Manual

Pump Controller 704

Effective for software version

834048 and later

Index:

General 3

Hydrostatic measuring system 3

Ultrasonic measuring system 3

On the front you find 3

Operation of pump controller 4

Functional indications 4

Programming the pump controller 5

Mounting 9

Pressure transmitter 9

Ultrasonic sensor 9

Electrical connection 10

Internal adjustments 10

Connection box for pressure transmitter 10

Electrical diagram for connection box 10

Changing the EPROM 11

Maintenance 11

Dimensions 11

Ordering details 11

Specifications 12

Signal list for Pump Controller 704 13

Operation of Pump Controller 704 14

Programming of Pump Controoler 704 15

704GB/9910

CE - CERTIFICATE OF CONFORMITY

This product complies with the requirements concerning electromagnetic compatibility (EMC) stipulated in

Council directive no. 89/336/EEC of 3rd May 1989, altered at directive no. 92/31/EEC, on the approximation

of the laws of the Member States relating to electromagnetic compatibility.

We declare that the product complies to the values stipulated in EN 50081-1 and EN 50082-1.

2

General

Thank you for choosing MJK Pump Controller 704. The

MJK Pump Controller 704 is a microprocessor controlled

pump controller, which is delivered with a hydrostatic

measuring system (704P) or ultrasonic measuring system

(704U). The pump controller can control up to 4 pumps,

valves etc. It is appropriate for plants, where the controller

manages the data transfer to a central computer. The

pump controller is operated with a combined menu and

functional keyboard, making the installation and operation

simple and clear.

Hydrostatic measuring system

MJK Pump Controller 704P is delivered with a pressure

transmitter, covering measuring ranges from 3 to 30 m

(10 to 100 ft). The pressure transmitters are developed for

measurement of waste water and liquids with suspended

solids. All transmitters are designed as 2-wire 4-20 mA

transmitters.

Measurement is based on the following principle. A

pressure transmitter is lowered to the bottom of the solids

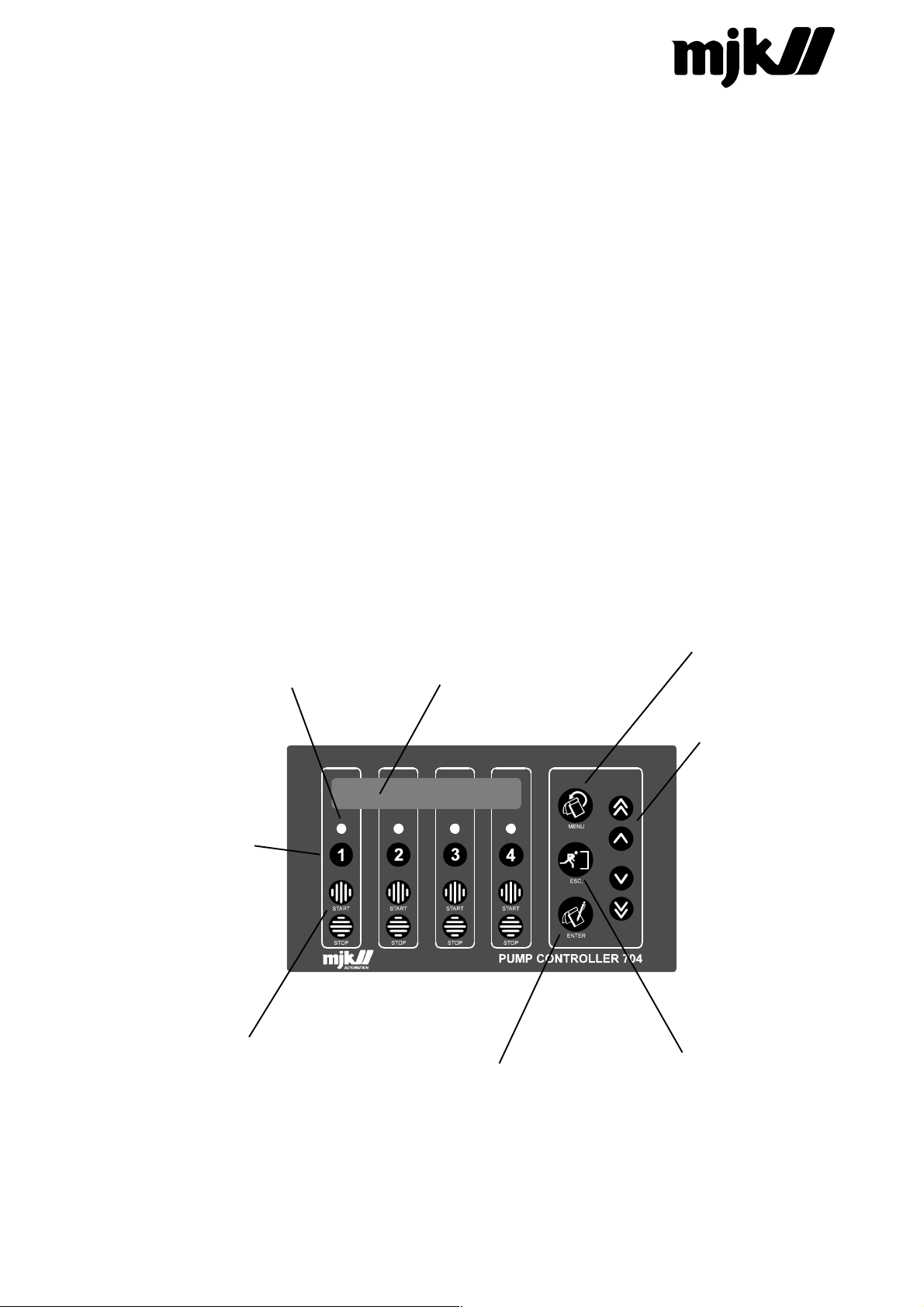

On the front you find:

Light emitting diodes

There are 4 light emitting diodes (LED's)

for indication of operation and alarms. The

LED´s light up when an output is active green when used for control and red when

used as alarm. The diode flashes during

the delay period.

1 to 4

By pressing one of the

keys from 1-4

(commonly

denominated as #) a

reading of the built in

datalogger is obtained

for number and period

of time, the output

relays have been

active.

If flow calculation is

applied, a second press

will show the pump

capacity and the

pumped out volume.

Third press will show

the pumped out volume

for the entire pumping

station.

Display

2 x 24 characters text display for

indication of user menus and

measuring values. When the keys

have not been pressed for approx.

