Brother MX-2002, MX-2003, MX-2001 Service Manual

R

MAILBOX UNIT

FOR LASER PRINTER

SERVICE MANUAL

MODEL:MX-2001 / MX-2002 / MX-2003

Note:

While the MX-2001 Mailbox unit is available in all countries, the MX2003 is available in U.S. and Canada only, and the MX-2002 is available in the other countries than U.S. and Canada.

Oct., 1998 54T050NE0

© Copyright Brother 1998 All rights reserved.

No part of this publication may be reproduced in any form or by any means without permission in writing from the publisher.

Specifications are subject to change without notice.

Trademarks:

The brother logo is a registered trademark of Brother Industries, Ltd.

Apple, the Apple Logo, and Macintosh are trademarks, registered in the United States and other countries and True Type is a trademark of Apple computer, Inc.

Epson is a registered trademark and FX-80 and FX-850 are trademarks of Seiko Epson Corporation.

Hewlett Packard is a registered trademark and HP Laser Jet is a trademark of Hewlett Packard Company.

IBM, IBM PC and Proprinter are registered trademarks of International Business Machines Corporation.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

PREFACE

This service manual contains basic information required for after-sales service of the optional Mailbox unit, MX-2001/MX-2002/MX-2003 for the HL-2060 laser printer (hereinafter referred to as “this unit” or "the Mailbox unit"). This information is vital to the service technician to maintain the high performance of the unit.

This service manual covers the MX-2001 / MX-2002 / MX-2003 Mailbox units.

The manual consists of the following chapters:

CHAPTER I : GENERAL

General view, specifications, etc.

CHAPTER II : THEORY OF OPERATION

Basic operation of the electrical system and the mechanical system

CHAPTER III : DISASSEMBLY

Procedures for disassembling the mechanical system.

CHAPTER IV : TROUBLESHOOTING

Reference values and adjustments, troubleshooting malfunctions, etc.

APPENDICES :PCB CIRCUIT DIAGRAMS, ETC.

Information in this manual is subject to change due to improvement or re-design of the product. All relevant information in such cases will be supplied in service information bulletins (Technical Information).

A thorough understanding of this unit, based on information in this service manual and service information bulletins, is required for maintaining its performance and for improving the practical ability to find the cause of problems.

|

|

|

CONTENTS |

|

CHAPTER I |

GENERAL............................................................................ |

I-1 |

||

1. INSTRUCTIONS.......................................................................................................... |

I-1 |

|||

2. OVERVIEW ................................................................................................................. |

|

I-2 |

||

3. SPECIFICATIONS....................................................................................................... |

I-3 |

|||

|

3.1 |

Functions............................................................................................................................... |

|

I-3 |

|

3.2 |

Electrical and Mechanical ..................................................................................................... |

I-3 |

|

|

3.3 |

Paper..................................................................................................................................... |

|

I-4 |

CHAPTER II THEORY OF OPERATION ................................................. |

II-1 |

|||

1. |

ELECTRONICS......................................................................................................... |

II-1 |

||

|

1.1 |

General Block Diagram................................................................................................... |

II-1 |

|

|

1.2 |

Main PCB........................................................................................................................ |

II-3 |

|

|

|

1.2.1 |

CPU............................................................................................................................... |

II-3 |

|

|

1.2.2 Bin solenoid drive circuit................................................................................................ |

II-3 |

|

|

|

1.2.3 Entrance solenoid drive circuit ...................................................................................... |

II-3 |

|

|

|

1.2.4 |

Bin capacity sensor ....................................................................................................... |

II-4 |

|

|

1.2.5 Infrared LED drive circuit............................................................................................... |

II-4 |

|

|

|

1.2.6 Power supply LED drive circuit...................................................................................... |

II-4 |

|

|

1.3 |

I/F PCB |

........................................................................................................................... |

II-4 |

|

|

1.3.1 |

Regulator....................................................................................................................... |

II-4 |

|

|

1.3.2 |

Serial I/F circuit.............................................................................................................. |

II-5 |

|

|

1.3.3 Feeding motor drive circuit ............................................................................................ |

II-5 |

|

|

|

1.3.4 |

Entrance sensor input ................................................................................................... |

II-5 |

|

1.4 |

Sensor PCB .................................................................................................................... |

II-5 |

|

|

1.5 |

Power supply LED PCB.................................................................................................. |

II-5 |

|

|

1.6 |

Communication with the Printer ...................................................................................... |

II-5 |

|

2. |

MECHANICS............................................................................................................. |

|

II-7 |

|

|

2.1 |

General Overview of Mechanism.................................................................................... |

II-7 |

|

|

2.2 |

Paper Feed Sequence.................................................................................................... |

