tekmar 260 User Manual

- Data Brochure |

D 260 |

Boiler Control 260 |

03/09 |

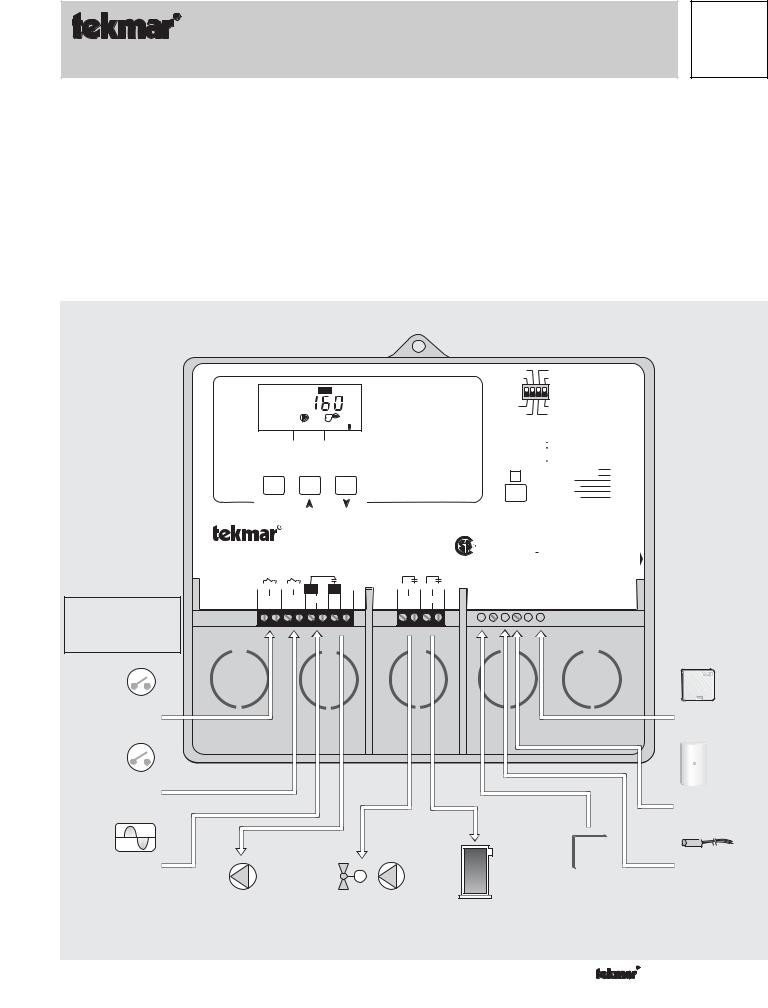

The Boiler Control 260 is designed to control a single stage heat source in order to provide outdoor reset or Domestic Hot Water (DHW) operation. The control has a Liquid Crystal Display (LCD) to view system status and operating information.

Additional functions include:

•Quick Setup for easy installation and programming of control

•User comfort adjustment to increase or decrease building space temperature

•Advanced settings to fine-tune building requirements

•Pump and valve exercising

•Optional indoor sensor for room air temperature control

•Powered boiler pump output

•DHW pump or valve operation

•Optional DHW priority

•Test sequence to ensure proper component operation

•Setback input for energy savings

•120 V (ac) power supply

•CSA C US certified (approved to applicable UL standards)

|

VIEW |

BOIL |

°F |

OCC |

|

Terminal Unit |

Boiler Demand |

Fire Delay |

DHW Demand |

To increase or decrease the building temperature:

Press the Item,

Press the Item, ,

,  buttons simultaneously for 1 sec. to enter the ADJUST menu

buttons simultaneously for 1 sec. to enter the ADJUST menu

Use the

Use the  ,

,  buttons to adjust the ROOM setting

buttons to adjust the ROOM setting

Display defaults back to VIEW menu after 20 sec.