1 min, the display will change

automatically to show the level.

to measure the hydrostatic pressure. The pressure

transmitter transmits an electrical signal proportional to

the pressure, resting on the pressure transmitters membrane. The pressure transmitter is connected to the

amplifier, where the signal is used for level indication, for

limits for start-, stop signals and alarms, as well as for the

level proportional 0-20/4-20 mA output signal.

Pressure transmitters are supplied in 2 versions for

absolute and gauge pressure.

Ultrasonic measuring system

MJK Pump Controller 704U with ultrasonic measuring

system, is delivered with 30 kHz ultrasonic sensor with a

resolution of 1 cm (0,3 in). The ultrasonic sensor both

sends and receives signals. In the amplifier the signals

received from the sensor are converted to a signal

proportional to the level.

With the ultrasonic sensor, the system has built in

temperature compensation for accurate measurings at

varying temperatures.

MENU

By activating the MENU-key,

a shift is made to the next

main menu, to see the view

of the menu.

Arrow keys

The arrow keys are

used for altering the

current setting. In a sub

menu with choice the

top line will show the

valid setting, the bottom

line, in parenthesis

shows the alternative

setting. Use arrow keys

to move between the

current and not current

settings. In and output

no. are also changed by

activating the arrow

keys. By activating the

-key, the number of

the display will

increase. By activating

the ¯-key the number

will decrease the

number.

START & STOP

The level corresponding the output relay is displayed

by pressing one of the 8 START/STOP keys.

If the START-key and one of the number keys are

pressed simultaneously, the pumps are forced to

start. If the STOP-key and one of the number keys

are pressed simultaneously, the pumps are forced to

stop.

ENTER

With the ENTER-key

selections are

confirmed. Also a shift

from a main-menu to a

sub-menu is carried out

with the ENTER-key.

3

ESC

(ESCape=undo):

This key will take you back to

the previous menu, or undo a

choice. By pressing the

ESC.-key 2-3 times you

always return to the level

indication.

Operation of pump controller

The keys under the display give access to the functions

used in the daily operation. The MENU key gives access

to programming of the pump controller. The programming

can be locked separately with an access code i.e. a code

must be keyed in, in order to get access to the

programming menus.

Functional indications

When the pump controller is connected to 230 V, the

display will show:

P2 RESET TIME-COUNTER?

YES: ENTER NO:MENU

F2 Capacity / Quantity

If key 1-4 is pressed while F1 is in the functional display,

menu F2 will show:

P2 CAPACITY 82 m3/h

QUANTITY 5508 m

3

PROGRAM 8340XX

STARTUP WAIT A MOMENT

If the pump controller is activated for the first time, the

display will show the following:

KEY IN NEW VALUES

PRESS ENTER

Now the pump controller can be configured. The settings

can always be altered later on.

If the sensor type is changed, or if an output relay is either

put into service or out of service, the programme will reset

and new values must be keyed in.

F0 Level measuring

When the programming is carried out, function F0, level

measuring in the display is shown:

MEASURING 1.50 m

If the pump controller is set up for level output according

to a given elevation, both the level and the level relative to

the elevation is shown in the display:

MEASURING 1,50 m

ELEVATION 1,65 m

The capacity of each single pump is shown at this point,

as well as the pumped out volume. When pressing the

MENU-key while functional indication F2, access is given

to reset the capacity and water quantities (if code is not

applied, see menu 3.3):

P2 RESET CAPACITY

YES: ENTER NO:MENU

P2 RESET QUANTITY

YES: ENTER NO:MENU

F3 Pumping station volume

When pressing key 1-4 while functional indication F2

shows on the display, menu F3 will appear:

PUMPING STATION

QUANTITY 27803 m

Displayed here is the pumped out volume for the entire

pumping station, as the sum of the pumped out volumes

from all the individual pumps. If the MENU key is

pressed, the volume can be reset:

P2 RESET QUANTITY

YES: ENTER NO:MENU

3

F1 Starts / Operational time

By pressing one of the keys 1-4 number of starts are

shown, as well as operation time for any of the relays 1-4

in use. If the relay is configured for operational relay the

relay number is shown with a prepositive P for pumps. If

the relays are configured as alarms an A will show:

P2 STARTS 4

OPERATIONAL TIME 2.9 h

If the MENU-key is pressed while the functional indication

F0 is in the display, access is given to reset the counter

and time counter:

P2 RESET COUNTER?

YES: ENTER NO:MENU

F4 Level Start/Stop

F5 Level Set/Reset

By pressing START or STOP keys, the levels activating

the relays can be read. If the relay is configured for

controlling, the levels for starting and stopping the pump

can be read. If the relay is configured as an alarm, the

levels for setting and resetting can be read.

If the pump controller is configured for filling (see menu

6.1) the start level will be lower than the stop level, and

vice versa if the pump controller is configured for

emptying.

LEVEL 2 START 1.80

STOP 0.20

If the relay is configured as a level alarm, there is an

alternative choice of adjusting the set levels to be either

higher (high alarm) or the contrary (low alarm) to the reset

4

level in menu 6.6.3.

LEVEL 1 SET 1.90

RESET 1.70

When adjusting a level, press one of the arrow keys,

consequently the setting will flash. Set the wanted value

with the arrow keys and confirm with ENTER. Double

arrow alters the value quickly, single arrow alters the

value slowly.

The highest value acceptable is the equivalent of the max.

level which has been programmed in menu 5.7. The

lowest value acceptable is 1% of the measuring range of

the sensor (reading in menu 5.1). The lowest range

acceptable between start and stop is 1% of the max. level

programmed into menu 5.7.

NB: If level indication with elevation is applied, the values

must be keyed in according to the elevation.

F6 Forced start

F7 Forced stop

Forced controlling is carried out by pressing one of the

keys 1-4 as well as the corresponding key for either start

or stop.

If the level is between the start and stop levels the pumps

stay started or stopped when the keys are released.

Above or below the interval between the start and stop

levels, the pump is only started/stopped while the keys are

pressed. The same applies if the level is not in use (menu

6.7.2).

If a pump which is configured for alternating control is run

forced, it is run as directly controlled during the forced

running. As soon as the forced running is stopped the

pump returns to alternating operation.

Programming of pump controller

When function F0 shows in the display press the MENU

key for access to the programming menus (if code is not

applied, see menu 3.3). Change between the main menus

by repeatedly pressing the MENU key. Press ENTER to

change to sub menus. Make choices and adjustments in

the sub menus with the arrow keys and confirm with

ENTER.

1.0 Language

Choose between languages with the arrow keys.

2.0 Key in access code

If access code has been chosen, key it into this menu

before the following menus become accessible. Key in

code with keys 1-4. Do not confirm with ENTER.

When the code is keyed in, access is given to make

alterations of all settings for 10 minutes after last key is

pressed.