II-8 |

|

CHAPTER III DISASSEMBLY AND REASSEMBLY............................... |

III-1 |

|||

1. |

SAFETY PRECAUTIONS......................................................................................... |

III-1 |

||

2. |

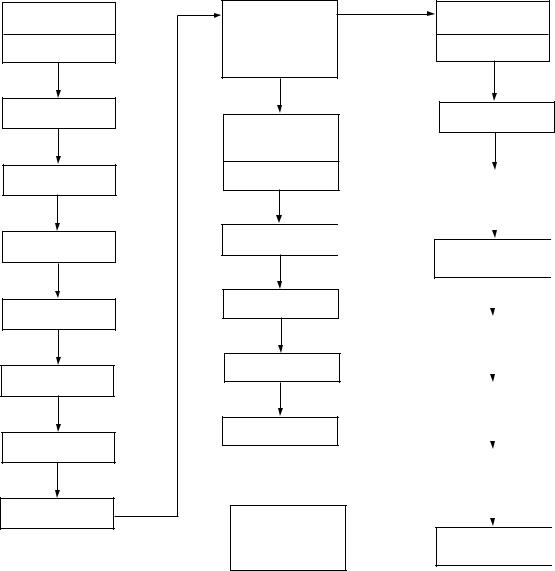

DISASSEMBLY FLOW............................................................................................. |

III-2 |

||

3. |

DISASSEMBLY PROCEDURE ................................................................................ |

III-3 |

||

|

3.1 |

External Covers ............................................................................................................. |

III-3 |

|

|

|

3.1.1 Cover UR (For MX-2001/2003 only)............................................................................. |

III-3 |

|

|

|

3.1.2 Cover UL (For MX-2001/2003 only) ............................................................................. |

III-3 |

|

|

|

3.1.3 |

Cover R ........................................................................................................................ |

III-4 |

|

|

3.1.4 |

Cover L......................................................................................................................... |

III-4 |

|

|

3.1.5 Rear Cover U ASSY (For MX-2001/2003 only) ............................................................ |

III-5 |

|

|

|

3.1.6 Rear Cover A ASSY ..................................................................................................... |

III-7 |

|

i

3.1.7PCB Cover A (MX-2001) / PCB Cover B (MX-2002) / PCB Cover D (MX-2003 Upper

|

Unit).............................................................................................................................. |

III-8 |

3.1.8 |

Bin ................................................................................................................................ |

III-8 |

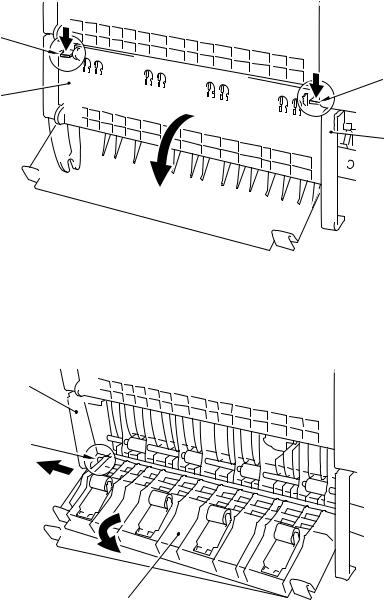

3.2Remove the Main Frame Unit from the Under Frame Unit (For MX-2001/2003 only) .III-10

3.3 |

Main Frame Unit .......................................................................................................... |

III-10 |

3.3.1I/F PCB A ASSY (MX-2001) / I/F PCB B ASSY (MX-2002) / I/F PCB C ASSY (MX-2003

Lower Unit) / I/F PCB D ASSY (MX-2003 Upper Unit) ............................................... |

III-10 |

3.3.2 Feeding Motor ASSY.................................................................................................. |

III-11 |

3.3.3Main PCB A ASSY (MX-2001, MX-2003 Lower Unit) / Main PCB B ASSY (MX-2002,

|

|

MX - 2003 Upper Unit) .................................................................................................. |

III-12 |

|

3.3.4 Solenoid A/B & LED PCB ASSY (MX-2001/2003 only) .............................................. |

III-13 |

|

|

3.3.5 |

Sensor PCB ASSY ..................................................................................................... |

III-14 |

|

3.3.6 |

Actuator A/B ............................................................................................................... |

III-15 |

|

3.3.7 Eject Roller ASSY / Feed Rollers A/B ASSY.............................................................. |

III-17 |

|

|

3.3.8 Eject Pinch Roller ASSY & Discharging Brush........................................................... |

III-19 |

|

3.4 |

Under Frame Unit (For MX-2001/2003 only) ............................................................... |

III-20 |

|

|

3.4.1 |

Actuator U .................................................................................................................. |

III-20 |

|

3.4.2 |

Solenoid U .................................................................................................................. |

III-21 |

|

3.4.3 |

Photo Interrupter ........................................................................................................ |

III-21 |

|

3.4.4 Feed Roller U ASSY................................................................................................... |

III-22 |

|

|

3.4.5 |

Flap U ......................................................................................................................... |

III-23 |

3.5 |

Remove the Upper Unit from the Lower Unit (For MX-2003 only)............................... |

III-24 |

|

3.6 |

Packing of MX-2003..................................................................................................... |

III-28 |

|

4. APPLICATION OF GREASE.................................................................................. |

III-29 |

||

4.1 |

Rollers |

.......................................................................................................................... |

III-29 |

|

4.1.1 Feed Roller A/B ASSY................................................................................................ |

III-29 |

|

|

4.1.2 ...................................................................................................... |

Eject Roller ASSY |

III-29 |

|

4.1.3 ...................................................................................................Feed Roller U ASSY |

