IQ SENSOR NET

FDO® 700 IQ

FDO

®

701 IQ

FDO

®

700 IQ

FDO

®

701 IQ SW

®

FDO

70x IQ (SW)

Operating manual

ba76014e01 02/2012

Optical IQ S

ENSOR NET D.O. sensors

FDO®70x IQ (SW)

Note

For the most recent version of the manual, please visit www.ysi.com

.

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2012 Xylem Inc.

2

ba76014e01 02/2012

FDO®70x IQ (SW) Contents

FDO®70x IQ (SW) - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 How to use this component operating manual . . . . . . . . 1-1

1.2 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Recommended fields of application . . . . . . . . . . . . . . . . 1-3

1.4 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 2-2

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Commissioning / Getting the instrument ready for

measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4 FDO

®

70x IQ (SW) setting table . . . . . . . . . . . . . . . . . . 3-4

4 Measuring / Operation . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Function check and user calibration . . . . . . . . . . . . . . . . 4-1

4.2.1 General information . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.2 Function check . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.3 User calibration . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.4 Calibration history . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.5 Reactivating previous calibration data . . . . . . . 4-7

5 Maintenance, cleaning, replacement parts . . . . . . . . 5-1

5.1 General maintenance instructions . . . . . . . . . . . . . . . . . 5-1

5.2 Handling of the sensor cap . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Exchanging the sensor cap . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 Cleaning the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.4.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.4.2 Interior cleaning of sensor cap and sensor

head . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.5 Replacement parts and accessories . . . . . . . . . . . . . . . 5-5

6 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

ba76014e01 02/2012

0 - 1

Contents FDO®70x IQ (SW)

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 General measurement characteristics . . . . . . . . . . . . . .7-1

7.2 Application conditions . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.3 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.5 Technical data of the SC-FDO

7.6 Technical data of the SC-FDO

®

700 . . . . . . . . . . . . . . . .7-4

®

701 . . . . . . . . . . . . . . . .7-5

8 Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Ordering & Technical Support . . . . . . . . . . . . . . . . . . . .8-1

8.2 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

9 Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Explanation of the messages . . . . . . . . . . . . . . . . . . . . .9-1

9.1.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.1.2 Info messages . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.2 Status info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

0 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Overview

IQ Sensor Net Operating Manual

System

Operating

Manual

(Ring Binder)

IQ Sensor

Operating

Manual

MIQ Module

Operating

Manual

MIQ Terminal

Operating

Manual

Component Operating Manuals

1Overview

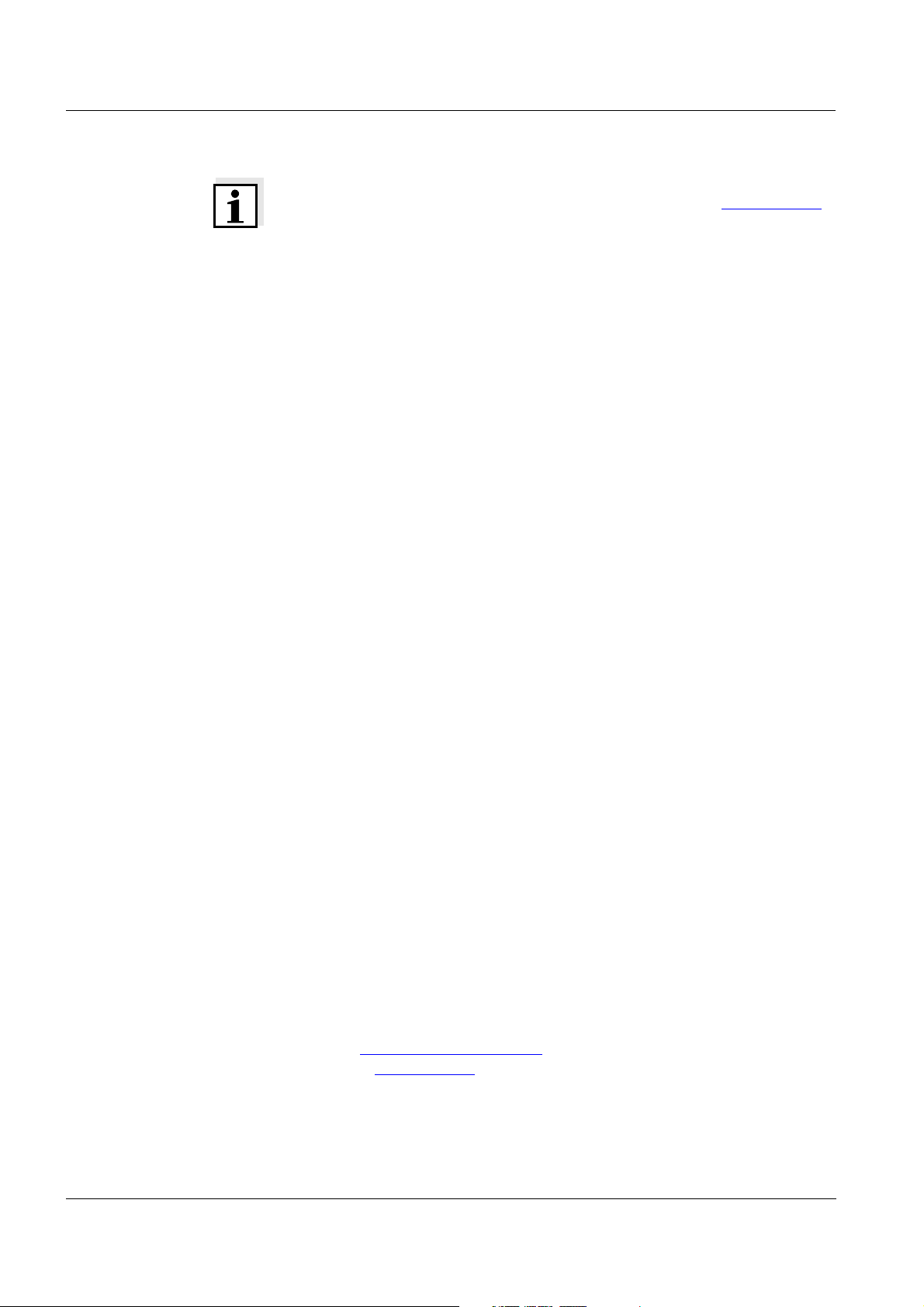

1.1 How to use this component operating manual

Structure of the

ENSOR NET

IQ S

operating manual

ba76014e01 02/2012

Fig. 1-1 Structure of the IQ SENSOR NET operating manual

The IQ SENSOR NET operating manual has a modular structure like the

IQ S

ENSOR NET system itself. It consists of a system operating manual

and the operating manuals of all the components used.

Please file this component operating manual into the ring binder of the

system operating manual.

1 - 1

Overview FDO®70x IQ (SW)

