Toyota Camry 2007-2009 Service Manual - Engine_Immobiliser

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–1 |

|

ENGINE IMMOBILISER SYSTEM (w/ Smart Key System)

PRECAUTION

1. PRECAUTIONS WHEN USING INTELLIGENT TESTER

(a) When using the intelligent tester to troubleshoot the smart access system: Connect the intelligent tester to the DLC3 while the engine switch off, and turn a door courtesy light switch on and off at 1.5-second intervals until communication between the tester and vehicle begins.

2. PRECAUTIONS FOR EACH FUNCTION |

|

|

(a) Precautions for the electrical key: |

|

|

The electrical key is a precision instrument. Be sure |

|

|

to observe the following: |

|

|

(1) |

Do not drop or strike the electrical key. |

|

(2) |

Do not allow the electrical key to be kept in a |

|

|

high temperature place for a long time. |

|

(3) |

Do not use an ultrasonic washing machine to |

|

|

clean the electrical key. |

|

(4) |

Keep the electrical key away from magnets or |

|

|

magnetized items during use. |

|

(5) |

Do not attach any stickers to the electrical key. |

|

(b) Precautions for the engine start function: |

|

|

(1) |

Before starting the engine, firmly depress the |

|

|

brake pedal until the indicator of the engine |

|

|

switch illuminates in green. |

|

(2) |

Be sure to turn the engine switch off before |

|

|

disconnecting the negative (-) battery terminal. |

|

|

When the battery terminal is disconnected, the |

|

|

power source mode (off, on (ACC), on (IG)) will |

|

|

remain in memory. When the vehicle's battery |

EI |

|

becomes discharged, be careful to remember |

|

the power source mode.

(3)After the battery is removed and reinstalled, be sure to wait 10 seconds or more before the next engine start. The engine may not start immediately after the battery is reinstalled.

(c)Precautions for the battery built into the electrical key and the vehicle battery:

(1)When the doors are locked (locked state), signals are emitted by the vehicle at a predetermined interval. If the vehicle were to remain parked for a long time, the vehicle battery could become discharged. To prevent this, periodically charge the vehicle battery, or disable the entry and start system.

