Panasonic ER-VW Installation Manual

INSTRUCTION MANUAL

Static Remover Ionizer Thin type

ER-VW

Thank you very much for using SUNX products. Please read this Instruction Manual carefully and thoroughly for the correct and optimum use of this product. Kindly keep this manual in a convenient place for quick reference.

|

This product is to remove static electricity for industrial equipments. |

|

|

Never use this product for medical equipment etc. relating to mainte- |

|

|

nance / supervision of human life or body, for prevention of accidents |

|

|

which damage a human life or properties, or for safety maintenance. |

|

|

Do not use this product near or around surroundings containing any dan- |

|

|

gerous materials, such as combustible material and flammable material. |

|

|

Dust gathers on and around the discharge needle, and inside the nozzle |

|

|

depending on the environment. Be sure to clean up the discharge needle, |

|

|

periodically once a week or so, or this product will be unable to exert the charge |

|

|

removal performance, which may also cause ignition or product malfunction. |

|

|

Be sure to ground the main body of this product via ground terminal |

|

|

to ensure electric shock prevention and reliable charge removal. |

|

|

Since the discharge needle is live with high voltage, never touch the |

|

WARNING |

discharge needle, or an electric shock may result. |

|

If this product is used in an airtight room, ozone emitted from this |

||

|

||

|

product may be detrimental. Therefore, in order for this product to be |

|

|

used in an airtight room, be sure to keep the room ventilated. |

|

|

Since the ion air contains ozone, do not aim this product at anyone. |

|

|

When loosening the nozzles for aligning the blowing air or mainte- |

|

|

nance, be sure to stop applying air. Otherwise, the discharge needle |

|

|

may be flu out by air pressure. Furthermore, after the work, screw up |

|

|

the nozzles by hand till they touch the main body. Insufficient tighten- |

|

|

ing may affect the charge removal capability or drop the nozzles. |

|

|

Since the tip of the discharge needle is pointed, take sufficient care |

|

|

in handling the discharge needle, or injuries may result. |

|

|

|

1 OUTLINE

This product is a corona discharge type electrostatic charge removal device.

The nozzle angle adjustable structure enables aligning the ionized air to desired area. The check function which a considerable abrasion or dirt on the discharge needle is notified via the output signal and the indicator is incorporated.

The air monitor function detects whether the air is supplied to this product or not. When the air is not supplied, a corona discharge is stopped.

2 CAUTIONS

Make sure to use the DC power supply insulated by an isolation transformer etc. for this product. If an auto-transformer etc. (single winding transformer) is used, this product or the power supply may get damaged due to short-circuit.

Do not use this product beyond its rated specifications. Doing so can cause product breakdown or damage. Furthermore, it may also cause a considerable reduction in product life. Never disassemble, repair, modify, or misuse this product, as it can cause accident or malfunction.

Do not throw this product in fire. There is a danger of it exploding, or generating poisonous gas. Since this product emits ozone into the atmosphere, circulate the air if it is foulsmelling. If ozone stays for long period, metals etc. may oxidize / decay. Further, do not try to confirm the foul-smelling ozone by drawing your face near the nozzle outlet. There is a danger of hurting your nose, throat, etc.

Do not use this product in steamy or dusty places and in places where water splashes or spatter flies when welding.

Make sure that the power supply is off while wiring and inspection. Otherwise, there is a danger of accident, electric shock or malfunction.

Do not use during the initial transient time (0.5 sec.) after the power supply is switched on. Verify that the supply voltage variation is within the rating.

If the power supply is switched on immediately after being switched off, fault output may be generated. After the power supply is switched off, keep an interval of 1 sec. or more, before switching it on again.

If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

In case a surge is generated in the used power supply, connect a surge absorber to the supply and absorb the surge.

Do not run the wires together with high-voltage lines or power lines or put them in the same raceway. This can cause malfunction due to induction.

Confirm the wiring and piping state before supplying power or air. Wrong wiring and piping may cause malfunction.

Use air (dried clean air) for the fluid. Fluid other than air (dried clean air) or that containing corrosive gas may cause accident or malfunction.

Do not use air containing foreign particles, such as, carbon dust or dust, water or oil. Since those may cause electric shock or malfunction, take appropriate measures, such as, installing an air-filter or an air-drier, etc.

Do not use this product for a purpose other than charge removal.

