Xylem EHR IM User Manual

Installation and Operating Instruc-

tions for Electric heater-circulator

unit EPR

Instruction manual Laing Electric heater circulator unit

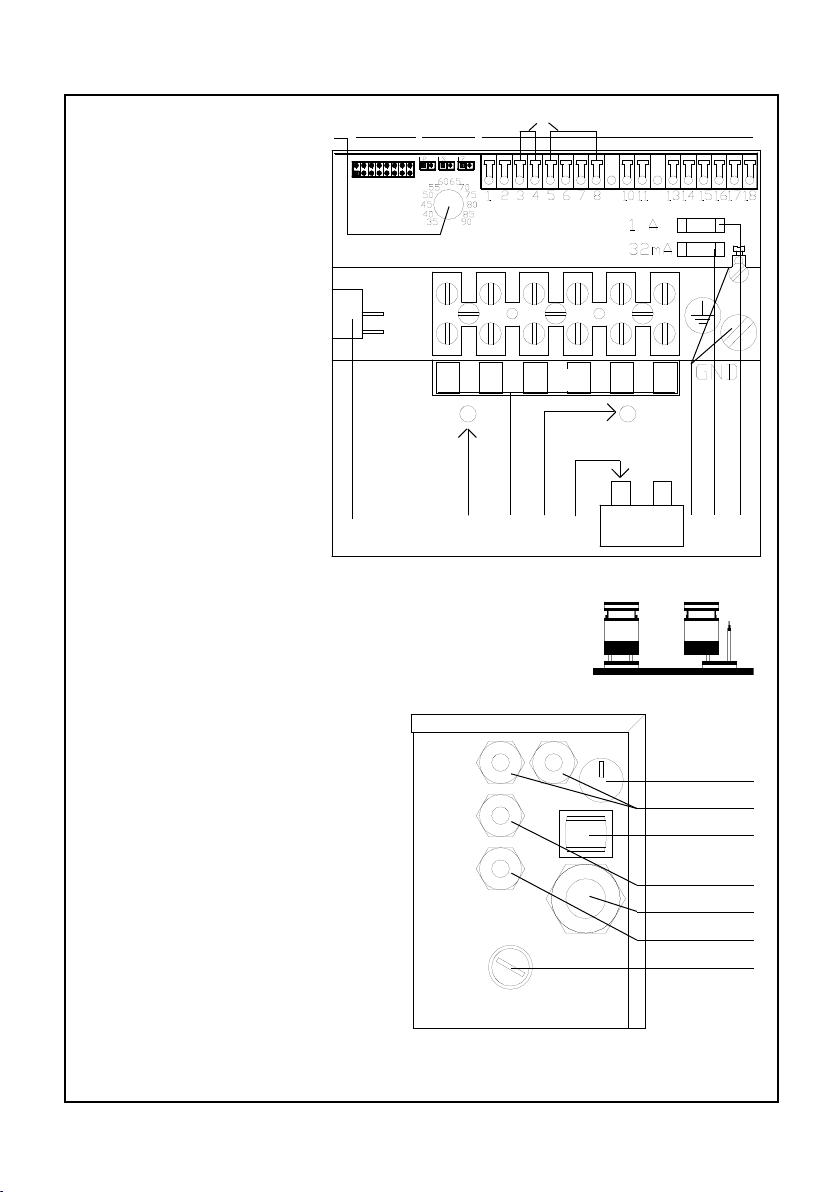

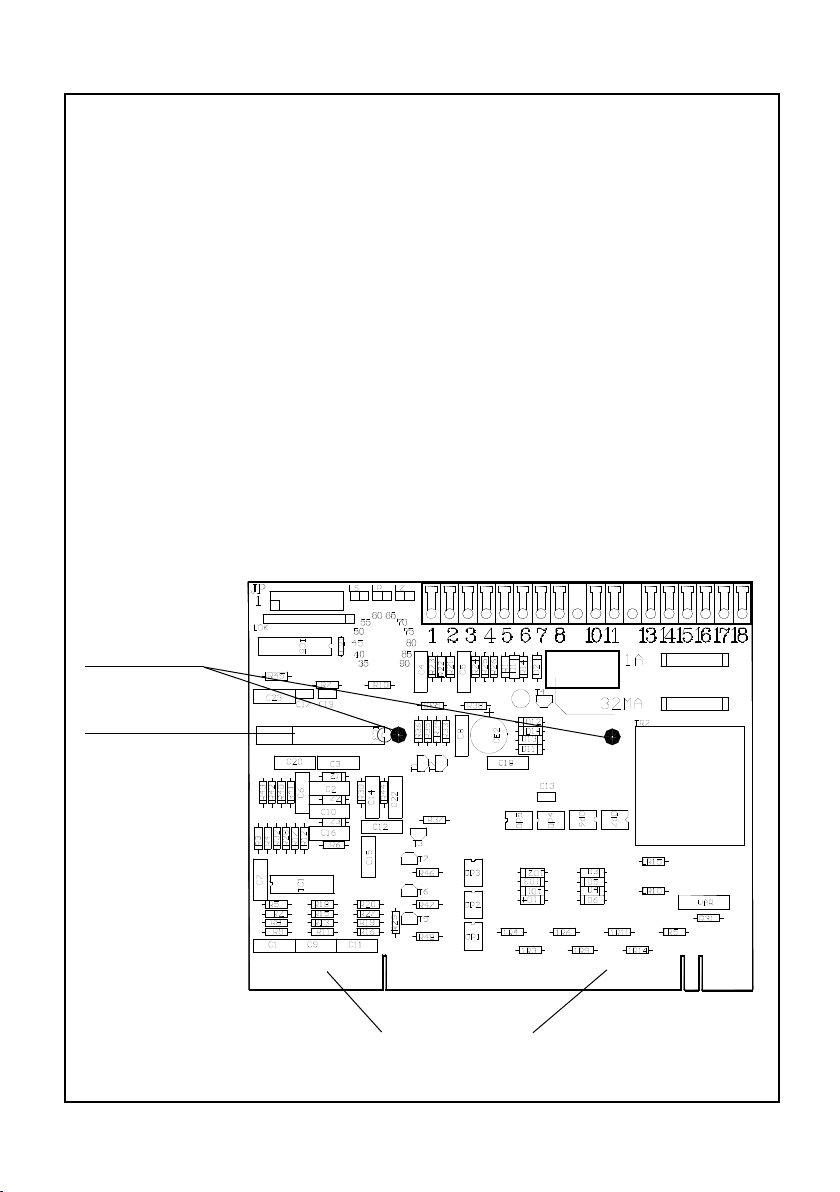

A Terminal strip for Mains

connection

E Ground terminal

F Fuse for pump

H Main switch

I Jumper wires for remote

control input and pump

module input

J Jumper 1 to 8

K Constant temperature

control

L LEDs

M Mounting screws for prin-

ted circuit board (behind

terminal bracket)

N Cable entry for Mains

connection

R Cable entry for control

and circulator

S Safety temperature limiter

U Fuse for control

V Terminals

Z Reset knob for safety

temperature limiter

S J L V

I

L1 L2 L3 N N N

H M A M T E U F

Jumperposition

closed open

Terminal usage

1,2 Remote control for heating

elements 2 and 3

3,4 Input from pump module

5,6 Remote control input

7,8 Remote control input

10,11 Potential free output for remo-

te trouble indicator

13,14 Power supply for daughter

board EPRBW

15,16 Power supply for circulator

17,18 used only for FP 5000 ER

models

See next to last page for jumper positions and error indicators.

2

K

R

H

R

N

R

Z

www.lainginc.com

Instruction manual Laing Electric heater circulator unit

Contents

Applications ............................................................................................................... 5

Design of the EPR model .......................................................................................... 5

Technical Data ........................................................................................................... 6

Dimensional Drawing................................................................................................. 7

Performance Curve ................................................................................................... 7

Models Available ........................................................................................................ 8

Mounting .................................................................................................................... 9

Connection to the feed and return line ...................................................................... 9

Electrical Connection ............................................................................................... 10

Power Supply .......................................................................................................... 10

400V N3 Electrical Diagram .................................................................................... 10

230V N1 Electrical Diagram .....................................................................................

230V N3 Electrical Diagram .....................................................................................

The integrated control.............................................................................................. 12

Schematics of the integrated control ....................................................................... 12

Design of the Main Printed Circuit Board ................................................................ 13

Main switch .............................................................................................................. 14

Fuses ....................................................................................................................... 14

Constant temperature control .................................................................................. 14

Overheating Protection ............................................................................................ 14

Program selection for the switching sequence of the heating elements ................. 15

Pump shut-off ......................................................................................................... 17

Deactivating heating elements ................................................................................ 17

Remote control of the second and third heating element ........................................ 17

Control input ............................................................................................................ 18

Room temperature guided control ........................................................................... 18

Outside temperature guided control ........................................................................ 20

Safety temperature limiter ....................................................................................... 20

Electronic means to prevent dry running ................................................................. 21

Circulator operation control ..................................................................................... 21

Malfunction detector ................................................................................................ 22

Attachment of the sensor for the remote control ..................................................... 23

Indirect domestic hot water heating with the Electric heater-circulator EPR ........... 24

Hydraulic connection of the EPR for domestic hot water heating............................ 25

