tekmar 132 User Manual

- Data Brochure

Pump Sequencer 132

D 132

04 /10

The Pump Sequencer 132 is designed to provide pump control for either stand-by or 2-stage operation. In stand-by mode, the 132

automatically switches over from the lead pump to the stand-by pump during a pump failure. In 2-stage mode, the 132 turns on the

second stage pump to meet additional flow requirements.

Additional functions include:

• Warm Weather Shut Down (WWSD)

• Exercising

• Equal Run Time Rotation

• Alert per Pump or Alert Levels

• Adjustable flow proof delay

• Test sequence to ensure proper component operation

• 120 V (ac) power supply

• CSA C US certified (approved to applicable UL standards)

Note:

Pump demand must

be powered with 20 to

260 V (ac) before the

pump will turn on.

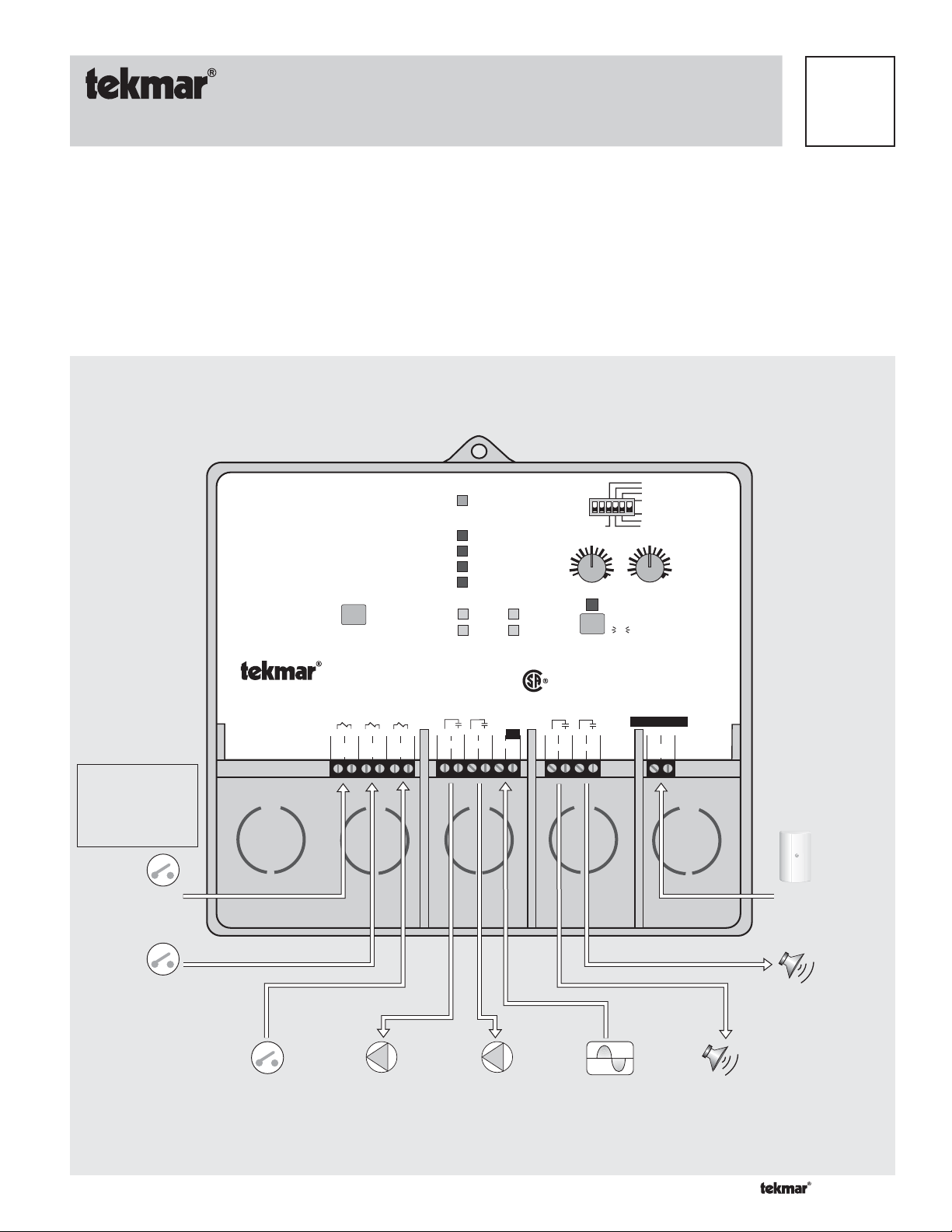

Input

Pump

Demand

Signal

Clear Alert

Pump Sequencer 132

Stand-by / 2-Stage

2

1

Use supply wires suitable for

120°F (50°C) above ambient

Pump

Demand

3

2-Stage

Demand

Pum p

1 2

Stand-by

70°F

Auto

Off

Power

WWSD

Pump Demand

2-Stage Demand

Flow Proof

Pump 1

Pump 2

Alert A

Alert B

35

WWSD

Test

Made in Canada by

tekmar Control Systems Ltd.