Do not block the air blowing outlet. Ozone is filled in the air, causing accident or malfunction. (The air monitoring function detects by a falling of the applied air pressure. Thus, if the air blowing outlet is blocked, the discharge is not halted by detection. ) This product is CE-conformed under the EMC Directive. The immunity adopted by this product should be conformable to EN 61000-6-2. In order for such immunity to be conformable to this standard, all wires connected to this product should be limited in length to less than 10m.

When this product is no longer usable or required, carry out the appropriate disposal process meant for industrial waste.

3 SPECIFICATIONS

|

Type |

Thin-type ionizer |

|

Item |

Model No. |

ER-VW |

|

Charge removal time |

1 sec. or less (1,000V |

100V) (Note 1) |

|

Ion balance |

|

15V or less (Note 1) |

|

Ozone generation |

0.05ppm or less (Note 2) |

||

Applicable fluid |

Air (dried clean air) (Note 3) |

||

Supplied air flow |

60 /min (ANR) or less |

||

Air pressure range |

0.05 to 0.5MPa |

||

Supply voltage |

24V DC |

10% |

|

Current consumption |

120mA or less |

||

Discharge method |

High frequency AC method |

||

Discharge output voltage |

2,000V approx. |

||

Output

Check output (CHECK)

NPN open-collector transistor

Error output (ERROR)

Maximum sink current: 50mA

Discharge state output (DSC)

Applied voltage: 30V DC or less (between output terminal and 0V)

(Note 4)

Residual voltage: 1V or less (at 50mA sink current)

|

|

Check output (CHECK) : ON when a dirt or wear etc. of the discharge needle is |

||

|

|

|

detected, OFF when operating correctly |

|

|

Output operation |

Error output (ERROR) |

: OFF when error in discharge is detected, ON |

|

|

|

during normal operation |

||

|

|

|

||

|

|

Discharge state output (DSC): ON during discharge operation, OFF when dis- |

||

|

|

(Note 4) |

charge operation is stopped |

|

|

|

|

|

|

|

Short-circuit protection |

|

Incorporated |

|

Discharge halt input |

Discharge halt: short-circuit with 0V |

|||

(DSC OFF) (Note 4) |

Discharge allowed (operation start): Open |

|||

Reset input |

In the state that operation is stopped due to an error detection, open 0V |

|||

(RESET) |

of the power supply from short-circuit state to cancel ERROR. |

|||

Indicators |

Power (POWER) |

Green LED (lights up when the power is ON) |

||

Check (CHECK) |

Orange LED (lights up when a dirt or wear etc. of the discharge needle is detected) |

|||

|

Discharge (DSC) (Note 4) |

Green LED (lights up when discharging) |

||

|

Air monitor (AIR) (Note 5) |

Orange LED (lights up when air is not supplied) |

||

|

|

|

|

|

|

Error (ERROR) |

Red LED (lights up when error in discharge is detected) |

||

Ambient temperature |

0 to +55 (No dew condensation), Storage: -10 to +65 |

|||

Ambient humidity |

35 to 65% RH, Storage: 35 to 65% RH |

|||

I/O connector |

For power supply / I/O: 8-way connector, For connection: 9-way connector |

|||

No. of series connection |

Maximum connectable number: 5 units (including this unit) |

|||

Enclosure earthing |

|

C (capacitor) earth |

||

Material |

Enclosure: ABS (Nickel plated), Nozzle mounting part: Stainless steel, Screw mount- |

|||

ing part: Stainless steel, Nozzle: Stainless steel, Discharge needle: Tungsten |

||||

|

|

|||

Weight |

|

110g approx. |

||

Accessory |

Connection cable: 1 pc. (cable length 0.5m) |

|||

End connector (9-way): 1 pc., Lead wire for F.G. connection: 1 pc. |

||||

|

|

|||

Notes: 1) A typical sample (measured on a sample left in the atmosphere at a relative humidity of 65% RH for 24 hours) applied with a supply voltage of 24V, a distance of 100mm from the front surface of the airflow inlet and a pressure of 0.25MPa.

2)A typical sample applied with a supply voltage of 24V, a distance of 300mm from the front surface of the air flow inlet and a pressure of 0.25MPa.

3)The dried clean air is dried (dew point: equivalent of -20 ) and filtered (mesh-size:

equivalent of 0.01 m) air.

4)'DSC' stands for 'DISCHARGE'.

5)Discharge is stopped when the indicator lights up.

