Yaskawa Sigma-5 User Manual

AC Servo Drives

Σ-V Series

USER'S MANUAL

Operation of Digital Operator

Model: JUSP-OP05A-1-E

Introduction |

1 |

Parameter/Monitor Modes |

2 |

Utility Function Mode |

3 |

Parameter Copy Mode |

4 |

MANUAL NO. SIEP S800000 55B

Copyright © 2007 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

About this Manual

This manual provides the users of the Σ-V series of SGM S/SGDV servodrives with an explanation of the digital operator (Model: JUSP-OP05A-1-E) and its features, including the following items:

•Functions and connection method

•Parameters and monitor mode

•Utility function mode

•Parameter copy mode

Intended Audience

This manual is intended for the following users.

•Those performing trial operation or adjustments of Σ-V Series servodrives.

•Those maintaining or inspecting Σ-V Series servodrives.

Description of Technical Terms

The following table shows the meanings of terms used in this manual.

Term |

Meaning |

|

Cursor |

Input position indicated by digital operator |

|

|

|

|

Servomotor |

Σ-V Series SGMJV, SGMAV, SGMPS, SGMGV, SGMSV, or |

|

SGMCS (Direct Drive) servomotor |

||

|

||

|

|

|

SERVOPACK |

Σ-V Series SGDV SERVOPACK |

|

|

|

|

Servo Drive |

A set including a servomotor and SERVOPACK (i.e., a servo |

|

amplifier) |

||

|

||

|

|

|

Servo System |

A servo control system that includes the combination of a servo |

|

drive with a host controller and peripheral devices |

||

|

||

|

|

|

Servo ON |

Power to motor ON |

|

|

|

|

Servo OFF |

Power to motor OFF |

|

|

|

Specific technical terms

Different technical terms are used for rotational servomotors and linear servomotors, and the terms for rotational servomotors are used in this manual.

Rotational Servomotors |

Linear Servomotors |

torque |

force |

|

|

rotation |

movement |

|

|

moment of inertia |

mass |

|

|

motor speed [min-1] |

moving speed [mm/s] |

iii

Indication of Reverse Signals

In this manual, the names of reverse signals (ones that are valid when low) are written with a forward slash (/) before the signal name, as shown in the following example:

•S-ON = /S-ON

•P-CON = /P-CON

Related Manuals

Refer to the following manuals as required.

|

SERVOPACKs, |

Ratings |

|

Panel |

|

Trial |

Inspec- |

|

|

System |

Trial |

tion |

|||||

Manuals |

Servomotors, |

and |

Configura- |

Operation |

||||

and |

||||||||

and Peripheral |

Charac- |

Design |

tion and |

operation |

and Servo |

|||

|

Mainte- |

|||||||

|

Devices |

teristics |

|

Wiring |

|

Adjustment |

||

|

|

|

|

|

|

|

nance |

|

Σ-V series |

|

|

|

|

|

|

|

|

Catalog |

9 |

9 |

9 |

|

|

|

|

|

(KAEP S800000 42) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Σ-V series |

|

|

|

|

|

|

|

|

User’s Manual |

|

|

|

|

|

|

|

|

Setup |

|

|

|

9 |

9 |

|

|

|

Rotational Motor |

|

|

|

|

|

|

|

|

(SIEP S800000 43) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Σ-V series |

|

|

|

|

|

|

|

|

User's Manual |

|

|

|

|

|

|

|

|

Setup |

|

|

|

9 |

9 |

|

|

|

Linear Motor |

|

|

|

|

|

|

|

|

(SIEP S800000 44) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Σ-V series |

|

|

|

|

|

|

|

|

User’s Manual |

|

|

|

|

|

|

|

|

Design and |

|

|

|

|

|

|

|

|

Maintenance |

|

|

9 |

|

9 |

9 |

9 |

|

Rotational Motor/ |

|

|

|

|

|

|

|

|

Analog and Pulse |

|

|

|

|

|

|

|

|

(SIEP S800000 45) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Σ-V series |

|

|

|

|

|

|

|

|

User's Manual |

|

|

|

|

|

|

|

|

Design and |

|

|

|

|

|

|

|

|

Maintenance |

|

|

|

|

|

|

|

|

Rotational Motor/ |

|

|

9 |

|

9 |

9 |

9 |

|

MECHATROLINK-II |

|

|

|

|

|

|

|

|

Communications |

|

|

|

|

|

|

|

|

Reference |

|

|

|

|

|

|

|

|

(SIEP S800000 46) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Σ-V series |

|

|

|

|

|

|

|

|

User's Manual |

|

|

|

|

|

|

|

|

Design and |

|

|

|

|

|

|

|

|

Maintenance |

|

|

9 |

|

9 |

9 |

9 |

|

Linear Motor/ |

|

|

|

|

|

|

|

|

Analog and Pulse |

|

|

|

|

|

|

|

|

(SIEP S800000 47) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

iv

|

SERVOPACKs, |

Ratings |

|

Panel |

|

Trial |

Inspec- |

|

|

|

|

tion |

|||||

Manuals |

Servomotors, |

and |

System |

Configura- |

Trial |

Operation |

||

and |

||||||||

and Peripheral |

Charac- |

Design |

tion and |

operation |

and Servo |

|||

|

Mainte- |

|||||||

|

Devices |

teristics |

|

Wiring |

|

Adjustment |

||

|

|

|

|

|

|

|

nance |

|

Σ-V series |

|

|

|

|

|

|

|

|

User’s Manual |

|

|

|

|

|

|

|

|

Design and |

|

|

|

|

|

|

|

|

Maintenance |

|

|

|

|

|

|

|

|

Linear Motor/ |

|

|

9 |

|

9 |

9 |

9 |

|

MECHATROLINK-II |

|

|

|

|

|

|

|

|

Communications |

|

|

|

|

|

|

|

|

Reference |

|

|

|

|

|

|

|

|

(SIEP S800000 48) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Σ series |

|

|

|

|

|

|

|

|

Digital Operator |

|

|

|

|

|

|

9 |

|

Safety Precautions |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

(TOBP C730800 00) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Σ-V series |