Electrical connection of the EPR for domestic hot water heating ............................ 26

Control method 1 ..................................................................................................... 26

Control method 2 ..................................................................................................... 27

Operation of heating elements with a load shedding device ................................... 28

Filling of the system ................................................................................................. 30

Pressure and leak tests ........................................................................................... 30

Starting operation .................................................................................................... 30

Replacement of the circulation pump ...................................................................... 31

Replacement of the safety temperature limiter STBR ............................................. 31

Replacement of the main circuit board EPRH ......................................................... 32

Important Notices .................................................................................................... 32

Important Notice: How to avoid overheating............................................................ 32

Important Notice: In the event of safety temperature limiter failure ......................... 33

Important Notice: For proper connection to a oor heating system ......................... 33

Factory settings ....................................................................................................... 33

11

11

www.lainginc.com

3

Instruction manual Laing Electric heater circulator unit

Applications

Electric heater circulator units Model EPR can be applied in all cases where

electric heating has to be installed in a small space to heat an apartment or

a single or multiple family house.

This applies to direct electrical heating as well as for electrical heating with

a heat storage.

A further application exists in connection with room additions where the

electric heating can supplement the existing hydronic heating.

The Electric heater-circulator is also very well suited to heat domestic

hot water. The application for heating of domestic hot water is described in

“Indirect domestic hot water heating - Application”.