Power:

13 14

Alert

A

Pump Relays:

Alert Relays:

Demands:

15 16

Alert

A

B

B

US

89101112

4

5

Flow

Proof

7

6

Pump

1

Pump

Power

N

1

L

2

2

2-Stage

30 second Delay

Exercising

Alert per Pump

Alert Levels

Off

10 second Delay

96 hours

48

100

Off

Frequency of Rotation

off

red

red

120 V ± 10% 60 Hz 6 VA

240 V (ac) 10 A 1/2 hp, pilot duty 720 VA

240 V (ac) 10 A 1/3 hp, pilot duty 240 VA

20 to 260 V (ac) 2 VA

12

Off

not testing

testing

testing paused

Do not apply power

17 18

Outdoor

Sensor

144

168

Signal wiring

must be rate d

at least 300 V.

Meets Class B

Canadian ICES

FCC Part 15

H1197E

Input

Outdoor

Sensor

Optional

Input

2-Stage

Demand

Signal

Input

Flow Proof

Signal

Output

Output

PumpPump

Input

120 V (ac) Power

Supply

Output

Alert

Output

Alert

1 of 12 © 2010 D 132 - 04/10

How To Use The Data Brochure

-----------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------

This brochure is organized into three main sections. They are: 1) Sequence of Operation, 2) Installation, 3) Tro uble shooti ng. The

Sequence of Operation section has three sub-sections. We recommend reading Section A: General Operation of the Sequence of

Operation, as this contains important information on the overall operation of the control. Then read the sub-sections that apply to your

installation.

Table of Contents

Sequence of Operation ..................................Pg 2

Section A: General Operation ..............Pg 2

Settings ............................................................Pg 8

Testing the Control ......................................... Pg 9

Section B: Pump Operation .................. Pg 3

Error Messages ............................................... Pg 10

Section C: Alert Operation ...................Pg 4

Technical D ata .................................................Pg 12

Installa tion ....................................................... Pg 5

Limited Warranty ............................................Pg 12

Sequence of Operation

Section A

General Operation

Page 2 - 3

Section B

Pump Operation

Page 3 - 4

Section C

Alert Operation

Page 4

Section A: General Operation

POWERING UP THE CONTROL

When the Pump Sequencer 132 is powered up, a software version code is displayed for 2 seconds, then the control turns on all

of the red LED’s for 2 seconds. After this test, the control enters its normal operating mode. When the control is powered up, the

Power light remains on continuously.

-----------------------------------------------------------------------------------------------------------------

OPERATION

The Pump Sequencer 132 has two modes of operation. The 132 is capable of operating two pumps in either a stand-by or 2-stage

configuration.

Stand-by

In the stand-by mode of operation the 132 automatically switches over from the lead pump to the stand-by pump if the lead pump

fails to provide flow in the system.

2-Stage

In the 2-stage mode of operation the 132 turns on the second stage pump if there is a requirement for additional flow in the

system. At the same time the control still provides stand-by pump operation.

PUMP DEMAND

A pump demand is required in order for the 132 to provide flow. A pump demand is generated by applying a voltage between 24 and 240 V (ac) across the Pump Demand terminals

(1 and 2). Once voltage is applied, the Pump Demand light is turned on and the pump(s)

operate as required. A pump demand can be permanently powered, or generated from an

external source such as a manual switch or another control system.

© 2010 D 132 - 04/10 2 of 12

--------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------

24 to 240 V (ac)

1

Pump

Demand

2

--------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------------------------------------------

FLOW PROOF

-----------------------------------------------------------------------------------------

A flow proof signal is required at all times during pump operation. A flow proof is generated

by applying a voltage between 24 and 240 V (ac) across the Flow Proof terminals (5 and 6).

Once voltage is applied, the Flow Proof light is turned on. Once a pump contact is turned

on, a flow proof signal must be present before the flow proof delay has expired. A flow

proof can come from a flow switch, pressure differential switch, current sensing switch, or

power sensing switch.

-----------------------------------------------------------------------------------------

24 to 240 V (ac)

5

Flow

Proof

6

FLOW PROOF DELAY (30 second Delay / 10 second Delay)

The 132 allows a time delay for detecting a flow proof signal once a pump contact is turned on. The amount of time is adjustable

from 10 to 30 seconds through a DIP switch. If a flow proof signal is not present within the selected time, the control turns off the

first pump contact and turns on the second pump contact. An alert contact is activated to indicate the failure.

FLOW PROOF TEST

The 132 has a flow proof test in order to determine if the flow proof device has failed. Once the pump contacts are turned off, a flow

proof signal should not be present. If a flow proof signal is still present after 4 minutes, the control activates an alert contact and

displays an error message. Refer to the Error Messages section at the back of this brochure.

