INSTRUCTION MANUAL

IM188

Model SPM/SPH

Self-Priming Pumps

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Owner’s Information

Owner’s Information

Please fill in data from your pump nameplate.

Warranty information is on page 8.

Model Number:

Serial Number:

Dealer:

Dealer Telephone:

Purchase Date:

Installation Date:

Table of Contents

Table of Contents

SUBJECT PAGE

Safety Instructions ..........................................................2

Description and Specifications ........................................2

Engineering Data ............................................................2

Piping

Suction .......................................................................2

Discharge ....................................................................3

Wiring and Grounding ...................................................3

Operation .......................................................................3

Rotation .........................................................................3

Maintenance...................................................................3

Disassembly ....................................................................4

Reassembly .....................................................................4

Repair Parts ....................................................................5

Troubleshooting .............................................................5

Limited Warranty ...........................................................8

Declaration of Conformity ...........................................23

2

SAFETY INSTRUCTIONS

DANGER

WARNING

WARNING

Hazardous fluids

can cause fire,

burns or death.

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR

MAJOR PROPERTY DAMAGE, READ AND FOLLOW ALL

SAFETY INSTRUCTIONS IN MANUAL AND ON PUMP.

This is a SAFETY ALERT SYMBOL. When

you see this symbol on the pump or in the

manual, look for one of the following signal

words and be alert to the potential for personal injury or property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

CAUTION

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

MAINTAIN ALL SAFETY DECALS.

NOTICE: INSPECT UNIT FOR DAMAGE AND

REPORT ALL DAMAGE TO THE CARRIER

OR DEALER IMMEDIATELY. DO NOT USE

PUMP IF DAMAGE IS SUSPECTED.

DESCRIPTION AND SPECIFICATIONS

DESCRIPTION AND SPECIFICATIONS

• The SPM/SPH Series embraces a line of end suction single

stage, self-priming centrifugal pumps for lawn

sprinkling, HVAC systems, and general water transfer.

• Casing is cast iron construction with tapped openings

provided for vacuum gauge and casing drain.

• Impeller is bronze, enclosed design, balanced for smooth

operation and keyed to motor shaft.

• ALL motors are NEMA standard, 3500 RPM, open drip

proof or TEFC enclosure.

Warns of hazards that CAN cause personal

injury or property damage.

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES.

ENGINEERING DATA

ENGINEERING DATA

Prime Line SP Data

Flange Size

SPH130

SPH330 3/60

SPM130

SMP330 3/60

SPH150

SPH350 3/60

SPM150

SPM350 3/60

Suction Impeller HP

Model

SPF20A 5.94

SPF25A 5.06 3 2

SPF25A 6.19 5 2

SPF30A

5.82 5 2½

Discharge Phase/Hz

3 1½

1/60

1/60

1/60

1/60

Table 1

• Maximum Liquid Temperature: 160º F (71º C)

• Starts per hour: 20 – evenly distributed.

PIPING

PIPING

• Pump MUST be installed horizontally on a solid flat surface,

with discharge on top.

• Allow adequate space for servicing and ventilation. Protect

the unit from weather and water damage due to rain or

flooding or freezing temperatures.

• Piping should be no smaller than the suction and discharge

connections and kept as short as possible, avoiding unneces-

sary ttings to minimize friction losses. See Table 1.

• All piping MUST be independently supported and MUST

NOT place any piping loads on the pump.

NOTICE: DO NOT FORCE PIPING INTO PLACE AT

PUMP SUCTION AND DISCHARGE

CONNECTIONS.

• The use of Teon™ tape, or equivalent, is recommended for

ALL pipe joints.

• All pipe joints MUST be airtight.

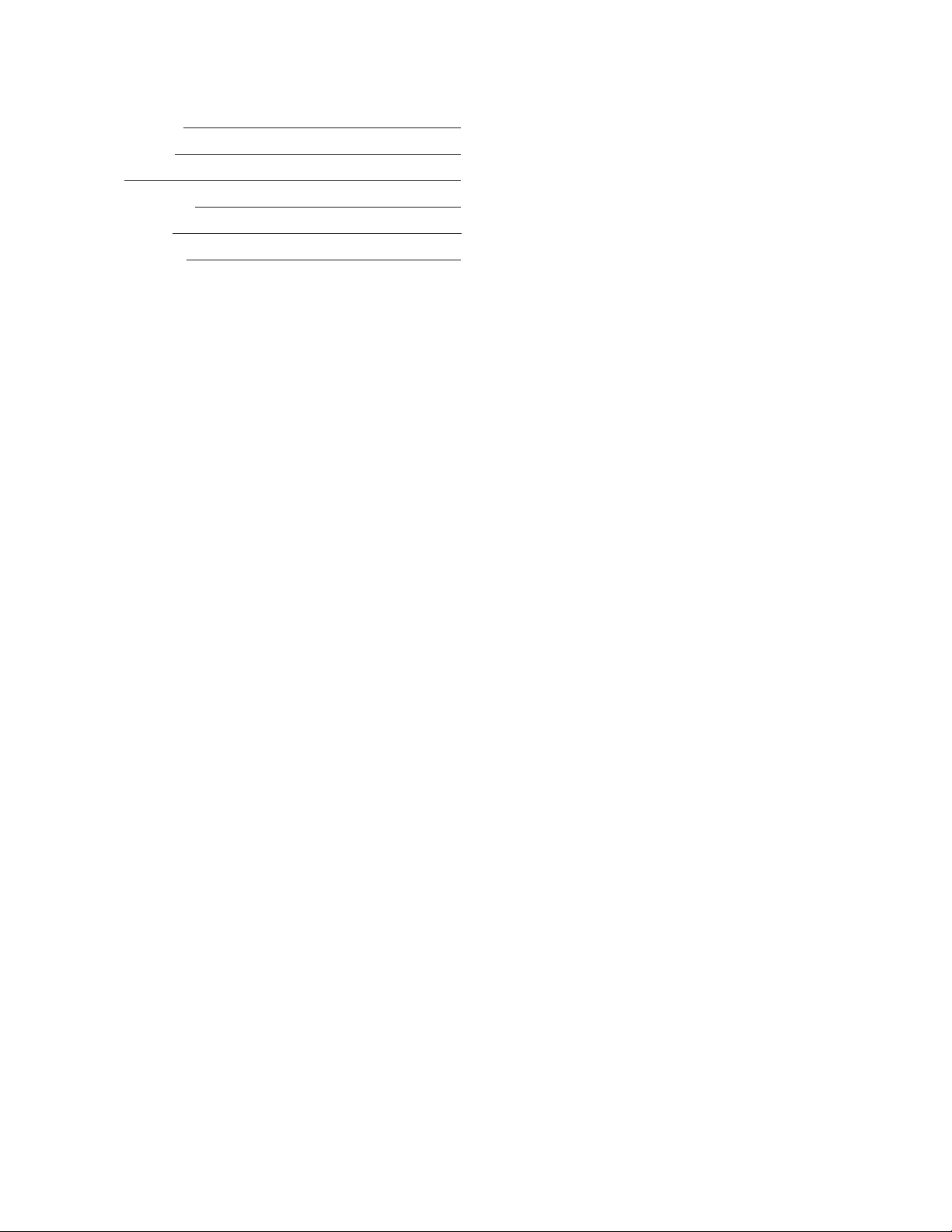

PIPING – SUCTION

• Total suction lift, including elevation and pipe friction loss,

should not exceed 25 feet.

• Install an airtight union in the suction line close to the pump.

See Figure 1.

PRIMING

FUSED OR

CIRCUIT BREAKER

DISCONNECT MEANS

OPENING

DISCHARGE

UNION

SUCTION

Figure 1

3

• Installation of a foot valve at the liquid source, or a check

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous voltage

can shock, burn or

cause death.

Extreme heat can

cause personal injury

or property damage.

WARNING

Hazardous

Machinery

WARNING

Hazardous pressure

can cause personal

injury or property

damage.

CAUTION

valve after the pump discharge, is recommended.

NOTICE: FOR INSTALLATIONS WITH LONG SUCTION

PIPING, BOTH A FOOT VALVE AND A

CHECK VALVE ARE RECOMMENDED.

• To avoid air pockets, no part of the piping should be above

the pump suction connection and piping should slope up-

ward from liquid source.

• For installations with long suction piping, ll the suction pipe

with water before connecting to pump.

PIPING – DISCHARGE

• Install a tee at the discharge connection of the pump. The top

opening of the tee is required for initial priming. See Figure 1.

