Panasonic SQ4-A21-N Installation Manual

INSTRUCTION MANUAL

Safety Liquid Leakage Sensor SQ4-A series

MJE-SQ4A No.0017-28V

Thank you very much for purchasing Panasonic products.

Please read this Instruction Manual carefully and thoroughly for the correct and optimum use of this product.

Kindly keep this manual in a convenient place for quick reference. English and Japanese are original instructions.

WARNING

WARNING

●This product is a sensor for detecting leak of fluids.

●When this product is used with safety devices, construct the system such that the device itself.

1 ATTENTION MARKS

This instruction manual employs the following attentions marks “  WARNING”, and “

WARNING”, and “ CAUTION”, depending on the degree of the danger.

CAUTION”, depending on the degree of the danger.

WARNING If you ignore the advice with this mark, death or serious injury could result.

WARNING If you ignore the advice with this mark, death or serious injury could result.

CAUTION If you ignore the advice with this mark, injury or material damage could result.

CAUTION If you ignore the advice with this mark, injury or material damage could result.

2SAFETY PRECAUTIONS

●Use this device as per its specifications. Do not modify this device since its functions and capabilities may not be maintained and it may malfunction.

●This device has been developed / produced for industrial use only.

●This device is suitable for indoor use only.

●Use of this device under the following conditions or environment is not presupposed.

1)Operating this device under conditions and environment not described in this manual.

2)Using this device in the following fields: nuclear power control, railroad, aircraft, automobiles, combustion facilities, medical systems, aerospace development, etc.

●Use this device by installing suitable protection equipment as a countermeasure for failure, damage, or malfunction of this device.

●Before using this device, check whether the device performs properly with the functions and capabilities as per the design specifications.

●In case of disposal, dispose this device as industrial waste.

WARNING

WARNING

♦Machine designer, installer, employer and operator

•The machine designer, installer, employer and operator are solely responsible to ensure that all applicable legal requirements relating to the installation and the use in any application are satisfied and all instructions for installation and maintenance contained in the instruction manual are followed.

•Whether this device functions as intended to and systems including this device comply with safety regulations depends on the appropriateness of the application, installation, maintenance and operation. The machine designer, installer, employer and operator are solely responsible for these items.

•The engineer would be a person who is appropriately educated, has widespread knowledge and experience, and can solve various problems which may arise during work, such as a machine designer, or a person in charge of installation or operation etc.

•The operator should read this instruction manual thoroughly, understand its contents, and perform operations following the procedures described in this manual for the correct operation of this device.

•In case this device does not perform properly, the operator should report this to the person in charge and stop the machine operation immediately. The machine must not be operated until correct performance of this device has been confirmed.

♦Installation

•There is the detection mount difference by directivity of a liquid leakage. When there are a direction from which a liquid leakage happens, and an inclination, please install the nose-of-cam side (opposite side of a cable) of a sensor towards a top.

•Use the mounting bracket MS-SQ4-□ (optional) which suits the liquid to detect. If selecting mounting bracket is wrong, it does not work properly.

•Periodical checking of operation is recommended with the liquids which are not dangerous (water, alcohol, etc.).

•The amount of detection may change with the conditions of the installation surface.

•Be sure to use the mounting bracket MS-SQ4-□ (optional) when installing this device to avoid human error, etc. Reliable detection cannot be guaranteed when this sensor is used alone.

•After installing this product, fix the cable at 100mm of base of this product on floor. Use the material which does not be effected by the chemical liquid for the fixing bracket for cable.

♦Wiring

•In case dangerous operation of the system installed this product by no wiring to ground is not considered , it may cause serious injure or death.

•To avoid turning the power ON by no wiring to ground, wire it to ground 0V side when using PNP and wire it to ground +24V when using NPN.

♦Environment

•Avoid using this device in an explosive atmosphere because this product does not have an explosive-proof protective construction.

•Do not use a mobile phone or a radio phone near this device.

•In case this device is used where electrostatic charge is present, use a metal leak pan, which should be connected to an actual ground.

•Do not install this device in the following environments.

1)Areas exposed to intense interference (extraneous) light such as highfrequency fluorescent lamp (inverter type), rapid starter fluorescent lamp, stroboscopic lights, flash beacon lights or direct sunlight.

2)Areas with high humidity where condensation is likely to occur

3)Areas exposed to too much steam or dust. Areas exposed to corrosive or explosive gases. And do not use this device where oil or grease splashes to this device

4)Areas exposed to vibration or shock of levels higher than that specified.

♦Maintenance

•When using chemical liquid, use proper protections such as groves, masks, goggles, helmets etc. When using protections, me sure to read manuals of them and use properly.

•Dispose or reinstall in different environment, flush with DI water.

3STANDARDS / REGULATIONS

●This product complies with following standards / regulations.

<International Standard>

IEC 60947-5-2, IEC 61508-1 to 7(SIL1),

IEC 13849-1: 2008 (Category 1, PLc), IEC 62061(SIL1)

<Regulations in Korea>

S1-G-1-2009, S2-W-5-2009

●This product is pursuant to following standard.

