XL™ Series

Models H-350XL™

H-500XL™

H-510XL™

H-522

H-522 - Plus

Owner’s Manual

XL™ Series

Data Logger /

Data Collection Platform

Owner’s Manual

Revision: 2.14 - 000

NOTICE

This product embodies technology that is confidential and proprietary technology of DESIGN

ANALYSIS ASSOCIATES, INC., and which is protected by United States copyright laws and

international copyright treaty provisions, and/or by contract and applicable laws of trade secrecy.

These include all Software, Printed Circuit Board Artwork, Schematic Diagrams, and

Technologies applied therein. The enclosure encasing the electronics of this instrument may not

be opened without written consent of DESIGN ANALYSIS ASSOCIATES, INC., and any

attempt to do so without such written authorization constitutes a breach of contract and will also

void any applicable warranty for the product.

Design Analysis Associates, Inc.

75 West 100 South

Logan, UT 84321 USA

Phone: (435) 753-2212

Fax: (435) 753-7669

Internet: www.waterlog.com

E-mail: sales@waterlog.com

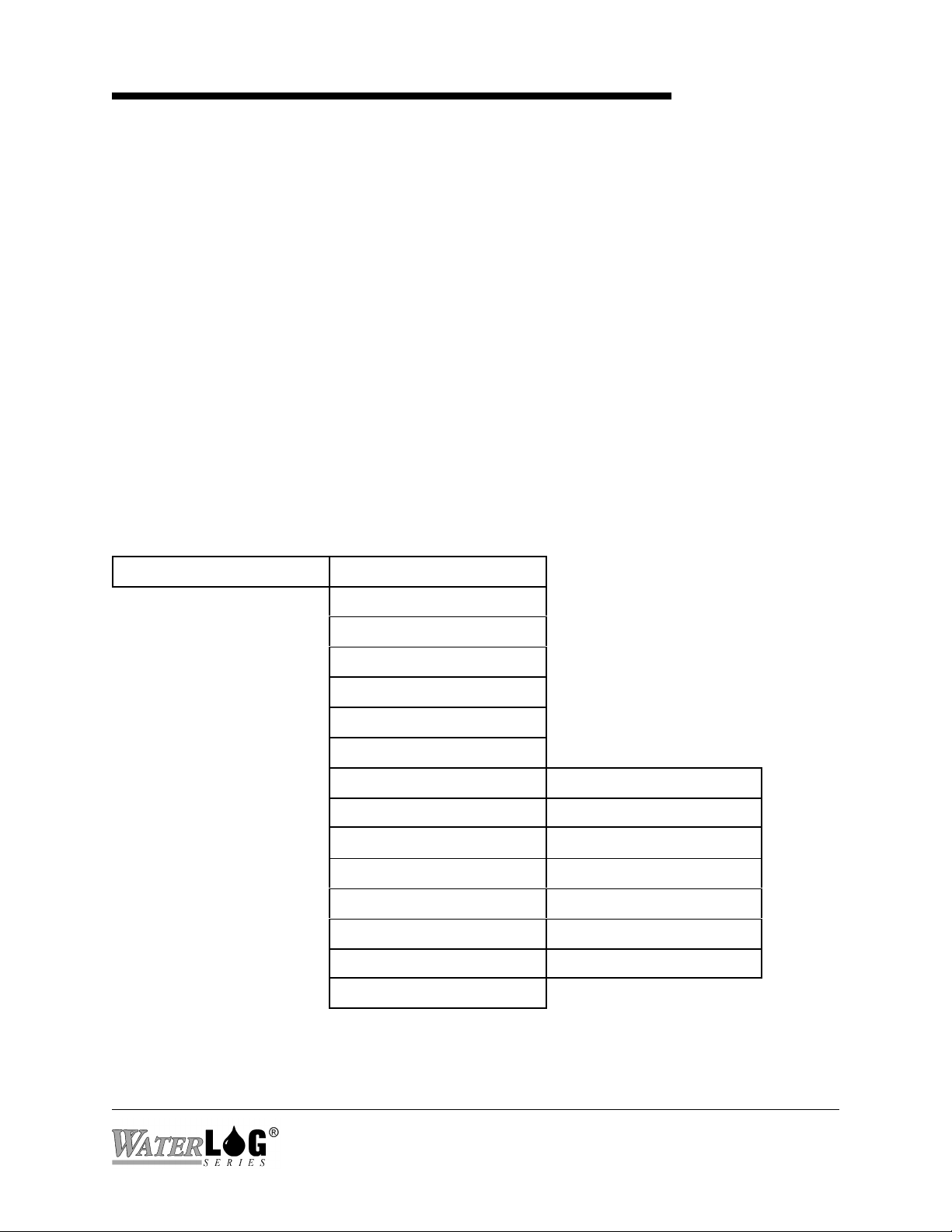

Table of Contents

User Agreement/WATERLOG Warranty.........................................®W-1

Chapter 1 Introduction

1.1 Introduction to the XL™ Series Data Logger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Unpacking the XL™ Series Data Logger. ..................................... 1-2

1.3 Modes Of Operation. ..................................................... 1-3

1.3.1 SDI-12 Sensor Mode..................................................... 1-3

1.3.2 Data Logger / DCP Master Mode........................................... 1-3

1.3.3 Operation Using Auxiliary Outputs. ........................................ 1-4

1.3.4 Operation With The H-355 Gas Purge System (Bubbler). . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 About this Manual........................................................ 1-4

1.5 Advanced Manual Sections................................................. 1-4

1.6 Web Page Support........................................................ 1-4

Chapter 2 Hardware Options and Installation

2.1 Mechanical Mounting. .................................................... 2-1

2.2 Front Panel Description.................................................... 2-1

2.2.1 Earth Ground Lug....................................................... 2-2

2.2.2 Pressure Reference Port (Vent)............................................. 2-2

2.2.3 Pressure Port (Input)..................................................... 2-2

2.2.4 GOES Antenna Output................................................... 2-3

2.2.5 GPS Antenna Connector.................................................. 2-3

2.2.3.1 Sample Installation for the Conoflow System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.3.2 Making the Pressure Connection to the H-355 Bubbler. . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.6 Bubbler / Aux Port. ..................................................... 2-6

2.2.7 RS-232 Ports........................................................... 2-7

2.2.8 Analog Input Section. ................................................... 2-8

2.2.8.1 Analog Input Channels.................................................. 2-8

2.2.8.2 Analog Grounds....................................................... 2-8

2.2.8.3 Switched +5 Volt Reference Excitation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.9 Wind Speed Input (AC Frequency Input). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.10 Event Counter Input................................................... 2-10

2.2.11 4 to 20 Milliamp Output................................................ 2-11

2.2.12 Digital I/O 1 and 2. ...................................................2–12

2.2.13 SDI-12 Section....................................................... 2-13

2.2.14 Power Connections.................................................... 2-14

2.3 Testing the Installation.................................................... 2-14

2.4 Hardware Revision Detection.............................................. 2-15

Chapter 3 Using The Built In keypad / Display

3.1 Overview............................................................... 3-1

3.2 Keypad/Display Operation.................................................. 3-1

3.3 Familiarization........................................................... 3-6

3.4 Main Menu Description.................................................... 3-7

Chapter 4 Using the PC Menu Interface Operation

4.1 PC Menu Interface........................................................ 4-1

4.2 PC Menu General Operations. .............................................. 4-2

4.3 Main Menu Screen........................................................ 4-3

Chapter 5 General System Options

5.1 Overview............................................................... 5-1

5.2 System Setup............................................................ 5-1

5.3 Time Sync Options........................................................ 5-5

5.4 Advanced System Setup Options............................................. 5-8

Chapter 6 Serial Port Options

6.1 Introduction. ............................................................ 6-1

6.2 Serial Port Menus......................................................... 6-1

6.3 Serial Port Hardware Description. ........................................... 6-6

6.4 Serial Port Functions...................................................... 6-7

Chapter 7 System Configuration Files

7.1 Overview............................................................... 7-1

7.2 Configuration Files Menus. ................................................ 7-1

7.3 Sample Configuration File.................................................. 7-3

Chapter 8 System Status Menus / Optioons

8.1 Status Options Overview................................................... 8-1

8.2 Status Menus............................................................ 8-1

8.3 Status Screen Operations................................................... 8-2

Chapter 9 Scanning Options

9.1 Introduction. ............................................................ 9-1

9.2 Scanning Menus.......................................................... 9-1

9.3 Scanning Options......................................................... 9-1

Chapter 10 Stage Menus / Options

10.1 Stage Sensor and Remote Stage Setup....................................... 10-1

10.2 Stage / Temperature Menus (H-350XL Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.3 Stage Options (H-350XL / H-510XL Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.4 PtTemp Sensor Setup (H-350XL Only)...................................... 10-4

