Yokogawa YVP110 User Manual

User’s

Manual YVP110

Advanced Valve Positioner

IM 21B04C01-01E

IM 21B04C01-01E

10th Edition

i

YVP110

Advanced Valve Positioner

|

|

|

IM 21B04C01-01E 10th Edition |

|

CONTENTS |

|

|

||

Introduction........................................................................................................... |

|

|

viii |

|

|

|

■ Notes on the User’s Manual.............................................................................. |

viii |

|

|

|

■ For Safe Use of Product.................................................................................... |

viii |

|

|

|

■ Warranty.............................................................................................................. |

ix |

|

|

|

■ Trade Mark........................................................................................................... |

ix |

|

|

|

■ATEX Documentation........................................................................................... |

x |

|

PART I: HARDWARE |

|

|||

1. |

Notes on Handling.................................................................................... |

1-1 |

||

|

1.1 |

Nameplate........................................................................................................... |

1-1 |

|

|

1.2 |

Transport............................................................................................................ |

|

1-1 |

|

1.3 |

Storage................................................................................................................ |

|

1-1 |

|

1.4 |

Choosing the Installation Location................................................................. |

1-1 |

|

|

1.5 |

Use of a Transceiver.......................................................................................... |

1-1 |

|

|

1.6 |

Insulation Resistance Test and Withstand Voltage Test............................... |

1-2 |

|

|

1.7 |

Notes for Saftey................................................................................................. |

1-2 |

|

|

1.8 |

EMC Conformity Standards............................................................................. |

1-3 |

|

|

1.9 |

Installation of Explosion Protected Type Positioner..................................... |

1-3 |

|

|

|

1.9.1 |

FM Certification.................................................................................. |

1-3 |

|

|

1.9.2 |

ATEX Certification.............................................................................. |

1-7 |

|

|

1.9.3 |

CSACertification.............................................................................. |

1-12 |

|

|

1.9.4 |

TIIS Certification............................................................................... |

1-12 |

2. |

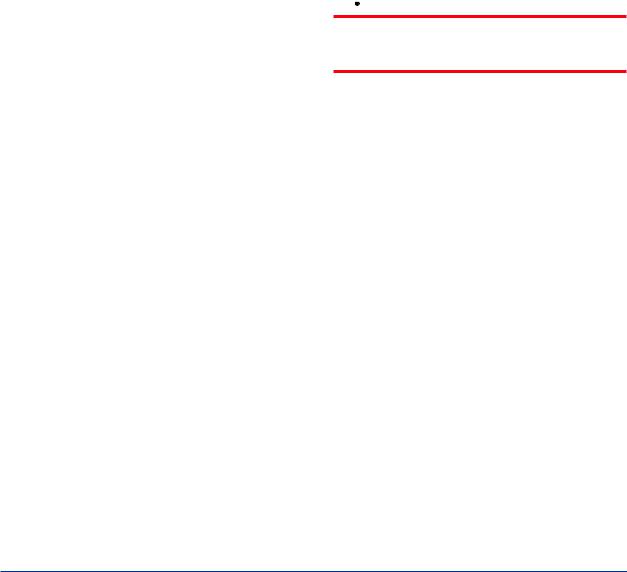

Part Names................................................................................................ |

|

2-1 |

|

|

2.1 |

Appearance and Part Names............................................................................ |

2-1 |

|

|

2.2 |

Block Diagram.................................................................................................... |

2-1 |

|

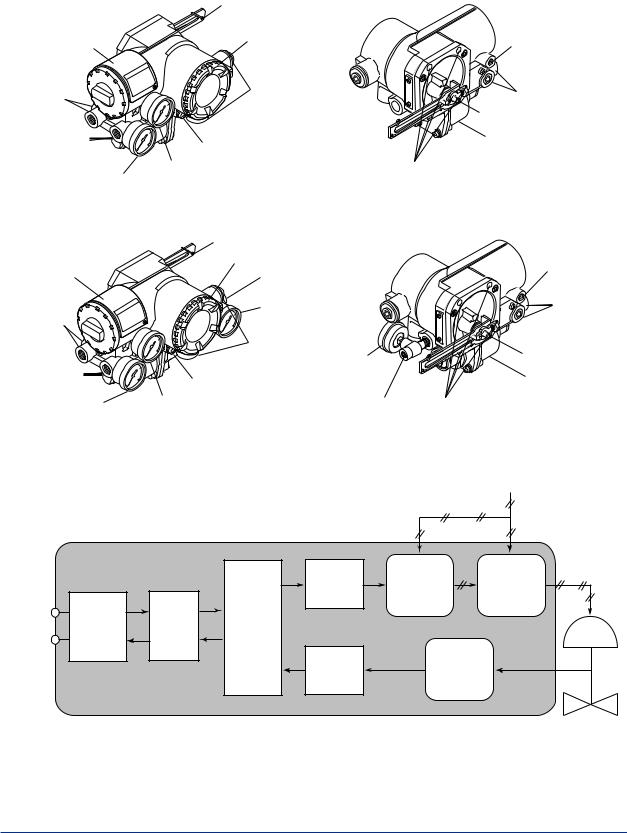

3. |

Installing YVP110 onActuator................................................................. |

3-1 |

||

|

3.1 |

General................................................................................................................ |

|

3-1 |

|

3.2 |

Installing YVP110 onActuator.......................................................................... |

3-1 |

|

|

|

3.2.1 |

Installing YVP110 on Linear-motion Control Valve............................. |

3-1 |

|

|

3.2.2 |

Installing YVP110 on Rotary-motion Control Valve............................ |

3-3 |

|

|

3.2.3 |

A/M Switching..................................................................................... |

3-5 |

10th Edition: Dec. 2013 (YK) |

IM 21B04C01-01E |

All Rights Reserved, Copyright © 2000, Yokogawa Electric Corporation |

|

ii

4. |

Wiring and Piping...................................................................................... |

4-1 |

||

|

4.1 |

General................................................................................................................ |

|

4-1 |

|

4.2 |

Piping.................................................................................................................. |

|

4-1 |

|

|

4.2.1 |

Air Supply........................................................................................... |

4-1 |

|

|

4.2.2 |

Pneumatic Piping................................................................................ |

4-1 |

|

4.3 |

Wiring.................................................................................................................. |

|

4-2 |

|

|

4.3.1 |

Recommended Cables....................................................................... |

4-2 |

|

|

4.3.2 |

Precautions on Wiring........................................................................ |

4-2 |

|

4.4 |

Grounding.......................................................................................................... |

4-4 |

|

5. |

Setup.......................................................................................................... |

|

|

5-1 |

|

5.1 |

General................................................................................................................ |

|

5-1 |

|

5.2 |

Setting Basic Parameters................................................................................. |

5-1 |

|

|

5.3 |

Carrying out Tuning .......................................................................................... |

5-2 |

|

|

5.4 |

Checking ValveActions.................................................................................... |

5-4 |

|

|

5.5 |

Setting Parameters of Transducer Block........................................................ |

5-4 |

|

6. |

Maintenance.............................................................................................. |

|

6-1 |

|

|

6.1 |

General................................................................................................................ |

|

6-1 |

|

6.2 |

Periodic Inspections......................................................................................... |

6-1 |

|

|

|

6.2.1 |

Cleaning the Fixed Nozzle................................................................. |

6-1 |

|

6.3 |

Part Replacement.............................................................................................. |

6-2 |

|

|

|

6.3.1 |

Replacing the Control RelayAssembly.............................................. |

6-2 |

|

|

6.3.2 |

Replacing the Screen Filters ............................................................. |

6-2 |

|

|

6.3.3 |

Replacing the InternalAir Filter.......................................................... |

6-2 |

|

|

6.3.4 |

Tuning the Pressure Balance of Control Relay.................................. |

6-3 |

7. |

Standard Specifications........................................................................... |

7-1 |

||

PART II: FUNCTIONS

8. |

About Fieldbus.......................................................................................... |

|

8-1 |

|

|

8.1 |

Outline................................................................................................................. |

|

8-1 |

|

8.2 |

Internal Structure of YVP110............................................................................ |

8-1 |

|

|

|

8.2.1 |

System/network Management VFD................................................... |

8-1 |

|

|

8.2.2 |

Function Block VFD............................................................................ |

8-1 |

|

8.3 |

Logical Structure of Each Block...................................................................... |

8-1 |

|

|

8.4 |

System Configuration....................................................................................... |

8-1 |

|

|

|

8.4.1 |

Connection of Devices....................................................................... |

8-2 |

|

8.5 |

Integration of DD................................................................................................ |

8-2 |

|

9. |

Configuration............................................................................................ |

|

9-1 |

|

|

9.1 |

Network Design................................................................................................. |

9-1 |

|

|

9.2 |

Network Definition............................................................................................. |

9-1 |

|

|

9.3 |

Definition of Combining Function Blocks...................................................... |

9-2 |

|

IM 21B04C01-01E

iii

|

9.4 |

Setting of Tags andAddresses........................................................................ |

9-3 |

|

|

9.5 |

Communication Setting.................................................................................... |