DHW Valve |

DHW Priority |

|

Advanced |

DHWReturnduring UnOcc |

|

Installer |

Off |

|

DHW Pump |

Off |

|

|

Installer Instructions |

|

|

ROOM - Set to desired room temp. |

|

|

OUTDR DSGN - Set to coldest (design) |

|

|

outdoor temp. |

|

|

Terminal Unit |

Set to |

|

Item |

|

|

|

|

|

|

|

|

|

|

|

Boiler Control 260 |

|

|

|

|

|

|

|

|||

|

One Stage Boiler & DHW |

|

|

|

|

|

|

|

|||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 12 |

|

Note: |

Boiler |

DHW |

Power |

Boil |

|

DHW |

Boiler |

||||

Demand |

Demand |

L |

N |

P1 |

N |

Pmp/Vlv |

|

||||

Boiler or DHW demand |

|

|

|

|

|

|

|

|

|

|

|

must be powered with 20 to |

|

|

|

|

|

|

|

|

|

|

|

260 V (ac) before the boiler |

|

|

|

|

|

|

|

|

|

|

|

is able to fire. |

|

|

|

|

|

|

|

|

|

|

|

Input |

|

|

|

|

|

|

|

|

|

|

|

Boiler Demand |

|

|

|

|

|

|

|

|

|

|

|

Signal |

|

|

|

|

|

|

|

|

|

|

|

Input |

|

|

|

|

|

|

|

|

|

|

|

DHW Demand |

|

|

|

|

|

|

|

|

|

|

|

Signal |

|

|

|

|

|

|

|

|

|

|

|

Input |

|

|

|

|

|

|

|

|

|

|

|

120 V (ac) Power |

|

|

|

|

|

|

|

M |

|

|

|

Supply |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Output |

|

|

|

|

|

|

Output |

|

|

|

|

Boiler System |

|

|

|

|

|

DHW Pump OR |

|

|

||

|

Pump |

|

|

|

|

|

|

DHW Valve |

|

|

|

|

|

|

|

|

|

|

|

|

1 of 20 |

||

High Mass Radiant |

1 |

Low Mass Radiant |

2 |

Fan Coil |

3 |

Convector |

4 |

Radiator |

5 |

Baseboard |

6 |

|

|

|

|

|

|

|

Test |

|

|

Refer to brochure for more information |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Meets Class B: |

|

|

|

|

|

|

|

Made in Canada by |

|

Canadian ICES |

|

||||||||

|

|

|

|

|

tekmar Control Systems Ltd. |

FCC Part 15 |

|

|||||||||

|

|

|

|

|

tektra 910-01 |

|

|

|

|

Code |

|

|||||

|

|

|

|

|

Relays: |

240V (ac) 10 A 1/3 hp |

|

|

||||||||

|

|

|

|

|

Power: |

120V + 10% 50/60 Hz 1300 VA |

|

|

|

|||||||

C |

|

US |

|

Demand: 20 to 260 V (ac) 2 VA |

|

Date |

|

|||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Do not apply power |

|

|

|

|

||||||||

|

|

|

13 |

14 |

15 |

16 |

17 |

18 |

|

|

H1154D |

|

||||

|

|

|

Sw |

Com |

Boil |

Out |

Com |

Indr |

rated at least 300V. |

|

|

|||||

|

|

|

UnO |

Signal wiring must be |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input

Indoor Sensor

Optional

Input

Outdoor

Sensor Included

Input

Universal

Input Sensor Included

tekmar Timer

Optional

Output

Boiler

Copyright © D 260 - 03/09

How To Use The Data Brochure

This brochure is organized into four main sections. They are: 1) Sequence of Operation, 2) Installation, 3) Control Settings, and 4) Troubleshooting. The Sequence of Operation section has three sub-sections. We recommend reading Section A: General Operation of the Sequence of Operation, as this contains important information on the overall operation of the control. Then read the subsections that apply to your installation. For quick installation and setup of the control, refer to the Installation section, DIP Switch Settings section, followed by the Quick Setup section.

The Control Settings section (starting at DIP Switch Settings) of this brochure, describes the various items that are adjusted and displayed by the control. The control functions of each adjustable item are described in the Sequence of Operation.