III-30 |

|

|

4.1.4 ...........................................................................Pressure Roller / Pressure Roller U |

III-30 |

|

4.2 |

Gears ........................................................................................................................... |

|

III-31 |

|

4.2.1 .......................................................................................Gears on the Main Frame R |

III-31 |

|

|

4.2.2 ........................................................................................Gears on the Main Frame L |

III-31 |

|

|

4.2.3 .............................................................................................Gears on the Frame UR |

III-32 |

|

4.3 |

Others .......................................................................................................................... |

|

III-32 |

CHAPTER IV TROUBLESHOOTING...................................................... |

IV-1 |

|

1. |

INITIAL CHECK ...................................................................................................... |

IV-1 |

2. |

MTBF / MTTR ......................................................................................................... |

IV-2 |

3. |

TROUBLESHOOTING ............................................................................................ |

IV-3 |

APPENDICES |

|

|

1. |

MAIN PCB CIRCUIT DIAGRAM (1/2)....................................................................... |

A-1 |

2. |

MAIN PCB CIRCUIT DIAGRAM (2/2)....................................................................... |

A-2 |

3. |

I/F PCB CIRCUIT DIAGRAM.................................................................................... |

A-3 |

INDEX

ii

CHAPTER I GENERAL

1.INSTRUCTIONS

The MX-2001/2002/2003 Mailbox units are optionally installed onto the HL-2060 printer. The MX-2001 Lower Mailbox unit consists of five bins. The MX-2002 Upper Mailbox unit is additionally installed onto the MX-2001, and also consists of five bins. The MX2003 Mailbox unit consists of ten bins.

Note: While the MX-2001 Mailbox unit is available in all countries, the MX-2003 is available in U.S. and Canada only, and the MX-2002 is available in the other countries than U.S. and Canada.

The unit works as a stacker, sorter and mailbox for the printer. See the table below for each function.

Function |

Description |

|

|

Stacker |

Printed paper is ejected into the multiple bins behaving as a single |

|

high-capacity tray. |

|

|

Sorter |

Printed paper is ejected as a set for a print job into a bin when multiple |

|

sets of documents are printed and collated. |

|

|

Mailbox |

Printed paper is ejected into the specific bin defined as your own mail |

|

box. |

|

|

When you install the unit onto the printer, the printed paper is ejected to the output tray of the printer and/or the bin(s) of the Mailbox unit by selection commands sent from the printer.

I-1

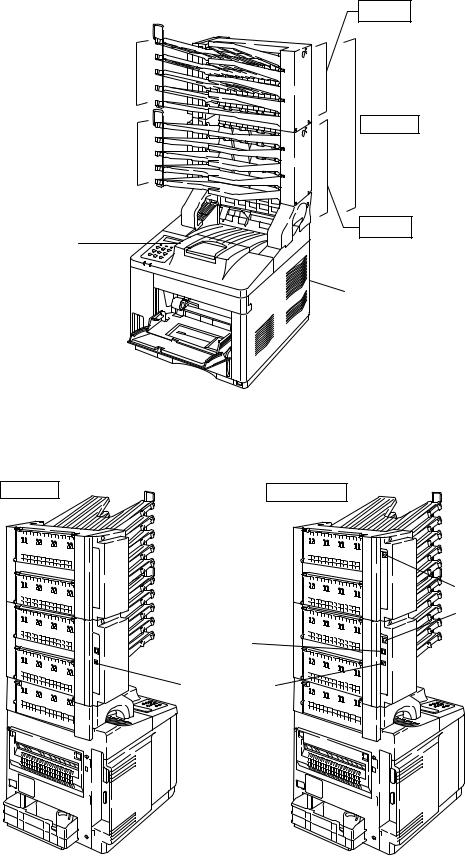

2.OVERVIEW

<Front View>

MX-2002

Paper Stopper

Bin 6 - 10

Paper Stopper

MX-2003

Bin 1 - 5

MX-2001

Printer Output

Tray

HL-2060 Printer

Fig. 1.1

<Rear View>

MX-2003 |

MX-2001/2002 |

Mini DIN connector

Mini DIN connector

Modular jack

Modular jack

DC jack connector

Fig. 1.2

I-2

3.SPECIFICATIONS

3.1 |

Function |

|

|

|

|||

|

(1) |

Stacking direction |

|

|

|||

|

|

|

Face down |

|

|

|

|

|

(2) |

Feeding speed (when feeding A4 size paper) |

|

||||

|

|

|

|

|

|

||

|

|

Printer Mode |

|

When the paper is ejected into |

When the paper is ejected |

||

|

|

|

|

|

multiple bins |

continuously into a single bin |

|

|

|

|

|

|

|

|

|

|

|

20ppm mode |

|

|

18 ppm |

20 ppm |

|

|

|

10ppm mode |

|

|

9 ppm |

10 ppm |

|

|

|

|

|

|

|

|

|

|

(3) |

Bin capacity |

|

|

|

||

|

|

Normal mode: |

|

100 sheet/bin |

|

||

|

|

Big stacker mode*: |

300 sheet/bin |

|

|||

* When bins #2, #4, #7 and/or #9 are removed, bins #1, #3, #6 and/or #8 bin(s) as big stacker bins with a capacity of 300 sheets each.