3.0 Programming of main functions

Access to the configuring menus are obtained by pressing

MENU.

3.1 Access code wanted / not wanted

Choose here if access code is to be used for gaining

access to the pump controller. If code is selected, it is not

allowed to change the settings.

3.2 Key in new access code

If a new access code is wanted, key it into this menu. If

the code is to remain unchanged press the MENU key.

3.3 Code only setup / all adjustments

The code can be chosen to only block the setup i.e.

menues which are made accessible with the MENU key.

Or it can be set to block all settings i.e. also start and stop

settings for levels as well as reset of counters.

If a code has been chosen for all settings, alterations are

made by entering menu 2.0 and keying in the code, now

access is given to make alterations of all settings for 10

minutes after last key is pressed.

4.0 Measurement level / levels + elevation

Setting of level indication either as absolute measurement

or relative measurement according to a given elevation.

An altitude is the level reset-point which is valid on the

relevant location, e.g. the elevation of the pumping station

above the sea. I.e., if a pumping station is placed 1.25 m

above the surface of the sea, and this is keyed in as an

elevation, a level measurement of 2.25 m will be indicated

as 3.50 m.

If level indication with elevation has been chosen, all start

/ stop values are programmed according to the elevation.

5

4.1 Select unit measurement

Level indication and unit of elevation can be chosen as:

m, bar, kPa, cm, mm, l/s, ft or in.

4.2 Select unit volume

Unit of volume can be chosen between

3

Gal, m

, CF, l

The resolution of measured volumes will be adjusted to

the accuracy of flow measurement possible with the pump

controller.

4.3 Select unit flow

Unit of flow can be chosen between

5.5 Key in elevation

If level indication with elevation has been chosen, the

elevation is keyed in at this point.

For ultrasonic systems the elevation is keyed in as the

0-point of measuring.

For hydrostatic measuring systems the sensor is placed in

the zero point of the measurement, therefore the elevation

for the sensor is keyed in. Use arrow keys for this setting.

Double arrow changes the value before the comma, single

arrow changes the value after the comma.

5.6 Sensor level

For ultrasonic measuring systems the sensor elevation

above the zero point is keyed in. Use the arrow keys for

this setting. Double arrow changes the value before the

comma, single arrow changes the value after the comma.

m3/h, l/s, MGD, CFS, G/mi

The resolution of measured flow will be adjusted to the

accuracy of flow measurement possible with the pump

controller.

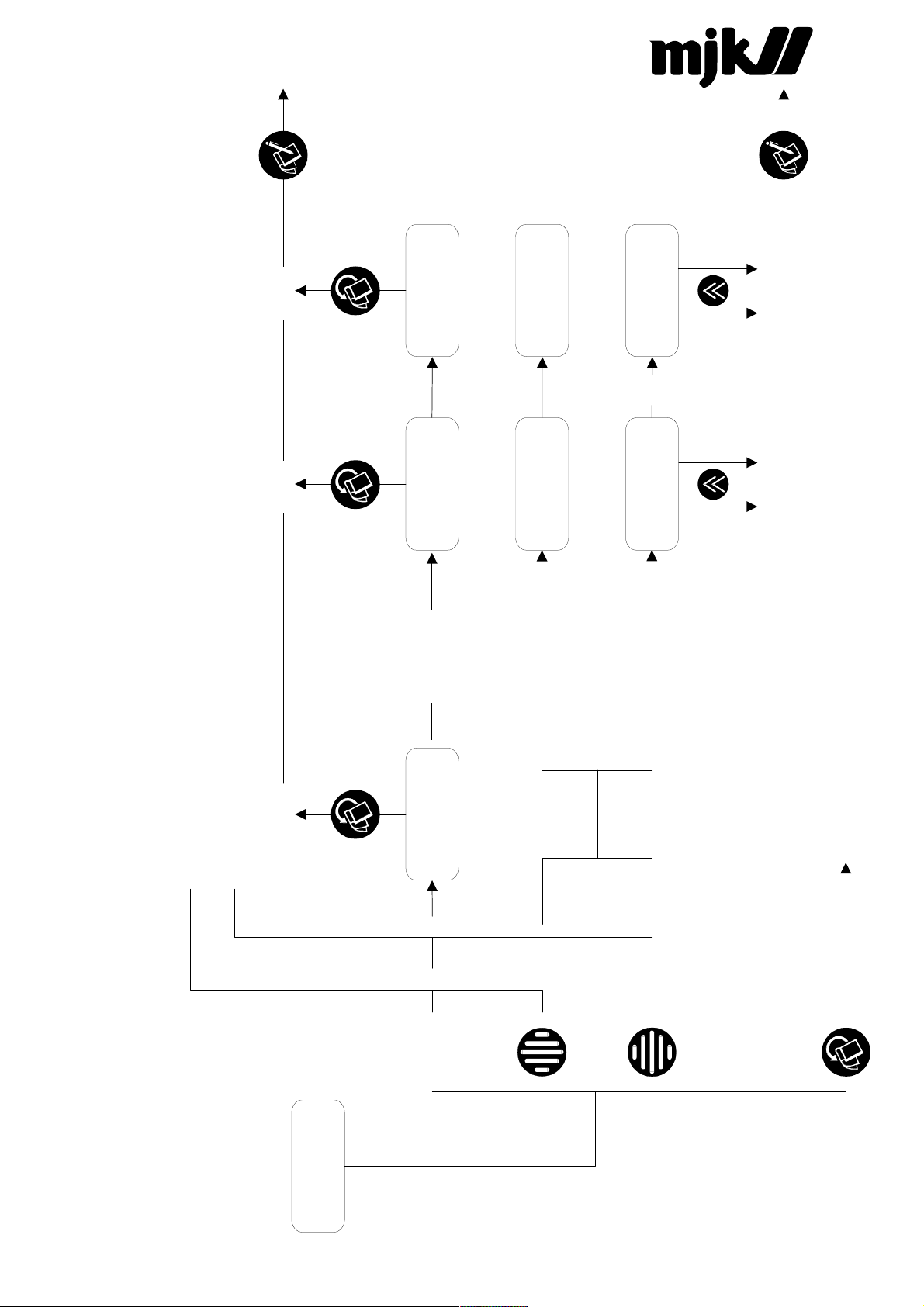

5.0 Sensor menu - data for mounting

Menus which are accessible, depend on the setup. The

pump controller can be either an ultrasonic measuring

system or a hydrostatic measuring system.

The flow-chart "Programming of Pump Controller 704" at

the end of this manual, shows which of the following

menus are accessible during system setup.

5.1 Select sensor / span

In ultrasonic measuring systems, the sensor and the

amplifier are calibrated together, and the measuring range

of the sensor can be read.