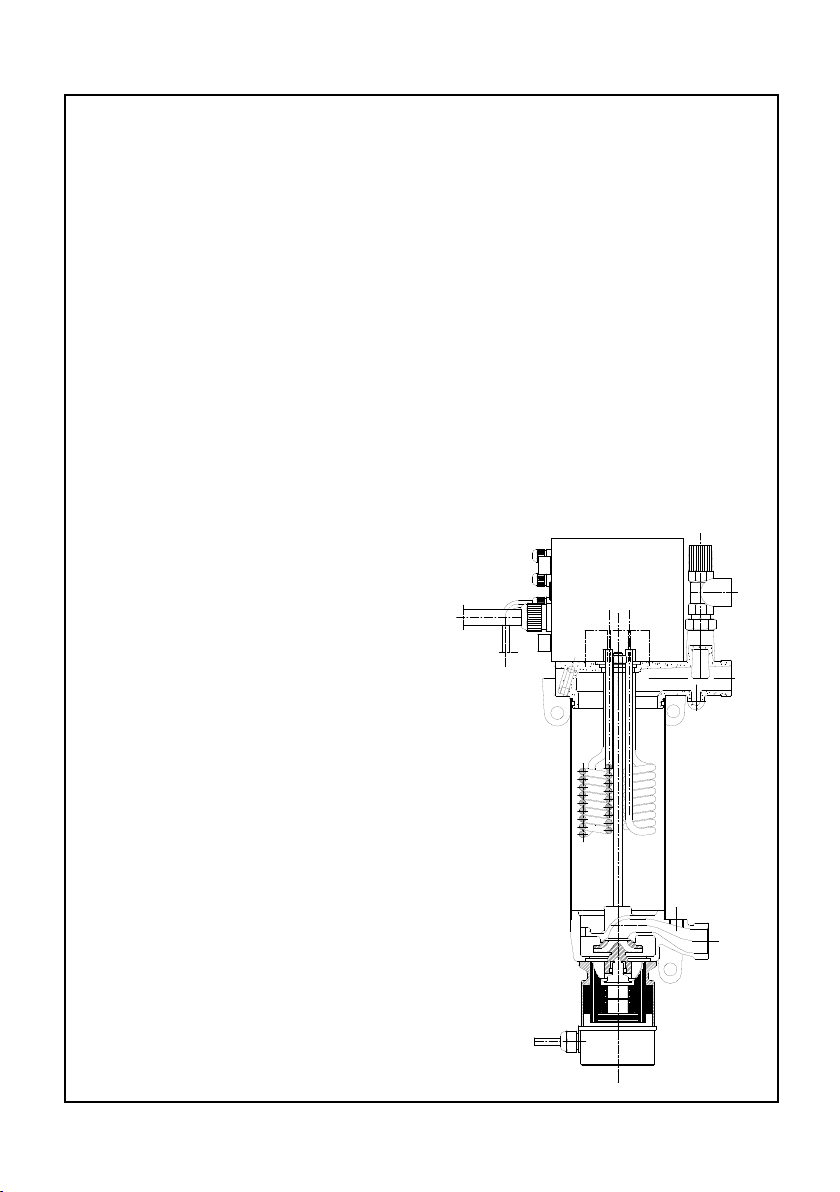

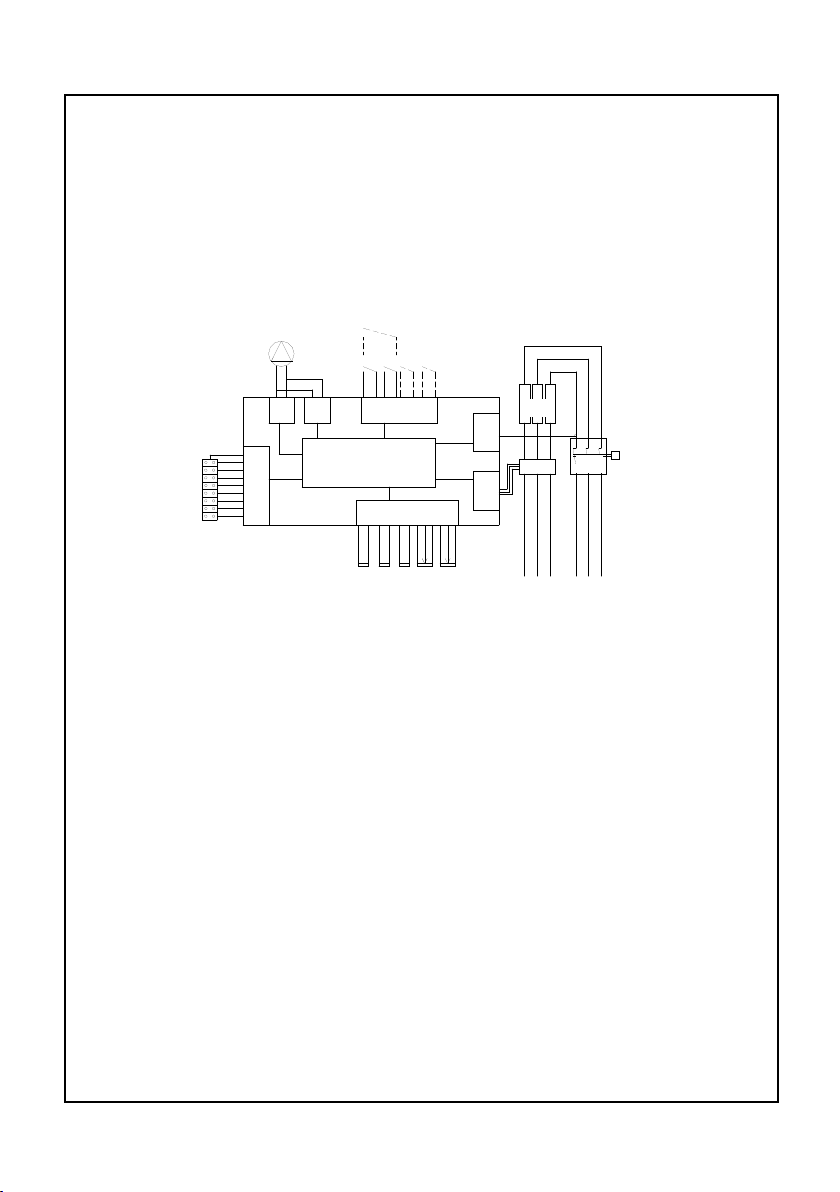

Design of the EPR model

The Electric heater circulator model EPR consists of a circulator pump, an

electric heater with three heating elements and an electronic microprocessor

control.

The spherical motor circulator

operates almost noiselessly and stays

quiet over its lifetime.

The arrangement of the pump below the heating elements guarantees

good heat conductivity from the heating elements since the swirl created

by the impeller extends over the length

of the heating elements. This avoids

overheating of the heating element

surfaces.

The water for the heating loop is drawn

in by the circulator, conveyed along

the heating elements and discharged

through the discharge port at the

upper part of the housing. The inlet

has an additional 3/8” port, to which

an expansion tank can be connected.

An automatic air vent and a pressure

relief valve communicate with the

outlet port.

Mounting eyelets are included in

the castings of the unit.

4

www.lainginc.com

Instruction manual Laing Electric heater circulator unit

The Electric heater circulator units EPR 6 to EPR 15 differ only in the performance of the electrical heating elements and the distance between the ports.

EPR 6 has a heating performance of 6000 W, EPR 9 has 9000 W, EPR 12

has 12000 W and EPR 15 has 15000W.

The control unit, which controls a variety of control and safety functions, is

arranged on top of the Electric heater circulator.