3.2Electrical / Mechanical

(1)Power source

AC 100 to 240V, 50Hz/60Hz

(2)Power consumption

Printing: |

25W or less (when MX-2001 is installed.) |

|

45W or less (when both MX-2001 and MX-2002, or MX-2003 are |

|

installed.) |

Stand-by: |

15W or less (when MX-2001 is installed.) |

|

20W or less (when both MX-2001 and MX-2002, or MX-2003 are |

|

installed.) |

(3)Temperature

|

Operating: |

10 to 32.5°C (50 to 90.5°F) |

|

Storage: |

0 to 40°C (38 to 104°F) |

(4) |

Humidity |

|

|

Operating: |

20 to 80% (non condensing) |

|

Storage: |

10 to 85% (non condensing) |

(5)Dimensions

MX-2001: 354 (W) x 356 (D) x 411 (H) mm MX-2002: 354 (W) x 356 (D) x 337 (H) mm MX-2003: 354 (W) x 356 (D) x 617 (H) mm

(6)Weight

MX-2001: |

Approx. 5.2 kg |

MX-2002: |

Approx. 4.1 kg |

MX-2003: |

Approx. 9.3 kg |

I-3

3.3Paper

(1)Paper type

Cut sheet

Normal paper / Specific recycled paper

*Special paper is not included.

(2)Feedable paper weight 60 ~ 90 g/m2 (16 ~ 24lb.)

(3)Feedable paper thickness 0.075 ~ 0.12 mm

(4)Paper size

A4, Letter, Executive, ISO B5

(5)Recommended paper

Xerox 4200 (For U.S.) / RANK Xerox 80 g/m2 Premier paper (For Europe)

I-4

CHAPTER II THEORY OF OPERATION

1.ELECTRONICS

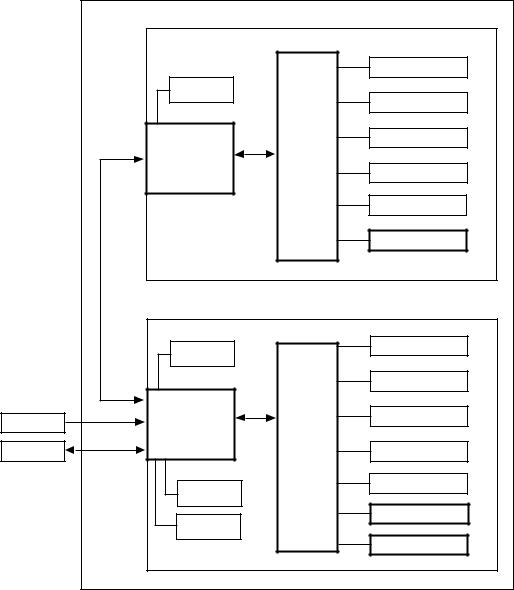

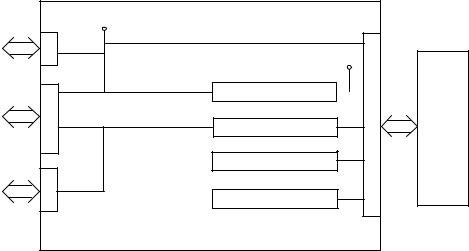

1.1General Block Diagram

<MX-2001 & MX-2002>

The MX-2001 Mailbox unit is operated according to signals sent from the printer by serial communication. The MX-2001 and MX-2002 also communicate with each other by serial communication. Refer to Fig. 2.1 which shows the general block diagram of the MX-2001 and MX-2002.

|

|

|

<MX-2002> |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

#10 bin solenoid |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Feeding |

|

|

|

|

|

|

|

|

|

|

|

Motor |

|

|

|

|

|

|

|

Serial |

|

|

|

|

|

#9 bin solenoid |

||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

#8 bin solenoid |

||

|

|

|

|

|

|

|

|

||||

Communication |

|

I/F PCB |

|

|

|

Main PCB |

|

|

|||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#7 bin solenoid |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#6 bin solenoid |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sensor PCB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<MX-2001> |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

Feeding |

|

|

|

#5 bin solenoid |

|||

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

Motor |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#4 bin solenoid |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

+24V Input |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

I/F PCB |

|

|

|

|

Main PCB |

|

#3 bin solenoid |

|||||||||

Adapter |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Printer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#2 bin solenoid |

|

Serial |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Communication |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

#1 bin solenoid |

|||||||

|

|

|

|

|

|

|

|

|

|

Entrance |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Solenoid |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sensor PCB |

|

|

|

|

|

|

|

|

|

|

Entrance |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Sensor |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LED PCB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 2.1

Note:

The following parts and circuits are not fitted on the PCBs in the MX-2002. <Main PCB>

Entrance solenoid circuit

LED PCB circuit

<I/F PCB>

Entrance sensor circuit

DC jack connector for the adapter

Modular jack connection to the printer

II-1

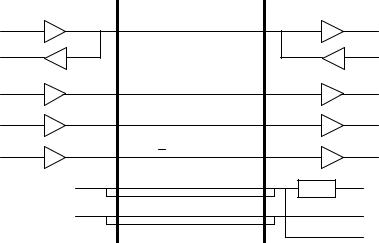

<MX-2003>

The electronic system of the MX-2003 is basically the same with the one of MX2001/2002. Refer to Fig. 2.2 which shows the general block diagram of the MX-2003.