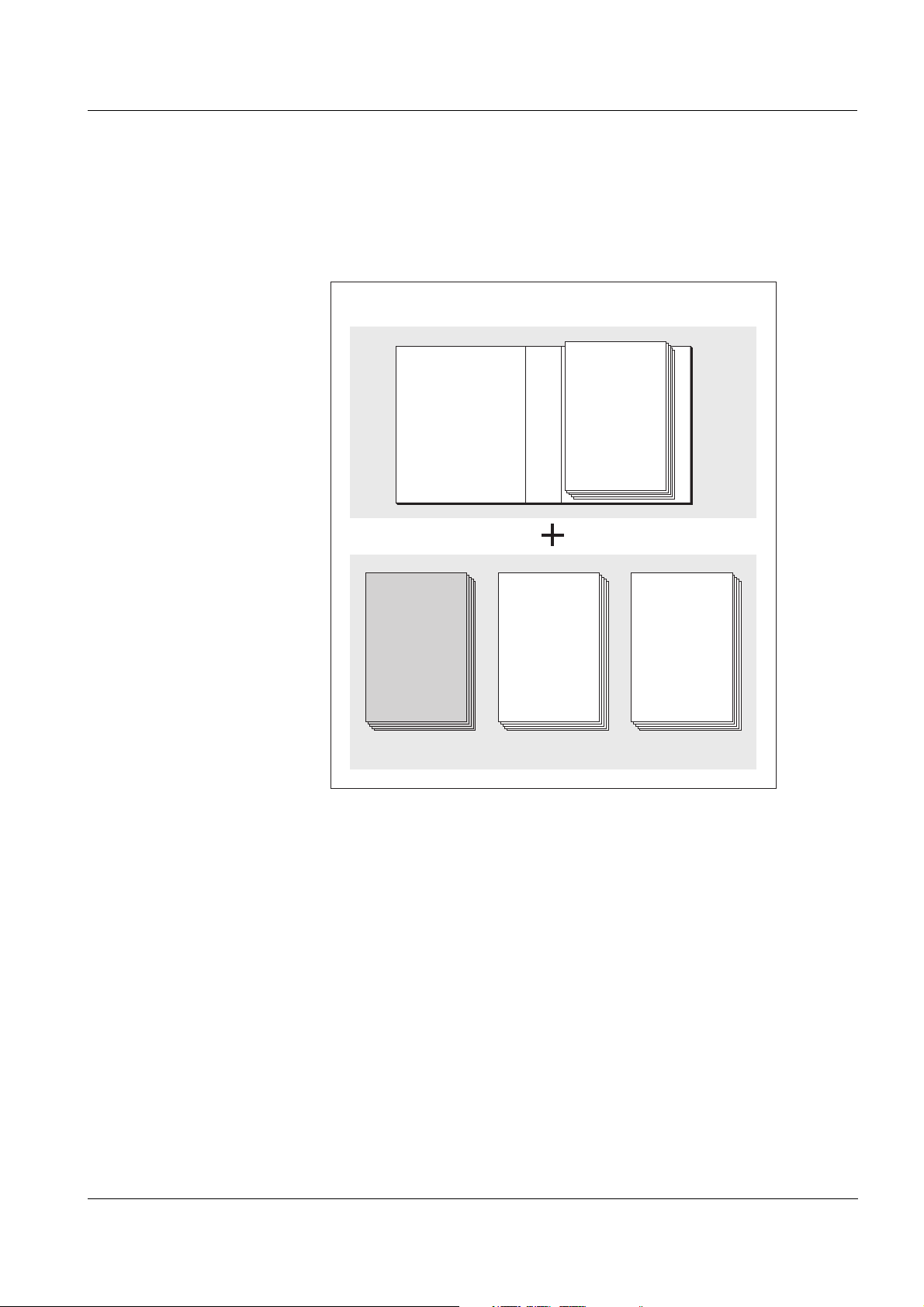

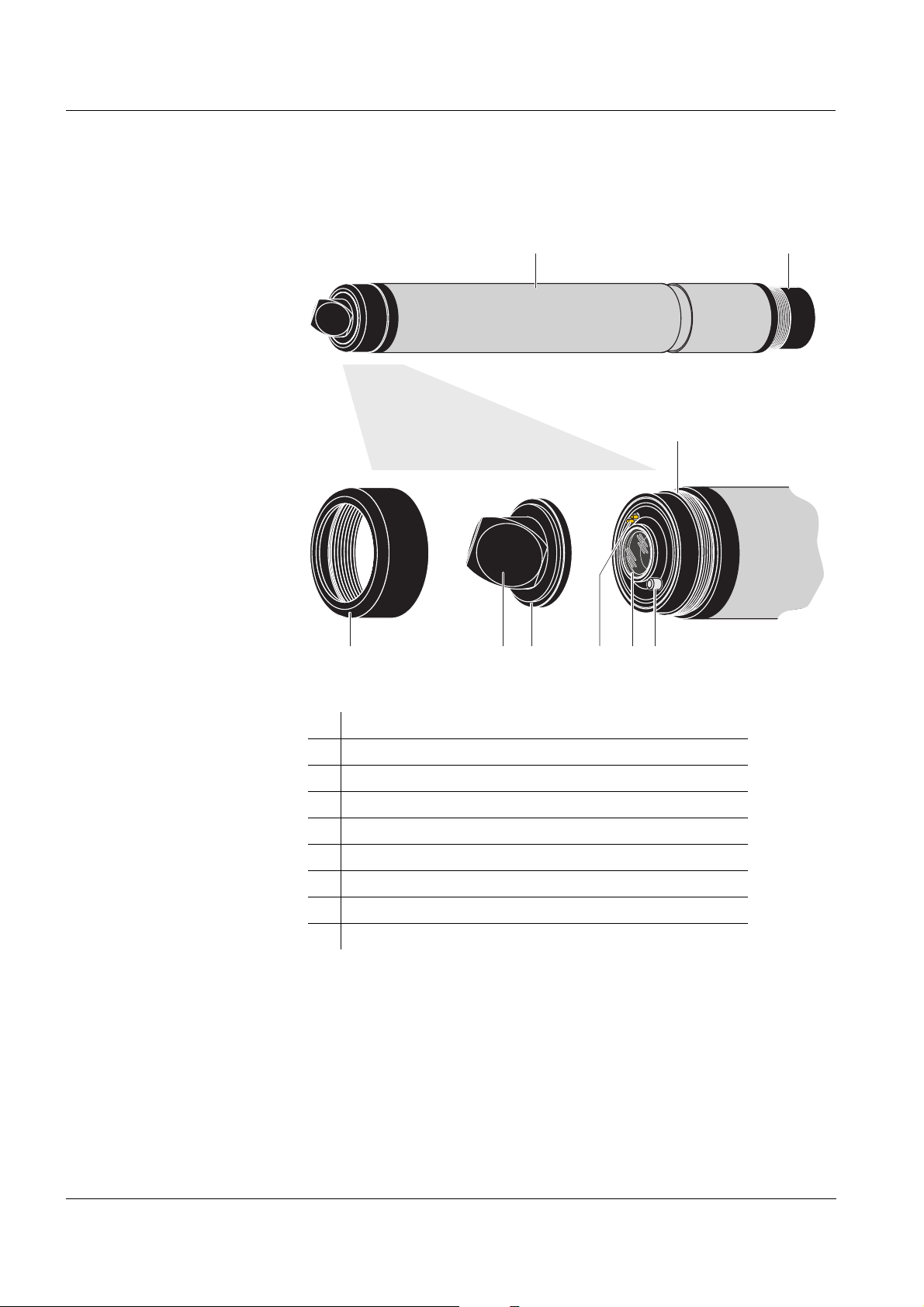

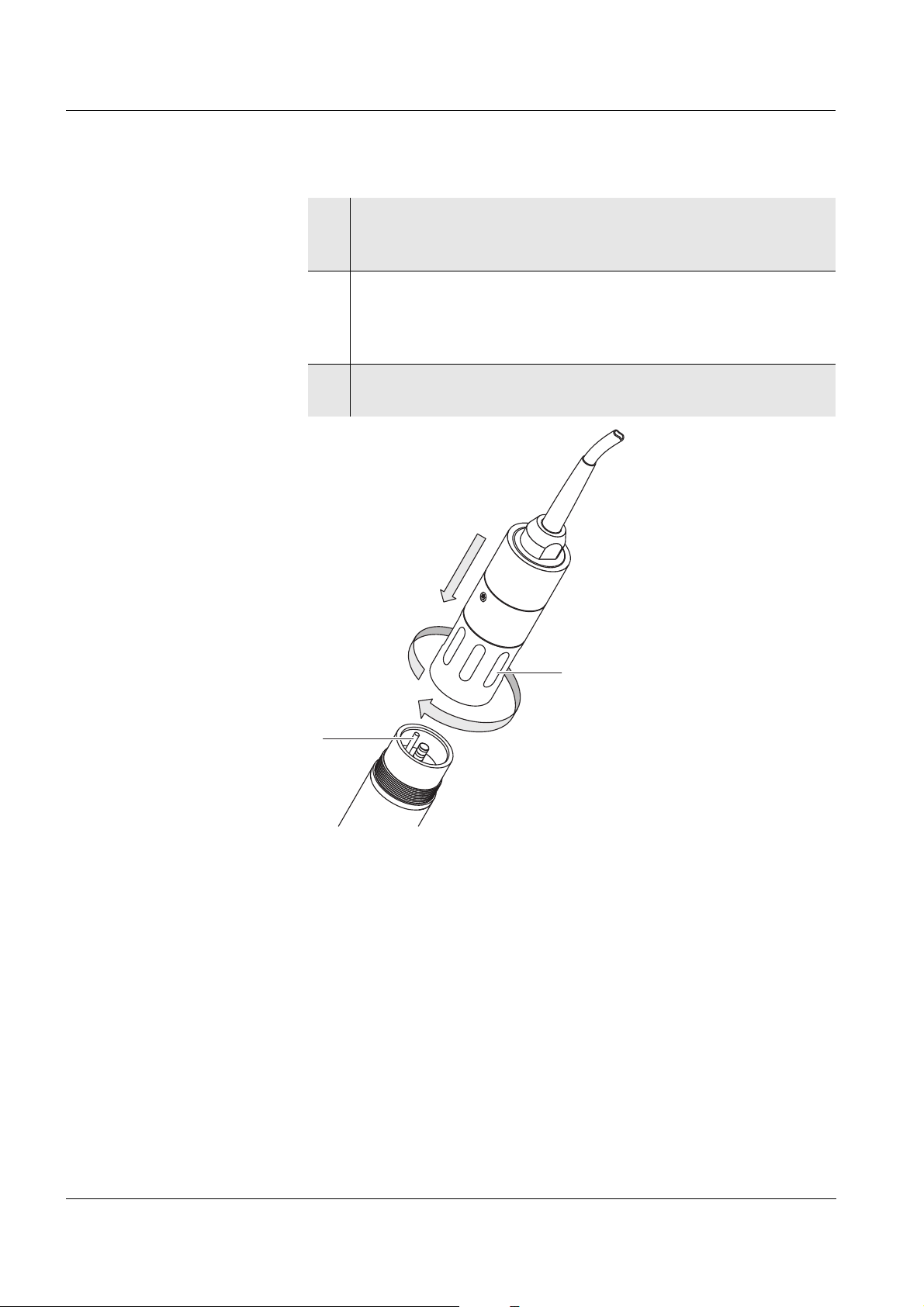

FDO 700 IQ

®

SC-FDO 700

®

SC-FDO 701

®

Sensor basis

Sensor basis

Sensor cap:

FDO 700 IQ SW

®

1.2 Models

The FDO®70x IQ (SW) consists of a sensor basis equipped with different sensor cap types, depending on the model:

Models

Sensor model Sensor basis * Sensor cap

®

FDO

FDO

FDO

FDO

700 IQ FDO® 700 IQ SC-FDO®700

®

700 IQ SW FDO® 700 IQ SW SC-FDO®700

®

701 IQ FDO® 700 IQ SC-FDO®701

®

701 IQ SW FDO® 700 IQ SW SC-FDO®701

* Designation on the name plate in the plug head connector

The sensor cap primarily determines the measuring characteristics of

the sensor as a whole. Thus the sensor can be adapted to the measuring job by exchanging the type of sensor cap. The specifications of the

individual sensor cap types are given in chapter 7 T

ECHNICAL DATA.

SW models Compared to the standard models, the sea water models of the sen-

sors (SW models) are optimized concerning their resistance to corrosion in sea water and brackish water.

1 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Overview

1.3 Recommended fields of application

Sensor model Recommended field of application.

FDO

FDO

FDO

FDO

®

700 IQ

®

701 IQ

®

700 IQ SW

®

701 IQ SW

Stationary measurements in water/wastewater applications.

Stationary measurements in seawater,

aquaculture.

®

The FDO

70x IQ SW is equipped with a

protective hood that is prepared for the connection of the MSK FDO