Table of Contents

User Interface ................................................... |

pg 2 |

Quick Setup ........................................................ |

pg 14 |

Description of Display Elements .................... |

pg 3 |

Control Settings ................................................. |

pg 15 |

Sequence of Operation .................................... |

pg 4 |

View Menu ................................................ |

pg 15 |

Section A: General Operation .............. |

pg 4 |

Adjust Menu ............................................. |

pg 16 |

Section B: Boiler Reset......................... |

pg 5 |

Testing and Troubleshooting ............................ |

pg 17 |

Section C: DHW ..................................... |

pg 8 |

Error Messages ....................................... |

pg 19 |

Installation ...................................................... |

pg 10 |

Technical Data .................................................... |

pg 20 |

DIP Switch Settings ....................................... |

pg 14 |

Limited Warranty ................................................ |

pg 20 |

Reference Material: Essay E 003 “Characterized Heating Curve and Reset Ratio”

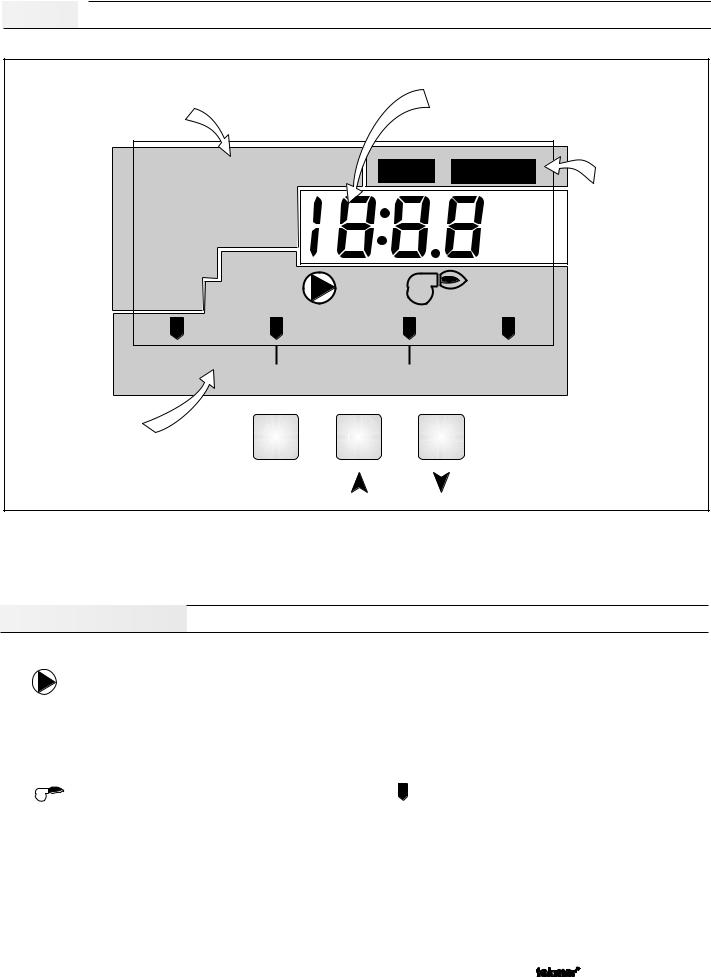

User Interface

The 260 uses a Liquid Crystal Display (LCD) as the method of supplying information. You use the LCD in order to set up and monitor the operation of your system. The 260 has three push buttons (Item,  ,

,  ) for selecting, viewing, and adjusting settings. As you program your control, record your settings in the ADJUST menu table which is found in the second half of this brochure.

) for selecting, viewing, and adjusting settings. As you program your control, record your settings in the ADJUST menu table which is found in the second half of this brochure.

Item

The abbreviated name of the selected item will be displayed in the item field of the display. To view the next available item, press and release the Item button. Once you have reached the last available item, pressing and releasing the Item button will return the display to the first item.

Adjust

To make an adjustment to a setting in the control, press and hold simultaneously for 1 second, all three buttons. The display will then show the word ADJUST in the top right corner. Then select the desired item using the Item button. Finally, use the  and / or

and / or

button to make the adjustment.

button to make the adjustment.