|

|

|

<MX-2003> |

|

<Upper Unit> |

|

|

|

|

|

#10 bin solenoid |

|

Feeding |

|

|

|

Motor |

|

#9 bin solenoid |

|

|

|

|

Serial |

|

|

|

Communica- |

|

|

#8 bin solenoid |

tion |

|

|

|

I/F PCB |

Main PCB |

|

|

|

|

||

|

|

|

#7 bin solenoid |

|

|

|

#6 bin solenoid |

|

|

|

Sensor PCB |

|

<Lower Unit> |

|

|

|

Feeding |

|

#5 bin solenoid |

|

Motor |

|

|

|

|

|

#4 bin solenoid |

Adapter |

I/F PCB |

Main PCB |

#3 bin solenoid |

|

|||

+24V Input |

|

|

|

Printer |

|

|

#2 bin solenoid |

Serial |

|

|

|

Communica- |

|

|

#1 bin solenoid |

tion |

Entrance |

|

|

|

Solenoid |

|

|

|

Entrance |

|

Sensor PCB |

|

|

|

|

|

Sensor |

|

|

|

|

|

LED PCB |

Fig. 2.2

II-2

1.2Main PCB

Fig. 2.2 shows the block diagram of the main PCB.

Main PCB

|

|

|

|

|

|

CPU |

|

||

|

|

|

|

|

|

M50727 |

|

||

|

+24V |

|

|

|

|

|

|

|

|

|

+5V |

|

|

|

|

||||

|

|

|

|

Bin solenoid drive circuit |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(for each bin) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bin capacity sensor |

|

|

|

|

|

|

|

|

|

|

I/F PCB |

|

|

|

|

|

|

|

|

(for each bin) |

|

Entrance solenoid drive circuit |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Infrared LED drive circuit

Power supply LED drive circuit

Power supply LED drive circuit

GND

Printer

Fig. 2.2

1.2.1CPU

The CPU M50727 is a 4 bit one-chip microcomputer which controls the Mailbox unit and communicates with the printer using serial communications. According to the commands from the printer, the CPU drives the feeding motor and the solenoid of each bin and then feeds the paper to the specified bin. If it detects paper full in the specified bin, the CPU sends the signal to the printer.

1.2.2Bin solenoid drive circuit

The bin solenoid drive circuit drives the solenoid of each bin which controls the diverter flap to send the paper to each bin. The diverter flap is opened when the solenoid is energized and the flap is closed when the solenoid is de-energized. Each drive circuit for each of the five bins works independently.

This circuit provides a constant current drive to the solenoid. The solenoid is driven at 600mA for 200msec when it is first energized and then it is held by being driven at 150mA.

1.2.3Entrance solenoid drive circuit

The entrance solenoid drive circuit drives the solenoid which controls the flap to switch the paper eject tray from the printer to the Mailbox unit. It is the same as the bin solenoid drive circuit and connected to the entrance solenoid through the I/F PCB.

II-3

1.2.4Bin capacity sensor

The bin capacity sensors, which are five infrared LEDs, detect whether the bin is full or not.

The infrared sensor output generated from the sensor PCB is shut off when the bin is full of paper. The CPU recognizes that the bin is full when the infrared sensor output is shut off for 20 seconds.

These sensors also detect paper jams. When paper is ejected into the bin, the sensor is covered temporarily by the actuator. The CPU recognizes that a paper jam has occurred when the sensor has not cleared after a specified time has passed.

1.2.5Infrared LED drive circuit

The infrared LED drive circuit drives the five infrared LEDs on the sensor PCB. This drive circuit is controlled by the CPU.

1.2.6Power supply LED drive circuit

The power supply LED drive circuit drives the power supply LED when the regulated DC power, +24V, is supplied when the adapter is connected and plugged in.

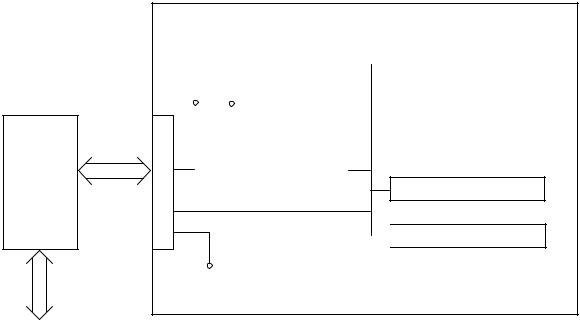

1.3I/F PCB

Fig. 2.3 shows the block diagram of the I/F PCB.

|

I/F PCB |

|

|

+24V |

|

Adapter |

+24V |

|

|

|

+5V |

|

+24V |

|

|

Regulator |

|

Printer |

|

Main PCB |

|

Serial I/F drive circuit |

|

|

|

Feeding motor drive circuit

Mail Box Unit

Entrance sensor input

Fig. 2.3

1.3.1Regulator

The regulator generates and supplies the +5V logic power supply from the +24V supplied by the adapter.