EI–2 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

|

|

(2) When the doors are locked (locked state), and |

|

the electrical key remains in the door oscillator |

|

detection area, the system will maintain periodic |

|

communication with the electrical key. If the |

|

vehicle remains parked in this state for a long |

|

time, the vehicle and key batteries could |

|

become discharged. If the vehicle is not being |

|

used, keep the electrical key at least 2 m (6.56 |

|

ft) from the vehicle. |

EI

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–3 |

|

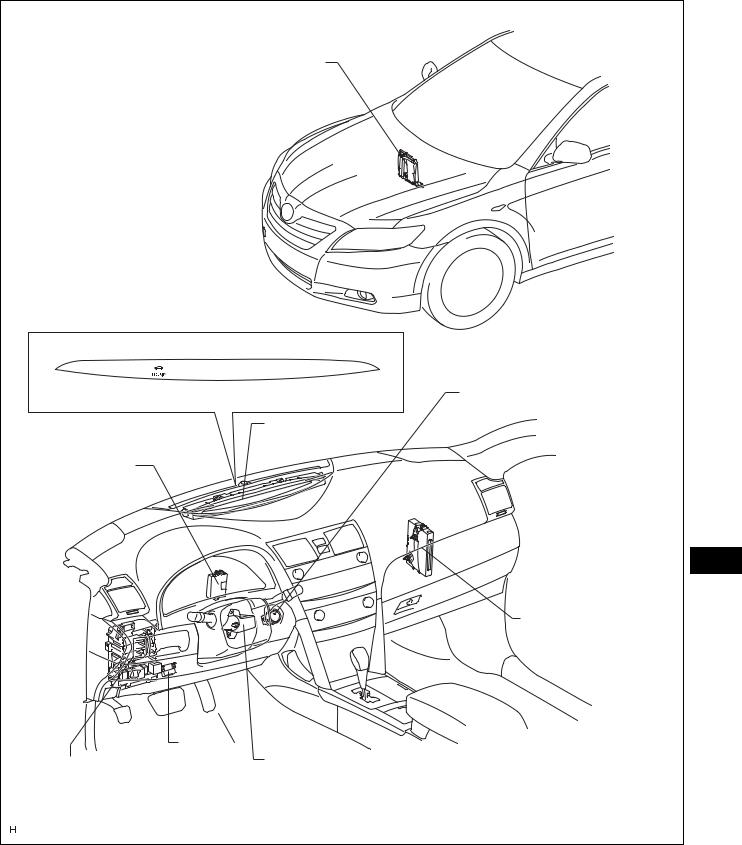

PARTS LOCATION

|

ECM |

SECURITY INDICATOR LIGHT: |

|

|

ENGINE SWITCH |

|

CLOCK |

ID CODE BOX |

|

|

EI |

|

CERTIFICATION ECU |

DLC3 |

|

MAIN BODY ECU |

STREEING LOCK ECU |

|

|

|

B128351E01 |

EI–4 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

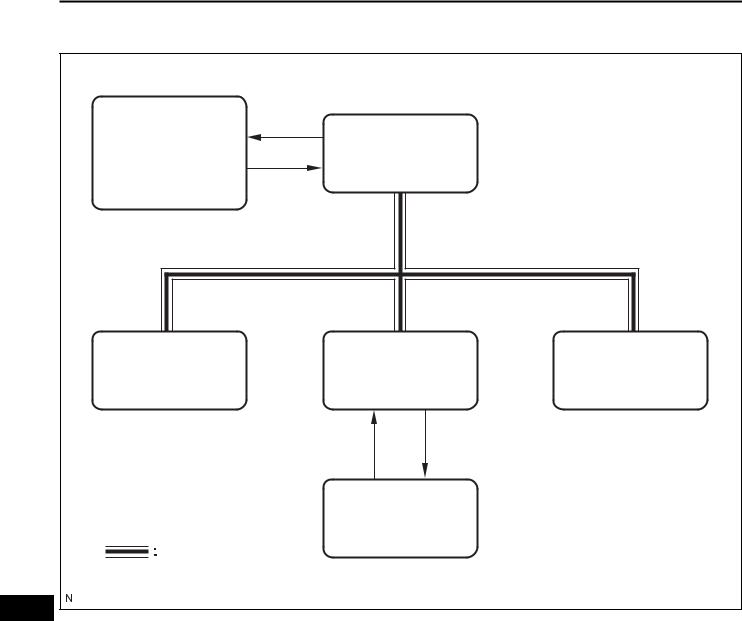

SYSTEM DIAGRAM

Enigine Switch |

|

|

- Transponder Key |

Certification ECU |

|

Amplifier (with Key Coil) |

|

|

|

|

|

Main Body ECU |

ID Code Box |

Steering Lock ECU |

|

ECM |

|

LIN Communication Line |

|

|

EI Communication table: |

|

B128344E02 |

|

|

Transmitting ECU (Transmitter) |

Receiving ECU (Receiver) |

Signals |

Communication method |

|

|

|

|

|

|

Main body ECU |

Certification ECU |

Key code recognition signal |

LIN |

|

|

|

|

|

|

ID code box |

Certification ECU |

DTC (B2791) signal |

LIN |

|

|

|

|

|

|

|

|

• Steering lock release signal |

|

|

ID code box |

Steering lock ECU |

• Matching request random |

LIN |

|

|

|

number signal |

|

|

|

|

|

|

|

ID code box |

Certification ECU |

Matching request random number |

LIN |

|

signal |

||||

|

|

|

||

|

|

|

|

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–5 |

|

SYSTEM DESCRIPTION

1. ENGINE IMMOBILISER SYSTEM DESCRIPTION

(a) The immobiliser system is a theft deterrent system

|

|

that determines whether to disable starting of the |

|

|

|

|

SFI system based on a comparison of the key's ID |

|

|

|

|

codes and the vehicle's pre-registered code. The |

|

|

|

|

immobiliser system compares the vehicle |

|

|

|

|

certification ECU's pre-registered ID code with the |

|

|

|

|

ID of the key-embedded transponder chip. If the ID |

|

|

|

|

codes do not match, the immobiliser system |

|

|

|

|

activates and the SFI system cannot be started. The |

|

|

|

|

certification ECU manages communication with the |

|

|

|

|

ECM, main body ECU, steering lock ECU and ID |

|

|

|

|

code box. When the ID codes of the transponder |

|

|

|

|

chip and certification ECU match, the certification |

|

|

|

|

ECU authorizes the SFI system to start. |

|

|

2. FUNCTION OF MAIN COMPONENT |

|

|||

|

|

|

|

|

Component |

|

Outline |

|

|

|

|

|

|

|

Transponder key coil/amplifier (built into engine switch) |

|

Receives key ID code, amplifies ID code and outputs the code to the |

|

|

|

certification ECU. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transmits key detection signals within the detection area in the vehicle |

|

|

|

|

interior upon receiving a transmission request signal from the |

|

|

Indoor electrical key oscillator |

|

certification ECU. |

|

|

|

|

Certification ECU request signal is activated when the key is brought |

|

|

|

|

into the vehicle interior and the engine switch is pushed. |

|

|

|

|

|

|

|

Door control receiver |

|

Receives an ID code from the key in the actuation area and transmits |

|

|

|

it to the certification ECU. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Security indicator |

|

Illuminates or starts flashing. |

|

|

|

Illumination is controlled by the certification ECU. |

|

|

|

|

|

|

|

|

|

|

|

|

|

3. |

SYSTEM FUNCTION |

|

||

|

(a) Using entry function |

|

||

|

|

(1) When the driver (or passenger) is sitting in the |

|

|

|

|

vehicle while carrying the key, and the engine |

|

|

|

|

switch is pressed while the brake pedal is |

|

|

|

EI |

|||

|

|

depressed, the main body ECU recognizes that |

||

|

|

|||

the engine start operation has occurred and sends a certification request signal to the certification ECU. Upon receipt of the certification request signal, the certification ECU sends a request signal to the indoor electrical key oscillator. Upon receipt of the request signal, the indoor electrical key oscillator sends a request signal to detect if the key is inside the vehicle. When the key receives this request signal, it answers by sending an ID code containing a response code through the glass antenna to the door control receiver. Upon receipt of the ID code, the certification ECU analyzes the code. If the interior certification passes, then the main body ECU sends a certification pass response signal. When the main body ECU receives this signal, the ACC relay is switched on and the IG1 and IG2 relays are switched on in sequence. At this time, the

|

|

EI–6 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

|

|

|

|

|

|

engine switch indicator illuminates in green. |

|

|

|

Then the certification ECU checks that the |

|

|

|

power source mode has been changed and |

|

|

|

sends a steering lock command signal to the |

|

|

|

main body ECU. After receiving this signal, the |

|

|

|

main body ECU supplies power to the steering |

|

|

|

lock actuator. Then (via the ID code box) the |

|

|

|

steering lock ECU confirms that the certification |

|

|

|

ECU is certified and drives the steering actuator |

|

|

|

motor until the steering lock is unlocked. After |

|

|

|

unlocking the steering lock, an unlock completed |

|

|

|

signal is sent to the certification ECU. Upon |

|

|

|

receipt of this signal, the certification ECU sends |

|

|

|

an unset command signal to the ID code box. |

|

|

|

Once this signal is received, the ID code box |

|

|

|

confirms that the certification ECU is certified, |

|

|

|

sends an immobiliser unset command signal to |

|

|

|

the ECM and sends a security indicator light off |

|

|

|

signal to the certification ECU. |

|

|

|

(b) Not using the entry function (when key battery is |

|

|

|

depleted) |

|

|

|

(1) When the driver is sitting in the vehicle while |

|

|

|

carrying the key and the brake pedal is |

|

|

|

depressed, the main body ECU recognizes that |

|

|

|

the stop light switch is on and sends a key |

|

|

|

confirmation request signal to the certification |

|

|

|

ECU. Upon receipt of this signal, the certification |

|

|

|

ECU drives the immobiliser amplifier built in the |

|

|

|

engine switch. At this time, the engine switch |

|

|

|

sends an RF wave communication signal to the |

|

|

|

immobiliser. If the driver holds the key up to the |

|

|

|

engine switch at this time, the engine switch |

|

|

|

receives the immobiliser RF wave signal and |

|

|

|

responds by sending a radio wave signal. When |

EI |

|

|

|

|

|

the engine switch receives the radio wave signal |

|

|

|

|

from the key, it duplicates the signal and sends |

|

|

|

an ID code to the certification ECU. Upon receipt |

|

|

|

of the ID code, the code is analyzed. If the |

|

|

|

certification passes, a key certification pass |

|

|

|

response signal is sent to the main body ECU |

|

|

|

while simultaneously sending a sound buzzer |

|

|

|

request signal to the meter ECU. When the main |

|

|

|

body ECU receives this signal, the ACC relay is |

|

|

|

switched on and the IG1 and IG2 relays are |

|

|

|

switched on in sequence. At this time, the |

|

|

|

engine switch indicator illuminates in green. |

|

|

|

Then the certification ECU checks that the |

|

|

|

power source mode has been changed and |

|

|

|

sends a steering lock command signal to the |

|

|

|

main body ECU. After receiving this signal, the |

|

|

|

main body ECU supplies power to the steering |

|

|

|

lock actuator. Then (via the ID code box) the |

|

|

|

steering lock ECU confirms that the certification |

|

|

|

ECU is certified and drives the steering actuator |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–7 |

|

motor until the steering lock is unlocked. After unlocking the steering lock, an unlock completed signal is sent to the certification ECU. Upon receipt of this signal, the certification ECU sends an unset command signal to the ID code box. Once this signal is received, the ID code box confirms that the certification ECU is certified, sends an immobiliser unset command signal to the ECM and sends a security indicator light off signal to the certification ECU.

EI

EI–8 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

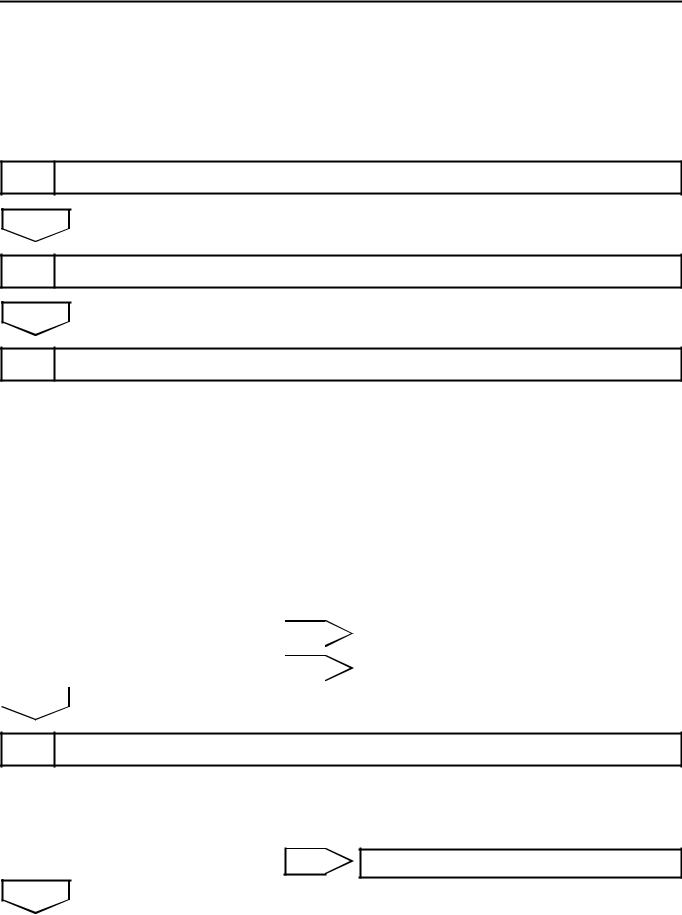

HOW TO PROCEED WITH TROUBLESHOOTING

HINT:

• Use the following procedures to troubleshoot the engine immobiliser system.