®

CS cleaning set

for compressed air-driven sensor cleaning

(order information, see section

5.5 R

EPLACEMENT PARTS AND ACCESSORIES).

ba76014e01 02/2012

1 - 3

Overview FDO®70x IQ (SW)

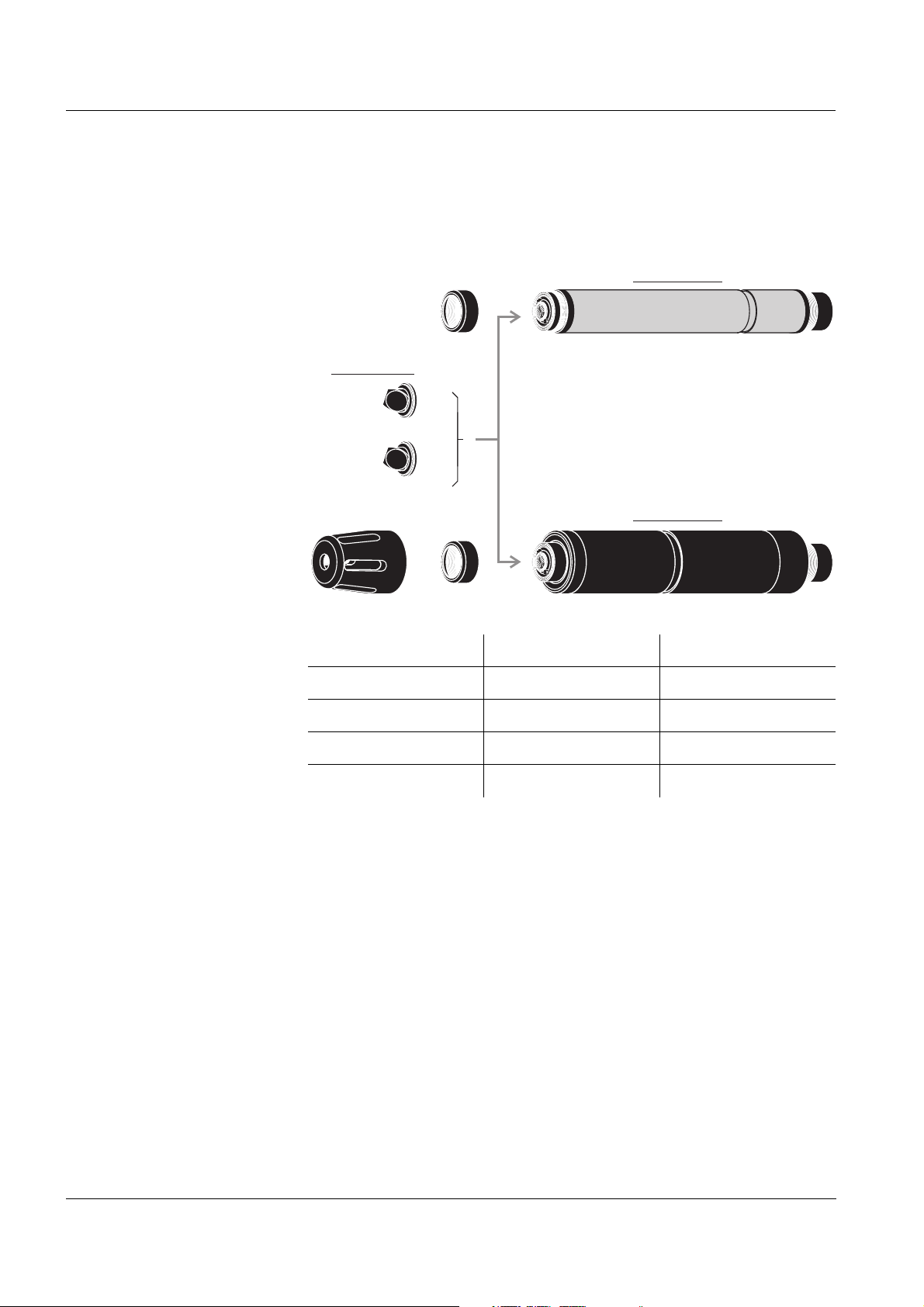

67

8453

9

12

1.4 Structure

Structure

Sensor cap with

memory chip

Intelligent membrane

(IQMC technology)

Fig. 1-2 Structure of the D. O. sensor (example: FDO® 70x IQ)

1 Shaft

2 Plug head connector

3 Fixing ring

4 Sensor membrane

5 Sensor cap with memory chip

6 Gold-plated contact pins for memory chip

7 Measurement window

8 Temperature sensor and locking device

9 Sensor head

A memory chip is integrated in the sensor cap. The following data is

stored on the memory chip:

Type designation of the sensor cap

Series number

Data of the factory calibration

For each membrane the individual calibration values are determined by

a factory calibration and stored on the memory chip of the sensor cap,

ensuring maximum accuracy over the whole lifetime of the sensor.

1 - 4

ba76014e01 02/2012

FDO®70x IQ (SW) Safety

2 Safety

General safety

instructions

This component operating manual contains special instructions that

®

must be followed during the operation of the FDO

70x IQ (SW) D.O.

sensor. Thus, it is essential to read this component operating manual

before carrying out any work using this sensor. In addition to this manual, the S

AFETY chapter of the IQ SENSOR NET system operating man-

ual must be followed.

