Using Quick Setting Function.............................................................................. |

5-1 |

5.2 |

Restarting Quick Setting Function.................................................................................... |

5-6 |

Chapter 6 Monitoring and Control of Regular Operations |

|

|

6.1 |

Monitoring and Control of Operation Displays.................................................................. |

6-1 |

|

6.1.1 Operation Display Transitions in Single-loop Control, Cascade Primary-loop |

|

|

Control, Cascade Secondary-loop Control, Loop Control for Backup, and Loop |

|

|

Control with PV-hold Function............................................................................. |

6-1 |

|

Standard Type...................................................................................................................... |

6-1 |

|

Position Proportional Type................................................................................................... |

6-2 |

|

Heating/cooling Type............................................................................................................ |

6-3 |

|

Single-loop Two-position two-level control........................................................................... |

6-4 |

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

App

Index

IM 05P01C31-01EN |

xvii |

Contents

|

6.1.2 Operation Display Transitions in Loop Control with PV Switching and |

|

|

Loop Control with PV Auto-selector..................................................................... |

6-5 |

|

Standard Type...................................................................................................................... |

6-5 |

|

Position Proportional Type................................................................................................... |

6-6 |

|

Heating/cooling Type............................................................................................................ |

6-7 |

|

6.1.3 Operation Display Transitions in Cascade Control.............................................. |

6-8 |

|

Standard Type...................................................................................................................... |

6-8 |

|

Position Proportional Type................................................................................................. |

6-10 |

|

Heating/cooling Type.......................................................................................................... |

6-12 |

6.2 |

Setting Target Setpoint.................................................................................................... |

6-20 |

|

Operation in the Operation Display.................................................................................... |

6-20 |

|

Operation in Parameter Setting Display............................................................................. |

6-21 |

6.3 |

Performing and Canceling Auto-tuning........................................................................... |

6-22 |

6.4 |

Adjusting PID Manually................................................................................................... |

6-25 |

6.5 |

Setting Alarm Setpoint.................................................................................................... |

6-31 |

6.6 |

Selecting Target Setpoint Number (SPNO)..................................................................... |

6-32 |

6.7 |

Switching Operation Modes............................................................................................ |

6-33 |

|

6.7.1 Switching between AUTO and MAN.................................................................. |

6-33 |

|

6.7.2 Switching between CAS (Cascade), AUTO, and MAN...................................... |

6-35 |

|

6.7.3 Switching between STOP and RUN.................................................................. |

6-37 |

|

6.7.4 Switching between REM (Remote) and LCL (Local)......................................... |

6-39 |

6.8 |

Manipulating Control Output during Manual Operation........................................................................ |

6-41 |

6.9 |

Releasing On-State (Latch) of Alarm Output.................................................................. |

6-43 |

Chapter 7 Input (PV, Remote, and Auxiliary Analog) Functions

7.1 |

Setting Functions of PV Input, Remote Input, and Auxiliary Analog Input........................ |

7-1 |

|

|

7.1.1 |

Setting Input Type, Unit, Range, Scale, and Decimal Point Position.................. |

7-1 |

|

7.1.2 |

Setting Burnout Detection for Input..................................................................... |

7-5 |

7.1.3Setting Reference Junction Compensation (RJC) or External Reference

|

|

Junction Compensation (ERJC).......................................................................... |

7-6 |

|

7.1.4 |

Correcting Input Value......................................................................................... |

7-7 |

|

|

(1) Setting Bias and Filter..................................................................................................... |

7-7 |

|

|

(2) Setting Square Root Extraction and Low Signal Cutoff Point.......................................... |

7-9 |

|

|

(3)Setting 10-segment Linearizer...................................................................................... |

7-10 |

|

7.1.5 |

Setting Ratio bias/filter...................................................................................... |

7-12 |

7.2 |

Setting Input Sampling Period (Control Period).............................................................. |

7-13 |

|

7.3 |

Using 4-wire RTD as PV Input........................................................................................ |

7-14 |

|

7.4 |

Using Larger, Smaller, Average, or Difference of Two to Four Inputs as PV .................. |

7-15 |

|

7.5 |

Setting Remote Input Method......................................................................................... |

7-16 |

|

7.6 |

Adjusting PV Range for Loop Control with PV Switching or Loop Control with PV Auto-selector.. |

7-17 |

|

7.7 |

Setting PV Switching Methods of Loop Control with PV Switching................................. |

7-18 |

|

Chapter 8 Control Functions

8.1 |

Setting Control Mode (CTLM)........................................................................................... |

8-1 |

|

|

8.1.1 |

Single-loop Control, Single-loop Heating/cooling Control, Single-loop Position |

|

|

|

Proportional Control, and Single-loop Two-position Two-level Control................ |

8-1 |

|

|

n Single-loop Control Function Block Diagram.................................................................... |

8-2 |

|

|

n Single-loop Heating/cooling Control Function Block Diagram.......................................... |

8-4 |

|

|

n Single-loop Position Proportional Control Function Block Diagram.................................. |

8-6 |

|

|

n Single-loop Two-position Two-level Control Function Block Diagram............................... |

8-8 |

|

8.1.2 |

Cascade Primary-loop Control........................................................................... |

