YOKOGAWA YFA11, YF100 User's Manual

INSTRUCTION MANUAL

Model YF100

Vortex Flowmeter

(Integral Type, Remote Type)

Model YFA11

Vortex Flow Converter

(Remote Type)

(Style E)

IM 1F2B4-01-YIA

IM 1F2B4-01-YIA 1st Edition, March 1998 Printed in U.S.A.

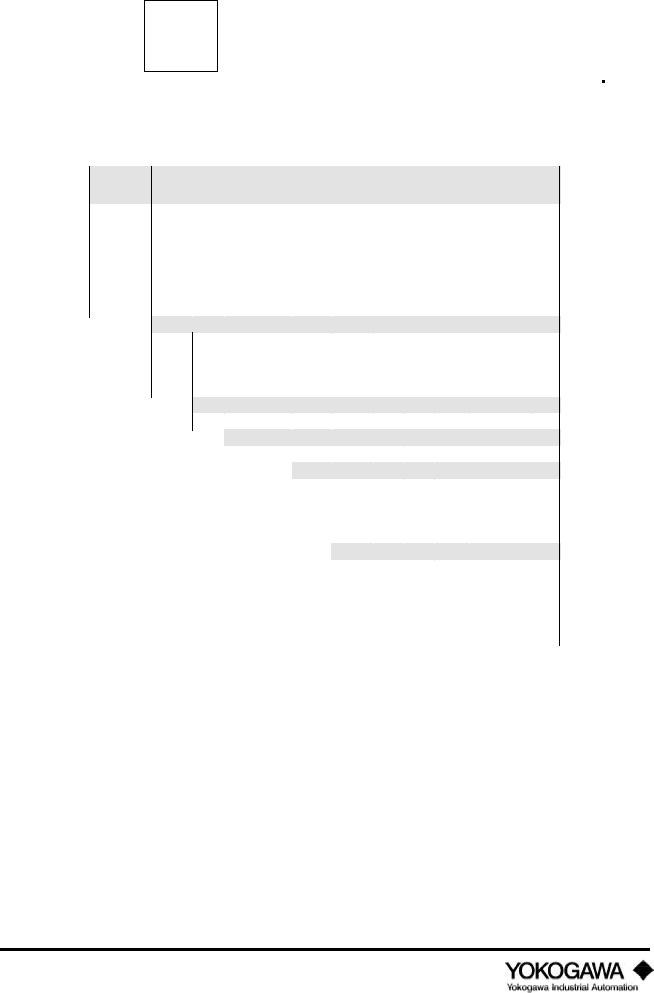

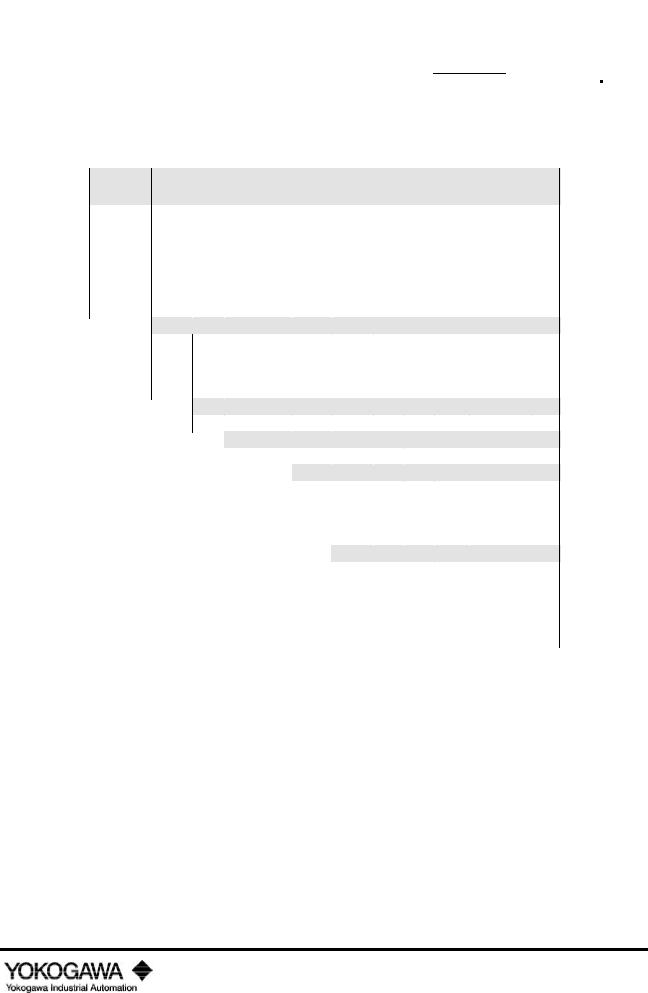

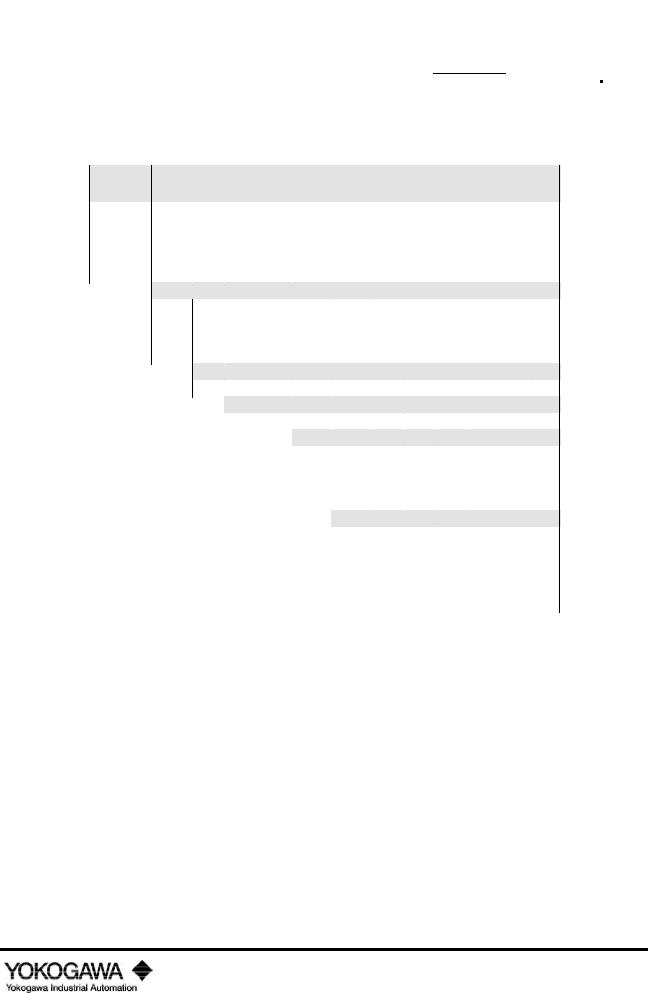

TABLE OF CONTENTS

I. |

INTRODUCTION ....................................................................................................... |

1 |

||

|

1.1 |

General Overview ............................................................................................. |

1 |

|

|

1.2 |

Principle of Operation....................................................................................... |

1 |

|

|

|

1.2.1 |

Vortex shedding.................................................................................... |

1 |

|

|

1.2.2 |

K-factor ................................................................................................ |

2 |

|

|

1.2.3 |

Qmin .................................................................................................... |

3 |

|

|

1.2.4 |

Uniquely vortex .................................................................................... |

3 |

|

|

1.2.5 |

Vortex frequency .................................................................................. |

3 |

|

|

1.2.6 |

Available outputs .................................................................................. |

3 |

|

1.3 |

Standard Specifications ..................................................................................... |

4 |

|

|

1.4 |

Basic Sizing ...................................................................................................... |

7 |

|

|

|

1.4.1 |

Flowmeter sizing .................................................................................. |

7 |

|

1.5 |

Model and Suffix Codes ................................................................................... |

9 |

|

II. |

QUICK START ......................................................................................................... |

22 |

||

|

2.1 |

Parameter Setting in BRAIN Communications ................................................ |

22 |

|

|

2.2 |

YEWFLO Setup ............................................................................................. |

