tekmar 284 User Manual

Installation & Operation Manual |

|

|

|

|

|

|

|

|

D 284 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

||||||||||

|

|

|

|

|

|

|

|

|||

Boiler Control 284 |

|

|

|

|

|

|

|

|

08/14 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

Multi-Staging Replaces: 04/14

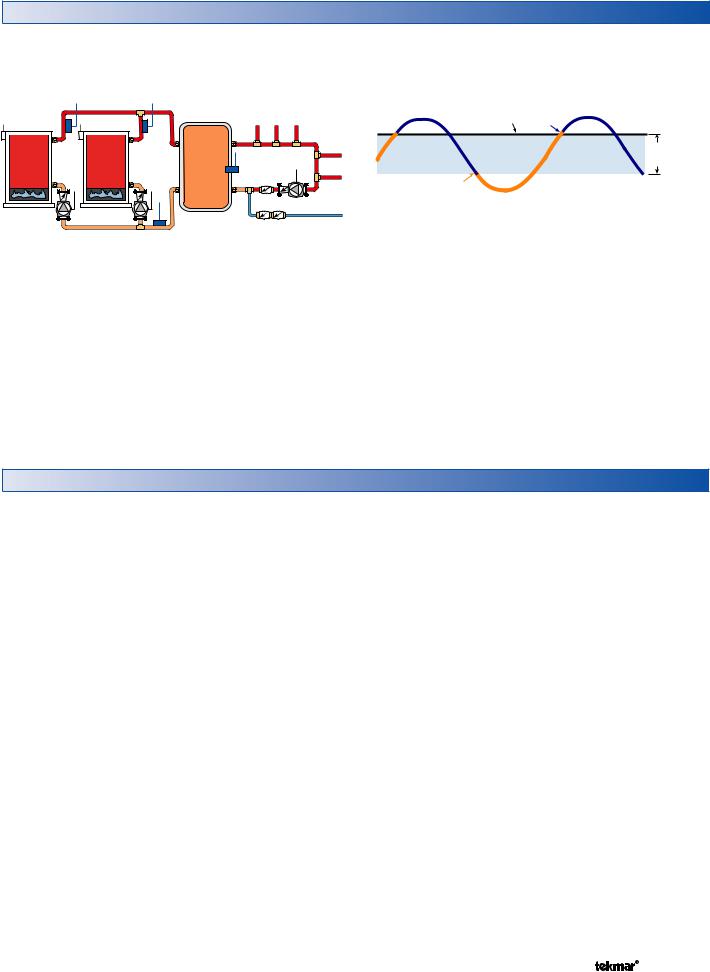

A Flexible Solution for Commercial & Multi-Residential Heating Plants

The Boiler Control 284 is designed to operate up to four boilers to accurately maintain a target water temperature. The 284 operates both condensing & non-condensing boilers that are either modulating, single stage or two stage to provide a flexible, cost effective mixed boiler plant solution with better system performance.

The target water temperature is based on outdoor temperature reset or a fixed setpoint for space or process heating applications. Additional loads supplied by the 284 include

domestic hot water & fixed setpoint heating. Boiler equal run-time rotation, stand-by primary pump operation & pump exercising all increase boiler plant reliability.

The 284 communicates with a Building Automation System (BAS) using BACnet® IP or Modbus® for remote monitoring

&adjustment capability. tekmarNet® Thermostats or a tN4 Gateway 483 can be added to optimize system performance

&provide remote monitoring capability.

Features

• Outdoor temperature reset

• Programmable schedules

• tekmarNet® compatible

• Control up to four boilers

• Condensing & non-condensing boiler groups

• Modulating, single stage or two stage

• Boiler isolation valves

• BACnet® IP or Modbus® communication

• Primary pump sequencing

• DHW priority

• Setpoint operation

• Combustion air damper control

• Energy, flow & pressure monitoring

Benefits

• Reduce energy costs

• Prolong equipment life

• Provide boiler redundancy

• Provide primary pump redundancy

• Remote monitoring & adjustment options

• Combine mid & high efficiency boilers to lower component cost

BACnet is a registered trademark of ASHRAE. ASHRAE does not endorse, approve or test products for compliance with ASHRAE standards. Compliance of listed products to the requirements of ASHRAE Standard 135 is the responsibility of BACnet International (BI). BTL is a registered trademark of BI.

A Watts Water Technologies Company |

1 of 60 |

© 2014 |

284_D - 08/14 |

Table of Contents

Sequence of Operation ..................................................... |

2 |

Boiler Setup ................................................................... |

2 |

System Setup ................................................................ |

5 |

Boiler Plant Operation ................................................... |

7 |

Outdoor Temperature Reset Operation ...................... |

10 |

Setpoint Operation ...................................................... |

12 |

Energy Management System (EMS) Operation.......... |

13 |

Indirect Domestic Hot Water (IDHW) Operation .......... |

14 |

Dedicated Domestic Hot Water (DDHW) Operation .... |

17 |

Building Automation System (BAS) Operation............. |

17 |

Pump Operation .......................................................... |

18 |

C.A. Damper & DHW Recirculation............................. |

20 |

Setting the Schedule ................................................... |

20 |

Time Clock................................................................... |

21 |

tekmarNet®4 Communication...................................... |

21 |

Installation ....................................................................... |

22 |

Installation Location..................................................... |

22 |

Control Wiring.............................................................. |

23 |

Sensor Installation & Wiring ........................................ |

26 |

EMS, Modbus® & BACnet® Connections .................... |

29 |

Wiring the tekmarNet® Devices ................................... |

30 |

Testing the Sensor Wiring ........................................... |

30 |

Testing the Control Wiring ............................................... |

31 |

Control Settings............................................................... |

33 |

Access Level ............................................................... |

33 |

DIP Switch Settings..................................................... |

33 |

User Interface.................................................................. |

34 |

Display & Symbols....................................................... |

34 |

Navigating the Display................................................. |

35 |

View Menu .................................................................. |

35 |

Setup Menu ................................................................ |

37 |

Source # Menu ............................................................ |

43 |

BAS Menu.................................................................... |

45 |

Monitor # Menu............................................................ |

47 |

Monitor Menu .............................................................. |

48 |

Time Menu ................................................................. |

50 |

Schedule Menu ........................................................... |

51 |

Toolbox Menu ............................................................. |

52 |

Manual Override ......................................................... |

54 |

Troubleshooting............................................................... |

56 |

Error Messages .......................................................... |

56 |

Technical Data ............................................................ |

60 |

Limited Warranty & Product Return Procedure............... |

60 |

Sequence of Operation

Boiler (Source (#) Menu) Setup & Operation

The 284 is able to operate up to four boilers as a heat source. Each boiler is independently configured allowing for maximum plant flexibility.

Boiler Enable-------------------------------------

This setting selects whether the boiler is operational or not.

OFF

The boiler is disabled & will not be included in the plant operation.

AUTO

The boiler is enabled & will be included in the plant operation.

Copy Boiler 1-------------------------------------

Many boiler installations will have multiple identical boilers. To reduce the number of settings required, certain settings of boiler 1 are copied to boiler 2 by setting the Boiler 2 Copy setting to Boil1. Copy settings are also available for boiler 3 & boiler 4.

OFF

The settings from boiler 1 are not copied. This allows for individual boiler settings.

Boil 1

The settings from boiler 1 are copied.

Condensing --------------------------------------

This setting selects whether the boiler is condensing or noncondensing & defines what boiler group it is part of.

NO

The boiler is non-condensing & is part of the non-condensing boiler group.

YES

The boiler is condensing & is part of the condensing boiler group.

Boiler Type ---------------------------------------

The 284 has four different boiler types to choose from. Use the Boil TYPE setting to select one of the following:

MOD

The modulating output operates a modulating boiler by controlling the burner firing rate. The Stage 1 relay is also used to give a boiler enable to allow the modulating boiler to go through ignition sequence. The Stage 1 relay may not be required on all modulating boilers.

1STG

The Stage 1 relay operates a single, stage boiler by cycling the burner stage on & off.

2STG

The Stage 1 & Stage 2 relays operate a single, two stage boiler by cycling the burner stages on & off.

EMS

The modulating output operates a boiler that interprets an analog input signal as a target temperature. The temperature rails (minimum and maximum) are adjustable between 50°F (10.0°C) & 210°F (99.0°C).

• VDC SIGN MIN

Sets the minimum analog Vdc signal which corresponds to the minimum temperature (EMS TEMP MIN).

• EMS TEMP MIN

Sets the temperature on the low end which corresponds to the minimum analog signal (Vdc Min / 4 mA).

• EMS TEMP MAX

Sets the temperature on the high end which corresponds to the maximum analog signal (10 Vdc / 20 mA).

A Watts Water Technologies Company |

2 of 60 |

© 2014 |

284_D - 08/14 |

Modulating Type ---------------------------------

The MOD TYPE setting selects the analog output signal used for modulating (MOD) and EMS boiler types.

0-10

The modulating output is 0-10 V (dc).

4-20

The modulating output is 4-20 mA.