WIRING AND GROUNDING

WIRING AND GROUNDING

Install, ground and wire according

to local and National Electrical

Code requirements.

Install an all leg electrical power

disconnect switch near the pump.

Disconnect electrical power, before

installing or servicing pump.

Electrical supply MUST match pump’s nameplate

specifications. Incorrect voltage can cause fire, damage to the motor, and voids warranty.

Motors without built-in protection MUST be

provided with contactors and thermal overloads

for single phase motors, or starters with heaters for

three phase motors. See motor nameplate.

• Follow motor manufacturer’s wiring diagram on the motor

nameplate or terminal cover carefully.

• Use only copper wire to motor and ground. The ground wire

MUST be at least as large as the wire to the motor. Wires

should be color coded for ease of maintenance.

WARNING

Hazardous

voltage

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN CAUSE

SHOCK, BURNS, OR DEATH.

• Fill pump through opening in top of tee with clean water.

See Figure 1.

• Install pipe plug in top using Teon™ tape or equivalent on

male threads.

NOTICE: IF PUMP IS DRAINED OR SHUT OFF DURING

PRIMING PERIOD, ENSURE CASING IS

REFILLED BEFORE RESTARTING PUMP.

• Start the pump motor and wait for system pressure to stabilize.

If system pressure is surging, or prolonged pressure drop is

experienced, the system may not be completely primed.

ROTATION

ROTATION

NOTICE: INCORRECT ROTATION MAY CAUSE

DAMAGE TO THE PUMP AND VOIDS THE

WARRANTY.

• Correct rotation is right hand, CLOCKWISE when viewed

from the motor end.

• Single phase motors with more than 4 wires (leads) may be

reversible designs. Insure that the motor is rotating in the correct direction. See motor nameplate for wiring instructions.

• Three phase unit rotation may be checked by removing motor end cap or plug and observing rotation of motor shaft. To

reverse rotation, reverse any two of the three motor leads.

MAINTENANCE

MAINTENANCE

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY MAINTENANCE CAN CAUSE SEVERE PERSONAL INJURY.

FAILURE TO RELIEVE SYSTEM PRESSURE AND DRAIN SYSTEM BEFORE

ATTEMPTING ANY MAINTENANCE

CAN CAUSE SERIOUS PERSONAL

INJURY OR PROPERTY DAMAGE.

OPERATION

OPERATION

4

SPLASHING OR IMMERSING OPEN

DRIP PROOF MOTORS IN WATER

CAN CAUSE FIRE, SHOCK, BURNS OR

DEATH.

OPERATION WITHOUT PRIME, OR

AGAINST A CLOSED DISCHARGE

VALVE, CAN GENERATE HOT WATER

OR STEAM CAUSING INJURY OR

PROPERTY DAMAGE OR EXPLOSION

RESULTING IN SERIOUS PERSONAL

INJURY, PROPERTY DAMAGE OR

DEATH.

• No lubrication is required on pump. For motor lubrication,

refer to and follow manufacturer’s instructions.

Seasonal Service

• To REMOVE pump from service, remove all drain plugs and

drain all piping.

• To RETURN pump to service, replace all drain plugs using

Teon™ tape or equivalent.

• Reconnect suction line if removed, examine union and repair

if necessary.

• Reprime and operate pump following all instructions and

warnings in the “OPERATION” section of manual.

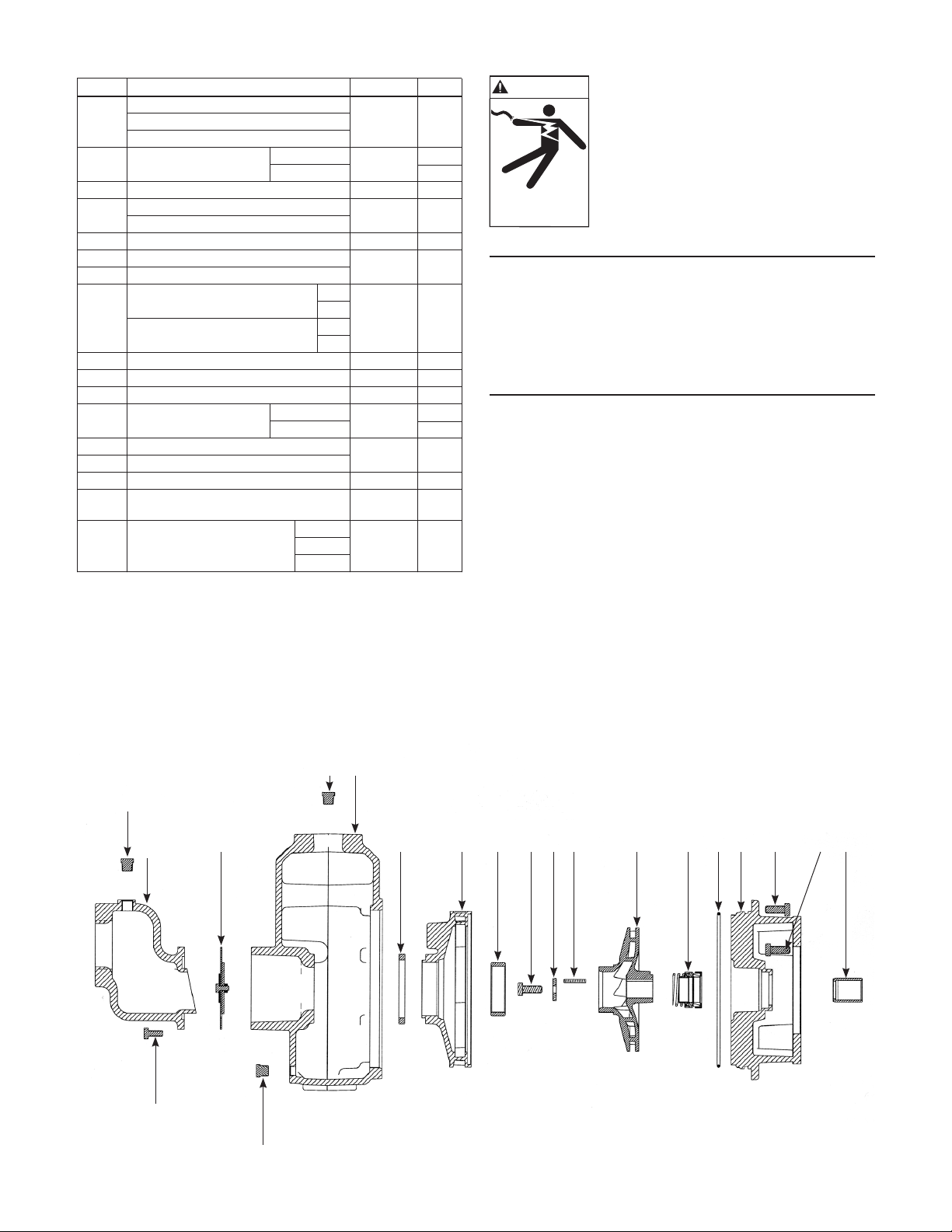

DISASSEMBLY

DISASSEMBLY

• Follow ALL warnings and instructions in the

“MAINTENANCE” section of this manual.

1. Remove motor hold down bolts.

2. Remove suction ange bolts (16).

3. Remove suction ange (17).

4. Remove check valve assembly (15).

5. Remove casing bolts (12).

6. Remove back pull-out assembly from casing (1).

7. Remove diffuser (4) and diffuser seal ring (3).

Discard ring.

8. Insert a screwdriver into one of the impeller waterways to

restrain motor shaft from rotation and remove impeller

bolt (6). Discard.

9. Remove impeller washer (7), impeller (8) and impeller

key (14). If the impeller is difcult to remove, insert two

pry bars between impeller and adapter, 180º apart and

CAREFULLY pry off impeller.

10. Remove motor adapter bolts (12) and adapter from motor

pulling with it the mechanical seal (9).

11. Push stationary seat of mechanical seal out of the motor

adapter and discard.

12. Inspect shaft sleeve (13). If damaged or badly scored,

remove by heating with a torch. Discard.

NOTICE: EXERCISE CARE IN HANDLING HOT SHAFT

SLEEVE.

REASSEMBLY

REASSEMBLY

• All parts should be cleaned before reassembly.

• Refer to parts list for description of replacement items.

Specify pump order number when ordering parts.