Always keep this component operating manual together with the system operating manual and any other component operating manuals in

the vicinity of the IQ S

ENSOR NET system.

Safety instructions in this operating manual are indicated by the warning symbol (triangle) in the left column. The signal word (e.g. "CAUTION") indicates the danger level:

WARNING

indicates instructions that must be followed precisely in order to

prevent serious dangers to personnel.

CAUTION

indicates instructions that must be followed precisely in order to

avoid slight injuries to personnel or damage to the instrument or

the environment.

Other labels

Note

indicates notes that draw your attention to special features.

Note

indicates cross references to other documents, e. g. operating manuals.

ba76014e01 02/2012

2 - 1

Safety FDO®70x IQ (SW)

2.1 Authorized use

The authorized use of the FDO®70x IQ (SW) comprises its use as a

D.O. sensor in the IQ S

The technical specifications according to chapter 7 T

ENSOR NET.

ECHNICAL DATA

must be observed. Only operation according to the instructions in this

operating manual is authorized.

Any other use is considered to be unauthorized. Unauthorized use

invalidates any claims with regard to the guarantee.

CAUTION

Only connect and operate the sensor together with IQ SENSOR NET

accessories.

2.2 General safety instructions

Function and

operational safety

The sensor left the factory in a safe and secure technical condition.

The failure-free function and operational safety of the sensor is only

guaranteed if the generally applicable safety measures and the special

safety instructions in this operating manual are followed during its use.

The failure-free function and operational safety of the sensor is only

guaranteed under the environmental conditions that are specified in

chapter 7 T

The specified temperature (chapter 7 T

ECHNICAL DATA.

ECHNICAL DATA) must be main-

tained during the operation and transport of the sensor. Protect the

sensor, particularly against frost or overheating.

CAUTION

The sensor may only be opened by specialists authorized by YSI.

The only exceptions to this are the activities described in chapter

5 M

AINTENANCE, CLEANING, REPLACEMENT PARTS.

2 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Safety

Safe operation If safe operation is no longer possible, the sensor must be taken out of

operation and secured against inadvertent operation.

Safe operation is no longer possible if the sensor:

has been damaged in transport

has been stored under adverse conditions for a lengthy period of

time

is visibly damaged

no longer operates as described in this manual.

If you are in any doubt, contact the supplier of your sensor.

Obligations of the

operator

The operator of the sensor must ensure that the following rules and regulations are followed when dealing with hazardous substances:

EC directives for protective labor legislation

National protective labor legislation

Safety regulations

Safety data sheets of the chemical manufacturer.

ba76014e01 02/2012

2 - 3

Safety FDO®70x IQ (SW)

2 - 4

ba76014e01 02/2012

FDO®70x IQ (SW) Commissioning

3 Commissioning

3.1 Scope of delivery

Sensor, consisting of sensor basis and sensor cap

Operating manual.

3.2 Installation

Connection cable A sensor connection cable of the SACIQ or SACIQ SW type is required

to connect the sensor. The cable is available in different lengths. Compared to the standard model SACIQ, the SACIQ SW sensor connection

cable is optimized regarding its corrosion resistance in seawater and

brackish water and adapted for use in conjunction with the FDO 70x

IQ SW. Information on this and other IQ S

given in the YSI catalog and on the Internet.

ENSOR NET accessories is

Are the plug

connections dry?

Note

How to connect the SACIQ (SW) sensor connection cable to the terminal strip of an MIQ module is described in chapter 3 I

ENSOR NET system operating manual.

IQ S

NSTALLATION of the

Before connecting the sensor and sensor connection cable, please

make sure the plug connections are dry. If moisture gets into the plug

connections, first dry the plug connections (dab them dry or blow them

dry using compressed air).

Note

Do not suspend the sensor on the sensor connection cable. Use a sensor holder or armature. Information on this and other IQ S

ENSOR NET

accessories is given in the YSI catalog and on the Internet.

ba76014e01 02/2012

3 - 1

Commissioning FDO®70x IQ (SW)

SACIQ

1

2

Connecting the sensor

to the sensor

connection cable

1 Take the protective caps off the plug connections of the sensor

and the SACIQ (SW) sensor connection cable and keep them

safe.

2 Plug the jack of the SACIQ (SW) sensor connection cable onto

the plug head connector of the sensor. At the same time, rotate

the socket so that the pin in the plug head connector (1) clicks

into one of the two holes in the socket.

3 Then screw the coupling ring (2) of the sensor connection

cable onto the sensor up to the stop.

Fig. 3-1 Connecting the sensor

3 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Commissioning

3.3 Commissioning / Getting the instrument ready for

measuring

Identification in the

ENSOR NET

IQ S

Commissioning steps

Both the sensor cap and sensor basis (sensor without cap) have a

series number of their own. The sensor has to be equipped with a sensor cap for a successful login to the IQ S

ENSOR NET. The operable sen-

sor is displayed as follows in the list of sensors:

Model: Model designation of the sensor cap

(="SC FDO 70x")

Ser. no.: Series number of the sensor cap

Sensor name: The series number of the sensor basis is preset

here. You can change this entry as necessary by

entering a user-defined name.

1 Pull the protective cap off the sensor.

2 If required, assign a user-defined name to the sensor (see rel-

evant IQ S

ENSOR NET system operating manual).

3 When using IQ SENSOR NET without automatic air

pressure compensation the mean air pressure value or the

location altitude has to be entered (for more detailed information see the relevant IQ S

ENSOR NET system operating man-

ual).

4 Set the sensor (see section 3.4).

ba76014e01 02/2012

3 - 3

Commissioning FDO®70x IQ (SW)

3.4 FDO®70x IQ (SW) setting table

Setting Selection/values Explanation

Measuring mode Concentration

Saturation

Measuring range

Concentration

Measuring range

0 ... 20.00 mg/l

0 ... 20.00 ppm

0 ... 200.0 % The measuring range is set permanently.

Saturation

Response time t90

150 .. 300 s

(with SC-FDO

®

or

60 ... 300 s

(with SC-FDO

®

Calibration Factory

calibration

User calibration

active

abort

700)

701)

Unit of the measured value on the measured

value display.

These measuring ranges are available for

selection.

Response time of the signal filter.

Depending on the sample matrix, the measured values may fluctuate more or less.

A signal filter in the sensor reduces the fluctuation range of the measured value. The

signal filter is characterized by the Response

time t90. This is the time after

which 90 % of a signal change is displayed.

The setting range depends on the sensor

cap type.

Determines which calibration data the measured value calculation will be based on. The

active calibration is displayed in the calibration history.

The selection, User calibration is only displayed if valid data of a User calibration is

stored in the sensor.

3 - 4

active

abort

Test

Temperature mode °C

°F

active indicates that the sensor is being cali-

brated.

If abort is selected, the active calibration is

canceled the next time the setting table is

quit with Save and quit.

active indicates that the sensor is being

checked.

If abort is selected, the active check is canceled the next time the setting table is quit

with Save and quit.

Unit of the measured temperature value

(Celsius, Fahrenheit).

ba76014e01 02/2012

FDO®70x IQ (SW) Commissioning

Setting Selection/values Explanation

Temp. adjustment -1.5 K ... +1.5 K The temperature compensation enables the

temperature display to be balanced (shifting

of the zero point by ±1.5K).

Notes:

Due to the thermal capacity of the sensor,

it is necessary to place it in a container

with at least 2 liters of water.

Leave the sensor in this container for at

least 15 minutes while stirring

occasionally until the balancing can be

performed.

With temperature differences between the

water and sensor > 10 °C, leave the

sensor for at least 1 hour in this container

while stirring occasionally until the

balancing can be performed.

Salinity On

Off

Determines whether the entered salinity

should be taken into account.

Salinity input 2.0 ... 70.0 The entry of the salinity enables a salt con-

tent correction that compensates for the

effect of salt contents > 0.1 % on the oxygen

measurement.

The salt content correction is recommended

for measurements in salt-contaminated

wastewater (salinity ≥ 2.0 corresponding to a

conductivity of ≥ 3.4 mS/cm at a reference

Sensor cap data Do not download

Transmit to log

book

temperature

Generates a log book message with all data

stored in the sensor cap when the settings

are quit with Save and quit (see section 1.2).