Item

Item

To exit the ADJUST menu, either select the ESC item and press the  or

or  button, or leave the adjustment buttons alone for 20 seconds.

button, or leave the adjustment buttons alone for 20 seconds.

When the Item button is pressed and held in the VIEW menu, the display scrolls through all the adjust items in both access levels.

Additional information can be gained by observing the status field and pointers of the LCD. The status field will indicate which of the control’s outputs are currently active. Most symbols in the status field are only visible when the VIEW menu is selected.

Copyright © D 260 - 03/09 |

2 of 20 |

Display

Item Field |

Number Field |

Displays an |

Displays the current |

abbreviated name of |

value of the selected |

the selected item |

item |

OUTDR DSGN |

DIFF |

VIEW |

ADJUST |

Menu Field |

BOIL TARGET |

|

|

°F |

|

|

|

Displays the |

||

MINMAX |

|

|

°C |

current menu |

|

|

|

||

ROOM WWSD |

|

|

min |

|

|

|

|

|

|

INDR UNOCC |

DHW |

|

|

|

Terminal Unit |

Fire Delay |

Boiler Demand |

|

DHW Demand |

|

Status Field |

|

Buttons |

Displays the current |

|

Selects Menus, Items and |

|

{adjusts settings |

|

status of the control’s |

|

|

inputs, outputs and |

Item |

|

operation |

|

Symbol Description

|

Pump |

UNOCC |

Unoccupied Schedule |

|

Displays when the boiler pump is in operation. |

Displays when the control is in unoccupied |

|

|

|

||

|

|

|

(Night) mode. |

|

|

|

|

DHW |

DHW |

°F, °C |

°F, °C |

Displays when the DHW pump or valve is in |

Displays the units of measure that all of the |

||

|

operation. |

|

temperatures are to be displayed in the control. |

|

|

|

|

|

Burner |

|

Pointer |

|

|

Displays the control operation as indicated by |

|

|

Displays when the boiler relay is turned on. |

|

|

|

|

the text. |

|

|

|

|

|

|

|

|

|

OCC |

Occupied Schedule |

|

|