1. Inspect shaft, removing any debris or burrs.

2. When replacing shaft sleeve, apply new shaft sleeve’s bore

with LOCQUIC® Primer N, or equivalent. Let parts dry

and then apply LOCTITE® #262 on the same surfaces.

Slide new sleeve over shaft with a twisting motion, wipe off

excess. Let cure according to instructions.

NOTICE: MECHANICAL SEAL MUST BE REPLACED

WHENEVER SEAL HAS BEEN REMOVED.

FOLLOW SEAL MANUFACTURER’S

INSTRUCTIONS CAREFULLY.

3. If necessary, seat ring may be lubricated with water or

glycerin to aid in installation. DO NOT contaminate the

seal face. Fully and squarely install the stationary seat into

the adapter. With a clean cloth, CAREFULLY wipe the

seat face clean of debris. DO NOT damage the seal

seat face.

4. Reinstall the motor adapter on the motor, making sure that

the motor shaft does not dislocate or damage the stationary

seal seat.

5. Fully and squarely install the seal rotary assembly against

the stationary seat. Be sure rotating seal face does not drop

out of the holding collar and DO NOT damage seal face.

6. Install impeller key in shaft keyway. Mount impeller on

shaft and push until it bottoms.

7. Install new impeller washer.

8. Insert a screwdriver in a waterway passage of the impeller

holding it against rotation and install the new impeller bolt.

Torque to 20 lbs-ft (27 N•M).

9. Remove any burrs caused by screwdriver on the impeller

waterway passages.

10. Remove and replace the “o” ring (10) on the motor

adapter. Lubricate lightly with Parker “O” ring lube or

equivalent.

11. Locate the diffuser on the motor adapter with the stop

piece in the 12 o'clock position.

12. Locate the diffuser seal ring on the machined nose of the

diffuser and make sure it's pushed rmly into place.

13. Install motor and rotating assembly into casing, check the

position of the seall ring, tighten casing bolts alternately

and evenly. Torque to 37 lbs-ft (50 N•M).

14. Check impeller for binding by rotating the motor shaft.

If binding occurs, loosen bolts, readjust diffuser until

impeller hub turns freely. Tighten bolts again.

15. Place suction flange bolts through holes and locate check

valve assembly (replace if damaged) over bolts. Carefully

bolt suction flange on casing making sure check valve

assembly is positioned so that the rubber face is against the

angled face of the suction flange.

16. Replace motor foot bolts.

17. Check for free rotation after assembly is complete.

18. Replace all drain plugs, using teon tape on male threads.

19. Prime according to instructions in the “OPERATION”

section of the manual.

5

COMPONENTS

WARNING

Hazardous voltage

can shock, burn or

cause death.

COMPONENTS TROUBLESHOOTING

Location Description Material Qty.

Case 1½" NPT

1 Case 2" NPT Cast Iron 1

Case 2½" NPT

2 Pipe Plug ¼" NPT

Case Steel 2

3 Diffuser Seal Ring BUNA 1

4 Diffuser – High Head

Diffuser – Medium Head

5 Casing Wear Ring Bronze* 1

6 Impeller Screw

7 Impeller Washer 1

8 3 HP

3 HP

9 Mechanical Seal ** 1

10 O-Ring BUNA-N 1

11 Motor Adapter – 140/180 FR Cast Iron 1

12 Hex Head Cap Screw Case Zinc Plated 8

.38 – 16 UNC .88 Lg Motor Steel 4

13 Shaft Sleeve

14 Key – Square End

15 Check Valve Assembly BUNA-SS 1

Steel

1" NPT

17 Suction Flange 2½" NPT Cast Iron 1

3" NPT

* Lead Free

** Consult Factory

Impeller – High Head

Impeller – Medium Head

16 Hex Head Cap Screw .31 – 18 UNC .75 Lg

Suction Flange Zinc Plated 1

Cast Iron

AISI 300 SS

5 HP

5 HP

AISI 300 SS 1

Zinc Plated

1

Sil-Brass* 1

1

4

TROUBLESHOOTING

FAILURE TO DISCONNECT

ELECTRICAL POWER BEFORE ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

SYMPTOM

Motor Not Running:

See Probable Causes 1 through 5.

Little or No Water Delivered:

See Probable Causes 3, 4, 6 through 12, 15, 16.

Excessive Noise and Vibration:

See Probable Causes 3, 6, 7, 10, 12, 13, 14.

PROBABLE CAUSES

1. Motor thermal protector tripped.

2. Open circuit breaker or blown fuse.

3. Impeller binding.

4. Motor improperly wired.

5. Defective motor.

6. Pump is not primed, air or gases in pumpage.

7. Discharge, suction plugged or valve closed.

8. Incorrect rotation.

9. Low voltage or phase loss.

10. Impeller worn or plugged.

11. System head too high.

12. NPSHA too low – excessive suction lift or loss.

13. Discharge head too low – excessive ow rates.

14. Pump, motor or piping loose.

15. End of suction piping not submerged.

16. Check valve damaged.

2 1

2

17

16

15 3 4 5 7 14 8 96 10 11 12 12 13

2

6

NOTES

NOTES

7

RED JACKET WATER PRODUCTS LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Red Jacket Water Products.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The war-

ranty period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever

period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Red Jacket Water Products distributor from whom the pump was

purchased and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Red Jacket Water

Products Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Red Jacket Water Products

and the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing

pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corpora-

tion, limited liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. IM188 Revision Number 1 July 2012

MANUAL DE INSTRUCCIÓN

IM188

Modelo SPM y SPH

Self-Priming Pumps

INSTRUCCIONES DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

INFORMACIÓN DEL PROPIETARIO

INFORMACIÓN DEL PROPIETARIO

Por favor complete los datos consultando la placa del

fabricante de la bomba. La información de la garantía está

en la página 16.

Número del modelo:

Número de serie:

Agente:

Teléfono del agente:

Fecha de compra:

Fecha de instalación:

ÍNDICE

ÍNDICE

ASUNTO PÁGINA

Instrucciones de seguridad ............................................10

Descripción y especificaciones ......................................10

Datos técnicos ..............................................................10

Tubería

Succión .....................................................................10

Descarga ...................................................................11

Cableado y conexión a tierra ........................................11

Operación ....................................................................11

Rotación .......................................................................11

Mantenimiento .............................................................11

Desmontaje ..................................................................12

Reensamblaje ................................................................12

Piezas de reparación .....................................................13

Investigación de averías ................................................13

Garantía limitada ..........................................................16

Declaración de Conformidad .........................................23

10

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

Los fluidos peligrosos

pueden originar fuego,

quemaduras o causar

la muerte.

INSTRUCCIONES DE SEGURIDAD

ES INTENCIÓN QUE ESTE MANUAL ASISTA EN

LA INSTALACIÓN DE ESTA UNIDAD Y DEBE

MANTENERSE CON LA BOMBA.

Este es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

en la bomba o en el manual, busque una

de las palabras de señal y esté alerta a las

lesiones corporales potenciales o daños a

la propiedad.

Advierte los peligros que CAUSARÁN

lesiones corporales serias, la muerte o

daños mayores a la propiedad.

Advierte los peligros que PUEDEN causar

lesiones corporales serias, la muerte o

daños mayores a la propiedad.

Advierte los peligros que PUEDEN causar

lesiones corporales o daños a la propiedad.

ES INTENCIÓN QUE ESTE MANUAL ASISTA

EN LA INSTALACIÓN Y OPERACIÓN DE ESTA

UNIDAD Y DEBE MANTENERSE CON LA BOMBA.

MANTENGA TODAS LAS CALCOMÍAS DE

SEGURIDAD.

AVISO: INSPECCIONE LA UNIDAD SI TIENE

DAÑOS Y REPORTE INMEDIATEMENTE

CUALQUIER DAÑO AL TRANSPORTISTA

O AL AGENTE. NO USE LA BOMBA SI SE

SOSPECHA QUE ESTÁ DAÑADA.

UNIDADES NO DISEÑADAS PARA

USO CON LÍQUIDOS PELIGROSOS O

GASES INFLAMMABLES.

AVISO: INDICA INSTRUCCIONES ESPECIALES QUE

SON MUY IMPORTANTES Y DEBEN

SEGUIRSE.

DESCRIPCIÓN Y ESPECIFICACIONES.

DESCRIPCIÓN Y ESPECIFICACIONES.

• La serie SPM/SPH abarca una línea de bombas centrífu-

gas de aspiración axial, de una etapa, autocebadas para la

aspersión de patios, sistemas de calefacción, ventilación y

aire acondicionado, y transferencia de agua en general.