When opening the menu again the setting is

T

REF

= 20 °C).

reset to Do not download.

Save and quit The system confirms the saving of the set-

tings and the display switches to the next

higher level.

Quit The display switches to the next higher level

without saving the new settings.

Carrying out settings Using s, switch from the measured value display to the main menu of

the settings. Then navigate to the setting menu (setting table) of the

sensor. The exact procedure is given in the relevant IQ S

ENSOR NET

system operating manual.

ba76014e01 02/2012

3 - 5

Commissioning FDO®70x IQ (SW)

3 - 6

ba76014e01 02/2012

FDO®70x IQ (SW) Measuring / Operation

4 Measuring / Operation

4.1 Measuring

WARNING

Contact with the sample can be dangerous for the user!

Depending on the type of sample, suitable protective measures

must be taken (protective clothing, protective goggles, etc.).

Factory calibration The FDO

When does a function

check or user calibration

make sense?

Note the data given in section 7.2 A

PPLICATION CONDITIONS, especially

the minimum immersion depth of the sensor (> 50 mm). The measured

value is available immediately on submersing.

Note

If keeping the sensor clean is a problem, we recommend using the

compressed air-driven cleaning system with the CH cleaning head (see

section 5.5 R

EPLACEMENT PARTS AND ACCESSORIES).

4.2 Function check and user calibration

4.2.1 General information

®

70x IQ (SW) is factory calibrated. In the recommended

application (see section 1.3 R

measuring characteristics of the sensor cap remain stable for the specified service life. Thus, a user calibration is not usually required.

A function check or user calibration can be useful in the following special cases:

If the measured values appear to be implausible and it is assumed

that the service life of the sensor cap is over

ECOMMENDED FIELDS OF APPLICATION), the

Check or calibration

medium

ba76014e01 02/2012

Routinely within the framework of the company quality assurance.

Select one of the following two variants depending on the air temperature at the calibration site:

With air temperatures over 5 °C, the function check and user calibra-

tion ideally take place in water vapor-saturated air. To do so, position the sensor approx. 2 cm above a water surface, for example in

a narrow bucket or similar container with water. The membrane

must be clean and dry for this.

4 - 1

Measuring / Operation FDO®70x IQ (SW)

2cm

With air temperatures under 5 °C we recommend performing the

function check and user calibration not in air but in air-saturated

water that has a higher temperature. You obtain air-saturated water

by pouring water several times in and out of two vessels so that it

sparkles.

4.2.2 Function check

A function check is the simplest way to determine whether the sensor

needs to be cleaned or user-calibrated.

Principle The function check can either be done in water vapor-saturated

air or in air-saturated water (see C

HECK OR CALIBRATION MEDIUM on

page 4-1).

Steps Generally, a check on the IQ S

tem specific details are given in the respective IQ S

ENSOR NET is carried out as follows. Sys-

ENSOR NET system

operating manual.

1 Switch to the measured value display with m and select the

®

FDO

2Press

70x IQ (SW) sensor.

c.

The next step switches on the maintenance condition for the

sensor. A corresponding message appears on the display.

3 Confirm the note with g.

The maintenance condition is active.

4 Select the TEST procedure and press

g.

4 - 2

5 Put the sensor into the calibration position (water vapor-satu-

rated air or air-saturated water - see section 4.2.1).

ba76014e01 02/2012

FDO®70x IQ (SW) Measuring / Operation

6Press

The sensor starts the check. The display switches to the measured value display. The CAL indicator flashes instead of the

main measured value. At the same time, the momentary relative slope flashes as the secondary measured value with the

addition of TEST. The process ends automatically as soon as

the measured values meet the criterion for the stability control.

With a great temperature difference between the sensor and

the environment this may take a while. Subsequently, the main

measured value and temperature are displayed.

7 Put the sensor in the measuring position again.

8 Wait for the measured value to be largely stable (temperature

adjustment).

9 Switch off the maintenance condition.

Canceling the check As long as the determination of the relative slope has not yet been

started (step 6), you can quit the check with

The running determination of the relative slope (after pressing

step 6) can be aborted as follows:

g.

m or e.

g in

1 Open the setting table (see section 3.4).

2 In the Test menu item, select the abort setting and then quit the

setting table with Save and quit.

Evaluation The result of the check is entered in the log book of the sensor. If the

relative slope is outside the tolerance range (0.90 ... 1.10), the check is

assessed as erroneous.

Note

The information recorded in the log book entry is partly identical with

that of the calibration history. The calibration history is described in

detail in section 4.2.4 CALIBRATION HISTORY.

ba76014e01 02/2012

4 - 3

Measuring / Operation FDO®70x IQ (SW)

4.2.3 User calibration

Principle The user calibration can either be done in water vapor-saturated

air or in air-saturated water (see C

HECK OR CALIBRATION MEDIUM on

page 4-1). With the calibration procedure, the relative slope of the sensor is determined. The calibration is evaluated based on the relative

slope and the intensity (successful <-> unsuccessful).

The result of the user calibration is stored in the calibration record and

calibration history respectively and can be viewed afterwards (see

respective IQ S

ENSOR NET system operating manual).

Note

We want to point out that the factory calibration of the membrane is

highly precise due to the IQMC technology. If you still want to carry out

a user calibration, influences due to environmental conditions have to

be taken into account.

Steps Generally, a user calibration on the IQ S

lows. System specific details are given in the respective

IQ S

ENSOR NET system operating manual.

1 Switch to the measured value display with m and select the

®

FDO

2Press

70x IQ (SW) sensor.

c.

The next step switches on the maintenance condition for the

sensor. A corresponding message appears on the display.

3 Confirm the note with g.

The maintenance condition is active.

4 Select the CALIBRATION procedure and press

5 Put the sensor into the calibration position (water vapor-satu-

rated air or air-saturated water - see section 4.2.1).

6Press

g.

The sensor determines the calibration data. The display

switches to the measured value display. The CAL indicator

flashes instead of the main measured value. At the same time,

the momentary relative slope flashes as the secondary measured value. The process ends automatically as soon as the

measured values meet the criterion for the stability control.

With a great temperature difference between the sensor and

the environment this may take a while. Subsequently, the main

measured value and temperature are displayed.

ENSOR NET is carried out as fol-

g.

4 - 4

7 If the user calibration was successful, bring the sensor into the

measuring position again.

ba76014e01 02/2012

FDO®70x IQ (SW) Measuring / Operation

8 Wait for the measured value to be largely stable (temperature

adjustment).

9 Switch off the maintenance condition.

Canceling the user

calibration

Possible results of the

user calibration

As long as the determination of the calibration data has not yet been

started (step 6), you can quit the calibration routine with

The running determination of calibration data (after pressing

m or e.

g in step

6) can be aborted as follows:

1 Open the setting table (see section 3.4).

2 In the Calibration menu item, select the abort setting and then

quit the setting table with Save and quit.

After the user calibration was canceled the sensor again works with the

calibration data that was used before the canceled user calibration.

The calibration data is evaluated by the system. A calibration can have

the following results:

Display Explanation

Measured value display Sensor was successfully calibrated.

The calibration data can be viewed in the

calibration history (section 4.2.4).

"----" The sensor could not be calibrated.

The sensor is blocked for further measurement.

Notes on possible causes are given in the

log book of the sensor.

ba76014e01 02/2012

4 - 5

Measuring / Operation FDO®70x IQ (SW)

Currently active

calibration

Chronological list of

the last user calibrations

4.2.4 Calibration history

Calibration history

(available in the

IQ S

ENSOR NET system

2020 XT only)

Fig. 4-1 Calibration historyFDO®70x IQ (SW)

The calibration history contains the following information:

Date Calibration date (Factory = factory calibration)

Rel.slope Relative slope (non-dimensional)

Intens. Intensity:

+ : sufficient

- : too low

Res Evaluation of the calibration

o.k. : Calibration successful.

The new calibration data was taken over for

measurement.

Error : Calibration unsuccessful.

Invalid calibration data were discarded. Measurement was continued with the last valid

values.

Note

The calibration history is stored in the sensor basis. If another sensor

cap (with different series number) is mounted, the calibration history is

deleted and cannot be restored afterwards.

