Whirlpool AGS 836, AGS 840, AGS 848, AGS 844, AGS 846 TECHNICAL SERVICE MANUAL

...WHIRLPOOL (R404a)

TECHNICAL SERVICE MANUAL

ICE CUBE MAKERS

MODELS:

WHIRLPOOL AGS 836/837

WHIRLPOOL AGS 838/839

WHIRLPOOL AGS 840/841

WHIRLPOOL AGS 842/843

WHIRLPOOL AGS 844/845

WHIRLPOOL AGS 846/847

WHIRLPOOL AGS 848/849

MODULARS:

WHIRLPOOL AGS 850/851 (MODULAR 200)

CAREFULLY READ THE INSTRUCTIONS CONTAINED IN THIS MANUAL SINCE THEY PROVIDE IMPORTANT INFORMATION RELATIVE TO SAFETY DURING INSTALLATION, USE, AND MAINTENANCE.

EDITION:

NOVEMBER 2006.

COD: WHP02MTIN.DOC

1

TABLE OF CONTENTS |

|

Introduction |

|

Warnings............................................................................................................................................................ |

3 |

Description......................................................................................................................................................... |

4 |

Operating Principles........................................................................................................................................... |

5 |

Specifications |

|

Diagrams of connections and dimensions (undercounter models) ..................................................................... |

6 |

Consumption data, weights, crated dimensions and volumes (undercounter models)........................................ |

8 |

Technical data (undercounter models) ............................................................................................................. |

10 |

Production Tables ............................................................................................................................................ |

11 |

Delivery & Unpacking |

|

Packing............................................................................................................................................................. |

13 |

Rating plate and serial number......................................................................................................................... |

13 |

Installation |

|

Recommended placement of unit ..................................................................................................................... |

14 |

Water and drainage .......................................................................................................................................... |

14 |

Connecting unit to water source....................................................................................................................... |

15 |

Connecting unit to drain................................................................................................................................... |

15 |

Electrical connection........................................................................................................................................ |

15 |

Operation principle |

|

Preliminary check ............................................................................................................................................ |

17 |

Cross check ...................................................................................................................................................... |

17 |

Adjustment |

|

Water level....................................................................................................................................................... |

18 |

Water pressure control valve............................................................................................................................ |

18 |

Pressure control................................................................................................................................................ |

19 |

Safety pressostat............................................................................................................................................... |

19 |

Maintenance and cleaning instructions |

|

Maintenance table ............................................................................................................................................ |

20 |

Water condenser .............................................................................................................................................. |

21 |

Air condenser................................................................................................................................................... |

21 |

Evaporator / water deposit ............................................................................................................................... |

21 |

Inlet filters........................................................................................................................................................ |

22 |

Special advice concerning r-404 refrigerant .................................................................................................... |

23 |

Troubleshooting ........................................................................................................................................................ |

24 |

2

INTRODUCTION

Thank you for choosing Whirlpool ice cube makers.

You have purchased one of the most reliable ice-making products on the market today. Carefully read the instructions contained in this manual since they provide important information relative to safety during installation, use, and maintenance.

WARNINGS

This appliance should be installed by approved Technical Service Personnel.

This plug should be accessible at all times.

To reduce the risk of electrical shock, ALWAYS disconnect the machine BEFORE cleaning or maintaining the equipment. Do not attempt to install, service, or modify this machine. Improper use by other than specially trained technicians is extremely dangerous and may result in a fire or electric shock.

This machine should not be placed outdoors or exposed to rain. Connect to drinking water mains.

This appliance is not intended for use by young children or infirm persons without supervision. Young children should be supervised to ensure that they do not play with the appliance.

IMPORTANT!

• DO NOT ATTEMPT TO SERVICE THIS MACHINE AS IT IS DANGEROUS AND COULD CAUSE SEVERE DAMAGE TO THE UNIT.

•SERVICE SHOULD ONLY BE CARRIED OUT BY TRAINED, CERTIFIED PERSONNEL.

•WE STRONGLY RECOMMEND USING ONLY ORIGINAL REPLACEMENT PARTS AVAILABLE FROM AN AUTHORIZED DISTRIBUTOR.

•WASTE AND OTHER MATERIAL SHOULD BE DISPOSED OF ACCORDING TO LOCAL REGULATIONS AND PROCEDURES FOR WASTE DISPOSAL.

•CLEANING AND MAINTENANCE ARE NOT COVERED BY THE WARRANTY.