10.5 Remote Stage Setup Overview. ...........................................10-5

10.6 Remote Stage Menus.................................................... 10-5

10.7 Remote Stage Options................................................... 10-5

Chapter 11 Analog Inputs / 5 Volt Excitation

11.1 Analog Inputs Overview. ................................................ 11-1

11.2 Analog Menus......................................................... 11-1

11.3 Analog Options. ....................................................... 11-2

11.4 Analog Input Connections................................................ 11-4

11.4.1 Analog Inputs and Analog Ground Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

11.4.2 Switched +5.00 Volt Reference Excitation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

11.5 Analog Input Setup Examples............................................. 11-6

11.6 Two Point Calibration Basics. ............................................ 11-7

Chapter 12 Digital I/O

12.1 Digital I/O Overview.................................................... 12-1

12.2 Digital I/O Menus. ..................................................... 12-1

12.3 Digital I/O Options...................................................... 12-2

12.4 Quadrature Shaft Encoder Options. ........................................12-7

Chapter 13 Counter And frequency Inputs

13.1 Introduction. .......................................................... 13-1

13.2 Counter and Frequency Menus. ........................................... 13-1

13.3 Counter Options........................................................ 13-2

13.4 Frequency Options...................................................... 13-6

Chapter 14 SDI-12 Operations

14.1 SDI-12 Overview....................................................... 14-1

14.2 SDI-12 Transparent Mode and Full Screen Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

14.3 SDI-12 Data Logger Mode................................................ 14-6

14.4 SDI-12 Sensor Mode.................................................... 14-9

14.5 H310 Setup........................................................... 14-12

14.6 H330 / H331 Setup..................................................... 14-14

14.7 SDI-12 Sensor Mode Supported Commands.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

14.7.1 SDI-12 Command and Response Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-17

14.7.2 Standard SDI-12 Command Set ......................................... 14-18

14.7.3 Send Acknowledge Command .......................................... 14-18

14.7.4 Send Identification Command .......................................... 14-19

14.7.5 Measure Command . ................................................. 14-20

14.7.6 Initiate Verify Command .............................................. 14-22

14.7.7 Send Data Command ................................................. 14-23

14.7.8 Change Sensor Address ............................................... 14-24

14.7.9 Extended SDI-12 Command Set . ....................................... 14-24

14.7.10 Write “User Units Slope” Command .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-25

14.7.11 Write “User Units Offset” Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-26

14.7.12 Read “User Units Slope” Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-27

14.7.13 Read “User Units Offset” Command .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-28

Chapter 15 Logging Options

15.1 Logging Overview...................................................... 15-1

15.2 Logging Options Menu. ................................................. 15-1

15.3 Logging Options. ...................................................... 15-2

Chapter 16 Operation with the GOES Radio

16.1 Introduction. .......................................................... 16-1

16.1.1 GOES Radio Data Connection........................................... 16-1

16.1.2 GOES Radio Types.................................................... 16-1

16.2 Configuring the GOES Radio, General Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-3

16.3 GOES Self Timed Options............................................... 16-10

16.4 GOES Random Options................................................. 16-24

16.5 GOES Diagnostics..................................................... 16-28

16.6 GOES Radio Setup Example............................................. 16-31

16.7 GOES Binary Data..................................................... 16-32

16.8 GOES Four Byte Pseudo-Binary Lookup Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-34

16.9 Common GOES Terms. ................................................ 16-35

16.10 Julian Day Tables..................................................... 16-37

16.11 GOES Downlink Message Header Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-39

Chapter 17 ALERT Radio Operation

17.1 Introduction. .......................................................... 17-1

17.2 ALERT Menus......................................................... 17-1

17.3 ALERT Options........................................................ 17-2

17.4 Special Cases For ALERT Transmissions.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-8

Chapter 18 4 to 20 Milliamp Output

18.1 Introduction. .......................................................... 18-1

18.2 4 To 20 Milliamp Menus................................................. 18-1

18.3 4 To 20 Milliamp Options................................................ 18-1

18.4 4 To 20 Hardware Connections / Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-4

Chapter 19 Alarm Call Out

19.1 Overview............................................................. 19-1

19.2 Alarm Call Out Menus................................................... 19-1

Chapter 20 Data Card Options

20.1 Data Card Options...................................................... 20-1

20.2 Data Card / Memory Options.............................................. 20-2

Chapter 21 Operation With the H-355 "Smart Gas" System

21.1 Introduction to the H-355................................................. 21-1

21.2 H-355 Menus.......................................................... 21-1

21.3 H-355 Options......................................................... 21-2

21.4 H-355 Configuration Drawing............................................. 21-7

Chapter 22 Functions

22.1 Introduction. .......................................................... 22-1

22.2 Function Menu......................................................... 22-1

Chapter 23 XL-Basic Programming Guide

Version Changes Information. ................................................. 23-1

Main Program Variables. ..................................................... 23-2

General Purpose Variables............................................... 23-2

Standard Input Variables................................................ 23-3

Read Only Variables. .................................................. 23-4

Math Functions. ............................................................ 23-5

XL-Basic Command Summary. ................................................ 23-6

XL-Basic Language Descriptions. .............................................. 23-8

Creating XL-Basic Programs.................................................. 23-18

XL-Basic Menu Screens. .................................................... 23-18

Example Program #1........................................................ 23-20

Example Program #2........................................................ 23-21

Chapter 24 Maintenance / Troubleshooting

24.1 Maintenance........................................................... 24-1

24.2 Troubleshooting........................................................ 24-1

Appendix A XL Series Specifications. ......................................... A-1

Appendix B Blank...........................................................B-1

Appendix C Remote Operation (Command Mode).................................C-1

User Agreement/

WATERLOG Warranty

1. NATURE OF THE PRODUCT

This agreement accompanies a pressure measuring/data collection system comprising firmware,

circuitry and other electronic equipment in an enclosed housing, and packaged together with written

instructional materials. The packaged electronic circuitry and instructional materials herein are

collectively referred to as the “PRODUCT.” The PRODUCT is made available from DESIGN

ANALYSIS ASSOCIATES, INC., of 75 West 100 South, Logan, Utah 84321 (hereinafter referred to as

“DESIGN ANALYSIS”), and contains information and embodies technology that is confidential and

proprietary to DESIGN ANALYSIS, and the availability and use of the PRODUCT is extended to you,

the USER, solely on the basis of the terms of agreement which follow.

2. ACKNOWLEDGMENTS BY USER

Opening the package which encloses the accompanying PRODUCT indicates your acceptance of the

terms and conditions of this agreement and constitutes an acknowledgment by you of the confidential and

proprietary nature of the rights of DESIGN ANALYSIS in the PRODUCT.

3. DUTIES OF YOU, THE USER

In consideration for the access to and use of the PRODUCT extended to you by DESIGN ANALYSIS

and to protect the confidential and proprietary information of DESIGN ANALYSIS, USER agrees as

follows:

®

(a) USER agrees that they will not remove from the exterior of the housing of the

PRODUCT any safety warnings or notices of proprietary interest placed thereon by

DESIGN ANALYSIS.

(b) USER agrees that they shall not disassemble or otherwise reverse engineer the

PRODUCT.

(c) USER agrees to treat the PRODUCT with the same degree of care as USER exercises in

relation to their own confidential and proprietary information.

4. TERM

USER may enjoy these rights only as long as their possession of the PRODUCT shall continue to be

rightful. These rights will cease if the PRODUCT is returned to DESIGN ANALYSIS under the terms of

any redemption offer, warranty, or money-back guarantee, or if USER transfers the PRODUCT to

another party on terms inconsistent with this agreement.

5. LIMITED WARRANTY

(a) What is Covered

DESIGN ANALYSIS warrants that for a period of twelve months from the time of delivery the

functions to be performed by the PRODUCT will be substantially in compliance with USER

documentation. DESIGN ANALYSIS also warrants that the PRODUCT will be free from

defects in materials and workmanship for a period of ONE YEAR from the date of delivery.

XL Series User Agreement/WATERLOG Warranty W-1

®

(b) What USER Must Do

If the product fails to satisfy the above warranty, USER must notify DESIGN ANALYSIS in

writing within the applicable period specified above and reasonably cooperate with the directions

they received from DESIGN ANALYSIS.

(c) What DESIGN ANALYSIS Will Do

DESIGN ANALYSIS will repair the PRODUCT or will endeavor to provide a replacement of

same within a reasonable period of time. In the event that DESIGN ANALYSIS is unable to

make the necessary repairs or replacement within a reasonable period of time, the original

purchase price will be refunded upon the return of the PRODUCT to DESIGN ANALYSIS.

(d) Limitations

(i) THE ENTIRE REMEDY FOR BREACH OF THIS LIMITED WARRANTY

SHALL BE LIMITED TO REPLACEMENT OF THE DEFECTIVE PRODUCT

OR REFUNDING OF THE PURCHASE PRICE, AS SET FORTH ABOVE.

IN NO EVENT WILL THE LIABILITY OF DESIGN ANALYSIS TO USER

OR TO ANY OTHER PARTY EXCEED THE ORIGINAL PURCHASE PRICE

OF THE PRODUCT, REGARDLESS OF THE FORM OF THE CLAIM.

(ii) EXCEPT FOR THE EXPRESS WARRANTIES ABOVE, DESIGN ANALYSIS

SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, INCLUDING,

WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

(iii) UNDER NO CIRCUMSTANCES WILL DESIGN ANALYSIS BE LIABLE

FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, OR ANY

OTHER DAMAGES OR CLAIMS ARISING FROM THE USE OF THIS

PRODUCT, THIS INCLUDES LOSS OF PROFITS OR ANY OTHER

COMMERCIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. IN NO EVENT WILL DESIGN ANALYSIS BE LIABLE

FOR ANY CLAIMS, LIABILITY, OR DAMAGES ARISING FROM

MODIFICATION MADE THEREIN, OTHER THAN BY DESIGN

ANALYSIS.

(iv) THIS LIMITED WARRANTY GIVES USER SPECIFIC LEGAL RIGHTS.

USER MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE

TO STATE. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS OR THE EXCLUSION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THOSE

LIMITATIONS OR EXCLUSIONS MAY NOT APPLY.

6. GOVERNING LAW

This Agreement and its validity and interpretation shall be governed by the laws of the State of Utah,

notwithstanding any choice of law rules of Utah or any other state or jurisdiction.

