Xylem H-335 User Manual

Model

H-335

SDI-12 Inclinometer

Owner's Manual

Version 1.3

Design Analysis Associates

75 West 100 South

Logan, UT 84321 USA

Phone: (435) 753-2212

Fax: (435) 753-7669

Internet: www.waterlog.com

E-mail: sales@waterlog.com

User Agreement/

W

ATER

1. NATURE OF THE PRODUCT

This agreement accompanies an interface module comprising firmware, circuitry and other electronic

equipment in an enclosed housing, and packaged together with written instructional materials. The

packaged electronic circuitry and instructional materials herein are collectively referred to as the

“PRODUCT.” The PRODUCT is made available from DESIGN ANALYSIS ASSOCIATES, INC., of

75 West 100 South, Logan, Utah 84321 (hereinafter referred to as “DESIGN ANALYSIS”), and contains

information and embodies technology that is confidential and proprietary to DESIGN ANALYSIS, and the

availability and use of the PRODUCT is extended to you, the USER, solely on the basis of the terms of

agreement which follow.

2. ACKNOWLEDGMENTS BY USER

Opening the package which encloses the accompanying PRODUCT indicates your acceptance of the terms

and conditions of this agreement and constitutes an acknowledgment by you of the confidential and

proprietary nature of the rights of DESIGN ANALYSIS in the PRODUCT.

3. DUTIES OF YOU, THE USER

In consideration for the access to and use of the PRODUCT extended to you by DESIGN ANALYSIS and

to protect the confidential and proprietary information of DESIGN ANALYSIS, USER agrees as follows:

LOG® Warranty

(a) USER agrees that they will not remove from the exterior of the housing of the PRODUCT any safety

warnings or notices of proprietary interest placed thereon by DESIGN ANALYSIS.

(b) USER agrees that they shall not disassemble or otherwise reverse engineer the PRODUCT.

(c) USER agrees to treat the PRODUCT with the same degree of care as USER exercises in relation to

their own confidential and proprietary information.

4. TERM

USER may enjoy these rights only as long as their possession of the PRODUCT shall continue to be

rightful. These rights will cease if the PRODUCT is returned to DESIGN ANALYSIS under the terms of

any redemption offer, warranty, or money-back guarantee, or if USER transfers the PRODUCT to another

party on terms inconsistent with this agreement.

5. LIMITED WARRANTY

(b) What is Covered

DESIGN ANALYSIS warrants that for a period of twelve months from the time of purchase the

functions to be performed by the PRODUCT will be substantially in compliance with USER

documentation. DESIGN ANALYSIS also warrants that the PRODUCT will be free from defects

in materials and workmanship for a period of ONE YEAR from the date of purchase.

(b) What USER Must Do

If the product fails to satisfy the above warranty, USER must notify DESIGN ANALYSIS in

writing within the applicable period specified above and reasonably cooperate with the directions

they received from DESIGN ANALYSIS.

H-355

User Agreement/W

ATER

LOG® Warranty W-1

(c) What DESIGN ANALYSIS Will Do

DESIGN ANALYSIS will repair the PRODUCT or will endeavor to provide a replacement of

same within a reasonable period of time. In the event that DESIGN ANALYSIS is unable to make

the necessary repairs or replacement within a reasonable period of time, the original purchase price

will be refunded upon the return of the PRODUCT to DESIGN ANALYSIS.

(d) Limitations

(i) THE ENTIRE REMEDY FOR BREACH OF THIS LIMITED WARRANTY SHALL

BE LIMITED TO REPLACEMENT OF THE DEFECTIVE PRODUCT OR

REFUNDING OF THE PURCHASE PRICE, AS SET FORTH ABOVE. IN NO

EVENT WILL THE LIABILITY OF DESIGN ANALYSIS TO USER OR TO ANY

OTHER PARTY EXCEED THE ORIGINAL PURCHASE PRICE OF THE PRODUCT,

REGARDLESS OF THE FORM OF THE CLAIM.

(ii) EXCEPT FOR THE EXPRESS WARRANTIES ABOVE, DESIGN ANALYSIS

SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING,

WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

(iii) UNDER NO CIRCUMSTANCES WILL DESIGN ANALYSIS BE LIABLE FOR

SPECIAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, OR ANY OTHER

DAMAGES OR CLAIMS ARISING FROM THE USE OF THIS PRODUCT, THIS

INCLUDES LOSS OF PROFITS OR ANY OTHER COMMERCIAL DAMAGES,

EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO EVENT

WILL DESIGN ANALYSIS BE LIABLE FOR ANY CLAIMS, LIABILITY, OR

DAMAGES ARISING FROM MODIFICATION MADE THEREIN, OTHER THAN

BY DESIGN ANALYSIS.