• The intelligent tester should be used in steps 3 and 5.

1 VEHICLE BROUGHT TO WORKSHOP

NEXT

2CRANK ENGINE FOR MORE THAN 10 SECONDS

NEXT

3CHECK FOR DTCS

(a)Check for DTCs and note any codes that are output (see page EI-24).

(b)Delete the DTCs.

(c)Recheck for DTCs. Based on the DTCs output above, try

to duplicate the SFI system DTC or engine immobiliser system DTC by simulating the symptoms indicated by the DTC.

Result

|

|

|

Result |

|

|

Proceed to |

||

|

|

|

|

|

|

|||

|

|

DTC output does not reoccur |

|

|

A |

|||

|

|

|

|

|

|

|||

|

|

SFI system DTC output reoccurs |

|

|

B |

|||

|

|

Engine immobiliser system DTC output reoccurs |

|

|

C |

|||

EI |

||||||||

|

|

|

B |

|

|

|

||

|

|

|

|

|

|

GO TO SFI SYSTEM |

||

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

GO TO DTC CHART |

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|||

4 PROBLEM SYMPTOMS TABLE

(a)If the fault is not listed on the problem symptoms table, proceed to A.

(b)If the fault is listed on the problem symptoms table, proceed to B.

B GO TO STEP 6

A

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–9 |

|

5OVERALL ANALYSIS AND TROUBLESHOOTING

(a)DATA LIST/ACTIVE TEST (See page EI-24)

(b)TERMINALS OF ECU (See page EI-15)

NEXT

6ADJUST, REPAIR OR REPLACE

NEXT

7CONFIRMATION TEST

NEXT

END

EI

EI–10 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

REGISTRATION

1.DESCRIPTION OF CODE REGISTRATION

HINT:

•ID codes are the same as recognition codes for the wireless transmitter and the engine immobiliser function. Registering an ID code enables the smart access system with push-button start, the wireless door lock control function and the engine immobiliser function to be operated.

•Code registration is needed when the certification ECU, ID code box, steering lock ECU or key is

replaced with a new one.

(a) PROCEDURE "1"

The vehicle with the smart access system with push-button start system does not have a key slot. Therefore, hold the key close to the engine switch to register the key, as shown in the illustration below.

Hold the key with its ornament surface within a range of 10 mm (0.39 in.) or less from the engine switch.

Communication distance: 10 mm (0.39 in.) or less from the engine switch. |

|

|

Engine Switch |

Key |

Key |

EI

TOYOTA Mark (Ornament Surface) |

TOYOTA Mark (Ornament Surface) |

B139204E01

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–11 |

|

2.PART REPLACEMENT KEY REGISTRATION

(a)The following table shows ECU replacement and key registration procedures in case the malfunctioning ECU has been identified after troubleshooting the smart access system with pushbutton start.

HINT:

•The following procedures indicated in the table below require the use of the intelligent tester:

New key ID registration Additional key ID registration Key ID erasure

ECU code registration

•If all of the registered keys are not available, replacement of the ID code box is also required.

•A maximum of 7 keys can be registered.

Part to be replaced |

Condition |

|

Procedure |

Reference |

|

||

|

|

|

|

|

|

|

|

|

|

|

1. |

Replace certification ECU |

- |

|

|

|

Customer has brought all keys |

|

|

|

|

||

|

2. Reregister all keys (new key ID |

PROCEDURE "B" |

|

|

|||

|

|

|

registration) |

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

1. |

Erase key codes (key ID erasure) |

PROCEDURE "D" |

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

Perform additional key registration |

PROCEDURE "C" |

|

|

|

|

|

procedure (additional key ID registration) |

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Key ID codes can be |

3. |

Replace certification ECU |

- |

|

|

|

|

|

|

|

|

|

|

|

|

4. Reregister all keys (new key ID |

|

|

|

||

|

|

registered and erased |

|

|

|

||

|

|

|

registration) |

|

|

|

|

|

|

|

HINT: |

PROCEDURE "B" |

|

|

|

|

|

|

If some keys are not registered during above |

|

|||

|

|

|

|

|

|

||

|

|

|

steps, they will be disabled because they |

|

|

|

|

Certification ECU |

|

|

cannot be registered later |

|

|

|

|

|

|

|

|

|

|

|

|

|

Some keys are lost |

|

1. |

Replace certification ECU |

- |

|

|

|

|

|

|

|

|

|

|

|

|

2. |

Replace ID code box |

- |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

3. |

Reregister all keys (new key ID |

|

|

|

|

|

|

registration) |

|

|

|

|

|

|

|

HINT: |

|

|

|

|

|

|

Key ID codes cannot |

|

|

EI |

||

|

|

If key codes cannot be erased or additional |

|

|

|||

|

|

be either registered or |

keys cannot be registered due to a |

PROCEDURE "A" |

|

||

|

|

|

|||||

|

|

erased |

malfunction in certification ECU, replace ID |

|

|||

|

|

|

|

|

|||

|

|

|

code box and certification ECU. If some keys |

|

|

|

|

|

|

|

are not registered during above steps, they |

|

|

|

|

|

|

|

will be disabled because they cannot be |

|

|

|

|

|

|

|

registered later |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. |

ECU communication ID registration |

PROCEDURE "F" |

|

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Replace ID code box |

- |

|

|

|

|

|

|

|

|

|

|

|

At least 1 key is available |

2. |

Register recognition codes in ECUs (ECU |

PROCEDURE "E" |

|

|

|

|

code registration) |

|

|||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

3. |

ECU communication ID registration |

PROCEDURE "F" |

|

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Replace ID code box |

- |

|

|

|

|

|

|

|

|

|

|

ID code box |

|

|

2. |

Replace certification ECU |

- |

|

|

|

|

|

|

|

|

|

|

|

|

3. |

Reregister all keys (new key ID |

|

|

|

|

|

|

|

|

|

|

||

|

All keys are lost |

registration) |

|

|

|

||

|

HINT: |

PROCEDURE "A" |

|

|

|||

|

|

|

If some keys are not registered during above |

|

|||

|

|

|

|

|

|

||

|

|

|

steps, they will be disabled because they |

|

|

|

|

|

|

|

cannot be registered later |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. |