9-4 |

|

|

|

9.5.1 |

VCR Setting ........................................................................................ |

9-4 |

|

|

9.5.2 |

Function Block Execution Control . ..................................................... |

9-4 |

|

9.6 |

Block Setting...................................................................................................... |

9-5 |

|

|

|

9.6.1 |

Link Object .......................................................................................... |

9-5 |

|

|

9.6.2 |

Trend Object ....................................................................................... |

9-5 |

|

|

9.6.3 |

View Object ......................................................................................... |

9-5 |

|

|

9.6.4 |

Function Block Parameters .............................................................. |

9-12 |

10. Actions of YVP110 During Operation................................................... |

10-1 |

|||

|

10.1 |

Block Modes..................................................................................................... |

10-1 |

|

|

10.2 |

Alarm Generation............................................................................................ |

10-2 |

|

|

10.3 |

Simulation Function........................................................................................ |

10-3 |

|

11. |

Resource Block ...................................................................................... |

11-1 |

||

|

11.1 |

General |

............................................................................................................. |

11-1 |

|

11.2 |

Alarm Processing ........................................................................................... |

11-1 |

|

|

11.3 |

Device Status .................................................................................................. |

11-1 |

|

12. |

Transducer Block.................................................................................... |

12-1 |

||

|

12.1 |

General.............................................................................................................. |

|

12-1 |

|

12.2 |

Forward ....................................................................................................Path |

12-1 |

|

|

|

12.2.1 .......................................................................... |

Input from AO Block |

12-1 |

|

|

12.2.2 ............................. |

Position - to - flow Rate Characteristic Conversion |

12-2 |

|

|

12.2.3 ............................................................... |

FINAL _ VALUE and Range |

12-2 |

|

|

12.2.4 ...................................................... |

Tight - shut and Full - open Actions |

12-2 |

|

12.3 |

Backward .................................................................................................Path |

12-2 |

|

|

|

12.3.1 .............................................................. |

FINAL _ POSITION _ VALUE |

12-2 |

|

|

12.3.2 ................................................................................... |

Limit Switches |

12-2 |

|

12.4 |

Auto Tuning...................................................................................................... |

12-3 |

|

|

12.5 |

Travel Calibration............................................................................................. |

12-4 |

|

|

12.6 |

Online Diagnostics.......................................................................................... |

12-4 |

|

|

|

12.6.1 ..................................................................................... |

XD _ ERROR |

12-4 |

|

|

12.6.2 ................................................................................. |

Fail - safe Action |

12-5 |

|

|

12.6.3 ........................................................... |

Operation Result Integration |

12-5 |

|

|

12.6.4 .................................................................... |

Recording of Revisions |

12-5 |

|

12.7 |

Control .........................................................................................Parameters |

12-5 |

|

|

12.8 |

Temperature ....................................................and Pressure Measurement |

12-5 |

|

13. |

AO Function Block.................................................................................. |

13-1 |

||

|

13.1 |

General.............................................................................................................. |

|

13-1 |

|

13.2 |

Modes................................................................................................................ |

|

13-1 |

|

13.3 |

Forward ....................................................................................................Path |

13-1 |

|

|

|

13.3.1 ......................................................................................... |

Fault state |

13-1 |

|

13.4 |

Backward .................................................................................................Path |

13-2 |

|

IM 21B04C01-01E

iv

|

13.5 |

IO_OPTS and STATUS_OPTS........................................................................ |

13-2 |

|

|

13.6 |

Mode Shedding upon Computer Failure ...................................................... |

13-3 |

|

|

13.7 |

Initialization at Start......................................................................................... |

13-3 |

|

|

13.8 |

Alarm Processing ........................................................................................... |

13-3 |

|

14. |

DI Function Block................................................................................... |

14-1 |

||

|

14.1 |

General.............................................................................................................. |

|

14-1 |

|

14.2 |

Modes................................................................................................................ |

|

14-1 |

|

14.3 |

PV Value (PV_D)............................................................................................... |

14-1 |

|

|

14.4 |

Filtering............................................................................................................. |

|

14-1 |

|

14.5 |

Output............................................................................................................... |

|

14-2 |

|

14.6 |

IO_OPTS and STATUS_OPTS........................................................................ |

14-2 |

|

|

14.7 |

Alarm Processing ........................................................................................... |

14-2 |

|

|

|

14.7.1 |

BlockAlarms..................................................................................... |

14-2 |

|

|

14.7.2 |

DiscreteAlarm.................................................................................. |

14-2 |

15. |

OS Function Block.................................................................................. |

15-1 |

||

|

15.1 |

General.............................................................................................................. |

|

15-1 |

|

15.2 |

Modes................................................................................................................ |

|

15-1 |

|

15.3 |

Output Processing.......................................................................................... |

15-1 |

|

|

15.4 |

Backward Path (BKCAL_OUT) ...................................................................... |

15-2 |

|

|

15.5 |

STATUS_OPTS ................................................................................................ |

15-2 |

|

|

15.6 |

Alarm Processing ........................................................................................... |

15-2 |

|

16. |

PID Function Block................................................................................. |

16-1 |

||

|

16.1 |

General.............................................................................................................. |

|

16-1 |

|

16.2 |

Modes................................................................................................................ |

|

16-1 |

|

16.3 |

Input Processing............................................................................................. |

16-1 |

|

|

16.4 |

Setpoint (SP) Limiters..................................................................................... |

16-1 |

|

|

16.5 |

PID Computation............................................................................................. |

16-2 |

|

|

16.6 |

Control Output................................................................................................. |

16-2 |

|

|

16.7 |

Direction of ControlAction............................................................................. |

16-2 |

|

|

16.8 |

ControlAction Bypass.................................................................................... |

16-2 |

|

|

16.9 |

Feed-forward.................................................................................................... |

16-3 |

|

|

16.10 |

External-output Tracking (LO)........................................................................ |

16-3 |

|

|

16.11 |

Measured-value Tracking............................................................................... |

16-3 |

|

|

16.12 |

CONTROL_OPTS............................................................................................. |

16-3 |

|

|

16.13 |

Initialization and Manual Fallback (IMan)...................................................... |

16-4 |

|

|

16.14 |

Manual Fallback............................................................................................... |

16-4 |

|

|

|

16.14.1 |

STATUS_OPTS................................................................................ |

16-4 |

|

16.15 |

Auto Fallback................................................................................................... |

16-4 |

|

|

16.16 |

Mode Shedding upon Computer Failure....................................................... |

16-4 |

|

|

16.17 |

Alarms............................................................................................................... |

|

16-5 |

|

|

16.17.1 |

BlockAlarm (BLOCK_ALM)............................................................. |

16-5 |

|

|

16.17.2 |

ProcessAlarms................................................................................. |

16-5 |

IM 21B04C01-01E

v

17. |

IS Function Block.................................................................................... |

17-1 |

||

|

17.1 |

IS Function Block Schematic......................................................................... |

17-1 |

|

|

17.2 |

Input Section ................................................................................................... |

17-3 |

|

|

|

17.2.1 |

Mode Handling ................................................................................ |

17-3 |

|

|

17.2.2 |

MIN_GOOD Handling ...................................................................... |

17-3 |

|

17.3 |

Selection |

.......................................................................................................... |

17-4 |

|

|

17.3.1 |

OP_SELECT Handling .................................................................... |

17-4 |

|

|

17.3.2 |

SELECTION Handling ..................................................................... |

17-5 |

|

17.4 |

Output Processing ....................................................................................... |

17-11 |

|

|

|

17.4.1 |

Handling of SELECTED ................................................................ |

17-11 |

|

|

17.4.2 |

OUT Processing ............................................................................ |

17-12 |

|

|

17.4.3 |

STATUS_OPTS ............................................................................. |

17-13 |

|

17.5 |

Application Example .................................................................................... |

17-13 |

|

18. |

AR Function Block.................................................................................. |

18-1 |

||

|

18.1 |

AR Function Block Schematic....................................................................... |

18-1 |

|

|

18.2 |

Input Section ................................................................................................... |

18-2 |

|

|

|

18.2.1 |

Main Inputs ...................................................................................... |

18-2 |

|

|

18.2.2 |

Auxiliary Inputs ................................................................................ |

18-2 |

|

|

18.2.3 |

INPUT_OPTS .................................................................................. |

18-3 |

|

|

18.2.4 |

Relationship between the Main Inputs and PV ............................... |

18-3 |

|

18.3 |

Computation Section ..................................................................................... |

18-3 |

|

|

|

18.3.1 |

Computing Equations ...................................................................... |

18-3 |

|

|

18.3.2 |

Compensated Values ...................................................................... |

18-4 |

|

|

18.3.3 |

Average Calculation ........................................................................ |

18-4 |

|

18.4 |

Output Section ................................................................................................ |

18-4 |

|

|

|

18.4.1 |

Mode Handling ................................................................................ |

18-4 |

|

|

18.4.2 |

Status Handling ............................................................................... |