Technical Data

Model EPR EPR EPR EPR

6 9 12 15

Pmax. 87 PSI

Tmax. 194°F

Connection on water side Union 1” male

Weight 21.8 lb 22.5 lb 23.8 lb 24.5 lb

Pump

Max. Head 4.6 PSI

Max. Flow 14.9 GPM

Motor

Design Shaftless spherical motor

Watts Input 99 W

Motor performance 35W

Volts AC 230 V

Amperes 0.43 A

Electric Heater

Electrical performance 6 kW 9 kW 12 kW 15 kW

Number of heating elements 3 3 3 3

Heat capacity per element 2 kW 3 kW 4 kW 5 kW

Voltage 400 V, 3P 400 V, 3P 400 V, 3P 4 0 0 V,

3P

Amperes 8.7 A 13.0 A 17.4 A 21.6 A

Connection Y Y Y Y

Safety Temperature Limiter

Maximum temperature 203°F+/- 5 K

www.lainginc.com

5

Instruction manual Laing Electric heater circulator unit

0

2

4

6

8

10

12

0 2 4 6 8 10 12 14

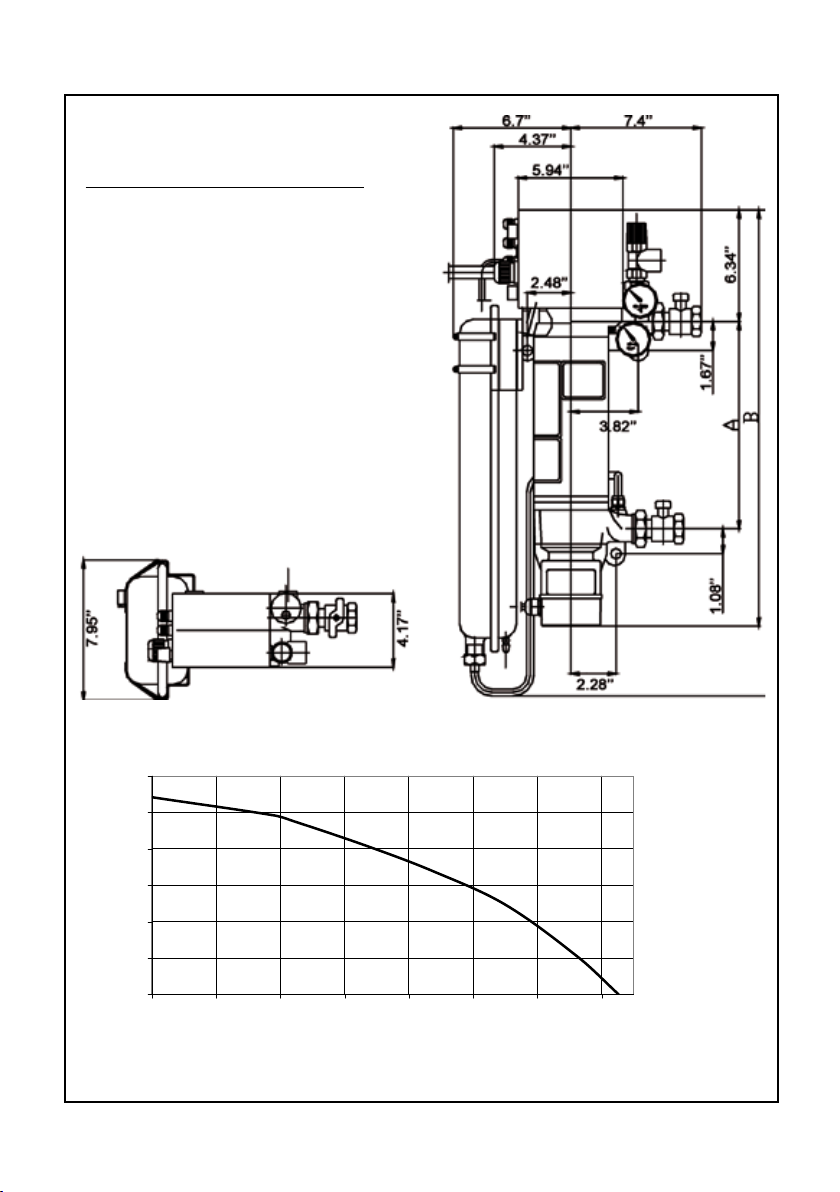

Dimension Drawing

Dimension

Model A B

EPR 6 11.8’’ 23.66’’

EPR 9 11.8’’ 23.66’’

EPR 12 14.37’’ 26.2’’

EPR 15 14.37’’ 26.2’’

Pump curve

Pump head (ft)

6

Flow rate (GPM)

www.lainginc.com

Instruction manual Laing Electric heater circulator unit

Mounting

For safety reasons, the Electric heater circulator must be mounted on a

reproof base. In addition, the unit must be installed with the circulator

motor pointing downwards!

The unit must be attached to a at wall with the help of the mounting eyelets

arranged at the top of the unit and at the pump housing. To avoid noise transfer to the wall, both sides of the mounting eyelets have to be covered with

rubber insulators. The rubber insulators are supplied with the Electric heater

circulator unit and have to be mounted in such a way that no metal contact

exists between the castings and the fastening screw. In addition, no part of

the Electric heater circulator unit - for example the outer shell or the pump

- should be in contact with the wall.