If the adapter is not connected, the regulator generates the +5V logic power supply from the +24V supplied by the printer. In this case, the +24V supplied by the printer is not connected with the +24V supply that should be provided to the Mailbox unit from the adapter.

II-4

1.3.2Serial I/F circuit

The serial interface circuit transmits and receives data to and from the printer.

1.3.3Feeding motor drive circuit

The feeding motor drive circuit drives the motor which feeds the paper in the Mailbox unit according to the signals from the CPU.

1.3.4Entrance sensor input

The entrance sensor which is connected with the CPU detects whether the paper is fed into the Mailbox unit or not.

1.4Sensor PCB

The five infrared LEDs are mounted on the sensor PCB to detect whether the bin is full or not. The sensor PCB is controlled according to signals from the CPU.

1.5Power supply LED PCB

The LED which turns on when the +24V is supplied from the adapter is mounted on the power supply LED PCB.

1.6Communication with the Printer

A 3-line clock synchronous serial interface is used for communication between the Mailbox unit and the printer.

The diagram below describes the timing of communications.

Printer |

Duplex unit |

|

SIDATA |

|

|

DATAOUT |

|

DATAIN |

DATAIN |

|

DATAOUT |

SICLK |

|

|

CLKOUT |

|

CLKIN |

/ATTN |

|

|

/ATNOUT |

|

/ATNIN |

/OP |

RESET |

|

/OPRST |

|

/RESET |

+24V |

|

+5V |

+24V |

REG. |

|

GND |

|

GND |

GND |

|

|

|

|

+24V |

Fig. 2.4

II-5

• Without a STATUS request

COMMAND transmission/receipt sequence

/ATTN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200 µs |

|

|

|

|

500 min |

|||

SICLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

4 µs 400 min 350 max |

|

|

|

6.4 min |

|

|

|

|

|

|

6.4 min |

|

|

|

|

|

|

|

|

||||||||||||||||||||||

SIDATA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

D0 |

D1 |

D2 |

D3 |

|

D4 |

|

|

D5 |

|

D6 |

D7 |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

500 max 50 µs |

|

|

12.8 µs |

|

|

|

|

|

|

|

|

|

|

|

|

|

350 max |

|

150 min |

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

6-II |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

• Within a STATUS request |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

COMMAND transmission/receipt sequence |

|

|

|

|

|

|

|

|

|

|

|

STATUS transmission/receipt sequence |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/ATTN

SICLK

4 µs 400 min 350 max |

6.4 min |

||||||

|

|

|

|

|

|

|

|

200 µs

350 max |

6.4 min |

200 µs |

|

|

|

|

500 min

350 max

SIDATA

|

|

|

|

|

D0 |

D1 |

D2 |

D3 |

D4 |

|

D5 |

D6 |

D7 |

|

|

|

|

|

|

D0 |

D1 |

D2 |

D3 |

D4 |

D5 |

D6 |

D7 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

500 max 50 µs |

|

12.8 µs |

|

|

|

350 max |

|

|

|

150 µs |

|

|

|

|

|

|

70 µs/1000 max |

|

|

350 min |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.MECHANICS

2.1General Overview of Mechanism

Paper Stopper

MX-2002

#10 Bin

#9 Bin

Feed Roller A

#8 Bin

#7 Bin

Actuator A/B

#6 Bin

Feed Roller B

Feed Roller B

Main Flap

Main Flap

Eject Roller

Paper Stopper

#5 Bin |

MX-2001 |

|

|

#4 Bin |

|

Feed Roller A

#3 Bin

#2 Bin

Actuator A/B

#1 Bin

Feed Roller B

Feed Roller B

Main Flap

Main Flap

Eject Roller

Actuator U

Actuator U

Feed Roller U

Feed Roller U

Flap U

Fig. 2.5

Note:

The mechanical system of the MX-2003 is the same with the one of MX-2001/2002.

II-7

2.2Paper Feed Sequence

This section describes the sequence when paper is fed from the printer to #1 bin as an example.

(1)When the paper is sensed at the eject actuator in the fixing unit, the printer specifies which bin of the Mailbox unit the paper is to be ejected to and sends the command to start the operation of the Mailbox unit. (Refer to Fig. 2.6.)

When the Mailbox unit receives the command, it drives the feeding motor and starts the timer to open the entrance flap (flap U).

MX-2001

HL-2060

Entrance Flap (Flap U)

Paper path

Eject actuator

Fixing Unit

Fig. 2. 6

(2)While the paper is being fed towards the entrance flap, the Mailbox unit starts driving the entrance solenoid (solenoid U) and turns on the entrance flap so that the paper is fed to the Mailbox unit. (Refer to Fig. 2.7.)

If the entrance sensor has not turned on after a specified time has passed, it detects that a paper jam has occurred.

MX-2001

HL-2060

Entrance Flap (Flap U)

Paper path

Paper path

Fig. 2. 7

II-8

(3)The Mailbox unit drives the #1 bin solenoid (solenoid A) and sets the #1 bin flap (main flap) so that the paper is fed to #1 bin. (Refer to Fig. 2.8.)