• La carcasa es de construcción de hierro fundido con

aberturas roscadas proporcionadas para el manómetro de

vacío y el drenaje de la carcasa.

• Impulsor de bronce, de diseño cerrado, equilibrado para

un funcionamiento suave y enchavetado al eje del motor.

• Todos los motores son de Norma NEMA, de 3500 rpm,

con cubierta abierta a prueba de goteo o con cubierta

totalmente cerrada enfriada con ventilador.

DATOS TÉCNICOS

DATOS TÉCNICOS

Datos sobre Prime Line SP

succión impulsor

SPH130

SPH330 3/60

SPM130

SMP330 3/60

SPH150

SPH350 3/60

SPM150

SPM350 3/60

Pestaña de Tamaño del

Modelo

SPF20A 5.94

SPF25A 5.06 3 2

SPF25A 6.19 5 2

SPF30A

HP

5.82 5 2½

3 1½

Descarga Fase/Hz

1/60

1/60

1/60

1/60

Tabla 1

• Máxima temperatura del líquido: 160º F (71º C)

• Arranques por hora: 20, distribuidos uniformemente.

TUBERÍA

TUBERÍA

• La bomba DEBE estar instalada horizontalmente sobre

una superficie plana y sólida, con la descarga por arriba.

• Deje suciente espacio superior para poder dar servicio y

ventilación. Proteja la unidad de la intemperie y del daño

de agua debido a la lluvia, inundaciones o temperaturas de

congelación.

• La tubería no debe ser más pequeña que las conexiones

de la succión y descarga y se deben mantener tan cortas

como sea posible, evitando accesorios innecesarios para

minimizar las pérdidas de fricción. Vea la tabla 1.

• Toda la tubería DEBE estar soportada

independientemente y NO DEBE agregar ninguna carga

de la tubería a la bomba.

AVISO: NO FUERCE LA TUBERÍA AL HACER LAS

CONEXIONES DE SUCCIÓN Y DESCARGA

CON LA BOMBA.

• El uso de la cinta de Teon™, o equivalente se recomienda

en TODAS las juntas de tubería.

• Todas las juntas de tubería DEBEN estar selladas para

evitar entrada de aire.

TUBERÍA – SUCCIÓN

• La altura de aspiración total, incluyendo la elevación y

las pérdidas de fricción de la tubería, no deben exceder

25 pies.

• Instale una unión estanca en la línea de succión, cerca de

la bomba. Vea la Figura 1.

INTERUPTOR

CON FUSIBLE O

CONMUTADOR

AUTOMÁTICO

ABERTURA DE

CEBADO

DESCARGA

UNIÓN

SUCCIÓN

Figura 1

• Se recomienda la instalación de una válvula de pie en

la fuente del líquido, o una válvula de retención después

de la descarga de la bomba.

11

AVISO: PARA INSTALACIONES CON TUBERÍAS DE

ADVERTENCIA

La tensión peligrosa puede

causar electrochoque,

quemaduras o la muerte.

Tensión

p

eligrosa

ADVERTENCIA

ADVERTENCIA

La tensión peligrosa puede

causar electrochoque,

quemaduras o la muerte.

ADVERTENCIA

El calor extremo

puede causar lesiones

personales o daños

materiales.

Maquinaria peligrosa

ADVERTENCIA

PRECAUCIÓN

Niveles de presión

peligrosos pueden causar

lesiones personales o

daños materiales.

SUCCIÓN LARGAS, SE RECOMIENDA UNA

VÁLVULA DE PIE Y UNA VÁLVULA DE

RETENCIÓN.

• Para evitar las bolsas de aire, ninguna parte de la tubería

• Para instalaciones con tuberías de succión largas, llene la

TUBERÍA – DESCARGA

• Instale una T en la conexión de descarga de la bomba. La

CABLEADO Y CONEXIÓN A TIERRA

CABLEADO Y CONEXIÓN A TIERRA

• Siga cuidadosamente el diagrama de alambrado del fabri-

• Use sólo cables de cobre al motor y a tierra. El alambre a

OPERACIÓN

OPERACIÓN

12

debe estar arriba de la conexión de succión de la bomba

y la tubería debe inclinarse hacia arriba, partiendo de la

fuente del líquido.

tubería de succión con agua antes de conectar la bomba.

abertura superior de la T se requiere para el cebado inicial.

Vea la Figura 1.

Instale la conexión a tierra y el

cableado de acuerdo con los

requerimientos del código

Nacional de Electricidad.

Instale un interruptor de

alimentación en todos los alam-

bres exteriores con corriente,

cerca de la bomba.

Desconecte la alimentación

eléctrica antes de instalar o dar

servicio a la bomba.

La alimentación eléctrica DEBE estar de acuerdo

con las especificaciones de la placa del fabricante.

La tensión incorrecta puede causar incendio o

dañar el motor y anular la garantía.

Los motores sin protección incorporada DEBEN

estar provistos de contactores y sobrecargas

térmicas para los motores monofásicos, o con

arrancadores con calentadores para los trifásicos.

Vea la placa del fabricante del motor.

cante del motor en la placa del fabricante del motor o en

la tapa terminal.

tierra DEBE ser por lo menos tan grande como el alambre

al motor. Los alambres deben ser de color codificado para

facilitar el mantenimiento.

LA OMISIÓN DE CONECTAR A

TIERRA PERMENENTEMENTE LA

BOMBA, EL MOTOR Y LOS CONTROLES, ANTES DE CONECTAR A LA

ALIMENTACIÓN ELÉCTRICA, PUEDE

CAUSAR ELECTROCHOQUES,

QUEMADURAS O LA MUERTE.

SALPICAR O SUMERGIR LOS

MOTORES DE CUBIERTA ABIERTA A

PRUEBA DE GOTEO EN UN FLUIDO

PUEDE CAUSAR INCENDIOS,

ELECTROCHOQUES, QUEMADURAS

O LA MUERTE.

TRABAJAR SIN CEBADOR, O

CONTRA UNA VÁLVULA DE

DESCARGA CERRADA, PUEDE

GENERAR AGUA CALIENTE O

VAPOR QUE PODRÍA CAUSAR

LESIONES O DAÑOS A LA

PROPIEDAD O UNA EXPLOSIÓN

QUE PODRÍA CAUSAR LESIONES

CORPORALES GRAVES, DAÑOS A

LA PROPIEDAD O LA MUERTE

• Llene la bomba a través de la abertura superior de la T,

con agua limpia. Vea la Figura 1.

• Instale el tapón de la tubería en la parte superior de la

T usando cinta de Teon™ o equivalente en las roscas

macho.

AVISO: SI LA BOMBA ESTÁ VACIA O CERRADA

AL MOMENTO DEL CEBADO, ASEGÚRESE

DE QUE LA CARCASA SE VUELVA A LLENAR

ANTES DE VOLVER A ARRANCAR

LA BOMBA.

• Arranque el motor de la bomba y espere que la presión

del sistema se estabilice. Si la presión del sistema está con

pulsación, o se experimenta una prolongada caída de presión, es probable que el sistema no esté totalmente cebado.

ROTACIÓN

ROTACIÓN

AVISO: LA ROTACIÓN INCORRECTA PUEDE

CAUSAR DAÑO A LA BOMBA Y ANULAR

LA GARANTÍA.

• La rotación correcta es la derecha, en sentido HORARIO

cuando se mira desde el extremo del motor.

• La rotación de la unidad trifásica se puede vericar

quitando la tapa extrema del motor o tapón y observando

la rotación del eje del motor. Para invertir la rotación, in-

vierta dos cualesquiera de los tres conductores del motor.

MANTENIMIENTO

MANTENIMIENTO

LA OMISIÓN DE DESCONECTAR

Y TRABAR LA ALIMENTACIÓN

ELÉCTRICA ANTES DE INTENTAR

CUALQUIER MANTENIMIENTO

PUEDE CAUSAR SEVERAS LESIONES

CORPORALES.

LA OMISIÓN DE ALIVIAR LA

PRESIÓN DEL SISTEMA Y DRENAR

EL SISTEMA ANTES DE INTENTAR

CUALQUIER MANTENIMIENTO

PUEDE CAUSAR LESIONES

CORPORALES GRAVES O DAÑOS

A LA PROPIEDAD.

• La bomba no requiere lubricación alguna. Para la lubricación del motor, consulte y siga las instrucciones del

fabricante.