W-2 User Agreement/WATERLOG Warranty XL Series

®

Chapter 1

Introduction

1.1 Introduction to the XL™ Series Data Logger

The XL Series of data loggers started with the H-350XL and the H-500XL and expanded from

there to a total of five major products, that all use the same basic programming methods and

other common features and functionality. The XL Series of data loggers / DCP’s now includes

the following products.

H-500XL Basic XL Series data logger.

H-350XL Basic XL Series data logger with built in pressure transducer.

H-510XL Basic XL Series data logger with built in shaft encoder.

H-522Plus Basic XL Series data logger with built in GOES HDR transmitter.

H-522 Same as H-522Plus but does not include the built in keypad / display.

Customer driven enhancements have vastly expanded the capabilities of the XL Series products

since its introduction early in 2000. Below is a quick overview of the common features of all the

XL Series data loggers followed by a list of differences for each product.

Uses, Functions, Features, and Attributes of the XL™ Series Data Logger / DCP:

!Operates over a wide temperature range: - 40EF to +140EF (- 40EC to +60EC).

!Easy to use program interface and push button keypad. Programming does not require an

external device (i.e., a laptop computer), although all programming and data retrieval can

be done through the serial port on a PC. (keypad and display not available on the H-522

model).

!Provides a bright, easy-to-read display with automatic power shut-off after 5 minutes.

!Four general purpose analog input channels.

!Switch closure event counter.

!AC frequency counter allows direct input for wind speed sensors, etc.

!Designed to output a 4-20 mA signal (No external module required).

!Three serial ports provide for easy installation of multiple serial devices.

!Complete serial interface provides both a command mode for automated use and a menu

mode for human interaction. Both modes provide complete system programming and data

retrieval.

!Built-in data logging functions which store the data in non-volatile internal memory.

!Common interface support for 100, 300, and 1200 Baud GOES Transmitters.

!Support for basic to complex math operations for non-linear sensors.

!Designed to be compatible with all SDI-12 data loggers, and sensors.

!Packaged in a sealed NEMA 4 enclosure.

!Built in BASIC language interpreter for user defined XL-Basic programs.

XL™ Series Introduction 1-1

Additional Features with the H-350XL™ Model only:

!Precision pressure measurement of dry gas.

!Direct replacement of pressure measurement systems such as the mercury manometer or

other industrial analog sensors.

Additional Features with the H-510XL™ Model only:

!Provides precision measurement based on shaft encoder technology.

(Resolution 1/200 of revolution).

!Provides accurate water level ±0.005 Post (SDI-12).

!Directly replaces ADR systems such as the Fisher Porter, Stevens, or other mechanical

tape recorders.

Additional Feature with the H-522Plus Model only:

!Integrated with a HDR (High Data Rate) GOES radio Transmitter.

Additional Feature with the H-522 Model only:

!Same as the H-522Plus but does not include the built in keypad / display.

!Must be programmed through the serial port connected to a PC

1.2 Unpacking the XL™ Series Data Logger

You should have received the following items:

!The XL™ Series instrument

!2-position power terminal block

!18-position sensor I/O terminal block

!The XL™ Series Owner's Manual

!Wall mounting hardware for the XL™: (4) 10-32 screws, (4) plastic mounting tabs

!Communication cable

!NULL modem adaptor

!Gender changer

Note: If the XL™ Series data logger was shipped on the H-250 mounting board or with other

equipment, additional items may be included, depending on how the unit was purchased.

1.3 Modes of Operation

The XL™ can operate as an SDI-12 sensor, as a data logger, or as a sensor and a data logger

simultaneously. The XL™ is compatible with industrial equipment that does not support SDI-12

1-2 Introduction XL™ Series

communications as well as common telemetry equipment. The XL™ Series is also specially

designed to operate with the H-355 Gas Purge System (Bubbler) for high accuracy pressure

measurement.

1.3.1 SDI-12 Sensor Mode

The XL™ will respond as a sensor to SDI-12 commands sent from an external data logger.

During normal SDI-12 communication, an external data logger issues commands to sensors

attached to the SDI-12 data bus. The command includes a sensor address and a command for the

sensor to perform. All of the sensors attached to the bus will wake up and receive the command,

but only the sensor with the matching address will respond to the command, and all of the other

sensors will return to a low power mode. Details on the SDI-12 commands and responses

supported by the XL™ can be found in Appendix B. When used as an SDI-12 sensor, the main

setup options that may need to be changed are the XL™ sensor address and the data parameters

that will be returned. In several applications, the factory defaults will allow the XL™ to be used

as a sensor ‘out of the box’. Detailed information on the XL™ SDI-12 sensor setup is given in

later chapters.

1.3.2 Data Logger / DCP Master Mode

This mode of operation allows the XL™ to log data at a user-defined interval. The data is stored

internally in non-volatile memory. There are several ways to retrieve data from the XL™.

!The data can be copied to an industry standard ATA FLASH Memory Card.

!The data can be downloaded through the serial port of the XL™ to the hard disk of a PC,

(via direct connection or modem connection).

!Data can be transmitted through the GOES system for near real time operation.

The data recorded to the internal memory is stored as ASCII text with a tabular format ready to

be imported into a spreadsheet, a word processor, decodes, etc. Data options for downloading the

recorded data to an external industry standard ATA FLASH memory card are explained in

chapter 20. Information on accessing the XL™ through the serial port is given in chapter 4, and a

detailed explanation of the GOES operations for retrieving data are given in chapter 16.

1.3.3 Operation Using Auxiliary Outputs

The XL™ can be setup to provide various outputs based on any of the sensor input values. The

Sensor data can be output as a 4 to 20 mA signal, as a quadrature output signal, as ASCII text, or

encoded in a special format for transmission using telemetry equipment. This allows the XL™ to

be compatible with industrial equipment that does not support the SDI-12 protocol. The serial

ports on the XL™ enable it to operate with a GOES Transmitter, a data or voice modem, an

ALERT/IFLOWS radio system, etc. The Digital I/O pins may be configured as outputs in order

to drive an external device through a relay, or to simulate a quadrature shaft encoder output.

XL™ Series Introduction 1-3

1.3.4 Operation with the H-355 Gas Purge System (Bubbler)

The H-355 is a self-contained gas purge system designed to replace mechanical gas purge

systems (Nitrogen tank and Conoflow). The XL™ interfaces with the H-355 via the RS-485

connector marked Bubbler/Aux on the front panel. The XL™ is used to adjust the operating

parameters of the H-355. Refer to Chapter 23 in this manual and to the H-355 manual for a

detailed description of the H-355 operation.

1.4 About this Manual

This manual will show you how to properly install and operate your XL™ Series Data Logger /

DCP. The installation procedures and operational functions are very simple and easy to use.

Please take time to read through the manual, it will help answer most questions you have

concerning the XL™ Series Data Logger / DCP and it’s capabilities. The web page at

http://www.waterlog.com will have manual updates and advanced sections of the manual in PDF

format, allowing customers to print extra copies or newer versions of the manual.

1.5 Advanced Manual Sections

There are a few chapters of the manual that are only needed by a small set of users. To save

paper, time and to avoid confusion, these chapters may not print using the main PDF file, but are

still available on the supplied CD or from the web page. The following are examples of chapters

that may be printed separately.

Appendix C Remote Operation (Command Mode)

This section discusses the command mode interface and list all the commands used to configure

the system. Some users have programmed their own user interface on the PC using the

commands so their users will only see the options that pertain to there applications.

Application Note: NOAA GOES Format

This application note discusses how the H-350XL is used when user mode is set to the NOAA

mode. This mode is used for tidal studies and has a very specific GOES format for data

transmissions.

1.6 Web Page Support

The web page at http://www.waterlog.com will provide ongoing support for the XL™ Series data

loggers and DCP products. This includes advanced sections of the manual, new versions of the

main manual, new firmware updates, brochures, technical notes, PC support software, etc. Also

included is example XL-Basic programs and functions.

1-4 Introduction XL™ Series

Chapter 2

Hardware Options and Installation

2.1 Mechanical Mounting

In this manual, referring to the XL is the same as referring to any of the XL Series data logger /

DCP’s. This chapter describes the basic procedure for installing the XL™. This includes all

wiring and plumbing. For proper installation you will need:

"The XL™ mounting hardware

"Two open end wrenches (7/16", 9/16")(Model H-350XL™ Only)

"Small flat blade screw driver

"Power and communication cables

"The XL™ Series Owner’s Manual

2.2 Front Panel Description

Figure 2-1A shows the wiring panel and illustrates the physical input and output features of the

XL™ Series models H-350XL™, H-500XL™ and the H-510XL™ and briefly describes their

purposes. Figure 2-1B shows the same wiring panel but for the H-522 and the H-522Plus. These

diagrams will help show where you should make connections to your XL™ Series data logger /

DCP.

Figure 2-1A Models H-350XL™/H-500XL™/H-510XL™ Front Panel Description

XL™ Series Hardware Options and Installation 2-1

Figure 4-1B Models H-522/H-522+ Front Panel Description

2.2.1 Earth Ground Lug

Run a heavy gauge (14awg) wire from the GND lug of the XL™ to the Earth ground of the

instrument shelter. If there is no Earth ground, one must be installed. This is most important in

the protection of your electronic equipment. It insures the equipment will function properly.

(PROPER GROUNDING IS A MUST!)

2.2.2 Pressure Reference Port (Vent) (H-350XL™ Model only)

In order to make accurate readings, the H-350XL unit must have a way to measure the

atmospheric pressure. This port provides that function. The user never has to make connections

to, or service this port.

Note: Model H-500XL™ and H-510XL™ only uses this location to secure the wiring panel to

the main box using a large hex bolt.