Displays when the control is in occupied (Day) |

|

|

|

|

mode. |

|

|

|

|

|

|

3 of 20 |

Copyright © D 260 - 03/09 |

Sequence of Operation

Section A |

Section B |

Section C |

General Operation |

Boiler Reset |

DHW |

Page 4 |

Page 5-8 |

Page 8-10 |

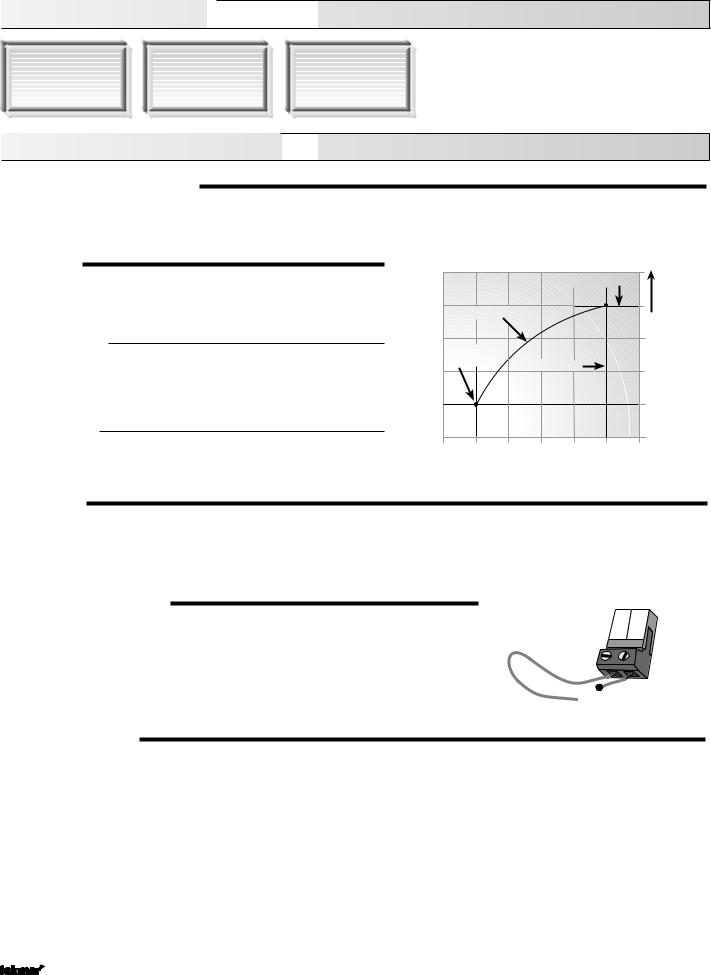

Section A —General Operation

POWERING UP THE CONTROL

When the Boiler Control 260 is powered up, the control displays the control type number in the LCD for 2 seconds. Next, the software version is displayed for 2 seconds. Finally, the control enters into the normal operating mode and the LCD defaults to displaying the current outdoor air temperature.

OPERATION

The 260 operates a single on / off heat source to control the supply water temperature to a hydronic system. The supply water temperature is based on either the current outdoor temperature, or on a DHW target.

Outdoor Reset

The 260 calculates a supply temperature based on the outdoor air temperature. The 260 uses a Characterized Heating Curve and optionally indoor temperature feedback from an indoor sensor in this calculation.

DHW Control

When a demand signal from a Domestic Hot Water (DHW) system is present, the control will operate the boiler to maintain the supply water temperature at 180°F (82°C). Refer to section C.

EXERCISING

Design Supply |

|

Terminal Unit |

Temperature |

Indoor Design |

|

Outdoor Design |

Increasing Water |

|

Decreasing Outdoor Temperature

The 260 has a built-in exercising function. If a pump or valve that is connected to the control has not been operated at least once every 3 days, the control turns on the output for 10 seconds. This minimizes the possibility of a pump or valve seizing during a long period of inactivity. While the control is exercising, the Test LED flashes.

Note: The exercising function does not work if power to the control, valves, or pumps is disconnected.

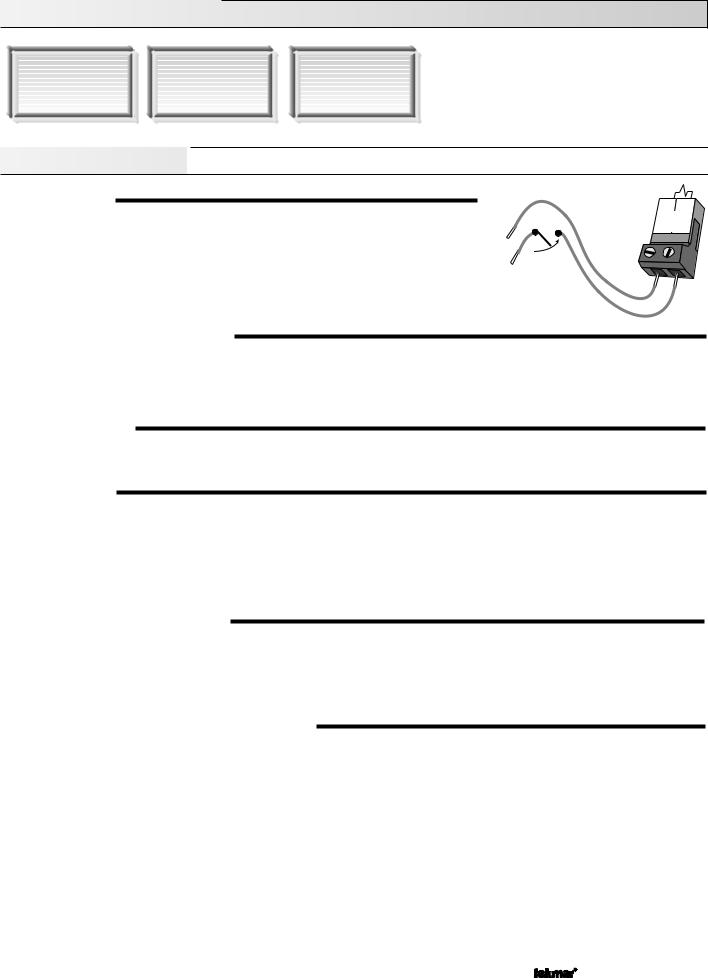

SETBACK (UNOCCUPIED)