25 |

|

|

|

2.2.1 Liquid, gas or steam in mass flow units .............................................. |

26 |

|

|

|

2.2.2 Steam flow in energy units ................................................................. |

28 |

|

|

|

2.2.3 Gas volumetric referenced to standard conditions ............................... |

30 |

|

|

|

2.2.4 Liquid, gas, or steam in volumetric units at flowing conditions .......... |

32 |

|

|

2.3 |

Parameter Setting in HART Communications ................................................. |

34 |

|

|

|

2.3.1 |

Communication Specifications ........................................................... |

34 |

|

|

2.3.2 |

Hardware Recommendations .............................................................. |

35 |

III. |

INSTALLATION ....................................................................................................... |

36 |

||

|

3.1 |

Piping Requirements ....................................................................................... |

36 |

|

|

|

3.1.1 |

Pipe schedule ..................................................................................... |

37 |

|

|

3.1.2 Flow direction and orientation ............................................................ |

37 |

|

|

|

3.1.3 Pressure and temperature taps ............................................................ |

37 |

|

|

|

3.1.4 |

Flushing the pipe ................................................................................ |

38 |

|

|

3.1.5 |

Gaskets .............................................................................................. |

38 |

|

3.2 |

Installing the Vortex Meter .............................................................................. |

38 |

|

|

|

3.2.1 Installing the wafer style vortex meter ................................................ |

38 |

|

|

|

3.2.2 Installing the wafer style vortex meter horizontally ............................ |

39 |

|

|

|

3.2.3 Installing the wafer style vortex meter vertically ................................ |

39 |

|

|

|

3.2.4 Installing the flanged vortex meter ..................................................... |

40 |

|

|

|

3.2.5 Insulating vortex meters with integral converter ................................. |

40 |

|

|

|

3.2.6 |

Rotating the meter housing ................................................................. |

41 |

|

|

3.2.7 |

Remote converter terminal box rotation .............................................. |

41 |

|

|

3.2.8 |

Integral converter rotation .................................................................. |

41 |

|

|

3.2.9 |

Installing the remote converter ........................................................... |

42 |

|

3.3 |

Wiring |

........................................................................................................... |

43 |

|

|

3.3.1 Cables and wires (analog or pulse output wires only) ......................... |

43 |

|

|

|

3.3.2 Analog output, 2-wire type (4-20 mADC)........................................... |

43 |

|

|

|

3.3.3 |

Pulse output, 3-wire type .................................................................... |

44 |

|

|

3.3.4 |

Interconnection for remote converter .................................................. |

45 |

|

3.4 |

Cable |

........................................................................................................... |

46 |

|

|

3.4.1 Field terminating the signal cable (YF011-0*E).................................. |

46 |

|

|

3.5 |

Wiring Cautions .............................................................................................. |

49 |

|

|

|

3.5.1 |

Flameproof transmitter installation ..................................................... |

49 |

|

|

3.5.2 Cautions for insulation and dielectric strength testing ......................... |

49 |

|

|

|

3.5.3 Instruction document for FM explosionproof instruments ................... |

50 |

|

|

|

3.5.4 Wiring cautions for CSA intrinsic safety............................................. |

52 |

|

|

|

3.5.5 |

Wiring cautions for FM intrinsic safety .............................................. |

54 |

IM 1F2B4-01-YIA i

TABLE OF CONTENTS

IV. |

MAINTENANCE ...................................................................................................... |

58 |

||

|

4.1 |

How to |

........................................................................................................... |

58 |

|

|

4.1.1 |

Communicating with the YEWFLO remotely ..................................... |

59 |

|

|

4.1.2 |

Adjusting zero and span ..................................................................... |

60 |

|

|

4.1.3 |

Using self-diagnostics ........................................................................ |

61 |

|

|

4.1.4 |

Simulating an output/performing a loop check.................................... |

62 |

|

|

4.1.5 |

Changing the output mode to analog or pulse ..................................... |

63 |

|

|

4.1.6 |

Increasing gas and steam flow measurement accuracy by correcting |

|

|

|

|

for gas expansion ............................................................................... |

64 |

|

|

4.1.7 |

Activating Reynolds number correction.............................................. |

65 |

|

|

4.1.8 |

Activating mismatched pipe schedule (bore) correction ...................... |

66 |

|

|

4.1.9 |

Setting up and resetting the internal totalizer ...................................... |

67 |

|

|

4.1.10 |

Scaling the pulse output ..................................................................... |

68 |

|

|

4.1.11 |

Setting up user defined flow units ...................................................... |

69 |

|

|

4.1.12 |

Setting up the local LCD indicator display mode ................................ |

70 |

|

|

4.1.13 |

Setting the low cut flowrate ................................................................ |

71 |

|

|

4.1.14 |

Trimming the 4-20 mA analog output ................................................. |

72 |

|

|

4.1.15 |

Using the upload/download feature .................................................... |

74 |

|

4.2 |

Disassembly and Reassembly.......................................................................... |

75 |

|

|

|

4.2.1 |

Indicator/Totalizer removal ................................................................ |

75 |

|

|

4.2.2 |

Amplifier replacement ........................................................................ |

75 |

|

4.3 |

Vortex Shedder Assembly Removal ................................................................ |

76 |

|

|

|

4.3.1 |

Removal of shedder from remote converter type................................. |

76 |

|

|

4.3.2 |

Removal of the shedder from integral type ......................................... |

77 |

|

4.4 |

Reassembly Cautions ...................................................................................... |

78 |

|

|

|

4.4.1 |

YEWFLO shedder bolt torque procedures .......................................... |

78 |

|

4.5 |

YEWFLO Style "E" Amplifier Calibration Procedure ..................................... |

81 |

|

|

|

4.5.1 |

General amplifier checkout ................................................................ |

82 |

|

|

4.5.2 |

Analog output test .............................................................................. |

82 |

|

|

4.5.3 |

Pulse output test ................................................................................. |

83 |

V. |

PARAMETER SETTING/CONFIGURATION ....................................................... |

84 |

||

|

5.1 |

Notes on the TBL optional digital display ....................................................... |

84 |

|

|

|

5.1.1 Display contents in display section ..................................................... |

85 |

|

VI. |

TROUBLESHOOTING ............................................................................................ |

88 |

||

|

6.1 |

Error Code Listing .......................................................................................... |

88 |

|

|

6.2 |

Operating Procedures ...................................................................................... |

89 |

|

|

6.3 |

Flow Computation .......................................................................................... |

92 |

|

|

|

6.3.1 |

Variable definitions ............................................................................ |

92 |

|

|

6.3.2 |

Flow conversion factor ....................................................................... |

93 |

|

6.4 |

Signal Conditioning ........................................................................................ |

94 |

|

|

|

6.4.1 YEWFLO Style "E" signal adjustment procedure ............................... |

94 |

|

|

|

6.4.2 |

Problem solving ................................................................................. |

94 |

|

|

6.4.3 |

Piping checkout procedure ................................................................. |

94 |

|

|

6.4.4 |

Noise balance adjustment ................................................................... |

95 |

|

|

6.4.5 |

Noise judge ........................................................................................ |

96 |

|

|

6.4.6 |

TLA adjustment ................................................................................. |

96 |

|

|

6.4.7 |

Low-cut flowrate adjustment .............................................................. |

97 |

|

|

6.4.8 |

High-frequency filter adjustment ........................................................ |

97 |

|

6.5 |

Flowcharts ...................................................................................................... |

98 |

|

|

|

6.5.1 No flowmeter output under flowing conditions ................................... |

98 |

|

|

|

6.5.2 |

Flowmeter output with no flow......................................................... |

100 |

|

|

6.5.3 |

Large flowmeter errors ..................................................................... |

101 |

|

|

6.5.4 Output is unstable when flowrate is low ........................................... |

102 |

|

IM 1F2B4-01-YIA ii

|

TABLE OF CONTENTS |

|

VII. GLOSSARY |

......................................................................................................... |

103 |

APPENDIXES: |

|

|

Appendix A: |

Parameter Details ............................................................................. |

107 |

Appendix B: |

HART Parameter Details ................................................................... |

115 |

Appendix C: |

Customer Maintenance Parts List |

|

Appendix D: |

Dimensional Diagrams |

|

INDEX |

|

|

IM 1F2B4-01-YIA iii

INTRODUCTION

I.INTRODUCTION

1.1GENERAL OVERVIEW

This manual provides installation, parameter setting, calibration, maintenance and troubleshooting instructions for the YEWFLO Vortex flowmeter. Also included are standard specifications, model code definitions, dimensional drawings and a parts lists.