2.2.3 Pressure Port (Input) (H-350XL™ Model only)

This is the pressurized line input port. The user will connect this line to the H-355 bubbler

system or to the conoflow system. Make sure the pressure on this line does not exceed the limits

of the sensor. The pressure range is listed on the serial number label on the side of the H-350XL.

Note: Model H-500XL™ and H-510XL™ only uses this location to secure the wiring panel to

the main box using a large hex bolt.

2-2 Hardware Options and Installation XL™ Series

2.2.4 GOES Antenna Output (Model H-522 and H-522Plus only)

This is the GOES antenna connector and uses an N-Type connector. The user will connect the

GOES antenna cable to this connector.

Note: Always connect an antenna or a dummy load to this connector when testing the integrated

GOES radio.

2.2.5 GPS Antenna connector (Model H-522 and H-522Plus only)

This is the GPS antenna connector. The user will connect the GPS antenna cable to this

connector.

When using the H-522 or the H-522Plus the GPS receiver will be built into the GOES HDR

radio. The H-522 and H-522Plus units shipping at this time have an Omnisat GOES radio from

Signal Engineering built into them. The GPS receiver will turn on and try to acquire the time

when power is applied to the unit. It will stay on until the time is acquired. Once the time is

acquired the GPS receiver will turn off and schedule the next update to happen in 25 hours and

15 minutes. This non repetitive time prevents the GPS receiver from continually failing due to

some external repeated condition. When the GPS receiver turns on to re-sync the time clock it

will try to do so for 30 minutes before giving up and waiting for the next day. If it misses a

single time sync the GOES radio will still transmit. The GOES radio will stop transmitting if

seven consecutive GPS time syncs have been missed. On the seventh time sync attempt the GPS

receiver will not power down after 30 minutes but will stay on trying to re-sync the time clock

and will only power down after it is successful.

When an Omnisat GOES radio is used externally with other XL Series data loggers the same

functionality will exist. This will be discussed in a later chapter.

XL™ Series Hardware Options and Installation 2-3

2.2.3.1 Sample Installation for the Conoflow System (H-350XL only)

Figure 2-2 shows a typical H-350XL™ installation for water depth measurement using the

Conoflow gas purge system. To install the H-350XL™, secure it to the wall of the instrument

shelter or bench top using the provided mounting hardware. This will prevent it from moving or

shifting and pulling on the wires and tubing connected to other equipment. The H-350XL™

should be mounted so moisture and dust will not settle on the main I/O panel. Normally

vertically is the best with the main I/O panel facing down and the display keypad facing out.

DIFFERENTIAL

H-350XL™

MOUNT

ON WALL

REGULATOR

FEEDBACK TUBE

20 - 30 PSI

PRESSURE

RELIEF VALVE

GAS PURGE

LINE ORIFICE

POWER

30 BUBBLES

PER MINUTE

TO RIVER

SITE-FEED

GAS PRESSURE

TO MANOMETER

REGULATOR

Figure 2-2 Conoflow Gas Purge Stream Gauge Installation

NITROGEN

SUPPLY

CYLINDER

2-4 Hardware Options and Installation XL™ Series

2.2.3.2 Making the Pressure Connection to the H-355 Bubbler System (H-350XL only)

Figure 2-3 illustrates the correct procedure for installing the pressure port fittings between the

H-350XL™ and the H-355 Gas Purge System. Chapter 23 goes into more detail on the Gas Purge

System. Refer to the manual provided with the H-355 for installation information.

Connect the pressure input line between the H-350XL™ and the H-355 bubbler system using the

H-350XL™ Install kit, which includes all the required hardware. You will need a 1/8" NPT male

tubing fitting for the pressure input port. It is recommended that you use 1/8" copper tubing. The

proper ferrules must be used to insure there are no leaks. The male 1/8" NPT fitting screws into

the pressure input port of the H-350XL™ connector panel shown in Figure 2-1. On the bubbler

manifold you will need a corresponding tubing fitting. Generally, a 1/4" NPT female to 1/8"

tubing fitting is required. The NPT threads of these fittings need a coat of Teflon tape or

anaerobic thread dope. This helps in preventing leaks.

Figure 2-3. H-350XL / H-355 Combination Installation

XL™ Series Hardware Options and Installation 2-5

2.2.6 Bubbler / Aux Port

Figure 2-4 is the Bubbler / Aux communication port, which is a 6-pin connector that interfaces

with the H-355 Gas Purge System and other WATERLOG products. The XL™ menu is setup to

®

give the user full control of the H-355 system. As other auxiliary devices are developed to

interface with the XL™, they too will be controlled through the XL™ menu system. This port

uses RS-485 hardware for communicating with the auxiliary devices. This provides noise

immunity and multi drop capability. As other devices are used, the cable will be daisy chained

from one device to the next.

Figure 2-4 Bubbler / Auxiliary Output connector pin out

The H-355 is normally used with the H-350XL because it has the built in pressure transducer.

However the H-355 may be used with any of the XL series data loggers and an H-350 Lite or

similar sensor to collect water level data.

2-6 Hardware Options and Installation XL™ Series

2.2.7 RS-232 Ports

The three RS-232 ports are used to connect to a PC, GOES Transmitter, modem, remote display,

or other serial equipment for standard serial communications. These ports are configured as a

DTE type of device. This means they will plug directly into a modem (a DCE type device), but

will require a NULL modem adaptor if connected to a PC (a DTE type device). The NULL

modem cable crosses the communication lines allowing two similar devices to communicate.

Figure 2-5 shows the pin out for all three ports. See the chapter covering the serial ports for

complete information on the port operations.

Figure 2-5 RS-232 Connector

SERIAL PORT PIN-OUT

PIN DIRECTION NAME

1 Input Data Carrier Detect (DCD)

2 Input Receive Data (RD)

3 Output Transmit Data (TD)

4 Output Data Terminal Ready (DTR)

5 Ground (GND)

6 Input Data Set Ready (DSR)

7 Output Request To Send (RTS)

8 Input Clear To Send (CTS)

9 Input Ring Indicator (RI)

XL™ Series Hardware Options and Installation 2-7

2.2.8 Analog Input Section

The first seven connections on the twenty pin terminal block are used for analog input functions.

This includes four analog inputs, two analog grounds and one +5.00 volt excitation connection.

Figure 2-6 Analog Input Section

2.2.8.1 Analog Input Channels

There are four analog input channels labeled Vin1 to Vin4. The standard input range for all

channels is 0 to 5 volts, and the optional range is 0 to 500 millivolts. The 500 millivolt range is

used for sensors that produce millivolt outputs. For example, some solar radiation sensors have a

full scale output of less than 500 millivolts. This type of sensor should be used with the 500

millivolt range. Channels 1 and 2 can also be used in a differential mode. The analog inputs use

a 20 bit analog to digital converter.

2.2.8.2 Analog Grounds

There are two analog ground connection points. In order to preserve signal integrity, it is

important to use the analog grounds only for sensors connected to the analog section of the

XL™. The current flowing through an analog sensor is relatively small and normally very stable.

This provides stable voltages produced by these sensors. If a digital sensor has its ground

connection tied into the analog ground, the currents from the digital sensor will flow through the

analog circuitry causing voltage level shifts and noise based on digital switching. There should

be sufficient digital ground connection points for the digital sensors.

2-8 Hardware Options and Installation XL™ Series

2.2.8.3 Switched +5.00 Volt Reference Excitation

The +5.00 Volt reference output is used for analog sensors requiring a precision reference

voltage. The output current source maximum level is 10 milliamps. Exceeding this limit will

cause the excitation to possibly sag, and result in possible data errors. The Analog to Digital

converter uses this excitation for its reference to provide a ratio-metric relationship for sensors

using the excitation. What this means is that if a sensor causes loading to the excitation and drags

it down to 4.75 volts for example, then the A/D converter will use the 4.75 volts as its reference,

and maintain a full scale input equal to the reduced excitation. To a point this will reduce errors

in data when the excitation is used. If the excitation is being loaded down and some analog input

channels are not using the excitation, but produce a voltage output on there own, then these

inputs will have a much greater error.

2.2.9 Wind Speed Input (AC Frequency Input)

Pins 8 and 9 of the terminal block provide connection points for a low-level AC signal. Several

wind speed sensors produce a low level AC sine wave directly compatible to this input.

Figure 2-7 Wind Speed Input

The wind speed input is a frequency counter capable of accepting low-level signals in the range

of ±0.075 volts and greater, however, this input should not be exposed to signals greater than

approximately ±5.0 volts. The input signal must be bipolar, that is, the input signal must vary

above and below the reference point or ground. Several wind speed sensors use a simple,

propeller driven generator that produces an AC signal suitable for this input.