ECU communication ID registration |

PROCEDURE "F" |

|

|

|

|

|

|

|

|

|

|

EI–12 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

||||

|

|||||

|

|

|

|

|

|

Part to be replaced |

Condition |

|

Procedure |

Reference |

|

|

|

|

|

|

|

|

|

|

1. |

Replace steering lock ECU |

- |

|

|

Customer has brought at least 1 key |

|

|

|

|

|

2. Register recognition codes in ECUs (ECU |

PROCEDURE "E" |

||

|

|

|

code registration) |

||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

1. |

Replace steering lock ECU |

- |

|

|

|

|

|

|

|

|

|

2. |

Replace certification ECU |

- |

|

|

|

|

|

|

Steering lock ECU |

|

3. |

Replace ID code box |

- |

|

|

|

|

|

||

|

4. |

Reregister all keys (new key ID |

|

||

|

|

|

|

||

|

|

All keys are lost |

registration) |

|

|

|

|

|

HINT: |

PROCEDURE "A" |

|

|

|

|

If some keys are not registered during above |

||

|

|

|

|

||

|

|

|

steps, they will be disabled because they |

|

|

|

|

|

cannot be registered later |

|

|

|

|

|

|

|

|

|

|

|

5. |

ECU communication ID registration |

PROCEDURE "F" |

|

|

|

|

|

|

Main body ECU |

|

No condition required |

Replace main body ECU |

- |

|

|

|

|

|

|

|

ECM |

|

No condition required |

1. |

Replace ECM |

- |

|

|

|

|

||

|

2. |

ECU communication ID registration |

PROCEDURE "F" |

||

|

|

|

|||

|

|

|

|

|

|

|

|

|

1. |

Using remaining key, erase lost key code |

PROCEDURE "D" |

|

|

|

(key ID erasure) |

||

|

|

Customer has brought at least 1 key |

|

||

|

|

|

|

|

|

|

|

2. |

Register additional keys as necessary |

PROCEDURE "E" |

|

|

|

|

|||

|

|

|

(additional key ID registration) |

||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

1. |

Replace certification ECU |

- |

|

|

|

|

|

|

Key |

|

|

2. |

Replace ID code box |

- |

|

|

|

|

|

|

|

|

|

3. |

Register all keys (new key ID registration) |

|

|

|

All keys are lost |

HINT: |

PROCEDURE "A" |

|

|

|

If customer brings lost keys at later date, they |

|||

|

|

|

|||

|

|

|

can be registered using additional key ID |

|

|

|

|

|

registration function |

|

|

|

|

|

|

|

|

|

|

|

4. |

ECU communication ID registration |

PROCEDURE "F" |

|

|

|

|

|

|

3.KEY REGISTRATION

(a)PROCEDURE "A"

New key ID registration (when replacing certification ECU and ID code box, or certification ECU, ID code box and steering lock ECU)

EI |

|

Process |

Procedure |

|

|

|

|

||

|

1. Start of registration |

1. Connect intelligent tester (with CAN VIM) to DLC3 |

||

|

||||

|

|

|

2. Turn engine switch on (IG) |

|

|

|

|

3. Select "SMART ACCESS / ID UTILITY / SMART CODE REG" |

|

|

|

|

from tester menu |

|

|

|

|

HINT: |

|

|

|

|

The engine switch cannot be turned on (IG) more than 10 times. After |

|

|

|

|

connecting tester, turn tester on while turning driver's side door |

|

|

|

|

courtesy light switch on and off repeatedly at 1.5-second intervals or |

|

|

|

|

less to continue key registration procedure |

|

|

|

|

|

|

|

|

2. Confirmation of ECU code |

Perform operation according to prompts on tester screen |

|

|

|

|

HINT: |

|

|

|

|

The mode is automatically selected by tester, new registration mode |

|

|

|

|

or add mode |

|

|

|

|

|

|

|

|

3. Verification of unregistered key *1 |

Hold unregistered key close to engine switch (For details, refer to |

|

|

|

|

PROCEDURE "1") |

|

|

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds. Place unregistered |

|

|

|

|

key on front passenger's side seat |

|

|

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds |

|

|

|

|

|

|

|

|

4. Registration of ID code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

|

|

|

5. End of registration |

Finish new key ID code registration |

|

|

|

|

|

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–13 |

|

|||

|

|

|

|

||

|

*1: Repeat this process for each key which is to be |

|

|||

|

registered for the vehicle. Finish the procedure for |

|

|||

|

each key within 30 seconds. If the procedure for any |

|

|||

|

of the keys has not been finished within the |

|

|

|

|

|

specified time, perform registration procedures from |

|

|||

|

process 1 again. Make sure that only 1 key is in the |

|

|||

|

cabin during registration procedures. If 2 or more |

|

|||

|

keys are in the cabin simultaneously, electric waves |

|

|||

|

will interfere with each other, preventing normal |

|

|||

|

registration. |

|

|

|

|

(b) |

PROCEDURE "B" |

|

|

|

|

|

New key ID registration (when replacing certification |

|

|||

|

ECU) |

|

|

|

|

|

|

|

|

|

|

Process |

Procedure |

|

|

|

|

|

|

|

|

|

|

1. Start of registration |

1. Connect intelligent tester (with CAN VIM) to DLC3 |

|

|

|

|

|

2. Turn engine switch on (IG) |

|

|

|

|

|

3. Select "SMART ACCESS / ID UTILITY / SMART CODE REG" |

|

|

||

|

from tester menu |

|

|

|

|

|

HINT: |

|

|

|

|

|

The engine switch cannot be turned on (IG) more than 10 times. After |

|

|

||

|

connecting tester, turn tester on while turning driver's side door |

|

|

|

|

|

courtesy light switch on and off repeatedly at 1.5-second intervals or |

|

|

||

|

less to continue key registration procedure |

|

|

|

|

|

|

|

|

|

|

2. Confirmation of ECU code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

HINT: |

|

|

|

|

|

The mode is automatically selected by tester, new registration mode |

|

|

||

|

or add mode |

|

|

|

|

|

|

|

|

||

3. Confirmation of all registered keys *1 |

Hold unregistered key close to engine switch (For details, refer to |

|

|

|

|

|

PROCEDURE "1") |

|

|

|

|

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds |

|

|

|

|

|

|

|

|

|

|

4. Confirmation of ECU code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

|

|

|

||

5. Verification of unregistered key *2 |

Hold unregistered key close to engine switch (For details, refer to |

|

|

|

|

|

PROCEDURE "1") |

|

|

|

|

|

|

|

|

||

|

Confirm that wireless door lock buzzer sounds. Place unregistered |

|

|

|

|

|

key on front passenger side seat |

|

|

|

|

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds |

|

|

|

|

|

|

|

|

|

EI |

5. Registration of ID code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

|

|

|

|

|

6. End of registration |

Finish new key ID code registration |

|

|

|

|

|

|

|

|

|

|

*1: Repeat this process for each key registered for the vehicle. Finish the procedure for each key within 30 seconds. If the procedure for any of the keys has not been finished within the specified time, perform registration procedures from process 1 again. If performing the key confirmation procedure for a key, the security indicator comes on and remains on until all the keys are confirmed.

*2: Repeat this process for each key which is to be registered for the vehicle. Finish the procedure for each key within 30 seconds. If the procedure for any of the keys has not been finished within the specified time, perform registration procedures from 1 again. Make sure that only 1 key is in the cabin during registration procedures. If 2 or more keys are in the cabin simultaneously, electric waves will interfere with each other, preventing normal registration.

EI–14 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

||

|

|

||

|

|

(c) |

PROCEDURE "C" |

|

|

|

Additional key ID registration |

|

|

|

|

|

|

Process |

Procedure |

|

|

|

|

1. |

Start of registration |

1. Connect intelligent tester (with CAN VIM) to DLC3 |

|

|

|

|

2. Turn engine switch on (IG) |

|

|

|

3. Select "SMART ACCESS / ID UTILITY / SMART CODE REG" |

|

|

|

from tester menu |

|

|

|

|

2. |

Confirmation of registered key *1 |

Perform operation according to prompts on intelligent tester screen |

|

|

|

|

HINT: |

|

|

|

The mode is automatically selected by tester, new registration mode |

|

|

|

or add mode |

|

|

|

|

|

|

|

Hold unregistered key close to engine switch (For details, refer to |

|

|

|

PROCEDURE "1") |

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds once |

|

|

|

|

3. |

Confirmation of ECU code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

4. |

Verification of unregistered key *2 |

Hold unregistered key close to engine switch (For details, refer to |

|

|

|

|

PROCEDURE "1") |

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds. Place unregistered |

|

|

|

key on front passenger's side seat |

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds |

|

|

|

|

5. |

Registration of ID code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

6. |

End of registration |

Finish key ID code registration |

|

|

|

|

|

EI

*1: Perform this process for one of the keys registered for the vehicle. Finish the procedure within 30 seconds. If the procedure has not been finished within the specified time, perform registration procedures from process 1 again.