All YEWFLO’s are shipped pre-configured for your application. Therefore, if you included correct process conditions with your order, no electronic setup or parameter setting is required. For piping and wiring connections, refer to the Installation section.

If your process conditions have changed since your order was placed, please refer to the ‘QUICK START’ section which is designed to simplify configuration of the YEWFLO software parameters. Please refer to the index for immediate access to a specific procedure or the glossary located at the end of this manual for further information on a specific term.

If you have any questions concerning the YEWFLO you received, please contact your local Yokogawa Industrial Automation Representative or our headquarters office in Newnan, GA at 770-254-0400.

If you have technical questions regarding the installation, operation, setup or application of a YEWFLO, please contact our Technical Assistance Center (TAC) at 800-524-SERV.

Yokogawa has manufactured this instrument according to rigorous ISO 9000 quality standards. To ensure quality performance we recommend referencing our YEWFLO sizing program to determine the level at which your application should be run as well as a straight meter run of 20 diameters upstream and 5 diameters downstream. In addition to these suggestions, please follow the instructions in this manual carefully.

We are not responsible for any instrument’s performance, if that instrument has not been properly applied or installed in accordance with this manual, nor can we be responsible for the performance of any instrument which has been modified or repaired by an unauthorized service center.

Note: Existing YEWFLO Style C vortex flowmeters may be upgraded to provide the features and benefits of the New microprocessor-based Style "E" YEWFLO.

1.2PRINCIPLE OF OPERATION

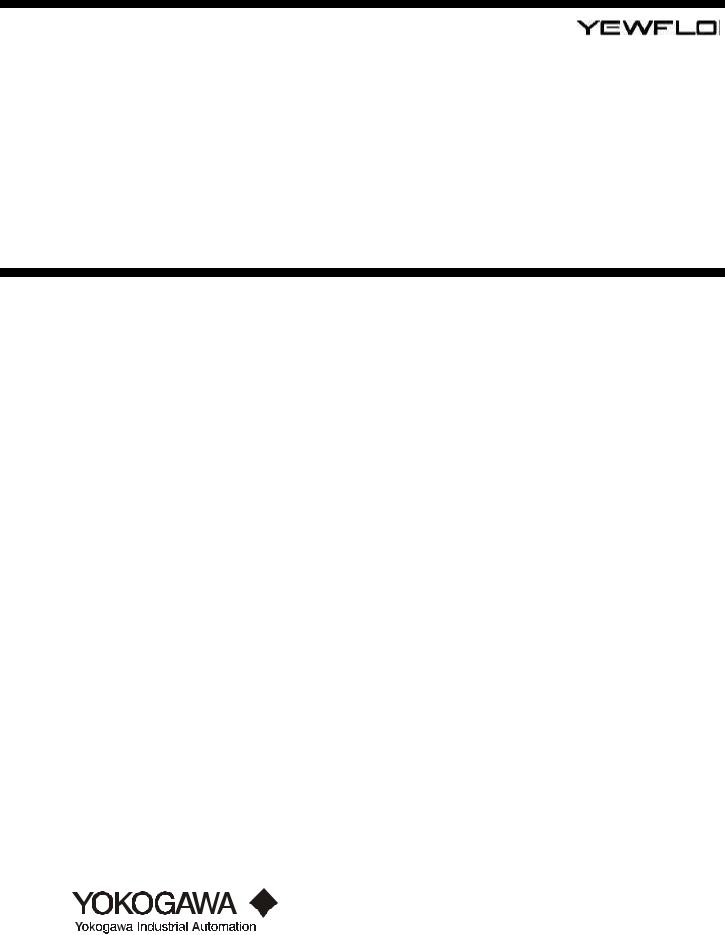

1.2.1 Vortex shedding

How many of you have seen a flag flapping in the breeze on a windy day? Everybody has. How many of you have noticed that the flag flaps faster as the wind blows faster? Few haven’t. When you see a flag flapping in the breeze, you are witnessing the same phenomenon that makes a vortex flowmeter work. The flapping frequency is proportional to the velocity of the wind, and it’s linear! The flapping is caused by a vortex alternately being created on either side of the flag, and moving downstream with the wind. The vortex is a swirl of low pressure, like a tornado, that pulls the flag in the direction of the vortex. The passing of alternating vortices down the length of the flag causes it to flap. The faster the wind blows, the faster these vortices are created, and the faster the flag flaps. Frequency is proportional to velocity .

IM 1F2B4-01-YIA

Page 1

INTRODUCTION

The flapping flag is a familiar example of vortex shedding that everyone should be comfortable with. Here’s how it’s used in a vortex flowmeter. A non-streamlined part (bluff body) is inserted in the flow stream, this obstruction in the pipe causes vortices to be alternately created (shed). We call this part the ‘shedder bar’. The shedder bar in a YEWFLO performs two functions, it creates the vortices, and with the addition of our piezoelectric crystals senses them too. The crystals generate an alternating voltage waveform whose frequency is proportional to fluid velocity. The rest of the magic is taken care of in the electronics.

Figure 1.2.1: Karman Vortices

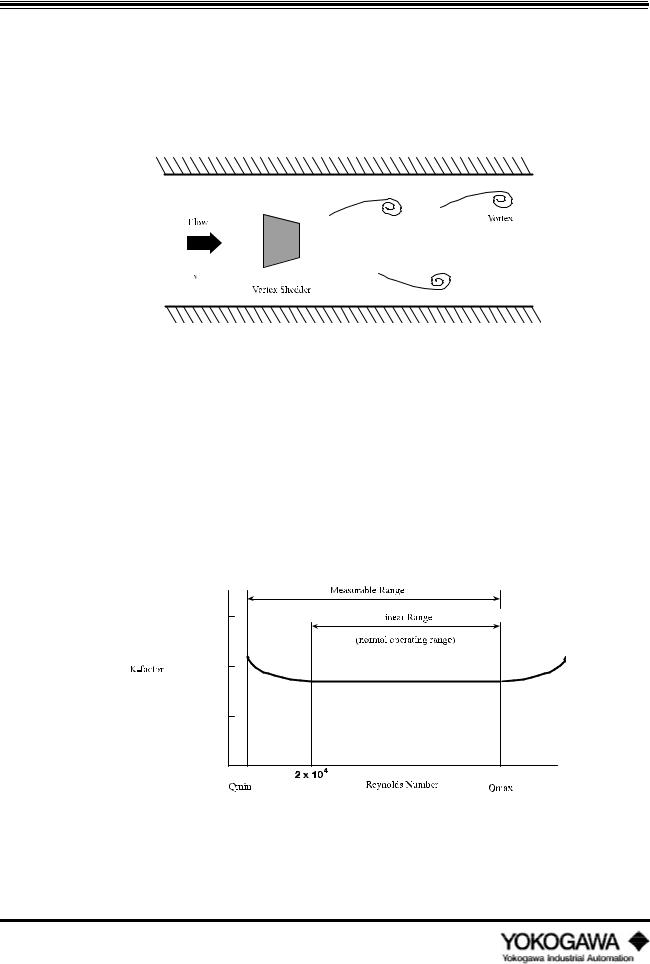

1.2.2K-factor

The most important fact about vortex shedding is that once the physical geometry, (pipe I.D., shedder bar width, etc.), are fixed, the frequency vs. flowrate (K-factor (pulse/gallon)) is unaffected by changes in viscosity, density or pressure over the operating range of the specific application. To determine the operating range use the YEWFLO Sizing program. On the other hand, an orifice plate is directly affected by changes in any of these parameters. There is a very small temperature effect due to expansion or contraction of the shedder bar width, which is easily compensated. Therefore, the K- factor created in our flow stand (all YEWFLOs are wet flow calibrated) on water, is accurate for gas too! Not so with an orifice plate. The benefit here is simplified calculations, and fewer things that can effect accuracy .