The 4-20 mA output can be converted to a 0 - 135 Ω output using a 0 - 135 Ω Converter 005. Refer to the Modulating Boiler Wiring section of the Control Wiring section.

Fire Delay ----------------------------------------

The Fire Delay sets the time it takes for the boiler to generate flame from the time the boiler turns on.

Boiler Contact Closed

Fire Delay

Burner On

Time

Modulation Delay ---------------------------------

The MOD DELAY is the time that the boiler burner must hold the modulation of the boiler at a minimum before allowing it to modulate any further.

Boiler Mass --------------------------------------

The Boil MASS setting selects the thermal mass characteristics of each boiler. Operation of the boiler can become unstable if the incorrect Boiler Mass setting is chosen. A key sign of unstable boiler operation is that the flame will continue to increase & then decrease in short periods of time. By choosing a lower boiler mass setting, the boiler response will become more stable.

LOW

The LO setting is selected if the boiler that is used has a low thermal mass. This means that the boiler has very small water content & has very little metal in the heat exchanger. A boiler that has a low thermal mass comes up to temperature quite rapidly when fired. This is typical of many copper fin-tube boilers.

The Low mass setting (LO) provides a fast response to the heating system.

MED

The MED setting is selected if the boiler that is used has a medium thermal mass. This means that the boiler either has a large water content & a low metal content or a low water content & a high metal content. This is typical of many modern residential cast iron boilers or steel tube boilers.

The Med mass setting provides a moderate response to the heating system.

HI

The HI setting is selected if the boiler that is used has a high thermal mass. This means that the boiler has both large water content & a large metal content. A boiler that has a high thermal mass is relatively slow in coming up to temperature. This is typical of many commercial cast iron & steel tube boilers.

The Hi mass setting provides a slow response to the heating system.

Low Fire & High Fire Boiler Output ---------------

In order to accommodate different boiler capacities in the same system, a low fire & high fire boiler output for each boiler

can be set. This allows the control to properly operate the boilers using either sequential or parallel modulation. Each boiler typically has a rating plate that specifies the minimum & maximum output. This information is also available in the boiler manual.

The minimum & maximum boiler output is expressed in MBtu/h. 1 MBtu/h = 1,000 Btu / hour. The range is from 10 MBtu/h to 9,990 MBtu/h.

For example, if a boiler has a maximum output of 100,000 Btu / hr & a minimum output of 20,000 Btu / hr (turn down ratio of 5):

Maximum Boiler Output = |

100,000 |

= 100 MBtu/h |

|

1,000 |

|

Minimum Boiler Output = |

20,000 |

= 20 MBtu/h |

|

1,000 |

|

Motor Speed -------------------------------------

The MOTOR SPD is the amount of time the boiler requires to go from 0% modulation to 100% modulation.

Gas valve actuating motors have a design time from fully closed to fully opened which can be found in the manufacturer’s manual. The Motor Speed should be set to this time.

The Motor Speed setting for a Variable Frequency Drive (VFD) is the amount of time required to go from a stopped position to 100% fan speed. Since a VFD has a very quick response rate, it may be necessary to increase the Motor Speed setting in order to increase the stability of the boiler modulation.

OR

Start Modulation ---------------------------------

The START MOD setting is the lowest modulation output required to obtain proper ignition. Whenever boiler operation is required, the control outputs an analog signal corresponding to the Start Modulation setting & closes the boiler contact to turn on the burner. After the Fire Delay has elapsed & the burner is ignited, the control modulates the firing rate between the Minimum Modulation setting & the Maximum Modulation setting.

Minimum Modulation ---------------------------------------------

The MIN MOD is the lowest signal the control can send to modulate the boiler. This operates the boiler at low fire. Use the MIN MOD setting in the Adjust Menu to select an appropriate boiler minimum modulation.

•Refer to the boiler manufacturer’s literature to determine the minimum output voltage V (dc) or current (mA) that the boiler will successfully operate at.

For 0 to 10 V (dc):

Minimum Modulation =

Boiler’s Minimum Input Signal x 100% 10 V (dc)

For 4 to 20 mA:

Minimum Modulation =

Boiler’s Minimum Input Signal - 4mA x 100% 16 mA

A Watts Water Technologies Company |

3 of 60 |

© 2014 |

284_D - 08/14 |

Example:

A boiler requires a 1.8 V (dc) signal to fire the boiler at low fire. The boiler can be modulated to 10 V (dc) where it reaches high fire.

Minimum Modulation = |

1.8 V |

x 100% = 18% |

|

|||||||||||

|

|

|

|

|

|

|

10 V |

|

|

|

|

|

|

|

10 V (dc) |

|

|

|

100% |

|

|

|

10 V (dc) |

|

|||||

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

88% |

|

|

|

|

Boiler’s |

|

|

Control’s |

|

|

|

|

|

|

|

Input |

|

|||||

Output |

|

|

|

|

|

|

|

Signal |

|

|||||

Signal |

|

|

|

|

|

|

|

|

|

Range |

|

|||

Range |

|

|

|

|

|

|

|

|

|

|

||||

Minimum |

|

|

|

|

|

|

|

|

|

Boiler’s |

||||

Modulation |

|

|

|

|

|

|

|

|

1.8 V (dc) |

|

Minimum |

|||

|

|

|

|

|

18% |

|

|

|

|

|||||

0 V (dc) |

|

|

|

0% |

|

|

|

|

|

|

Input |

|||

|

|

|

|

|

|

|

|

|

Signal |

|||||

|

|

|

|

|

|

|

|

|

|

|||||

Maximum Modulation -----------------------------------------------

The Maximum Modulation is the highest signal the control can send to modulate the boiler. For boilers with electronic operators, the boiler’s input signal range may not match the output signal range of the 284. Use the MAX MOD setting in the Source (#) Menu to select an appropriate boiler maximum modulation.

For 0 to 10 V (dc):

Maximum Modulation =

Boiler’s Maximum Input Signal x 100% 10 V (dc)

For 4 to 20 mA:

Maximum Modulation =

Boiler’s Maximum Input Signal - 4mA x 100% 16 mA

Example:

A boiler’s input signal range is 0 to 9 V (dc). The 284 control has an output signal range of 0 to 10 V (dc).

Maximum Modulation = |

9 V x 100% = 90% |

|

|||||||||||||

|

|

|

|

|

|

|

10 V |

|

|

|

|

|

|

|

|

10 V (dc) |

|

|

|

100% |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||||

Maximum |

|

|

|

|

|

|

9 V (dc) |

|

|

Boiler’s |

|||||

Modulation |

|

|

|

|

|

|

|

|

|

|

Maximum |

||||

|

|

|

|

90% |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control’s |

|

|

|

|

|

|

|

|

|

|

|

Signal |

|||

|

|

|

|

|

|

|

Boiler’s |

|

|||||||

Output |

|

|

|

|

|

|

|

|

Input |

|

|||||

Signal |

|

|

|

|

|

|

|

|

Signal |

|

|||||

Range |

|

|

|

|

|

|

|

Range |

|

||||||

0 V (dc) |

|

|

|

0% |

|

|

|

0 V (dc) |

|

||||||

|

|

|

|

|

|

|

|

||||||||

Maximum Boiler Outlet ---------------------------

The control has the capability for each boiler outlet temperature to be monitored & limited. The MAX OUT setting sets the maximum boiler outlet temperature. For modulating boilers, as the boiler outlet temperature approaches the boiler outlet maximum temperature, the control will reduce the firing rate. Once the boiler outlet temperature reaches the boiler outlet maximum temperature less 15°F (8.0°C), firing rate reduction will begin. Once the boiler outlet temperature reaches the boiler outlet maximum temperature less 5°F (2.5°C), the firing rate will be reduced to minimum modulation. If the boiler outlet temperature reaches the boiler outlet maximum, the boiler is turned off. In order for the boiler to be able to be turned back on again, the boiler outlet temperature must drop 5°F (2.5°C) below the boiler outlet maximum.

If MAX OUT is set to OFF, the control only monitors the boiler outlet temperature.

Boiler Pump / Valve Post Purge -----------------------------

This setting sets the amount of time the control operates the boiler pump / valve after the boiler is turned off. This will purge heat out of the boiler, reducing stand-by losses, & also aid in reducing “kettling”. The amount of time for the boiler pump post purge is adjustable between 10 seconds & 20:00 minutes. Auto is also available in which the control automatically determines the amount of time based on the boiler mass.

A Watts Water Technologies Company |

4 of 60 |

© 2014 |

284_D - 08/14 |

System Setup & Operation

Application Mode --------------------------------

There are five possible application modes that the 284 can be configured for including:

•Outdoor Temperature Reset (RSET)

•Fixed Setpoint (SETP)

•Dedicated Domestic Hot Water (DDHW)

•Energy Management System (EMS)

•Building Automation System (BAS)

Refer to the appropriate section of this brochure for a description of the each of the application modes.