|

|

|

|

|

|

|

|

User’s Manual |

|

|

|

|

|

|

|

|

MECHATROLINK-II |

|

|

9 |

|

9 |

9 |

|

|

Command |

|

|

|

|

|

|

|

|

(SIEP S800000 54) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Σ-Vseries |

|

|

|

|

|

|

|

|

AC SERVOPACK |

|

|

|

|

|

|

|

|

SGDV |

9 |

|

|

9 |

|

|

9 |

|

Safety Precautions |

|

|

|

|

|

|

|

|

(TOBP C710800 10) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AC SERVOMOTOR |

|

|

|

|

|

|

|

|

Safety Precautions |

|

|

|

9 |

|

|

9 |

|

(TOBP C230200 00) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

v

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided in this manual can result in serious or possibly even fatal

injury or damage to the products or to related equipment and systems.

WARNING

WARNING

CAUTION

CAUTION

PROHIBITED

PROHIBITED

MANDATORY

MANDATORY

Indicates precautions that, if not heeded, could possibly result in loss of life or serious injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have serious consequences if not heeded.

Indicates prohibited actions that must not be performed. For example, this symbol would be used to

indicate that fire is prohibited as follows:  .

.

Indicates compulsory actions that must be performed. For example, this symbol would be used as follows to

indicate that grounding is compulsory:  .

.

vi

Notes for Safe Operation

Read this manual thoroughly before checking products on delivery, storage and transportation, installation, wiring, operation and inspection, and disposal of the AC servodrives.

WARNING

WARNING

•Never touch any rotating servomotor parts while the servomotor is running.

Failure to observe this warning may result in injury.

•Before starting operation with a machine connected, make sure that an emergency stop can be applied at any time.

Failure to observe this warning may result in injury or damage to the equipment.

•Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

•Do not remove the cover of the power supply terminal block while the power is ON.

Failure to observe this warning may result in electric shock.

•After the power is turned OFF or after a voltage resistance test, do not touch terminals while the CHARGE lamp is ON.

Residual voltage may cause electric shock.

•Follow the procedures and instructions provided in the manuals for the products being used in the trial operation.

Failure to do so may result not only in faulty operation and damage to equipment, but also in personal injury.

•The output range of the rotational serial data for the Σ-V absolute position

detecting system is different from that of earlier systems for 12-bit and 15bit encoders. As a result, the infinite-length positioning system of the Σ Series must be changed for use with products in the Σ-V Series.

•The multiturn limit value need not be changed except for special applications.

Changing it inappropriately or unintentionally can be dangerous.

•If the Multiturn Limit Disagreement alarm occurs, check the setting of parameter Pn205 in the SERVOPACK to be sure that it is correct.

If Fn013 is executed when an incorrect value is set in Pn205, an incorrect value will be set in the encoder. The alarm will disappear even if an incorrect value is set, but incorrect positions will be detected, resulting in a dangerous situation where the machine will move to unexpected positions.

•Do not remove the top front cover, cables, connectors, or optional items from the SERVOPACK while the power is ON.

Failure to observe this warning may result in electric shock.

•Do not damage, pull, exert excessive force on, or place heavy objects on the cables.

Failure to observe this warning may result in electric shock, stopping operation of the product, or fire.

•Do not modify the product.

Failure to observe this warning may result in injury, damage to the equipment, or fire.

vii

WARNING

WARNING

•Provide appropriate braking devices on the machine side to ensure safety. The holding brake on a servomotor with a brake is not a braking device for ensuring safety.

Failure to observe this warning may result in injury.

•Do not come close to the machine immediately after resetting an instantaneous power interruption to avoid an unexpected restart. Take appropriate measures to ensure safety against an unexpected restart.

Failure to observe this warning may result in injury.

•Connect the ground terminal according to local electrical codes (100 Ω or

Ωor less for a

SERVOPACK with a 400 V power supply).

Improper grounding may result in electric shock or fire.

•Installation, disassembly, or repair must be performed only by authorized personnel.

Failure to observe this warning may result in electric shock or injury.

•The person who designs a system using the safety function (Hard Wire Baseblock function) must have full knowledge of the related safety standards and full understanding of the instructions in this manual.

Failure to observe this warning may result in injury or damage to the equipment.

viii

Storage and Transportation

CAUTION

CAUTION

• Do not store or install the product in the following places.

Failure to observe this caution may result in fire, electric shock, or damage to the equipment.

• Locations subject to direct sunlight

• Locations subject to temperatures outside the range specified in the storage or installation temperature conditions

• Locations subject to humidity outside the range specified in the storage or installation humidity conditions

• Locations subject to condensation as the result of extreme changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust, salts, or iron dust

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

• Do not hold the product by the cables or motor shaft, or encoder while transporting it.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

• If disinfectants or insecticides must be used to treat packing materials such as wooden frames, pallets, or plywood, the packing materials must be treated before the product is packaged, and methods other than fumigation must be used. Example: Heat treatment, where materials are kiln-dried to a core temperature of

56°C for 30 minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are packed with fumigated wooden materials, the electrical components may be greatly damaged by the gases or fumes resulting from the fumigation process. In particular, disinfectants containing halogen, which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the capacitors.

Installation

CAUTION

CAUTION

•Never use the product in an environment subject to water, corrosive gases, inflammable gases, or combustibles.

Failure to observe this caution may result in electric shock or fire.

•Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury.

•Do not cover the inlet or outlet ports and prevent any foreign objects from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

•Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

•Provide the specified clearances between the SERVOPACK and the control panel or with other devices.

Failure to observe this caution may result in fire or malfunction.

•Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

ix

Wiring

CAUTION

CAUTION

•Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or malfunction.

•Do not connect a commercial power supply to the U, V, or W terminals for the servomotor connection.

Failure to observe this caution may result in injury or fire.

•Securely connect the main circuit terminals.

Failure to observe this caution may result in fire.

•Do not bundle or run the main circuit cables together with the I/O signal cables or the encoder cables in the same duct. Keep the main circuit cables separated from the I/O signal cables and encoder cables by at least 30 cm.

Placing these cables too close to each other may result in malfunction.

•Use shielded twisted-pair cables or screened unshielded twisted-pair cables for I/ O signal cables and the encoder cables.

•The maximum wiring length is 3 m for I/O signal cables, 50 m for encoder cables or servomotor main circuit cables, and 10 m for control power supply cables for the SERVOPACK with a 400-V power supply (+24 V, 0 V).

•Do not touch the power supply terminals while the CHARGE lamp is ON after turning power OFF because high voltage may still remain in the SERVOPACK.

Make sure the charge indicator is OFF first before starting to do wiring or inspections.

•Be sure to observe the following precautions when wiring the SERVOPACK main circuit terminal blocks.

•Do not turn the SERVOPACK power ON until all wiring, including the main circuit terminal blocks, has been completed.

•Remove detachable main circuit terminals from the SERVOPACK prior to wiring.

•Insert only one power line per opening in the main circuit terminals.

•Make sure that no part of the core wire comes into contact with (i.e., short-circuits) adjacent wires.

•Install a battery at either the host controller or the SERVOPACK, but not both.

It is dangerous to install batteries at both ends simultaneously, because that sets up a loop circuit between the batteries.

•Always use the specified power supply voltage.

An incorrect voltage may result in fire or malfunction.

•Make sure that the polarity is correct.

Incorrect polarity may cause ruptures or damage.

•Take appropriate measures to ensure that the input power supply is supplied within the specified voltage fluctuation range. Be particularly careful in places where the power supply is unstable.

An incorrect power supply may result in damage to the equipment.

•Install external breakers or other safety devices against short-circuiting in external wiring.

Failure to observe this caution may result in fire.

•Take appropriate and sufficient countermeasures for each form of potential interference when installing systems in the following locations.

•Locations subject to static electricity or other forms of noise

•Locations subject to strong electromagnetic fields and magnetic fields

•Locations subject to possible exposure to radioactivity

•Locations close to power supplies

Failure to observe this caution may result in damage to the equipment.

x

CAUTION

CAUTION

•Do not reverse the polarity of the battery when connecting it.

Failure to observe this caution may damage the battery, the SERVOPACK or servomotor, or cause an explosion.

•Wiring or inspection must be performed by a technical expert.

•Use a 24-VDC power supply with double insulation or reinforced insulation.

xi

Operation

CAUTION

CAUTION

•Always use the servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution may result in fire or malfunction.

•Conduct trial operation on the servomotor alone with the motor shaft disconnected from the machine to avoid accidents.

Failure to observe this caution may result in injury.

•During trial operation, confirm that the holding brake works correctly. Furthermore, secure system safety against problems such as signal line disconnection.

•Before starting operation with a machine connected, change the parameter settings to match the parameters of the machine.

Starting operation without matching the proper settings may cause the machine to run out of control or malfunction.

•Do not turn the power ON and OFF more than necessary.

Do not use the SERVOPACK for applications that require the power to turn ON and OFF frequently. Such applications will cause elements in the SERVOPACK to deteriorate.

As a guideline, at least one hour should be allowed between the power being turned ON and OFF once actual operation has been started.

•When carrying out JOG operation (Fn002), origin search (Fn003), or EasyFFT (Fn206), forcing movable machine parts to stop does not work for forward overtravel or reverse overtravel. Take necessary precautions.

Failure to observe this caution may result in damage to the equipment.

•When using the servomotor for a vertical axis, install safety devices to prevent workpieces from falling due to alarms or overtravels. Set the servomotor so that it will stop in the zero clamp state when overtravel occurs.

Failure to observe this caution may cause workpieces to fall due to overtravel.

•When not using the turning-less function, set the correct moment of inertia ratio (Pn103).

Setting an incorrect moment of inertia ratio may cause machine vibration.

•Do not touch the SERVOPACK heat sinks, regenerative resistor, or servomotor while power is ON or soon after the power is turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

•Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury or damage to the equipment due to unstable operation.

•When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then resume operation.

Failure to observe this caution may result in damage to the equipment, fire, or injury.

•Do not use the holding brake of the servomotor for braking.

Failure to observe this caution may result in malfunction.

•An alarm or warning may occur if communications are performed with the host controller while the SigmaWin+ or digital operator is operating.

If an alarm or warning occurs, it may stop the current process and stop the system.

xii

Maintenance and Inspection

CAUTION

CAUTION

•Do not disassemble the SERVOPACK.

Failure to observe this caution may result in electric shock or injury.

•Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

•When replacing the SERVOPACK, resume operation only after copying the previous SERVOPACK parameters to the new SERVOPACK.

Failure to observe this caution may result in damage to the equipment.

Disposal

CAUTION

CAUTION

•When disposing of the products, treat them as ordinary industrial waste.

General Precautions

Observe the following general precautions to ensure safe application.

•The products shown in illustrations in this manual are sometimes shown without covers or protective guards. Always replace the cover or protective guard as specified first, and then operate the products in accordance with the manual.

•The drawings presented in this manual are typical examples and may not match the product you received.