4 - 6

ba76014e01 02/2012

FDO®70x IQ (SW) Measuring / Operation

4.2.5 Reactivating previous calibration data

®

The FDO

70x IQ (SW) enables you to reactivate the last valid user

calibration or the factory calibration. Thus you can immediately go on

measuring if a calibration procedure failed or you suspect that the calibration conditions were not optimally met.

Note

Reactivating old calibration data is only a temporary solution. Please

take into account that the sensor might thus possibly provide incorrect

measured values. Please make sure the sensor works correctly by carrying out a function check and/or recalibration.

Reactivating calibration

data

1 Open the setting table (see section 3.4).

2 In the Calibration menu item, select the User calibration or Fac-

tory calibration setting and then quit the setting table with Save

and quit.

ba76014e01 02/2012

4 - 7

Measuring / Operation FDO®70x IQ (SW)

4 - 8

ba76014e01 02/2012

FDO®70x IQ (SW) Maintenance, cleaning, replacement parts

5 Maintenance, cleaning, replacement

parts

5.1 General maintenance instructions

WARNING

Contact with the sample can be dangerous for the user!

Depending on the type of sample, suitable protective measures

must be taken (protective clothing, protective goggles, etc.).

Maintenance condition We recommend to switch on the maintenance condition each time the

sensor is taken out of the measuring position. This avoids unwanted

reactions of linked outputs. For more detailed information on the maintenance condition please refer to the respective IQ S

tem operating manual.

Note

We do not recommend unscrewing the sensor from the sensor connection cable in order to do maintenance work. Otherwise, moisture and/or

dirt can get into the plug connection where it can cause contact problems.

ENSOR NET sys-

If you would like to disconnect the sensor from the sensor connection

cable, please note the following points:

Before disconnecting the sensor from the SACIQ (SW) sensor con-

nection cable, the sensor has to be cleaned on the outside (see section 5.4.1).

Unscrew the sensor from the SACIQ (SW) sensor connection cable.

Place a protective cap on the sensor plug head connector and on

the SACIQ (SW) sensor connection cable each time so that no moisture or dirt can get on the contacting surfaces.

In corrosive environments, close the socket of the sensor connec-

tion cable with the screwable SACIQ-Plug when it is dry in order to

protect the electrical contacts from corrosion. The protective plug is

available as an accessory (see section 5.5 R

ACCESSORIES). It is included in the standard scope of delivery of the

SACIQ SW sensor connection cable.

EPLACEMENT PARTS AND

ba76014e01 02/2012

5 - 1

Maintenance, cleaning, replacement parts FDO®70x IQ (SW)

5.2 Handling of the sensor cap

Despite its exterior robustness, the sensor is an optical high precision

instrument. Therefore, special care should be taken when doing any

maintenance or cleaning work:

Dirt and moisture under the sensor cap can affect the functioning

and shorten the service life of the sensor cap. Therefore, make sure

the working environment is clean and dry prior to removing the sensor cap.

Please do not touch the outer sensor membrane with your fingers.

Touch the sensor cap at the sides only (shaded area in figure on the

left).

Avoid any great mechanical stress of the sensor membrane (pres-

sure, scratches).

Exposure to light, particularly daylight of the interior of the sensor

cap will, by-and-by, affect the measurement characteristics and

shorten the service life of the sensor cap. Therefore, the interior of

the sensor cap should not be exposed to direct sunlight. Avoid any

exposure to light that exceeds the extent required for necessary

maintenance and cleaning activities. Store dismantled sensor caps

in a light-protected environment only.

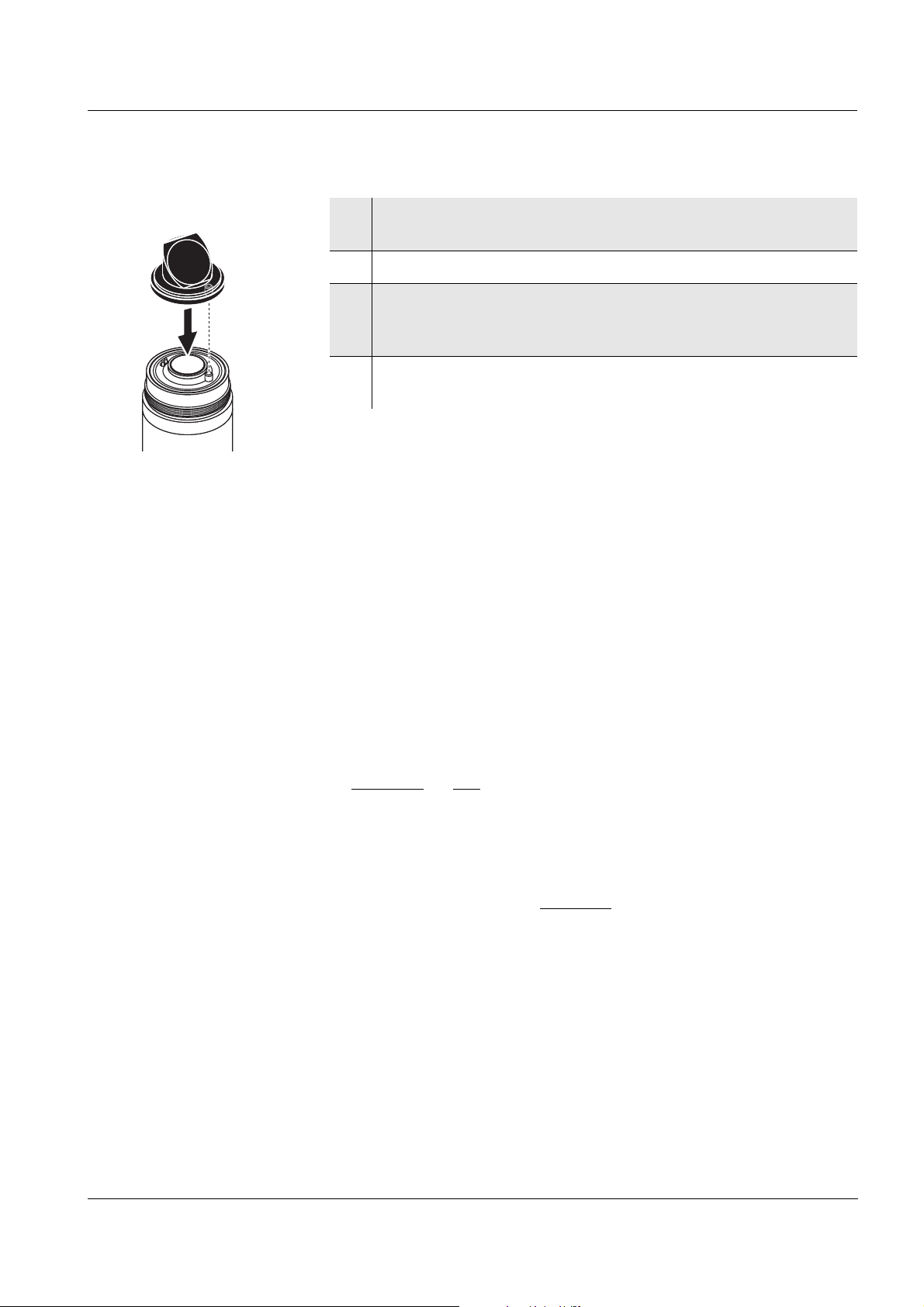

Removing the sensor

cap

5.3 Exchanging the sensor cap

1 Pull the sensor out of the sample.

2 Clean the outside of the sensor (see section 5.4.1).

3 Unscrew the fixing ring from the sensor by hand.

4 Thoroughly clean and dry the sensor head once again.

5 Grasp the sensor cap on the sides (arrows in figure on the left)

and remove it by pulling it away from the sensor in a straight

upward direction.

Caution

Do not push any tools or other sharp objects between the sealing

surfaces. This might damage the sealing surfaces.

5 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Maintenance, cleaning, replacement parts

Mounting the sensor

cap

6 Check the front surface of the sensor for absolute cleanness

and clean it if necessary (see section 5.4.1).

7 Thoroughly clean the thread of the fixing ring.

8 Place the new sensor cap on the sensor so that the tempera-

ture sensor fits into the hole inside the sensor cap (see figure

opposite).

9 Put the fixing ring on the sensor head and screw it tight by

hand.

5.4 Cleaning the sensor

5.4.1 Exterior cleaning

Dirt on the sensor can affect the measuring characteristics. Biological

deposits for example, consume oxygen and can, when occurring on the

sensor cap membrane, impair the responding behavior and cause values that are too low. Therefore, we recommend regular visual inspections and exterior cleaning as necessary.