18-5 |

19. |

Diagnostics.............................................................................................. |

|

19-1 |

|

|

19.1 |

Overview........................................................................................................... |

|

19-1 |

|

19.2 |

Integration Functions...................................................................................... |

19-1 |

|

|

19.3 |

Signature Measurement Functions............................................................... |

19-2 |

|

|

|

19.3.1 |

Signature Measurement Procedure................................................. |

19-2 |

|

|

19.3.2 |

Signatures and Relevant Parameters.............................................. |

19-3 |

|

|

19.3.3 |

Signature Measuring Result............................................................. |

19-4 |

20. |

Troubleshooting...................................................................................... |

20-1 |

||

|

20.1 |

What to Do First............................................................................................... |

20-1 |

|

|

20.2 |

Troubleshooting Communications............................................................... |

20-1 |

|

|

20.3 |

Troubleshooting Function Block Parameters.............................................. |

20-1 |

|

|

20.4 |

Troubleshooting Valve Control...................................................................... |

20-2 |

|

|

20.5 |

TroubleshootingAuto Tuning........................................................................ |

20-3 |

|

|

20.6 |

Troubleshooting Position, Pressure, and Temperature Sensors.............. |

20-3 |

|

IM 21B04C01-01E

vi

Appendix 1. Function Block Parameters....................................................... |

A-1 |

||

A1.1 |

Parameters of Resource Block....................................................................... |

A-1 |

|

A1.2 |

Parameters of Transducer Block ................................................................... |

A-3 |

|

A1.3 |

Parameters ofAO Block .................................................................................. |

A-8 |

|

A1.4 |

Parameters of DI Block ................................................................................. |

A-10 |

|

A1.5 |

Parameters of OS Block ................................................................................. |

A-11 |

|

A1.6 |

Parameters of PID Block (Optional) ............................................................. |

A-12 |

|

A1.7 |

Parameters of IS Block.................................................................................. |

A-14 |

|

A1.8 |

Parameters ofAR Block................................................................................. |

A-16 |

|

A1.9 |

IO_OPTS -Availability of Options for Each Block ...................................... |

A-18 |

|

A1.10 |

STATUS_OPTS -Availability of Options for Each Block ........................... |

A-18 |

|

A1.11 |

CONTROL_OPTS -Availability of Options for Each Block ....................... |

A-18 |

|

Appendix 2. Link Master Functions............................................................. |

A-19 |

||

A2.1 |

LinkActive Scheduler.................................................................................... |

A-19 |

|

A2.2 |

Link Master...................................................................................................... |

A-19 |

|

A2.3 |

Transfer of LAS............................................................................................... |

A-19 |

|

A2.4 |

LM Functions.................................................................................................. |

A-20 |

|

A2.5 |

LM Parameters................................................................................................ |

A-21 |

|

|

A2.5.1 |

LM Parameter List............................................................................ |

A-21 |

|

A2.5.2 Descriptions for LM Parameters....................................................... |

A-22 |

|

A2.6 |

FAQs................................................................................................................. |

|

A-25 |

Appendix 3. DD Methods and DD Menu....................................................... |

A-26 |

||

A3.1 |

Overview.......................................................................................................... |

|

A-26 |

A3.2 |

DD Methods .................................................................................................... |

A-26 |

|

|

A3.2.1 |

Transducer Block.............................................................................. |

A-26 |

|

A3.2.2 |

AO Block........................................................................................... |

A-28 |

|

A3.2.3 |

OS Block........................................................................................... |

A-29 |

Appendix 4. |

Software Download.................................................................. |

A-30 |

|

A4.1 |

Benefits of Software Download.................................................................... |

A-30 |

|

A4.2 |

Specifications................................................................................................. |

A-30 |

|

A4.3 |

Preparations for Software Downloading..................................................... |

A-30 |

|

A4.4 |

Software Download Sequence...................................................................... |

A-30 |

|

A4.5 |

Download Files............................................................................................... |

A-31 |

|

A4.6 |

Steps afterActivating a Field Device............................................................ |

A-31 |

|

A4.7 |

Troubleshooting............................................................................................. |

A-32 |

|

A4.8 |

Resource Block’s Parameters Relating to Software Download................ |

A-32 |

|

A4.9 |

System/Network Management VFD Parameters Relating to Software |

A-34 |

|

|

Download......................................................................................................... |

||

A4.10 |

Comments on System/Network Management VFD Parameters Relating to |

||

|

Software Download........................................................................................ |

A-35 |

|

Appendix 5. PositionAdjustment of Feedback Lever................................ |

A-37 |

||

IM 21B04C01-01E

|

|

vii |

|

|

|

Appendix 6. Manual Tuning Guideline......................................................... |

A-38 |

|

A6.1 |

General............................................................................................................. |

A-38 |

A6.2 |

Control Parameter Tuning Procedure.......................................................... |

A-38 |

A6.3 |

Examples of Tuning Control Parameters..................................................... |

A-40 |

A6.4 |

Description of Control Parameters............................................................... |

A-41 |

Installation and Operating Precautions for TIIS Flameproof Equipment |

||

.............................................................................................................. |

|

EX-B03 |

Customer Maintenance Parts List |

|

|

YVP110Advanced Valve Positioner................................................ |

CMPL21B04C01-01E |

|

Revision Record |

|

|

IM 21B04C01-01E

<Introduction> viii

Introduction

The YVP110 advanced valve positioner is fully factory-tested according to the specifications indicated upon the order.

This User’s Manual consists of two parts: Hardware and Functions. The Hardware part gives instructions on handling, wiring set-up and maintenance of YVP110, and the Functions part describes the software functions of YVP110.

In order for the YVP110 to be fully functional and to operate in an efficient manner, both parts in this manual must be carefully read, so that users become familiar with the functions, operation, and handling of the YVP110.

■Notes on the User’s Manual

•This manual should be delivered to the end user.

•The information contained in this manual is subject to change without prior notice.

•The information contained in this manual, in whole or part, shall not be transcribed or copied without notice.

•In no case does this manual guarantee the merchantability of the instrument or its adaptability to a specific client need.

•Should any doubt or error be found in this manual, submit inquiries to your local dealer.

•No special specifications are contained in this manual.

•Changes to specifications, structure, and components used may not lead to the revision of this manual unless such changes affect the function and performance of the instrument.

•Some of the diagrams in this instruction manual are partially omitted, described in writing, or simplified for ease of explanation. The drawings contained in the instruction manual may have a position or characters (upper/lower case) that differ slightly from the what are actually seen to an extent that does not hinder the understanding of functions or monitoring of operation.

•Symbols used in this manual

WARNING

WARNING

Contains precautions to protect against the chance of explosion or electric shock which, if not observed, could lead to death or serious injury.

CAUTION

CAUTION

Contains precautions to protect against danger, which, if not observed, could lead to personal injury or damage to the instrument.

IMPORTANT

IMPORTANT

Contains precautions to be observed to protect against adverse conditions that may lead to damage to the instrument or a system failure.

NOTE

NOTE

Contains precautions to be observed with regard to understanding operation and functions.

■ For Safe Use of Product

For the protection and safety of the operator and the instrument or the system including the

instrument, please be sure to follow the instructions on safety described in this manual when handling this instrument. In case the instrument is handled in contradiction to these instructions, Yokogawa does not guarantee safety. Yokogawa will not be liable for malfunctions or damage resulting from any modification made to this instrument by the customer. Please give your highest attention to the followings.

(a) Installation

•The instrument must be installed by an expert engineer or skilled personnel. The procedures described about INSTALLATION are not permitted for operators.

IM 21B04C01-01E

<Introduction> ix

•Some of the operations will stroke the valve. Keep clear of the valve while the positioner is pneumatically or electrically supplied, so as not to be hit by unexpected movements of the valve.

•In case where ambient temperature is high, care should be taken not to burn yourself, because the surface of the body of the instrument reaches a high temperature.

•All installation shall comply with local installation requirement and local electrical codes.

•Do not supply air at a pressure exceeding the maximum rated air supply pressure. Doing so may result in a high risk of damage or cause an accident.

•To avoid injury or the process being affected when installing or replacing a positioner on a control valve, ensure that;

1)All inputs to the valve actuator and other accessories of the valve and actuator, including air supply and electrical signal, are cut off;

2)The process has been shut down or the control valve is isolated from the process by using bypass valves or the like; and

3)No pressure remains in the valve actuator.

•Auto-Manual switch must not be moved by anyone except for the authorized engineer.

(b) Wiring

•The instrument must be installed by an expert engineer or skilled personnel. The procedures described about WIRING are not permitted for operators.

•Please confirm voltages between the power supply and the instrument before connecting the power cables and that the cables are not powered before connecting.

(c) Operation

•Wait three minutes after power is turned off, before opening the covers.

(d) Maintenance

•Only the procedures written in maintenance descriptions are allowed for users. When further maintenance is needed, please contact nearest YOKOGAWAoffice.

•Care should be taken to prevent the build up of drift, dust or other material on the data plate. In case of its maintenance, use clean, soft and dry cloth.