(iv) THIS LIMITED WARRANTY GIVES USER SPECIFIC LEGAL RIGHTS. USER

MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS OR THE EXCLUSION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THOSE LIMITATIONS OR EXCLUSIONS

MAY NOT APPLY.

6. GOVERNING LAW

This Agreement and its validity and interpretation shall be governed by the laws of the State of Utah,

notwithstanding any choice of law rules of Utah or any other state or jurisdiction.

W-2 User Agreement/W

ATER

LOG® Warranty

H-355

Chapter 1

H-335 Operation

1.1 Operation

The W

ATER

LOG® H-335 is a precision, single axis, wide range inclinometer which measures the angle

(position) of radial water control gates. The H-335 is easy to use, works with any data recorder/logger with

a SDI-12 interface and can be interfaced with SCADA systems. The “Serial-Digital Interface” is ideal for

data logging applications with the following requirements:

Multiple sensors on a 3-wire bus

Low system cost

Up to 200 feet of cable between a sensor and the data recorder

The H-335 has the following features:

Easily attaches to I-beam of gate structure

Gravity referenced sensor allows installation anywhere on the gate structure

Scales the gate position into user units of feet, inches, meters, etc.

Built-in intelligence automatically calculates both gate height and arc length

No hysteresis or backlash

0.03 accuracy over full position and temperature range

Sealed water-tight enclosure

No moving parts or bearings

H-335

Chouteau Lock and Dam, OklahomaCopan Lake, Oklahoma

H-335 Operation 1-1

1.2 Theory of Operation

The H-335 has a single axis tilt sensor, signal processing circuitry, 14-bit analog to digital converter and a

microprocessor. The sensor is a ceramic based electrolytic tilt sensor which provides high resolution and

very good linearity. The sensor is constructed as a hermetically sealed ceramic cavity with electrodes

partially submerged in a conductive fluid. The ratio between submersed areas of the facing electrodes is

proportional to the inclination angle. The electronics provide an AC sensor excitation together with a

precision, ratiometric peak-hold detector. Because scale factor of electrolytic sensors is sensitive to

temperature, the H-335 has a built-in digital temperature sensor. The microprocessor uses a math

polynomial to correct for temperature induced effects and any non-linear characteristics of sensor.

1.3 Problems with Winch Mechanism and Existing Measurement Systems

Tainter gates are typically controlled with a motor operated winch mechanism. The gear box for the winch

has a “sundial” scale and pointer which shows the current gate opening. Often the mechanism also has a

selsyn transmitter which allows the gate position to be monitored in a nearby control room. The sundial and

selslyn driven scales are usually marked in units of “feet”. Unfortunately most winch mechanisms have no

provisions for monitoring the gate position with a data logger or SCADA (System Control and Data

Acquisition) system. In the past, users have tried using incremental shaft encoders connected to the winch

with a sprocket and chain. This technique has the following shortcomings:

The radius of the winch drum changes as the cable winds up, giving a non-linear readout.

The lift cables stretch as the gate is raised off the sill.

The backlash (hysteresis) in the drive chain between the winch drum and encoder can be large.

Each installation requires custom mechanisms, enclosures and setup.

The winch shaft is not accessible on some gearboxes.

The H-335 overcomes many of the problems associated with measuring the position of a tainter gate by

directly monitoring the angle of the gate structure. Backlash and non-linear effects of the winch drum and

cables are completely bypassed.