Boiler Minimum ----------------------------------

The Boil MIN is the lowest temperature that the control is allowed to use as a boiler target temperature. During mild conditions, if the control calculates a boiler target temperature that is below the boiler minimum setting, the boiler target temperature is adjusted to at least the boiler minimum setting. MIN is displayed in the status field while viewing the boiler supply or target & when the boiler target is boiler minimum & the boiler supply is less than boiler minimum plus 5°F (2.5°C). Set the Boiler Minimum setting to the boiler manufacturer’s recommended temperature.

The Boil MIN is only applicable when at least one of the boilers is configured for non-condensing.

Boil MIN + 5°F (2.5°C)

Boiler Di erential

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

|

|

r |

|

|

Boil MIN |

B |

|

|

|

|

|

|

tu |

|

|

|

o |

|

|

|

|

a |

|

|

|

||

|

|

|

|

r |

|

|

|

|

||

|

i |

|

|

e |

|

|

|

|

||

|

|

l |

|

p |

|

|

|

|

|

|

|

|

|

m |

|

|

|

|

|

|

|

|

|

|

Water Te |

|

|

|

|

|

|

|

MIN segment on

MIN segment on

Boiler Maximum ----------------------------------

The Boil MAX is the highest temperature that the control is allowed to use as a boiler target temperature. MAX is displayed in the status field viewing the boiler supply or target & when the boiler target is boiler maximum & the boiler supply is greater than boiler maximum minus 5°F (2.5°C). Set the boiler maximum setting below the boiler operator or aquastat temperature.

|

|

|

|

|

e |

|

B |

|

|

|

r |

|

|

|

|

|

u |

|

|

|

o |

|

|

t |

|

|

|

|

a |

|

|

Boil MAX |

||

l |

r |

|

|

|

||

i |

e |

|

|

|

|

|

|

W |

|

|

p |

|

|

|

|

|

|

|

|

a |

|

em |

|

|

|

Boil MAX – 5°F (2.5°C) |

||

|

|

T |

|

|

|

|

||||

|

|

t er |

|

|

|

|

|

Boiler Di erential |

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

MAX |

|

|

|

|

MAX |

|

|

|

|

|

segment |

|

|

|

|

segment |

|

|

|

|

|

on |

|

|

|

on |

|||||

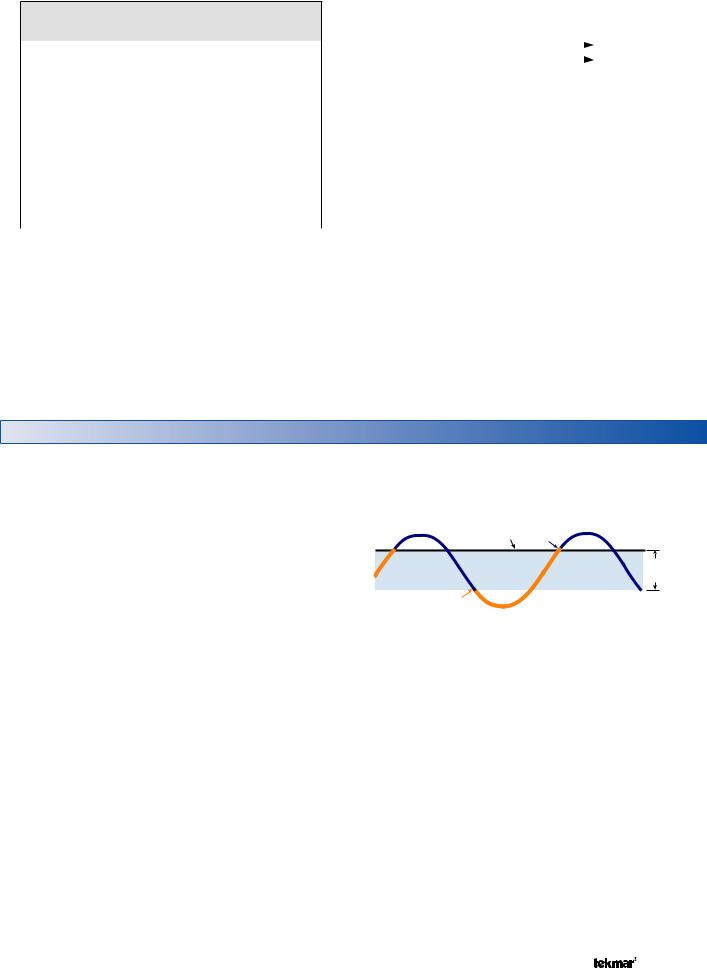

Boiler Differential --------------------------------

Both on/off (single stage & two stage) & modulating boilers are operated with a differential. In some cases, a modulating boiler must be operated with a differential at low fire. This indicates the load is smaller than the minimum modulation of the boiler. For modulating boilers, the differential no longer applies once operating the boiler above low fire.

The differential operates by turning on the boiler when the boiler supply water temperature is 1/2 of the differential below the boiler target temperature. As the boiler supply water temperature reaches 1/2 of the differential above the boiler target temperature, the boiler is shut off.

Manual Differential

Di erential = 10°F (6°C)

165°F (74°C) |

|

Target + 1/2 Di erential |

160°F (71°C) |

|

Target |

155°F (68°C) |

|

Target – 1/2 Di erential |

Boiler |

Boiler |

|

On |

On |

|

Automatic Differential |

|

|

Off |

|

|

Differential |

On |

Load |

|

||

|

Heating |

|

|

|

|

Time |

|

|

Exercising----------------------------------------

The control will exercise all pumps, & tN4 zones (zone valves & zone pumps) for 10 seconds every three days of inactivity to prevent seizure. To enable exercising, switch the Exercise / Off DIP to the Exercise position.

Boost --------------------------------------------

When the control changes from the UnOccupied mode to the Occupied mode, it enters into a boosting mode. In this mode, the supply water temperature to the system is raised above its normal values for a period of time to provide a faster recovery from the setback temperature of the building. The maximum length of the boost is selected using the BOOST setting in the Setup menu.

Typical settings for the boost function vary between 30 minutes & two hours for buildings that have a fast responding heating system. For buildings that have a slow responding heating system, a setting between four hours & eight hours is typical. After a boost time is selected, the setback timer must be adjusted to come out of setback some time in advance of the desired occupied time. This time in advance is normally the same as the BOOST setting.

If the building is not up to temperature at the correct time, the BOOST setting should be lengthened & the setback timer should be adjusted accordingly. If the building is up to temperature before the required time, the BOOST setting should be shortened & the setback timer should be adjusted accordingly. If the system is operating near its design conditions or if the supply water temperature is being limited by settings made in the control, the time required to bring the building up to temperature may be longer than expected.

A Watts Water Technologies Company |

5 of 60 |

© 2014 |

284_D - 08/14 |

Flow Monitoring ----------------------------------

The control has the capability to monitor flow rate through the connection of a 4-20 mA style flow sensor. Flow is measured in either gallons per minute (gpm) or meters cubed per hour (m3/h). The units are adjustable through the FLOW UNIT setting in the Toolbox menu.

Varying flow rates are accommodated & the flow range of the flow sensor being used is configured using the following items in the Setup menu:

• FLOW RATE 4 mA

Sets the flow rate on the low end which corresponds to 4 mA.

• FLOW RATE 20 mA

Sets the flow rate on the high end which corresponds to 20mA.

Examples of compatible aftermarket flow sensors include the Kele SDI series, 2200 & 3100 series and 200 series (requires 310 transmitter).

In addition to flow monitoring, the flow sensor can also be used to prove primary pump flow. Refer to the Pump Operation section of this brochure for additional details.

Energy Monitoring -------------------------------

The control has the capability to monitor Energy. The control requires the boiler supply, boiler return sensor & the flow sensor in order to calculate & display energy in either Therms (THRM) or Gigajoules (GJ). The units are adjustable through the ENERGY UNIT setting in the Toolbox menu. Select MBtu for display in THRM and kWh for display in GJ.

Pressure Monitoring -----------------------------

The control has the capability to monitor system pressure through the connection of a V(dc) style pressure sensor with a signal range of 0.5 to 4.5 V (dc). Pressure is measured in either psi or kPa. The units are adjustable through the PRESSURE UNIT setting in the Toolbox menu.

The Pressure Sensor Range item in the Setup menu selects from the available pressure ranges for the pressure sensor to be used.

Examples of compatible aftermarket pressure sensors include the Honeywell PX2 (AA) series and the Measurement Specialties 7100 series.

Vent Temperature Monitoring & Limiting ---------

The control has the capability to measure & limit the vent temperature. The VENT MAX setting defines the operation of the vent sensor. If the vent temperature exceeds the VENT MAX, the boiler plant is shut down. The boiler plan will not be allowed to operate until the vent temperature drops 10°F (6°C) below the VENT MAX. If OFF is selected, the vent temperature is only monitored.

Alert Relay ---------------------------------------

The control has an Alert relay that closes whenever a control or sensor error is detected, or when a warning or limiting condition is detected. When the alert contact closes, refer to the Error Messages section of this brochure to determine the cause of the alert & how to clear the error.

