Bosch GSB18V-535C, GSR18V-535C Owner's Guide

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 1

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 1

IMPORTANT: |

IMPORTANT : |

IMPORTANTE: |

Read Before Using |

Lire avant usage |

Leer antes de usar |

|

|

|

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

GSB18V-535C

GSR18V-535C

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Call Toll Free for |

Pour obtenir des informations |

Llame gratis para |

|

|||

|

|

Consumer Information |

et les adresses de nos centres |

obtener información |

|

|||

|

|

& Service Locations |

de service après-vente, |

para el consumidor y |

|

|||

|

|

|

|

|

appelez ce numéro gratuit |

ubicaciones de servicio |

|

|

|

|

|

|

|

|

|

|

|

|

|

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

For English Version |

Version française |

Versión en español |

|

|||

|

|

See page 2 |

Voir page 19 |

Ver la página 36 |

|

|||

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 2

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 2

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential personal

!injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, will result in minor or moderate injury.

General Power Tool Safety Warnings

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a Ground Fault Circuit Interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

2 |

SAVE THESE INSTRUCTIONS |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 3

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and / or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

Battery tool use and care

Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

When battery pack is not in use, keep it away from other metal objects like paper clips, coins, keys, nails, screws, or other small metal objects that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behaviour resulting in fire, EXPLOSION or risk of injury.

Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature above 265 °F (130 °C) may cause explosion.

Follow all charging instructions and do not charge the battery pack or tool outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the BATTERY and increase the risk of fire.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

SAVE THESE INSTRUCTIONS |

3 |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 4

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 4

Safety Rules for Cordless Hammer Drills

Wear ear protectors when impact drilling.

Exposure to noise can cause hearing loss.

Use auxiliary handle(s) if supplied with the tool. Loss of control can cause personal injury.

Hold power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could give the operator an electric shock.

Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body leaves it unstable and may lead to loss of control.

Do not drill, fasten or break into existing walls or other blind areas where electrical wiring may exist. If this situation is unavoidable, disconnect all fuses or circuit breakers feeding this worksite.

Always wear safety goggles or eye protection when using this tool. Use a dust mask or respirator for applications which generate dust.

Use thick cushioned gloves and limit the exposure time by taking frequent rest periods.

Vibration caused by hammer-drill action may be harmful to your hands and arms.

Secure the material being drilled. Never hold it in your hand or across legs. Unstable support can cause the drill bit to bind causing loss of control and injury.

Disconnect battery pack from tool before making any assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

Position yourself to avoid being caught between the tool or side handle and walls or posts. Should the bit become bound or jammed in the work, the reaction torque of the tool could crush your hand or leg.

If the bit becomes bound in the workpiece, release the trigger immediately, reverse the direction of rotation and slowly squeeze the trigger to back out the bit. Be ready for a strong reaction torque. The drill body will tend to twist in the opposite direction as the drill bit is rotating.

Do not grasp the tool or place your hands too close to the spinning chuck or drill bit. Your hand may be lacerated.

When installing a drill bit, insert the shank of the bit well within the jaws of the chuck. If the bit is not inserted deep enough, the grip of the jaws over the bit is reduced and the loss of control is increased.

Do not use dull or damaged bits and accessories. Dull or damaged bits have a greater tendency to bind in the workpiece.

When removing the bit from the tool avoid contact with skin and use proper protective gloves when grasping the bit or accessory.

Accessories may be hot after prolonged use.

Check to see that keys and adjusting wrenches are removed from the drill before switching the tool "ON". Keys or wrenches can fly away at high velocity striking you or a bystander.

Do not run the tool while carrying it at your side. A spinning drill bit could become entangled with clothing and injury may result.

Safety Rules for Cordless Drill/Drivers

Use auxiliary handle(s) if supplied with the tool. Loss of control can cause personal injury.

Hold power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could give the operator an electric shock.

Use clamps or another practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body leaves it unstable and may lead to loss of control.

Do not drill, fasten or break into existing walls or other blind areas where electrical wiring may exist. If this situation is unavoidable, disconnect all fuses or circuit breakers feeding this worksite.

Always hold the tool with both hands. If the bit jams two hands will give you maximum control over torque reaction or kickback.

4 |

SAVE THESE INSTRUCTIONS |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 5

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 5

Always wear safety goggles or eye protection when using this tool. Use a dust mask or respirator for applications which generate dust.

Secure the material being drilled. Never hold it in your hand or across legs. Unstable support can cause the drill bit to bind causing loss of control and injury.

Disconnect battery pack from tool or place the switch in the locked or off position before making any assembly, adjustments or changing accessories. Such preventive safety measures reduce the risk of starting the tool accidentally.

Position yourself to avoid being caught between the tool or side handle and walls or posts. Should the bit become bound or jammed in the work, the reaction torque of the tool could crush your hand or leg.

If the bit becomes bound in the workpiece, release the trigger immediately, reverse the direction of rotation and slowly squeeze the trigger to back out the bit. Be ready for a strong reaction torque. The drill body will tend to twist in the opposite direction as the drill bit is rotating.

Do not grasp the tool or place your hands too close to the spinning chuck or drill bit.

Your hand may be lacerated.

When installing a bit, insert the shank of the bit well within the chuck. If the bit is not inserted deep enough, the grip of the chuck over the bit is reduced and the loss of control is increased. After bit insertion, pull on bit to ensure it is locked.

Do not use dull or damaged bits and accessories. Dull or damaged bits have a greater tendency to bind in the workpiece.