1-2 Introduction

H-335

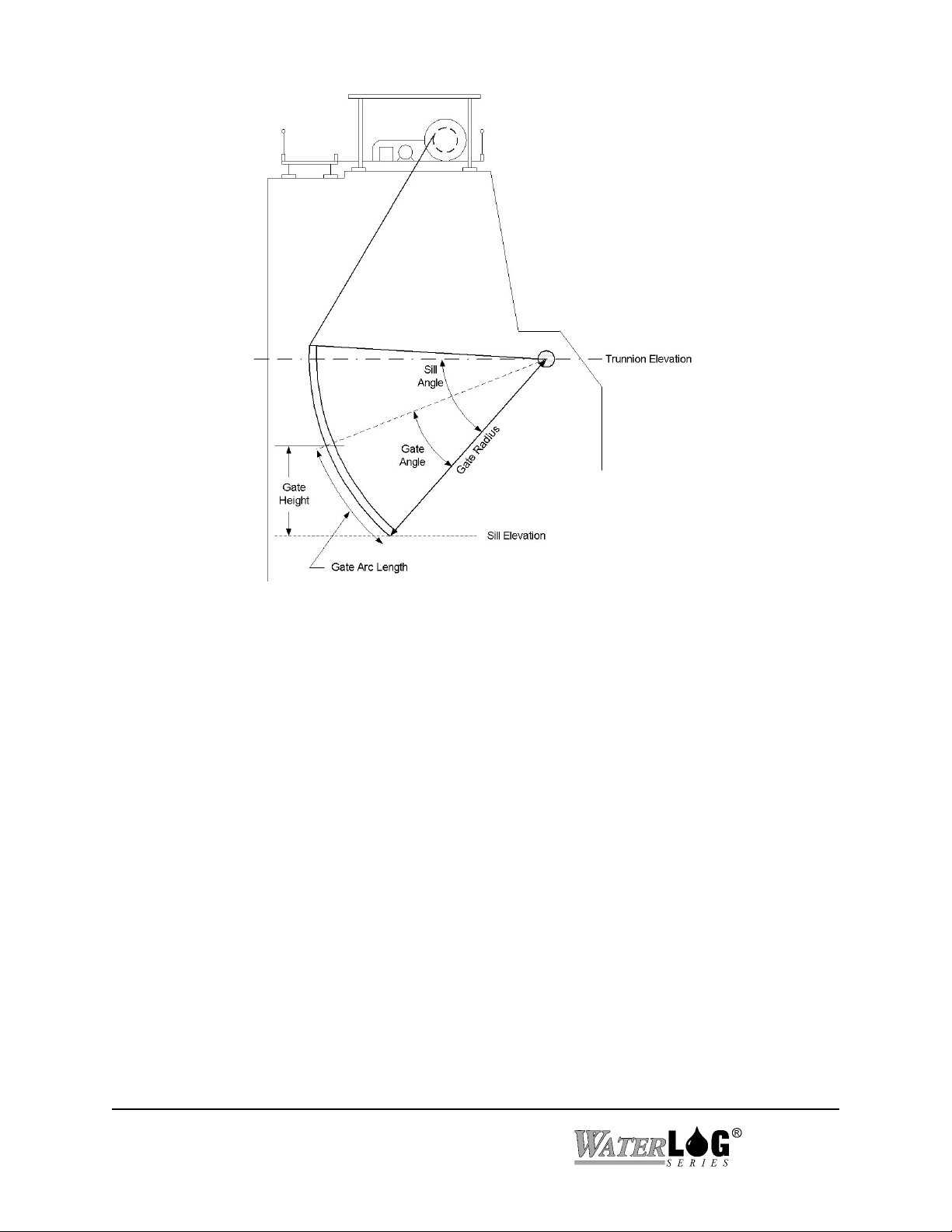

1.4 Gate Geometry

Most users are interested in measuring the gate opening or “height”. Upon closer examination, however, the

geometry of a tainter gate is somewhat complex. The following definitions and illustration shows the

geometry of a typical tainter gate.

1.4.1 Terms and Definitions

Trunnion Bearing: The pivot point of the gate structure.

Sill Elevation: The elevation relative to a datum of the point where the gate seals against the

bottom of the spillway.

Gate Radius: The distance between the center of the trunnion bearing and the outside of the gate

skin plate.

Gate Angle: The angle, in degrees, through which the gate has opened (0 = closed).

Gate Arc Length: The distance the gate face moves through the partial curve of a circle.

Gate Height: The vertical distance between the bottom of the gate and a horizontal line passing

through the sill.

Sill Angle: The angle, in degrees, between a horizontal line through the trunnion bearing and

the point at which the gate rests on the spillway.

The tilt sensor in the H-335 measures the angle of the gate structure referenced to gravity. The H-335 can

be installed anywhere on the gate structure since the entire structure rotates the same relative to gravity.

The sensor does not need to be on the center of the gate’s rotating axis.