Figure 1.2.2: Relationship between K-factor and Reynolds Numbers

IM 1F2B4-01-YIA

Page 2

INTRODUCTION

1.2.3Qmin

Those of you who haven’t used many vortex flowmeters may be wondering, ‘Why do we need to know viscosity, density, pressure and temperature?’. While the K-factor is unaffected by changes in viscosity, density and pressure, the velocity at which vortices begin to be created and become stable enough to measure accurately will vary. We refer to this velocity as Qmin, stated in desired flow units GPM, SCFH, etc. Here’s an example to help you understand. Let’s go back to the flag example. We’ve all seen the flag flapping in the breeze; however, on some days we can feel the breeze blowing, but the flag isn’t flapping. Why not? For the flag to flap, there must be enough breeze blowing, or energy, to lift the flag and create fully developed vortices. This is the same thing that happens in the vortex flowmeter.

The higher the fluid viscosity, the higher the velocity (more energy) required to start vortex shedding. On the other hand, the higher the density, the lower the velocity needed to start vortex shedding. In gases, viscosity and density can vary with pressure and temperature. Sounds complicated, but compared to an orifice plate it’s quite simple. By using the YEWFLO sizing program, vortex meter selection is simple. Simply enter the process conditions, the program will prompt you for them, and presto, a performance table for all meter sizes is generated. This performance table will help you select the best YEWFLO for the application.

1.2.4Uniquely vortex

Vortex shedding flowmeters measure flow digitally. This means, amplitude of the vortex signal is unimportant. As long as the flow is above the Qmin threshold, only the presence or absence of a vortex is important. Just like digital electronics, as long as the voltage is above or below a threshold value, it is either on or off. Digital flow measurement means no zero drift or span shift . Orifice plate flowmeters, for example, cannot make this claim, even if they are using microprocessor-based digital D/P transmitters, they still measure the small amplitude of deflection caused by differential pressure, and changes in temperature or pressure can shift zero and span.

1.2.5Vortex frequency

The YEWFLO uses piezoelectric crystals embedded in the shedder bar . Note that they are 1) hermetically sealed , and 2) surrounded by a heavy wall thickness , to protect them from the environment and the process. The positioning of the crystals is important. Although one crystal primarily measures flow frequency, it unfortunately picks up some pipe vibration noise. The other crystal is positioned such that it picks up primarily the pipe vibration noise. By electronically subtracting these two signals, we are able to obtain a high signal to noise ratio for the flow signal . The new Style "E" body design also improves the signal to noise ratio, by stiffening the shedder bar mounting in the measurement plane, further isolating it from pipe vibration.

1.2.6Available outputs

After processing the digital vortex frequency as described above, what outputs can you get? You can select either 4-20 mA output or voltage pulse, digital output. Output is selected by setting jumpers on the amplifier board, and the setting the software for pulse or analog output. Analog output is twowire, and pulse output is a three-wire connection (for details see the wiring section). The pulse output can be scaled over a range of 0-6000 Hz, down or up to maximize pulse resolution. Scaling up the frequency output can be done to improve resolution. The pulse output is also capable of driving many electromechanical totalizers directly without additional power.

IM 1F2B4-01-YIA

Page 3

INTRODUCTION

1.3STANDARD SPECIFICATIONS

NOTE: For special applications, please contact your local Yokogawa Industrial Automation representative to discuss possible enhancements to these standard specifications.

Fluids to be measured: Liquid, gas or steam

Performance specifications:

Repeatability: 0.2% of reading

Accuracy and velocity range :

Fluid |

Accuracy: Pulse Output |

Accuracy: Analog Output |

Velocity |

Liquid |

±0.8% of reading |

±0.8% of reading plus |

up to 32 ft/sec |

|

|

±0.1% of full scale |

|

Gas or |

±0.8% of reading |

±0.8% of reading plus |

up to 115 ft/sec |

Steam |

|

±0.1% of full scale |

|

|

±1.5% of reading |

±1.5% of reading plus |

from 115 ft/sec |

|

|

±0.1% of full scale |

to 262 ft/sec |

Note: Gas accuracy can be improved to 0.8% over the full range by built-in software compensation. (See how to section 4.10.)

Output signal:

Analog: 4 to 20 mADC

Pulse: Low level 0 to 2 V

High level Vs - 2V ( Vs = input supply voltage)