3

DESCRIPTION

The ice cubes maker is the result of years of experience in this field and the development of a high technology factory.

Main Features

∙Storage bin made of polyester strengthened with glass fibre or ABS

∙Stock bin made of high resistance plastic materials

∙Polyurethane insulation injected “IN SITU”

∙Heavy duty door (pat.) except AGS 836/837/838/839 and 850/851.

∙Agitator motor for continuous service

∙Tough cam motor (50 Kg/cm)

∙Safety device and clutch for the water pan preventing its breakage during the upward cycle, (pat.)

∙Machine stoppage and water pan protection during the downward cycle, (pat.)

∙The stock ice is the maximum than it could be thanks to the stop machine system.

∙Low noise

∙High pressure safety pressostats even in air-cooled machine.

∙Large condensers (work well at high ambient temperatures; and reduce cooling water consumption in water-cooled machines).

∙Clear cubes.

∙Ices Cubes can be adjusted (height and diameter).

∙Easy to maintain and repair.

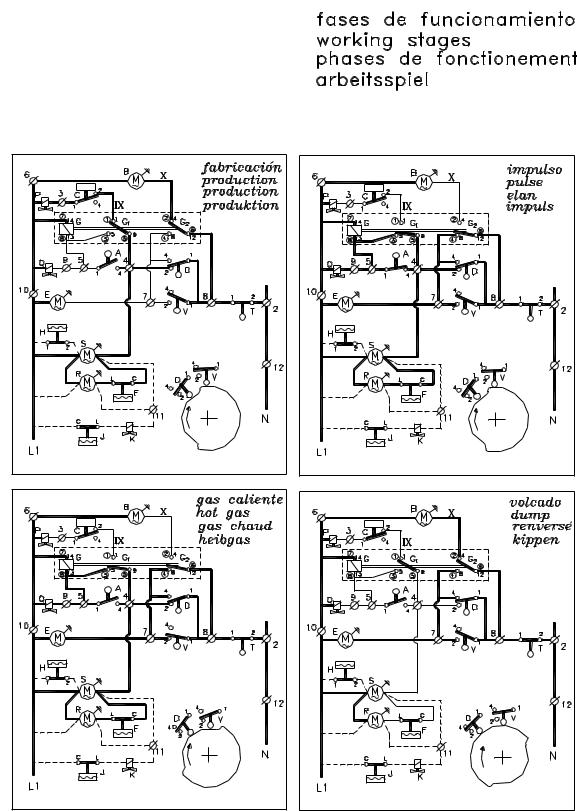

HOW IT WORKS

When the machine is switched on the compressor and the agitator motor start, the water entry valve opens and allows water into the production pan up to a level where the float makes a micro-switch cut the current to the valve and so stop water entering the tray. The compressor, controlled by capillaries produces enough cold in the evaporator to gradually freeze the water around its “fingers”.

When the ice so formed reaches the proper size the paddles of the agitator are stopped and its motor, suspended, works the end of cycle micro-switch.

This micro-switch connects the relay that starts the cam motor. When the micro-switch has fallen, opens the hot gas valve and stops the agitator motor. The compressor continues working for another 20”, then stops, and the agitator motor is connected. The cam motor starts to move downwards, making part of the surplus water flow to the drain, and dropping the ice cubes, pushed by the ejection plate into the storage bin.

The pan eventually gets back to its initial position and so starts another production cycle.

Once the storage bin is full the pan stops in its downward movement as it touches the cubes, so working the safety stop micro-switch and switching off the machine. Production will start again as soon as the cubes which detained it move or are removed.