•If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or one of the offices listed on the back of this manual.

xiii

Warranty

(1)Details of Warranty

Warranty Period

The warranty period for a product that was purchased (hereinafter called “delivered product”) is one year from the time of delivery to the location specified by the customer or 18 months from the time of shipment from the Yaskawa factory, whichever is sooner.

Warranty Scope

Yaskawa shall replace or repair a defective product free of charge if a defect attributable to Yaskawa occurs during the warranty period above. This warranty does not cover defects caused by the delivered product reaching the end of its service life and replacement of parts that require replacement or that have a limited service life.

This warranty does not cover failures that result from any of the following causes.

1.Improper handling, abuse, or use in unsuitable conditions or in environments not described in product catalogs or manuals, or in any separately agreed-upon specifications

2.Causes not attributable to the delivered product itself

3.Modifications or repairs not performed by Yaskawa

4.Abuse of the delivered product in a manner in which it was not originally intended

5.Causes that were not foreseeable with the scientific and technological understanding at the time of shipment from Yaskawa

6.Events for which Yaskawa is not responsible, such as natural or human-made disasters

(2)Limitations of Liability

1.Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer that arises due to failure of the delivered product.

2.Yaskawa shall not be responsible for any programs (including parameter settings) or the results of program execution of the programs provided by the user or by a third party for use with programmable Yaskawa products.

3.The information described in product catalogs or manuals is provided for the purpose of the customer purchasing the appropriate product for the intended application. The use thereof does not guarantee that there are no infringements of intellectual property rights or other proprietary rights of Yaskawa or third parties, nor does it construe a license.

4.Yaskawa shall not be responsible for any damage arising from infringements of intellectual property rights or other proprietary rights of third parties as a result of using the information described in catalogs or manuals.

xiv

(3)Suitability for Use

1.It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations that apply if the Yaskawa product is used in combination with any other products.

2.The customer must confirm that the Yaskawa product is suitable for the systems, machines, and equipment used by the customer.

3.Consult with Yaskawa to determine whether use in the following applications is acceptable. If use in the application is acceptable, use the product with extra allowance in ratings and specifications, and provide safety measures to minimize hazards in the event of failure.

•Outdoor use, use involving potential chemical contamination or electrical interference, or use in conditions or environments not described in product catalogs or manuals

•Nuclear energy control systems, combustion systems, railroad systems, aviation systems, vehicle systems, medical equipment, amusement machines, and installations subject to separate industry or government regulations

•Systems, machines, and equipment that may present a risk to life or property

•Systems that require a high degree of reliability, such as systems that supply gas, water, or electricity, or systems that operate continuously 24 hours a day

•Other systems that require a similar high degree of safety

4.Never use the product for an application involving serious risk to life or property without first ensuring that the system is designed to secure the required level of safety with risk warnings and redundancy, and that the Yaskawa product is properly rated and installed.

5.The circuit examples and other application examples described in product catalogs and manuals are for reference. Check the functionality and safety of the actual devices and equipment to be used before using the product.

6.Read and understand all use prohibitions and precautions, and operate the Yaskawa product correctly to prevent accidental harm to third parties.

(4)Specifications Change

The names, specifications, appearance, and accessories of products in product catalogs and manuals may be changed at any time based on improvements and other reasons. The next editions of the revised catalogs or manuals will be published with updated code numbers. Consult with your Yaskawa representative to confirm the actual specifications before purchasing a product.

xv

CONTENTS

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi Notes for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Switching Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2 Parameter/Monitor Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Parameter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1 Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2 Parameter Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2 Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.1 Monitor Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.2 Monitor Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3 Utility Function Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 |

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 3-3 |

|

3.2 |

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 3-6 |

|

|

3.2.1 |

Alarm History Display (Fn000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 3-6 |

|

3.2.2 |

JOG Operation (Fn002) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 3-8 |

|

3.2.3 |

Origin Search (Fn003) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-11 |

|

3.2.4 Program JOG Operation (Fn004) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-14 |

|

|

3.2.5 |

Initializing Parameter Settings (Fn005) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-17 |

|

3.2.6 |

Clearing Alarm History (Fn006) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-19 |

|

3.2.7 |

Absolute Encoder Multiturn Reset and Encoder Alarm Reset (Fn008) . . . . . . . |

3-20 |

|

3.2.8 |

Automatic Tuning of Analog (Speed, Torque) Reference Offset (Fn009) . . . . . |

3-22 |

|

3.2.9 |

Manual Servo-tuning of Speed Reference Offset (Fn00A) . . . . . . . . . . . . . . . . |

3-24 |

|

3.2.10 |

Manual Servo-tuning of Torque Reference Offset (Fn00B) . . . . . . . . . . . . . . . |

3-26 |

|

3.2.11 |

Offset Adjustment of Analog Monitor Output (Fn00C) . . . . . . . . . . . . . . . . . . . |

3-28 |

|

3.2.12 |

Gain Adjustment of Analog Monitor Output (Fn00D) . . . . . . . . . . . . . . . . . . . |

3-30 |

|

3.2.13 |

Automatic Offset-Signal Adjustment of the Motor Current Detection Signal |

|

|

|

(Fn00E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-32 |

|

3.2.14 |

Manual Offset-Signal Adjustment of the Motor Current Detection Signal |

|

|

|

(Fn00F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-34 |

|

3.2.15 |

Write Prohibited Setting (Fn010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-36 |

|

3.2.16 |

Servomotor Model Display (Fn011) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-39 |

|

3.2.17 |

Software Version Display (Fn012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-41 |

|

3.2.18 |

Multiturn Limit Value Setting Change When a Multiturn Limit Disagreement |

|

|

|

Alarm Occurs (Fn013) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-42 |

|

3.2.19 |

Resetting Configuration Errors in Option Modules (Fn014) . . . . . . . . . . . . . . |