ROTATION

The 132 has a function which automatically changes the operating sequence of the pumps based on Equal Run Time Rotation.

Equal Run Time Rotation is based on pump running hours and allows for equal usage of both pumps. The 132 uses the Frequency

of Rotation dial to set the rotation of the pumps.

The control rotates the operating sequence of the pumps when the pumps are off. In a constant circulation system where the lead

pump runs continuously, the control waits for up to 12 hours to rotate the operating sequence of the pumps.

Note: The Equal Run Time Rotation function is reset by pressing the Clear Alert button.

EXERCISING

The 132 has a built-in pump exercising function. This function is only operational if the Exercising / Off DIP switch is set to

Exercising. If a pump has not been operated at least once every three days, the control turns on the output for 10 seconds. This

minimizes the possibility of a pump seizing during a long period of inactivity.

Note: The exercising function does not work if power to the control or pumps is off.

----------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------

WARM WEATHER SHUT DOWN (WWSD)

When the 132 is used as a stand alone control, the pumps can be operated based on outdoor air temperature. The WWSD feature

is only operational when an outdoor sensor is installed and the WWSD dial is not set to Off. When the outdoor air temperature rises

above the WWSD setting, the 132 turns on the WWSD light. When the control is in Warm Weather Shut Down, the demand LED’s

are displayed if there is a demand. However, the control does not operate the pumps to satisfy these demands. If the 132 receives

a pump demand from a reset control, the outdoor sensor should not be installed and the WWSD dial must be set to Off.

----------------------------------------------------------------------------------------------------

Section B: Pump Operation

Section B1

Stand-by

Section B2

2-Stage

Section B1: Stand-by

PUMP OPERATION

The lead pump contact closes whenever there is a pump demand and the 132 is not in WWSD. If a flow proof is not present after the

flow proof delay has expired, the control turns off the lead pump contact and turns on the stand-by pump contact. An alert contact

is activated to indicate the failure. The stand-by pump contact also turns off if a flow proof is not obtained once the flow proof delay

has expired.

3 of 12 © 2010 D 132 - 04/10

----------------------------------------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------

Section B2: 2-Stage

----------------------------------------------------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------

2-STAGE DEMAND

A 2-stage demand is required in order for the 132 to provide additional flow. A 2-stage

demand is generated by applying a voltage between 24 and 240 V (ac) across the 2-Stage

Demand terminals (3 and 4). Once voltage is applied, the 2-Stage Demand light is turned

on. A 2-stage demand can come from an additional pressure differential switch, a temperature differential device, or a setpoint control based on an outdoor air temperature.

Note: The 2-stage demand device should provide an appropriate differential to prevent the

second stage pump from short cycling.

PUMP OPERATION

The first stage pump contact closes whenever there is a pump demand and the 132 is not in WWSD. The second stage pump contact closes whenever there is a pump demand, flow proof, 2-stage demand, and the 132 is not in WWSD.

If flow is not established by the first stage pump, the 132 turns off the first stage pump contact and turns on the second stage pump

contact. An alert contact is activated to indicate the failure. The second stage pump contact also turns off if a flow proof is not

obtained once the flow proof delay has expired.

Section C: Alert Operation

Section C1

Alert Levels

----------------------------------------------------------------------------------

3

4

2-Stage

Demand

24 to 240 V (ac)

----------------------------------------------------------------------------------------------------------------------------------

Section C2

Alert per Pump

There are two alert contacts (Alert A and Alert B) on the Pump Sequencer 132. These contacts are used to indicate either pump or

control failures. The alert contacts have two modes of operation. The mode of operation for the alert contacts is selected using the

Alert per Pump / Alert Levels DIP switch. When an alert contact is activated, refer to the Error Messages section of this brochure to

determine the cause of the alert signal. To clear an alert, press the Clear Alert button.

Section C1: Alert Levels

When operating in the Alert Levels mode, the alert contacts are used to indicate the level of failure in the system.

ALERT A (Non-Critical)

The Alert A contact closes when a non-critical failure occurs. Non-critical failures include: a single pump failure, a control error, an

outdoor sensor failure, or short cycling of the 2-stage demand. With these failures, it is still possible to establish flow in the system.

ALERT B (Critical)

The Alert B contact closes when a critical failure occurs. Critical failures include: the failure of both pumps, or a failure of the flow

proof device. With these failures, the control is no longer able to operate the pumps, and it is not possible to provide flow.

-----------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------

Section C2: Alert per Pump

When operating in Alert per Pump mode, the alert contacts are related to the pump contacts on the control. The Alert A contact closes

anytime Pump 1 fails, and the Alert B contact closes anytime Pump 2 fails. The Alert A contact also closes to indicate an outdoor

sensor failure, a control error, a flow proof device failure, or if the 2-stage demand is short cycling.

© 2010 D 132 - 04/10 4 of 12

Loading...

Loading...