The H-335 measures and reports the UserAngle relative to the closed position (0 = closed). For

convenience, the H-335 also internally calculates and reports GateHeight and GateArcLength. Normally,

users program their data recorder to record only one of the three parameters. Each of these three

measurement parameters has advantages and disadvantages:

H-335

H-335 Operation 1-3

Figure 1 Gate Geometry

×

1.4.2 User Angle

The UserAngle is the angle, in degrees, thru which the gate has moved relative to the closed position. All

other calculations are based on this measurement. Some dams have a spillway which slopes rapidly

downward from the point where the gate contacts the sill. For these structures, the water flow calculation is

a complex geometric problem because the actual weir opening (distance between the gate and the spillway)

changes as the vertical point from the bottom of the gate first moves upward, then down the incline of the

spillway. For complex gate geometries, program your data logger to record the UserAngle and do the

necessary calculations during post-processing of the data. The UserAngle parameter is calculated internally

in the H-335 using the following equation:

UserAngle = (SensorAngle UserSlope) - UserOffset

The UserSlope is a constant set to either +1.0 or -1.0 and must be programmed into the H-335 at

installation (see Section 1.8). The UserOffset value is automatically calculated when the extended “aXZO”

command is issued after the installation is completed.

1-4 Introduction

H-335

()(

)

[

]

1.4.3 Arc Length

The ArcLength is distance the gate face moves through the partial curve of a circle. Normally this value is

not recorded by the data logger. The H-335 calculates and reports this value for field test and verification

purposes and is calculated internally in the H-335 using the following equation:

UserAngle GateRadius

× ×

π

GateArcLength =

180

If water is flowing through the gate, the GateHeight cannot be directly measured with a measuring tape

because the water flow sweeps the tape away. However, if the tape is attached to the face of the gate, and is

tangent to the gate, the Arc Length can be directly measured in the field.

1.4.4 Gate Height

The GateHeight is the vertical distance between the bottom of the gate and a horizontal line passing thru

the sill. Normally this value is recorded and used in a weir calculation to determine water flow. The

GateHeight parameter is calculated internally in the H-335 using the following equation:

GateHeight = GateRadius sin SillAngle sin SillAngle-UserAngle

The GateRadius and SillAngle are constants and must be programmed into the H-335 during installation.

1.5 Programming the Data Recorder

You must prepare your data recorder to receive and record the H-335 data. Since data recorders differ

widely, refer to your recorder manufacturer's directions. In general, program the data recorder to input four

values via the SDI-12 port. Usually only one or two of the parameters is actually recorded. Your data

recorder must issue an “aM!” command, then collect the data with a “aD0 ” command, as explained in

Chapter 2. The H-335 places four data values in its data buffer:

−

Where:

a+AA.AA+BB.BB+CC.CC+DD.DD<CR><LF>

+AA.AA = GateArcLength (inches, meters etc.)

+BB.BB = GateHeight (inches, meters etc.)

+CC.CC = UserAngle (Degrees of angle)

+DD.DD = SensorTemperature (C)