3-44 |

|

3.2.20 |

Vibration Detection Level Initialization (Fn01B) . . . . . . . . . . . . . . . . . . . . . . . |

3-46 |

|

3.2.21 Display of SERVOPACK and Servomotor ID (Fn01E) . . . . . . . . . . . . . . . . . . |

3-49 |

|

|

3.2.22 |

Display of Servomotor ID in Feedback Option Module (Fn01F) . . . . . . . . . . . |

3-51 |

xvi

3.2.23 Origin Setting (Fn020) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53 3.2.24 Software Reset (Fn030) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54 3.2.25 Polarity Detection (Fn080) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56 3.2.26 Tuning-less Levels Setting (Fn200) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58 3.2.27 Advanced Autotuning (Fn201) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60 3.2.28 Advanced Autotuning by Reference (Fn202) . . . . . . . . . . . . . . . . . . . . . . . . . 3-67 3.2.29 One-parameter Tuning (Fn203) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-71 3.2.30 Anti-Resonance Control Adjustment Function (Fn204) . . . . . . . . . . . . . . . . . 3-79 3.2.31 Vibration Suppression Function (Fn205) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-87 3.2.32 EasyFFT (Fn206) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91 3.2.33 Online Vibration Monitor (Fn207) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-95

4 Parameter Copy Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

4.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.1 Read-out Parameters from SERVOPACK (SERVO → OP) . . . . . . . . . . . . . . . . 4-3

4.2.2 Write-in Parameters (OP → SERVO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.3 Verify Parameters (VERIFY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.2.4 Parameter Block List Display (LIST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Revision History

xvii

1

Introduction

1.1 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Switching Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Introduction

1

1-1

1 Introduction

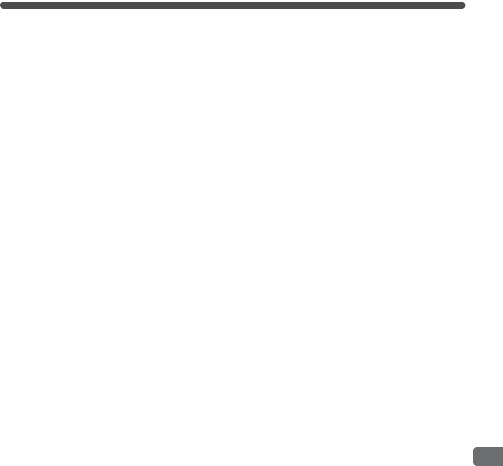

The JUSP-OP05A-1-E optional digital operator for the Σ-V Series SGDV SERVOPACK is used to set and display the SERVOPACK parameters. Connect the digital operator to the CN3 connector of the SERVOPACK.

JUSP-OP05A-1-E |

||

Digital Operator |

||

SVON COIN |

|

TGON REF CHARGE |

VCMP |

|

|

|

YASKAWA |

|

ALARM |

SCROLL MODE/SET |

|

RESET |

|

|

JOG |

|

DATA |

SVON |

|

|

|

|

|

SGDV SERVOPACK |

|

|

READ |

WRITE |

|

SERVO |

|

SERVO |

DIGITAL OPERATOR JUSP-OP05A-1-E |

||

Insert securely to the CN3 connector of the SERVOPACK

Note: JUSP-OP05A digital operators are used with Σ-III SERVOPACKs. A special connector (JZSP-CVS05-A3-E) is required to use these operators with Σ-V SERVOPACKs. For details, refer to Σ-V Series User’s Manual, Setup, Rotational Motor (Manual No.: SIEP S800000 43).

1-2

1.1 Part Names and Functions

1.1Part Names and Functions

SVON COIN |

|

TGON |

REF |

CHARGE |

VCMP |

|

|

|

|

LCD display (17 characters × 5 lines) |

||||

|

YASKAWA |

|

||

ALARM |

SCROLL |

MODE/SET |

||

RESET |

|

|

|

|

JOG |

|

|

|

DATA |

SVON |

|

|

|

|

|

|

|

|

|

READ |

WRITE |

|||

SERVO |

|

|

|

SERVO |

DIGITAL OPERATOR JUSP-OP05A-1-E |

||||

LED indicators (Five LEDs in red)

Operation keys

(1)LED Display

The digital operator has an LCD display with a maximum of 17 characters for each of the 5 lines. It also has 5 LED indicators to show the status of the servo ON, positioning completion, and others. Details of the LED indicators are as follows.

Name |

Function |

|

SVON |

Lit when the servo is ON. |

|

Unlit when the servo is OFF. |

||

|

||

|

|

|

COIN |

Lit when positioning is completed. |

|

VCMP |

Lit when the speed is coincident. |

|

|

|

|

TGON |

Lit while the servomotor is running. |

|

|

|

|

|

Position control: |

|

|

Lit when the reference pulse is input. |

|

REF |

Speed control: |

|

Lit when the speed reference input is greater than the setting value of |

||

|

Pn502. |

|

|

Torque control: |

|

|

Lit when the torque reference input exceeds 10 % of the rated torque. |

|

|

|

|

CHARGE |

Lit when the main circuit power supply is ON. |

|

|

|

Introduction

1

1-3

1Introduction

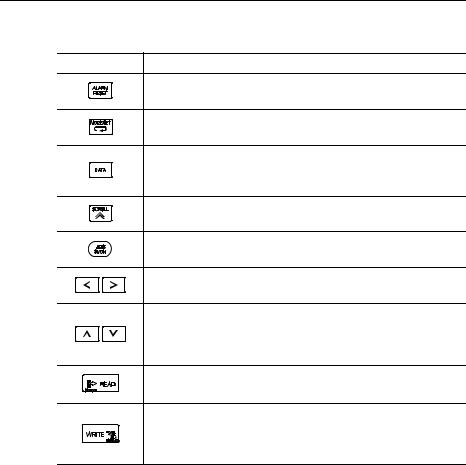

(2)Operation Keys

Operation Key |

Main Function |

|

|

Resets the alarm. (The alarm cannot be reset unless the cause of the alarm is removed.)