If the eject sensor of #1 bin has not turned on after a specified time has passed, it detects that a paper jam has occurred.

MX-2001

#1 Bin

HL-2060

#1 Bin Actuator

(Actuator A/B)

#1 Bin Flap (Main Flap) |

Entrance Actuator |

(Actuator U) |

Feed Motor U |

Paper path |

Fig. 2. 8

(4)After the paper end is ejected from the printer to the Mailbox unit, the printer sends the command to stop the entrance solenoid to the unit. As soon as the Mailbox unit receives the command, it stops driving the entrance solenoid.

(5)After the paper is correctly ejected into the #1 bin, the printer sends the command to stop the operation of the Mailbox unit. As soon as the Mailbox unit receives the command, it stops driving the feeding motor and the #1 bin solenoid.

II-9

Paper Feed Timing Chart

<Example: #1 Bin > |

|

|

Feeding |

|

|

motor |

|

|

Entrance |

1.2 sec |

|

|

|

|

solenoid |

|

|

Entrance |

1.0 sec |

2.5 sec |

|

||

sensor |

|

|

#1 bin |

0.7 sec |

4.0 sec |

|

||

solenoid |

|

|

#1 bin eject |

0.7 sec |

|

|

|

|

sensor |

|

|

The command to start the operation received

The command to stop the entrance solenoid received

Fig. 2.9

The command to stop the operation received

Note:

The above timing applies to the 20ppm mode. It takes twice as long when the printer is in the 10ppm (1200 dpi) mode.

The timing delay to eject the paper into the next bin upwards is about 0.3 seconds later than the bin below because the distance between each bin is 39mm. Also, note that the distance between the #5 bin and the #6 bin is 55mm and the timing is 0.43 seconds later.

II-10

CHAPTER III DISASSEMBLY

1.SAFETY PRECAUTIONS

To avoid creating secondary problems by mishandling, be careful to follow the following precautions during maintenance work.

(1)Always unplug the power cord from the power outlet of the Mailbox unit before accessing any parts inside the unit.

(2)Be careful not to lose screws, washers, or other parts removed during servicing.

(3)Be sure to apply grease to the gears and applicable positions specified in this chapter.

(4)When using soldering irons or other heat-generating tools, take care not to accidentally damage parts such as wires, PCBs and covers.

(5)Before handling any PCBs, touch a metal portion of the equipment to discharge any static electricity charge on your body, or the electronic parts or components may be damaged.

(6)When transporting PCBs, be sure to wrap them in the correct protective packaging.

(7)Be sure to replace self-tapping screws correctly, if removed. Unless otherwise specified, tighten screws to the following torque values.

TAPTITE, CUP B

M3 : 7kgf • cm

M4 : 10kgf • cm

TAPTITE, CUP S

M3 : 8kgf • cm

SCREW

M3 : 8kgf • cm

(8)When connecting or disconnecting cable connectors, hold the connector body, not the cables. If the connector has a lock, release the connector lock first to release it.

(9)After a repair, check not only the repaired portion but also all connectors. Also check that other related portions are functioning properly before operational checks.

III-1

2.DISASSEMBLY FLOW

3.1 External |

|

Covers |

3.1.1 |

Cover UR |

(MX-2001/2003 only)

Cover UL |

3.1.2 |

|

(MX-2001/2003 only)

3.1.3

Cover R

3.1.4

Cover L

Rear Cover U ASSY 3.1.5

(MX-2001/2003 only)

Rear Cover A ASSY 3.1.6

3.1.7

PCB Cover A(B/D)

3.1.8

Bin

Note:

3.2 Remove the Main Frame Unit from the Under Frame Unit

(MX-2001/2003 only)

3.4 Under

Frame Unit

(MX-2001/2003 only)

3.4.1

Actuator U

Solenoid U |

3.4.2 |

|

|

|

|

3.4.3

Photo Interrupter

Feed Roller U ASSY 3.4.4

3.4.5

Flap U

3.5 Remove the Upper Unit from the Lower Unit

(MX-2003 only)

3.3 Main Frame

Unit

I/F PCB A(B//C/D) 3.3.1 ASSY

Feeding Motor ASSY 3.3.2

Main PCB A(B) |

|

|

3.3.3 |

||||

ASSY |

|

|

|

|

|||

|

|

|

|

3.3.4 |

|||

|

|||||||

Solenoid A/B & |

|

||||||

LED PCB ASSY |

|

|

|

|

|

||

(MX-2001/2003 only) |

|

|

|

|

|

||

|

|

|

|

|

|

3.3.5 |

|

|

|

|

|

|

|||

Sensor PCB ASSY |

|

|

|||||

|

|

|

|

|

|

|

3.3.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Actuator A/B |

|

|

|

||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

3.3.7 |

||

|

|

|

|

|

|||

Eject Roller ASSY |

|

||||||

& Feed Roller |

|

|

|

|

|||

A/B ASSY |

|

|

|

|

|||

|

|

|

|

3.3.8 |

|||

|

|

||||||

Eject Pinch Roller |

|

||||||

ASSY & Discharging |

|

|

|

|

|

||

Brush |

|

|

|

|

|

||

1)When disassembling the MX-2003, see Section 3.5 first to remove the upper unit from the lower unit.