•The instrument modification or parts

replacement for explosion-protected type instruments by other than authorized representative of Yokogawa Electric Corporation is prohibited and will void the approval.

■Warranty

•The warranty period of the instrument is written on the estimate sheet that is included with your purchase.Any trouble arising during the warranty period shall be repaired free of charge.

•Inquiries with regard to problems with the instrument shall be accepted by the sales outlet or our local dealer representative.

•Should the instrument be found to be defective, inform us of the model name and the serial number of the instrument together with a detailed description of nonconformance and a progress report. Outline drawings or related data will also be helpful for repair.

•Whether or not the defective instrument is repaired free of charge depends on the result of our inspection.

•The following conditions shall not be eligible for charge-exempt repair.

•Problems caused by improper or insufficient maintenance on the part of the customer.

•Trouble or damage caused by mishandling, misusage, or storage that exceeds the design or specification requirements.

•Problems caused by improper installation location or by maintenance conducted in a nonconforming location.

•Trouble or damage was caused by modification or repair that was handled by a party or parties other than our consigned agent.

•Trouble or damage was caused by inappropriate relocation following delivery.

•Trouble or damage was caused by fire, earthquake, wind or flood damage, lightning strikes or other acts of God that are not directly a result of problems with this instrument.

■Trade Mark

•FOUNDATION Fieldbus is a trademark of the Fieldbus Foundation.

•Registered trademarks or trademarks appearing in this manual are not designated by a TM or ® symbol.

•Other company names and product names used in this manual are the registered trademarks or trademarks of their respective owners.

IM 21B04C01-01E

<Introduction>

■ATEX Documentation

This procedure is only applicable to the countries in European Union.

GB |

SK |

CZ

DK

I |

LT |

E |

LV |

EST

NL

PL

SF

SLO

P

H

F

BG

D

RO

S

M

GR

x

IM 21B04C01-01E

<1. Notes on Handling> |

1-1 |

1.Notes on Handling

The YVP110 advanced valve positioner is fully factory-tested upon shipment. When the YVP110 is delivered, visually check that no damage occured during the shipment.

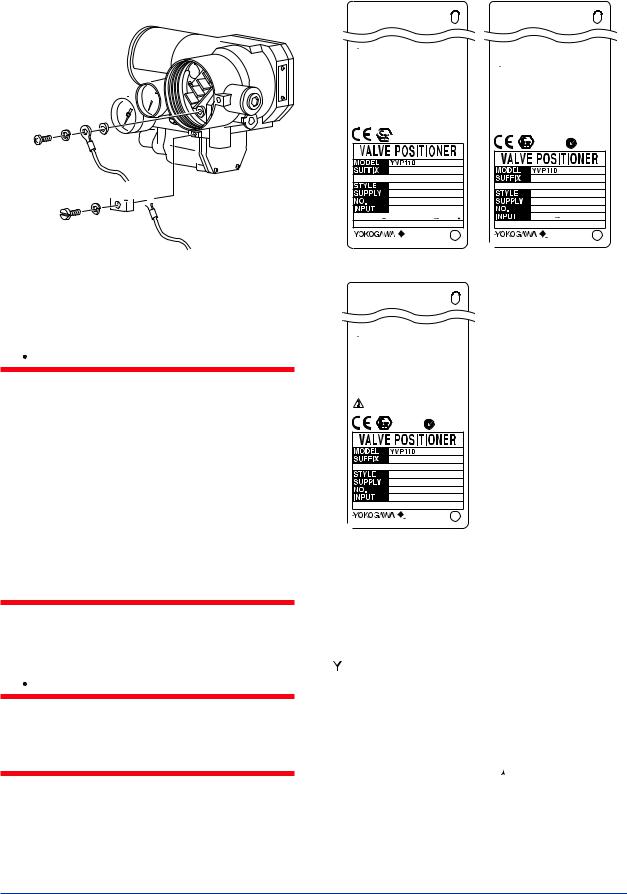

1.1Nameplate

The model name and configuration are indicated on the nameplate. Verify that the configuration indicated in the “Model and Suffix Code” in Chapter 7 is in compliance with the specifications written on the order sheet.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F0101.ai |

|||

Figure 1.1 |

Nameplate |

|||||||||

1.2Transport

To prevent damage while in transit, leave the positioner in the original shipping container until it reaches the installation site.

1.3Storage

When an extended storage period is expected, observe the following precautions:

(1)If at all possible, store the positioner in factoryshipped condition, that is, in the original shipping container.

(2)Choose a storage location that satisfies the following requirements.

•Alocation that is not exposed to rain or water.

•Alocation subject to a minimum of vibration or impact.

•The following temperature and humidity range is recommended. Ordinary temperature and humidity (25°C, 65%) are preferable.

Temperature: –40 to 85°C Humidity: 5 to 100% RH (at 40°C)

(3)The performance of the positioner may be impaired if stored in an area exposed to direct rain and water.

To avoid damage to the positioner, install it immediately after removal from the shipping container. Follow wiring instructions in this manual.

1.4Choosing the Installation Location

Although the advanced valve positioner is designed to operate in a vigorous environment, to maintain stability and accuracy, the following is recommended:

(1) Ambient Temperature

It is preferable not to expose the instrument to extreme temperatures or temperature fluctuations. If the instrument is exposed to radiation heat a thermal protection system and appropriate ventilation is recommended.

(2) Environmental Requirements

Do not allow the positioner to be installed in a location that is exposed to corrosive atmospheric conditions. When using the

positioner in a corrosive environment, ensure the location is well ventilated. The unit and its wiring should be protected from exposure to rainwater.

(3) Impact and Vibration

It is recommended that the positioner is installed in a location that is subject to a minimum amount of impact and vibration.

1.5Use of a Transceiver

Although the positioner is designed to resist influence from high frequency noise, use of a transceiver in the vicinity of installation may cause problems. Installing the transmitter in an area free from high frequency noise (RFI) is recommended.

IM 21B04C01-01E

<1. Notes on Handling> |

1-2 |

1.6Insulation Resistance Test and Withstand Voltage Test

CAUTION

CAUTION

(1)Overvoltage of the test voltage that is so small that it does not cause an dielectric breakdown may in fact deteriorate insulation and lower the safety performance; to prevent this it is recommended that the amount of testing be kept to a minimum.

(2)The voltage for the insulation resistance test must be 500V DC or lower, and the voltage for the withstand voltage test must be 500V AC or lower. Failure to heed these guidelines may cause faulty operation.

(3)Where a built-in arrester is provided (suffix code: /A), the voltage for the insulation resistance test must be 100V DC or lower, and the voltage for the withstand voltage test must be 100VAC or lower. Failure to heed these guidelines may cause faulty operation.

Follow the steps below to perform the test, the wiring of the communication line must be removed before initiating testing.

Insulation resistance test procedure

1.Lay transition wiring between the + terminal and the − terminal.

2.Connect the insulation resistance meter (with the power turned OFF) between the transition wiring of Step 1 above and ground terminal. The polarity of the input terminals must be positive and that of the ground must be negative.

3.Turn the power of the insulation resistance meter ON and measure the insulation resistance. The duration of the applied voltage must be the period during which 100 MΩ

or more is confirmed (or 20 MΩ if the unit is equipped with a built-in arrester).

4.Upon completion of the test, remove the insulation resistance meter, connect a 100 kΩ resistor between the transition wiring, and allow the electricity to discharge. Do not touch the terminal with your bare hands while the electricity is discharging for more than one second.

Withstand voltage test procedure

Testing between the input terminals and the grounding terminal

1.Lay the transition wiring between the + terminal and the − terminal, and connect the withstand voltage tester (with the power turned OFF) between the transition wiring and the grounding terminal. Connect the grounding side of the withstand voltage tester to the grounding terminal.

2.After setting the current limit value of the withstand voltage tester to 10 mA, turn the power ON, and gradually increase the impressed voltage from 0 V to the specified value.

3.The voltage at the specified value must remain for a duration of one minute.

4.Upon completion of the test, carefully reduce the voltage so that no voltage surge occurs.

1.7Notes for Saftey

CAUTION

CAUTION

When air is supplied to a valve, do not touch the moving part (a stem of the valve), as it may suddently move.

CAUTION

CAUTION

•WhileA/M selection switch is set to manual side (M), the pressure set in the regulator for air supply will be directly output to the actuator regardless of the control signal. Before changing the mode from auto to manual, check and confirm thoroughly that there will be no effect which may cause

a danger in process or personal injury by changing the mode.

•Do not change the mode by using auto/ manual switch during the operation. If the mode is changed from auto to manual or manual to auto, the valve stem will happnen to move to the position which is different from the control signal (the input signal to the positioner), and thus dangerous.

•As soon as the manual operation is finished, make it sure to change the mode to auto by moving theA/M selection switch toAuto(A) side.

IM 21B04C01-01E

<1. Notes on Handling> |

1-3 |

1.8EMC Conformity Standards

EN61326-1 ClassA, Table 2 (For use in industrial locations)

CAUTION

CAUTION

This instrument is a ClassAproduct, and it is designed for use in the industrial environment. Please use this instrument in the industrial environment only.