To provide greater energy savings, the 260 has a setback capability. With setback, the supply water temperature in the system is reduced when the building is unoccupied. By reducing the supply water temperature, air temperature in the space may be reduced even when thermostat’s are not turned down. Any time the UnO Sw (13) and the Com (14) terminals are shorted together, the control operates in the unoccupied (Night) mode. When in the unoccupied (Night) mode, the UNOCC segment is displayed in the LCD. The 260 adjusts the supply water temperature based on the UNOCC settings made in the control.

FACTORY DEFAULTS

13 |

14 |

UnO Com |

|

Sw |

|

Timer Switch

Timer Switch

The control comes preset with several factory defaults. These defaults are based on the terminal unit selection (see section B2). To finetune building requirements, these defaults may be changed. If a factory default value for a terminal unit is changed, the terminal unit number will flash when selected in the ADJUST menu.

To reload the factory defaults listed in section B2, power down the control and wait for 10 seconds. Power up the control while simultaneously holding the Item and  buttons. The terminal unit number should now be displayed constantly in the LCD rather than flashing.

buttons. The terminal unit number should now be displayed constantly in the LCD rather than flashing.

Copyright © D 260 - 03/09 |

4 of 20 |

Section B: Boiler Reset

Section B1 |

Section B2 |

Section B3 |

General |

Installer |

Advanced |

Section B1: General

BOILER DEMAND

12

A boiler demand is required in order for the 260 to provide heat to the heating system. A

boiler demand is generated by applying a voltage between 24 and 240 V (ac) across the Boiler Demand terminals (1 and 2). Once voltage is applied, the Boiler Demand pointer is displayed in the LCD. If the 260 is not in WWSD, the 260 closes the Boil P1 contact. The

260 calculates a BOIL TARGET supply temperature based on the outdoor air temperature

24 to 240 V (ac)

and settings. The 260 then fires the boiler, if required, to maintain the target supply temperature.

Boiler

Demand

BOILER PUMP OPERATION (Boil P1)

The boiler pump contact (Boil P1, terminal 7) closes whenever there is a boiler demand and the 260 is not in WWSD. The boiler pump segment is displayed in the LCD. After the boiler demand has been satisfied, the 260 continues to operate the boiler pump for 20 seconds. This allows some residual heat to be purged out to the heating system. During WWSD, the boiler pump is operated based on the exercise function. For boiler pump contact operation during DHW operation, refer to section C.

BOILER OPERATION

When the 260 determines that boiler operation is required, the Boiler contact (11 and 12) closes. While the Boiler contact is closed, the burner segment in the LCD is displayed.

INDOOR SENSOR

The indoor sensor is connected to the Com and Indr terminals (17 and 18). In addition, power must be applied to the Boiler Demand terminals (1 and 2) as described in the BOILER DEMAND section. With the indoor sensor connected, the 260 is able to sense the actual room temperature. Indoor temperature feedback fine-tunes the supply water temperature in the heating system to maintain room temperature. To adjust the room temperature, use the ROOM OCC or ROOM UNOCC setting in the ADJUST menu at the control.

If a multiple zone system is used with an indoor sensor, proper placement of the indoor sensor is essential. The indoor sensor should be located in an area which best represents the average air temperature of the zones.

CHARACTERIZED HEATING CURVE

The 260 varies the supply water temperature based on the outdoor air temperature. The control takes into account the type of terminal unit that the system is using. Since different types of terminal units transfer heat to a space using different proportions of radiation, convection and conduction, the supply water temperature must be controlled differently. Once the control is told what type of terminal unit is used, the control varies the supply water temperature according to the type of terminal unit. This improves the control of the air temperature in the building.