In the hydrostatic measuring system, the type of sensor

applied can be coded into the system and the measuring

scale of the sensor can be read.

5.3 Select comma

When choosing selectable span in hydrostatic measuring

systems, the comma is adjusted to set where the decimal

point will be in the level readings. The choices are:

1.234, 12.35, 123.4 or 1234

5.4 Select span

When choosing the selectable span with hydrostatic

measuring systems; the span is set with the arrow keys.

Double arrow changes the value before the comma, single

arrow changes the value after the comma.

5.7 Max level

The max level is set to restrict the setting of start and stop

level. Use arrow keys for this setting. Double arrow

changes the value before the comma, single arrow

changes the value after the comma.

6.0 Output relays programming

In this menu the function for the four output relays are

programmed. In menu 6.1 and 6.2 joint settings for the

four outputs are programmed. In menu 6.3 to 6.8 the

individual outputs are programmed.

6.1 Controlling of emptying / filling

The relays which are configured for control, are programmed to control either an emptying or a filling function. At

the emptying function the pump-start levels are higher

than the pump-stop levels. At the filling function the

pump-start levels are lower than the pump-stop levels.

6.2 Alternating normally / in pairs

At this point the outputs programmed to run as alternating

(see menu 6.7.1), can be set up to run normally or in

pairs.

At normal alternating, there is alternating between all the

outputs which are set up to alternate.

At alternating in pairs, output 1 and 2 are alternated as

one of the pairs and between output 3 and 4 as the other

pair. If alternating in pairs is chosen all four outputs are

used as alternating, and it is therefore not possible to

configure any of the relays as alarms or as directly

controlled.

6.3 Relay programming

Choose with arrow keys or key 1-4 which output relay is to

be programmed, confirm choice with ENTER.

6

6.4 Relay operating / not operating

Choose whether to have the relay operating or not

operating.

6.5 Relay controlling / alarm

Set whether the relay is to be an alarm relay or a pump

controlling relay.

When the relays are activated, the light emitting diodes

under the display will show, whether it is an alarm relay or

a control relay: When an alarm relay is activated the

diode will flash a red light; when a control relay is

activated the diode will flash a green light.

6.6.1 Relay level alarm / system error

If the relay is set for alarm relay, set the alarm to be a

level (high/low) alarm or an alarm for system error.

6.7.4 Level not in use / in use

To avoid all pumps running at the same time in alternating

operation, levels can be left unused.

One level minimum, must be left in use for the pump

controller to function correctly. If the pump controller is set

up to alternate in pairs at least one of level 1 and 2 as well

as either level 3 or 4 must be left in use.

6.8 Relay delay

To avoid short error conditions, or levels continuously

activating the relays, a delay time can be set. If the

connected pumps are not started simultaneously for over

load reasons, the delay time can be set differently for the

relays.

In case of an error condition or level continuously

exceeding, the diode will flash. If the condition proceeds

after the delay time has expired the relay will be activated

and the diode will be permanently lit.

6.6.2 Relay NC / NO

Choose the relay function for the output, (Normally Open)

or (Normally Closed).

6.6.3 Relay set>reset (high) / set<reset (low)

Set the level alarm to be registered as a high or low

alarm. If the alarm needs to be a high alarm, choose set >

reset. If the alarm needs to be a low alarm choose set <

reset.

6.7.1 Relay alternating / directly controlled

The output relays can be set as directly controlled or

alternating. At direct control, the start and stop values

which have been keyed in for the individual relay activate

the outputs, nothing else activates them. At alternating

operation the alternating pumps will take it in turns to start

up in a cycle, so that when a start level is activated the

next relay in the cycle is activated. If several start levels

are passed several pumps will consequently be started.

6.7.2 Temporary operation

In this menu you choose whether the output relay, which

you have chosen for alternating operation, has to be

forced stopped after a given amount of time. Operating

hours before forced stop is chosen in menu 6.7.3. Please

note that if one output is stopped, the next output relay in

the alternation sequence will be activated as soon as start

level has been reached, and output delay has passed

through.

6.7.3 Stop after XXX minutes

If temporary stop is chosen in menu 6.7.2., key in the

operating hours that will cause a forced stop of the output.

The interval can be set from 1 999 minutes.

7.0 mA output programming

Set the voltage analog for the pump controller.

7.1 mA output 0-20mA / 4-20mA

Set the mA output as either a 4-20 mA signal or a 0-20

mA signal.

7.2 mA output 4-20mA / 20-4 mA

Set the voltage output to be either 4-20 mA signal or 20-4

mA signal.

If (0 or 4) - 20 mA is chosen, a high level will give a high

mA-signal and a low level a low mA-signal.

If 20 - (4 or 0) mA is chosen, a high level will give a low

mA-signal and a low level a high mA-signal.

7.3 mA output 4 mA = (elevation)

If 4-20 mA has been chosen in 7.2, key in which level the

low mA value represents. If 20-4 mA has been chosen,

the value represented by the high mA is set here.

7.4 mA output 20 mA = (elevation)

If 4-20 mA has been chosen in 7.2, key in here which level

the high mA value represents. If 20-4 mA is chosen, key

in the value represented by the low mA.

8.0 Pump flow programming

At flow calculation a known volume between two levels is

programmed. The pump controller is then able to

calculate the flow from the measured level differences.

In the flow calculation the fact, that inlets can occur

simultaneously with pumping out is taken into consideration.

To calculate flow the following conditions must be met:

7

1.All start / stop levels must be outside the interval in

which calculation takes place.

The flow calculation can only be carried out between the

lowest set start level and the highest set stop level with

a margin of sensor span/200.

2.The connected pumps must regularly run on their own

to obtain reliable flow measuring.

If the above mentioned conditions are not present the

following message will appear in the display, when

entering menu 8.0 is attempted:

PUMP FLOW NOT POSSIBLE

SEE THE MANUAL

This message will also appear if the pump settings are

changed, so the conditions are no longer present. If flow

calculation is needed again after this, the level must be

set so the conditions are present again.

If it is established that all stop / stop levels comply with

the above conditions, access is given to menus 8.1 to 8.5.

8.1 Flow calculation yes / no

Choose whether flow calculation is desired.

8.2 Level for volume: Stop

Set the level where known volume stops. If the control is

set for the filling function, the stop level is the highest

level. If it is set for emptying, this is the lowest level.

8.3 Level for volume: Start

Set the level for the known volume in this menu. If the

control is set for filling, the start level is the lowest level, if

it is set for emptying, this is the highest level.