Switches the display mode of digital operator.

• Switches the cursor position between the parameter number and the setting when setting a parameter.

• Saves the parameter setting in the SERVOPACK.

• Opens the selected utility function display in the utility function mode.

• Moves the cursor up or down in parameter/monitor mode.

• Moves the cursor four lines up in the utility function mode.

Switches between the servo ON and servo OFF signals while executing a utility function, such as a JOG operation or advanced autotuning.

Moves the cursor to left or right in parameter/monitor mode.

•Switches between parameters (Pn) and monitors (Un).

•Increases or decreases the parameter number, setting data, monitor number, and utility function number.

•Rotates the servomotor in a forward or reverse direction at a JOG operation.

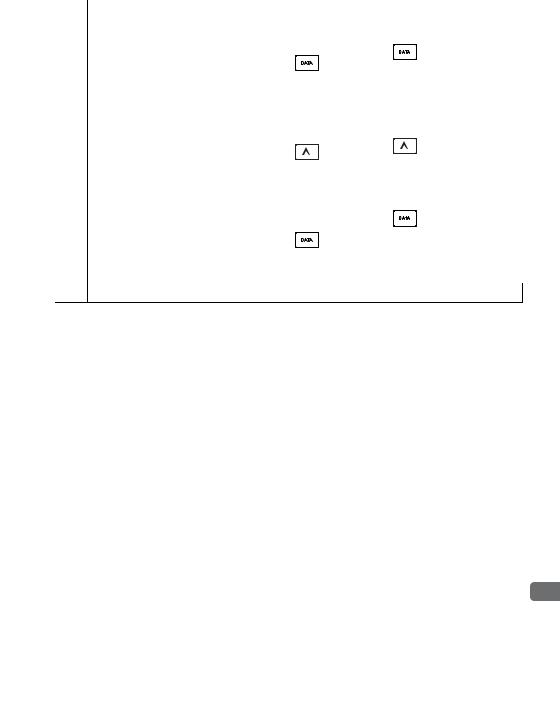

In the parameter copy mode, reads parameters saved in the SERVOPACK to the digital operator.

•In the parameter copy mode, writes parameters in the digital operator to the SERVOPACK.

• In the parameter/monitor mode, saves the status of the display to the digital operator. When the power is turned ON, that saved display will appear first.

1-4

1.2 Switching Mode

1.2Switching Mode

Connect the digital operator to the SERVOPACK, and turn ON the power to the SERVOPACK. The initial display appears, and then the parameter/monitor mode display

appears. Press the  Key to change the mode.

Key to change the mode.

Power ON

F i l e l i s t l o a d i n g

P l e a s e w a i t . . . .

B B – P R M / M O N – U n 0 0 0 = 0 0 0 0 0 0

U n 0 0 2 = 0 0 0 0 0 0

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0

B B |

– F U N C T I O N – |

F n 0 1 E : V – M o n i t o r |

|

F n 0 0 0 : A l m H i s t o r y |

|

|

|

|

|

F n 0 0 2 |

: J O G |

|||

|

|

F n 0 0 3 : Z – S e a r c h |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

– C O P Y – |

|

|

|

1 |

: S E R V O → O P |

|

||

|

2 |

: O P → S E R V O |

||||

|

3 |

: V E R I F Y |

||||

|

4 |

: L I S T |

||||

|

|

|

|

|

|

|

[Initial Display]

Displayed for two seconds

[Parameter/Monitor Modes]

Parameter Functions

Sets and displays the parameters of the SERVOPACK.

Monitoring Functions

Shows the numerical values and signal statuses that indicate the internal data (speed, position and torque) of the SERVOPACK. (The figure to the left shows the monitoring function screen.)

[Utility Function Mode]

Sets up the SERVOPACK, adjusting the servo gains, and maintains the SERVOPACK.

[Parameter Copy Mode]

Copies and stores the SERVOPACK parameters settings to the digital operator, or writes them into the SERVOPACK.

An abbreviation of the name of the active mode is displayed in the upper right, and the SERVOPACK status is displayed in the upper left.

B B |

|

|

− P R M / M O N − |

|

|

Mode |

|

|

|

||||||

U n 0 0 0 = 0 0 0 0 0 0 |

|

|

−PRM/MON− : Parameter/Monitor Modes |

||||

|

|

|

|

|

|

−FUNCTION− : Utility Function Mode |

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||

|

|

−COPY− |

: Parameter Copy Mode |

||||

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|||

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|||

Status |

|

|

|

|

|

|

|

BB: |

Base blocked |

|

|

|

|||

RUN: |

Servomotor is ON |

|

|

|

|||

A. : An alarm occurs ( : Alarm code) |

|

|

|

||||

PT NT: Forward run and reverse run prohibited (Overtravel) |

|

||||||

P-OT: |

Forward run prohibited (Overtravel) |

|

|

|

|||

N-OT: |

Reverse run prohibited (Overtravel) |

|

|

|

|||

NO-OP: Setting disabled or setting error

HBB: During hard wire base block

Introduction

1

1-5

1 Introduction

<NOTE> Other Alarm Displays

If a communications error occurs between the SERVOPACK and digital operator, the following communications error codes are displayed. These errors may be caused by incorrect connector connection. Check the connection and correct it. Then, turn the power OFF and ON. If the communications error message still appears, replace the digital operator or the SERVOPACK.