Boiler Alert

If no temperature increase is detected at the boiler supply sensor within this delay period, the Alert relay will close & the control will display the NO HEAT error message. To clear the error, press the CLEAR button while viewing the error message.

A Watts Water Technologies Company |

6 of 60 |

© 2014 |

284_D - 08/14 |

Boiler Plant Operation

The 284 is able to operate up to four boilers to maintain a boiler target temperature. Proportional, Integral & Derivative (PID) logic is used in order to satisfy the boiler target temperature for all plant configurations with the exception of Dedicated Domestic Hot Water (DDHW). Proportional (P) logic is used for DDHW. For proper operation of the boilers, the 284 must be the only control that determines when a boiler is to fire.

*Important: The boiler operator, or aquastat, remains in the burner circuit & acts as a secondary upper limit on the boiler temperature. The boiler aquastat temperature setting must be adjusted above the 284’s boiler maximum setting in order to prevent short cycling of the burner.

Boiler Operation----------------------------------

Single Stage On/Off Boiler

Once a boiler is required to operate, the control turns on the Stage 1 relay. Once the control turns on the Stage 1 relay, it will display the “Boiler” icon & “100%” under the respective boiler output status in the display.

Two Stage On/Off Boiler

Once a boiler is required to operate, the control turns on the Stage 1 relay. Once the Fire Delay time plus the Stage Delay time has expired, the control can turn on the Stage 2 relay if it is required. Once the control turns on the Stage 1 relay, it will display the “Boiler” icon & “50%” under the respective boiler output status in the display. Once the control turns on the Stage 2 relay, it will display “100%”.

Modulating Boiler

Once a boiler is required to operate, the control outputs an analog signal corresponding to the Start Modulation setting & then turns on the Stage 1 relay. Once the Fire Delay time has expired, the modulating output is adjusted to the Minimum Modulation setting. The control then holds the modulating output at the Minimum Modulation until the Minimum Modulation Delay time has elapsed. The control can then adjust the modulating output from the Minimum Modulation as required. Once the control turns on the Stage 1 relay, it will display the “Boiler” under the respective boiler output status in the display. The current firing rate is also displayed in the boiler output field.

EMS Boiler

Once a boiler is required to operate, the control outputs an appropriate analog signal corresponding to the boiler target temperature & then turns on the Stage 1 relay. Once the control turns on the Stage 1 relay, it will display the “Boiler” under the respective boiler output status in the display. The target water temperature is also displayed in the boiler output field.

Boiler Target Temperature ------------------------

The Boil TARG temperature is determined by the application mode & the type of call received. The control displays the temperature that it is currently trying to maintain at the boiler supply sensor in the View menu. If the control does not presently have a requirement for heat, it does not show a boiler target temperature. Instead, “---” is displayed in the LCD.

Stage Delay --------------------------------------

The STG DELAY is the minimum time delay between the firing of each boiler or boiler stage. After this delay has expired the control can fire the next boiler or boiler stage if it is required. This

setting can be adjusted manually or set to an automatic setting. When the automatic setting is used, the control determines the best stage delay based on the operation of the system.

Modulation Mode ---------------------------------

When using multiple modulating boilers, a selection must be made regarding the sequencing of the boilers. Two modulation mode settings are provided considering condensing & noncondensing boiler groups.

Modulation Mode is not available when the Application Mode is configured for Dedicated Domestic Hot Water (DDHW).

•MOD COND (Modulation Mode - Modulating, Condensing Boiler Group)

This setting is applicable for a group at least two modulating, condensing boilers.

•MOD NC (Modulation Mode - Modulating, Non-Condensing Boiler Group)

This setting is applicable for a group of at least two modulating, non-condensing boilers.

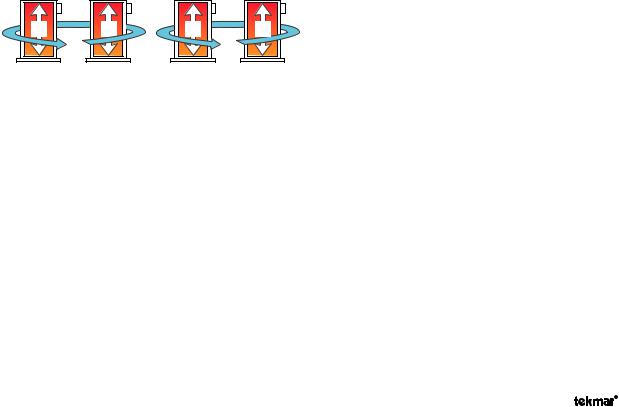

Sequential Modulation (SEQ)

With Sequential Modulation, the control will turn on the fewest boilers possible to meet the load. The control will bring a boiler from its Minimum Modulation setting up to its Maximum Modulation setting before bringing on another boiler. When another boiler is turned on, the previous boiler will keep its output at full fire.

100% |

60% |

Off |

Off |

Parallel Modulation (PAR)

With Parallel Modulation, the control will turn on the most boilers possible to meet the load. The control will bring on the first boiler at Minimum Modulation & does not increase its modulation. If more boiler output is required, the second boiler will turn on at Minimum Modulation & does not increase its modulation. Additional boilers are turned on at their Minimum Modulation setting until all boilers are on. If still more boiler output is required, all boilers are modulated up in parallel until they reach their Maximum Modulation settings.

40% |

40% |

40% |

40% |

Staging Mode Setup ------------------------------

When using multiple two-stage boilers, a selection must be made regarding the staging order of the boilers. Two staging modes are provided considering condensing & non-condensing boiler groups.

•STG COND (Staging Mode - Two-Stage, Condensing Boiler Group)

A Watts Water Technologies Company |

7 of 60 |

© 2014 |

284_D - 08/14 |

This setting is applicable for a group of at least two, two-stage condensing boilers.

•STG NC (Staging Mode - Two-Stage Non-Condensing Boiler Group)

This setting is applicable for a group of at least two, two-stage non-condensing boilers.

Lo/Hi

If the Lo/Hi staging option is selected the control stages in sequence all of the stages in a single boiler. Once all of the stages are turned on, the control then stages in sequence all of the stages of the next boiler in the rotation sequence.

Lo/Lo

If the Lo/Lo staging option is selected, the control stages all of the Lo stage outputs in all of the boilers first. Once all of the boilers are operating on their Lo stages, the control then operates the second stage in each boiler in the same order.

Boiler Group Rotation ----------------------------

The control has two rotation settings including one for the condensing boiler group & another for the non-condensing boiler group.

• ROT COND (Rotation - Condensing Boiler Group)

This setting is applicable for a group of at least two, two-stage condensing boilers.

• ROT NC (Rotation - Non-Condensing Boiler Group)

This setting is applicable for a group of at least two, two-stage non-condensing boilers.

The Rotate feature changes the firing order of the boilers whenever one boiler accumulates 48 hours more run time than any other boiler. Rotation will be forced if any boiler accumulates 60 hours more run time. After each rotation, the boiler with the least running hours is the first to fire & the boiler with the most running hours is the last to fire. This function ensures that all of the boilers receive equal amounts of use. When the Rotation setting is set to Off, the firing sequence always begins with lowest boiler to the highest boiler.

1 |

2 |

2 |

1 |

720 hours |

672 hours |

672 hours |

720 hours |

To reset the rotation sequence, clear the Burner Run Time in the Monitor (#) Menu.

Boiler Run Time Monitoring ----------------------

The running time of each boiler is logged in its respective Monitor

(#) menu. To reset the running time, select the appropriate BURNER item in the Monitor (#) menu & select CLEAR until “0” is displayed.

Fixed Lead ---------------------------------------

When the boiler plant includes only one boiler group, either a condensing or a non-condensing group, a selection must be made regarding operation of the lead boiler.

ON

In some applications, it may be desirable to have the first boiler fire first at all times while the firing sequence of the remaining boilers is changed using Equal Run Time Rotation. This configuration is typical of installations where the boiler plant includes similar boilers but the first boiler is required to be the first to fire in order to establish sufficient draft for venting. With a fixed lead rotation, the lead boiler is always turned on first & turned off first. The Fixed Lead is always applied to the boiler 1 output.

OFF

The lead boiler is not fixed to operate first in the firing sequence. It is included in the rotation sequence with the other boilers.

Fixed Last ----------------------------------------

When the boiler plant includes only one boiler group, either a condensing or a non-condensing group, a selection must be made regarding operation of the last boiler.

ON

In some applications, it may be desirable to have the last boiler fire last at all times while the firing sequence of the remaining boilers is changed using Equal Run Time Rotation. This configuration is typical of installations where the boiler plant includes higher efficient boilers & a single lesser efficient boiler. The lesser efficient boiler is only desired to be operated when all other boilers in the plant are on & the load cannot be satisfied. With a fixed last rotation, the last boiler is the last to turn on & the first to turn off. The Fixed Last is always applied to the boiler 4 output.

OFF

The last boiler is not fixed to operate last in the firing sequence. It is included in the rotation sequence with the other boilers.