Pulse width 50% duty cycle

Ambient temperature limits: |

|

|

|

-40º to 175ºF |

(-40º to 80ºC): |

standard unit w/o agency approval ratings |

|

-20º to 175ºF |

(-30º to 80ºC): |

with optional digital indicator |

|

-40º to 140ºF |

(-40º to 60ºC): |

with FM explosion-proof rating |

|

-40º to 120ºF |

(-40º to 50ºC): |

with CSA intrinsically safe rating for integral converter |

|

-40º to 175ºF |

(-40º to 80ºC): |

with CSA intrinsically safe rating for remote converter |

|

Process temperature limits: |

|

|

|

Standard remote converter: |

-40º to 575ºF |

(-40º to 300ºC) |

|

HPT remote converter: |

-40º to 755ºF |

(-40º to 402ºC) |

|

Cryogenic remote converter: |

-320º to 300ºF (-200º to 150ºC) |

||

Integral converter: |

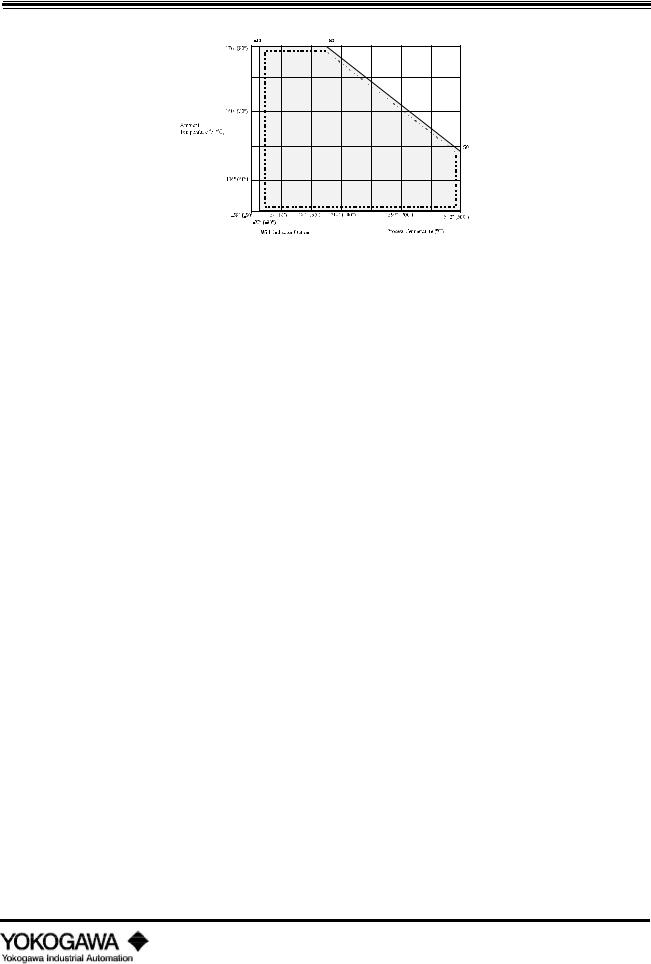

See Figure 1.3.1 |

||

Storage temperature limits: |

|

|

|

Integral or remote standard unit: |

-40º to 176ºF (-40º to 80ºC) |

||

With integral indicator or totalizer: |

-22º to 80ºF |

(-30º to 140ºC) |

|

IM 1F2B4-01-YIA

Page 4

INTRODUCTION

Figure 1.3.1: Operating temperature range for integral type converter

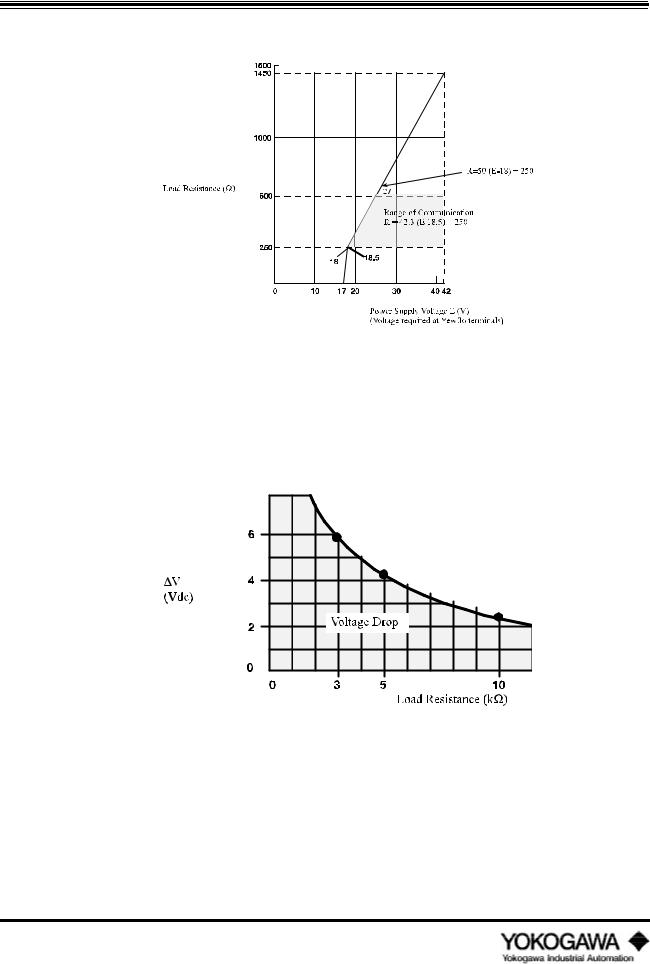

Power supply and load resistance: |

|

|

Analog output: |

|

17 to 42 VDC (see Figure 1.3.2) |

Pulse output: |

|

14 to 30 VDC |

Maximum output wire resistance: |

50 ohms |

|

Maximum line capacitance: |

0.22 microfarad |

|

Ambient humidity limits: |

|

|

5 to 100% relative humidity |

|

|

Process pressure limits: |

|

|

-14.7 psi (full vacuum) to flange rating |

|

|

Materials of construction: |

|

|

Process wetted parts: |

|

|

Body: |

CF8M (ANSI 316 stainless steel) or Hastelloy C (equivalent of |

|

|

ASTM494, CW12MW) |

|

Shedder bar: |

Duplex stainless steel (CD4MCU equivalent to ANSI 329 stainless |

|

|

steel) or Hastelloy C (equivalent of ASTM494, CW12MW) |

|

Non-wetted parts: |

|

|

Amplifier housing: |

Aluminum alloy casting |

|

Paint: |

Case - Polyurethane resin baked coating, frosty white |

|

|

Cover - Polyurethane resin baked coating, deep, sea moss green |

|

IM 1F2B4-01-YIA

Page 5

INTRODUCTION

Analog Output :

Figure 1.3.2: Relationship between power supply voltage and load resistance for analog output version

Pulse Output: Pulse output voltage = Vs-2v- v

where v = due to external load resistance Vs = Power Supply Voltage

2v = 2 volts

Figure 1.3.3: Load resistance vs. pulse output voltage drop

IM 1F2B4-01-YIA

Page 6

INTRODUCTION

1.4BASIC SIZING

1.4.1Flowmeter sizing

Notes: 1) This table assumes standard conditions of 59ºF (15ºC).

2)Maximum flowrates are based on 32 ft/sec.

3)These figures are approximations. Refer to the Yewflo sizing program for the exact minimum and maximum for your application.

4)The values shown in parenthesis is the minimum linear flowrate.

5)Proper pipe bracing may be required to obtain minimum flowrate.

LIQUID

Nominal |

Size |

|

Minimum and Maximum |

|

|

mm |

inch |

Measurable Flow Rates in U.S. gpm1 |

|||

15 |

½ |

1.3 |

-4.2 |

and |

27 |

25 |

1 |

2 |

-7.3 |

and |

82 |

40 |

1½ |

5.9 |

-11.3 |

and |

196 |

50 |

2 |

9.8 |

-14.5 |

and |

324 |

80 |

3 |

20 |

|

and |

628 |

100 |

4 |

33 |

|

and |

1100 |

150 |

6 |

79 |

|

and |

2400 |

200 |

8 |

150 |

|

and |

4290 |

250 |

10 |

265 |

|

and |

6460 |

300 |

12 |

300 |

|

and |

9260 |

Table 1.4.1: Water -Flowmeter Range

GAS

Nominal Size |

Flow Rate |

|

Minimum |

Linear and |

Maximum |

Measurable |

Air Flow Rates in SCFH |

|

|

(inches) |

Limits |

|

(Standard |

conditions |

are 59ºF |

and 14.7 psia) |

at process line pressure |

|

|

|

|

0 psig |

50 psig |

100 psig |

150 psig |

200 psig |

300 psig |

400 psig |

500 psig |

½ |

min |

172 |

361 |

500 |

719 |

939 |

1379 |

1822 |

2266 |

|

max |

1700 |

7492 |

13302 |

19128 |

24967 |

36692 |

48454 |

60266 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

1 |

min |

400 |

839 |

1118 |

1486 |

1940 |

2851 |

3765 |

4683 |

|

max |

5267 |

23215 |

41217 |

59268 |

77362 |

113692 |

150137 |

186737 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

1½ |

min |

792 |

1919 |

3037 |

4061 |

5026 |

6838 |

8970 |

11157 |

|

max |

1267 |

55397 |

98355 |

141428 |

184604 |

271296 |

358263 |

445599 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

2 |

min |

1313 |

2756 |

4080 |

5867 |

7658 |

11254 |

14862 |

18485 |

|

max |

20821 |

91779 |

162951 |

234313 |

305846 |

449474 |

593557 |

738253 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

3 |

min |

2534 |

5321 |

7877 |

11326 |

14784 |

21726 |

28691 |

35685 |

|

max |

40196 |

177182 |

314580 |

452347 |

590443 |

867720 |

1145876 |

1425214 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

4 |

min |

4423 |

10710 |

16953 |

22670 |

28055 |

38174 |

50076 |

62283 |

|

max |

70157 |

309249 |

549061 |

789516 |

1030544 |

1514497 |

1999984 |

2487535 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

6 |

min |

9685 |

29678 |

46977 |

64927 |

84749 |

124548 |

164473 |

204567 |

|

max |

153618 |

677145 |

1202247 |

1728757 |

2256524 |

3316208 |

4379250 |

5446812 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

8 |

min |

20851 |

68121 |

107827 |

144185 |

178437 |

242799 |

303286 |

265774 |

|

max |

274675 |

1010761 |

2149664 |

3091086 |

4034753 |

5929510 |

7830269 |

9739113 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

10 |

min |

37370 |

122437 |

193804 |

259153 |

320716 |

436397 |

545115 |

649056 |

|

max |

424752 |

1872295 |

3324193 |

4779987 |

6239253 |

9169263 |

12108556 |

15060351 |

|

|||||||||

|

|||||||||

|

|

|

|

|

|

|

|

|

|

12 |

min |

53518 |

175343 |

277549 |

371134 |

459300 |

624968 |

780663 |

929518 |

|

max |

608291 |

2681328 |

4760604 |

6845457 |

8935284 |

13131375 |

17340759 |

21568047 |

|

|

|

|

|

|

|

|

|

|

Table 1.4.2: Air-Flowmeter Range

Notes: 1) Maximum flowrates are based on 262 ft/sec.

2)These figures are approximations. Refer to the sizing program for the exact minimum and maximum flowrates for your application.