1.9Installation of Explosion Protected Type Positioner

CAUTION

CAUTION

To preserve the safety of explosionproof equipment requires great care during mounting, wiring and piping. Safety requirements also place restrictions on maintenance and repair activities. Please read the following section very carefully.

1.9.1 FM Certification

A) FM Intrinsically Safe Type

Cautions for FM Intrinsically safe type. (Following cotents refer “Doc No. IFM017-A12 P.1, 1-1, 2, 2-1, and 2-2.”)

Note 1. Model YVP110Advenced Valve Positioner with optional code /FS15 are applicable for use in hazardous locations.

•Applicable standard: FM3600, FM3610, FM3611, FM3810,ANSI/NEMA250

•Intrinsically safe, with FISCO parameters, for use in Class I, II, III, Division 1, GroupsA, B, C, D, E, F, G and Class I, Zone 0,AEx ia IIC

•Non-incendive for Class I, Division 2, Groups A, B, C, D and Class I, Zone 2, Group IIC

•Indoor/Outdoor hazardous locations, NEMA 4X

•Ambient Temperature: –40 to 60°C

Note 2. Electrical Data

Rating 1

For GroupsA, B, C, D, E, F and G or Group IIC

Maximum Input Voltage Vmax: 24 V

Maximum Input Current Imax: 250 mA

Maximum Input Power Pmax: 1.2 W

Maximum Internal Capacitance Ci: 1.76 nF

Maximum Internal Inductance Li: 0 µH

or

Rating 2

For GroupsA, B, C, D, E, F and G or Group IIC Maximum Input Voltage Vmax: 17.5 V Maximum Input Current Imax: 360 mA Maximum Input Power Pmax: 2.52 W Maximum Internal Capacitance Ci: 1.76 nF Maximum Internal Inductance Li: 0 µH

or

Rating 3

For Groups C, D, E, F and G or Group IIB Maximum Input Voltage Vmax: 17.5 V Maximum Input Current Imax: 380 mA Maximum Input Power Pmax: 5.32 W Maximum Internal Capacitance Ci: 1.76 nF Maximum Internal Inductance Li: 0 µH

•In the rating 1, the output current of the barrier must be limited by a resistor “Ra” such that

Io = Uo/Ra.

•In the rating 2 or 3, the output characteristics of the barrier must be the type of trapezoid which are certified as the FISCO model.

•The safety barrier may include a terminator.

•More than one field instruments may be connected to the power supply line.

Note 3. Installation

•Dust-tight conduit seal must be used when installed in Class II and Class III environments.

•Control equipment connected to the AssoiciatedApparatus must not use or generate more than 250 Vrms or Vdc.

•Installation should be in accordance with ANSI/ISARP12.6 “Installation of Intrinsically Safe Systems for Hazardous (Classified) Locations” and the National Electrical Code (ANSI/NFPA70) Sections 504 and 505.

•The configuration ofAssociatedApparatus must be Factory Mutual ResearchApproved under FISCO Concept.

•AssociatedApparatus manufacturer’s installation drawing must be followed when installing this equipment.

•The YVP series are approved for Class I, Zone 0, applications. If connecting

AEx[ib] associatedApparatus orAEx ib I.S. Apparatus to the YVP series the I.S. circuit is only suitable for Class I, Zone 1, or Class I, Zone 2, and is not suitable for Class I, Zone 0, or Class I, Division 1, Hazardous (Classified) Locations.

IM 21B04C01-01E

<1. Notes on Handling> |

1-4 |

|

|

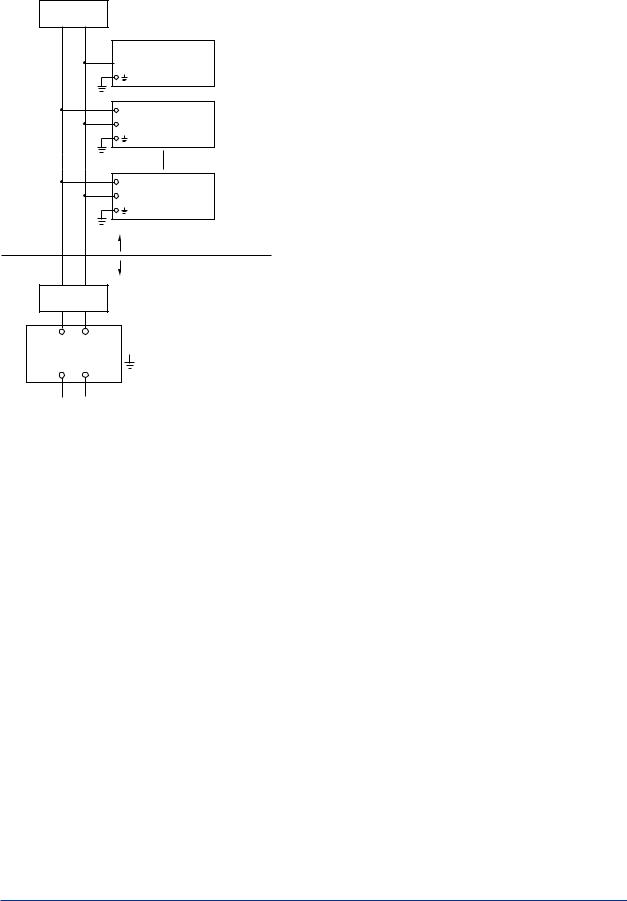

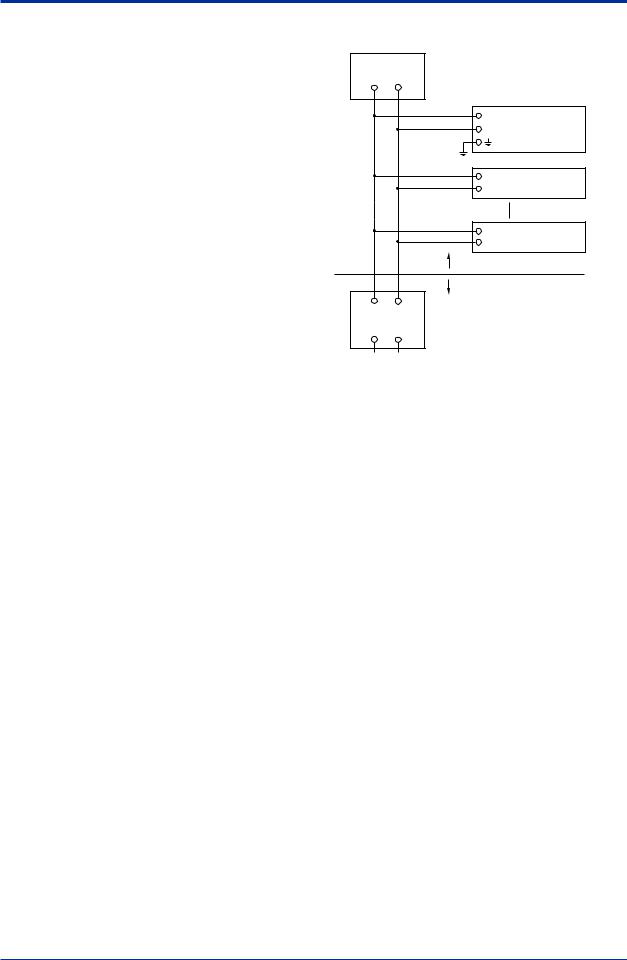

Installation Diagram (Intrinsically safe, Division 1 Installation)

Terminator

+ Valve Positioner

+ Valve Positioner

−

−

+ |

Transmitter |

− |

|

+ |

Transmitter |

− |

|

Hazardous Location

Non-hazardous Location

Terminator

+−

Safety Barrier

+ −

F0102.ai

Note 4. FISCO rules

The FISCO concept allows the interconnection of intrinsically safe apparatus to associated apparatus not specifically examined in

such combination. The criterion for such interconnection is that the voltage (Ui), the current (Ii) and the power (Pi) which intrinsically safe apparatus can receive and remain intrinsically safe, considering faults, must be equal or greater than the voltage (Uo, Voc, Vt), the current (Io) and the power (Po) which can be provided by the associated apparatus (supply unit). In addition, the maximum unprotected residual capacitance (Ci) and inductance (Li) of each apparatus (other than the terminators) connected to the fieldbus must be less than or equal to 5 nF and 10 µH respectively.

In each I.S. fieldbus segment only one active source, normally the associated apparatus, is allowed to provide the necessary power for the fieldbus system. The allowed voltage Uo of the associated apparatus used to supply the bus is limited to the range of 14 V d.c. to 24 V d.c. All other equipment connected to the bus cable has to be passive, meaning that the apparatus

is not allowed to provide energy to the system, except to a leakage current of 50 µAfor each connected device.

Supply unit

trapezoidal or rectangular output characteristic only

Uo = 14 to 24 V (I.S. maximum value)

Io according to spark test result or other assessment,

e.g. 133 mAfor Uo = 15 V (Group IIC, rectangular characteristic)

No specification of Lo and Co in the certificate and on the label.