Condensing & Non-Condensing Boiler Groups ---

Operating a boiler plant that contains both condensing (high initial cost) & non-condensing (lower initial cost) boilers allows the boiler plant to achieve nearly the same operating efficiencies as operating all condensing boilers but at a much lower installed cost to the building owner. High system efficiency can be achieved as long as the condensing boilers are the first to operate in the firing sequence. During mild weather, the lead condensing boilers operate at lower boiler temperatures & achieve their peak boiler efficiencies while the non-condensing boilers are rarely operated. During very cold weather, the boiler target temperature is often above the boiler’s condensation point & the condensing & non-condensing boilers operate together at roughly the same efficiency level.

When a condensing boiler is operating, it is desirable to operate the boilers without a boiler minimum temperature being applied to the boiler target. This allows the condensing boiler to operate at its maximum efficiency. When a non-condensing boiler is operating, a boiler minimum temperature should be applied to the boiler target to prevent damage to the non-condensing boiler’s heat exchanger from sustained flue gas condensation.

A Watts Water Technologies Company |

8 of 60 |

© 2014 |

284_D - 08/14 |

The 284 supports operation of a condensing & a non-condensing boiler group. A condensing boiler group is created when at least one boiler is selected to be condensing & a non-condensing boiler group is created when at least one boiler is selected to be non-condensing. The condensing boiler group is always sequenced on first, followed by the non-condensing boiler group.

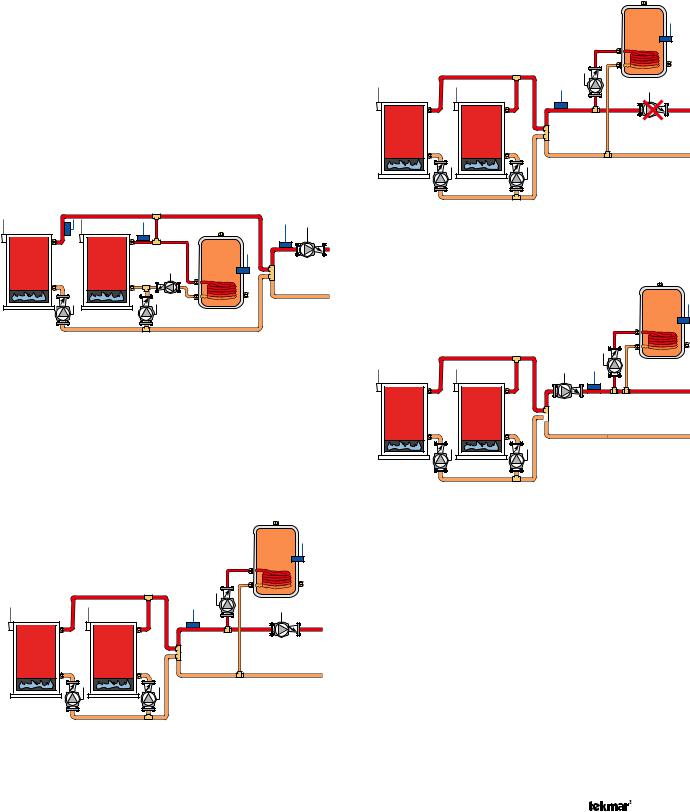

Boiler Plant Flow (PLANT FLW) -------------------

The control supports the option of having all boilers in the plant to use either a pump or an isolation valve.

Boiler Pump (PUMP)

PUMP is to be selected when each boiler in the plant includes its own circulator. This is typical of a conventional boiler plant configuration that includes boilers that are flow sensitive.

PUMP is also to be selected when each boiler in the plant neither includes a pump nor an isolation valve. This boiler plant configuration could be used with boilers that are not flow sensitive. It is expected that the primary pump provides flow through all boilers, regardless of whether they are on or off.

Boiler Isolation Valve (VALV)

VALVE is to be selected when each boiler in the plant includes an isolation valve. This boiler plant configuration could be used with boilers that are not flow sensitive & is typical of systems that incorporate a variable frequency drive (VFD) with the primary pump. Systems incorporating variable speed primary pumping (via a VFD) allow for increased pump electrical energy savings during milder heating loads.

The purpose of the isolation valve is to isolate the boiler from plant operation when the boiler is turned off. As a boiler is isolated, the VFD will adjust the flow rate accordingly. The isolation valve must include a spring return motor that is of the normally open / fail open type. As the control does not include a proof input for proving that the isolation valve is fully open prior to burner ignition, the motor end switch, if available, should be wired into the burner’s safety circuit.

Boiler isolation valve operation is dependent on whether the Heat Call is permanent or intermittent.

• Permanent Heat Call (e.g. external Heat Call shorted)

As the heating load becomes satisfied & a boiler is required to be turned off, the boiler will turn off while its isolation valve remains open for the boiler purge period time. After the boiler purge time expires, the isolation valve will close. When the last boiler in the plant turns off, its isolation valve will remain open, allowing for a flow path of the primary pump.

When there is a subsequent requirement for plant operation and a boiler is required to be turned on, its isolation valve will be opened (if not already open) prior to burner ignition. Also, if applicable, the isolation valve of the last boiler turned off in the previous cycle will be turned off.

•Intermittent Heat Call (e.g. external Heat Call interlocked with space heating thermostat)

When the Heat Call is present, operation is consistent with the operation defined for a Permanent Heat Call.

When the external Heat Call is removed, the isolation valve of every boiler will be opened. When the external Heat Call is re-applied, the control will keep open the valve of the boiler that is due to be turned on first. The isolation valves of all other boilers will be closed.

A Watts Water Technologies Company |

9 of 60 |

© 2014 |

284_D - 08/14 |

Outdoor Temperature Reset Operation

Outdoor Temperature Reset is available by setting the Application Mode in the Setup Menu to RSET.

In a heating system, the rate of heat supplied to the building must equal the rate at which heat is lost. If the two rates are not equal, the building will either cool off or over heat.

The rate of building heat loss depends mostly on the outdoor temperature. Outdoor Reset allows a hot water heating system to increase the water temperature, adding heat to the building, as the outdoor temperature drops. The rate at which the water temperature is changed as a function of outdoor temperature is defined by the characterized heating curve.

Indirect Domestic Hot Water (IDHW) & setpoint operation are both available during outdoor temperature reset operation.

Heat Call -----------------------------------------

A Heat Call is required in order for the control to provide target water temperature for the space heating system. Once the control registers a Heat Call, it will display the “Heat” icon under the Calls in the display. A heat call can be provided in two ways:

Contact Closure

A dry contact or 24 V (ac) signal is applied across the Heat Call terminals 5 & 6.

tekmarNet® Device

A tN4 thermostat wired to one of the tN4 Bus terminals.

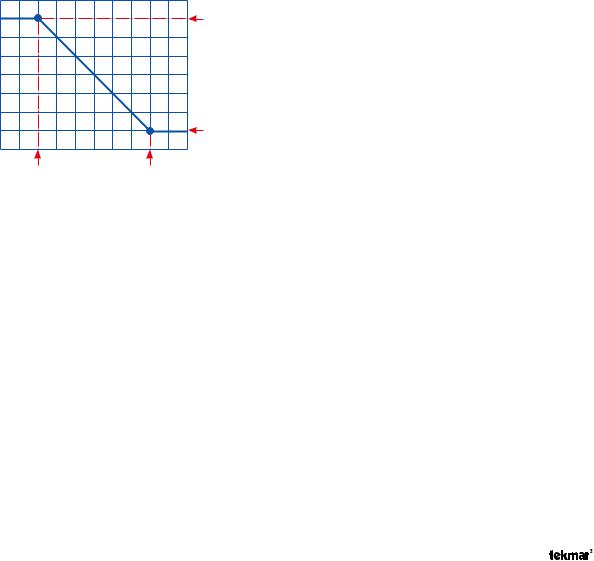

Characterized Heating Curve ---------------------

A characterized heating curve determines the amount the target water temperature is raised for every 1° drop in outdoor air temperature.

The characterized heating curve takes into account the type of terminal unit that the system is using. Since different types of heating terminal units transfer heat to a space using different proportions of radiation, convection & conduction, the supply water temperature must be controlled differently. The control uses the terminal unit setting to vary the supply water temperature to suit the terminal unit being used. This improves the control of the air temperature in the building.