Optional

AC adapter

Model No. |

Description |

IN: 100 to 120V AC, 50/60Hz, 40VA ER-VAPS-W OUT: 24V DC, 750mA

(Accessory: Conversion connector)

Discharge needle set (2 pcs./set)

Model No. |

Description |

ER-VWANT Unit with a tungsten needle

Connection cable

Model No. |

Description |

ER-VWCC2 |

Cable length 2m |

ER-VWCC5 |

Cable length 5m |

ER-VWCC9 |

Cable length 9m |

Series connection set |

|

|

|

Model No. |

Description |

ER-VWAR80 |

Series connection cable (Cable |

length 0.8m), Air inlet fitting |

|

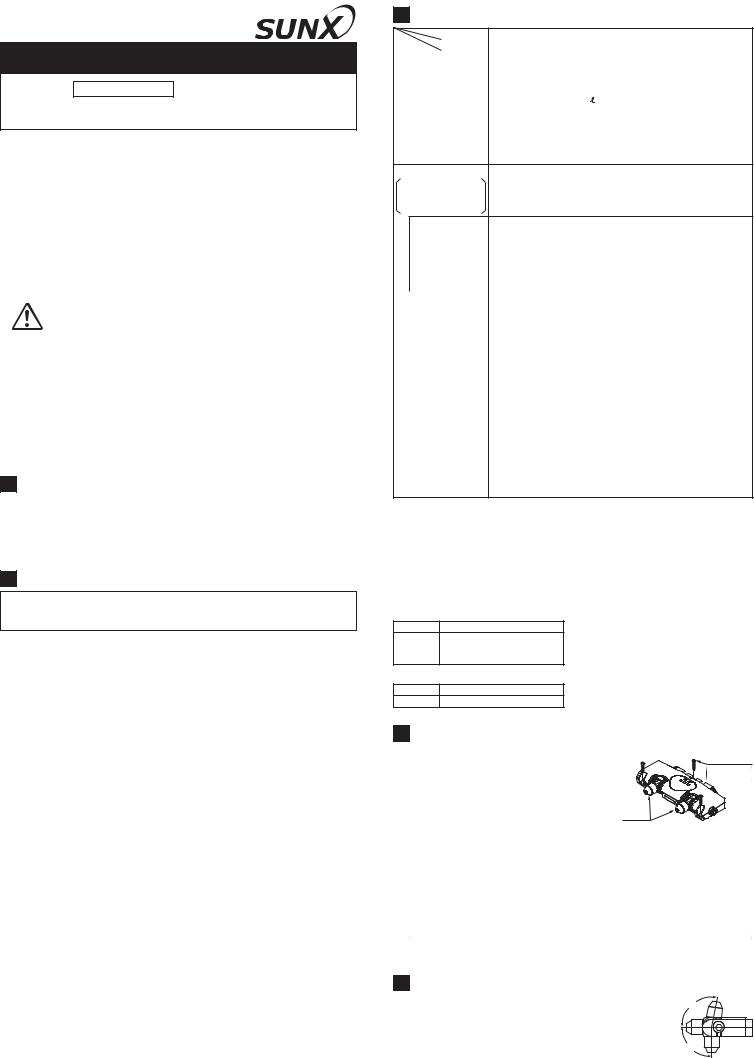

4 MOUNTING

When this product is mounted on to a surface, |

M4 pan-head |

|

use M4 pan-head screw (please arrange sepa- |

screw |

|

Please arrange |

||

rately). The tightening torque should be 0.5N m |

||

separately |

||

or less. |

||

|

||

|

Nozzle |

Be sure to ground the F.G. terminal. If the grounding is not proper, the charge removal capability deteriorates considerably. (Direct earth or power supply common earth) The power supply common earth can also be connected with the accessory lead wire for F.G.connection.

0V earth: Connect No. 2 and No. 3 of the end connector (9-way) with the lead wire for F.G.connection.

+V earth: Connect No. 1 and No. 3 of the end connector (9-way) with the lead wire for F.G.connection.

Wrong wiring of the grounding causes accident or malfunction. Check the grounding condition to be used beforehand and take care not to short-circuit the power supply when wiring.

If AC adopter is used, be sure to connect the F.G. terminal to the power supply common earth.

5 ALIGNMENT OF BLOWING AIR

After screwing the nozzle down, aim the nozzle to the object |

100 |

|

being charged. After aligning, tighten the nozzle by hand till |

||

|

||

it touches the main body and confirm that the nozzle doesn't |

|

|

move. If the nozzle is not tightened enough, the charge re- |

|

|

moval capability may deteriorate or the nozzle may drop. |

90 |

|

The adjustable range of the nozzle is shown in the right figure. |

||

|

Loading...

Loading...