Cable

The cable used to interconnect the devices needs to comply with the following parameters:

loop resistance R’: 15 to 150 Ω/km inductance per unit length L’: 0.4 to 1 mH/km capacitance per unit length C’: 80 to 200 nF/km

C’= C’ line/line + 0.5 C’line/screen, if both lines are floating

or

C’= C’line/line + C’line/screen, if the screen is connected to one line

length of spur cable: max. 30 m (Group IIC) or 120 m (Group IIB)

length of trunk cable: max. 1 km (Group IIC) or 1.9 km (Group IIB)

Terminators

At each end of the trunk cable an approved line terminator with the following parameters is suitable:

R = 90 to 100 Ω

C = 0 to 2.2 µF

The resistor must be infallible according to IEC 60079-11. One of the two allowed terminators might already be integrated in the associated apparatus (bus supply unit).

System evaluation

The number of passive devices like transmitters, actuators, hand held terminals connected to a single bus segment is not limited due to I.S. reasons. Furthermore, if the above rules are respected, the inductance and capacitance of the cable need not to be considered and will not impair the intrinsic safety of the installation.

IM 21B04C01-01E

<1. Notes on Handling> |

1-5 |

|

|

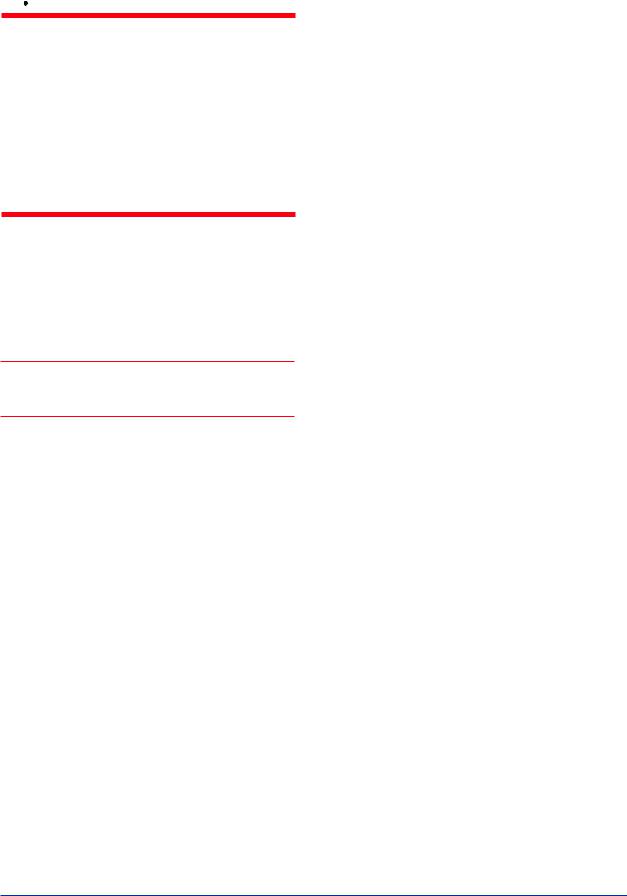

SAFE AREA |

HAZARDOUS AREA |

|

Supply Unit |

Terminator |

|

(FISCO Model) |

(FISCO Model) |

|

U |

Ex i |

|

|

|

|

U |

|

|

I |

|

|

Terminator |

|

|

Data |

|

|

|

Field Instruments |

|

|

(Passive) |

F0103.ai |

|

|

Note 5. Maintenance and Repair

The instrument modification or parts replacement by other than authorized representative of Yokogawa Electric Corporation is prohibited and will void Factory Mutual Intrinsically Safe and Non-incendive Approval.

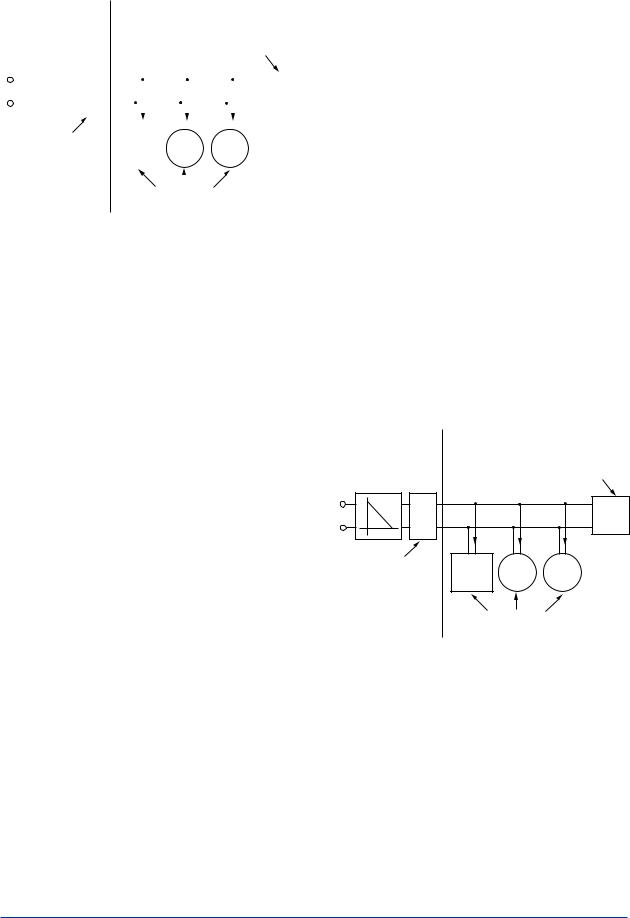

Installation Diagram (Nonincendive, Division 2 Installation)

Terminator

+ Valve Positioner

+ Valve Positioner

−

−

+ |

Transmitter |

− |

|

+ |

Transmitter |

− |

|

Hazardous Location

Non-hazardous Location

Terminator

(Nonincendive) Power Supply

FM Approved Associated

Nonincendive Field Wiring Apparatus

Vt or Voc

It or Isc

Ca

La

F0104.ai

*1: Dust-tight conduit seal must be used when installed in Class II and Class III environments.

*2: Installation should be in accordance with the National Electrical Code® (ANSI/NFPA70) Sections 504 and 505.

*3: The configuration ofAssociated Nonincendive Field WiringApparatus must be FMApproved.

*4: Associated Nonincendive Field Wiring Apparatus manufacturer’s installation drawing must be followed when installing this equipment.

*5: No revision to drawing without prior FM Approvals.

*6: Terminator and supply unit must be FM Approved.

*7: If use ordinary wirings, the general purpose equipment must have nonincendive field wiring terminal approved by FMApprovals.

*8: The nonincendive field wiring circuit concept allows interconection of nonincendive field wiring apparatus with associated nonincendive field wiring apparatus, using any of the wiring methods permitted for unclassified locations.

*9: Installation requirements; Vmax ≥ Voc or Vt Imax = see note 10. Ca ≥ Ci + Ccable

La ≥ Li + Lcable

*10: For this current controlled circuit, the parameter (Imax) is not required and need not be aligned with parameter (Isc or It) of the barrier or associated nonincendive field wiring apparatus.

Electrical Data:

Maximum Input Voltage Vmax: 32 V

Maximum Internal Capacitance Ci: 1.76 nF

Maximum Internal Inductance Li: 0 µH

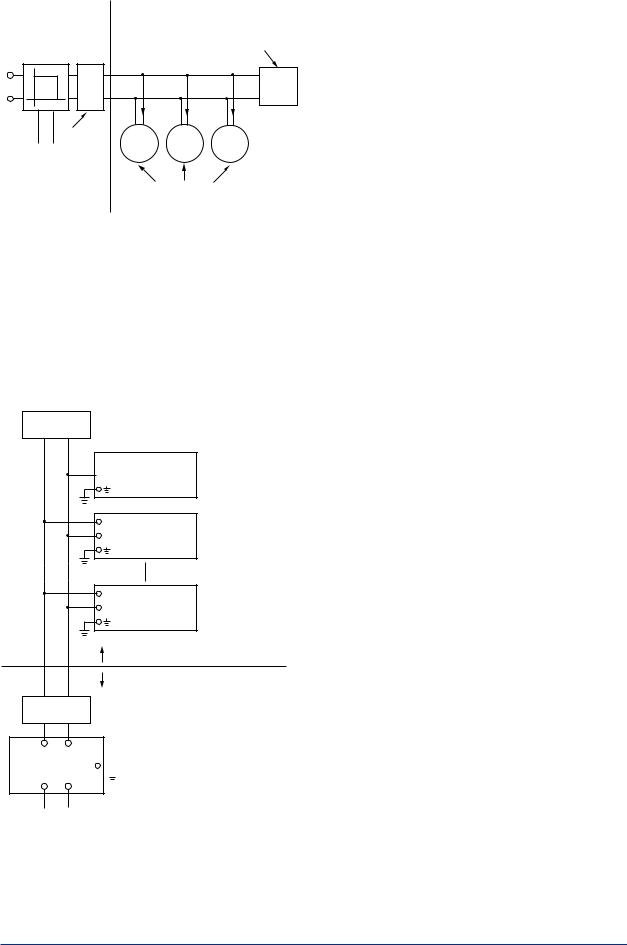

B) FM Explosionproof Type

Caution for FM explosionproof type.