8.4 Size of the volume

At this point the known volume is keyed in, between start

and stop level. The resolution of the volume will reflect the

measurement accuracy of the pump controller.

8.5 Correction factor

It is possible to adjust a correction factor. As a starting

point it should be reset at 1.00. If heights or other similar

uncertain factors regularly occur, the flow can be adjusted

by means of control measuring.

8

Mounting

Pressure Transmitter

When measuring in a well, it

is advantageous to mount

the transmitter in a tube,

fastening it at the top of the

tube by means of the fittings

supplied. This mounting

facilitates subsequent

cleaning and inspection.

Tube-mounted pressure

transmitter

Min. table

value +100%

Sensor mounted in tube

for scum protection.

When measuring

through a hole in

for example a

metal plate or

grate, a pipe that

ends near the

lower edge of the

sensor should be

applied as shown

here:

Min. 25in (30kHz)

o

45

Sensor mounted near the

top of a closed container.

Min. table

value

+25%

o

30 - 45

Ultrasonic Sensor

When mounting the sensor for example at the top of a

well or a container, ensure that no pipes or cables etc.

are disturbing the path between the sensor and the liquid

surface. The maximum distance between the sensor and

the surface must not exceed the measuring range of the

transmitter. Optimum operation is obtained by placing the

sensor approx. 1 m (3 ft) for 30 kHz sensor, and approx.

0.5 m (1,7 ft) for the 100 kHz sensor, above the

maximum liquid level. The sensor should be positioned

perpendicular to the liquid surface (check with a spirit

level!). When installing the sensor, ensure that the signal

is able to pass any obstruction, taking in consideration

that signal spreads relative to the sensor/surface distance

as described in the table. If the signal travels along a

hard surface such as the side of a well or tank, the table

values can be applied directly. Otherwise you may refer

to the following mounting examples.

If a sensor is mounted above an obstruction ex. a

concrete deck, we recommend that it should be installed

as shown below:

Min. table value +100%

Table values for the signal

spreading relative to sensor/

surface distance.

If the upward edges on the obstruction are angled as

shown below, the sensor can be mounted as the

following:

Min. table value +50%

9

Electrical Connection

Electrical connection of the pump controller for hydrostatical and ultrasonic measuring systems respectively.

Hydrostatic Measuring System

Supply Relay 1-4 0-20/4-20mA

Pressure transmitter

Ultrasonic Measuring System

Supply Relay 1-4 0-20/4-20mA

Connection Box for transmitters

Ultrasonic sensor

Internal Adjustments

Level measurement

The Pump Controller 704 is factory pre-set for level

measurement and pumps or valves control.

Zero point, span and response time

The Pump Controller 704 is factory pre-set for level

measurement in water. The response time is set to

minimum at delivery. When replacing the transmitter or

when using the 704P for differential level measurement or

measurements in pressure or vacuum tanks, it may be

necessary to reset both the zero point and the span. The

resetting is carried out by simulating the zero point and

the span. Depending on the use, it may also be necessary

to reset the response time. If the pump controller is used

in liquids with a specific gravity different from that of water

(e.g. sludge), the span will need to be adjusted.

If the pump controller 704U is used in water with foam or

uncalm surfaces, it might be nescessary to adjust the

gain.

Connection box 202922 is used for outdoor connections

of cables from the pressure transmitter. The box is made

of ABS plastic, and the housing meets IP65. The box is

ventilated in consideration of the tube for pressure

equlizing. This allows the cable to be extended with

ordinary installation-cable from the box.

Connection box 200590 is used to connect the ultrasonic

sensor with cable.

The connection boxes have a plug for connection of an

indicator. When the indicator is applied the lid is replaced

with a display.

Electrical diagram

Soldering bridge "Display" (indicator)

Soldering bridge "Connected up in series"

+ -

4-20 mA to

power supply

10

Changing the EPROM

If the EPROM with the pump control

program is to be replaced, you must

follow these instructions:

1.Turn off the pump controller

2.Turn off all pumps, to ensure that

no accidents will occur when the

pump controller is turned back on.

This can be accomplished by

disconnecting the pumps at the

terminals on the pump controller.

3.Remove the top lid

4.Remove the EPROM (IC5) from

the socket, be very careful not to

ruin the IC.

5.Insert the new EPROM (IC5), the

notch must face upwards as shown

on printboard, be very careful not

to ruin the IC.

6.Mount the top lid once again.

Dimensions

Amplifier

Wall mounting

Pressure

transmitter

Bracket

Ultrasonic

sensor

7.Configure the new pump control

program.

8.Connect the pumps again.

Maintenance

The pump controller and the

ultrasonic sensor does not require

any particular maintenance.

When cleaning the pressure transmitter, care must be taken not to

damage the membrane.

Universal

bracket

Bracket for ultrasonic sensor

Ordering Details

Part no.: Specifications:

201040 704U-1111 Controller, with 7005-1013, range 0 - 10 m

202025 704P-1103 Controller, input 4-20mA (only absolute pressure)

202030 704P-1104 Controller, input 4-20mA

202035 704P-1114 Controller, with 7060-1413, range 0-3 m

202040 704P-1124 Controller, with 7060-1423, range 0-10 m

202045 704P-1134 Controller, with 7060-1433, range 0-30 m

202050 704P-1113 Controller, with 7050-1413, range 0-10 m

(With air pressure compensation)

Accessories

200050 Update from old version of 704 to new version (from serial no. 9500)

200052 Extra input for reference transmitter for level difference measuring.

(Order transmitter separate)

200055 Galvanic separation of mA output

200105 Panel Mounting kit

200115 Local mounting set with rain roof

Accessories Ultrasonic Sensor 7005:

200205 Universal bracket

200220 Bracket for ultrasonic sensor 7005

200590 Connection box for cable for sensor 7005

200595 Cable not in standard length for sensor 7005

690010 Cable for ultrasonic sensor 7005

Accessories Pressure Transmitters 7050 and 7060:

202920 Cable not in standard length for transmitters 7050/7060

202922 Connection box for cable with compensation tube

202923 Connection box as 202922 with plug for programming unit

691010 Cable for hydrostatic transmitter 7050

691014 Cable for hydrostatic transmitter 7060

11

Specifications

Ultrasonic Sensor 7005-1013

Measuring range: 0,75-10 m

Frequency: 30 kHz

Beam spread: 3

Temperature: 20 - +60 oC

Dimensions: Ø 103 × 94 mm

Materials: PP green / POM, black

Cable: 12 m shielded oilresistant PVC, can be extended to 100 m

Protection: IP 68, withstands immersion, max. 1 bar

Pressure Transmitter 7050 or 7060

Measuring range: 0-10m Transmitter 7050-1413, absolute pressure

Function: 2 wire, 4-20 mA

Accuracy: ±1%

Temperature: 10 - +60 oC

Dimensions: Ø 60 × 140mm

Materials: House: PP Diaphragm: Acid-proof steel, AISI 316 L

Cable: 2 x 0,5mm², length 12 m (with 7060-1433: 35m),

Mounting: On bracket (supplied).