When removing the bit from the tool avoid contact with skin and use proper protective gloves when grasping the bit or accessory.

Accessories may be hot after prolonged use.

Check to see that keys and adjusting wrenches are removed from the drill before switching the tool "ON". Keys or wrenches can fly away at high velocity striking you or a bystander.

Do not run the drill while carrying it at your side. A spinning drill bit could become entangled with clothing and injury may result.

Additional Safety Warnings

GFCI and personal protection devices like electrician’s rubber gloves and footwear will further enhance your personal safety.

Do not use AC only rated tools with a DC power supply. While the tool may appear to work, the electrical components of the AC rated tool are likely to fail and create a hazard to the operator.

Keep handles dry, clean and free from oil and grease. Slippery hands cannot safely control the power tool.

Develop a periodic maintenance schedule for your tool. When cleaning a tool be careful not to disassemble any portion of the tool since internal wires may be misplaced or pinched or safety guard return springs may be improperly mounted. Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

Ensure the switch is in the off position before inserting battery pack. Inserting the battery pack into power tools that have the switch on invites accidents.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from lead-based paints,

•Crystalline silica from bricks and cement and other masonry products, and

•Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

THINK SAFETY

SAFETY IS A COMBINATION OF OPERATOR COMMON SENSE AND ALERTNESS AT ALL TIMES WHEN POWER TOOLS ARE BEING USED.

SAVE THESE INSTRUCTIONS |

5 |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 6

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 6

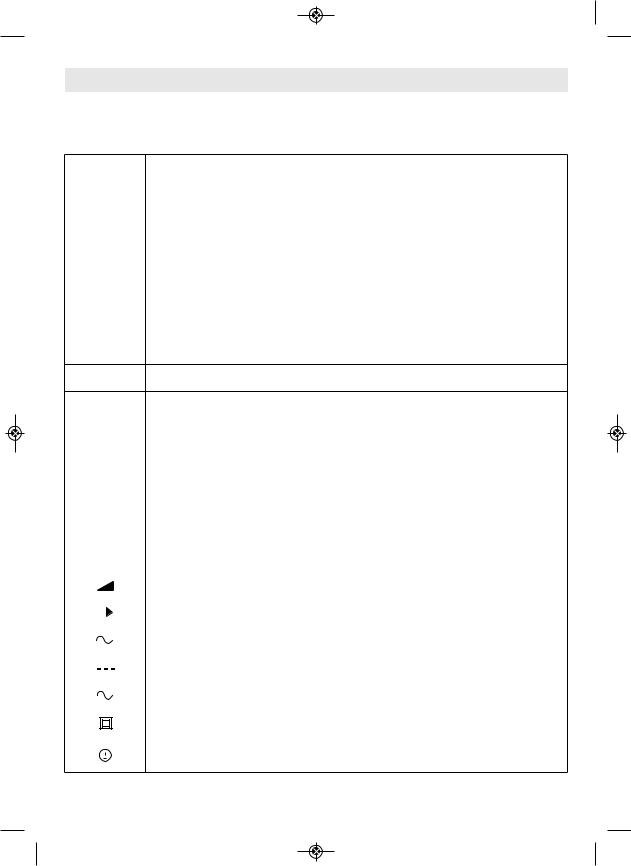

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol |

Designation / Explanation |

|

|

V |

Volts (voltage) |

|

|

A |

Amperes (current) |

|

|

Hz |

Hertz (frequency, cycles per second) |

|

|

W |

Watt (power) |

|

|

kg |

Kilograms (weight) |

|

|

min |

Minutes (time) |

|

|

s |

Seconds (time) |

Diameter (size of drill bits, grinding wheels, etc.)

|

n0 |

No load speed (rotational speed at no load) |

|||||

|

|

n |

Rated speed (maximum attainable speed) |

||||

|

|

|

|

|

|

|

|

.../min |

Revolutions or reciprocation per minute (revolutions, strokes, surface speed, orbits etc. |

||||||

per minute) |

|||||||

|

|

|

|

|

|

||

|

|

|

|

||||

0 |

|

|

Off position (zero speed, zero torque...) |

||||

|

|

||||||

1, 2, 3, ... |

Selector settings (speed, torque or position settings. Higher number means greater |

||||||

I, II, III, |

speed) |

||||||

|

|

|

|

|

|

||

0 |

|

|

|

|

Infinitely variable selector with off (speed is increasing from 0 setting) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arrow (action in the direction of arrow) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternating current (type or a characteristic of current) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direct current (type or a characteristic of current) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternating or direct current (type or a characteristic of current) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Class II construction (designates double insulated construction tools) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earthing terminal (grounding terminal) |

|

|

|

|

|

|

|

||

6 |

SAVE THESE INSTRUCTIONS |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 7

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 7

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

|

|

Symbol |

|

|

Designation / Explanation |

||||

|

|

|

|

|

|

|

|

|

Designates Li-ion battery recycling program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Designates Ni-Cad battery recycling program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alerts user to read manual |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alerts user to wear eye protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This symbol designates that this tool is listed by Underwriters Laboratories. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This symbol designates that this component is recognized by Underwriters |

|

|

|

|

|

|

|

|

|

Laboratories. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This symbol designates that this tool is listed by Underwriters Laboratories, to |

|

|

|

|

|

|

|

|

|

United States and Canadian Standards. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This symbol designates that this tool is listed by the Canadian Standards |

|

|

|

|

|

|

|

|

|

Association. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This symbol designates that this tool is listed by the Canadian Standards |

|

|

|

|

|

|

|

|

|

Association, to United States and Canadian Standards. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This symbol designates that this tool is listed by the Intertek Testing Services, to |

|

|

|

|

|

|

|

|

|

United States and Canadian Standards. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This symbol designates that this tool complies to NOM Mexican Standards. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SAVE THESE INSTRUCTIONS |

7 |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 8

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 8

Functional Description and Specifications

Disconnect battery pack from tool before making any assembly, adjustments or changing accessories. Such preventive safety measures reduce the risk of

starting the tool accidentally.