<SEMI standard>

SEMI-S2-0310a

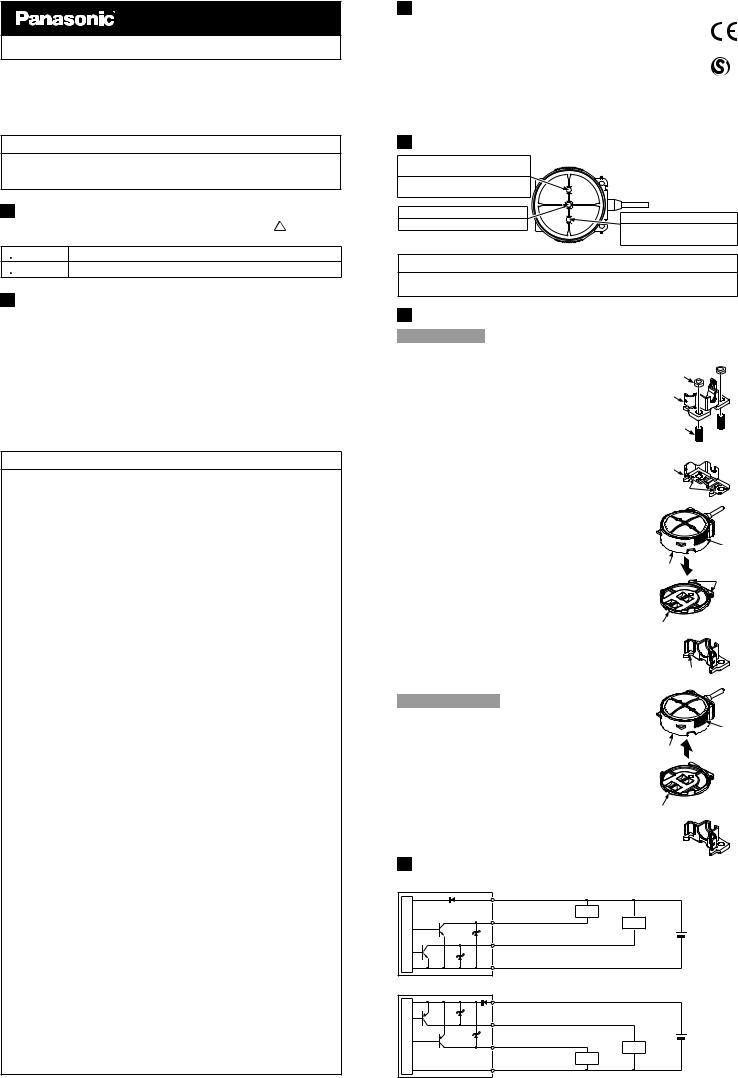

4PART DESCRIPTION

Detection auxiliary output indicator (Orange)

Initial detection, leakage detection and wrong installation: Light up

Detection output indicator (Green) |

Detection output indicator (Red) |

|

Normal or Initial detection: Light up |

||

Detection leakage and wrong |

||

|

||

|

installation: Light up |

CAUTION

CAUTION

In case of installation error, detection output indicator (red) and detection auxiliary output indicator (Orange) light up

5 MOUNTING

Mounting method

1. Mount the mounting bracket set MS-SQ4-□ (optional) with M4 stud-bolts or adhesive.

<Mounting with M4 stud-bolts> |

|

|

1-1 |

Weld the M4 stud-bolts (length: 10mm or |

M4 nut |

|

more) to your system. |

Mounting |

1-2 |

Insert the M4 stud-bolts (length 10mm or more) |

|

|

welded on the user's facilities into the mounting |

bracket |

|

|

|

|

hole of the mounting bracket and screw with an |

|

|

M4 nut (purchase separately). The tightening |

M4 stud-bolt |

|

torque should be 0.98N·m or less. |

|

<Mounting the PVC mounting bracket with adhesive> |

||

1-1 |

Put the adhesive to underside of the mounting |

Mounting |

|

bracket and stick it on surface of the system. |

bracket |

|

Thickness of the adhesive after sticking is set |

Adhesive face |

|

to 0.1mm or less. And use adhesive for vinyl |

|

chlovide (PVC).

Note: if the excess adhesive from the bottom surface of the exclusive mounting bracket is remained, the detection capability may be affected.

2.The attachment is set according to A part of the mounting bracket.

3.Inserts from a top by holding knurling part. Then press in downward in the attachment.

Dismounting method

1.Hold the knurling part of this product and pull out from mounting bracket upward.

Note: When pulling out this product, it may cause break of cables. Be careful.

2.Pull out the attachment upward from the mounting bracket.

3.In case the mounting bracket is mounted with the M4 stud-bolts, remove M4 nuts.

In case the mounting bracket is mounted with the M4 stud-bolts, do not remove.

|

Knurling |

|

part |

This |

3. Press |

product |

A part |

Attachment  2. Insert

2. Insert

Chase

|

Knurling |

|

part |

This |

1. Pull out |

product |

|

Attachment  2. Pull out

2. Pull out

6I/O CIRCUIT DIAGRAMS

●NPN output type

|

(Brown) +V |

|

|

|

|

circuit |

(Black) Detection output |

Load |

Load |

+ |

12 to 24V DC |

|

|

||||

|

|

|

|

|

|

Main |

(White) Detection auxiliary output |

|

- |

±10% |

|

|

|

|

|

|

|

|

(Blue) 0V |

|

|

|

|

● PNP output type |

|

|

|

|

|

|

(Brown) +V |

|

|

|

|

circuit |

(Black) Detection output |

|

|

+ |

|

(White) |

|

|

12 to 24V DC |

||

Main |

Detection auxiliary output |

Load |

- |

±10% |

|

|

|

|

|

||

|

|

|

|

|

|

|

(Blue) 0V |

Load |

|

|

|

|

|

|

|

|

|

Loading...

Loading...