IM 1F2B4-01-YIA

Page 7

INTRODUCTION

STEAM

Nominal Size |

Flow Rate |

|

|

Minimum |

Linear and Maximum |

Measurable |

Saturated |

Steam Flow Rates in lb/hr |

|

|

|||

(inches) |

Limits |

|

|

|

|

|

at |

process line |

pressure |

|

|

|

|

|

|

15 psig |

25 psig |

50 psig |

75 psig |

100 psig |

|

125 psig |

150 psig |

175 psig |

200 psig |

250 psig |

300 psig |

½ |

min |

12.8 |

14.6 |

18.4 |

21.5 |

24.1 |

|

26.5 |

28.7 |

30.7 |

32.6 |

36.6 |

43.4 |

|

max |

122 |

161 |

254 |

346 |

437 |

|

527 |

616 |

705 |

765 |

973 |

1154 |

|

|

||||||||||||

1 |

min |

29.7 |

34 |

42.8 |

49.9 |

56.1 |

|

61.6 |

66.6 |

71.3 |

75.7 |

83.7 |

91.2 |

|

max |

379 |

498 |

788 |

1071 |

1353 |

|

1632 |

1910 |

2185 |

2464 |

3014 |

357 |

|

|

||||||||||||

1½ |

min |

58.7 |

67.3 |

84.6 |

98.6 |

118 |

|

137 |

156 |

173 |

191 |

224 |

257 |

|

max |

905 |

1188 |

1879 |

2554 |

3228 |

|

3894 |

4557 |

5215 |

5879 |

7192 |

8530 |

|

|

||||||||||||

2 |

min |

97.5 |

111 |

140 |

164 |

184 |

|

202 |

219 |

234 |

248 |

298 |

354 |

|

max |

1500 |

1969 |

3113 |

4232 |

5349 |

|

6452 |

7550 |

8639 |

9740 |

11916 |

14133 |

|

|

||||||||||||

3 |

min |

188 |

216 |

271 |

316 |

355 |

|

390 |

422 |

452 |

480 |

576 |

683 |

|

max |

2895 |

3800 |

6010 |

8170 |

10326 |

|

12455 |

14576 |

16678 |

18804 |

23004 |

27283 |

|

|

||||||||||||

4 |

min |

328 |

376 |

472 |

551 |

659 |

|

766 |

869 |

967 |

1065 |

1251 |

1434 |

|

max |

5054 |

6633 |

10490 |

14260 |

18023 |

|

21739 |

25440 |

29109 |

32820 |

40150 |

47620 |

|

|

||||||||||||

6 |

min |

719 |

824 |

1184 |

1515 |

1827 |

|

2122 |

2407 |

2681 |

2951 |

3467 |

3974 |

|

max |

11065 |

14523 |

22969 |

31224 |

39463 |

|

47600 |

55705 |

63739 |

71864 |

87914 |

104270 |

|

|

||||||||||||

8 |

min |

1549 |

1885 |

2720 |

3477 |

4193 |

|

4872 |

5525 |

6153 |

6773 |

7958 |

9122 |

|

max |

19785 |

25968 |

41070 |

55830 |

70561 |

|

85111 |

99603 |

113968 |

128496 |

157194 |

186439 |

|

|

||||||||||||

10 |

min |

2725 |

3387 |

4888 |

6249 |

7536 |

|

8756 |

9930 |

11060 |

12174 |

14304 |

16396 |

|

max |

30596 |

40157 |

63509 |

86334 |

109114 |

|

131614 |

154024 |

176238 |

198703 |

243081 |

288305 |

|

|

||||||||||||

12 |

min |

3903 |

4851 |

7000 |

8949 |

10793 |

|

12539 |

14220 |

15839 |

17434 |

20485 |

23481 |

|

max |

43816 |

57590 |

90952 |

123640 |

156263 |

|

188485 |

220578 |

252392 |

284564 |

348119 |

412883 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 1.4.3: Steam - Flowmeter Range

Notes: 1) Maximum flowrates are based on 262 ft/sec.

2)These figures are approximations. Refer to the sizing program for the exact minimum and maximum flowrates for your applications.

Nominal Size |

Internal Diameter |

Cross Sectional |

Nominal Pulse Rate |

Nominal |

K-factor |

(inches) |

(inches) |

Area (ft2) |

(Hz/ft/s) |

Pulse/US gal |

Pulse/ft3 |

½ |

0.57 |

0.0018 |

19.1 |

1423 |

10645 |

1 |

1.01 |

0.0056 |

10.8 |

259 |

1940 |

1½ |

1.56 |

0.133 |

7.05 |

70.8 |

530 |

2 |

2.01 |

0.022 |

5.59 |

33.9 |

253 |

3 |

2.8 |

0.043 |

4.02 |

12.6 |

94.3 |

4 |

3.69 |

0.074 |

3 |

5.39 |

40.3 |

6 |

5.46 |

0.163 |

2.03 |

1.67 |

12.5 |

8 |

7.31 |

0.291 |

1.52 |

0.7 |

5.24 |

10 |

9.09 |

0.45 |

1.23 |

0.366 |

2.74 |

12 |

10.9 |

0.645 |

1.03 |

0.213 |

1.59 |

Table 1.4.4: Nominal K-factor and general flowmeter information

IM 1F2B4-01-YIA

Page 8

YEWFLO |

*E |

STAINLESS |

|

|

|||

*E VORTEX FLOWMETERS |

WAFER |

||

|

|||

|

|

|

|

|

|

|

|

|

|

|

MODEL |

|

|

YEWFLO |

*E - STAINLESS |

|

WAFER |

|

|

||

CODE |

|

|

|

|

|

|

|

|

|

|

YF101 |

0.5" I.D. Stainless Steel Wafer |

|

|

|

|

|

|

|||

YF102 |

1.0" I.D. Stainless Steel Wafer |

|

|

|

|

|

|

|||

YF104 |

1.5" I.D. Stainless Steel Wafer |

|

|

|

|

|

|

|||

YF105 |

2.0" I.D. Stainless Steel Wafer |

|

|

|

|

|

|

|||

YF108 |

3.0" I.D. Stainless Steel Wafer |

|

|

|

|

|

|

|||

YF110 |

4.0" I.D. Stainless Steel Wafer |

|

|

|

|

|

|

|||

|

|

|

|

|

CERTIFICATION |

|

|

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

|

|

|

|

|

|

||

|

-AAD |

Integral, 4-20 mA for intrinsic safety |

|

|

|

|

|

|||

|

-AAR |

Integral, pulse output for intrinsic safety |

||||||||

|

-NNN |

Remote converter |

|

|

|

|

|

|

||

|

|

PROCESS |

CONNECTIONS |

(wafer |

style for mounting between) |

|||||

|

|

B1 |

ANSI 150 lb Wafer Flanges |

|

|

|

|

|

||

|

|

B2 |

ANSI 300 lb Wafer Flanges |

|

|

|

|

|

||

|

|

B3 |

ANSI 600 lb Wafer Flanges |

|

|

|

|

|

||

|

|

|

|

|

|

MATERIALS |

|

|

|

|

|

|

|

A-S3S3*E |

Stainless Steel shedder bar & body |

||||||

|

|

|

|

|

|

CERTIFICATION |

|

|

||

|

|

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

|

|

/HPT |

High temperature |

||||

|

|

|

|

|

/TBL |

Local interface |

||||

|

|

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

|

|

/BLT |

304 SS nuts and bolts |

||||

|

|

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

|

|

|

|

|

|

|

|

|

|

|

IM 1F2B4-01-YIA

Page 9

STAINLESS |

*E |

YEWFLO |

FLANGED 150# |

*E VORTEX FLOWMETERS |

|

|

||

|

|

|

|

|

|

|

|

|

MODEL |

|

YEWFLO *E - |

STAINLESS |

150# |

FLANGE |

|

||||

CODE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

YF101 |

0.5" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF102 |

1.0" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF104 |

1.5" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF105 |

2.0" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF108 |

3.0" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF110 |

4.0" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF115 |

6.0" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF120 |

8.0" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF125 |

10.0" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

YF130 |

12.0" I.D. Stainless Steel 150 lb RF flange |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