Note 1. Model YVP110 Valve Positioner with

optional code /FF1 are applicable for use in

hazardous locations.

•Applicable standard: FM3600, FM3615, FM3810,ANSI/NEMA250

•Explosionproof for Class I, Division 1, GroupsA, B, C and D

•Dust-ignitionproof for Class II/III, Division 1, Groups E, F and G

•Enclosure Rating: NEMA4X

•Temperature Class: T6

•Ambient Temperature: –40 to 80°C

IM 21B04C01-01E

|

<1. Notes on Handling> |

1-6 |

|

Note 2. Wiring |

NFM010-A12 |

|

|

• All wiring shall comply with National Electrical |

Installation Diagram: |

|

|

CodeANSI/NEPA70 and Local Electrical |

|

|

|

|

|

|

|

Codes. |

Terminator |

|

|

• “FACTORY SEALED, CONDUIT SEALNOT |

|

|

|

REQUIRED.” |

+ |

YVP |

|

Note 3. Operation |

|

||

− |

|

||

Valve Positioner |

|

||

• Note a warning label worded as follows; |

|

|

|

WARNING: OPEN CIRCUIT BEFORE |

−+ |

|

|

REMOVING COVER. |

Field Instruments |

|

|

• Take care not to generate mechanical spark |

|

|

|

when accessing to the instrument and |

+ |

|

|

peripheral devices in hazardous locations. |

Field Instruments |

|

|

|

− |

|

|

Note 4. Maintenance and Repair |

Hazardous Area |

|

|

• The instrument modification or parts |

Safe Area |

|

|

replacement by other than authorized |

|

||

|

|

|

|

representative of Yokogawa Electric |

Nonincendive |

|

|

Corporation is prohibited and will void |

Power Supply |

|

|

the approval of Factory Mutual Research |

|

|

|

Corporation. |

|

F0105.ai |

|

|

|

|

|

C) FM Nonincendive approval

Model YVP110Advanced Valve Positioner with optional code /FN15.

•Applicable standard: FM3600, FM3611, FM3810

•NonincendiveApproval

Class I, Division 2, GroupsA, B, C and D Class II, Division 2, Groups F and G Class III, Division 1 and

Class I, Zone 2, Group IIC in Hazardous (Classified) Locations.

Temperature Class: T4

Ambient Temperature: –40 to 60°C Enclosure: NEMAType4X

•Electrical Parameters:

Vmax = 32 Vdc

Ci = 1.76 nF

Li = 0 µ H

•Caution for FM Nonincendive type. (Following contents refer to “DOC. No. NFM010-A12 p.1 and p.2”)

Note 1.

Dust-tight conduit seal must be used when installed in Class II and Class III environments.

Note 2.

Installation should be in accordance with National Electrical Code (ANSI/NFPA70) Sections 504, 505 and Local Electrical Code.

Note 3.

The configuration ofAssociatedApparatus must be Factory Mutual ResearchApproved.

Note 4.

AssociatedApparatus manufacturer's installation drawing must be followed when installing this equipment.

Note 5.

No revision to drawing without prior Factory Mutual ResearchApproval.

Note 6.

Terminator and supply unit must be FM approved.

Note 7.

Installation requirements;

Vmax ≥ Voc or Vt

Ca ≥ Ci + Ccable

La ≥ Li + Lcable

IM 21B04C01-01E

<1. Notes on Handling> |

1-7 |

|

|

1.9.2 ATEX Certification

WARNING

WARNING

•Do not open the cover when energized.

•When the ambient temp.≥70°C, Use the heat-resisting cable≥90°C

•Take care not to generate mechanical sparking when access to the instrument and peripheral devices in hazardous locations.

•Electrostatic charge may cause an explosion hazard.

Avoid any actions that cause the generation of electrostatic charge, such as rubbing with a dry cloth on coating face of product.

(1)Technical Data

A) ATEX Intrinsically Safe Type (Ex ia)

Caution forATEX Intrinsically Safe Type.

NOTE

NOTE

Keep the safety use conditions for both 1G and 1D when used in the hazardous gas and dust area.

Note1. Model YVP110Advanced Valve Positioner with optional code /KS25 for potentially explosive atmospheres:

•Applicable standard: EN60079-0:2006, EN60079-11:2007, EN60079-26:2007, EN60079-27:2006, EN61241-0:2006, EN61241-1:2004, EN61241-11:2006 and EN60529

•Certificate: KEMA08ATEX0114 X

Note 2. Ratings Type of Protection:

II 1G Ex ia IIB/IIC T4

II 1D Ex iaD 20 IP65 T100°C

II 1D Ex tDA20 IP65 T100°C

Maximum Surface Temperature for dust proof.: T100°C

Ambient Temperature Ex ia or Ex iaD: –40°C to +60°C

Ambient Temperature Ex tD: –40°C to +80°C Ambient Humidity: 0 to 100%RH

(No condensation)

Degree of Protection of the Enclosure: IP65 Electrical Parameters:

For Ex ia IIC or Ex iaD

Ui = 24.0 V, Ii = 250 mA, Pi = 1.2 W, Cint = 1.76 nF, Lint = 0 μH

or

For Ex ia IIB/ IIC or Ex iaD (FISCO model) Ui = 17.5 V, Ii = 380 mA, Pi = 5.32 W, Cint = 1.76 nF, Lint = 0 μH

For II 1D Ex tD Input signal: 32 Vdc,

Output current: 17 mA

Note 3. Installation

All wiring shall comply with local installation requirements.

(Refer to the installation diagram)

Note 4. Maintenance and Repair

The instrument modification or parts replacement by other than authorized representative of Yokogawa Electric Corporation is prohibited and will void KEMA Intrinsically safe Certification.

Note 5. Special Conditions for Safe Use Because the enclosure of the Valve Positioner is made of aluminium, if it is mounted in an area where the use of category 1G apparatus is required, it must be installed such, that, even in the event of rare incidents, ignition sources due to impact and friction sparks are excluded.

Once used as apparatus of equipment category 1D in type of protection Ex tD, the valve positioner is no longer suitable as apparatus of equipment category 1G or 1D in type of protection Ex ia or Ex iaD.

Note 6. Installation Instructions

When used in a potentially explosive atmosphere, requiring the use of apparatus of equipment category 1D, suitable certified cable entry devices or certified blanking elements with a degree of ingress protection of at least IP6X according to EN 60529 shall be used and correctly installed.

Note 7. Installation

When used in potentially explosive atmosphere for category 1D, need not use safety barrier.

IM 21B04C01-01E

<1. Notes on Handling> |

1-8 |

|

|

FISCO Model

|

|

Non-hazardous |

Hazardous Locations |

|

||||||||||||||||||

|

|

|

|

|

Locations |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

Supply Unit |

|

|

|

|

|

|

Terminator |

|

||||||||||||

|

|

(FISCO Model) |

|

|

|

|

|

|

(FISCO Model) |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ex i |

|

|

|||||

|

|

U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

Terminator |

Hand- |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

held- |

|

|

|

|

|

|

|

|||

|

|

|

|

Data |

|

|||||||||||||||||

|

|

|

|

Terminal |

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Field Instruments |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Passive) |

F0106.ai |

||||||

I.S. fieldbus system complying with FISCO

The criterion for such interconnection is that the voltage (Ui), the current (Ii) and the power (Pi), which intrinsically safe apparatus can receive, must be equal or greater than the voltage (Uo), the current (Io) and the power (Po) which can be provided by the associated apparatus (supply unit). In addition, the maximum unprotected residual capacitance (Ci) and inductance (Li) of each apparatus (other than the terminators) connected to the fieldbus line must be equal or less than 5 nF and 10 µH respectively.

Supply unit

The supply unit must be certified by a notified body as FISCO model and following trapezoidal output characteristic is used.

Uo = 14 to 24 V (I.S. maximum value)

Io based on spark test result or other assessment, ex. 133 mAfor Uo = 15 V (Group IIC)

The maximum allowed Co and Lo are determined by the combinations as specified below.

Cable

The cable used to interconnect the devices needs to comply with the following parameters:

loop resistance R': 15 to 150 Ω/km inductance per unit length L': 0.4 to 1 mH/km capacitance per unit length C': 80 to 200 nF/km C' = C' line/line + 0.5 C' line/screen, if both lines are floating

or

C' = C' line/line + C' line/screen, if the screen is connected to one line

length of spur cable: max. 30 m (Ex ia IIC T4) or 120 m (Ex ia IIB T4)

length of trunk cable: max. 1 km (Ex ia IIC T4) or 1.9 km (Ex ia IIB T4)

Terminators

The terminator must be certified by a notified body as FISCO model and at each end of the trunk cable an approved line terminator with the following parameters is suitable:

R = 90 to 100 Ω

C = 0 to 2.2 µF

The resistor must be infallible according to EN 50020. One of the two allowed terminators might already be integrated in the associated apparatus (bus supply unit).