Cordless Drill Drivers and Cordless Hammer Drills

MODE SELECTOR RING |

GEAR SHIFTER / |

|

(Model GSB18V-535C only) |

SPEED RANGE SELECTOR |

|

ADJUSTABLE |

VENTILATION |

|

CLUTCH |

||

OPENINGS |

||

|

||

KEYLESS |

FORWARD/REVERSING |

|

CHUCK |

||

|

LEVER AND TRIGGER LOCK |

|

|

RUBBERIZED GRIP |

|

FIG. 1 |

CONNECTIVITY MODULE |

|

COMPARTMENT |

||

VARIABLE SPEED |

|

|

TRIGGER SWITCH |

|

|

|

KICKBACK CONTROL |

|

|

INSTRUCTION LABEL |

|

BUILT IN WORK LIGHT AND |

|

|

RED FUNCTION LIGHT |

|

|

|

BELT CLIP |

|

BATTERY PACK |

BATTERY PACK |

|

RELEASE BUTTON |

Model number |

GSR18V-535C |

GSB18V-535C |

||||

Voltage rating |

18 V |

|

|

18 V |

|

|

|

|

|||||

No load speed 1 |

n0 0-600/min |

n0 0-600/min |

||||

No load speed 2 |

n0 0-1,900/min |

n0 0-1,900/min |

||||

Beats per minute |

NA |

0-28,500 bpm |

||||

Maximum Capacities |

|

|

|

|

|

|

Chuck size |

1/2" |

|

|

1/2" |

|

|

Driving screw sizes |

#16 x 3" |

#16 x 3" |

||||

Drilling mild metal |

1/2" |

|

|

1/2" |

|

|

Drilling hard wood |

1-1/2" |

|

1-1/2" |

|

||

Drilling soft wood |

2" |

|

|

2" |

|

|

Drilling Masonry |

NA |

1/2" |

|

|

||

Data Transmission (GCY30-4 installed) |

|

|

|

|||

Bluetooth® |

|

Bluetooth® 4.1 (Low Energy)A |

||||

Signal interval, approx. |

8 s |

8 s |

||||

Signal range |

maximum 98ftB |

maximum 98ftB |

||||

NOTE: For tool specifications refer to the nameplate on your tool.

Battery Packs/Chargers

Please refer to the Charger Manual included with your tool.

AThe mobile terminal devices must be compatible with Bluetooth® Low Energy devices (version 4.1) and support the Generic Access Profile (GAP).

BThe signal range may vary greatly depending on external conditions. The Bluetooth® range may be significantly weaker inside closed rooms and through metallic barriers (e.g. walls, shelving units, cases, etc.).

8 |

SAVE THESE INSTRUCTIONS |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 9

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 9

Assembly

Disconnect battery pack from tool before making any assembly, adjustments or changing accessories. Such preventive safety measures reduce the risk of

starting the tool accidentally.

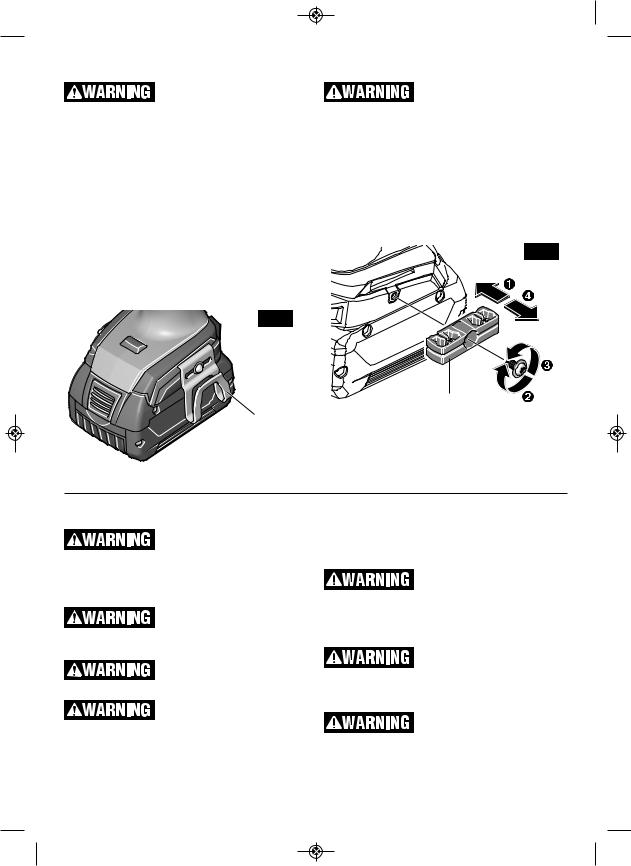

INSERTING AND RELEASING

BATTERY PACK

Set Forward/Reversing lever to the center (off position). Slide charged battery pack into the housing until the battery pack locks into position (Fig. 2).