Pay attention to the following points for cleaning:

First, thoroughly rinse the sensor with tapwater to remove loosely

adhering dirt.

Rough dirt on the sensor shaft can be brushed off with a soft brush.

Attention:

Do not use the brush in the area of the sensor membrane.

Risk of damage!

The sensor cap including the sensor membrane should be wiped

with a soft and moist microfiber cloth.

In the case of persisting dirt you can add some household washing-

up liquid to the tapwater. Attention:

Never use any alcohol for clean-

ing!

If the are any salt or lime deposits, the sensor can be cleaned with

aqueous citric acid solution (10 % weight percent).

ba76014e01 02/2012

5 - 3

Maintenance, cleaning, replacement parts FDO®70x IQ (SW)

5.4.2 Interior cleaning of sensor cap and sensor head

If moisture or dirt have penetrated under the sensor cap, e.g. because

the sensor cap is damaged, you can make the sensor ready for operation again as follows:

Caution

Only use nonabrasive, alcohol-free detergents, as otherwise the

optical surfaces could be damaged.

1 Remove the sensor cap (see section 5.3).

2 Clean the sensor head and sensor cap:

– Rinse all inner surfaces with tapwater

– Remove contamination containing fat and oil with warm

water and household washing-up liquid

3 Dry all surfaces with a clean, lint free cloth. A lint-free cloth

such as a microfiber cloth used to clean eyeglasses is suitable.

4 Allow the sensor and sensor cap to dry completely at a dry

location so moisture can evaporate even from corners difficult

to access. When doing, so protect the inside of the sensor cap

from light.

Note

If the sensor cap is visibly damaged it has to be replaced.

5 - 4

ba76014e01 02/2012

FDO®70x IQ (SW) Maintenance, cleaning, replacement parts

5.5 Replacement parts and accessories

Description Model Order no.

®

Sensor cap SC-FDO

Sensor cap SC-FDO

700 201 654

®

701 201 655

Components for

compressed air cleaning

system

Protective screw cap for sensor

SACIQ-Plug 480 065

connection cable

Protective hood against damage

MSK FDO

®

205 253

caused by fish, with connection for

®

the MSK FDO

Cleaning set for connection of the

protective hood MSK FDO

CS cleaning set

®

to a

MSK FDO

®

CS 205 254

valve module or Cleaning Air Box

Description Model Order no.

Cleaning head CH 900 107

Active valve module (does not

MIQ/CHV PLUS 480 018

require a free relay output in the

ENSOR NET system)

IQ S

Valve module for the

IQ S

ENSOR NET system 182

DIQ/CHV 472 007

(external relay and compressed

air supply)

ba76014e01 02/2012

Air compressor to be triggered by

relay, power supply 115 V AC

Air compressor to be triggered by

relay, power supply 230 V AC

Note

Information on further IQ S

ENSOR NET accessories is given in the YSI

catalog and on the Internet.

Cleaning Air Box

- 115 VAC

Cleaning Air Box

- 230 VAC

480 017

480 019

5 - 5

Maintenance, cleaning, replacement parts FDO®70x IQ (SW)

5 - 6

ba76014e01 02/2012

FDO®70x IQ (SW) What to do if...

6 What to do if...

Sensor does not appear

in the measured value

display and list of

sensors

Measured value

implausible

Cause Remedy

– Sensor cap not mounted or

defective

– Sensor cap (see section 5.3)

– Replace a defective sensor

cap as necessary

Cause Remedy

– Coating on sensor cap – Clean the outside of the sen-

sor (see section 5.4.1)

– Service life of the sensor cap

over

– Check the sensor (see sec-

tion 4.2.2)

– Replace the sensor cap as

necessary (see section 5.3)

– Dirt inside the sensor cap and

sensor head.

– Fixing ring not properly tight-

ened.

– Sensor cap untight or defec-

tive.

– Dismantle sensor cap

– Clean the insides of the sen-

sor cap and sensor head (see

section 5.4.2)

– Mount the sensor cap cor-

rectly and tighten the fixing

ring as far as it will go (see

section 5.3)

– Replace a defective sensor

cap as necessary

Measured value

fluctuating heavily

ba76014e01 02/2012

Cause Remedy

– Coating on sensor cap – Clean the outside of the sen-

sor (see section 5.4.1)

– Service life of the sensor cap

over

– Dirt inside the sensor cap and

sensor head.

– See point "Measured value

implausible"

– See point "Measured value

implausible"

– Fixing ring not properly tight-

ened.

– Sensor cap untight or defec-

tive.

6 - 1

What to do if... FDO®70x IQ (SW)

Measured value invalid

( "----" displayed)

Incorrect temperature

display

Cause Remedy

– User calibration unsuccessful.

The sensor is blocked for measurement.

– As a temporary measure to

quickly restore the readiness

for service: Activate the factory calibration (see section

4.2.5)

– For exact measurements,

carry out a function check and

repeat the user calibration if

necessary.

Cause Remedy

– Temperature sensor defective – Return the sensor

6 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Technical data

7 Technical data

7.1 General measurement characteristics

Note

The measurement characteristics are primarily determined by the sensor cap type. The relevant data are given in the sections 7.5 and 7.6.

Measuring principle Optical measurement based on photoluminescence.

Measurement in water According to solubility function according to ISO 5814

Measurement in salt-

contaminated

wastewater

Salinity input from 2.0 ... 70.0;

corresponds to 3.4 mS/cm ... 86.2 mS/cm at T

REF

20 °C

(salinity measurement according to IOT = International Oceanographic

Tables)

Temperature

Temperature sensor Integrated NTC

measurement

Measuring range - 5 °C ... + 50 °C (23 ... 122 °F)

Accuracy ± 0.5 K

Resolution 0.1 K

Temperature

In the range -5 °C ... + 50 °C (23 ... 122 °F)

compensation

7.2 Application conditions

Pressure resistance Sensor with connected SACIQ (SW) sensor connection cable:

Max. allowed overpressure 106 Pa (10 bar)

Type of protection Sensor with connected SACIQ (SW) sensor connection cable:

Immersion depth Min. 10 cm; max. 100 m depth

Operating position Any

ba76014e01 02/2012

The sensor meets all requirements according to article 3(3) of 97/23/

EC ("pressure equipment directive").

6

IP 68, 10 bar (10

Pa)

7 - 1

Technical data FDO®70x IQ (SW)

59.5

40.0

276

34

400

400

39.7

39.7

FDO 70x IQ SW:

FDO 70x IQ:

Socket SACIQ...

Socket SACIQ...

7.3 General data

Dimensions

Weight (without sensor

Connection technique Connection via SACIQ (SW) sensor connection cable

connection cable)

Material

FDO® 70x IQ Approx. 900 g

®

70x IQ SW Approx. 1500 g

FDO

Shaft:

–FDO

–FDO

®

70x IQ

70x IQ SW

V4A stainless steel 1.4571 *

POM

®

Plug head connector housing POM

Sensor head POM and PVC

Sensor cap See section 7.5 or section 7.6

Plug, 3-pole ETFE (blue) Tefzel

®

Fixing ring POM

Protective hood

®

(FDO

70x IQ SW)

POM

* Stainless steel can be corrodible if there are chloride concentrations

of 500 mg/L or more. For applications in such media we recommend to

use the SW sensors.

7 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Technical data

Automatic sensor

monitoring

(SensCheck function)

Instrument safety

Monitoring of the membrane function

Applicable norms – EN 61010-1

– UL 3111-1

– CAN/CSA C22.2 No. 1010.1

7.4 Electrical data

Nominal voltage Max. 24VDC

via the IQ S

details, see chapter T

DATA of the IQ SENSOR NET sys-

tem operating manual)

Power consumption 0.7 W

Protective class III

ENSOR NET (for more

ECHNICAL

ba76014e01 02/2012

7 - 3

Technical data FDO®70x IQ (SW)

7.5 Technical data of the SC-FDO®700

Measuring ranges and

resolutions

Measurement accuracy

Repeatability ± 0.05 mg/L (ppm) according to EN ISO 15839

Response time t

D. O. partial pressure 0 ... 400 hPa

Measuring

Adjustable measuring range Resolution

mode

D. O. concentration

0 ... 20.00 mg/L

0 ... 20.00 ppm

0.01 mg/L

0.01 ppm

D. O. saturation 0 ... 200.0 % 0.1 %

In the range Accuracy

< 1 mg/L (ppm) ± 0.05 mg/L (ppm)

> 1 mg/L (ppm) ± 0.1 mg/L (ppm)

(90 % of the final display value after) < 150 s according to

90

EN ISO 15839

t

(95 % of the final display value after) < 200 s according to

95

EN ISO 15839

Minimum approach flow No incident flow required

Interferences Non-sensitive to against hydrogen sulfide, chlorine, and ionogenic

substances

Allowed temperature

Measuring medium -5 °C ... + 50 °C (23 ... 122 °F)

range

Storage/transport - 25 °C ... + 50 °C (-33 ... 122 °F)

Allowed pH range of the

4 ... 12

test sample

Calibration procedure Factory calibration by means of IQMC (Intelligent Membrane Calibra-

tion) procedure. User calibration possible in water vapor-saturated air

or air-saturated water.