XL™ Series Hardware Options and Installation 2-9

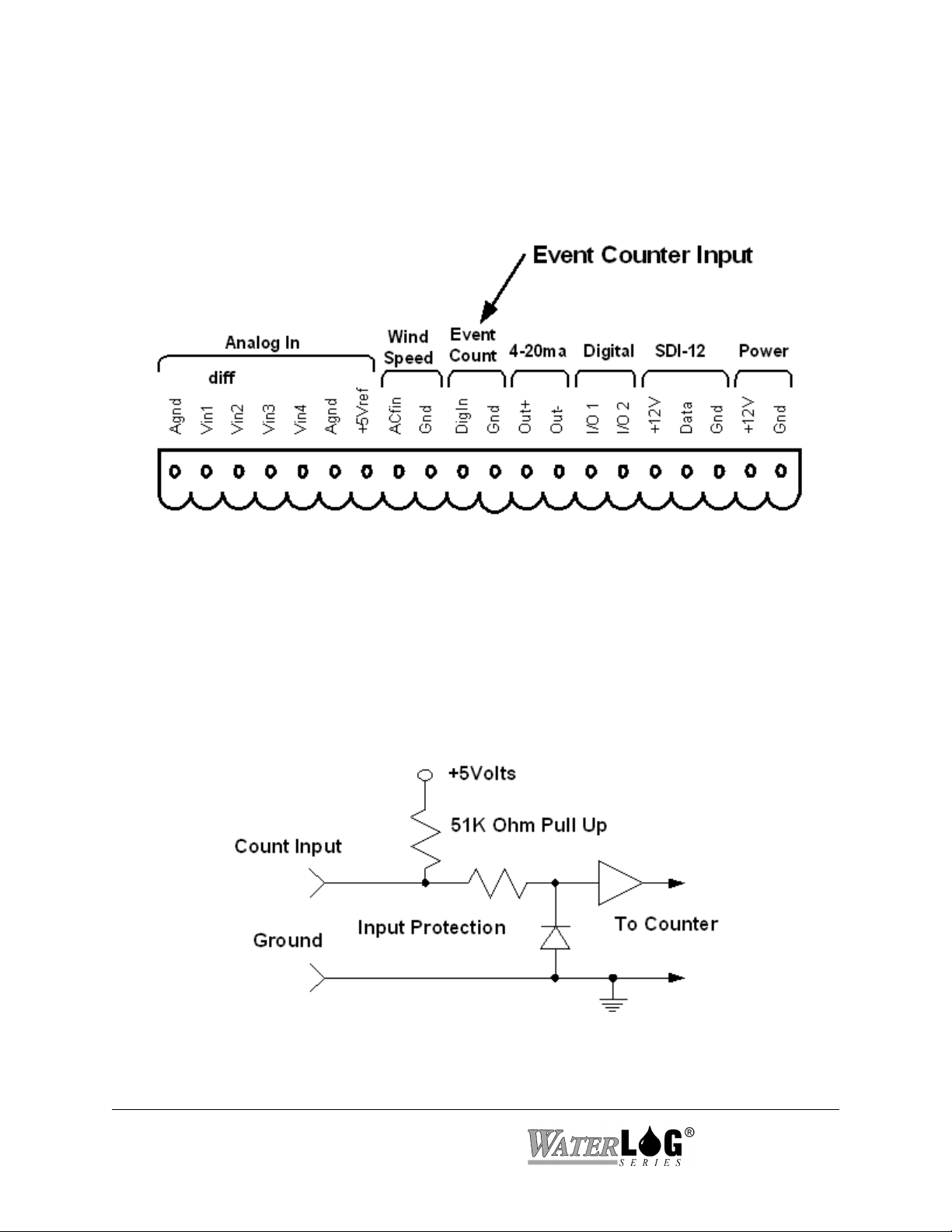

2.2.10 Event Counter Input

Pins 10 and 11 of the terminal block provide connection points for the digital event counter

input.

Figure 2-8 Event Counter Input

This input is normally used with a tipping bucket rain gauge. However, it can be used for other

counter type of applications also. Transient protection is provided for this input to prevent

damage from static discharge or over voltage conditions. This input is pulled high through a 51K

Ohm resistor allowing a switch closure to ground to activate the counter. Figure 2-9 shows a

simplified circuit for this input.

Figure 2-9 Event Counter Circuit

2-10 Hardware Options and Installation XL™ Series

2.2.11 4 to 20 Milliamp Output

Pins 12 and 13 of the terminal block provide connection points for the 4 to 20 milliamp output

signal.

Figure 2-10 4 to 20mA Output Section

Several instrumentation applications use sensors that provide an industry standard 4 to 20

milliamp output signal. The XL™ Series data logger / DCP can output a 4 to 20 milliamp signal

based on any of its inputs. For example, a user may want to connect a temperature probe to the

XL™ and convert the temperature value into a 4 to 20 milliamp output. A temperature probe on

Analog Channel 1 that produces a 0 to 5 volt output representing 0 to 100 degrees Celsius could

easily be setup to produce a 4 to 20 milliamp output that represents the 0 to 100 degrees. The

XL™ does not actually output a 4 to 20 milliamp signal, but rather controls the current in a loop

that is powered externally. Figure 2-11 shows a basic connection diagram.

Figure 2-11 Basic 4-20 mA Wiring Configuration

XL™ Series Hardware Options and Installation 2-11

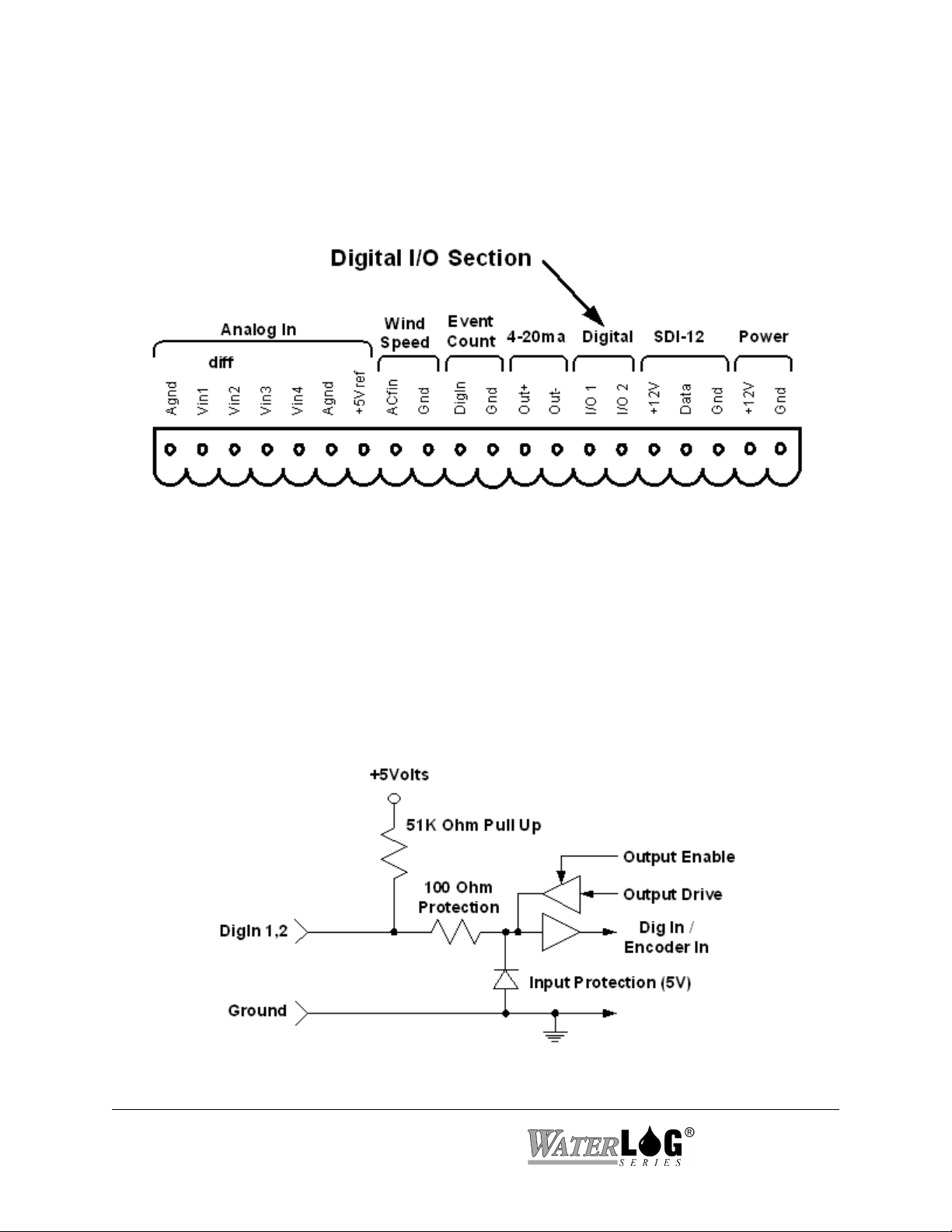

2.2.12 Digital I/O 1 and 2

Pins 14 and 15 of the terminal block provide connection points for the two digital I/O signals.

Notice there is no specific ground point for these signals. Use the digital ground pin of the event

counter or the SDI-12 ground. Do not use the analog grounds.

Figure 2-12 Digital I/O Section

The two digital I/O signals can be configured independently as inputs or as outputs. In the input

mode, the signal has an internal pull up resistor of 51K Ohms. This allows a switch closure to

ground to activate the input. It can also be driven using normal logic levels. As an output, the

drive capability is limited by a 100 Ohm protection resistor. The output will still be about 4.0

volts with a 10.0 mA or less load. When both pins are configured as inputs, they may be used as

a quadrature shaft encoder input. The two digital signals can also be used to simulate a

quadrature shaft encoder. Figure 2-13 shows a simplified schematic of how these pins are

configured.

Figure 2-13 Basic Digital I/O Schematic

2-12 Hardware Options and Installation XL™ Series

2.2.13 SDI-12 Section

Pins 16, 17, and 18 of the terminal block provide connection points for SDI-12 senors and data

loggers. The XL™ can be used as both an SDI-12 sensor and as an SDI-12 data logger. In either

case these connections are made at the same place. The +12V power connection under the SDI12 section is limited to about one amp so it may be necessary to connect the SDI-12 sensor power

line directly to the battery or to main power.