Your tool is equipped with a secondary locking latch to prevent the battery pack from completely

falling out of the handle, should it become loose due to vibration.

To remove the battery pack, press the battery pack release button and slide the battery pack forward (Fig. 3).

Press the battery pack release button again and slide the battery pack completely out of tool housing (Fig. 3).

FIG. 2 |

FIG. 3 |

|

BATTERY PACK |

BATTERY PACK |

|

RELEASE BUTTON |

||

|

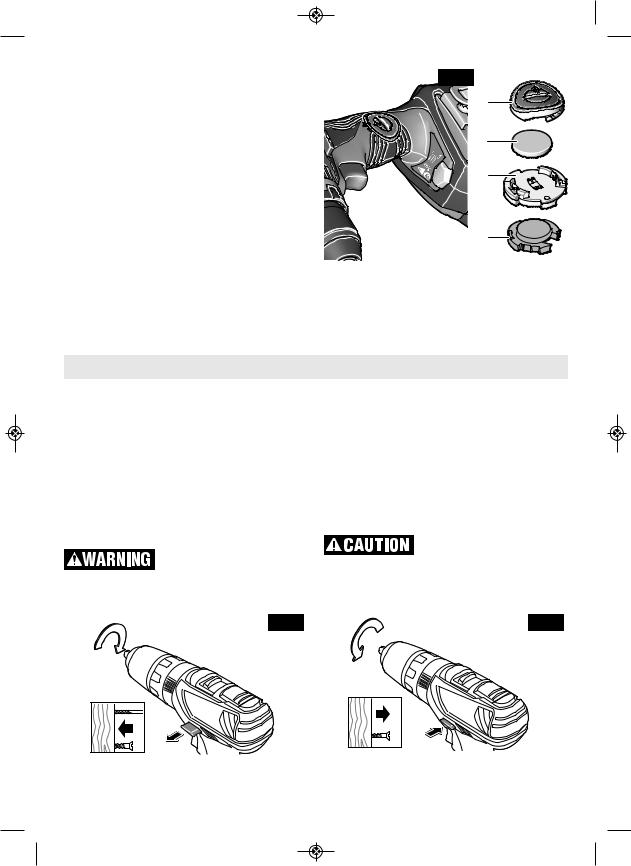

INSERTING BITS

Move reverse switch lever to the center “OFF” position. Remove battery pack and rotate the clutch ring (Model GSR18V-535C) or mode selctor ring (Model GSB18V-535C) to the drill bit symbol “

”. To open rotate the chuck sleeve counter-clockwise viewing from chuck end, and open chuck to approximate drill bit diameter. Insert a clean bit up to the drill bit flutes for small bits, or as far as it will go for large bits. Close chuck by rotating the chuck sleeve clockwise and securely tighten by hand (Fig. 4). Return the clutch ring or mode selector ring to desired position.

”. To open rotate the chuck sleeve counter-clockwise viewing from chuck end, and open chuck to approximate drill bit diameter. Insert a clean bit up to the drill bit flutes for small bits, or as far as it will go for large bits. Close chuck by rotating the chuck sleeve clockwise and securely tighten by hand (Fig. 4). Return the clutch ring or mode selector ring to desired position.

Do not use the power of the drill while grasping chuck to loosen or tighten bit. Friction burn or hand injury

is possible if attempting to grasp the spinning chuck.

FIG. 4 CHUCK CLOSE

SLEEVE

DRILL BIT

OPEN

BIT HOLDER

SCREWDRIVER BIT

SCREWDRIVER BIT

SAVE THESE INSTRUCTIONS |

9 |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 10

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 10

BELT CLIP

When the tool is attached to the belt, position yourself to avoid entanglement with surrounding objects.

Unexpected entanglement could cause the tool to fall resulting in injury to the operator or bystanders.

The belt clip accessory will allow you to conveniently attach your tool to your belt. This feature will allow you to have both hands free when climbing a ladder or moving to another work area.

The belt clip can be attached to either side of the tool by securing it with a mounting screw. Always make sure you securely tighten the mounting screw before use (Fig. 5).

To use clip, turn tool upside down and attach to your belt.

FIG. 5

BELT CLIP

4X BIT TIP HOLDER

Store only bit tips in the ontool bit holder. Longer bits could interfere with proper tool operation and result

in user injury.

The four piece bit tip holder can be used for convenient on tool storage of your most commonly used bits.

When mounting bit holder accessory, mount on the side of the drill opposite the belt clip.

Always make sure you securely tighten the mounting screw before use. (Fig. 6).

FIG. 6

BIT HOLDER

GCY30-4 CONNECTIVITY MODULE

INSTALLATION

To reduce the risk of injury read the operating instructions included with Bosch GCY30-4

connectivity module. Operating instructions for GCY30-4 connectivity module include important information not covered in this manual.

Only use Button/coin cell 3V lithium CR2032 battery. Do not use any other button/coin cells or other forms

of electrical power supply.

Ensure that battery replacement is carried out

properly. There is a risk of explosion.

Chemical Burn Hazard. Keep batteries away from children. This product contains a lithium

button/coin cell battery. If a new or used lithium button/coin cell battery is swallowed or enters the

body, it can cause severe internal burns and can lead to death in as little as 2 hours. If you think a battery might have been swallowed or placed inside any part of the body, seek immediate medical attention.

Always completely secure the connectivity module compartment. If the connectivity module

compartment does not close securely, stop using the product, remove the battery, and keep it away from children.