Protection: IP 68, waterproof, withstands immersion, max. 3 bar

Amplifier 704

Measuring range: Determined by sensor, scaleable in range -999.99 - +999.99

Voltage: 220 - 240/110 - 120/24V AC, consumption approx. 10V A

Temperature: 20 - +60 oC.

Input signal: From ultrasonic sensor, pressure transmitter or 4 - 20 mA

Accuracy: ±1%

Outputs: Analog: 0-20/4-20 mA max. 500W

Indication: Menus and other text in clear language, measured values in

Operation: From keyboard: Menu and function control

Dimensions: 185 x 240 x 115mm (hxwxd)

Materials: Polystyrol, with clear cover

CE: EN50081-1, EN50082-1

Protection: IP 65

o

0-3m Transmitter 7060-1413, gauge pressure

0-10m Transmitter 7060-1423, gauge pressure

0-30m Transmitter 7060-1433, gauge pressure

can be extended

(m, bar, kPa, cm, mm, l/s, ft or in))

Digital: 4 relays with voltage free charge-over contact

Inductive load: 250V, 4A ohmic, max. 100V A

Data: RS232

the range 100m to +300m

12

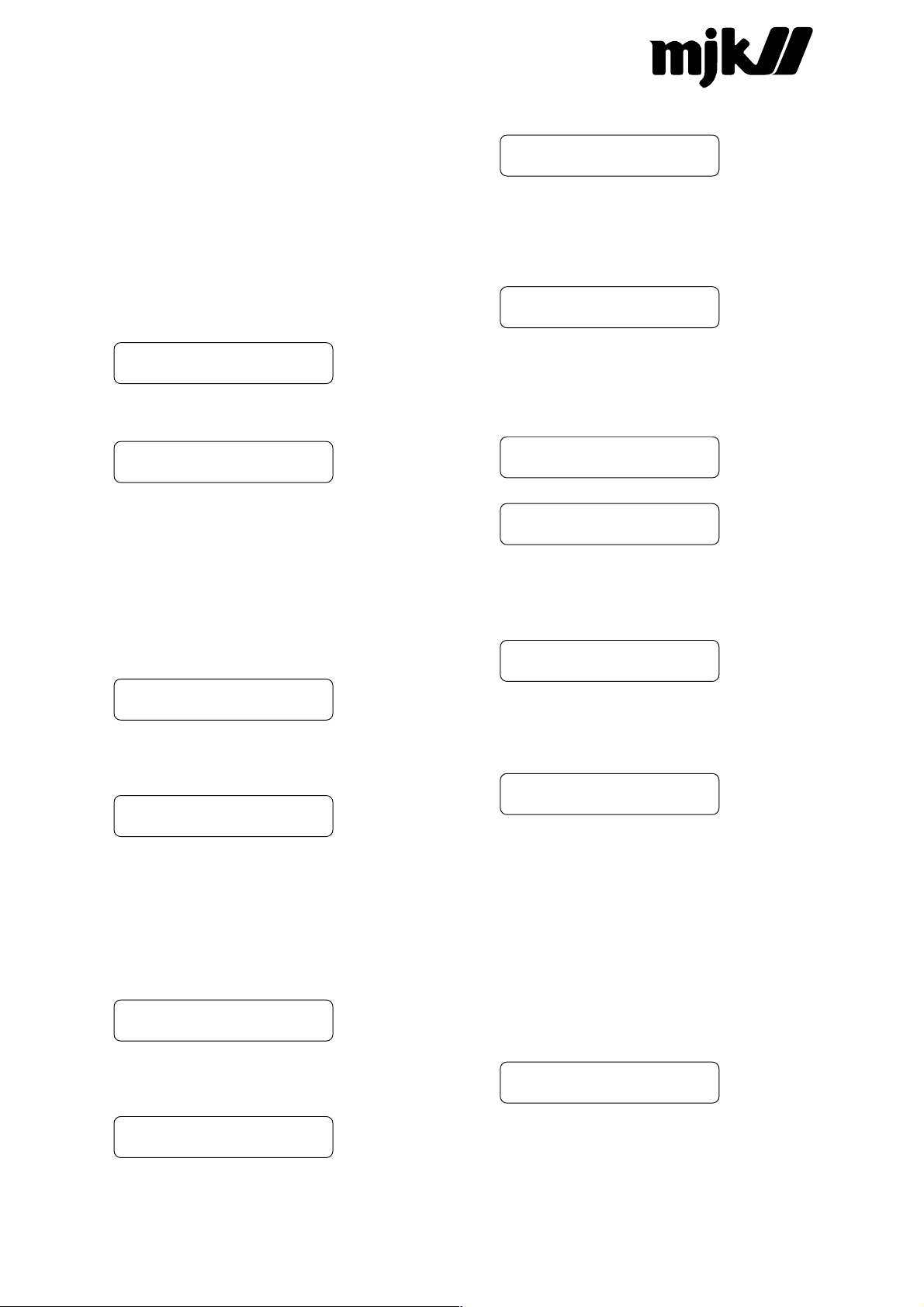

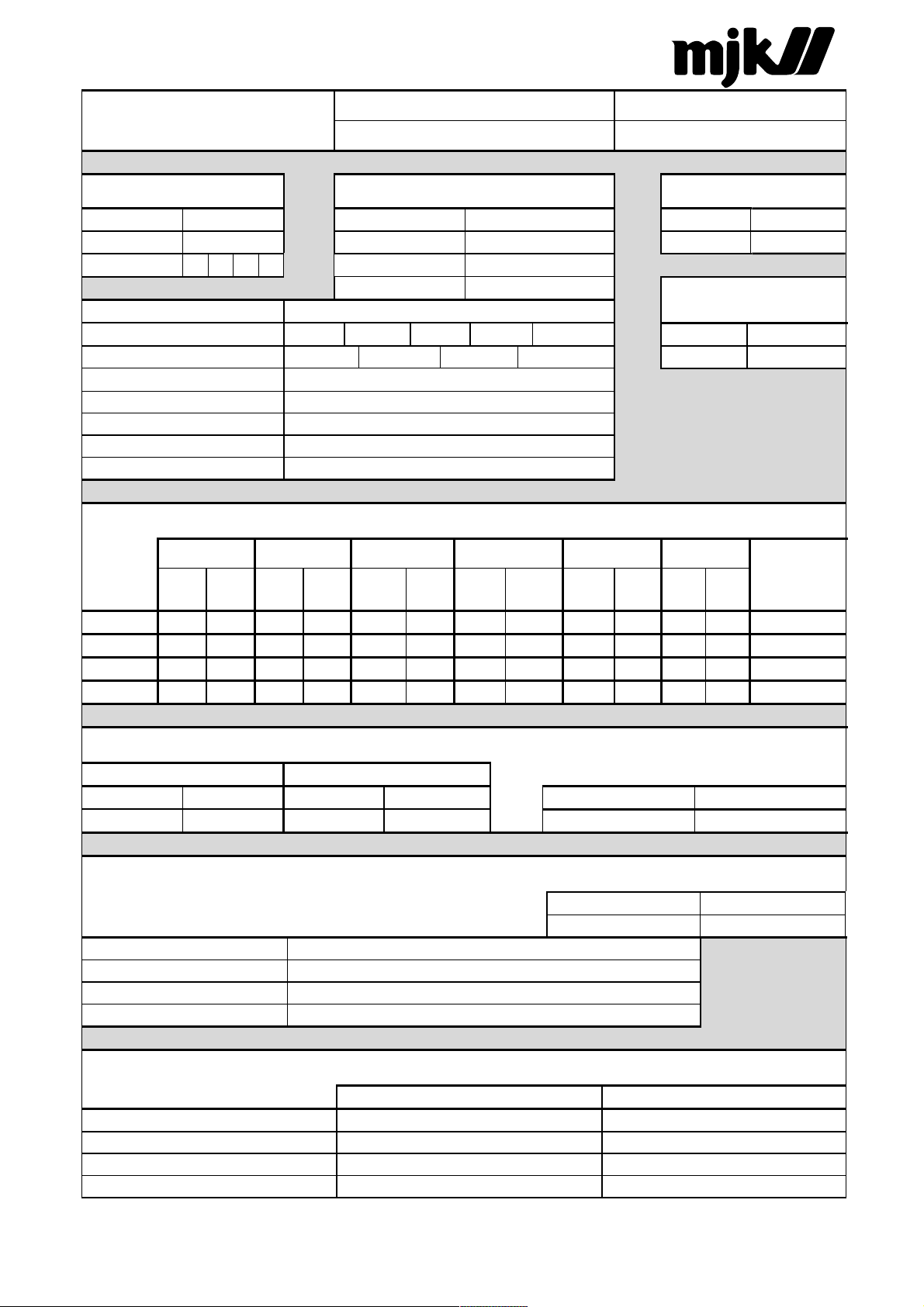

Pumping Station name: Pumping Station no.: Date:

Serial no.: Sensor no.:

ACCESS CODE MEASURING SYSTEM CONTROLLER FOR

yes no ultrasonic hydrostatic pump out pump in

code level level and altitude

ALTERNATING

sensor and span

select unit

select comma

m bar kPa cm mm

1 . 234 12 . 34 123 . 4

1234

normal in pairs

select span

altitude

sensor altitude

max. level

sensor level (704U)

RELAY PROGRAMMING

in use relay for at control at alternating

yes no control alarm alter-

nating

direct level in

control

use

level not

in use

at alarm at level alarm relay delay

system

failure

level

alarm

set

>

reset

set

<

reset

relay 1 sec.

relay 2 sec.

relay 3 sec.

relay 4 sec.