Boiler Characterized Heating Curve

|

|

Boiler |

|

|

|

Design |

Temperatures |

Terminal |

|

|

|

|

|

|

|

Unit |

|

|

Water |

|

Outdoor |

|

|

|

Design |

|

Increasing |

Boiler |

|

|

|

Indoor |

|

|

|

Decreasing Outdoor Temperatures

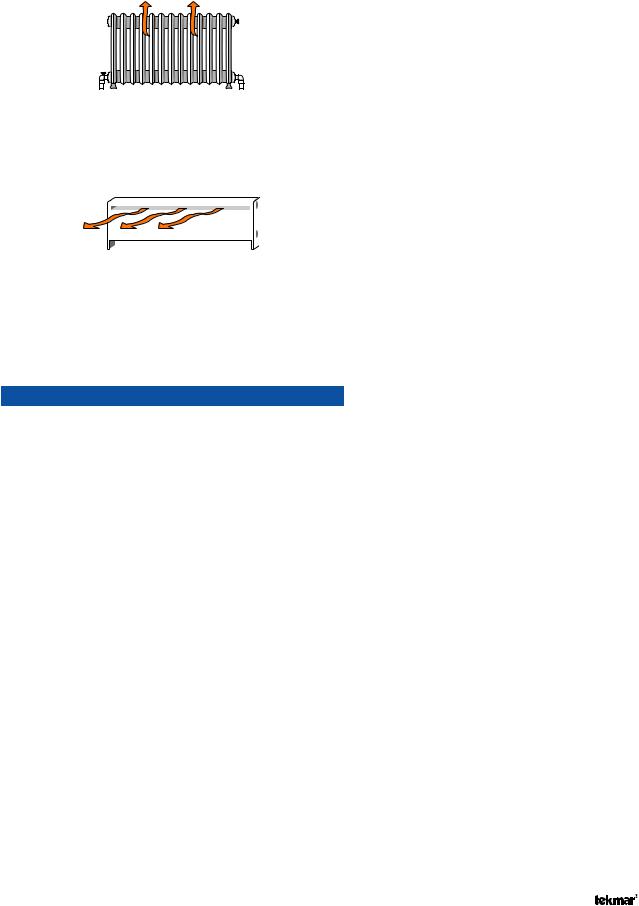

Terminal Unit -------------------------------------

Select the appropriate terminal unit in the Setup Menu. This will change the shape of the characterized heating curve to better match the heat transfer properties of that specific terminal unit.

Hydronic Radiant Floor (HRF1)

A heavy or high mass, hydronic radiant floor system. This type of a hydronic radiant floor is embedded in either a thick concrete or gypsum pour. This heating system has a large thermal mass & is slow acting.

Hydronic Radiant Floor (HRF2)

A light or low mass, hydronic radiant floor system. Most commonly, this type of radiant heating system is attached to the bottom of a wood sub floor, suspended in the joist space, or sandwiched between the subfloor & the surface. This type of radiant system has a relatively low thermal mass & responds faster than a high mass system.

Fancoil (COIL)

A fancoil terminal unit or air handling unit (AHU) consisting of a hydronic heating coil & either a fan or blower. Air is forced across the coil at a constant velocity by the fan or blower & is then delivered into the building space.

Fin–tube Convector (CONV)

A convector terminal unit is made up of a heating element with fins on it. This type of terminal unit relies on the natural convection of air across the heating element to deliver heated air into the space. The amount of natural convection is dependant on the supply water temperature to the heating element & the room air temperature.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A Watts Water Technologies Company |

10 of 60 |

© 2014 |

284_D - 08/14 |

|||||||

Radiator (RAD)

A radiator terminal unit has a large heated surface that is exposed to the room. A radiator provides heat to the room through radiant heat transfer & natural convection.

Baseboard (BASE)

A baseboard terminal unit is similar to a radiator, but has a low profile & is installed at the base of the wall. The proportion of heat transferred by radiation from a baseboard is greater than that from a fin-tube convector.

Boiler Terminal Unit Defaults

When a terminal unit is selected for boiler zones, the control loads default values for the boiler design, boiler maximum supply, & boiler minimum supply temperatures. The factory defaults can be changed to better match the installed system. Locate the Terminal Unit setting in the Setup menu.

Terminal Unit |

Boil DSGN |

Boil MAX |

*Boil MIN |

|

|

|

|

High Mass Radiant |

120°F (49.0°C) |

140°F (60.0°C) |

140°F (60.0°C) |

|

|

|

|

Low Mass Radiant |

140°F (60.0°C) |

160°F (71°C) |

140°F (60.0°C) |

|

|

|

|

Fancoil |

190°F (88.0°C) |

210°F (99.0°C) |

140°F (60.0°C) |

Fin-Tube Convector |

180°F (82.0°C) |

200°F (93.5°C) |

140°F (60.0°C) |

|

|

|

|

Radiator |

160°F (71.0°C) |

180°F (82.0°C) |

140°F (60.0°C) |

|

|

|

|

Baseboard |

150°F (65.5°C) |

170°F (76.5°C) |

140°F (60.0°C) |

|

|

|

|

Boil MIN is only available if at least one boiler is set to noncondensing. If all available boilers are set to condensing, Boil MIN is not available & is hard-coded to OFF.

Room --------------------------------------------

The Room setting is the desired room air temperature, according to the outdoor reset heating curve. The Room setting parallel shifts the heating curve up or down to change the target water temperature. Adjust the Room setting to increase or decrease the amount of heat available to the building. Once the heating curve has been set up properly, the Room setting is the only setting that needs to be adjusted. The default Room setting is 70°F (21.0°C), & it can be adjusted for both the occupied & unoccupied periods.

Outdoor Design ----------------------------------

The outdoor design temperature is typically the coldest outdoor air temperature of the year. This temperature is used when doing the heat loss calculations for the building & is used to size the heating system equipment. If a cold outdoor design temperature is selected, the supply water temperature rises gradually as the outdoor temperature drops. If a warm outdoor design temperature is selected, the supply water temperature rises rapidly as the outdoor temperature drops.

Boiler Indoor -------------------------------------

The boiler indoor design temperature is the indoor temperature the heating designer chose while calculating the heat loss for the boiler water heated zones. This temperature is typically 70°F (21.0°C). This setting establishes the beginning of the boiler characterized heating curve.

Boiler Design-------------------------------------

The boiler design supply temperature is the boiler water temperature required to heat the zones at the outdoor design temperature, or on the typical coldest day of the year.

(Default automatically changes based on terminal unit setting)

Warm Weather Shut Down (WWSD)---------------

Warm Weather Shut Down disables the heating system when the outdoor air temperature rises above this programmable setting. When the control enters into WWSD, WWSD is indicated in the status field. WWSD is only available when the Application Mode is set to RSET.

While in WWSD, the control will still operate to provide Indirect Domestic Hot Water or Setpoint operation.

A Watts Water Technologies Company |

11 of 60 |

© 2014 |

284_D - 08/14 |

Setpoint Operation

Setpoint operation is dependant on the application mode setting.

•If the Application Mode is configured for Outdoor Temperature Reset (RSET) or Energy Management System (EMS), the control provides heat for an additional setpoint load. The control does respond to a Heat Call from a space heating system.

•If the Application Mode is configured for Setpoint (SETP), the control provides heat only for the setpoint load. The control does not respond to a Heat Call for space heating.

Indirect Domestic Hot Water (IDHW) operation is available during setpoint operation.

Setpoint Call ------------------------------------

A Setpoint Call is required in order for the control to provide heat to a setpoint load, such as a spa, pool or snowmelt load. Once the control registers a Setpoint Call, it will display the “Setpoint” icon under the Calls in the display. A setpoint call can be provided in two ways:

Contact Closure

A dry contact or 24 V (ac) signal is applied across the Setpoint Call terminals 9 & 10.

tekmarNet® Setpoint Control with Sensor

A Setpoint Call is provided through the tekmarNet® system. This can be done through the tN4 Boiler Bus terminals with a tekmarNet® setpoint device such as a Setpoint Control 161.

Boiler Target Temperature During a Setpoint Call ----

When a Setpoint Call is present, a boiler target is determined.

•When using a Contact Closure, the boiler target is set to the SETP Setpoint setting.

•When using a tekmarNet® Setpoint Control, the boiler target is set to the devices Exchange Supply setting.

If there are multiple devices calling for heat, the boiler target is set to the highest temperature requirement.

Setpoint During UnOccupied

When using a Contact Closure, a second SETP Setpoint setting is available for the Unoccupied periods.

DIP Switch must be set to Setback to view UnOccupied items.

During the Away Scene, Setpoint Calls are ignored.

Setpoint Mode------------------------------------

The control has a Setpoint Mode setting that selects whether or not setpoint heating is operational.

OFF

Setpoint operation is not provided. All Setpoint Calls are ignored. If this mode is selected while setpoint operation is underway, all setpoint operation ceases.

ON

Setpoint heating is provided. All Setpoint Calls are responded to. Operation is dependant on the Primary Pump During Setpoint operation setting.

Primary Pump During Setpoint ------------------

This setting selects whether or not primary pump operation is required during setpoint heating.

OFF

The primary pump does not turn on during setpoint heating. It is assumed that the setpoint load pump will provide adequate flow through the setpoint load & the boiler system loop.

Setpoint

Primary

ON

The primary pump turns on during setpoint heating.

Setpoint

Primary

Setpoint Priority----------------------------------

This setting selects whether or not priority of setpoint over space heating is required. Setpoint priority stops or limits the delivery of heat to the space heating system while the setpoint load calls for heat. This allows for quick recovery of the load.

OFF

Setpoint priority is not provided. The primary pump can operate when a Heat Call is present. Heating zones are unaffected by setpoint heating.

ON

Setpoint priority is provided & is dependant on the type of space heating zones & whether or not the primary pump is required to operate during setpoint heating.