SERVICIO DE TEMPORADA

• Para RETIRAR la bomba del servicio, quite todos los

tapones de drenaje y drene toda la tubería.

• Para DEVOLVER la bomba al servicio, vuelva a poner

todos los tapones usando cinta de Teon™ o equivalente.

• Reconecte la línea de succión si se quitó, examine la unión

y repare si es necesario.

• Vuelva a cebar y hacer funcionar la bomba siguiendo

todas las instrucciones y advertencias en la sección “OPERACIÓN” de este manual.

DESMONTAJE

DESMONTAJE

• Siga TODAS las advertencias e instrucciones en la sección

“MANTENIMIENTO” de este manual.

1. Remueva los pernos de sujeción del motor.

2. Remueva los pernos de la brida de succión (16).

3. Remueva la brida de succión (17).

4. Remueva el montaje de la válvula de retención (15).

5. Remueva los pernos de la carcasa (12).

6. Remueva el adaptador del motor de la carcasa (1).

7. Remueva el difusor (4) y el anillo de estancamiento

del difusor (3). Deseche el anillo.

8. Inserte un destornillador en uno de los canales del impulsor

para restringir la rotación del eje del motor y quite el perno

del impulsor (6). Deseche.

9. Remueva la arandela del impulsor (7), el impulsor (8) y la

chaveta del impulsor (14). Si es difícil quitar el impulsor,

inserte dos barras de palanca entre el impulsor y

el adaptador, espaciadas en 180º y CUIDADOSAMENTE

haga palanca y retire el impulsor.

10. Remueva los pernos del adaptador del motor (12) y

desconecte el adaptador del motor, halando con él,

el sello mecánico (9).

11. Empuje el asiento estacionario del sello mecánico fuera

del adaptador del motor y deséchelo.

12. Inspeccione la camisa del eje (13). Si está dañada o muy

rayada, remuevala aplicando calor con un soplete.

Deséchela.

AVISO: TENGA CUIDADO AL MANEJAR LA CAMISA

CALIENTE DEL EJE.

REENSAMBLE

REENSAMBLE

• Limpie e inspeccione todas las piezas antes de reensamblar.

• Consulte la lista de piezas para la descripción de los artículos

de reemplazo. Especique el número de índice de la bomba

cuando ordene piezas de repuesto.

1. Inspeccione el eje, quitando cualquier residuo o rebabas.

2. Al cambiar la camisa del eje, aplique LOCQUIC® Primer

“N”, o equivalente, al agujero de la camisa del eje nuevo.

Deje que las piezas de sequen y luego aplique LOCTITE®

#262 a las mismas supercies. Deje deslizar la nueva

camisa sobre el eje con un movimiento de torsión, limpie

el exceso. Deje curar de acuerdo a las instrucciones.

AVISO: EL SELLO MECÁNICO SE DEBE CAMBIAR

SIEMPRE QUE SE HAYA SIDO QUITADO.

SIGA CUIDADOSAMENTE LAS

INSTRUCCIONES DEL FABRICANTE

DEL SELLO.

3. Si es necesario, el anillo del asiento se puede lubricar con

agua o glicerina para ayudar a la instalación. NO contamine

la cara del sello. Instale en forma completa y encuadrada

el asiento estacionario en el adaptador. Con una tela limpia

y sin pelusas, CUIDADOSAMENTE limpie la cara del

sello de todo residuo. NO dañe la cara del asiento del sello.

4. Vuelva a instalar el adaptador del motor en el motor,

asegurándose de que el eje no disloque o dañe el asiento de

sello estacionario.

5. Instale en forma completa y encuadrada el conjunto

giratorio del anillo contra el asiento estacionario. Asegúrese

de que la cara del sello no caiga fuera del collar de sujeción

y NO dañe la cara del sello.

6. Instale la chaveta del impulsor en el chavetero del eje.

Monte el impulsor en el eje y empuje a fondo hasta que

haga tope.

7. Instale una nueva arandela de impulsor.

8. Inserte un destornillador en un pasaje de canal del impulsor

sosteniéndolo contra la rotación e instale el perno del

impulsor nuevo. Ajuste con un torque de 20 libras-pie

(27 N•M).

9. Quite cualquier rebaba que cause el destornillador sobre la

periferia del impulsor en los pasajes de los canales.

10. Quite y reemplace el aro tórico (10) del adaptador del

motor. Lubrique ligeramente con lubricante Parker para

aros tóricos o uno equivalente.

11. Ubique el difusor en el adaptador del motor con el tope en

posición de las agujas del reloj marcando las 12.

12. Ubique el anillo de estancamiento del difusor en la oreja

mecanizada del difusor y asegúrese de que esté bien

colocado en su lugar.

13. Instale el motor y el conjunto de rotación en la carcasa,

verique la posición del anillo de estancamiento, apriete los

pernos de la carcasa en forma alternativa y pareja. Ajuste

con un torque de 37 libras-pie (50 N•M).

14. Verique la jación del impulsor haciendo girar el eje del

motor. Si existe jación, aoje los pernos, reajuste el difusor

hasta que el núcleo de impulsor rote libremente. Ajuste los

pernos nuevamente.

15. Coloque los pernos de la brida de succión a través de

los agujeros y coloque el montaje de la válvula de retención

sobre los pernos (reemplace si está dañado).

Cuidadosamente, apriete los pernos de la brida de succión

a la carcasa, asegurándose de que el montaje de la válvula

de retención esté posicionada de manera tal que la cara

de goma quede enfrentada a la cara de la brida

de succión.

16. Reemplace los pernos de pie del motor.

17. Verique la rotación libre después de que termine

el montaje.

18. Reemplace todos los tapones de drenaje, usando cinta

teflón en las roscas macho.

19. Cebe de acuerdo con las instrucciones de la sección

“OPERACIÓN” del manual.

13

PIEZAS DE REPARACIÓN

ADVERTENCIA

La tensión peligrosa puede

causar electrochoque,

quemaduras o la muerte.

PIEZAS DE REPARACIÓN INVESTIGACIÓN DE AVERÍAS

Ubicación Descripción Material Cant.

Carcasa 1½" NPT

1 Carcasa 2" NPT Hierro fundido 1

Carcasa 2½" NPT

2 Tapón de Tubería ¼" NPT

Carcasa pado en Zinc 2

3 Anillo de estancamiento del difusor BUNA 1

4 Difusor – Carga alta

Difusor – Carga media

5 Anillo de desgaste de la carcasa Bronce* 1

6 Tornillo del impulsor

7 Arandela del impulsor 1

8 3 HP

3 HP

9 Sello Mecánico ** 1

10 Aro tórico BUNA-N 1

11 Adaptador del motor – 140/180 FR Hierro fundido 1

12 Tornillo de cabeza hexagonal Carcasa Acero encha- 8

.38 – 16 UNC .88 Lg Motor pado en Zinc 4

13 Camisa del eje

14 Chaveta cuadrada

15 Montaje de válvula de retención BUNA-SS 1

.31 – 18 UNC .75 Lg pado en Zinc

1" NPT

17 Flanje de Succión 2½" NPT Cast Iron 1

3" NPT

* Sin plomo

** Consultar en fábrica

Impulsor – Carga alta

Impulsor – Carga media

Tornillo de cabeza hexagonal

16

Flanje de succión Acero encha- 1

Hierro fundido 1

AISI 300 SS

5 HP

5 HP

Sil-Brass*

AISI 300 SS 1

Acero encha-

1

1

4

INVESTIGACIÓN DE AVERÍAS

LA OMISIÓN DE DESCONECTAR LA

ALIMENTACIÓN ELÉCTRICA ANTES

DE INTENTAR CUALQUIER

MANTENIMIENTO PUEDE CAUSAR

ELECTROCHOQUES, QUEMADURAS

O LA MUERTE.

SÍNTOMA

Motor no funciona:

Vea las causas probables del 1 al 5.

Poca o ninguna entrega de agua:

Vea las causas probables 3, 4, 6 a 12, 15, 16.

Excesivo ruido y vibraciones:

Vea las causas probables 3, 6, 7, 10, 12,13,14.

CAUSAS PROBABLES

1. Protector térmico del motor disparado.

2. Interruptor automático abierto o fundido el fusible.

3. Impulsor atascado.

4. Motor mal conectado.

5. Motor defectuoso.

6. Bomba no está cebada, hay aire o gases en el líquido

bombeado.