4

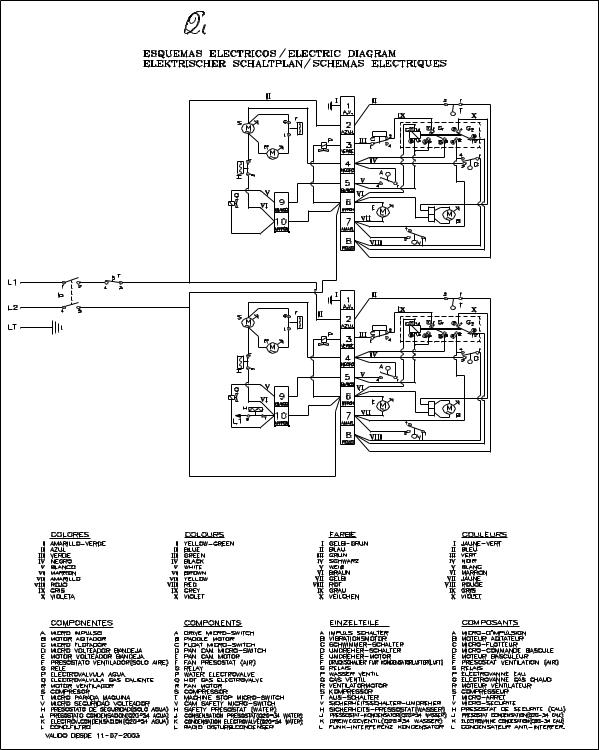

WHIRLPOOL

5

WHIRLPOOL AGS |

6

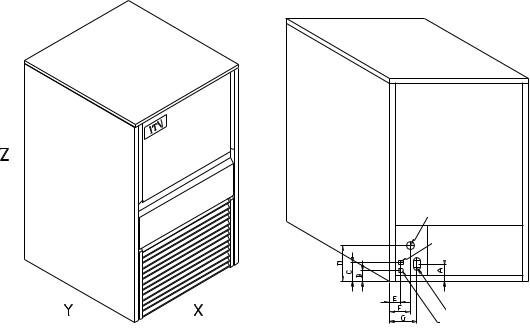

SPECIFICACIONS

Models: WHIRLPOOL AGS 836….849

Water

entry

entry

Electrical connection

Bin drain

Cooling

water

water

* HEIGHT Z REPRESENTS MINIMUM MACHINE HEIGHT. IF LEGS ARE PLACED UNDER MACHINE, THEN ADD AN EXTRA 80 MM.*

MODEL |

X |

Y |

Z |

A |

B |

C |

D |

E |

F |

G |

WHP AGS 836/837 |

405 |

510 |

690 |

60 |

35 |

65 |

123 |

45 |

65 |

105 |

WHP AGS 838/839 |

405 |

510 |

745 |

60 |

35 |

65 |

123 |

45 |

65 |

105 |

WHP AGS 840/841 |

405 |

510 |

870 |

60 |

35 |

65 |

123 |

45 |

65 |

105 |

WHP AGS 842/843 |

515 |

555 |

870 |

60 |

42 |

74 |

123 |

65 |

75 |

105 |

WHP AGS 844/845 |

595 |

555 |

995 |

60 |

42 |

74 |

123 |

65 |

75 |

105 |

WHP AGS 846/847 |

675 |

555 |

995 |

60 |

42 |

74 |

123 |

65 |

75 |

105 |

WHP AGS 848/849 |

845 |

555 |

995 |

60 |

42 |

74 |

123 |

65 |

75 |

105 |

7

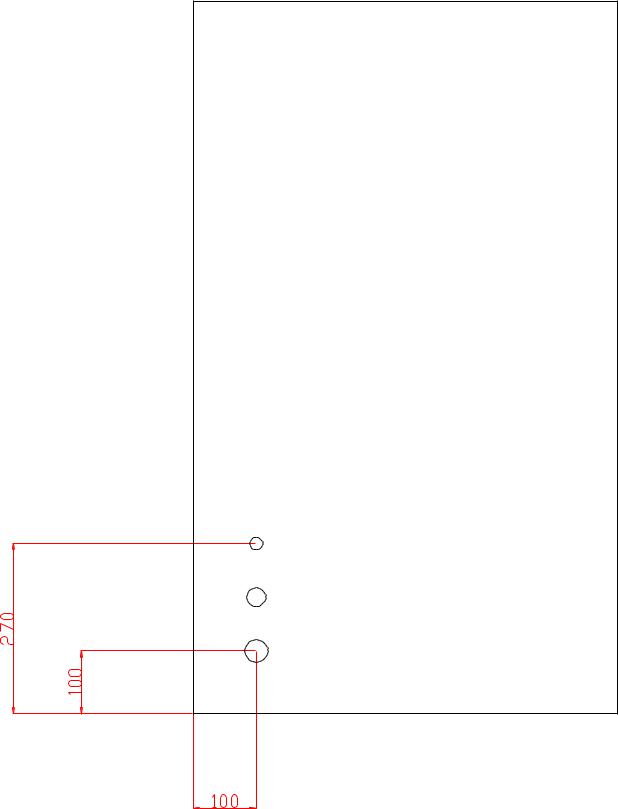

WHIRLPOOL AGS |

850-851 |

ELECTRICAL CONNECTION |

STOCK THERMOSTAT |

WATER INLET |

8

Loading...

Loading...