For non-tN4 space heating, the primary pump shuts off to provide priority. If the primary pump is required to operate for setpoint heating, priority requires the use of an external relay to force the heating zones off.

For tN4 space heating, the primary pump can operate when a Heat Call is present. If the boilers are unable to maintain the boiler target temperature, the tN4 zones are sequentially shut off using tN4 communication to provide priority.

A Watts Water Technologies Company |

12 of 60 |

© 2014 |

284_D - 08/14 |

Priority Override ---------------------------------

Priority Override applies when Setpoint Priority is set to ON. It prevents the building from cooling off too much or the possibility of a potential freeze up during setpoint priority.

When set to auto, the priority time is calculated based on outdoor temperature. At or below the design outdoor temperature, 15 minutes are allowed for setpoint priority. At or above the Indoor Design temperature, 2 hours are allowed for setpoint priority. The time allowed for setpoint priority varies linearly between the above two points. There is a manual setting also available in the Setup menu.

The priority timer does not start timing until priority is selected & both a Setpoint Call & a Heat Call exist together. Once the allowed time for priority has elapsed, the control overrides the setpoint priority & resumes space heating.

Conditional Setpoint Priority ---------------------

If the boiler supply temperature is maintained at or above the required temperature during setpoint heating, this indicates that the boilers have enough capacity for setpoint & possibly space heating as well. As long as the boiler supply temperature is maintained near the target, setpoint & heating occurs simultaneously.

Setpoint Post Purge ------------------------------

After a Setpoint Call from a tN4 device is removed, the control can perform a post purge. The control shuts off the boilers & continues to operate, if applicable, the primary pump. This purges the residual heat from the boilers into the setpoint load. The control continues this purge until one of the following occurs:

1.A Heat Call is detected.

2.The boiler supply drops 20°F (11.0°C) below the setpoint target temperature.

3.Two minutes elapse.

Energy Management System (EMS) Operation

The control can accept an external DC signal from an Energy Management System (EMS). The control converts the DC signal into the appropriate boiler target temperature for the space heating system.

EMS is available by setting the APP MODE in the Setup Menu to EMS.

Indirect Domestic Hot Water (IDHW) & setpoint are both available during EMS operation.

Heat Call -----------------------------------------

A Heat Call is required in order for the control to provide a target water temperature for the space heating system. Once the control registers a Heat Call, it will display the “Heat” icon under the Calls in the display.

A Heat Call is provided by:

Input Signal

An external signal is generated by applying a voltage between 0 V (dc) & 10 V (dc) across the EMS (+) In & Com (-) terminals (16 & 19). Voltages that exceed 10 V (dc) will still be considered a 10 V (dc) signal.

If the EMS signal goes below the minimum voltage, the “Heat” icon under the Calls in the display is turned off. The boiler target temperature is displayed as “– – –” to indicate that there is no longer a call for heating.

External Heat Call terminals are not operational.

EMS Signal ---------------------------------------

The control can accept either a 0-10 V (dc) signal or a 2-10 V (dc) signal. The EMS SGNL setting must be set to the proper setting based on the signal that is being sent to the control.

0 - 10 V (dc) or 0 - 20 mA

When the 0-10 V (dc) signal is selected, an input voltage of 1 V (dc) corresponds to a boiler target temperature of 50°F (10.0°C). An input voltage of 10 V (dc) corresponds to a boiler target temperature of 210°F (99.0°C). As the voltage varies between 1 V (dc) & 10 V (dc) the boiler target temperature varies linearly between 50°F (10.0°C) & 210°F (99.0°C). If a voltage below 0.5 V (dc) is received the boiler target temperature is

displayed as “– – –” indicating that there is no longer a call for heating.

A 0 - 20 mA signal can be converted to a 0 - 10 V (dc) signal by installing a 500 Ω resistor between the EMS (+) In & Com (-) terminals (16 & 19).

2 - 10 V (dc) or 4 - 20 mA

When the 2 - 10 V (dc) signal is selected, an input voltage of 2 V (dc) corresponds to a boiler target temperature of 50°F (10.0°C). An input voltage of 10 V (dc) corresponds to a boiler target temperature of 210°F (99.0°C). As the voltage varies between 2 V (dc) & 10 V (dc) the boiler target temperature varies linearly between 50°F (10.0°C) & 210°F (99.0°C). If a voltage below 1.5 V (dc) is received the boiler target temperature is displayed as “– – –” indicating that there is no longer a call for heating.

A 4 - 20 mA signal can be converted to a 2 - 10 V (dc) signal by installing a 500 Ω resistor between the EMS (+) In & Com (-) terminals (16 & 19).

CONVERSION TABLE 0 - 10

0 - 20 mA* |

0 - 10 V (dc) |

Boiler Target |

0 |

0 |

– – – (OFF) |

|

|

|

2 |

1 |

50°F (10.0°C) |

|

|

|

4 |

2 |

68°F (20.0°C) |

|

|

|

6 |

3 |

86°F (30.0°C) |

|

|

|

8 |

4 |

103°F (39.5°C) |

|

|

|

10 |

5 |

121°F (49.5°C) |

|

|

|

12 |

6 |

139°F (59.5°C) |

|

|

|

14 |

7 |

157°F (69.5°C) |

|

|

|

16 |

8 |

174°F (79.0°C) |

18 |

9 |

192°F (89.0°C) |

|

|

|

20 |

10 |

210°F (99.0°C) |

*Requires 500 Resistor in Parallel

A Watts Water Technologies Company |

13 of 60 |

© 2014 |

284_D - 08/14 |

CONVERSION TABLE 2 - 10

4 - 20 mA* |

2 - 10 V (dc) |

Boiler Target |

|

|

|

0 |

0 |

– – – (OFF) |

|

|

|

4 |

2 |

50°F (10.0°C) |

6 |

3 |

70°F (21.0°C) |

|

|

|

8 |

4 |

90°F (32.0°C) |

10 |

5 |

110°F (43.5°C) |

|

|

|

12 |

6 |

130°F (54.5°C) |

14 |

7 |

150°F (65.5°C) |

|

|

|

16 |

8 |

170°F (76.5°C) |

|

|

|

18 |

9 |

190°F (88.0°C) |

|

|

|

20 |

10 |

210°F (99.0°C) |

*Requires 500 Resistor in Parallel

EMS Offset

For external input operation, the boiler target (determined from the external input signal) may be fine tuned. The EMS OFFST setting is used to provide the fine tuning. The setting may be adjusted ±10°F (±5.5°C). When set to 0°F (0.0°C), if the temperature determined from the external signal is 140°F (60.0°C), the boiler target will be 140°F (60.0°C). When set to +5°F (+3.0°C) & with the same external signal represents 140°F (60.0°C), the boiler target will be 145°F (63.0°C).

|

Example |

|

|

|

|

|

|

|

|

|

Range |

= |

0 |

- 10 V (dc) |

|

|

|

|

|

|

|

|

|

|

|

||||

|

Input |

= |

7 |

V (dc) |

|

|

157°F (69°C) |

||

|

|

|

|||||||

|

Offset |

= |

+5°F (3°C) |

|

|

+5°F (3°C) |

|

||

|

|

|

|||||||

|

Boiler Target |

= |

|

|

|

|

|

162°F (72°C) |

|

|

|

|

|

|

|

|

|

|

|

The minimum & maximum settings also apply for external input operation. For example, if a boiler minimum of 140°F (60.0°C) is set & the external signal received represents 80°F (27.0°C), the boiler target will be 140°F (60.0°C). MIN will also be displayed in the status field to indicate that a limiting condition is in effect. This also applies for the MAX limit.

Indirect Domestic Hot Water (IDHW) Operation

IDHW operation is applicable during the following application modes: outdoor temperature reset, fixed setpoint & EMS.

DHW Call -----------------------------------------

A DHW Call is required in order for the control to provide heat to an indirect DHW tank. Once the control registers a DHW Call, it will display the “DHW” icon under Calls in the display. A DHW Call can be provided in three ways:

DHW Tank Aquastat

If a DHW Tank Aquastat (mechanical switch) is used to apply a DHW Call, the tank is heated to the aquastat temperature setting. A dry contact or 24 V (ac) signal is applied across the IDHW Call terminals 7 & 8.

IDHW Sensor must be set to Off.

DHW Sensor

A DHW Tank Sensor provides superior temperature control of the tank compared to an aquastat. The control can register a DHW Call when a DHW Sensor is wired to terminals 21 & 22. Once the DHW Sensor temperature drops 1/2 of the IDHW Differential setting below the iDHW Setpoint, the control registers a DHW Call.

The IDHW Sensor must be set to On. There cannot be an external IDHW Call when using a DHW sensor.

tekmarNet® Setpoint Control with Sensor

A DHW Call is provided through the tekmarNet® system. This can be done through the tN4 Boiler Bus terminals with a tekmarNet® setpoint device such as a Setpoint Control 161.

DHW Differential ---------------------------------

Due to large differences between the heating load & the DHW load, a separate DHW differential should be used whenever a DHW Call is present. This will improve staging & boiler cycling.