H-335

H-335 Operation 1-5

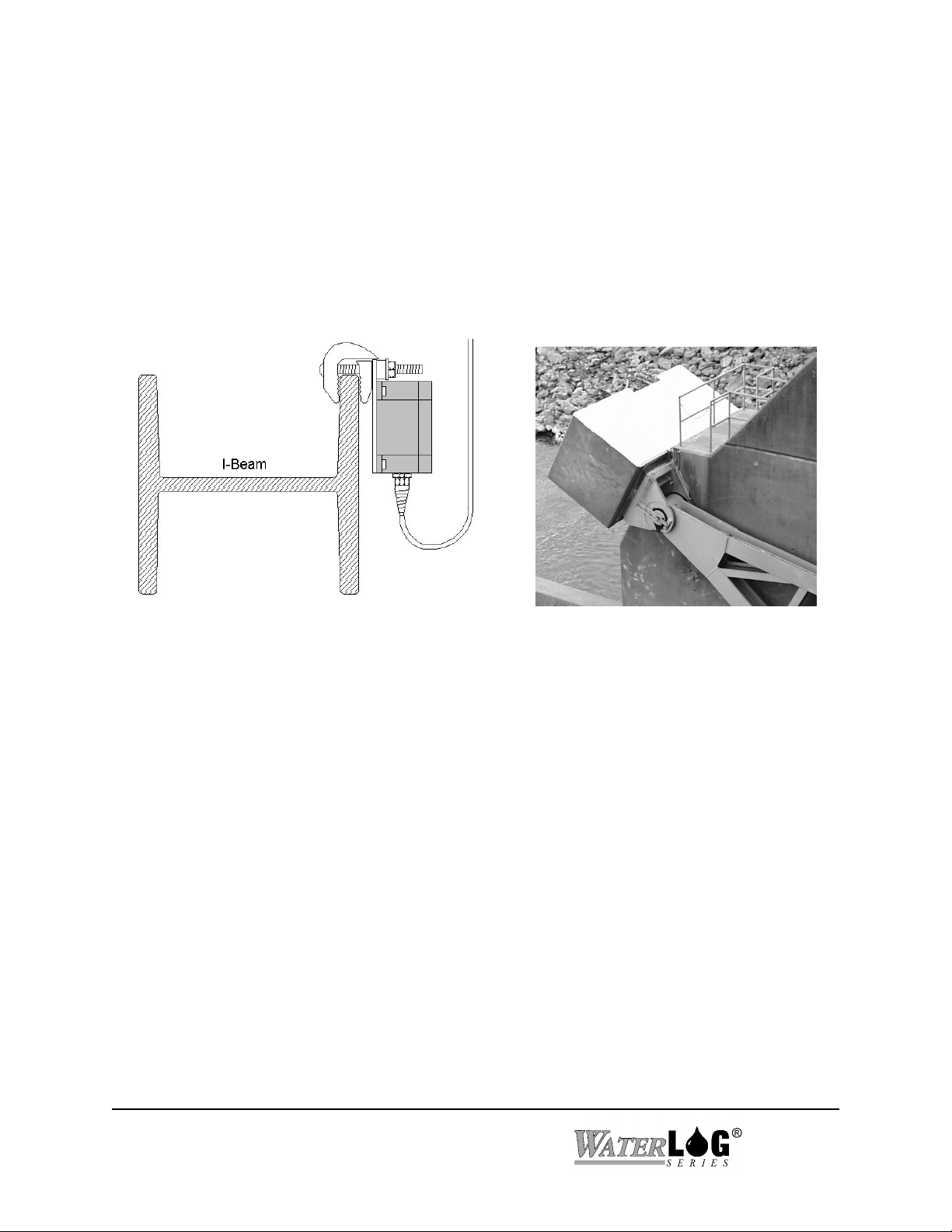

1.6 Installation

Since the H-335 is a gravity referenced tilt sensor, it can be installed anywhere on the gate structure. The

H-335 must be installed exactly vertical and in the plane the tainter gate rotates. If the H-335 is not vertical

the senor will suffer an off-axis trigonemetric error as the gate is raised. The mount clamp has a 2-axis

gimbal which allows the inclinometer to be adjusted to compensate for camber in the gate structure.

The best place to install the sensor is near the trunnion bearing between the I-beam of the gate arm and the

concrete pier. Either the left or right arm will work. This location is protected from direct sunlight, logs and

debris, and allows for a short cable. The beam clamps allow easy installation with no drilling and will work

for beams up to 2.0 inches thick. Make certain the cable has sufficient slack for the entire rotation of the

gate.

The UserAngleSlope coefficient in the H-335 must be programmed appropriately depending on whether the

H-335 is installed on the left or right arms of a gate and whether on the inside or outside of the I-beam (see

Figure 2).

1.7 Making Connections to the H-335

Since the H-335 is normally exposed to the sun and weather, a cable rated for water immersion and

sunlight resistance is required. A black urethane or similar sunlight/waterproof rated cable is recommended.

Make certain the power is OFF before making any connections. To access the wiring terminal block, open

the cover of the H-335 by removing the four cover screws. Whenever tightening or loosening the cover

screws, turn each screw only a turn or two at a time. Try to equalize the stress on the lid. This is especially

important when the O-ring in the lid is near full compression.

Make certain the cable properly seals in the grommet of the liquid-tight cable fitting and that the O-ring in

the fitting is tight against the box. The connection must be water tight. Other grommet diameters and

fittings are available from the factory.

The H-335 has a removable 4-pin wiring terminal block for connecting the SDI-12 cable. Unplug the

terminal block and make the connections to the cable. The connections are labeled on the circuit board.

Check to make certain the connections are correct, then plug the terminal block into the H-335 circuit

1-6 Introduction

H-335

Loading...

Loading...