7. Tapada la descarga, succión o cerrada la válvula.

8. Rotación incorrecta.

9. Baja tensión o pérdida de fase.

10. Impulsor desgastado o tapado.

11. Cabeza del sistema muy elevada.

12. Demasiado baja la ASPND (altura de succión positiva neta

disponible) – excesiva la altura de aspiración o las pérdidas.

13. Demasiado baja la altura de descarga – caudales excesivos.

14. Bomba, motor o tubería flojos.

2 1

15. No sumergido el extremo de succión de la tubería.

16. Válvula de retención dañada.

2

14

17

16

15 3 4 5 7 14 8 96 10 11 12 12 13

2

NOTAS

NOTAS

15

GARANTÍA LIMITADA DE RED JACKET WATER PRODUCTS

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Red Jacket Water Products.

Toda parte o partes que resultaren defectuosas dentro del período de garantía serán reemplazadas durante dicho período de garantía sin cargo para el

comerciante. Tal período de garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de

fabricación, la que se cumpla primero.

El comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Red Jacket Water

Products del cual adquiriera la bomba y brindar información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los

reclamos por garantía a través del Departamento de Servicios a Clientes de Red Jacket Water Products.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Red Jacket Water Products y el comer-

ciante para la compra, consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing)

de bombas a los clientes.

(3) “Cliente” es toda entidad que compra o adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente”

puede signicar un individuo, sociedad, corporación, sociedad de responsabilidad limitada, asociación o cualquier otra entidad jurídica con actividades en cualquier tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products son una marca registrada de Xylem Inc. o una de sus filiales.

© 2012 Xylem Inc. IM188 Revisión Número 1 Julio 2012

MANUEL D'UTILISATION

IM188

Modèle SPM et SPH

Self-Priming Pumps

DIRECTIVES D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

INFORMATIONS POUR LE PROPRIÉTAIRE

INFORMATIONS POUR LE PROPRIÉTAIRE TABLE DES MATIÈRES

Noter ci-dessous les informations de la plaque signalétique de

la pompe. La garantie est présentée en page 24.

Numéro de modèle :

Numéro de série :

Détaillant :

Nº de tél. du détaillant :

Date d’achat :

Date d’installation :

SUJET PAGE

Consignes de sécurité ...................................................18

Description et caractéristiques ......................................18

Données techniques ......................................................18

Tuyauterie

Aspiration .................................................................18

Refoulement .............................................................19

Câblage et mise à la terre ..............................................19

Utilisation .....................................................................19

Sens de rotation ............................................................19

Entretien ......................................................................19

Démontage ...................................................................20

Remontage ...................................................................20

Liste de pièces de rechange ...........................................21

Diagnostic des anomalies ..............................................21

Déclaration de conformité ..............................................23

Garantie limitée ............................................................24

TABLE DES MATIÈRES

18

CONSIGNES DE SÉCURITÉ

DANGER

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

Les fluides dangereux

peuvent causer un

incendie, des brûlures

ou la mort.

AVIS : INSPECTER L’APPAREIL ET SIGNALER

IMMÉDIATEMENT TOUT DOMMAGE

AU TRANSPORTEUR OU AU DÉTAILLANT.

NE PAS UTILISER LA POMPE SI L’ON

SOUPÇONNE QU’ELLE EST

ENDOMMAGÉE.

DESCRIPTION ET CARACTÉRISTIQUES

DESCRIPTION ET CARACTÉRISTIQUES

• La série SPM/SPH consiste en une gamme de pompes

• Le corps de pompe est en fonte et comporte des orices

• La roue est en bronze, fermée, équilibrée pour un fonc-

• TOUS les moteurs sont conformes à la NEMA, sont du

AFIN DE PRÉVENIR LES BLESSURES GRAVES OU

MORTELLES ET LES DOMMAGES MATÉRIELS

IMPORTANTS, LIRE ET SUIVRE TOUTES LES

CONSIGNES DE SÉCURITÉ FIGURANT DANS LE

MANUEL ET SUR LA POMPE.

Le symbole ci-contre est un SYMBOLE

DE SÉCURITÉ employé pour signaler

les mots-indicateurs dont on trouvera la

description ci-dessous. Sa présence sert à

attirer l’attention afin d’éviter les blessures

et les dommages matériels.

Prévient des risques qui VONT causer des

blessures graves, la mort ou des dommages

matériels importants.

Prévient des risques qui PEUVENT causer

des blessures graves, la mort ou des

dommages matériels importants.

Prévient des risques qui PEUVENT causer

des blessures ou des dommages matériels.

AVIS : SERT À ÉNONCER LES DIRECTIVES

SPÉCIALES DE GRANDE IMPORTANCE

QUE L’ON DOIT SUIVRE.

LE PRÉSENT MANUEL A POUR BUT DE

FACILITER L’INSTALLATION ET L’UTILISATION

DE LA POMPE ET DOIT RESTER PRÈS DE

CELLE-CI.

N’ENLEVER AUCUN AUTOCOLLANT DE

SÉCURITÉ.

APPAREIL NON CONÇU POUR LES

LIQUIDES DANGEREUX NI POUR

LES GAZ INFLAMMABLES.

centrifuges autoamorçantes, à un étage et à aspiration

en bout, servant à l’arrosage des pelouses, aux systèmes

CVCA (chauffage, ventilation et conditionnement d’air)

et au transfert d’eau de nature générale.

taraudés pour la vidange et la pose d’un vacuomètre.

tionnement en douceur et clavetée sur l’arbre de moteur.

type à carcasse abritée (à ouvertures de ventilation

protégées) ou fermée autoventilée, et tournent

à 3 500 r/min.

DONNÉES TECHNIQUES

DONNÉES TECHNIQUES

Données sur la série Prime Line SP

d’aspiration la roue (po) refoulem. (po)

SPH130

SPH330 3/60

SPM130

SMP330 3/60

SPH150

SPH350 3/60

SPM150

SPM350 3/60

Bride Diam. de

Modèle

SPF20A 5,94

SPF25A 5,06 3 2

SPF25A 6,19 5 2

SPF30A

Orifice de

hp

5,82 5 2½

3 1½

Ø/Hz

1/60

1/60

1/60

1/60

Table 1

• Température maximale du liquide : 71 ºC (160 ºF)

• Démarrages par heure : 20, répartis uniformément

TUYAUTERIE

TUYAUTERIE

• On DOIT installer la pompe sur une surface plane, hori-

zontale et solide, l’orifice de refoulement en haut.

• Laisser sufsamment d’espace pour l’entretien et

l’aération. Protéger l’appareil contre les intempéries, les

inondations et le gel.

• An de réduire les pertes de charge (par frottement) au

minimum, maintenir la tuyauterie aussi courte que

possible, ne pas employer un calibre de tuyau inférieur

à celui des raccords d’aspiration et de refoulement

(v. table 1) ni utiliser d’accessoires ou de raccords de

tuyauterie superflus.

• La tuyauterie DOIT posséder ses propres supports et

N’appliquer AUCUNE contrainte sur la pompe.

AVIS : LA TUYAUTERIE DOIT ÉTRE POSÉE DE

FAÇON À NE PAS APPLIQUER DE

CONTRAINTES SUR LES RACCORDS

D’ASPIRATION ET DE REFOULEMENT

DE LA POMPE.

• L’emploi de ruban de TéonMC ou l’équivalent est recommandé pour TOUS les joints de tuyauterie.

• Chaque joint de tuyauterie DOIT être étanche.

ASPIRATION

• La hauteur d’aspiration ne devrait pas dépasser 7,6 m

(25 pi).

• Poser un raccord union étanche sur le tuyau d’aspiration,

près de la pompe (v. g.1).

ORIFICE

SECTIONNEUR À

FUSIBLES OU

DISJONCTEUR

D’AMORÇAGE

REFOULEMENT

RACCORDS UNIONS

ASPIRATION

Figure 1

• Il est recommandé de poser un clapet de pied à l’entrée

du tuyau d’aspiration ou un clapet de non-retour après

l’orifice de refoulement de la pompe.

19

AVIS : LES DEUX CLAPETS PRÉCITÉS SONT

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

ou la mort.

AVERTISSEMENT

Tension

dangereuse

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

ou la mort.

AVERTISSEMENT

Machinerie

dangereuse

ATTENTION

Les pressions élevées

peuvent causer des

blessures et des

dommages matériels.

RECOMMANDÉS QUAND LE TUYAU

D’ASPIRATION EST LONG.