When discarding batteries, insulate the ‘+’ and ‘–’ terminals with insulating tape. When disposed

of improperly, lithium batteries may short, causing them to become hot, burst or ignite.

Never dispose of the batteries in a fire or expose

to high heat. The batteries may explode.

10 |

SAVE THESE INSTRUCTIONS |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 11

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 11

If GCY30-4 connectivity module is not purchased |

FIG. 7 |

|

with the tool, or if the replacement of the module |

||

|

||

or the battery becomes necessary, please follow |

1 |

|

this procedure (See Fig. 7): |

|

|

- Using a flat screwdriver or a coin, remove the |

|

|

cover 1 from the side of the handle, by turning |

2 |

|

it 1/4 turn counter-clockwise. |

|

|

- If the tool is already equipped with the |

3 |

|

connectivity module, remove the battery 2, but |

||

do not remove the connectivity module 3. |

|

|

- If the connectivity module is installed for the |

|

|

first time, remove the plastic placeholder 4 |

|

|

from the connectivity module compartment, |

4 |

|

and place the connectivity module 3 in the |

||

|

||

compartment observing correct orientation. |

|

|

Note: Store the placeholder 4 in a safe place. |

- Place the cover 1 over the battery and turn it |

|

Reinsert the placeholder again if the |

¼-turn clockwise to lock using a flat |

|

communications module is removed. |

screwdriver or a coin. |

-Next place new battery 2 on the top of the connectivity module with the “+” polarity facing up.

Operating Instructions

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed trigger switch. The tool can be turned "ON" or "OFF" by squeezing or releasing the trigger. The speed can be adjusted from the minimum to maximum nameplate RPM by the pressure you apply to the trigger. Apply more pressure to increase the speed and release pressure to decrease speed (Fig. 1).

FORWARD/REVERSING

LEVER & TRIGGER LOCK

After tool use, lock trigger in “OFF” position to help prevent

accidental starts and accidental discharge.

Your tool is equipped with a forward/ reversing lever and trigger lock located above the trigger (Fig. 8). This lever was designed for changing rotation of the bit, and for locking the trigger in an “OFF” position.

For forward rotation, (with chuck pointed away from you) move the lever to the far left (Fig. 8).

For reverse rotation move the lever to the far right (Fig. 9). To activate trigger lock move lever to the center off position.

Do not change direction of rotation until the tool comes to a complete stop. Shifting during

rotation of the chuck can cause damage to the tool.

FIG. 8 |

FIG. 9 |

SAVE THESE INSTRUCTIONS |

11 |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 12

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 12

GEAR SHIFTING

Your tool is equipped with two separate gear ranges, low gear and high gear. Low gear provides high-torque and slower drilling speeds for heavy duty work or for driving screws. High gear provides faster speeds for drilling lighter work. To change speeds slide switch, to the high or low position (Fig. 10).

ATTENTION: If your tool appears to be running, but the chuck will not turn, check to make sure the gear shifting switch is pushed fully into desired setting.

ADJUSTABLE CLUTCH

Your tool features 20 clutch settings. Output torque will increase as the clutch ring, is rotated from 1 to 20. The drill “

” position will lock up the clutch to permit drilling and driving heavyduty work, and also enables bits to be changed quickly and easily in the keyless chuck (Fig. 11).

” position will lock up the clutch to permit drilling and driving heavyduty work, and also enables bits to be changed quickly and easily in the keyless chuck (Fig. 11).

ADJUSTABLE |

FIG. 11 |

CLUTCH |

|

BRAKE

When the trigger switch is released it activates the brake to stop the chuck quickly. This is especially useful in the repetitive driving and removal of screws.

BUILT IN LED WORK LIGHT

Your tool is also equipped with an LED light that turns on automatically when the switch is activated, for better visibility when drilling/ driving (Fig. 1). The light turns off automatically a short time after the trigger is released. You can adjust this time frame using Bosch Tool Box app. See “Connectivity” section.

DRILL/HAMMER DRILL SELECTOR RING (Model GSB18V-535C only)

The selector ring allows the tool to be set for

FIG. 10

GEAR

SHIFTER

SHIFTER

various drilling/hammer drilling applications. Rotate the selector dial right or left depending on the below applications (Fig. 12).

Drill only action: For drilling in woods, metals, plastics or other non concrete materials.

Drill with hammer action: For drilling in concrete, asphalt, tile or other similar hard materials. The hammer drill position overrides the clutch for drilling.

FIG. 12

MODE

SELECTOR

RING

TEMPERATURE OVERLOAD

PROTECTION

Avoid using battery operated tools continuously, for long periods of time, while subjecting the tool to overload conditions, such as drilling with large diameter accessories into hard materials. Using battery powered tools at extreme loads, may cause the battery to exceed its allowable operating temperature range. When the battery exceeds normal operating temperature caused by overload, the speed of the tool may be reduced and the tool may appear to lose power. To regain the tool's full performance, the battery must be allowed to cool, until the operating temperature returns to normal.

