Yokogawa UT35A, UT32A User Manual

Digital Indicating Controller

UTAdvanced

Digital Indicating Controller |

UT75A / UT55A / UT52A / UT35A / UT32A |

|

||||||||

Program Controller |

UP55A / UP35A / UP32A |

|

||||||||

Digital Indicator with Alarms |

UM33A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bulletin 05P01A02-01EN

Reliable and secure lin

Welcome new members: 2-loop and DIN rail models, and the UP32A UP55A

Program Controller

UP35A

UP32A

UT75A

UT55A

UT52A

UT35A

UT32A

Digital Controller

|

UT52A/MDL |

|

UT55A/MDL |

|

Rail Mounting Controller |

|

UT32A/MDL |

UT32A-D |

UT35A/MDL |

(Dual-loop type) |

DIN Rail Mounting Controller |

Con guration and Programming Software

LL50A

UM33A

Digital Indicator with Alarms

2

eup

Tools and |

Operation and |

functions that |

clear display that |

go easy on your |

go easy on the |

equipment |

user |

A variety |

Helpful |

of functions, and |

ladder sequence |

easy-to-connect |

control |

communication |

function |

Reliability • RoHS/WEEE

• NEMA4*/IP66 Front Panel * Hose down

172608

CSA C22.2 61010-1 UL61010-1

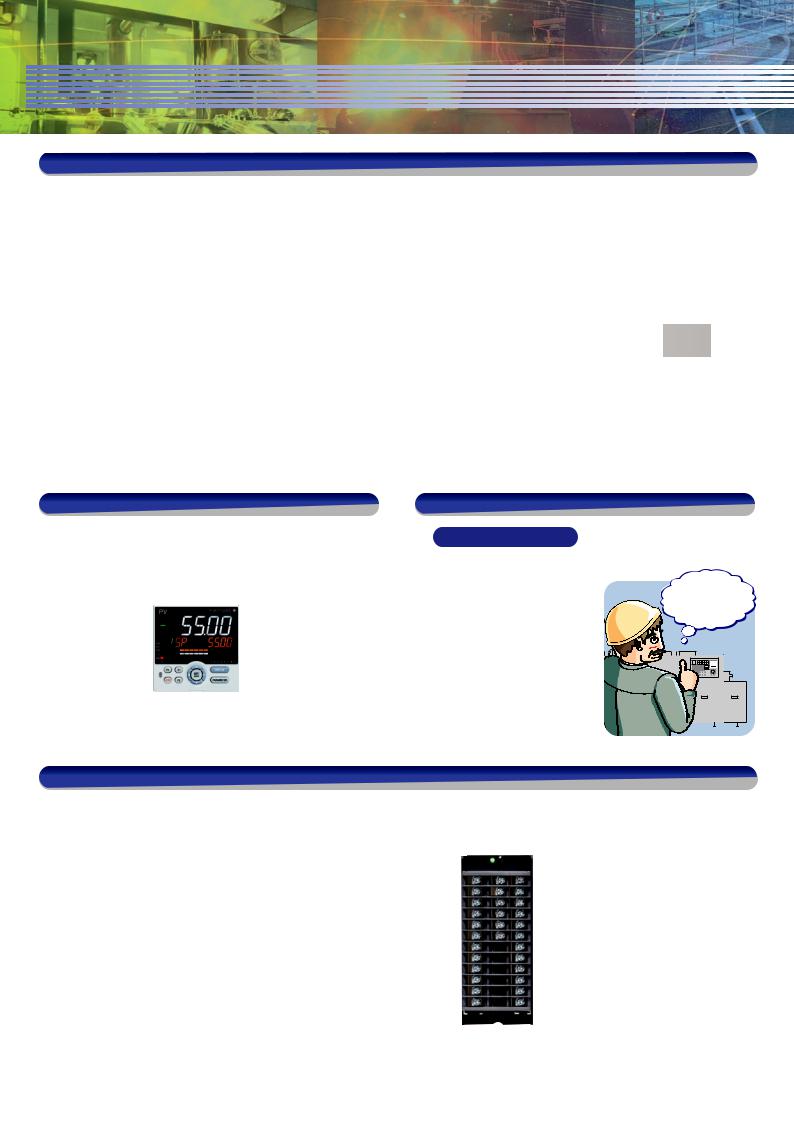

Space saving options

Space saving options

•1/8th DIN 2-loop controller (UT32A-D)

•CC-Link communication available in a 48 x 96 mm (1/8 DIN) size

•1/8th DIN Program controller (UP32A)

•DIN rail mounting controller (/MDL option)

More UP55A program patterns

More UP55A program patterns

• 99 program patterns (/AP option)

3

Tools and functions that go easy on your equipment

Setting and managing parameters

Easily edit settings from a PC while the unit is mounted on the controller board.