C P F 0 0

C O M − E R R ( O P & S V )

C P F 0 1

C O M − E R R ( O P & S V )

1-6

2

Parameter/Monitor Modes

2.1 Parameter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1 Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2 Parameter Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2 Monitor Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.1 Monitor Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.2 Monitor Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Parameter/Monitor Modes

2

2-1

2 Parameter/Monitor Modes

2.1.1 Parameter Setting

2.1Parameter Mode

This section describes how to display and set parameters in the parameter/monitor mode.

There are two types of notation used for parameters, one for parameter that requires a value setting (parameter for numeric settings) and one for parameter that requires the selection of a function (parameter for selecting functions).

Note: 1. The details of parameters are not described in this manual. For more information on parameters, refer to manuals listed in Related Manuals on page iv.

2.To indicate a specific digit of the parameters whose each digit has a meaning and has to be set, the digit number is added to the parameter number. For example, Pn000.0 (the 1st digit of parameter Pn000).

2.1.1Parameter Setting

(1)Operation Example 1: Setting the Parameters for Selecting Functions

There are some parameters which require the setting of each digit such as Pn000 (function selection basic switch) and Pn001 (function selection application switch 1).

This example shows the operation procedure to set “1” (reverse rotation) for Pn000.0 (motor direction selection).

Step |

|

|

Display after Operation |

Keys |

|

Operation |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

− P R M / M O N − |

|

|

|

|

|

1 |

|

U n 0 0 0 = 0 0 0 0 0 0 |

|

|

Press the |

Key to select the |

||||

|

|

|

|

|

|

|

||||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

parameter/monitor mode. |

|

||||

|

|

|

|

|

|

|

||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

− P R M / M O N − |

|

|

|

|

|

2 |

|

U n 0 0 0 = 0 0 0 0 0 0 |

|

|

Press the |

or |

Key to move |

|||

|

|

|

|

|

||||||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

the cursor to “Un.” |

|

||||

|

|

|

|

|

|

|

||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

− P R M / M O N − |

|

|

|

|

|

3 |

|

P n 0 0 0 = n.0 0 0 0 |

|

|

Press the |

or |

Key to |

|||

|

|

|

|

|

||||||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

switch “Un” to “Pn.” |

|

||||

|

|

|

|

|

|

|

||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-2

|

|

|

|

|

|

|

|

|

|

|

|

2.1 Parameter Mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Step |

Display after Operation |

Keys |

|

Operation |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

− P R M / M O N − |

|

|

|

|

|||||

|

4 |

P n 0 0 0 = n.0 0 0 |

0 |

|

|

|

|

Press the |

Key to move the cur- |

|||

|

|

|

|

|

||||||||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

sor to the setting side (to the position of |

||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

the first digit of Pn000.0). |

|||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

B B |

− P R M / M O N − |

|

|

|

|

|||||

|

5 |

P n 0 0 0 = n.0 0 0 1 |

|

|

Press the |

Key once to set “1” |

||||||

|

|

|

|

|

|

|

||||||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

for the first digit of Pn.000.0. |

|||||||

|

|

|

|

|

|

|||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

A . 9 4 1 |

− P R M / M O N − |

|

|

Press the |

Key. |

|||||

|

|

P n 0 0 0 = n.0 0 0 1 |

|

|

||||||||

|

6 |

|

|

The new setting of Pn000 is written to |

||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||||

|

|

|

the SERVOPACK. The cursor moves to |

|||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

the parameter number side and the |

|||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

warning A.941 is displayed. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

7To enable the change in the setting, turn the power OFF and ON again.*

When the setting is modified, the parameters whose modified setting is validated only after setting validation, the warning A.941 “Change of Parameters Requires the Setting Validation” is displayed. Turn the power OFF then ON to clear the warning and validate the new setting.

Parameter/Monitor Modes

2

2-3

2 Parameter/Monitor Modes

2.1.1Parameter Setting

(2)Operation Example 2: Setting the Parameters for Numeric Settings

This example shows the operation procedure to set “1000” (min-1) for Pn304 (JOG speed).

Step |

|

|

|

Display after Operation |

Keys |

|

Operation |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

|

|

− P R M / M O N − |

|

|

|

|

|

||

|

|

U n 0 0 0 = 0 0 0 0 0 0 |

|

|

Press the |

Key to select the |

||||||||

1 |

|

|

|

|

|

|

|

|

|

|

|

|||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

parameter/monitor mode. |

|

||||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

|

|

− P R M / M O N − |

|

|

|

|

|

||

|

|

U n 0 0 0 = 0 0 0 0 0 0 |

|

|

Press the |

or |

Key to move |

|||||||

2 |

|

|

|

|

|

|

|

|

|

|||||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

the cursor to “Un.” |

|

||||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

|

|

− P R M / M O N − |

|

|

|

|

|

||

3 |

|

P n 0 0 0 = n.0 0 0 0 |

|

|

Press the |

or |

Key to |

|||||||

|

|

|

|

|

|

|

|

|

||||||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

switch “Un” to “Pn.” |

|

||||||||

|

|

|

|

|

|

|

||||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

|

|

− P R M / M O N − |

|

|

|

|

|

||

4 |

|

P n 0 0 0 = n.0 0 0 0 |

|

|

Press the |

Key once to move the |

||||||||

|

|

|

|

|

|

|

|

|

||||||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|||||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 p u l s e |

|

|

cursor to the right side of “Pn.” |

|||||||||

|

|

|

|

|

|

|

||||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press the arrow keys to display |