The Electric heater circulator should be mounted at least 2.4’’ above the

oor to allow replacement of the circulator motor if necessary.

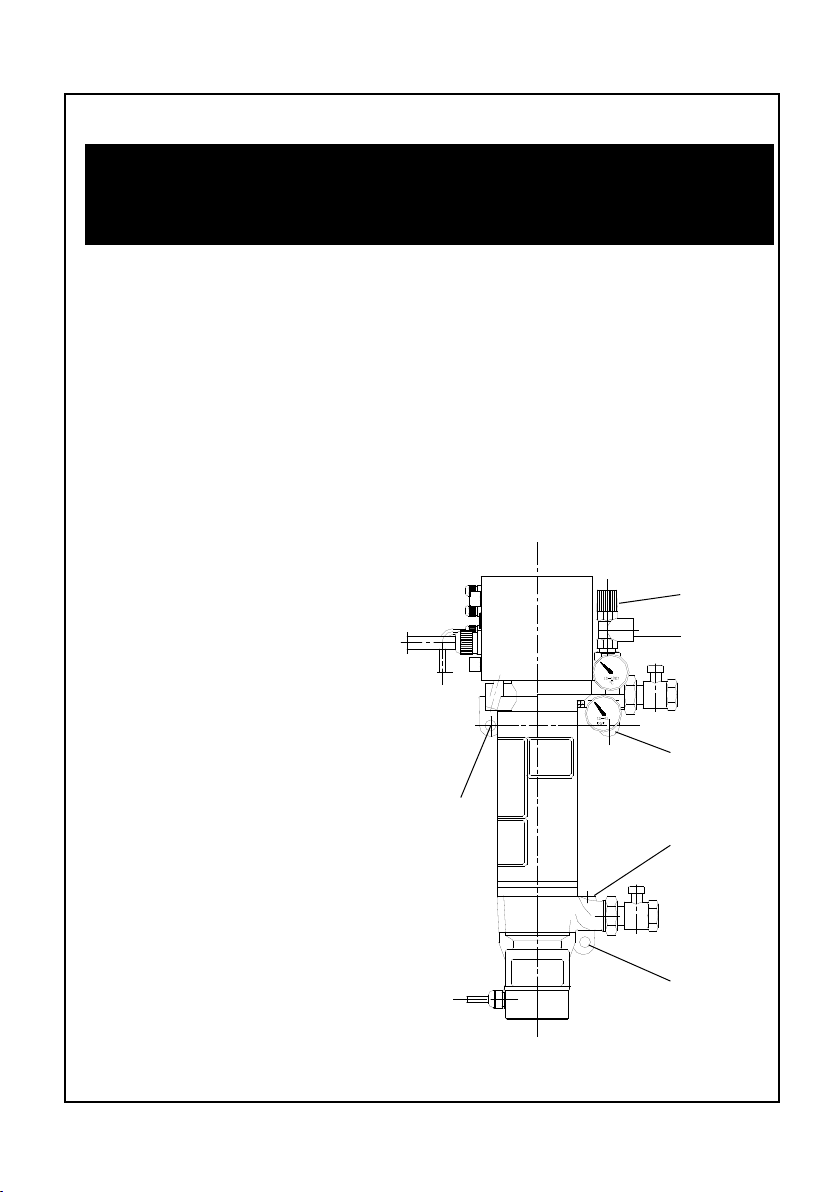

Connection to the feed and return line

The unit is connected to the heating loop by 1” male threaded t-

Air vent

tings. The feed line is at the top of

the unit, the return line at the bottom. The expansion tank should

be connected to the 3/8” port next

to the return line. If the expansion

tank cannot be connected there, it

should be connected somewhere

else in the return line, but not in

the feed line. There are two ˝”

ports at the top of the unit. The

automatic air vent for the heating

circuit is connected to the ˝” port

Mounting

eyelet

Safety relief

valve

Heating

loop feed

side

Mounting

eyelet

Connection

for expansion tank

closest to the wall, the pressure

relief valve to the port in front.

When the Electric heater cir-

Heating

loop return

side

culator unit is used solely for oor

heating, the chapter “Important

Notice: Proper connection to a

Mounting

eyelet

oor heating system” has to be

observed.