*2: Repeat this process for each key which is to be registered for the vehicle. Finish the procedure for each key within 30 seconds. If the procedure for any of the keys has not been finished within the specified time, perform registration procedures from 1 again. Make sure that only 1 key is in the cabin during registration procedures. If 2 or more keys are in the cabin simultaneously, electric waves will interfere with each other, preventing normal registration.

(d)PROCEDURE "D" Key ID erasure HINT:

Erase all registered key codes except one.

|

Process |

|

Procedure |

|

|

|

|

1. |

Start of erasure |

1. |

Connect intelligent tester (with CAN VIM) to DLC3 |

|

|

2. |

Turn engine switch on (IG) |

|

|

3. |

Select "SMART ACCESS / ID UTILITY / SMART CODE ERS" |

|

|

|

from tester menu |

|

|

|

|

2. |

Confirmation of registered key *1 |

Perform operation according to prompts on intelligent tester screen |

|

|

|

|

|

|

|

Hold unregistered key close to engine switch (For details, refer to |

|

|

|

PROCEDURE "1") |

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds once |

|

|

|

|

|

3. |

Confirmation of ECU code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

4. |

Erasure of ID code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

5. |

End of erasure |

Finish key ID code erasure |

|

|

|

|

|

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–15 |

|

*1: Perform this process for one of the keys registered for the vehicle. Finish the procedure within 30 seconds. If the procedure has not been finished within the specified time, perform erasure procedures from process 1 again.

(e)PROCEDURE "E" ECU code registration

|

Process |

|

Procedure |

|

|

|

|

1. |

Start of registration |

1. |

Connect intelligent tester (with CAN VIM) to DLC3 |

|

|

2. |

Turn engine switch on (IG) |

|

|

3. |

Select "SMART ACCESS / ID UTILITY / ECU COMM ID REG / ID |

|

|

|

Code Box and Steering Lock" from tester menu |

|

|

|

|

2. |

Confirmation of registered key *1 |

Hold unregistered key close to engine switch (For details, refer to |

|

|

|

PROCEDURE "1") |

|

|

|

|

|

|

|

Confirm that wireless door lock buzzer sounds once |

|

|

|

|

|

3. |

Registration of ECU code |

Perform operation according to prompts on tester screen |

|

|

|

|

|

4. |

End of registration |

Finish ECU code registration |

|

|

|

|

|

*1: Perform this process for one of the keys registered for the vehicle. Finish the procedure within 30 seconds. If the procedure has not been finished within the specified time, perform erasure procedures from process 1 again.

(f)PROCEDURE "F"

ECU communication ID registration

NOTICE:

•The ECU communication ID should be registered when the ID code box and/or the ECM is replaced in order to match these ECM communication ID.

•The engine cannot be started unless the ECM communication ID matches.

Register the ECU communication ID.

EI |

CG |

TC |

SST |

B139171E01 |

(1)Using SST, connect terminals TC and CG of the DLC3.

SST 09843-18040

EI–16 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

|

||

|

(2) |

Turn the engine switch on (IG) and leave it for |

|

|

30 minutes. |

|

|

HINT: |

|

|

Do not start the engine. |

|

(3) |

Turn the engine switch off and disconnect |

|

|

terminals TC and CG. |

|

(4) |

Check that the engine starts. |

EI

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–17 |

|

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of the problem symptom. The potential cases of the symptoms are listed in order of probability in the "Suspected Area" column of the table. Check each symptom by checking the suspected area in the order they are listed. Replace parts as necessary.

Engine Immobiliser System:

Symptom |

|

Suspected area |

See page |

|

|

|

|

|

|

|

1. |

Key |

EI-24 |

|

|

|

|

|

|

|

2. |

ID code box power source circuit |

EI-45 |

|

|

|

|

|

|

Engine does not start |

3. |

Certification ECU power source circuit |

EI-48 |

|

|

|

|

||

4. |

Steering lock ECU power source circuit |

SR-30 |

||

|

||||

|

|

|

|

|

|

5. |

Smart access system |

DL-142 |

|

|

|

|

|

|

|

6. |

SFI system |

ES-15 |

|

|

|

|

|

EI

EI–18 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

TERMINALS OF ECU

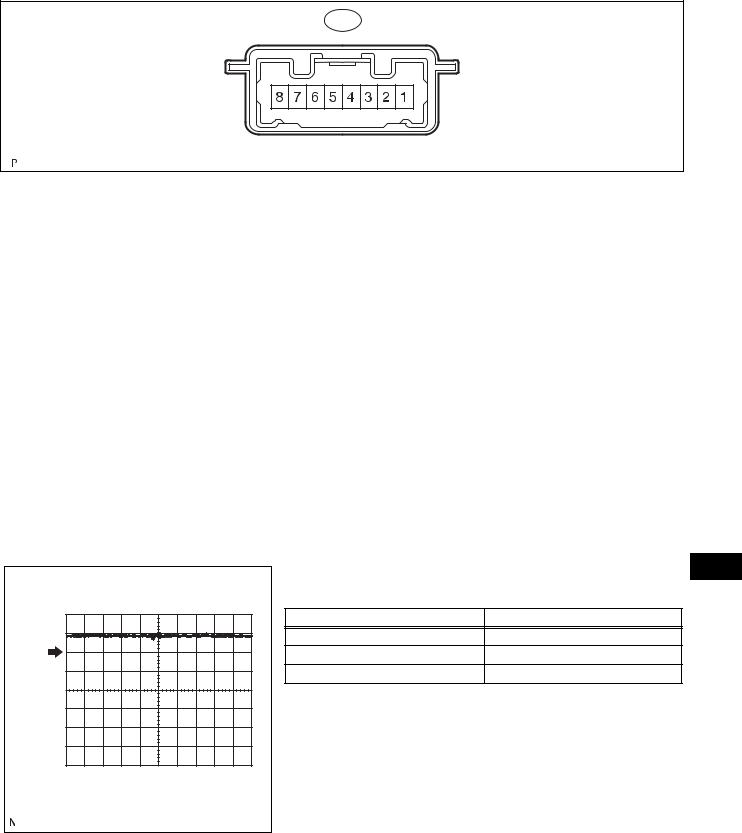

1.CHECK ENGINE SWITCH

|

E52 |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

B146454E01 |

|

|

|

|

(a) Disconnect the E52 switch connector. |

||

|

|

|

|

(b) Measure the resistance according to the value(s) in |

||

|

|

|

|

the table below. |

|

|

|

|

|

|

|

|

|

|

|

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

|

|

|

|

AGND (E52-8) - Body ground |

G - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

|

|

If the result is not as specified, there may be a |

||

|

|

|

|

malfunction on the wire harness side. |

||

|

|

|

|

(c) Reconnect the E52 switch connector. |

||

|

|

|

|

(d) Measure the resistance and voltage according to |

||

|

|

|

|

the value(s) in the table below. |

|

|

|

|

|

|

|

|

|

|

|

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

|

|

|

|

AGND (E52-8) - Body ground |

G - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

VC5 (E52-14) - AGND (E52-8) |

R - G |

Power supply |

Key is not in cabin |

Below 1 V |

|

|

|

|

|||

|

|

Press engine switch |

4.6 to 5.4 V |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Key is not in cabin |

Below 1 V |

|

|

|

|

Demodulated signal of key |

|

|

|

|

CODE (E52-10) - AGND (E52-8) |

W - G |

Press engine switch and |

Pulse generation |

|

|

|

code data |

hold key close to engine |

|||

|

|

|

|

(see waveform 1) |

||

|

|

|

|

|

switch* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Key is not in cabin |

Below 1 V |

EI |

|

|

|

|

||

|

|

|

|

|

|

|

|

TXCT (E52-9) - AGND (E52-8) |

GR - G |

Key code output signal |

Press engine switch and |

Pulse generation |

|

|

hold key close to engine |

|||||

|

|

|

|

|

(see waveform 2) |

|

|

|

|

|

|

switch* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HINT:

*: Remove the key battery before performing this inspection.