12 |

SAVE THESE INSTRUCTIONS |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 13

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 13

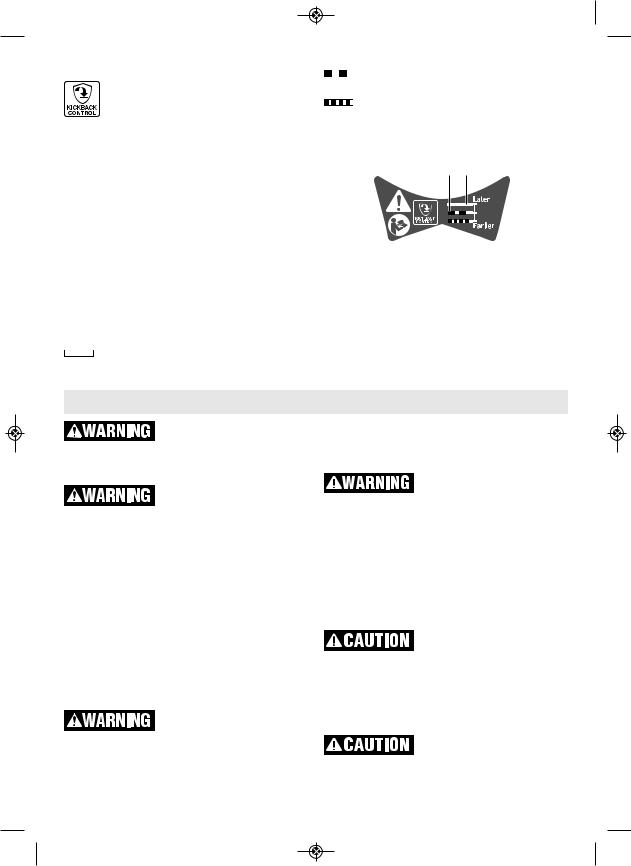

KickBack Control (Rapid Shut-off)

To ensure better control of the tool during operation, this tool is design to shut-off while in use if a sudden or unexpected

bind up situation occurs. Bind up occurs when the bit gets jammed during operation, which forces the bit to stop spinning abruptly. If this occurs, the tool will shut down and the KickBack Control will be indicated by flashing LED lights on the tool.

The sensitivity level of this feature is adjustable. Using Bosch Toolbox app on a mobile device, operator may select one of three settings between “Earlier” and “Later” markers on the app. The settings only control the KickBack Control activation delay, and do not change the capacity of this feature.

When the switch trigger is pressed, operator is notified about the KickBack Control settings, by the work light and function red light identified in Fig. 1 on page 8.

The setting indications are as follows:

WContinuous white light (W) = Later (delayed Kick Back activation).

R W R W Slow alternating red (R) and white (W) light = Mid-Level (less delayed activation).

RWRWRWRW Fast alternating red (R) / white (W) light = Earlier (minimum delay to activation).

The label next to the work light displays the Kick Back setting indicator light pattern.

RED LIGHT WHITE LIGHT

This feature can only be activated when the tool is running at maximum speed.

NOTE: The default KickBack Control setting for the tool is “Later”. KickBack Control setting for the tool without GCY30-4 module installed is always set to default.

Connectivity

To reduce the risk of injury read the operating instructions included with Bosch GCY30-4 connectivity module. Operating instructions for GCY30-4

connectivity module include important information not covered in this manual.

BLUETOOTH®

Do not use the power tool with Bluetooth® in the vicinity of gas stations, chemical plants, areas

where there is danger of explosion and areas subject to blasting. Do not use the power tool with Bluetooth® in airplanes. Do not use the power tool with Bluetooth® in the vicinity of medical devices. Avoid operation in the direct vicinity of the human body over longer periods of time. When using the power tool with Bluetooth®, interference with other devices and systems, airplanes and medical devices (e.g., cardiac pacemakers, hearing aids) may occur.

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such marks by Robert Bosch Tool Corporation is under license.

Follow all instructions and warnings provided by your Bluetooth® device manufacturer. Failure to

follow recommended procedures could result in personal injury or property damage.

Exercise extreme caution when using Bluetooth® devices to control or change power tool

functions. Operation of the device may be in a different area than the paired power tool. Paired devices may have functionality which allows timed event programming, including automatically powering on (e.g. flood light). Depending upon the power tool, these unattended operations or function changes without direct line of sight to the paired tool could result in personal injury or property damage.

Always check tool settings before use. Settings may be different than when the tool was last used. The

connectivity module enables transfer of data and settings based on Bluetooth® wireless technology. With module installed, select tool settings may be changed remotely by a paired Bluetooth® device and user installed app.

The connectivity module GCY30-4 is equipped with a radio interface. Local operating restrictions, e.g. in

SAVE THESE INSTRUCTIONS |

13 |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 14

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 14

military sites or hospitals, are to be observed. Transmitters have demonstrated an ability to unintentionally interfere with other devices.

THINK SAFETY

SAFETY IS A COMBINATION OF OPERATOR COMMON SENSE AND ALERTNESS AT ALL TIMES WHEN THE TOOL IS BEING USED.

FCC Caution

The manufacturer is not responsible for radio interference caused by unauthorized modifications to this equipment. Such modifications could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1)This device may not cause harmful interference, and

2)This device must accept any interference received, including interference that may cause undesired operation.

NOTE! This equipment has been tested and found to comply with the limits for a Class B digital devices, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

“Exposure to Radio Frequency (RF) Signals: The wireless device is a radio transmitter and receiver. It is designed and manufactured not to exceed the emission limit for exposure to radio frequency (RF) energy set by the Ministry of Health (Canada), Safety Code 6. These limits are part of comprehensive guidelines and established permitted levels of RF energy for the general population.

These guidelines are based on the safety standards previously set by international standard bodies. These standards include a substantial safety margin designed to assure the safety of all persons, regardless of age and health.

This device and its antenna must not be colocated or operating in conjunction with any other antenna or transmitter.

Industry Canada

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions:

(1)this device may not cause interference, and

(2)this device must accept any interference, including interference that may cause undesired operation of the device.