Connection EPR series

www.lainginc.com

7

Instruction manual Laing Electric heater circulator unit

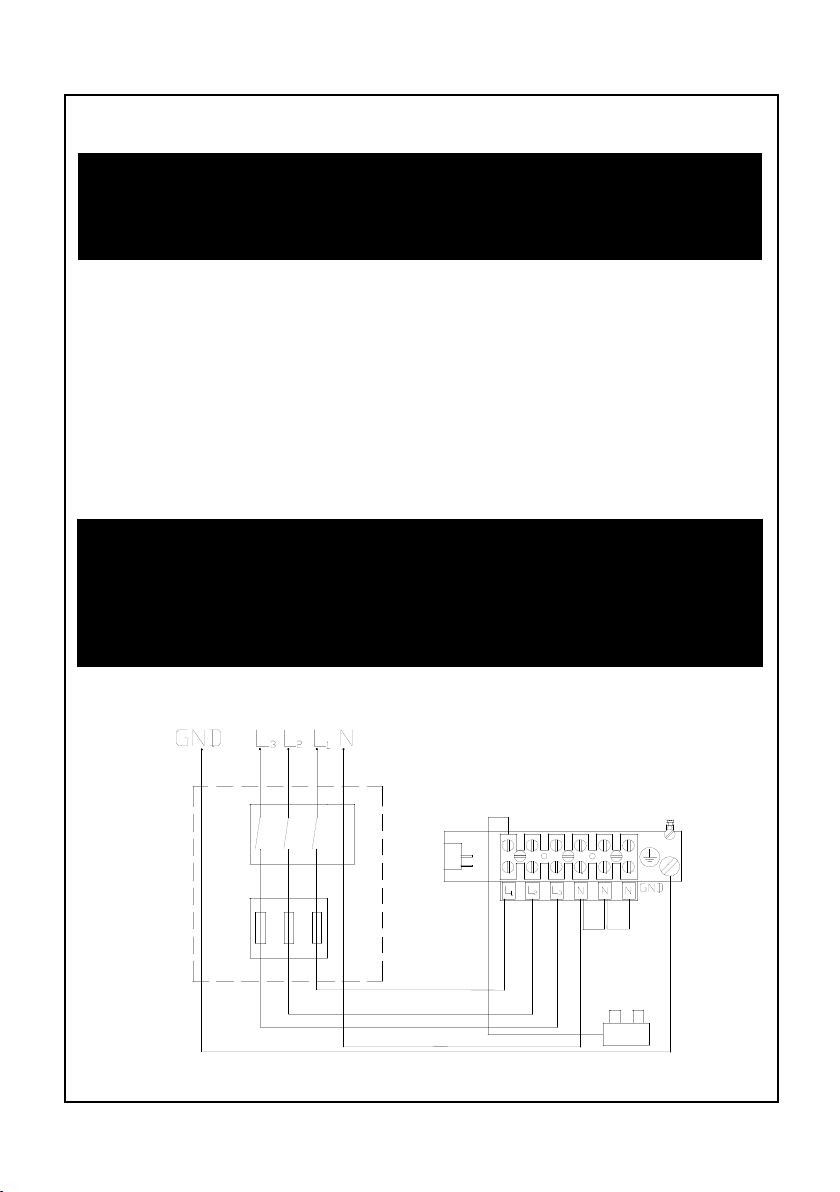

Electrical Connection

Notice: The electrical connection has to be performed by a licensed

electrician!

The pump must not be operated without water.

To make the electrical connections, the control box at the top of the heater

has to be opened by removing the 4 screws. A cable with a sufcient cross

section for the performance of the Electric heater circulator unit has to be

inserted through the strain relief and connected to the input terminal (see

Electrical Diagram below)

The circulator is already wired to the control box.

Power Supply

The Electric heater-circulator is designed for three different kinds of power

supply. In all cases the following information has to be taken into account:

The electronic switches integrated into the Electric heater circulator unit do

not separate the heating elements from the power supply. Therefore, a master

switch that interrupts all phases has to be installed in an accessible place,

taking into account all applicable safety codes.

As a protection for the semiconductor relays each phase has to have a fast

acting fuse.