If the result is not as specified, the switch may have a malfunction.

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–19 |

|

GND |

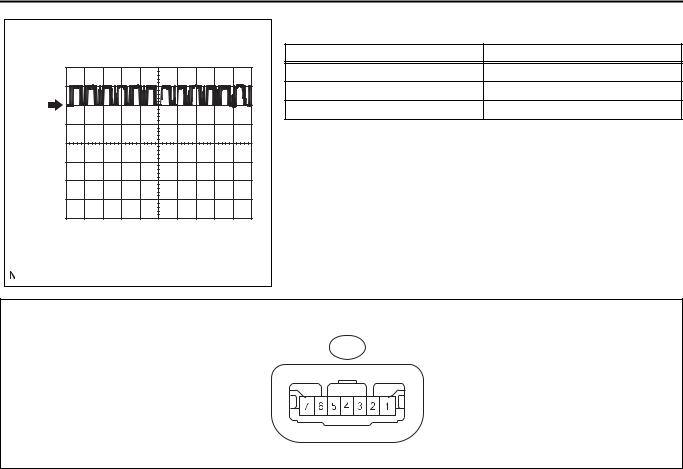

Tool Setting: 2 V/DIV., 20 ms./DIV. |

B139211E01 |

(e)Inspect using an oscilloscope.

(1) Waveform 1 (Reference)

Item |

Content |

|

Symbols (Terminal No.) |

CODE (E52-10) - AGND (E52-8) |

|

Tool Setting |

2 V/DIV., 20 ms./DIV. |

|

Condition |

Press engine switch and hold key close |

|

to engine switch* |

||

|

HINT:

*: Remove the key battery before performing this inspection.

|

|

|

|

|

|

|

|

|

|

(2) Waveform 2 (Reference) |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

|

|

|

Content |

|

||

|

|

|

|

|

|

Symbols (Terminal No.) |

|

|

|

|

TXCT (E52-9) - AGND (E52-8) |

|||||||||||

|

|

|

|

|

|

Tool Setting |

|

|

|

|

|

|

2 V/DIV., 20 ms./DIV. |

|

|

|||||||

|

|

|

|

|

|

Condition |

|

|

|

|

|

|

|

Press engine switch and hold key close |

||||||||

GND |

|

|

|

|

|

|

|

|

|

|

|

|

to engine switch* |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

HINT: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*: Remove the key battery before performing this |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

inspection. |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

2. |

|

CHECK CERTIFICATION ECU |

|

|

|

|

|

|||||||||

Tool Setting: 2 V/DIV., 20 ms./DIV. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

B139212E01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

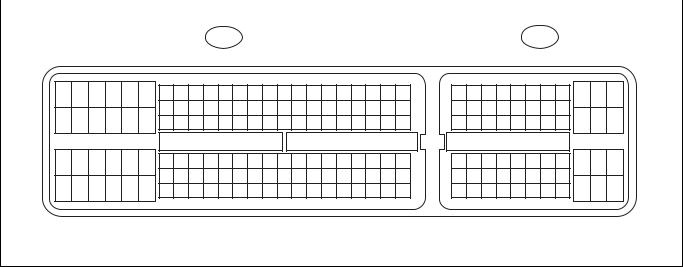

E58 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EI |

17 16 15 |

14 13 12 11 |

10 |

9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

11 |

10 |

9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 |

28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 |

|||||||||||||||||||||

B106648E23

(a)Disconnect the E58 ECU connector.

(b)Measure the resistance and voltage according to the value(s) in the table below.

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

E (E58-17) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

+B (E58-1) - E (E58-17) |

W - W-B |

+B power supply |

Always |

10 to 14 V |

|

|

|

|

|

IG (E58-18) - E (E58-17) |

LG - W-B |

Ignition power supply |

Engine switch off |

Below 1 V |

|

|

|

|

|

If the result is not as specified, there may be a malfunction on the wire harness side.

(c) Reconnect the E58 ECU connector.

EI–20 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

(d)Measure the resistance and voltage according to the value(s) in the table below.

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

|

|

AGND (E58-40) - Body ground |

G - Body ground |

Engine switch ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

VC5 (E58-30) - AGND (E58-40) |

R - G |

Engine switch power |

Key is not in cabin |

Below 1 V |

|

supply |

Press engine switch* |

4.6 to 5.4 V |

|||

|

|

||||

|

|

|

|

|

|

|

|

|

Key is not in cabin |

Below 1 V |

|

|

|

|

|

|

|

CODE (E58-9) - AGND (E58-40) |

W - G |

Engine switch CODE input |

Press engine switch and |

Pulse generation (see |

|

|

|

|

hold key close to engine |

waveform 1) |

|

|

|

|

switch* |

||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Key is not in cabin |

Below 1 V |

|

|

|

Engine switch TXCT |

|

|

|

TXCT (E58-8) - AGND (E58-40) |

GR - G |

Press engine switch and |

Pulse generation (see |

||

output |

hold key close to engine |

||||

|

|

waveform 2) |

|||

|

|

|

switch* |

||

|

|

|

|

||

|

|

|

|

|

HINT:

*: Remove the key battery before performing this inspection.

If the result is not as specified, the ECU may have a malfunction.

|

|

(e) Inspect using an oscilloscope. |

|

|

|

(1) Waveform 1 (Reference) |

|

|

|

Item |

Content |

|

|

Symbols (Terminal No.) |

CODE (E58-9) - AGND (E58-40) |

|

|

Tool Setting |

2 V/DIV., 20 ms./DIV. |

|

GND |

Condition |

Press engine switch and hold key close |

|

|

to engine switch* |

|

|

|

|

|

|

|

HINT: |

|

|

|

*: Remove the key battery before performing this |

|

|

|

inspection. |

|

|

|

Tool Setting: 2 V/DIV., 20 ms./DIV. |

|

EI |

|

B139211E01 |

|

GND |

Tool Setting: 2 V/DIV., 20 ms./DIV. |

B139212E01 |

(2) Waveform 2 (Reference)

Item |

Content |

|

Symbols (Terminal No.) |

TXCT (E58-8) - AGND (E58-40) |

|

Tool Setting |

2 V/DIV., 20 ms./DIV. |

|

Condition |

Press engine switch and hold key close |

|

to engine switch* |

||

|

HINT:

*: Remove the key battery before performing this inspection.