Settings are accessed through a dedicated adapter on the front panel. Maintenance of Ethernet-equipped controllers can be handled remotely.

Control board |

(Powered) |

Optical communication adapter and dedicated cable (Light loaderTM)

To USB port

•Set up parameters

•Controller data read/write/compare

•Data management

•Print parameters and data, and create reports

•Con gure user defaults

Set up right out of the box

To USB port

No power cable

required  LL50A Parameter Setting Software

LL50A Parameter Setting Software

Dedicated cable

With DIN rail mountable controllers (/MDL option), used to perform maintenance when powered.

Free software now available on the web for converting GREEN series parameters to UTAdvanced.

Can be supported with a single spare unit

Universal Input and Output

Supports different sensors, heaters, and actuators

TC |

|

mV |

4 to 20 mA current |

V |

|

mA |

Voltage pulse |

|

|

RTD |

Relay contact |

|

2-wire |

|

|

|

|

Motor operated valve* |

|

transmitter |

|

|

|

|

|

|

|

|

|

|

|

|

*Select a position proportional model |

|

|

|

|

|

|

|

|

|

|

|

|

|

for motorized valve control output. |

Universal Inputs |

Universal Control Outputs |

|||||

Gets you back home. Fast.

Shorter recovery time User defaults function

The LL50A lets you con gure user default values.

Ever get lost in a maze of con guration changes? Now you can restore user-personalized default parameters. Recover quickly without disturbing operations.

Easily restored by key operation

Save space on the panel and control board

Side-by-side close mounting on DIN rails in the board

Status display (LED)

Green:Normal

Red: Abnormal

• Ambient temperature: -10 to 50 °C

(0 to 50 °C with CC-Link installed)

DIN rail |

• 2-loop control in a single unit |

(UT32A-D/MDL)

• Displays controller and I/O status

UT32A/MDL

UT52A/MDL

UT32A-D/MDL

4

Operation and clear display that go easy on the user

Bright & Easy to Read Active Color LCD Display

Full size

PV display

(text height: 21.55 mm)

5

digit display

14

segment display

UT55A 1/4 DIN (96×96mm)size |

UT52A 1/8 DIN (48×96mm)size |

Active Color PV Display

See the status of your process conditions INSTANTLY!

Normal According to… |

|

• Alarms |

Alarm |

• Deviation values |

|

Display color changes! |

|

• Measured values |

|

• Contact input |

|

|

|

• Choice of xed white or red

Navigation guides and keys make it easy to operate |

Fast one-touch operations |

Controller will guide the key you press. |

Programmable Function Keys |

Navigation Guide

Navigation Keys

You can assign frequently used operations (start/stop, remote/local, etc.) and parameter entry screens (PID value, etc.) to function keys for one-touch availability.

Move freely (up/down/left/right)

between parameters!