When using a DHW Sensor, a DHW Call is registered when the temperature at the DHW sensor drops the IDHW DIFF setting below the IDHW Setpoint setting. The DHW Call is satisfied once the temperature at the DHW Sensor rises to the IDHW Setpoint setting.

DHW Target OFF

IDHW

Differential

ON

Boiler Target Temperature during a DHW Call ------

When a DHW Call is present, a boiler target is determined.

•When using a DHW Tank Aquastat, the boiler target is set to the IDHW Exchange setting.

•When using a DHW Tank Sensor, the boiler target is fixed at the IDHW Setpoint setting plus 40°F (22.0°C).

•When using a tekmarNet® Setpoint Control, the boiler target is set to the devices Exchange Supply setting.

If there are multiple devices calling for heat, the boiler target is set to the highest temperature requirement.

IDHW During UnOccupied ------------------------

When using a DHW Tank Aquastat, a second IDHW Exchange setting is available for the UnOccupied or Sleep period.

When using a DHW Sensor, a second IDHW Setpoint setting is available for the UnOccupied or Sleep period.

DIP Switch must be set to Setback to view UnOccupied items. During the Away Scene, DHW Calls are ignored.

A Watts Water Technologies Company |

14 of 60 |

© 2014 |

284_D - 08/14 |

IDHW Mode -------------------------------------

The control has a IDHW MODE setting that selects whether or not indirect DHW operation is active.

OFF

IDHW operation is inactive. All DHW Calls are ignored. If this mode is selected while DHW operation is underway, all DHW operation ceases.

ON

IDHW operation is active. All DHW Calls are responded to.

IDHW Location ----------------------------------

The control has a IDHW Location setting that selects where the indirect DHW tank is located in the system. This setting determines the operating sensor & affects pump operation.

NEAR

The indirect DHW tank is piped in parallel within the near boiler piping of boiler 4. When a valid DHW Call is present, the IDHW Pump relay turns on & boiler pump 4 turns off. The control uses the boiler 4 outlet sensor as the operating sensor in order to measure the boiler supply temperature supplied to the indirect DHW tank. There are two boiler target temperatures. One for the space heating system (Boil TARG) & one for the indirect DHW system (IDHW TARG).

Primary Pump During IDHW ---------------------------------------

The control has a Primary Pump during IDHW setting that selects whether or not the primary pump is required during indirect DHW operation.

OFF

The primary pump does not turn on during indirect DHW operation. This would be typical of an indirect DHW tank piped in parallel in the boiler system loop. It is assumed that the DHW pump will provide adequate flow through the indirect DHW heat exchanger & the boiler system loop.

DHW

Pump

ON

Primary

Pump OFF

ON

The primary pump turns on during indirect DHW operation. This would be typical of an indirect DHW tank piped in primary/secondary in the boiler system loop.

Near Boiler |

•All boilers are used for space heating requirements.

•Boiler 4 is used for indirect DHW when there is a DHW Call.

•The dedicated indirect DHW boiler is always boiler 4, even if there are less than four boilers.

•If boiler 4 is disabled & NEAR is selected for the IDHW Location, the dedicated indirect DHW boiler 4 will not operate.

Boil

The indirect DHW tank is piped in the boiler system loop. When a valid DHW Call is present, the IDHW Pump relay turns on.

Piped off boiler system loop

DHW

Pump

ON

Primary

Pump ON

Pump ON

IDHW Priority-------------------------------------

The control has a IDHW Priority setting that selects whether or not priority of indirect DHW is required over the space heating system. Indirect DHW priority stops or limits the delivery of heat to the space heating system while the indirect DHW tank calls for heat. This allows for quick recovery of the indirect DHW tank.

OFF

IDHW priority is not provided. The primary pump can operate when a Heat Call is present. Heating zones are unaffected by indirect DHW operation.

ON

IDHW priority is provided & is dependant on the type of space heating zones & whether or not the primary is required to operate during IDHW operation.

A Watts Water Technologies Company |

15 of 60 |

© 2014 |

284_D - 08/14 |

For non-tN4 space heating, the primary pump shuts off to provide priority. If the primary pump is required to operate for IDHW, priority requires the use of an external relay to force the heating zones off.

For tN4 space heating, the primary pump can operate when a Heat Call is present. If the boilers are unable to maintain the boiler target temperature, the tN4 zones are sequentially shut off using tN4 communication to provide priority.

Priority Override ---------------------------------

Priority override applies when IDHW Priority is set to ON & prevents the building from cooling off too much or the possibility of a potential freeze up during IDHW priority.

When set to auto, the priority time is calculated based on outdoor temperature. At or below the design outdoor temperature, 15 minutes is allowed for IDHW priority. At or above the design indoor temperature, 2 hours is allowed for IDHW priority. The time allowed for IDHW priority varies linearly between the above two points. There is a manual setting also available in the Setup menu.

The priority timer does not start timing until priority is selected & both a DHW Call & a Heat Call exist together. Once the allowed time for priority has elapsed, the control overrides the DHW priority & resumes space heating.

Automatic Priority Override

2 hours |

15 mins |

Indoor Design |

Outdoor Design |

Temperature |

Temperature |

Conditional IDHW Priority |

------------------------ |

If the boiler supply temperature is maintained at or above the required temperature during IDHW operation, this indicates that the boilers have enough capacity for IDHW & possibly heating as well. As long as the boiler supply temperature is maintained near the target, IDHW & heating occurs simultaneously.

IDHW Post Purge ---------------------------------

After the DHW Call is removed, the control performs a purge. The control shuts off the boilers & continues to operate the IDHW Pump & the primary pump if applicable. This purges the residual heat from the boilers into the DHW tank. The control continues this purge until one of the following occurs:

1.A Heat Call is detected.

2.The boiler supply drops 20°F (11.0°C) below the DHW target temperature.

3.The DHW tank temperature rises above the DHW setpoint plus 1/2 DHW Differential.

4.Two minutes elapse.

IDHW Mixing Purge-------------------------------

After IDHW operation, the boiler is extremely hot. At the same time, the heating zones may have cooled off considerably after being off for a period of time. When restarting the heating system after a DHW Call with priority, the control shuts off the boiler & continues to operate the IDHW pump while the primary pump is turned on. This allows some of the DHW return water to mix with the cool return water from the zones & temper the boiler return water.

IDHW with Low Temperature Boilers -------------

If DHW heating is to be incorporated into a low temperature system such as a radiant floor heating system, a mixing device is often installed to isolate the high DHW supply temperature from the lower system temperature. If a mixing device is not installed, high temperature water could be supplied to the low temperature system while trying to satisfy the DHW Call. This may result in damage to the low temperature heating system.

The control is capable of providing IDHW heating in such a system while minimizing the chance that the temperature in the heating system exceeds the design supply water temperature. In order to do this, the following must be true:

•All available boilers are set to condensing.

•IDHW Location set to Boil.

•IDHW Priority set to ON.

•tN4 present (IF Primary Pump during IDHW operation is set to ON)

On a DHW Call, the control provides IDHW priority by sending a message on the boiler temperature bus to the tN4 thermostats to shut off the heating zones for a period of time. The length of time is based on the outdoor air temperature, or selectable time, as described in the IDHW Priority Override section. However, if the DHW Call is not satisfied within the allotted time, the boiler shuts off & the heat of the boiler is purged into the DHW tank. A IDHW mixing purge occurs in order to reduce the boiler water temperature & once the boiler supply temperature is sufficiently reduced, the IDHW Pump contact shuts off. The heating system zones are allowed to turn on for a period of time to prevent the building from cooling off. After a period of heating, & if the DHW Call is still present, the control shuts off the heating system & provides heat to the DHW tank once again.

IDHW Boil COUNT IDHW -------------------------

Selects the number of boilers to be used for IDHW operation. This applies when only there is a requirement for IDHW. All available boilers are allowed to operate if there is both a requirement for space heating & IDHW.

A Watts Water Technologies Company |

16 of 60 |

© 2014 |

284_D - 08/14 |

Dedicated Domestic Hot Water (DDHW) Operation

The control can operate to provide heat for a Dedicated Domestic Hot Water (DDHW) system.

DDHW heating is available by setting the Application Mode in the Setup Menu to DDHW.

DHW Call -----------------------------------------

A DHW Call is required in order for the control to provide heat to a dedicated DHW tank. Once the control registers a DHW Call, it will display the “DHW” icon under Calls in the display. This can be done by:

DHW Sensor

The control can register a DHW Call when a DHW Sensor is wired to terminals 21 & 22. Once the DHW Sensor temperature drops 1/2 of the DDHW Differential setting below the DDHW Setpoint, the control registers a DHW Call.

DDHW Differential --------------------------------

A DHW Call is registered when the temperature at the DHW sensor drops the DDHW DIFF setting below the DDHW Setpoint setting. The DHW Call is satisfied once the temperature at the DHW Sensor rises to the DDHW Setpoint setting.

DHW Target OFF

IDHW

Differential

ON

Boiler Target Temperature During a DDHW Call ----