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–21 |

|

3.CHECK ID CODE BOX

E50 |

B118534E03 |

|

|

(a) |

Disconnect the E50 ECU connector. |

||

|

|

(b) |

Measure the resistance and voltage according to |

||

|

|

|

the value(s) in the table below. |

|

|

|

|

|

|

|

|

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

|

|

GND (E50-8) - Body ground |

W-B - Body ground |

Ground |

|

Always |

Below 1 Ω |

|

|

|

|

|

|

+B (E50-1) - GND (E50-8) |

W - W-B |

+B power supply |

Always |

10 to 14 V |

|

|

|

|

|

|

|

|

|

|

If the result is not as specified, there may be a |

||

|

|

|

malfunction on the wire harness side. |

||

|

|

(c) |

Reconnect the E50 ECU connector. |

||

|

|

(d) |

Measure the voltage according to the value(s) in the |

||

|

|

|

table below. |

|

|

|

|

|

|

|

|

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

|

|

|

|

|

|

Engine switch off |

Below 1 V |

EFII (E50-5) - GND (E50-8) |

G - W-B |

ECM input signal |

|

|

|

Engine switch on (IG) |

Pulse generation |

||||

|

|

|

|

(see waveform 1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine switch off |

Below 1 V |

EFIO (E50-6) - GND (E50-8) |

L - W-B |

ECM output signal |

|

|

|

Engine switch on (IG) |

Pulse generation |

||||

|

|

|

|

(see waveform 2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If the result is not as specified, the ECU may have a |

|

|

|

malfunction. |

|

EI |

|

(e) Inspect using an oscilloscope. |

||

|

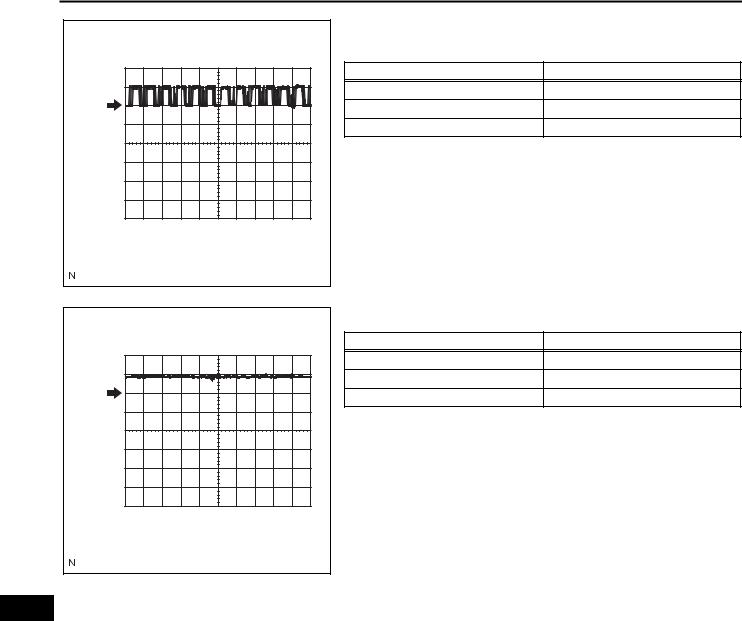

(1) Waveform 1 (Reference) |

|

|

|

Item |

Content |

|

|

Symbols (Terminal No.) |

EFII (E50-5) - GND (E50-8) |

|

GND |

Tool Setting |

10 V/DIV., 100 ms./DIV. |

|

|

Condition |

Engine switch on (IG) |

|

|

Tool Setting: 10 V/DIV., 100 ms./DIV. |

|

|

|

B139209E01 |

|

|

EI–22 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

GND |

Tool Setting: 10 V/DIV., 100 ms./DIV. |

B139210E01 |

(2) Waveform 2 (Reference)

Item |

Content |

Symbols (Terminal No.) |

EFIO (E50-6) - GND (E50-8) |

Tool Setting |

10 V/DIV., 100 ms./DIV. |

Condition |

Engine switch on (IG) |

4.CHECK STEERING CONTROL ECU

E51 |

B118684E03 |

(a)Disconnect the E51 ECU connector.

(b)Measure the resistance and voltage according to the value(s) in the table below.

|

|

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

|

|

|

|

|

|

SGND (E51-2) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

|

|

GND (E51-1) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

|

|

B (E51-7) - Body ground |

P - Body ground |

+B power supply |

Always |

10 to 14 V |

|

EI |

|||||||

|

|

|

|

|

|

||

|

IG2 (E51-6) - Body ground |

B - Body ground |

Ignition power supply |

Engine switch off |

0 V |

||

|

|

|

|

||||

|

|

Engine switch on (IG) |

10 to 14 V |

||||

|

|

|

|

|

|||

|

|

|

|

|

|

|

If the result is not as specified, there may be a malfunction on the wire harness side.

|

|

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–23 |

||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

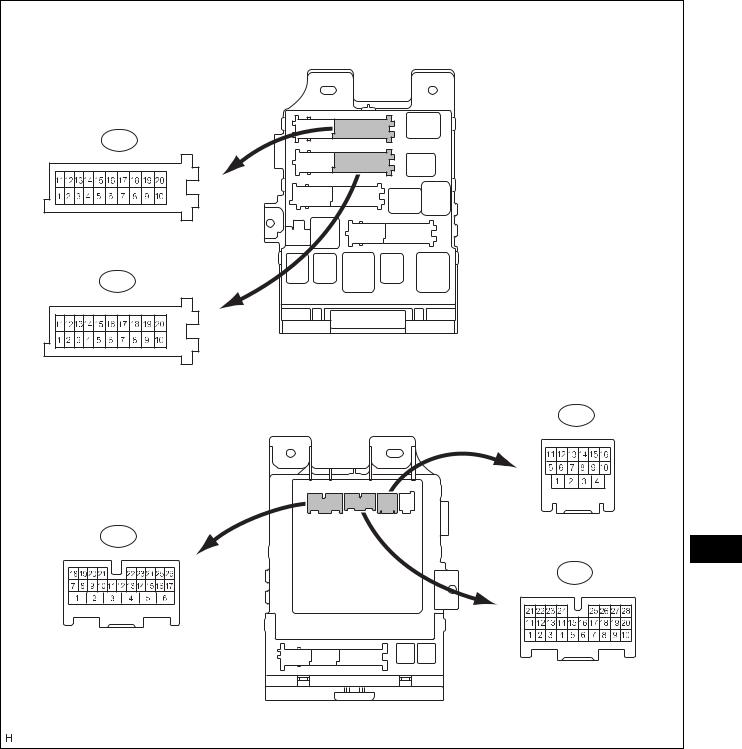

5. |

CHECK ECM |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

C55 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A55 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

A107881E14

(a)Measure the resistance and voltage according to the value(s) in the table below.

|

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

|

|

|

|

|

||

E1 (C55-81) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

||

|

|

|

|

|

|

|

|

|

E01 |

(C55-22) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

|

|

|

E02 |

(C55-21) - Body ground |

B-W - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

|

|

|

E03 |

(C55-104) - Body ground |

B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

|

|

|

E04 |

(C55-23) - Body ground |

W - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

|

|

|

E05 |

(C55-46) - Body ground |

W - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

|

|

|

|

|

||

ME01 (C55-20) - Body ground |

B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Battery (for measuring |

|

|

|

|

|

BATT (A55-20) - E1 (C55-81) |

Y - W-B |

battery voltage and for |

Always |

10 to 14 V |

|

|

||

|

|

|

ECM memory) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+B (A55-2) - E1 (C55-81) |

R - W-B |

Power source of ECM |

Engine switch off |

Below 1 V |

|

|

||

|

|

|

|

|||||

Engine switch on (IG) |

10 to 14 V |

|

|

|||||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine switch off |

Below 1 V |

|

|

|

IMI (A55-11) - E1 (C55-81) |

Y - W-B |

Immobiliser code ECU |

EI |

|||||

|

|

|

||||||

|

Pulse generation |

|

||||||

input signal |

Engine switch on (IG) |

|

||||||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|

(see waveform 1) |

|

|

|

|

|

|

Immobiliser code ECU |

Engine switch off |

Below 1 V |

|

|

|

IMO (A55-10) - E1 (C55-81) |

G - W-B |

|

|

|

|

|||

|

Pulse generation |

|

|

|||||

output signal |

Engine switch on (IG) |

|

|

|||||

|

|

|

(see waveform 2) |

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

If the result is not as specified, the ECM may have a malfunction.