2)Most of the parts are common or similar among the MX-2001, the MX-2002 and the MX2003, and the procedures to disassemble them are also the same. Therefore;

MX-2001 is used for the figures in the following sections.

The parts name descriptions such as ‘Main PCB A(B)’ indicates ‘Main PCB A’ for MX2001 and ‘Main PCB B’ for MX-2002 in this chapter.

III-2

3.DISASSEMBLY PROCEDURE

3.1External Covers

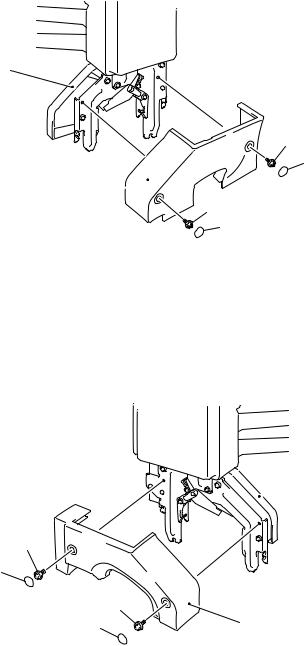

3.1.1Cover UR (For MX-2001/2003 only)

(1)Remove the two screw cover sheets, then remove the two M3x6 Taptite screws.

(2)Remove the cover UR from the frame UR.

Frame UR

Taptite, M3x6

Screw Cover Sheet

Cover UR

Taptite, M3x6

Screw Cover Sheet

Fig. 3.1

3.1.2Cover UL (For MX-2001/2003 only)

(1)Remove the two screw cover sheets, then remove the two M3x6 Taptite screws.

(2)Remove the cover UL from the frame UL.

Frame UL

Frame UL

Taptite, M3x6

Screw Cover Sheet

Taptite, M3x6

Cover UL

Screw Cover Sheet

Fig. 3.2

III-3

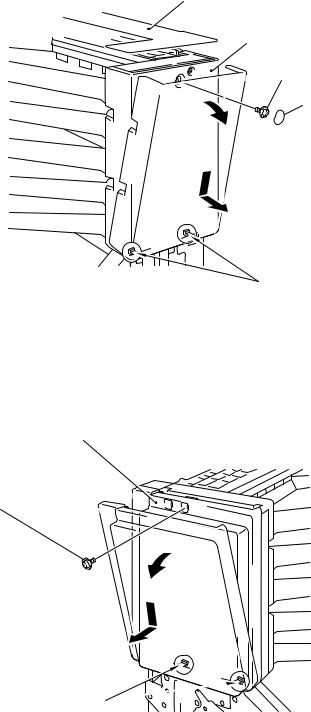

3.1.3Cover R

(1)Unstick the upper sheet.

(2)Remove the one screw cover sheet, then remove the one M3x6 Taptite screw.

(3)Incline the cover R outwards using the two hooks as supporting points, then remove the cover R.

Upper Sheet

Cover R

Taptite, M3x6

Screw Cover Sheet

hook

Fig. 3.3

3.1.4Cover L

(1)Remove the one screw cover sheet L, then remove the one M3x6 Taptite screw.

(2)Incline the cover L outwards using the two hooks as supporting points, then remove the cover L.

Cover L

Taptite, M3x6

Screw Cover Sheet L

hook

Fig. 3.4

Note:

When refitting cover L, ensure that the cover is lift fully upwards to reduce the gap on the upper side of the cover.

III-4

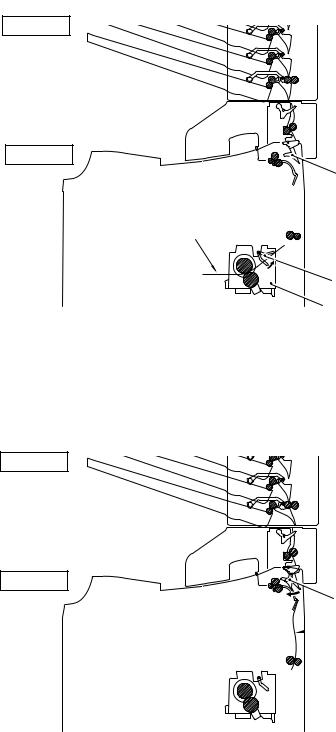

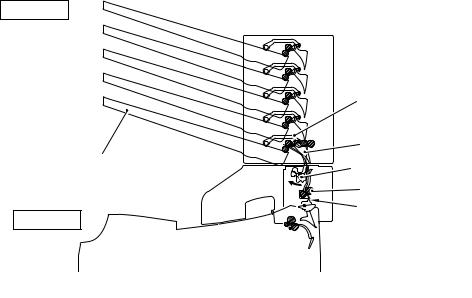

3.1.5Rear Cover U ASSY (For MX-2001/2003 only)

(1)Release the two hooks to open the rear cover U ASSY.

hook

hook

Rear Cover U ASSY

Frame UL

Fig. 3.5

(2)Release the left hand side of the cover by pulling the hinge of the frame UR outwards, then remove the cover from the right hand side.

Frame UR

hinge

Rear Cover U ASSY

Fig. 3.6

III-5

Loading...

Loading...