Material PMMA, PVC and silicone

Working life 2 years guaranteed with authorized use

7 - 4

ba76014e01 02/2012

FDO®70x IQ (SW) Technical data

7.6 Technical data of the SC-FDO®701

Measuring ranges and

resolutions

Measurement accuracy

Repeatability ± 0.05 mg/L (ppm) according to EN ISO 15839

Response time t

D. O. partial pressure 0 ... 400 hPa

Measuring

Adjustable measuring range Resolution

mode

D. O. concentration

0 ... 20.00 mg/L

0 ... 20.00 ppm

0.01 mg/L

0.01 ppm

D. O. saturation 0 ... 200.0 % 0.1 %

In the range Accuracy

< 1 mg/L (ppm) ± 0.05 mg/L (ppm)

> 1 mg/L (ppm) ± 0.1 mg/L (ppm)

(90 % of the final display value after) < 60 s according to

90

EN ISO 15839

t

(95 % of the final display value after) < 80 s according to

95

EN ISO 15839

Minimum approach flow No incident flow required

Interferences Non-sensitive to against hydrogen sulfide, chlorine, and ionogenic

substances

Allowed temperature

Measuring medium -5 °C ... + 40 °C (23 ... 104 °F)

range

Storage/transport - 25 °C ... + 40 °C (-33 ... 104 °F)

Allowed pH range of the

4 ... 12

test sample

Calibration procedure Factory calibration by means of IQMC (Intelligent Membrane Calibra-

tion) procedure. User calibration possible in water vapor-saturated air

or air-saturated water.

Material PMMA, PVC and silicone

Working life 6 months guaranteed for authorized use under the specified environ-

mental conditions

ba76014e01 02/2012

7 - 5

Technical data FDO®70x IQ (SW)

7 - 6

ba76014e01 02/2012

FDO®70x IQ (SW) Contact Information

8 Contact Information

8.1 Ordering & Technical Support

Telephone

Fax

: (937) 767-1058

Email

Mail: YSI Incorporated

Internet

When placing an order please have the following information available:

YSI account number (if available) Name and Phone Number

Model number or brief description Billing and shipping address

Quantity Purchase Order or Credit Card

: (800) 897-4151

(937) 767-7241

Monday through Friday, 8:00 AM to 5:00 PM ET

: environmental@ysi.com

1725 Brannum Lane

Yellow Springs, OH 45387

USA

: www.ysi.com

8.2 Service Information

YSI has authorized service centers throughout the United States and

Internationally. For the nearest service center information, please visit

www.ysi.com

directly at 800-897-4151.

When returning a product for service, include the Product Return form

with cleaning certification. The form must be completely filled out for an

YSI Service Center to accept the instrument for service. The Product

Return form may be downloaded at www.ysi.com

‘Support‘ tab.

and click ‘Support’ or contact YSI Technical Support

and clicking on the

ba76014e01 02/2012

8 - 1

Contact Information FDO®70x IQ (SW)

8 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Indexes

9 Indexes

9.1 Explanation of the messages

This chapter contains a list of all the message codes and related message texts that can occur in the log book of the IQ S

®

for the FDO

70x IQ (SW) sensor.

Note

Information on the contents and structure of the log book, and how to

call it up, is given in the L

OG BOOK chapter of the IQ SENSOR NET sys-

tem operating manual.

Note

The last three digits of the message code identify the source of the

message:

334 = SC FDO 700 (sensor cap SC-FDO

335 = SC FDO 701 (sensor cap SC-FDO

®

®

ENSOR NET system

700)

701)

531 = FDO700IQ (sensor basis / component class, adapter ADA)

9.1.1 Error messages

Message code Message text

EA133x Meas. range exceeded or undercut

* Check process

* Select other meas. range

EA233x Sensor temperature too high!

* Check process and application

EA333x Sensor temperature too low!

* Check process and application

EAP33x Measurement interfered

* SensCheck: Sensor cap is missing, leaky, depleted, or defective

* Clean sensor and space between cap and sensor according to

op.instructions

* Screw on sensor cap securely

* Replace sensor cap

EAP531 Measurement interfered

* SensCheck: Sensor cap is missing, leaky, depleted, or defective

* Clean sensor and space between cap and sensor according to

op.instructions

* Screw on sensor cap securely

* Replace sensor cap

ba76014e01 02/2012

9 - 1

Indexes FDO®70x IQ (SW)

Message code Message text

EC833x Sensor could not be calibrated,

sensor blocked for measurement

Cause: instable signal

* Check temperature adjustment

* Check calibration conditions (see operating manual)

* Repeat calibration

EC933x Calibration error, measurement disabled

Cause: Sensor cap is missing, leaky, depleted, or defective

* Clean sensor and space between cap and sensor according to

op.instructions

* Screw on sensor cap securely

* Repeat calibration

* Replace sensor cap

EI133x Operational voltage too low

* Check installation and cable lengths, Follow installation instructions

* Power unit(s) overloaded, add power unit(s)

* Check terminal and module connections

* Defective components, replace components

EI233x Operational voltage too low, no operation possible

* Check installation and cable lengths, Follow installation instructions

* Power unit(s) overloaded, add power unit(s)

* Check terminal and module connections

* Defective components,

replace components

ES133x Component hardware defective

* Contact service

9 - 2

ba76014e01 02/2012

FDO®70x IQ (SW) Indexes

9.1.2 Info messages

Message code Message text

IC133x Sensor has been successfully calibrated

* For calibration data, see calibration history

IC333x Factory calibration has been activated. Make sure the sensor operates

correctly.

IC433x Last valid user calibration has been activated. Make sure the sensor

operates correctly.

IC533x Invalid user calibration has been replaced by last valid user calibration.

Caution! Wrong measured values possible. Carry out a new successful

user calibration to make sure the sensor operates correctlyes correctly.

IC633x The invalid user calibration was replaced by the factory calibration.

Caution! Wrong measured values possible. Check whether the sensor

operates correctly or carry out a new successful user calibration user

calibration.

IC733x This message displays the result of the last check (see section 4.2.2)

IS133x This message displays the information stored in the sensor cap

(see section 1.2)

ba76014e01 02/2012

9 - 3

Indexes FDO®70x IQ (SW)

9.2 Status info

The status info is a coded piece of information on the current status of

a sensor. Each sensor sends this status info to the controller. The status info of sensors consists of 32 bits, each of which can have the value

0 or 1.

Status info,

general structure

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 (general)

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 (internal)

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

The bits 0 - 15 are reserved for general information.

The bits 16 - 21 are reserved for internal service information.

You obtain the status info:

via a manual query in the Einstellungen/Settings/Service/List of all

components menu (see system operating manual)

by an automated query

– from a superordinate process control (e. g. when connected to

the Profibus)

– from the IQ Data Server (see IQ S

ENSOR NET Software Pack

operating manual)

Note

The evaluation of the status info, e.g. in the case of an automated

query, has to be made individually for each bit.

9 - 4

FDO

®

70x IQ (SW)

Status info

Status bit Explanation

Bit 0 Component hardware defective

Bit 1 Sensor cap missing, untight, depleted or defective

Bit 2-31 -

ba76014e01 02/2012

1725 Brannum Lane

Yellow Springs, Ohio 45387 USA

+1 937-767-7241

800-765-4974 (US)

FAX (937) 767-1058

Email: environmental@ysi.com

Internet: www.ysi.com

Loading...

Loading...