• An de prévenir les poches d’air, aucun élément de la

• Lorsque le tuyau d’aspiration est long, le remplir d’eau

REFOULEMENT

• Poser au-dessus de l’orice de refoulement un té dont

CÂBLAGE ET MISE À LA TERRE

CÂBLAGE ET MISE À LA TERRE

• Suivre soigneusement le schéma de câblage sur la plaque

• N’utiliser que du l de cuivre pour la mise à la terre et

UTILISATION

UTILISATION

20

tuyauterie d’aspiration ne devrait être plus haut que le

raccord d’aspiration de la pompe, et les tronçons de

tuyauterie horizontaux devraient avoir une légère pente

ascendante vers la pompe.

avant de le raccorder à la pompe.

une branche sera orientée vers le haut pour permettre

l’amorçage initial de la pompe (v. g. 1).

Installer la pompe, la mettre à la

terre et la brancher suivant les

prescriptions du code provincial

ou national de l’électricité perti-

nent et les réglements locaux.

Poser un sectionneur tout conducteur près de la pompe.

Couper le courant avant de

procéder à l’installation ou à

l’entretien de la pompe.

L’alimentation électrique DOIT être conforme

aux spécications de la plaque signalétique du

moteur. Une tension inappropriée peut causer un

incendie ou des dommages au moteur et annule la

garantie.

Les moteurs sans protection intégrée DOIVENT

être munis de contacteurs et de dispositifs de

protection contre les surcharges thermiques

s’ils sont alimentés en monophasé, et s’ils

fonctionnent en triphasé, de démarreurs à

dispositif de protection contre la surcharge.

Consulter la plaque signalétique du moteur.

signalétique ou le cache-bornes du moteur.

l’alimentation du moteur. Le calibre du fil de terre DOIT

être au moins égal à celui des fils d’alimentation, et les fils

devraient tous être chromocodés pour faciliter l’entretien.

OMETTRE LA MISE À LA TERRE PERMANENTE DE LA POMPE, DU MOTEUR OU DES COMMANDES AVANT

LE BRANCHEMENT À LA SOURCE

DE COURANT PEUT CAUSER UN

CHOC ÉLECTRIQUE, DES BRÛLURES

OU LA MORT.

L’ÉCLABOUSSEMENT OU

L’IMMERSION DES MOTEURS

ABRITÉS (À OUVERTURES DE

VENTILATION PROTÉGÉES) PEUT

CAUSER UN INCENDIE, UN CHOC

ÉLECTRIQUE, DES BRÛLURES OU

LA MORT.

AVERTISSEMENT

L’UTILISATION D’UNE POMPE

DÉSAMORCÉE OU DONT LE

ROBINET DE REFOULEMENT

EST FERMÉ PEUT SURCHAUFFER

L’EAU QU'ELLE CONTIENT, LA

TRANSFORMER EN VAPEUR ET

Les hautes températures

peuvent causer des

blessures et des

dommages matériels.

CAUSER DES BLESSURES, DES

DOMMAGES MATÉRIELS OU UNE

EXPLOSION POUVANT ENTRAÎNER

DES BLESSURES GRAVES, VOIRE

MORTELLES, ET DES DOMMAGES

MATÉRIELS IMPORTANTS.

• Amorcer la pompe en la remplissant d’eau propre par

l’orice supérieur du té (v. g. 1).

• Recouvrir les lets du bouchon d’amorçage de ruban de

TéflonMC ou l’équivalent et visser le bouchon sur le té.

AVIS : SI LA POMPE SE VIDE OU S'ARRÊTE

PENDANT L’AMORÇAGE, ON DOIT LA

REMPLIR DE NOUVEAU AVANT DE LA

REMETTRE EN MARCHE.

• Mettre la pompe en marche et attendre que la pression se

stabilise. Des à-coups ou des chutes de pression prolongées

peuvent indiquer que l’amorçage est incomplet.

SENS DE ROTATION

SENS DE ROTATION

AVIS : LA ROTATION DANS LE MAUVAIS SENS

PEUT ENDOMMAGER LA POMPE ET

ANNULE LA GARANTIE.

• La rotation appropriée est en sens HORAIRE (vers la

droite), vue de l’extrémité du moteur.

• Tout moteur monophasé ayant plus de quatre (4) ls

(conducteurs) peut être du type réversible. On s’assurera

alors qu’il tourne dans le bon sens. Voir le schéma de

câblage sur la plaque signalétique du moteur.

• On peut vérier le sens de rotation de l’arbre des moteurs

triphasés en ôtant le couvercle ou l’obturateur situé à

l’extrémité du moteur. Pour inverser la rotation, intervertir

deux des trois conducteurs du moteur.

ENTRETIEN

ENTRETIEN

OMETTRE LE VERROUILLAGE

DE LA SOURCE DE COURANT

EN POSITION OUVERTE (HORS

CIRCUIT) AVANT D’EFFECTUER

L’ENTRETIEN PEUT ENTRAÎNER DES

BLESSURES GRAVES.

POUR PRÉVENIR LES BLESSURES

GRAVES ET LES DOMMAGES

MATÉRIELS IMPORTANTS, METTRE

LE SYSTÈME HORS PRESSION ET LE

VIDANGER AVANT D’EN EFFECTUER

L’ENTRETIEN.

• La pompe ne nécessite aucune lubrication. Quant au

moteur, consulter et suivre les directives du fabricant.

USAGE SAISONNIER

• Pour mettre la pompe HORS service, déposer tous les

bouchons de vidange et vider tous les tuyaux.

• Pour remettre la pompe EN service, reposer tous les

bouchons de vidange après en avoir recouvert les filets de

ruban de TéflonMC ou l’équivalent.

• Raccorder le tuyau d’aspiration à la pompe s’il a été

désaccouplé, examiner le raccord union et effectuer les

réparations nécessaires.

• Réamorcer et utiliser la pompe suivant les directives et les

avertissements de la section UTILISATION ci-dessus.

DÉMONTAGE

DÉMONTAGE

• Suivre CHAQUE directive et avertissement de la section

ENTRETIEN du présent manuel.

1. Enlever les boulons d’ancrage du moteur.

2. Ôter les vis de xation (16) de la bride d’aspiration (17).

3. Déposer la bride d’aspiration.

4. Enlever le clapet de non-retour (15).

5. Ôter les vis de xation (12) du corps de pompe (1)

à l’adaptateur de moteur (11).

6. Écarter l’ensemble d’entraînement de la roue d’avec le

corps de pompe.

7. Déposer le diffuseur (4) et en jeter l’anneau

d’étanchéité (3).

8. Bloquer la roue avec un tournevis inséré dans l’une de

ses sorties, puis enlever et jeter la vis de roue (6) et sa

rondelle (7).

9. Déposer la roue (8) et sa clavette (14). Si la roue est

grippée, la décoincer DÉLICATEMENT au moyen

de deux leviers insérés l’un en face de l’autre entre

l’adaptateur de moteur et la roue.

10. Ôter les vis (12) xant l’adaptateur de moteur au mo-

teur. Enlever l’adaptateur et la garniture mécanique (9).

11. Pousser l’élément xe de la garniture mécanique hors de

l’adaptateur. Jeter l’élément.

12. Inspecter la chemise d’arbre (13). Si elle est endomma-

gée, très éraflée, etc., la chauffer au chalumeau, la retirer

et la jeter.

AVIS : MANIPULER LA CHEMISE D’ARBRE AVEC

PRÉCAUTION QUAND ELLE EST CHAUDE.

REMONTAGE

REMONTAGE

• Chaque pièce devrait être nettoyée avant le remontage.

• Pour commander une pièce, utiliser la description de la

pièce dans la liste de pièces ainsi que le numéro d’article

(catalogue) de la pompe.

1. Inspecter l’arbre et en enlever les résidus et les aspérités.

2. Avant de poser une nouvelle chemise d’arbre, en

enduire la face intérieure d’apprêt (« primer ») N de

LOCQUICMD ou l’équivalent. Laisser l’apprêt sécher, le

recouvrir de LOCTITEMD no 262, puis enler la

chemise sur l’arbre dans un mouvement de rotation et

essuyer l’arbre. Laisser le produit durcir selon les

directives du fabricant.

AVIS : ON DOIT REMPLACER LA GARNITURE

MÉCANIQUE CHAQUE FOIS QU’ON

L’ENLÈVE. SUIVRE LES DIRECTIVES DU

FABRICANT DE LA GARNITURE AVEC

SOIN.