CONFIGURATION |

|

|

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

|

|

|

|

|

|

||

|

-AAD |

Integral, 4-20 mA for intrinsic safety |

||||||||

|

-AAR |

Integral, pulse output for intrinsic safety |

||||||||

|

-NNN |

Remote converter |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROCESS |

CONNECTIONS |

|

|

|

||

|

|

A1 |

ANSI 150 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIALS |

|

|

|

|

|

|

|

A-S3S3*E |

Stainless Steel shedder bar & body |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CERTIFICATION |

|

|

||

|

|

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

|

|

/HPT |

High temperature |

||||

|

|

|

|

|

/TBL |

Local interface |

||||

|

|

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

|

|

|

|

|

|

|

|

|

|

|

IM 1F2B4-01-YIA

Page 10

YEWFLO |

*E |

STAINLESS |

|

|

|||

*E VORTEX FLOWMETERS |

FLANGED 300# |

||

|

|||

|

|

|

|

|

|

|

|

|

|

|

MODEL |

|

YEWFLO *E - |

STAINLESS |

300# |

FLANGE |

|

||||

CODE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

YF101 |

0.5" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF102 |

1.0" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF104 |

1.5" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF105 |

2.0" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF108 |

3.0" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF110 |

4.0" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF115 |

6.0" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF120 |

8.0" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF125 |

10.0" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

YF130 |

12.0" I.D. Stainless Steel 300 lb RF flange |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

CONFIGURATION |

|

|

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

|

|

|

|

|

|

||

|

-AAD |

Integral, 4-20 mA for intrinsic safety |

||||||||

|

-AAR |

Integral, pulse output for intrinsic safety |

||||||||

|

-NNN |

Remote converter |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROCESS |

CONNECTIONS |

|

|

|

||

|

|

A2 |

ANSI 300 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIALS |

|

|

|

|

|

|

|

A-S3S3*E |

Stainless Steel shedder bar & body |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CERTIFICATION |

|

|

||

|

|

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

|

|

/HPT |

High temperature |

||||

|

|

|

|

|

/TBL |

Local interface |

||||

|

|

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

|

|

|

|

|

|

|

|

|

|

|

IM 1F2B4-01-YIA

Page 11

STAINLESS |

*E |

YEWFLO |

|

||

FLANGED 600# |

*E VORTEX FLOWMETERS |

|

|

|

|

|

|

|

|

|

|

MODEL |

|

YEWFLO *E - |

STAINLESS |

600# |

FLANGE |

|

||||

CODE |

|

|

|

|

|

|

|

|

|

|

YF101 |

0.5" I.D. Stainless Steel 600 lb RF flange |

|

|

|

|

|

||||

YF102 |

1.0" I.D. Stainless Steel 600 lb RF flange |

|

|

|

|

|

||||

YF104 |

1.5" I.D. Stainless Steel 600 lb RF flange |

|

|

|

|

|

||||

YF105 |

2.0" I.D. Stainless Steel 600 lb RF flange |

|

|

|

|

|

||||

YF108 |

3.0" I.D. Stainless Steel 600 lb RF flange |

|

|

|

|

|

||||

YF110 |

4.0" I.D. Stainless Steel 600 lb RF flange |

|

|

|

|

|

||||

YF115 |

6.0" I.D. Stainless Steel 600 lb RF flange |

|

|

|

|

|

||||

YF120 |

8.0" I.D. Stainless Steel 600 lb RF flange |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

CONFIGURATION |

|

|

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

|

|

|

|

|

|

||

|

-AAD |

Integral, 4-20 mA for intrinsic safety |

||||||||

|

-AAR |

Integral, pulse output for intrinsic safety |

||||||||

|

-NNN |

Remote converter |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROCESS |

CONNECTIONS |

|

|

|

||

|

|

A3 |

ANSI 600 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIALS |

|

|

|

|

|

|

|

A-S3S3*E |

Stainless Steel shedder bar & body |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CERTIFICATION |

|

|

||

|

|

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

|

|

/HPT |

High temperature |

||||

|

|

|

|

|

/TBL |

Local interface |

||||

|

|

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

|

|

|

|

|

|

|

|

|

|

|

IM 1F2B4-01-YIA

Page 12

YEWFLO |

*E |

HASTELLOY C |

|

|

|||

*E VORTEX FLOWMETERS |

WAFER |

||

|

|||

|

|

|

|

|

|

|

|

|

|

|

MODEL |

|

|

YEWFLO |

*E - |

HASTELLOY |

C |

WAFER |

|

||

CODE |

|

|

|

|

|

|

|

|

|

|

YF101 |

0.5" I.D. Hastelloy C Wafer |

|

|

|

|

|

|

|||

YF102 |

1.0" I.D. Hastelloy C Wafer |

|

|

|

|

|

|

|||

YF104 |

1.5" I.D. Hastelloy C Wafer |

|

|

|

|

|

|

|||

YF105 |

2.0" I.D. Hastelloy C Wafer |

|

|

|

|

|

|

|||

YF108 |

3.0" I.D. Hastelloy C Wafer |

|

|

|

|

|

|

|||

YF110 |

4.0" I.D. Hastelloy C Wafer |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

CERTIFICATION |

|

|

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

|

|

|

|

|

|

||

|

-AAD |

Integral, 4-20 mA for intrinsic safety |

|

|

|

|

|

|||

|

-AAR |

Integral, pulse output for intrinsic safety |

||||||||

|

-NNN |

Remote converter |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

PROCESS CONNECTIONS (wafer |

style for mounting between) |

|

||||||

|

|

B1 |

ANSI 150 lb RF flanges |

|

|

|

|

|

||

|

|

B2 |

ANSI 300 lb RF flanges |

|

|

|

|

|

||

|

|

B3 |

ANSI 600 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIALS |

|

|

|

|

|

|

|

A-HCHC*E |

Hastelloy C Shedder wetted parts |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CERTIFICATION |

|

|

||

|

|

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

|

|

/TBL |

Local interface |

||||

|

|

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

|

|

|

|

|

|

|

|

|

|

|

IM 1F2B4-01-YIA

Page 13

HASTELLOY C |

*E |

YEWFLO |

FLANGED 150# |

*E VORTEX FLOWMETERS |

|

|

||

|

|

|

|

|

|

|

|

|

MODEL YEWFLO *E - HASTELLOY C 150# FLANGE

CODE

YF101 0.5" I.D. Hastelloy C 150 lb RF flange

YF102 1.0" I.D. Hastelloy C 150 lb RF flange

YF104 1.5" I.D. Hastelloy C 150 lb RF flange

YF105 2.0" I.D. Hastelloy C 150 lb RF flange

YF108 3.0" I.D. Hastelloy C 150 lb RF flange

YF110 4.0" I.D. Hastelloy C 150 lb RF flange

YF115 6.0" I.D. Hastelloy C 150 lb RF flange

|

|

|

CERTIFICATION |

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

||||||

-AAD |

Integral, 4-20 mA for intrinsic safety |

||||||

-AAR |

Integral, pulse output for intrinsic safety |

||||||

-NNN |

Remote converter |

||||||

PROCESS CONNECTIONS (wafer style for mounting between)

A1 |

ANSI 150 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIALS |

|

|

|

|

|

A-HCHC*E |

Hastelloy C Shedder wetted parts |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

CERTIFICATION |

|

|

||

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

/TBL |

Local interface |

||||

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

|

|

|

|

|

|

|

|

|

IM 1F2B4-01-YIA

Page 14

YEWFLO |

*E |

HASTELLOY C |

|

|

|||

*E VORTEX FLOWMETERS |

FLANGED 300# |

||

|

|||

|

|

|

|

|

|

|

|

|

|

|

MODEL YEWFLO *E - HASTELLOY C 300# FLANGE

CODE

YF101 0.5" I.D. Hastelloy C 300 lb RF flange

YF102 1.0" I.D. Hastelloy C 300 lb RF flange

YF104 1.5" I.D. Hastelloy C 300 lb RF flange

YF105 2.0" I.D. Hastelloy C 300 lb RF flange

YF108 3.0" I.D. Hastelloy C 300 lb RF flange

YF110 4.0" I.D. Hastelloy C 300 lb RF flange

YF115 6.0" I.D. Hastelloy C 300 lb RF flange

|

|

|

CERTIFICATION |

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

||||||

-AAD |

Integral, 4-20 mA for intrinsic safety |

||||||

-AAR |

Integral, pulse output for intrinsic safety |

||||||

-NNN |

Remote converter |

||||||

PROCESS CONNECTIONS (wafer style for mounting between)