400V N3 Electrical Diagram

230V N1 Electrical Diagram

8

T

www.lainginc.com

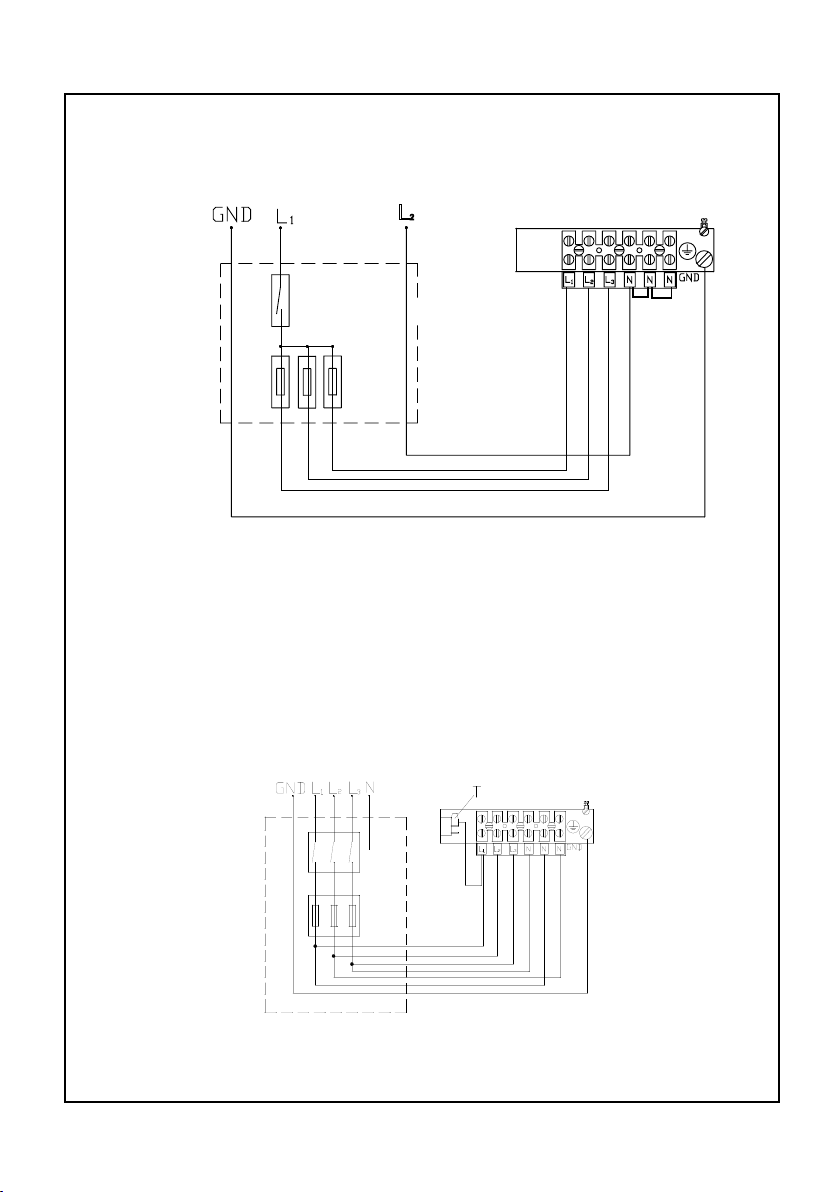

Instruction manual Laing Electric heater circulator unit

L2

In this case, the Electric heater circulator unit has to be connected with 7 leads

to protect each of the semiconductor relays separately. After this has been

done, the leads are combined into one phase.

230V N3 Electrical Diagram

In this case, it is important to ensure the proper phase sequence of the connectors 1 to 3 and 4 to 6.

The integrated control

T

T

www.lainginc.com

9

Instruction manual Laing Electric heater circulator unit

The integrated microprocessor control in the housing on top of the Electric

heater circulator unit performs a variety of control functions for a large number

of applications.

The heating elements are noiselessly switched by electronic relays.

Schematics of the integrated control

The block diagram shows the control in schematic presentation

PI G IS W

TI

Y MP X Q

O

RA

B C D P TS

B Temperature sensor for feed temperature

C Temperature sensor for the safety temperature limiter

D Temperature sensor for the semiconductor relays

G Pump operation control logic

IS Input for external control and remote control

MP Microprocessor

O Control for the semiconductor relays

P Potentiometer for constant temperature setting

PI Pump performance control

Q Safety temperature limiter

RA Analog inputs for temperature sensors and temperature pre-selection

T Potentiometer for safety temperature setting

TI Safety temperature limiter control logic

W Heating elements

X Semiconductor relays

Y Jumper settings for operation mode

Temperature sensor B monitors the temperature of the feed line water and

10

www.lainginc.com

Instruction manual Laing Electric heater circulator unit

passes the information on to the microprocessor. The microprocessor then

activates the solid state relays which in turn activate the heating elements

according to the jumper selected program. An independent sensor C also

monitors the temperature of the feed line water and switches the pump off

when the temperature exceeds a pre-set temperature.

A further sensor D monitors the temperature of the solid state relays and

turns off the heating elements in case of overheating.

A special control logic veries the rotation of the circulator and prevents

the heating elements from being turned on if the circulator is not running.

The safety temperature limiter turns the heating elements off permanently - independent of the electronic control - when the temperature exceeds 194°F.

Design of the Main Printed Circuit Board

(See also page 2)

Fastening

points

Processor

Connector for

www.lainginc.com

solid state relays, power supply and sensors.

11

Loading...

Loading...