8-11 |

|

|

n Cascade Primary-loop Control Function Block Diagram................................................ |

8-12 |

xviii

IM 05P01C31-01EN

Contents

8.1.3Cascade Secondary-loop Control, Cascade Secondary-loop Heating/cooling

Control, and Cascade Secondary-loop Position Proportional Control............... |

8-15 |

n Cascade Secondary-loop Control Function Block Diagram........................................... |

8-17 |

n Cascade Secondary-loop Heating/cooling Control Function Block Diagram.................. |

8-18 |

n Cascade Secondary-loop Position Proportional Control Function Block Diagram......... |

8-21 |

8.1.4Cascade Control, Cascade Heating/cooling Control, and Cascade Position

Proportional Control.......................................................................................... |

8-23 |

n Cascade Control Function Block Diagram...................................................................... |

8-24 |

n Cascade Heating/cooling Control Function Block Diagram............................................ |

8-27 |

n Cascade Position Proportional Control Function Block Diagram................................... |

8-29 |

8.1.5Loop Control for Backup, Heating/cooling Loop Control for Backup, and

|

Position Proportional Loop Control for Backup................................................. |

8-31 |

|

n Loop Control for Backup Function Block Diagram.......................................................... |

8-33 |

|

n Heating/cooling Loop Control for Backup Function Block Diagram................................ |

8-35 |

|

n Position Proportional Loop Control for Backup Function Block Diagram....................... |

8-37 |

8.1.6 |

Loop Control with PV Switching, Heating/cooling Loop Control with |

|

|

PV Switching, and Position Proportional Loop Control with PV Switching........ |

8-39 |

|

n Loop Control with PV Switching Function Block Diagram.............................................. |

8-40 |

|

n Heating/cooling Loop Control with PV Switching Function Block Diagram.................... |

8-43 |

|

n Position Proportional Loop Control with PV Switching Function Block Diagram............ |

8-45 |

8.1.7Loop Control with PV Auto-selector, Heating/cooling Loop Control with PV

Auto-selector, and Position Proportional Loop Control with PV Auto-selector.. 8-47

n Loop Control with PV Auto-selector (2 inputs) Function Block Diagram......................... |

8-49 |

n Heating/cooling Loop Control with PV Auto-selector (2 inputs) Function Block Diagram... |

8-51 |

nPosition Proportional Loop Control with PV Auto-selector (2 inputs) Function Block Diagram..8-52

nLoop Control with PV Auto-selector (4 inputs) Function Block Diagram (only for UT55A).8-55

nHeating/cooling Loop Control with PV Auto-selector (4 inputs) Function Block Diagram

|

|

(only for UT55A)............................................................................................................ |

8-57 |

|

|

n Position Proportional Loop Control with PV Auto-selector (4 inputs) Function Block |

|

|

|

Diagram (only for UT55A)............................................................................................. |

8-59 |

|

8.1.8 Loop Control with PV-hold Function, Heating/cooling Loop Control with PV-hold |

||

|

|

Function, and Position Proportional Loop Control with PV-hold Function ........ |

8-61 |

|

|

n Loop Control with PV-hold Function Function Block Diagram........................................ |

8-63 |

|

|

n Heating/cooling Loop Control with PV-hold Function Function Block Diagram.............. |

8-64 |

|

|

n Position Proportional Loop Control with PV-hold Function Function Block Diagram...... |

8-66 |

8.2 |

Setting Control Type (CNT)............................................................................................. |

8-68 |

|

|

8.2.1 |

PID Control........................................................................................................ |

8-69 |

|

8.2.2 ON/OFF Control (1 point of hysteresis / 2 points of hysteresis)........................ |

8-70 |

|

|

8.2.3 |

Heating/cooling Control..................................................................................... |

8-72 |

|

8.2.4 |

Two-position Two-level Control.......................................................................... |

8-78 |

|

8.2.5 PD Control (Stable Control in Which a Setpoint is not Exceeded).................... |

8-80 |

|

|

8.2.6 Sample PI Control (Controlling a Process with Long Dead Time)..................... |

8-81 |

|

|

8.2.7 Batch PID Control (Performing Control with Rapidly Settling Setpoints)........... |

8-83 |

|

|

8.2.8 |

Feedforward Control.......................................................................................... |

8-85 |

8.3 |

Setting PID Control Mode (ALG)..................................................................................... |

8-87 |

|

8.4 |

Switching PID.................................................................................................................. |

8-89 |

|

|

8.4.1 Switching PID According to Target Setpoint Number (SPNO)........................... |

8-89 |

|

|

8.4.2 Switching PID According to PV......................................................................... |

8-90 |

|

|

8.4.3 Switching PID According to SP.......................................................................... |

8-92 |

|

|

8.4.4 Switching PID According to Target SP............................................................... |

8-94 |

|

|

8.4.5 Switching PID According to Deviation (Reference Deviation)........................... |

8-96 |

|

|

8.4.6 Setting Hysteresis at Time of PID Switch.......................................................... |

8-97 |

|

|

8.4.7 Switching PID by Contact Input......................................................................... |

8-97 |

|

8.5 |

Suppressing Overshoot (Super Function)....................................................................... |

8-98 |

|

|

|

|

|