Number of Devices

The number of devices (max. 32) possible on a fieldbus link depends on factors such as the power consumption of each device, the type of cable used, use of repeaters, etc.

Entity Model

Non-hazardous |

Hazardous Locations |

Locations |

|

Supply Unit |

Terminator |

Ex i

U

U

I

Terminator Handheld- Data Terminal

Terminator Handheld- Data Terminal

Field Instruments

(Passive) F0107.ai

I.S. fieldbus system complying with Entity model

IM 21B04C01-01E

<1. Notes on Handling> |

1-9 |

|

|

I.S. values Power supply-field device: Po ≤ Pi, Uo ≤ Ui, Io ≤ Ii

Calculation of max. allowed cable length:

Ccable ≤ Co - ∑ci - ∑ci (Terminator) Lcable ≤ Lo - ∑Li

Number of Devices

The number of devices (max. 32) possible on a fieldbus link depends on factors such as the power consumption of each device, the type of cable used, use of repeaters, etc.

B) ATEX Flameproof Type

Caution forATEX flameproof type.

Note 1. Model YVP110 Valve Positioner with optional code /KF2 is applicable for potentially explosive atmospheres:

•Applicable standard: EN60079-0:2009, EN60079-1:2007

•Certificate: KEMA10ATEX0023 X

•Group: II

•Category: 2G

•Type of Protection and Marking Code: Ex d IIC, T6 or T5 Gb

•Ambient Temperature: T6; –40 to 65°C

T5; –40 to 80°C

Note 2. Electrical Data

•Supply voltage: 32 V DC max.

•Output signal: 17 mADC

Note 3. Installation Instructions

•The cable glands and blanking elements shall be certified in type of protection flameproof enclosure “d” suitable for the conditions of use and correctly installed.

•With the use of conduit entries a sealing device shall be provided either in the flameproof enclosure or immediately on the entrance thereto.

•To maintain the degree of ingress protection IP65 according to EN 60529 special care must be taken to avoid water entering the breathing and draining device when the valve positioner is mounted with the feedback shaft in the upright position.

Note 4. Operation

•Keep strictly the WARNING on the label on the positioner.

AFTER DE-ENERGIZING, DELAY 5 MINUTES BEFORE OPENING. WHEN THEAMBIENTTEMP. ≥ 70°C,

USE HEAT-RESISTING CABLE & CABLE GLAND ≥ 90°C.

Note 5. Maintenance and Repair

•The instrument modification or parts replacement by other than authorized representative of Yokogawa Electric Corporation is prohibited and will void KEMA Flameproof Certification.

C)ATEX Intrinsically safe (Ex ic)/Type n (Ex nA)

Note 1. Model YVP110Advanced Valve Positioner

with optional code /KN25

•Applicable standard: EN60079-0:2009/EN60079-0:2012(Ex ic/Ex nA), EN60079-11:2012(Ex ic) EN60079-15:2010(Ex nA)

•Ex ic: II 3G Ex ic IIC T4 Gc (Intrinsically safe)

•Ex nA: II 3G Ex nAIIC T4 Gc (Non-sparking)

•Ambient Temperature: -30 to 75°C

•Ambient Humidity:

0 to 100%RH (No condensation)

•Enclosure: IP65

•Installation category: I

Note 2. Electrical Data

•Ex ic: Ui = 32 V, Ci = 3.52 nF, Li = 0 μH

•Ex nA: 32 V DC MAX

Note 3. For the installation of this positioner, once a particular declared type of protection is selected, the other type of protection

cannot be used. The installation must be in accordance with the description about type of protection in this instruction manual.

Note 4. In order to avoid confusion, unnecessary marking is crossed out on the label other than the selected type of protection when positioner is installed.

Note 5. Installation Instructions

•Cable glands, adapters and/or blanking elements shall be of Ex “n”, EX “e” or Ex “d” and shall be installed so as to maintain the specified degree of protection (IP Code) of the equipment.

•To maintain the degree of protection IP65 according to IEC 60529, special care must be taken to avoid water.

Note 6. Maintenance and Repair

•The instrument modification or parts replacement by other than authorized representative of Yokogawa Electric Corporation is prohibited and will voidATEX Ex ic and Ex nA.

IM 21B04C01-01E

<1. Notes on Handling> |

1-10 |

|

|

Note 7. Ex ic Installation

•All wiring shall comply with local installation requirements (refer to the installation diagram)

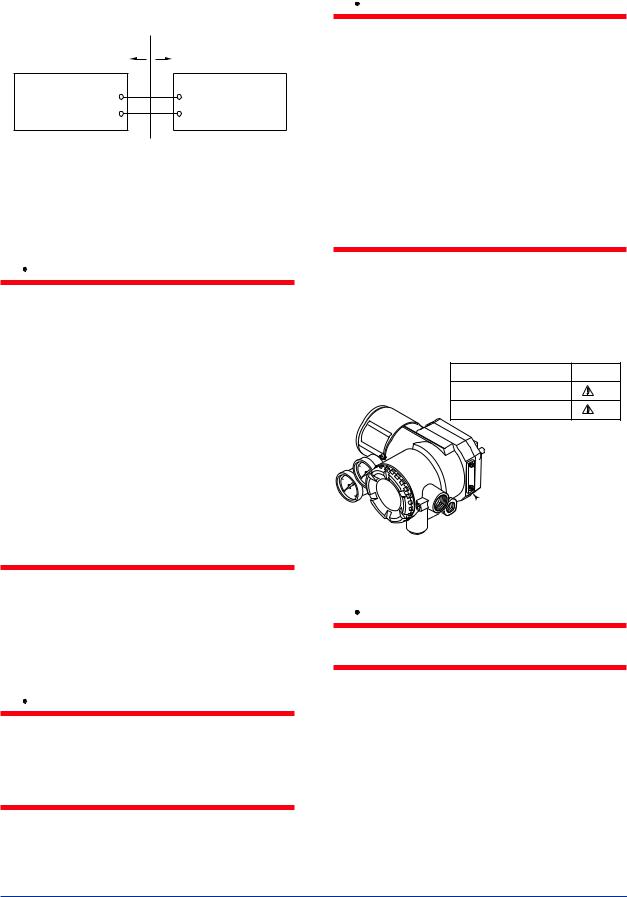

Installation Diagram

Hazardous Area |

Non-hazardous Area |

Valve Positioner |

Associated Apparatus |

+ |

+ |

− |

− |

F0108.ai

Electrical Data: Ui = 32 V

Ci = 3.52 nF

Li = 0 μH

Note 8. Ex ic Specific Conditions of Use

WARNING

WARNING

•Electrostatic charge may cause an explosion hazard.Avoid any actions that cause the generation of electrostatic charge, such as rubbing with a dry cloth on coating face of product.

•When the lightning protector option is specified (/A), the apparatus is not capable of withstanding the 500V insulation test required by EN60079-11. This must be taken into account when installing the apparatus.

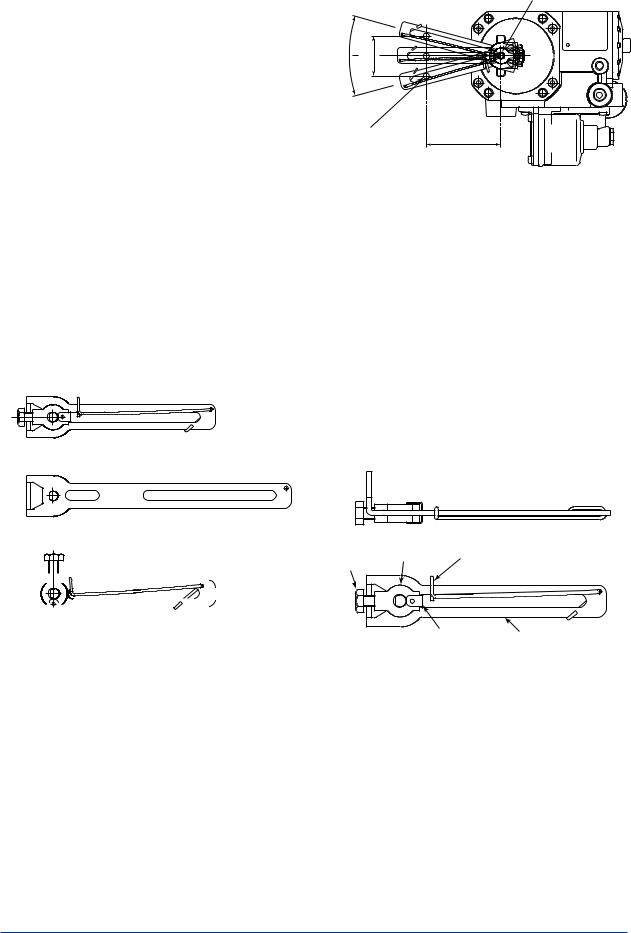

•WHEN THEAMBIENTTEMP.≥70°C, USE THE HEAT-RESISTING CABLEAND CABLE GRAND≥90°C