14 |

SAVE THESE INSTRUCTIONS |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 15

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 15

Using ‘Bosch Toolbox’ app

After pairing your tool with a mobile device you can adjust certain functions or check the status of the power tool using Bosch Toolbox app.

Every time you change any setting the tool will confirm the changes by flashing the white LED work light.

A.Help button – tapping this button will bring up help screen.

B.Tool photo – tapping on the photo will let you customize the photograph of the tool.

C.Power tool battery charge status – the number of green ‘batteries’ indicates the estimated charge level for the battery pack.

D.Power tool nickname – tapping on the ‘pencil’ icon will let you customize the tool nickname. You can also do it when changing the tool photo.

E.Connection status bar – Here you can see the connection (signal) strength indicated by vertical bars. You can use toggle switch to disconnect the tool from you mobile device.

F.KickBack Control adjustment slide – you can choose between three settings: ‘Earlier’, Middle (unmarked) and ‘Later’.

G.LED Afterglow timer – you can set the number of second that the LED worklight stays on after the trigger switch of the tool is released.

H.Factory Reset toggle switch – you can reset tool settings back to factory default settings. When you do so the LED after glow will reset to ‘10s’ and KickBack Control will be reset to ‘Later’ setting.

I.Tool alerts – tapping the ‘alerts triangle’ will display any alerts received from the tool.

J.Info button – displays tool information and specifications.

|

GSB18V-535C |

? |

A |

|

|

|

B |

|

|

|

C |

|

GSB18V-535C |

|

D |

Connected |

|

|

E |

KickBack Control |

|

F |

|

(Activation) |

Earlier |

Later |

|

LED Afterglow |

|

G |

|

Reset to Factory Default |

|

H |

|

J |

|

|

I |

SAVE THESE INSTRUCTIONS |

15 |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 16

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 16

Operating Tips

DRIVING NUTS AND BOLTS

Variable speed control must be used with caution for driving nuts and bolts with socket set attachments. The technique is to start slowly, increasing speed as the nut or bolt runs down. Set the nut or bolt snugly by slowing the drill to a stop. If this procedure is not followed, the tool will have a tendency to torque or twist in your hands when the nut or bolt seats.

DRILLING

You will extend the life of your bits and do neater work if you always put the bit in contact with the work before pulling the trigger. During the oper a- tion, hold the tool firmly and exert light, steady pressure. Too much pressure at low speed will stall the tool. Too little pressure will keep the bit from cutting and cause excess friction by sliding over the surface. This can be damaging to both tool and bit.

DRILLING WITH VARIABLE SPEED

The variable speed trigger allows you to slowly increase RPM. By using a slow starting speed, you are able to keep the bit from “wander ng”i. You can increase the speed as the bit “bites” into the work by squeezing the trigger.

DRIVING WITH VARIABLE SPEED

Variable speed drills will double as a power screwdriver by using a screwdriver bit. Prior to driving screws, pilot and clearance holes should be drilled. Place the threaded end of the screw in the pilot or clearance hole and start driving the screw slowly, increasing the speed as the screw runs down. Set the screw snugly by slowing to a stop.

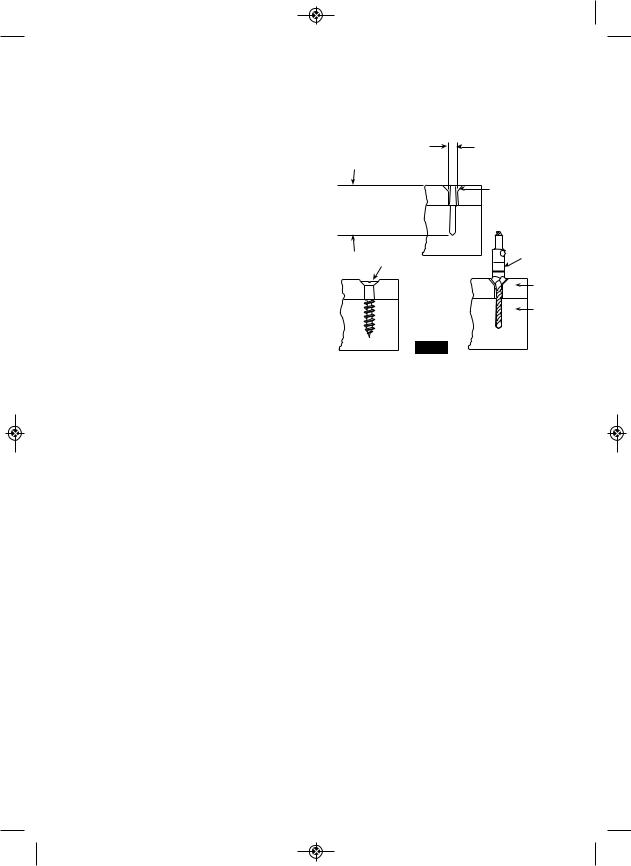

FASTENING WITH SCREWS

The procedure shown in Fig. 13 will enable you to fasten materials together using your drill without stripping, splitting or separating the material.

First, clamp the pieces together and drill the hole 2/3 the diameter of the screw. If the material is soft, drill only 2/3 the proper length. If it is hard, drill the entire length.

Second, unclamp the pieces and drill the hole in the top piece of wood again to the same diameter as the shank of the screw.

Third, if flat head screw is used, countersink the hole to make the screw flush with the surface. Realign the holes on the two pieces and apply even pressure when driving the screw. The screw shank clearance hole in the first piece allows the screw head to pull the pieces tightly together.