BOILER TARGET TEMPERATURE (BOIL TARGET)

The BOIL TARGET temperature is determined from the Characterized Heating Curve settings, outdoor air temperature, and optionally, indoor air temperature. The control displays the temperature that it is currently trying to maintain as the boiler supply temperature. If the control does not presently have a requirement for heat, it does not show a boiler target temperature. Instead, “- - -” is displayed in the LCD.

5 of 20 |

Copyright © D 260 - 03/09 |

Section B2: Installer

OUTDOOR DESIGN (OUTDR DSGN)

The OUTDR DSGN is the outdoor air temperature that is the typical coldest temperature of the year where the building is located. This temperature is used when doing the heat loss calculations for the building. If a cold outdoor design temperature is selected, the boiler supply temperature rises gradually as the outdoor temperature drops. If a warm outdoor design temperature is selected, the boiler supply temperature rises rapidly as the outdoor temperature drops.

|

BOIL DSGN |

|

Temperature |

cold |

|

OUTDR |

||

DSGN |

||

Water |

||

warm |

||

|

||

Increasing |

BOIL INDR |

|

|

Decreasing Outdoor Temperature

ROOM OCC & UNOCC (ROOM)

The ROOM is the desired room temperature for the boiler zones, and it provides a parallel shift of the Characterized Heating Curve. The room temperature desired by the occupants is often different from the design indoor temperature (BOIL INDR). If the room temperature is not correct, adjusting the ROOM setting increases or decreases the amount of heat available to the building. A ROOM setting is available for both the occupied (Day) and unoccupied (Night) modes.

Increasing Water Temperature

|

. |

|

|

p |

|

|

m |

|

|

e |

|

|

T |

|

|

l |

|

|

a |

|

|

tu |

|

c |

n |

|

A |

|

|

|

|

ig |

|

s |

|

|

e |

|

|

D |

|

|

l |

|

|

a |

|

|

rm |

|

|

o |

|

|

N |

|

ROOM

ROOM

BOIL INDR

BOIL INDR

Decreasing OutdoorTemperature

TERMINAL UNITS

When using a Characterized Heating Curve, the control requires the selection of a terminal unit. The terminal unit determines the shape of the Characterized Heating Curve according to how the terminal unit delivers heat into the building space (refer to Essay E 003). The 260 provides for selection between six different terminal unit types: two types of radiant floor heat, fancoil, fin-tube convector, radiator and baseboard. When a terminal unit is selected, the control automatically loads the design supply temperature (BOIL DSGN), maximum supply temperature (BOIL MAX), and minimum supply temperature (BOIL MIN). The factory defaults are listed below. To change defaults, refer to section B3. If a default has been changed, refer to section A to reload the factory defaults.

Terminal Unit |

High Mass Radiant |

Low Mass Radiant |

Fancoil |

Fin-tube Convector |

Radiator |

Baseboard |

|

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

||

|

|||||||

BOIL DSGN |

120°F (49°C) |

140°F (60°C) |

190°F (88°C) |

180°F (82°C) |

160°F (71°C) |

150°F (66°C) |

|

BOIL MAX |

140°F (60°C) |

160°F (71°C) |

210°F (99°C) |

200°F (93°C) |

180°F (82°C) |

170°F (77°C) |

|

BOIL MIN |

OFF |

OFF |

140°F(60°C) |

140°F (60°C) |

140°F (60°C) |

140°F (60°C) |

High Mass Radiant (1)

This type of a hydronic radiant floor is embedded in either a thick concrete or gypsum pour. This heating system has a large thermal mass and is slow acting.

Default values: BOIL DSGN = 120°F (49°C), BOIL MAX = 140°F (60°C), BOIL MIN = OFF

Low Mass Radiant (2)

This type of radiant heating system is either attached to the bottom of a wood sub-floor, suspended in the joist space, or sandwiched between the sub-floor and the surface. This type of radiant system has a relatively low thermal mass and responds faster than a high mass system.

Default values: BOIL DSGN = 140°F (60°C), BOIL MAX = 160°F (71°C), BOIL MIN = OFF

Copyright © D 260 - 03/09 |

6 of 20 |

Loading...

Loading...