EI–24 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

GND |

Tool Setting: 10 V/DIV., 100 ms./DIV. |

B139210E01 |

GND |

Tool Setting: 10 V/DIV., 100 ms./DIV. |

B139209E01 |

(b)Inspect using an oscilloscope.

(1) Waveform 1 (Reference)

Item |

Content |

Symbols (Terminal No.) |

IMI (A55-11) - E1 (C55-81) |

Tool Setting |

10 V/DIV., 100 ms./DIV. |

Condition |

Engine switch on (IG) |

(2) Waveform 2 (Reference)

Item |

Content |

Symbols (Terminal No.) |

IMO (A55-10) - E1 (C55-10) |

Tool Setting |

10 V/DIV., 100 ms./DIV. |

Condition |

Engine switch on (IG) |

6.CHECK MAIN BODY ECU (INSTRUMENT PANEL J/B)

(a)Disconnect the IF and IM junction block connectors.

EI

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–25 |

|

(b)Disconnect the E8, E7 and E6 main body ECU connectors.

|

Vehicle Rear Side |

IM |

|

IF |

|

|

Vehicle Front Side |

|

E8 |

E7 |

EI |

|

|

|

E6 |

|

B128347E01 |

(c)Measure the resistance and voltage according to the value(s) in the table below.

Symbols (Terminal No.) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

|

GND1 (IF-10) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

GND2 (IM-9) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

GND3 (E8-1) - Body ground |

W-B - Body ground |

Ground |

Always |

Below 1 Ω |

|

|

|

|

|

AM1 (E7-6) - Body ground |

L - Body ground |

+B power supply |

Always |

10 to 14 V |

|

|

|

|

|

AM2 (E6-1) - Body ground |

L - Body ground |

+B power supply |

Always |

10 to 14 V |

|

|

|

|

|

EI–26 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

CG |

SG CANH |

SIL |

|

CANL |

BAT |

|

|

H100769E16 |

If the result is not as specified, there may be a

malfunction on the wire harness side.

DIAGNOSIS SYSTEM

1.CHECK DLC3

(a)The vehicle's ECU uses ISO 15765-4 for communication protocol. The terminal arrangement of the DLC3 complies with SAE J1962 and matches the ISO 15765-4 format.

Symbols (Terminal No.) |

Terminal Description |

Condition |

Specified Condition |

|

|

|

|

SIL (7) - SG (5) |

Bus "+" line |

During transmission |

Pulse generation |

|

|

|

|

CG (4) - Body ground |

Chassis ground |

Always |

Below 1 Ω |

|

|

|

|

SG (5) - Body ground |

Signal ground |

Always |

Below 1 Ω |

|

|

|

|

BAT (16) - Body ground |

Battery positive |

Always |

10 to 14 V |

|

|

|

|

CANH (6) - CANL (14) |

CAN bus line |

Engine switch off* |

54 to 69 Ω |

CANH (6) - CG (4) |

HIGH-level CAN bus line |

Engine switch off* |

200 Ω or higher |

CANL (14) - CG (4) |

LOW-level CAN bus line |

Engine switch off* |

200 Ω or higher |

CANH (6) - BAT (16) |

HIGH-level CAN bus line |

Engine switch off* |

6 kΩ or higher |

CANL (14) - BAT (16) |

LOW-level CAN bus line |

Engine switch off* |

6 kΩ or higher |

|

NOTICE: |

|

|

*: Before measuring the resistance, leave the |

|

|

vehicle as is for at least 1 minute and do not |

|

|

operate the engine switch, any other switches or |

|

|

the doors. |

|

|

If the result is not as specified, the DLC3 may have |

|

|

a malfunction. Repair or replace the harness and |

|

EI |

connector. |

|

(b) Connect the cable of the intelligent tester (with CAN |

||

|

||

|

VIM) to the DLC3, turn the engine switch on (IG) |

|

|

and attempt to use the intelligent tester. If the |

|

|

screen displays a communication error message, a |

|

|

problem exists in the vehicle side or tester side. |

|

|

HINT: |

|

|

• If communication is normal when the tool is |

|

|

connected to another vehicle, inspect the DLC3 |

|

|

on the original vehicle. |

|

|

• If communication is still impossible when the tool |

|

|

is connected to another vehicle, the problem is |

|

|

probably in the tool itself. Consult the Service |

|

|

Department listed in the tool's instruction manual. |

|

|

DLC3 |

|

|

Intelligent Tester |

|

|

C131977E01 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

EI–27 |

|

DTC CHECK / CLEAR |

|

1. |

CHECK DTC |

|

(a) Connect the intelligent tester to the Controller Area |

|

Network Vehicle Interface Module (CAN VIM). Then |

|

connect the CAN VIM to the DLC3. |

|

(b) Turn the engine switch on (IG). |

|

(c) Read the DTCs by following the directions on the |

|

tester screen. |

|

HINT: |

|

Refer to the intelligent tester operator's manual for |

|

further details. |

2. |

CLEAR DTC |

DLC3 |

(a) Connect the intelligent tester (with CAN VIM) to the |

Intelligent Tester |

DLC3. |

|

|

C131977E01 |

(b) Turn the engine switch on (IG). |

|

|

(c)Erase the DTCs by following the directions on the tester's screen.

HINT:

Refer to the intelligent tester operator's manual for further details.

EI

EI–28 |

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM (w/ Smart Key System) |

|

DATA LIST / ACTIVE TEST

1. READ DATA LIST

|

|

|

HINT: |

|

||

|

|

|

Using the intelligent tester to read the DATA LIST allows |

|||

|

|

|

the values or states of switches, sensors, actuators and |

|||

|

|

|

other items to be read without removing any parts. This |

|||

|

|

|

non-intrusive inspection can be very useful as |

|||

|

|

|

intermittent conditions or signals may be discovered |

|||

|

|

|

before parts or wiring is disturbed. Reading the DATA |

|||

|

|

|

LIST information early in troubleshooting is one way to |

|||

|

|

|

save diagnostic time. |

|

||

|

|

|

(a) Connect the intelligent tester (with CAN VIM) to the |

|||

|

|

|

|

DLC3. |

|

|

|

|

|

(b) Turn the engine switch on (IG). |

|

||

|

|

SMART: |

(c) Read the DATA LIST. |

|

||

|

|

|

|

|

|

|

|

|

Item |

Measurement Item / Display |

Normal Condition |

|

Diagnostic Note |

|

|

(Range) |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine switch on (IG) signal / ON |

ON: Engine switch on (ACC, IG) |

|

|

|

|

IG SW |

or start |

|

- |

|

|

|

or OFF |

|

|||

|

|

|

OFF: Engine switch off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine switch on (ACC) signal / |

ON: Engine switch on (ACC, IG) |

|

|

|

|

ACC SW |

or start |

|

- |

|

|

|

ON or OFF |

|

|||

|

|

|

OFF: Engine switch off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IMMOBILISER |

Immobiliser system status / SET |

SET: Key is not in cabin |

|

- |

|

|

or UNSET |

UNSET: Key is in cabin |

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Master key code signal / MATCH |

MATCH: Master key code is sent |

|

|

|

|

MASTER KEY |

NO MATCH: Unmatched master |

|

- |

|

|

|

or NO MATCH |

|

|||

|

|

|

key code is sent |

|

|

|

|

|

|

|

|

|

|

|