mA OUTPUT

mA span mA orientation

4 - 20 mA 0 - 20 mA 0/4 - 20 mA 20 - 0/4 mA 0 / 4 mA =

20 mA =

PUMPFLOW CALCULATION

yes no

level for volume start

level for volume stop

the volumes capacity

correction factor

relay 1

relay 2

relay 3

relay 4

START / STOP LEVELS

start stop

13

WITH

CONFIRM

RESET

3

F3

PUMPING STATION

VOLUME 125 m

3

/h

3

F2

VOLUME 10 m

P# CAPACITY 655 m

F4.2

F4.1

START X,XX m

LEVEL# STOP X,XX m

STOP X,XX m

LEVEL # START X,XX m

F5.2

F5.1

SET X,XX m

LEVEL # RESET X,XX m

RESET X,XX m

NIVEAU # SET X,XX m

WITH

CONFIRM

SET VALUE

SET VALUE

see next page

RESET RESET

F6 FORCED START

F7 FORCED STOP

AT CONTROL

F1

P# STARTS X

OPERATING HOURS X,XX h

#

CONTROL

LEVEL FOR

ALARM

LEVEL FOR

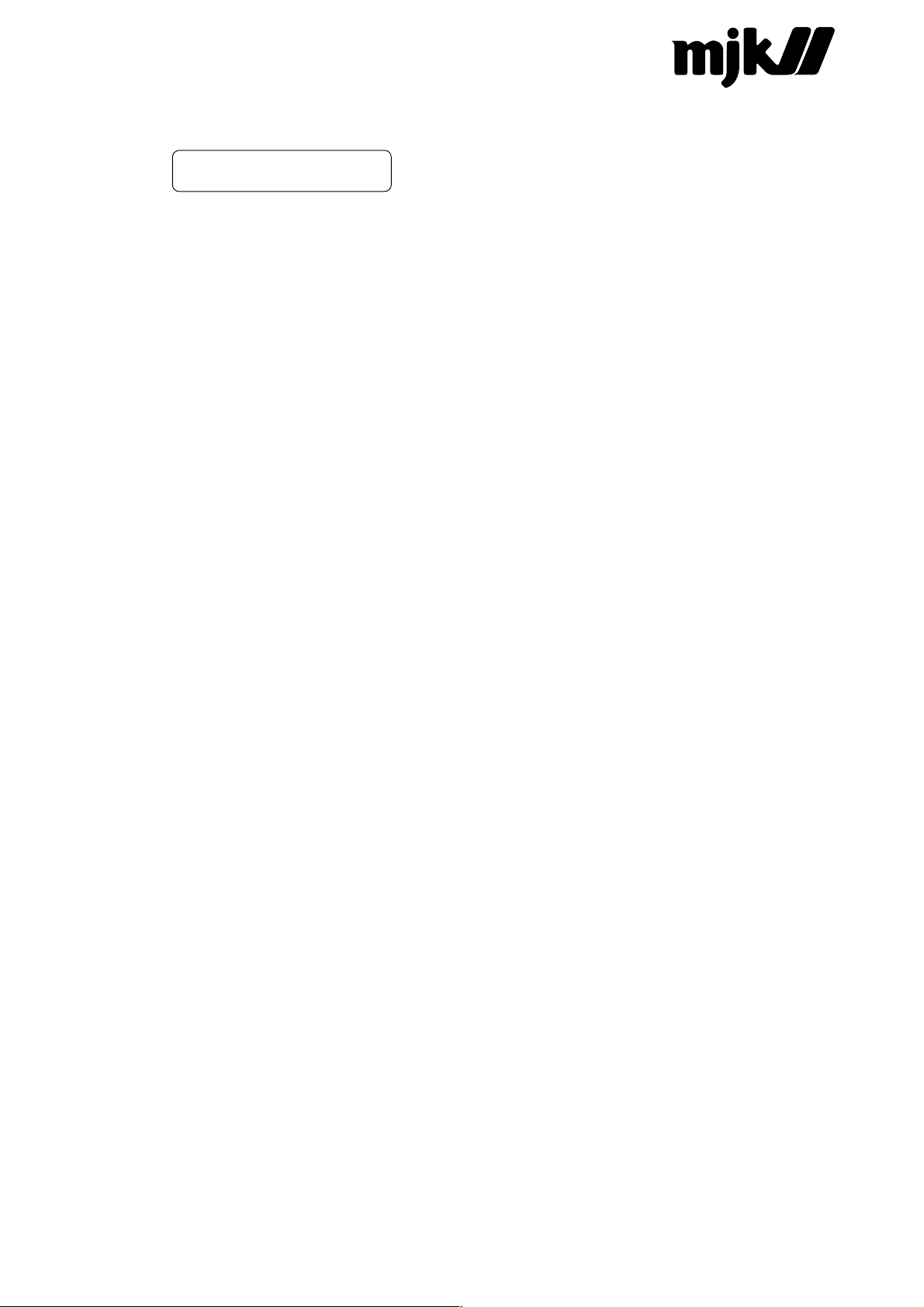

Programming of Pump Controller 704

F0

Operation of Pump Controller 704

# sign valid for key 1,2,3 & 4

MEASUREMENT X,XX m

14

Programming of Pump Controller 704

# sign valid for relay no. 1,2,3 & 4

NO

8.0

8.1

PUMPFLOW PROGRAMMING

FLOWCALCULATION YES

0-20mA

7.0

6.0

7.1

mA OUTPUT

PROGRAMMING

mA OUTPUT 4-20mA

6.1

RELAY OUTPUT

CONTROL F. PUMPING OUT

PROGRAMMING

PUMPING IN

8.2

7.2

6.2

LEVEL FOR STOP 0,30

VOLUME START 0,40

20-4mA

mA OUTPUT 4-20mA

IN PAIRS

ALTERNATING NORMAL

8.3

LEVEL FOR STOP 0,30

7.3

mA OUTPUT 4mA X,XX

6.3

RELAY #

3

2,00 m

8.4

VOLUME START 0,40

THE VOLUMES CAPACITY

20mA X,XX

PROGRAMMING

4mA X,XX

7.4

mA OUTPUT 20mA X,XX

6.4

NOT IN USE

RELAIS # IN USE

1,00

8.5

CORRECTION FACTOR

6.5

IF IN USE

RELAY # CONTROL

ALARM

CONTROL

ALARM

6.7.1

DIRECT CONTROLLED

RELAY # ALTERNATING

6.6.1

SYSTEM FAILURE

RELAY # LEVEL ALARM

ALTERNATING

6.6.2

RELAY # NO

DIRECT CONTROLLED

6.7.2

TEMPORARY OPERATION