A2 |

ANSI 300 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIALS |

|

|

|

|

|

A-HCHC*E |

Hastelloy C wetted parts |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

CERTIFICATION |

|

|

||

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

/TBL |

Local interface |

||||

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

|

|

|

|

|

|

|

|

|

IM 1F2B4-01-YIA

Page 15

NACE MTLS7 |

*E |

YEWFLO |

|

||

WAFER |

*E VORTEX FLOWMETERS |

|

|

|

|

|

|

|

|

|

|

|

|

|

YEWFLO |

*E - |

NACE |

MATERIALS |

WAFER |

|

||

MODEL |

|

|

|

METER SIZES |

|

|

||||

CODE |

|

|

|

|

|

|

|

|

|

|

YF101 |

0.5" I.D. NACE Wafer |

|

|

|

|

|

|

|||

YF102 |

1.0" I.D. NACE Wafer |

|

|

|

|

|

|

|||

YF104 |

1.5" I.D. NACE Wafer |

|

|

|

|

|

|

|||

YF105 |

2.0" I.D. NACE Wafer |

|

|

|

|

|

|

|||

YF108 |

3.0" I.D. NACE Wafer |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

CERTIFICATION |

|

|

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

|

|

|

|

|

|

||

|

-AAD |

Integral, 4-20 mA for intrinsic safety |

|

|

|

|

|

|||

|

-AAR |

Integral, pulse output for intrinsic safety |

||||||||

|

-NNN |

Remote converter |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

PROCESS CONNECTIONS (wafer |

style for mounting between) |

|

||||||

|

|

B1 |

ANSI 150 lb RF flanges |

|

|

|

|

|

||

|

|

B2 |

ANSI 300 lb RF flanges |

|

|

|

|

|

||

|

|

B3 |

ANSI 600 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MATERIALS |

|

|

|

|

|

|

|

A-HCS3*E |

Hastelloy C shedder bar w/stainless steel body |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CERTIFICATION |

|

|

||

|

|

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

|

|

/TBL |

Local interface |

||||

|

|

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

|

|

|

|

|

|

|

|

|

|

|

IM 1F2B4-01-YIA

Page 16

YEWFLO |

*E |

NACE MTLS7 |

|

|

|||

*E VORTEX FLOWMETERS |

FLANGED 150# |

||

|

|||

|

|

|

|

|

|

|

|

|

|

|

MODEL YEWFLO *E - NACE MATERIALS 150# FLANGE

CODE

YF101 0.5" I.D. NACE 150 lb RF Flange

YF102 1.0" I.D. NACE 150 lb RF Flange

YF104 1.5" I.D. NACE 150 lb RF Flange

YF105 2.0" I.D. NACE 150 lb RF Flange

YF108 3.0" I.D. NACE 150 lb RF Flange

|

|

|

CERTIFICATION |

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

||||||

-AAD |

Integral, 4-20 mA for intrinsic safety |

||||||

-AAR |

Integral, pulse output for intrinsic safety |

||||||

-NNN |

Remote converter |

||||||

PROCESS CONNECTIONS

A1 |

ANSI 150 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

MATERIALS |

|

|

|

|

|

A-HCS3*E |

Hastelloy C shedder bar w/stainless steel body |

||||||

|

|

|

|

CERTIFICATION |

|

|

||

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

/TBL |

Local interface |

||||

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

IM 1F2B4-01-YIA

Page 17

NACE MTLS7 |

*E |

YEWFLO |

FLANGED 300# |

*E VORTEX FLOWMETERS |

|

|

||

|

|

|

|

|

|

|

|

|

MODEL YEWFLO *E - NACE MATERIALS 300# FLANGE

CODE

YF101 0.5" I.D. NACE 300 lb RF Flange

YF102 1.0" I.D. NACE 300 lb RF Flange

YF104 1.5" I.D. NACE 300 lb RF Flange

YF105 2.0" I.D. NACE 300 lb RF Flange

YF108 3.0" I.D. NACE 300 lb RF Flange

|

|

|

CERTIFICATION |

|

|

|

|

-AAU |

Integral, 4-20 mA or pulse |

||||||

-AAD |

Integral, 4-20 mA for intrinsic safety |

||||||

-AAR |

Integral, pulse output for intrinsic safety |

||||||

-NNN |

Remote converter |

||||||

PROCESS CONNECTIONS

A2 |

ANSI 300 lb RF flanges |

|

|

|

|

|

||

|

|

|

|

MATERIALS |

|

|

|

|

|

A-HCS3*E |

Hastelloy C shedder bar w/stainless steel body |

||||||

|

|

|

|

CERTIFICATION |

|

|

||

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|||||

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|||||

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|||||

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

|

|

/HART |

HART communications |

||||

|

|

|

/TBL |

Local interface |

||||

|

|

|

/EPF |

Epoxy-coated electronics housing |

||||

|

|

|

/OSW |

Oxygen cleaning |

||||

|

|

|

/SCT |

Stainless Steel tags wired into place |

||||

IM 1F2B4-01-YIA

Page 18

YEWFLO |

*E |

NACE MTLS7 |

|

*E VORTEX FLOWMETERS |

FLANGED 600# |

||

|

|

|

|

|

|

|

|

|

|

|

MODEL YEWFLO *E - NACE MATERIALS 600# FLANGE

CODE

YF101 0.5" I.D. NACE 600 lb RF Flange

YF102 1.0" I.D. NACE 600 lb RF Flange

YF104 1.5" I.D. NACE 600 lb RF Flange

YF105 2.0" I.D. NACE 600 lb RF Flange

YF108 3.0" I.D. NACE 600 lb RF Flange

|

|

CERTIFICATION |

|

-AAU |

Integral, 4-20 mA or pulse |

|

-AAD |

Integral, 4-20 mA for intrinsic safety |

|

-AAR |

Integral, pulse output for intrinsic safety |

|

-NNN |

Remote converter |

|

|

|

PROCESS CONNECTIONS

|

A3 |

ANSI 600 lb RF flanges |

|

||

|

|

|

|

|

MATERIALS |

|

|

A-HCS3*E |

Hastelloy C shedder bar w/stainless steel body |

||

|

|

|

|

|

CERTIFICATION |

|

|

|

/FM F |

FM explosionproof housing w/FM stamp |

|

|

|

|

/FM S |

FM intrinsic safety w/FM stamp |

|

|

|

|

/CSF |

CSA explosionproof housing w/CSA stamp |

|

|

|

|

/CSS |

CSA intrinsic safety w/CSA stamp |

|

|

|

|

|

|

|

|

|

|

|

|

OPTIONS |

|

|

|

|

/HART |

HART communications |

|

|

|

|

/TBL |

Local interface |

|

|

|

|

/EPF |

Epoxy-coated electronics housing |

|

|

|

|

/OSW |

Oxygen cleaning |

|

|

|

|

/SCT |

Stainless Steel tags wired into place |

IM 1F2B4-01-YIA

Page 19

REMOTE |

*E |

YEWFLO |

|

||

CONVERTER |

*E VORTEX FLOWMETERS |

|

|

|

|

|

|

|

|

|

|

MODEL |

|

YEWFLO *E |

- REMOTE |

CONVERTER |

|

|

||||

CODE |

|

|

|

|

|

|

|

|

|

|

YFA11 |

Remote Converter |

|

|

|

|

|

|

|

||

|

|

|

|

CONFIGURATION |

|

|

|

|

|

|

|

-AUPA |

4-20 mA or pulse output |

|

|

|

|

|

|

||

|

-ADPA |