Figure 2-14 SDI-12 Section

If several SDI-12 sensors are to be connected to the XL™, it may be necessary to use an external

terminal strip to provide enough connection points.

Figure 2-15 SDI-12 Expanded Connector System

XL™ Series Hardware Options and Installation 2-13

2.2.14 Power Connections

The last two pins at the far right of the terminal block provide the main connection points for

system power and ground.

Figure 2-16 Main Power Connection Point

Note: When connecting to or removing the wires from these connection points, it is important

to remove the terminal block from the XL™ first, or to have the other end of the wires

disconnected from the battery. This helps prevent loose wires with live voltages

accidently come in contact with other I/O connection points.

2.3 Testing the Installation

After hooking up the battery, the Power light should begin flashing every 5 to 10 seconds. This

indicates that the battery is providing 10 volts or more to the XL™. Press the display On/Off

button and the display should come on, indicating the instrument is functional and ready to use.

You will find detailed user setup information and menu options that will allow complete test and

verification of all sensor connections and operation in the next two chapters.

2-14 Hardware Options and Installation XL™ Series

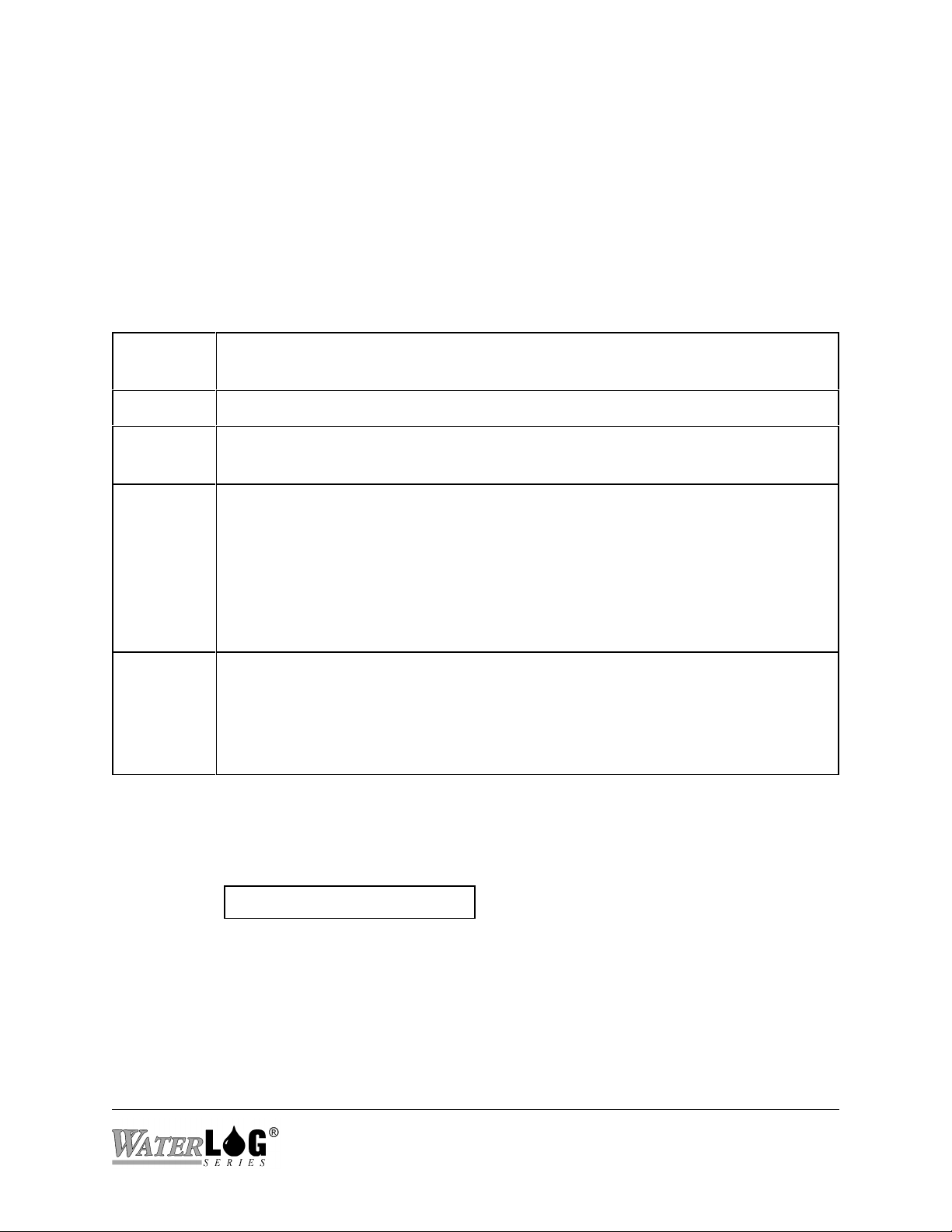

2.4 Hardware Revision Detection

As the XL series data logger has continued to evolve, changes and enhancements involve both

the hardware and the firmware. The following list shows some of the major changes to the

hardware and how to check as a user what revisions may affect you. For example if your

application requires the +12Volt excitation to be switchable, then you must use board revision

3.1 or newer. The firmware can detect the board revision and if an old board is detected, then the

menu option to set the +12Volt excitation mode will not be displayed because it has no affect.

The table below shows the changes to the hardware over the life of the product.

Board

Revision

Rev 2.1 - Original board

Rev 2.2 - New Power down sequence from normal mode to low power mode.

Rev 3.1 - New 24 bit A to D converter for the generic analog inputs and stage sensor.

Rev 3.3 - A new 16 bit DAC is now used for the 4 to 20 milliamp output option. The

Description

This change will not affect the user operation.

The older boards used a 16 bit A to D converter.

- Added differential mode to analog inputs 1 and 2.

- 500 millivolt range added to all generic analog inputs.

- The 12 volt excitation is able to be turned on and off.

- Able to use higher baud rates on the serial ports, now up to 115200 baud. The

older board would only go to 19200.

older boards used a 12 bit DAC.

- A new internal comm port for H-522 and H-522Plus is used for the built in

GOES radio. This allows com port 2 on the H-522 and H-522 Plus to still be

used for other purposes.

From the built in keypad / display interface the user can see what board revision is in use. Under

the ‘System Status’ menu is a status screen that will show the board revision, for example:

Hardware Rev = 3.1

XL™ Series Hardware Options and Installation 2-15

2-16 Hardware Options and Installation XL™ Series

Chapter 3

Using The Built In Keypad / Display

3.1 Overview

The XL™ series of data loggers is easy to set up and operate. The built-in display and keypad

allow you to view and edit all of the configuration options. This chapter focuses on the operation

of the built-in display and keypad. With a built-in keypad and display there is little need for

external programming devices such as a laptop computer, but remote operations are supported as

explained in chapter 4.

Note: The H-522 has no built in keypad / display, therefore options in this chapter will not apply

to the H-522.

3.2 Keypad/Display Operation (Not available with model H-522)

The XL™ can be fully configured using the built-in keypad and display. The user can easily

move through the different menus using the arrow keys. Changes are made using the ENTER key

and the arrow keys. Most configuration changes are made from a pick list of valid options. Figure

3-1 shows an illustration of the XL™ keypad and display.

Figure 3-1 The XL™ Keypad and Display (Not available with model

H-522)

XL™ Series Using The Built In Keypad / Display 3-1

BATTERY INDICATOR / MONITOR LED or POWER LED

The Power light flashes on and off to show that the XL™ is receiving proper +12V

power. If the power source has failed or provides less than +10V, the power light will

stop flashing. This is a visual indication that the system battery is low.

ERROR LED

The Error light is not used at this time.

MEMORY CARD SLOT

The memory card slot accepts an industry standard ATA PCMCIA FLASH Memory

Card. When operated as a data logger, the XL™ stores the data internally in non-volatile

memory. The data can be transferred from the internal memory to an ATA FLASH

Memory Card for use in computers that have PCMCIA support. Most laptop PC’s have

PCMCIA support built into them, and desktop PC’s can be equipped with PCMCIA card

readers. PCMCIA card readers are available at most PC outlets or from Design Analysis.

All XL™ firmware updates are uploaded from an ATA FLASH Memory Card using this

memory card slot

.

ON / OFF Key

The ON/OFF key is used to turn the display on and off. This key will only turn the

display off from the top level of the menu system. If the unit is on and in a submenu, this

key, much like the CANCEL key, will cause the system to return to the previous menu

screen in the menu system hierarchy until the HOME menu screen is displayed, at which

time pressing the ON/OFF key will turn the display off.

Note: If the unit does not respond to a key press, it may be in the process of measuring.

Wait a few seconds and try again.

To save power, the XL™ display will turn off automatically after five minutes of

inactivity.

ENTER Key

The ENTER key has four functions:

I. Pressing the ENTER key while displaying a status screen such as “Stage = 2.45”

or “PtTemp = 23.65” will cause the H-350XL™ model to make a new

measurement of the selected input and update the screen with the new reading.

II. The ENTER key acts as a “YES” key on screens that are looking for a yes or no

response. For example, pressing the ENTER key on the “Erase Data ?” screen will

cause the erase process to start, but pressing the CANCEL key will abort the

option.

III. The ENTER key starts the editing process for fields that can be modified or

3-2 Using The Built In Keypad / Display XL™ Series

changed. These fields are surrounded by brackets such as [Option] . For example,

the option “Logging [Off]” can be changed to “On” by pressing the ENTER key to

start the editing process, and the text between the brackets starts to flash. In this

case the “Off” flashes and the UP and DOWN arrow keys are used to select the

“On” option, and the ENTER key is used to accept the change.