UT series

5

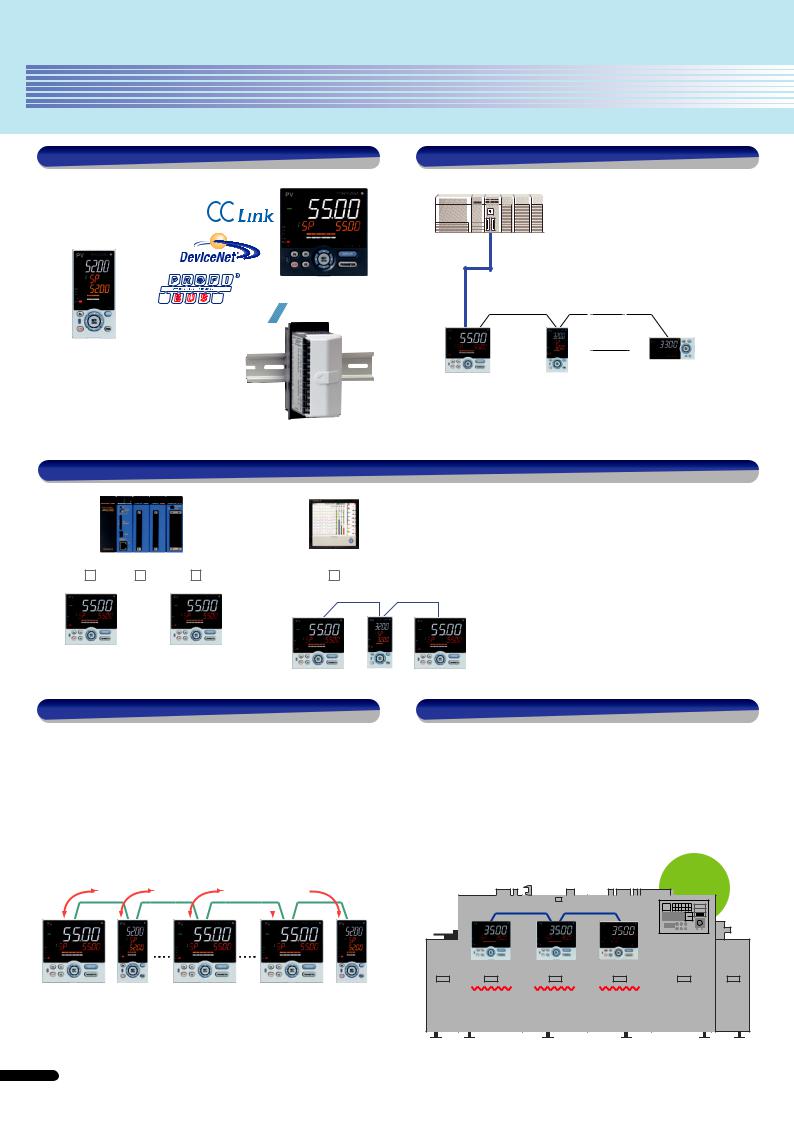

A variety of functions, and easy-to-connect communication

Communication protocol

Connect to PLCs easily without programming!

programming!

Modbus/TCP

Modbus

RTU/ASCII

Ladder communication

PC-Link

Open Network

PLC • Recipe management

• Remote monitoring

DeviceNet

You can easily set setpoints (SP),

PID, and alarms from a PLC.

Serial gateway function |

Modbus slave |

UTAdvanced with RS-485 communication

Space-saving built-in CC-Link models

• UT52A, UT32A, UM33A, UT52A/MDL, UT32A/MDL

Modbus/TCP

|

|

|

|

|

|

|

|

|

FA-M3V |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SMARTDAC+ |

|

|

|

|

|

|

|

|

|

PLC |

|

|

GX10/GX20 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ethernet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ethernet-serial Gateway Function |

RS-485 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Modbus TCP, a protocol that allows the controller to connect to Ethernet network and have the ability to exchange data with the computers or devices on that network.

•Gateway function allows RS-485 Modbus devices to communicate via Ethernet.

•Physical layer: 10 BASE-T/100 BASE-TX

•Max. number of connection : 2

UTAdvanced with RS-485 communication

Peer to Peer

The use of the ladder sequence program makes it possible to exchange analog data and status data between communication-capable UTs.

Example: A UT in which an input error occurs sends a signal to another UT to enable that UT switch to MAN operation, thus shifting the whole system into a safe mode. In such a case, the safety mechanism can be built into the UTAdvanced and is not required in the host system.

* Create ladder sequence programs by the LL50A Parameter Setting software (sold separately).

RS485

RS485

1 |

2 |

4 |

15 |

32 |

Up to 4 master units, total 32 units

Coordinated operation

Coordinated operation: This function syncs operation of the slave with that of the master through Yokogawa's proprietary communication protocol.

•Finely adjust the temperature setting of the slave with the bias and ratio

•Upstream PLC or other device not needed for tuning

•No programming means fewer engineering manhours

|

|

Continuous |

|

|

furnace |

|

RS-485 |

|

Slave UT35A |

Slave UT35A |

Master UP35A |

Zone 3 |

Zone 2 |

Zone 1 |

SP is zone 1 |

SP is zone 1 |

SP is programmed |

SP minus 5 °C |

SP plus 10 °C |

|

6

Loading...

Loading...