||

|

|

B B |

|

|

|

|

− P R M / M O N − |

|

|

“Pn304.” |

|

|

||

|

|

P n 3 0 4 = 0 0 5 0 0 |

|

|

To move the cursor to different columns: |

|||||||||

5 |

|

|

|

|

|

|

|

|

, |

Key |

|

|||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|

||||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

To change the settings: |

|

||||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

or |

Key |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

|

|

− P R M / M O N − |

|

|

|

|

|

||

|

|

P n 3 0 4 = 0 0 5 0 0 |

|

|

Press the |

Key. |

|

|||||||

6 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

The cursor moves to the setting side (to |

||||||||||

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

the position of the first digit of Pn304). |

|||||||||

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-4

|

|

|

|

|

|

|

|

|

|

|

|

2.1 Parameter Mode |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Step |

|

|

Display after Operation |

Keys |

|

Operation |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

|

− P R M / M O N − |

|

|

|

|

|

|

|

|

P n 3 0 4 = 0 0 5 0 0 |

|

|

Press the |

Key twice to move the |

|||||

|

7 |

|

|

|

|

|

|

|

|

|||

|

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

||||||||

|

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

cursor to the third digit of Pn304. |

||||||

|

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

|

− P R M / M O N − |

|

|

|

|

|

|

|

|

P n 3 0 4 = 0 1 0 0 0 |

|

|

Press the |

Key five times to |

|||||

|

8 |

|

|

|

|

|

|

|

|

|||

|

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

||||||||

|

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

change the setting to “1000.” |

||||||

|

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B B |

|

|

|

− P R M / M O N − |

|

|

Press the |

Key to write the set- |

|

|

|

|

P n 3 0 4 = 0 1 0 0 0 |

|

|

|||||||

|

9 |

|

|

|

|

|

|

tings. |

|

|||

|

|

U n 0 0 2 = 0 0 0 0 0 0 |

|

|

|

|||||||

|

|

|

U n 0 0 8 = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

The cursor moves to the parameter |

||||||

|

|

|

|

|

number side. |

|

||||||

|

|

|

U n 0 0 D = 0 0 0 0 0 0 0 0 0 0 0 |

|

|

|

||||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: If the  Key has not been pressed but the

Key has not been pressed but the  Key has been pressed to select another mode such as the utility function mode, any changes that have been made to the parameter will be saved in the SERVOPACK.

Key has been pressed to select another mode such as the utility function mode, any changes that have been made to the parameter will be saved in the SERVOPACK.

Parameter/Monitor Modes

2

2-5

2 Parameter/Monitor Modes

2.1.2 Parameter Classification

2.1.2Parameter Classification

Parameters of the Σ-V Series SERVOPACK are classified into two types of parameters. One type of parameters is required for setting up the basic conditions for operation and the other type is required for tuning parameters that are required to adjust servomotor characteristics.

Classification |

Meaning |

Display Method |

Setting Method |

|

Setup Parameters |

Parameters required |

Always displayed |

Set each parameter |

|

(Factory setting: |

||||

for setup. |

individually. |

|||

|

Pn00B.0 = 0) |

|||

|

|

|

||

|

|

|

|

|

Tuning Parameters |

Parameters for tun- |

Set Pn00B.0 to 1. |

There is no need to |

|

ing control gain and |

set each parameter |

|||

|

other parameters. |

|

individually. |

|

|

|

|

|

2-6

2.2 Monitor Mode

2.2Monitor Mode

This section describes available monitor modes and operation procedures in the parameter/monitor mode.

2.2.1Monitor Items

Parameter No |

Content of Display |

Unit |

|

Un000 |

Motor rotating speed |

min-1 |

|

Un001 |

Speed reference |

min-1 |

|

Un002 |

Internal torque reference (in percentage to the |

% |

|

rated torque) |

|||

|

|

||

|

|

|

|

Un003 |

Rotational angle 1 (encoder pulses from the |

Encoder pulse |

|

phase-C origin: decimal display) |

|||

|

|

||

|

|

|

|

Un004 |

Rotational angle 2 (from polarity origin (electric |

Degree |

|

angle)) |

|||

|

|

||

|

|

|

|

Un005 |

Input signal monitor *1 |

− |

|

Un006 |

Output signal monitor*2 |

− |

|

Un007 |

Input reference pulse speed (displayed only in |

min-1 |

|

position control mode) |

|||

|

|

||

|

|

|

|

Un008 |

Position error amount |

Reference unit |

|

(displayed only in position control mode) |

|||

|

|

||

|

|

|

|

Un009 |

Accumulated load ratio (in percentage to the |

% |

|

rated torque: effective torque in cycle of 10 sec- |

|||

|

onds) |

|

|

|

|

|

|

Un00A |

Regenerative load ratio (in percentage to the |

% |

|

processable regenerative power: regenerative |

|||

|

power consumption in cycle of 10 seconds) |

|

|

|

|

|

|

Un00B |

Power consumed by DB resistance (in percent- |

% |

|

age to the processable power at DB activation: |

|||

|

display in cycle of 10 seconds) |

|

|

|

|

|

|

Un00C |

Input reference pulse counter |

Reference unit |

|

|

|

|

|

Un00D |

Feedback pulse counter |

Encoder pulse |

|

|

|

|

|

Un00E |

Fully-closed feedback pulse counter |

External encoder |

|

resolution |

|||

|

|

||

|

|

|

|

Un010 |

Upper limit setting of motor maximum speed/ |

− |

|

Upper limit setting of encoder output resolution |

|

||

|

|

||

|

|

|

|

Un011 |

Hall sensor signal monitor |

− |

|

|

|

|

|

Un012 |

Total run time |

100 ms |

|

|

|

|

|

Un013 |

Feedback pulse counter |

Reference unit |

|

|

|

|

|

Un014 |

Effective gain monitor |

− |

|

(gain settings 1=1, gain settings 2=2) |

|

||

|

|

||

|

|

|

Parameter/Monitor Modes

2

2-7

Loading...

Loading...