IV. The ENTER key is used to accept edits or changes. For instance, if you changed

the option “Stage Units [Feet ]” to “Stage Units [Meters],” you would press the

ENTER key to accept the change and the selection would stop flashing.

CANCEL Key

The CANCEL key has three main functions:

I. The CANCEL key is similar to the Escape key on your computer. For example, if

you are editing an option and decide not to make a change, pressing the CANCEL

key will abort the change.

II. The CANCEL key also works as a “HOME” key. If you are in a sub-menu and

wish to return to the previous menu, press the CANCEL key. Pressing the

CANCEL key several times will always take you to the beginning menu screen.

III. The CANCEL key acts as a “NO” key on screens looking for a yes or no response.

For example, pressing the CANCEL key on the “Erase Data?” screen will abort

the option.

Arrow Keys

The UP, DOWN, LEFT, and RIGHT arrow keys have the following functions:

I. The UP and DOWN arrow keys enable you to scroll from one menu to another.

When you reach the bottom screen, the DOWN arrow key will no longer work.

When you are at the top screen, the UP arrow key will no longer work.

II. When moving through the menus, the LEFT and RIGHT arrow keys allow you to

move into and out of sub menus. Screens that have an arrow (->) on the right side

of the display have associated sub menus.

III. The LEFT and RIGHT arrow keys let you move the cursor back and forth across

the field when editing a numerical value such as the slope or the offset. The digit

or blank space will flash to let you know the location of the cursor within the

field. When editing numerical or character options, the UP and DOWN arrow

keys let you move through the list of valid characters or options.

IV. The UP and DOWN arrow keys enable you to scroll through the options within a

menu. For example, if you want to change the XL™ logging option from [Off] to

XL™ Series Using The Built In Keypad / Display 3-3

[On], start the editing process by pressing the ENTER key, and then use the UP

and DOWN arrow keys to choose the desired option. Once the desired option is

selected, pressing the ENTER key will accept the change and the new option will

be displayed.

DECIMAL (or Dot) Key

When editing an option screen with a pick list of valid options, the DECIMAL key lets

you toggle between the first and last option in the list. This is very useful when you want

to select an option near the bottom of a large list.

When first turned on and a status screen is displayed, pressing the DECIMAL key will

cause the menu system to skip all the status screens and move directly to the first menu

item past the status screens. This is handy of several status screens are used.

DISPLAY

The 1 line by 20 character display is used to view and edit all of the menu items. Each

screen represents a unique menu item or system option. There are four types of menu

screens: status screens, sub menu header screens, option screens, and table screens.

STATUS SCREENS

Status screens are normally used to display system information or sensor values. The user

can select what values or information is used for status screens. The system will

automatically update some status screens, such as the battery voltage. As the battery

voltage level goes up and down the displayed value will go up and down automatically.

BATT = 13.2 Volts

There are a few status screens the user can have the system update. A screen that shows

the stage value may be displaying a value that was measured several minutes earlier.

Pressing the ENTER key will cause the system to take a new measurement and display

the new value. When the ENTER key is first pressed the display will show the following

screen indicating the ENTER key was acknowledged, and a measurement is in process.

Scanning...

The updated status value will be redisplayed once the measurement is complete.

Stage = 34.56

3-4 Using The Built In Keypad / Display XL™ Series

SUB MENU HEADER SCREENS

Screens that have an arrow (->) on the right side are classified as sub menu header

screens. The sub menu may be entered by pressing the RIGHT arrow key. There may be

several levels in a sub menu, and each sub menu relates to the header screen text. For

example, the sub menu options of the main menu header screen “Scan Setup” relate to the

scanning process.

Scan Setup -> Scanning [Off]

Scan Rate [HH:MM:SS]

Next Scan = HH:MM:SS

Nxt Scn At[HH:MM:SS]

OPTION SCREENS

Screens with brackets surrounding a system option ( [Option] ) are called option screens.

The user can edit or change the option which will always be shown between the brackets.

In some cases, the option inside the brackets may include several characters, but the

editing process will only change one character at a time, such as with the time or the date

value.

Time [12:34:42]

Pressing the ENTER key will start the editing process, and one of the characters in the

brackets will begin to blink. The UP and DOWN arrow keys are used to change the

blinking character, and the LEFT and RIGHT arrow keys are used to move to the next

character. Pressing the ENTER key will accept the new value, or pressing the CANCEL

key will keep the original value.

On some option screens, all of the text between the brackets will flash when the option is

to be edited. The UP and DOWN arrow keys are used to select a valid option from a list

specific for that option.

Baud Rate [9600]

Pressing the ENTER key will start the editing process and the text “9600” will start

blinking. Use the UP and DOWN arrow keys to change between valid choices of 19200,

9600, 4800, 2400, 1200 or 300 baud, or use the DECIMAL key to toggle between the first

and last option of the list. Press the ENTER key to accept the new value or the CANCEL

key to stay with the original value. For these type of options, invalid entries are not

possible.

XL™ Series Using The Built In Keypad / Display 3-5

TABLE SCREENS

Complex screens that look like both option screens and sub menu header screens are

called table screens. The following table shows the menus used to define the logging

report options.

Source 1 [Date ] -> Source 2 [Time ] -> ... Source 25 [None ]

Header 1[ ] -> Header 2[ ] -> ... Header25[ ]

Log Rate 1[00:15:00]-> Log Rate 2[00:15:00]-> ... Log Rate25[00:15:00]

Digits 1 [2] -> Digits 2 [2] -> ... Digits 25 [2]

Col 1 Fn()[NOW ] -> Col 2 Fn()[NOW ] -> ... Col 25 Fn()[NOW ]

Stat Scrn 01 [No ] -> Stat Scrn 02 [No ] -> ... Stat Scrn 25 [No ]

The LEFT and RIGHT arrow keys let you to move through the table horizontally, and the

UP and DOWN arrow keys let you to move through the table vertically. While moving

through a table, pressing the CANCEL key will take the system back to the sub menu

header screen used to enter the table. Options in the table may be edited as previously

explained.

3.3 Familiarization

The best way to become familiar with the system is to explore the system options and features.

Turn the unit on, move through the menus, and make changes to some of options in order to

experiment with the system. Do not worry about mis-programming the unit, the “Reset Defaults”

option will change the unit back to the factory settings.

3-6 Using The Built In Keypad / Display XL™ Series

3.4 Main Menu Description

The tables on the following pages show the main menu structure of the XL™. The main menu

includes status screens, which allow the user a quick view at sensor data, and sub menu header

screens that separate the main configuration options of the XL™ into there respective sections.

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

Output Options ->

Data Options ->

Scan Setup ->

System Setup ->

System Status ->

Accessory Setup ->

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

Output Options ->

Data Options ->

This table represents the main menu of the XL™ Series DCP. The

user can easily move through the menu using the UP and DOWN

arrow keys. Pressing the CANCEL key repeatedly will cause the

system to return to the top of this menu structure.

Menu items with the pointer (->) on the right side of the screen

have a sub menu related to the displayed menu. Use the RIGHT

arrow key to enter the sub menu.

Use the CANCEL key or the LEFT arrow key to return from the

sub menu to the header screen in the main menu.

The shaded screen on the left is a user definable status screen

³

showing the last measured stage value. When the display is

turned on, this screen will be displayed (unless the user

changes or disables the status screens). This screen is also

considered the “HOME” position, as pressing the

CANCEL key several times will always cause the system to

return here.

Scan Setup ->

System Setup ->

System Status ->

Accessory Setup ->

XL™ Series Using The Built In Keypad / Display 3-7

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

The 25 log columns can be enabled as status screens. The

³

user defined header text is the label used for the status screen.

³

The default status screens the H-350XL report the last

measured stage value, the last measured internal system

³

temperature, and the current battery voltage. The other status

screens are initially disabled.

Output Options ->

Data Options ->

Scan Setup ->

System Setup ->

System Status ->

Accessory Setup ->

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

Output Options ->

Data Options ->

Scan Setup ->

System Setup ->

Note: Depending on the XL™ Series Model the status

screens by default will be different from each other. All the

XL™ Series DCP’s are programmable to use or disable the

status screens.

Status screens are enabled or disabled in the logging options

table, see chapter 15.

The “Sensor Input Setup” screen is a sub menu header screen

as indicated by the arrow (->). Pressing the RIGHT arrow

key will cause the system to enter into the sub menu for all of

the sensor input setup options of the XL™.

³

For example in the H-350XL™ model this menu would

include defining how the pressure sensor will be used to

calculate the stage value and defining how the temperature

sensor will report its results. This menu also is used for

defining the generic analog inputs, the counter input, etc.

System Status ->

Accessory Setup ->

3-8 Using The Built In Keypad / Display XL™ Series

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

Output Options ->

Data Options ->

Scan Setup ->

System Setup ->

System Status ->

Accessory Setup ->

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

Output Options ->

Data Options ->

Scan Setup ->

System Setup ->

The “Output Options” screen is a sub menu header screen.

The sub menu options allow the user to indicate what to do

with the data once it has been measured. The data can be

³

saved to internal memory, sent to a GOES transmitter, sent

to a printer or terminal through the serial port, or converted

to a 4 to 20 mA signal and sent to other types of control

equipment. Some of the options here are complex enough

that they are described in a separate chapters dedicated to the

application.

The “Data Options” screen is a sub menu header screen. The

sub menu options allow the user to erase data, copy data to

an external data card, view the data file, and see how many

³

free bytes are still left in data memory or on the data card.

For more information refer to the Data Options chapter.