3. Au besoin, mouiller ou glycériner l’élément xe de la

garniture mécanique pour en faciliter la pose. NE PAS

le salir. Le pousser à fond et à angle droit dans son

siège, sur l’adaptateur. Puis, avec un linge propre,

nettoyer SOIGNEUSEMENT le siège. NE PAS

l’endommager.

4. Poser l’adaptateur en veillant à y insérer l’arbre de

moteur avec soin pour ne pas déloger ni endommager

l’élément xe ni en abîmer le siège.

5. Enfiler l’élément mobile de la garniture sur l’arbre et le

pousser à fond et à angle droit contre l’élément xe.

S’assurer que l’élément mobile est bien maintenu en

place par son collet de retenue. NE PAS endommager

la garniture mécanique.

6. Insérer la clavette dans sa rainure, puis poser la roue et

la pousser à fond.

7. Mettre une rondelle de roue neuve.

8. Bloquer la roue avec un tournevis introduit dans l’une

de ses sorties, puis assujettir la roue avec une vis de roue

neuve, serrée à 27 N·m (20 lbf·pi).

9. Débarrasser la roue de toute aspérité due au tournevis.

10. Enlever et remplacer le joint torique (10) de l’adaptateur

de moteur. Enduire le joint neuf de lubrifiant à joints

Parker ou l’équivalent.

11. Poser le diffuseur sur l’adaptateur de moteur, la plaque

d’appui du diffuseur en haut.

12. Placer l’anneau d’étanchéité du diffuseur sur

l’embouchure usinée de celui-ci et pousser l’anneau à

fond.

13. Enfiler le corps de pompe sur l’ensemble d’entraînement

de la roue tout en s’assurant que l’anneau d’étanchéité

reste en place, puis serrer les vis de xation du corps de

pompe en croix et uniformément à 50 N·m (37 lbf·pi).

14. Faire tourner l’arbre de moteur pour s’assurer qu’il n’est

pas grippé. S’il l’est, desserrer les vis retenant le corps de

pompe et déplacer le diffuseur jusqu’à ce que la roue

tourne sans frotter, puis resserrer les vis au

couple indiqué.

15. Insérer les vis de la bride d’aspiration dans leur trou,

enler le clapet de non-retour (le remplacer s’il est

endommagé) sur les vis, le côté en caoutchouc du clapet

contre l’orice oblique de la bride, puis assujettir la bride

au corps de pompe avec précaution.

16. Reposer les boulons d’ancrage du moteur.

17. Une fois le remontage terminé, s’assurer que l’arbre

tourne librement.

18. Reposer chaque bouchon de vidange après en avoir

recouvert les filets avec du ruban de téflon.

19. Réamorcer la pompe selon les directives de la section

UTILISATION ci-dessus.

21

LISTE DE PIÈCES DE RECHANGE

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

ou la mort.

LISTE DE PIÈCES DE RECHANGE DIAGNOSTIC DES ANOMALIES

Pièce Description Matériau Quantité

Corps de pompe — orifices de 1½ po, NPT

1 Corps de pompe — orifices de 2 po, NPT Fonte 1

Corps de pompe — orifices de 2½ po, NPT

Corps de pompe 2

3 Anneau d’étanchéité du diffuseur Buna 1

4 Diffuseur — hauteur de charge élevée

Diffuseur — hauteur de charge moyenne

5 Bague d’usure du corps de pompe Bronze* 1

6 Vis de roue 1

7 Rondelle de roue 1

8 3 hp

3 hp

9 Garniture mécanique ** 1

10 Joint torique Buna-N 1

11 Adaptateur de moteur (140 ou 180FR) Fonte 1

12 Corps de pompe

Moteur 4

13 Chemise d’arbre

14 Clavette — à bouts carrés

15 Clapet de non-retour Buna-inox 1

hex. 0,31-18 UNC-0,75 zingué

1 po, NPT

17 Bride d’aspiration 2½ po, NPT Fonte 1

3 po, NPT

* Sans plomb.

** Communiquer avec l’usine.

Bride d’aspir. 1

Bouchon de tuyau

2

de ¼ po, NPT

Roue — hauteur de charge élevée

Roue — hauteur de charge moyenne

Vis d’assemblage à tête

hex. 0,38-16 UNC-0,88

Vis d’assemblage à tête Acier

16

5 hp

5 hp

Acier

zingué

Fonte

Inox

AISI 300

Laiton-

silicium*

Acier

zingué

Inox

1

AISI 300

1

1

8

4

DIAGNOSTIC DES ANOMALIES

OMETTRE DE COUPER LE

COURANT AVANT D’EFFECTUER

L’ENTRETIEN PEUT SE TRADUIRE

PAR UN CHOC ÉLECTRIQUE, DES

BRÛLURES OU LA MORT.

ANOMALIES

Le moteur ne fonctionne pas.

(V. causes probables 1 à 5)

Le débit de refoulement est faible ou nul.

(V. causes probables 3, 4, 6 à 12, 15 et 16)

La vibration et le bruit sont excessifs.

(V. causes probables 3, 6, 7, 10 et 12 à 14)

CAUSES PROBABLES

1. Protecteur thermique du moteur déclenché

2. Disjoncteur ouvert ou fusible sauté

3. Roue grippée

4. Moteur mal connecté

5. Moteur défectueux

6. Pompe non amorcée, air ou gaz présent dans le

liquide pompé

7. Tuyau d’aspiration ou de refoulement obstrué ou

robinet(s) fermé(s)

8. Mauvais sens de rotation

9. Basse tension électrique ou perte de phase

10. Roue usée ou engorgée

11. Hauteur de charge du système trop élevée

12. Hauteur nette d’aspiration disponible (NPSHA) trop

faible — hauteur ou perte d’aspiration excessives

13. Hauteur de refoulement trop faible — débit excessif

14. Pompe, moteur ou tuyauterie mal assujettis

15. Entrée du tuyau d’aspiration non immergée

16. Clapet de non-retour endommagé

2 1

22

2

17

16

15 3 4 5 7 14 8 96 10 11 12 12 13

2

Declaration of Conformity

Declaration of Conformity

We at,

Red Jacket Water Products/Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

Declare that the following products: NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line

SP, HB, HMS, LC, NPV, LB, LBS comply with Machine Directive 06/42/EC. This equipment is intended

to be incorporated with machinery covered by this directive, but must not be put into service until the

machinery into which it is to be incorporated has been declared in conformity with the actual provisions

of the directive.

Declaración de Conformidad

Declaración de Conformidad

Nosotros en

Red Jacket Water Products/Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

Declaramos que los siguientes productos: NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime

Line SP, HB, HMS, LC, NPV, LB, LBS cumplen con las Directivas para Maquinarias 06/42/EC. Este

equipo ha sido diseñado para ser incorporado a la maquinaria cubierta por esta directiva pero no debe

ponerse en funcionamiento hasta que se declare que la maquinaria en la que será incorporado cumple

con las disposiciones reales de la directiva.

Déclaration de Conformité

Déclaration de Conformité

Nous, à

Red Jacket Water Products/Xylem Inc.

1 Goulds Drive

Auburn, NY, U.S.A. 13021,

déclarons que les produits NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line SP, HB,

HMS, LC, NPV, LB et LBS sont conformes à la directive 06/42/EC (législation relative aux machines). Ils

sont destinés à être intégrés dans la machinerie faisant l’objet de ladite directive, mais ne doivent pas être

mis en service tant que la machinerie en question ne sera pas déclarée conforme aux stipulations de la

directive.

23

GARANTIE LIMITÉE DE RED JACKET WATER PRODUCTS

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Red Jacket Water Products.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant la première : douze (12)

mois à compter de la date d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Red Jacket Water Products agréé

chez lequel la pompe a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du

service à la clientèle de Red Jacket Water Products.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ni de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux ns de la présente garantie, les termes ci-dessous sont dénis comme suit :

1) « Distributeur » signie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant

d’intermédiaire entre Red Jacket Water Products et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) « Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités

commerciales sont la vente ou la location de pompes à des clients.

3) « Client » signie une entité qui achète ou loue les pompes en question chez un détaillant. Le « client » peut être une personne, une société de personnes, une société de capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (866) 325-4210

Télécopie: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products est une marque déposée de Xylem Inc. ou d'une de ses filiales.

© 2012, Xylem Inc. IM188 Révision numéro 1 Juillet 2012

Loading...

Loading...