The adjustable screw drill accessory will do all of these operations quickly and easily. Screw drills are available for screw sizes No. 6, 8, 10 and 12.

FASTENING |

|

2. Drill same diameter |

WITH SCREWS |

|

as screw shank |

1. Drill 2/3 diameter |

|

3. Countersink |

and 2/3 of screw |

|

same diameter |

length for soft |

|

as screw head |

materials, full |

|

|

length for hard |

|

|

materials |

|

|

|

|

Adjustable |

Screw |

|

Screw |

|

Drill |

|

|

|

|

|

|

Top |

|

Apply a slight |

|

|

even pressure |

Bottom |

|

when driving |

|

|

|

|

|

screws |

|

FIG. 13

DRILL BITS

Always inspect drill bits for excessive wear. Use only bits that are sharp and in good condition.

TWIST BITS: Available with straight and reduced shanks for wood and light duty metal drilling. High speed bits cut faster and last longer on hard materials.

CARBIDE TIPPED BITS: Used for drilling stone, con crete, plaster, cement and other unusually hard nonmetals. Use continuous heavy feed pres sure when employing carbide tip bits.

DRILLING WOOD

Be certain workpiece is clamped or anchored firm - ly. Always apply pressure in a straight line with the drill bit. Maintain enough pressure to keep the drill “biting”.

When drilling holes in wood, twist bits can be used. Twist bits may overheat unless pulled out frequently to clear chips from flutes.

Use a “back-up” block of wood for work that is likely to splinter, such as thin materials.

You will drill a cleaner hole if you ease up on the pressure just before the bit breaks through the wood. Then complete the hole from the back side.

DRILLING METAL

There are two rules for drilling hard materials. First, the harder the material, the greater the pres sure you need to apply to the tool. Second, the harder the material, the slower the speed. Here are a couple of tips for drilling in metal. Lubri cate the tip

16 |

SAVE THESE INSTRUCTIONS |

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 17

2610045250.qxp_GSB18V-535C 6/20/18 10:26 AM Page 17

of the bit occasionally with cutting oil except when drilling soft metals such as alu minum, cop per or cast iron. If the hole to be drilled is fairly large, drill a smaller hole first, then enlarge to the required size, it’s often faster in the long run. Main tain enough pressure to assure that the bit does not just spin in the hole. This will dull the bit and greatly shorten its life.

DRILLING MASONRY

Soft materials such as brick are relatively easy to drill. Concrete however, will require much more pressure to keep the bit from spinning. Be sure to use carbide tip bits for all masonry work.

Before using an accessory, be certain that its maximum safe operating speed is not exceeded by the

nameplate speed of the tool. Do not exceed the recommended wheel diameter.

SANDING AND POLISHING

Fine sanding and polishing re quire “touch”. Select the most efficient speed.

When using polishing bonnets, alway be sure the excess string that secures the bonnet is tucked well within the bonnet during operation.

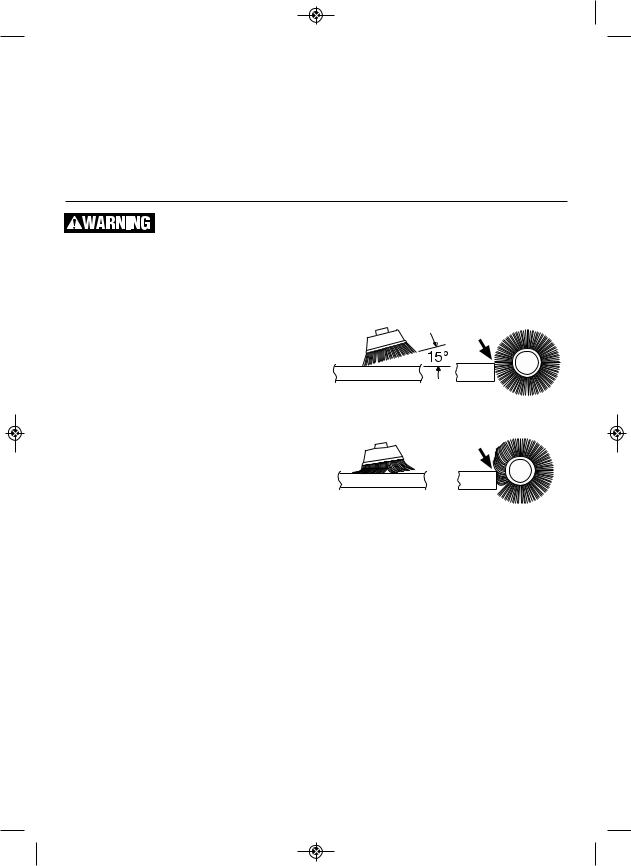

WIRE BRUSHES

Work with brushes requires high speeds.

BRUSHING PRESSURE

1.Let the tips of a wire brush do the work. Operate the brush with the lightest pressure so only the tips of the wire come in contact with the work.

2.If heavier pressures are used, the wires will be overstressed, resulting in a wiping action; and if this is continued, the life of the brush will be shortened due to wire fatigue.

3.Apply the brush to the work in such a way

that as much of the brush face as possible is in full contact with the work. Applying the side or edge of the brush to the work will result in wire breakage and shortened brush life.

CORRECT: Wire tips doing the work.

INCORRECT: Excessive pressure can cause wire breakage.

SAVE THESE INSTRUCTIONS |

17 |

Loading...

Loading...