System Status ->

Accessory Setup ->

XL™ Series Using The Built In Keypad / Display 3-9

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

Output Options ->

Data Options ->

Scan Setup ->

System Setup ->

System Status ->

Accessory Setup ->

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

Output Options ->

The “Scan Setup” screen is a sub menu header screen. The

sub menu options allow the user to enable and disable

scanning and define how often to scan the connected sensors.

NOTE: Scanning is the heart of the system. All major

operations are based on scanning being enabled. Logging,

³

GOES radio operations, ALERT radio operations, and

several other options will only happen if scanning is enabled.

Data Options ->

Scan Setup ->

System Setup ->

System Status ->

Accessory Setup ->

The “System Setup” screen is a sub menu header screen. The

sub menu options under this heading are used to define

³

generic system options such as the time of day, date, serial

port settings, etc.

3-10 Using The Built In Keypad / Display XL™ Series

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

Output Options ->

Data Options ->

Scan Setup ->

System Setup ->

System Status ->

Accessory Setup ->

Stage = X.XX

PtTemp= XX.XX

BATT = XX.XX

Sensor Input Setup->

The “System Status” screen is a sub menu header screen. The

sub menu options under this heading are used to view how

the system is operating; if there have been any unexpected

³

power resets, battery voltage levels, etc.

Output Options ->

Data Options ->

Scan Setup ->

System Setup ->

System Status ->

Accessory Setup ->

The “Accessory Setup” screen is a sub menu header screen.

The sub menu options under this header allow the user to

control accessory products connected to the XL™ such as the

H-355 Bubbler system. The H-355 bubbler is discussed in a

separate chapter.

³

XL™ Series Using The Built In Keypad / Display 3-11

3-12 Using The Built In Keypad / Display XL™ Series

Chapter 4

PC Menu Interface Operation

4.1 PC Menu Interface

All remote communications with the XL™ are through a command interface or menu interface

using the first RS-232 Serial Port. Note: A NULL modem connector must be used between the

PC and the XL™ for direct connections. If in the command mode, the command “MENU” is

used to start up the menu interface allowing simple human access to the system options. To

access the command or menu interface, the XL™ must be connected to a computer that is

running some type of terminal emulation program. The terminal emulation program must use the

same communication settings as used by the XL™. The default XL™ communication settings

are shown below along with other valid options.

COMMUNICATION

SETTING

BAUD RATE:

DATA BITS:

STOP BITS:

PARITY:

DUPLEX:

TERMINAL

EMULATION:

FLOW CONTROL:

STARTUP MODE:

Basically all options available through the menu interface are also available using the command

interface or the built in keyboard and display. This chapter focuses only on the remote menu

interface.

DEFAULT XL™

SETTING

9600

8

1

None

Full

VT-100, (VT-52 on

older firmware

versions)

Software (Xon / Xoff)

Menu Mode (SW Rev

2.04) (Command mode

on older Versions)

OTHER XL™ OPTIONS

300 to 19200 on hardware Rev A to

M 300 to 115200 on hardware Rev

N up.

None

None

None

None

VT-52, VT-100

None or Hardware

Command Mode, Menu Mode

When the computer is connected (direct connection or modem connection), pressing any key will

wake up the XL. If the XL is set to startup in menu mode then the main menu will be displayed.

If the startup mode is set to command mode, then pressing the ENTER key a few times will

cause the command interface prompt to be displayed. This prompt appears as an arrow “->” on

the left side of the screen. It may take a few key presses to “wake up” the XL™ and display this

prompt. Once the prompt is displayed, the XL™ is ready to receive commands. If no commands

are received in a five minute time period, the XL™ will turn off automatically and return to a low

power mode. Enter the command “MENU” at the prompt to access the menu interface.

XL™ Series PC Menu Interface Operation 4-1

4.2 PC Menu General Operations

Each menu option is preceded with a letter or number that when pressed will activate the

indicated option. The ENTER key does not have to be pressed after an option key is pressed.

Some options will open a sub menu and others will allow the user to set or change a system

parameter. When in a sub menu, pressing the ESC key will back up one menu. At the main menu

the ESC key has no effect. Pressing the ENTER key or SPACE bar at any time will refresh the

current screen.

At the bottom of each menu screen is an “Enter Option >” prompt. When an option key is

pressed that allows a system parameter to be changed, any additional information for that option

will be displayed after the prompt. There are two types of system parameter change options, first

is an option that requires direct keyboard input like a file name or a column header label. The

second is an option that has a pick list of valid options such as an input source option. This type

of option allows the user to scroll through the valid options using UP and DOWN arrow keys.

Pressing the ENTER key will select the option that is visible.

4-2 PC Menu Interface Operation XL™ Series

4.3 Main Menu Screen

The following shows what the “Main Menu” screen looks like. This may also include a user

defined ‘welcome message’ on the top line of the display. The product here is shown as an H350 XL but could be any of the XL series of products.

H-350 XL Main Menu

V - View Status

I - Sensor Input Options

D - Data Options

O - Output Options

S - Scan Options

C - Configure System

A - Accessory Setup

E - Enter Command Mode

X - Exit

Enter Option >

Each option in the main menu is a link to a submenu. Each section will be described in detail in

a later chapter dealing with the specific menu items.

V - View status: Displays the main system status information.

I - Sensor Input Options: Used to configure the sensor input parameters such as slopes and

offsets for the analog inputs, configure the Digital I/O modes, and

SDI-12 sensor configuration.

D - Data Options: Allows the user to retrieve data from the unit, erase data from

memory and perform other internal data and card operations.

O - Output Options: Defines if and how the data is stored internaly, transmitted via

GOES or displayed on remote displays, etc.

S - Scan Options: Defines when and how often the unit scans the sensors, and

performs data output operations.

C - Configure System: Used to set basic system options such as time and date, site ID,

serial port options and other system level options.

A - Accessory Setup: Configures system accessories such as the H-355 bubbler.

E - Enter Command Mode Exit the menu mode and enter the command mode immediately.

X - Exit Exit the menu mode and return to the low power sleep mode.

XL™ Series PC Menu Interface Operation 4-3

4-4 PC Menu Interface Operation XL™ Series

Chapter 5

Miscellaneous System Setup

5.1 Overview

The following menu structure represents all the sub menus under the “System Setup” header.

General system options unrelated to input options or output options are normally found here.

These options include setting the time and date, and defining a name for the site. Other options

for saving and retrieving setup information or resetting the system to factory defaults are also

found here.

Several of the options under this menu are big or complex enough that they are explained in their

own chapter.

5.2 System Setup

Built in Menu Structure: System Setup Options Menu.

The order of options in the built in menu differs slightly than that of the PC menu options. The

text below will follow the order of the PC menu.

System Setup -> Time [HH:MM:SS]

Date [MM/DD/YY]

Date Fmt [MM/DD/YY]

Sync [Sync Disabled]

Sync Time Now?

Last Synced On DD/MM

Site ID [Site_ID ]

Advanced Options -> == See Section 5.4==

Serial Port Setup -> == See Chapter 6 ==

SDI12 Sensor Setup-> == See Chapter 14 ==

SDI12 Logger Setup-> == See Chapter 14 ==

System Config Opts-> == See Chapter 7 ==

Functions Options-> == See Chapter 21 ==

XL-Basic Options-> == See Chapter 22 ==

Update Firmware?

XL™ Series Miscellaneous system Setup 5-1

PC Menu Screen: System Setup Options.

System Setup (Esc to Return)

T - Time: HH:MM:SS

D - Date: MM/DD/YY

E - Date Fmt:MM/DD/YY

I - Site ID: Site_ID

A - Advanced Setup Options

M - SDI Sensor Mode Setup (See chapter 14)

L - SDI Logger Mode Setup (See Chapter 14)

P - Port Setup (See Chapter 6)

C - Configuration Files (See Chapter 7)

R - Reset Defaults (See Chapter 7)

G - Sync Time Options

F - Functions Menu (See Chapter 21)

B - XL-Basic Code Menu (See Chapter 22)

U - Update Firmware

Enter Option >

PC Interface View Built In Display Screen

T - Time: HH:MM:SS

Time [HH:MM:SS]

This option is used to check or set the time clock used by the data logger. This is normally set to

local time or to international standard time. This is the time used to tag each scan placed in the

data file. This is a different time clock the one in the GOES radio. The GOES radio time clock

is normally set automatically by a GPS system and must be set to international standard time.

The display will be updated each second to allow easy viewing of the current time.

PC Interface View Built In Display Screen

D - Date: MM/DD/YY

Date [MM/DD/YY]

This option is used to view or set the system date. The default format is MM/DD/YY, but it may

be changed using the date format option if needed.

PC Interface View Built In Display Screen

E - Date Fmt: MM/DD/YY

Date [MM/DD/YY]

This option is used to set the date format. The default format is MM/DD/YY, but it may be

changed to other formats such as DD/MM/YY, YY/MM/DD, or DD/MM/YYYY. This format

will be used when the date is logged to the data file.

5-2 Miscellaneous System Setup XL™ Series

PC Interface View Built In Display Screen

I - Site ID: Site_ID

This option allows the user to enter in an eight character label that defines the site. This will also

be used as the filename for data files and other files related to this site. A file extension will be

added automatically when the file is created. Data files will have a numerical extension such as

.000 .001 or .002 and so on up to .099. Configuration files will have a .CFG extension. A

system log file will have a .LOG extension. Other file types will also exist using this variable as

the file name.

Note: Since the ‘Site ID’ variable is used as a file name, it must not contain any imbedded

blanks or wildcard characters (*) and must be left justified, in other words it must be a DOS

compatible filename. Valid site ID labels may include letter, numbers, or the underscore. Spaces