NC

6.6.3

SET<RESET(LOW)

IF LEVEL ALARM

RELAY # SET>RESET(HIGH)

6.8

6.7.4

6.7.3

IN USE

IF IN USE

LEVEL # NOT IN USE

STOP AFTER XXX MINUTES

6.8

RELAY # DELAY XX s

RELAY # DELAY XX s

6.8

RELAY # DELAY XX s

5.0

3.0

2.0

IF CODE

SENSOR MENUES

DEPENDENT ON THE

THE LEVEL INDICATION

MEASURING SYSTEM AND

NOT IN USE

3.1

IF CODE

PROGRAMMING OF

MAIN FUNCTIONS

ACCESS CODE IN USE

ENTER CODE

KEY 1-2-3-4 XXXX

3.2

3.3

IF CODE

KEY IN NEW ACCESS CODE

KEY IN 1-2-3-4 XXXX

CODE ONLY INSTALLATION

4.0

ALL SETTINGS

MEAS. IN LEVEL

mm

4.1

ELEVATION+LEVEL

UNIT MEASUREMENT ft

0-XX,XX m

5.0.4

5.1.4

5.3.4

5.4.4

5.5.4

5.7.4

LEVEL X,XX m

AND LEVEL INDICATION

SYSTEM WITH ALTITUDE

HYDROSTATIC MEASURING

3

m

MGD

HYDROSTATIC SENSOR

DATA FOR MOUNTING

SELECT SENSOR/SPAN

SELECT COMMA X,XXX

SELECT SPAN 3,00

SENSOR ELEVATION X,XX m

ELEVATION X,XX m

MAX. LEVEL X,XX m

0-XX,XX m

5.0.3

LEVEL INDICATION

UNIT VOLUME Gal

4.3

SYSTEM WITH

UNIT FLOW l/s

HYDROSTATIC MEASURING

4.2

5.0.2

AND LEVEL INDICATION

SYSTEM WITH ALTITUDE

ULTRASONIC MEASURING

5.1.3

HYDROSTATIC SENSOR

DATA FOR MOUNTING

5.1.2

ULTRASONIC SENSOR

DATA FOR MOUNTING

5.3.3

SELECT SENSOR/SPAN

5.5.2

SENSOR/SPAN

0-10.00 m 0-30.0 ft

SELECT COMMA X,XXX

MEASUR. HEIGHT X,XX m

0-POINT LEVEL X,XX m

5.4.3

5.6.2

SELECT SPAN 3,00

LEVEL X,XX m

SENSOR ELEVATION X,XX m

5.7.3

MAX. LEVEL XX,XX m

5.7.2

ELEVATION X,XX m

MAX. LEVEL X,XX m

1.0

FRANCAIS

DEUTSCH

LANGUAGE ENGLISH

ITALIANO

NEDERLANDS

DANSK

NORSK

SVENSKA

15

SYSTEM WITH

LEVEL INDICATION

ULTRASONIC MEASURING

ULTRASONIC SENSOR

5.0.1

5.1.1

DATA FOR MOUNTING

5.6.1

SENSOR/SPAN

0-10.00 m 0-30.0 ft

SENSOR LEVEL XX,XX m

5.7.1

MAX. LEVEL X,XX m

Loading...

Loading...