Trane 2TTB3 User Manual

2TTB-SVN01A-EN

18-AC56D1-1

Installer’s Guide

Condensing Units

2TTB3

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT — This Document is customer property and is to remain with this unit. Please return to service information pack upon completion of work.

These instructions do not cover all variations in systems nor provide for every possible contingency to be met in connection with installation. All phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred to your installing dealer or local distributor.

A. GENERAL

!WARNING

This information is intended for use by individuals possessing adequate backgrounds of electrical and mechanical experience. Any attempt to repair a central air conditioning product may result in personal injury and or property damage. The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection with its use.

NOTICE:

Trane has always recommended installing Trane approved matched indoor and outdoor systems.

The benefits of installing approved matched systems are maximum efficiency, optimum performance and best overall system reliability.

Check for transportation damage after unit is uncrated. Report promptly, to the carrier, any damage found to the unit.

To determine the electrical power requirements of the unit, refer to the nameplate of the unit. The electrical power available must agree with that listed on the nameplate.

B.LOCATION AND PREPARATION OF THE UNIT

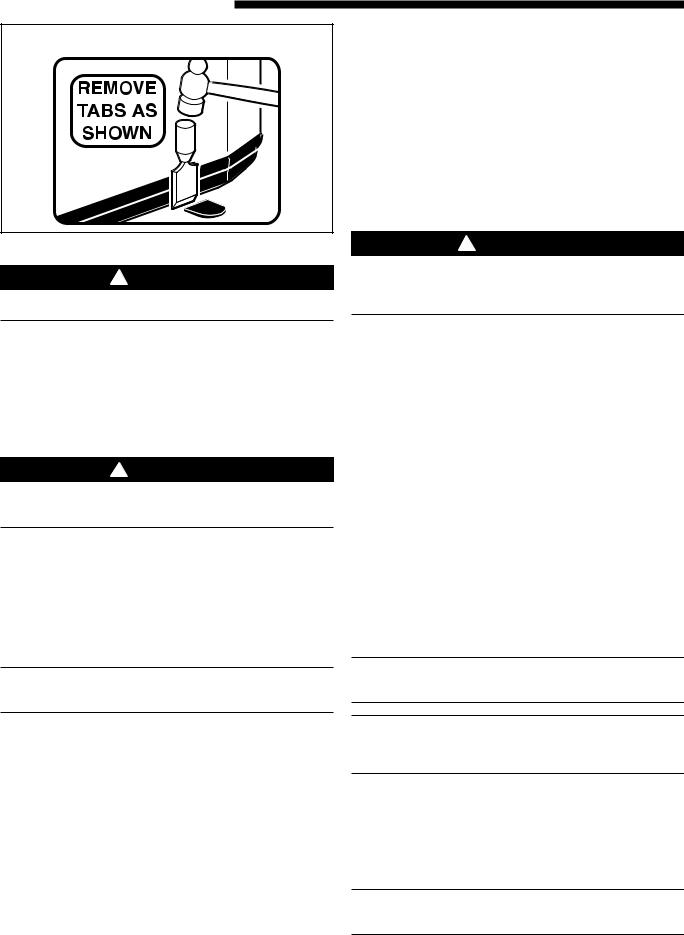

1.When removing unit from the pallet, notice the tabs on the basepan. Remove tabs by cutting with a sharp tool as shown in Figure 2 (see page 2).

2.The unit should be set on a level support pad at least as large as the unit base pan, such as a concrete slab. If this is not the application used please refer to application bulletin “Trane APB2001-02”.

3.The support pad must NOT be in direct contact with any structure. Unit must be positioned a minimum of 12" from any wall or surrounding shrubbery to insure adequate airflow. Clearance must be provided in front of control box (access panels) & any other side requiring

15 FT. ABOVE UNIT — UNRESTRICTED

service access to meet National Electrical Code. Also, the unit location must be far enough away from any structure to prevent excess roof run-off water from pouring directly on the unit. Do not locate unit(s) close to bedroom(s).

4.The top discharge area must be unrestricted for at least five (5) feet above the unit.

5.When the outdoor unit is mounted on a roof, be sure the roof will support the unit’s weight. Properly selected isolation is recommended to prevent sound or vibration transmission to the building structure.

6.The maximum length of refrigerant lines from outdoor to indoor unit should NOT exceed sixty (60) feet.

7.If outdoor unit is mounted above the air handler, maximum lift should not exceed sixty (60) feet (suction line). If air handler is mounted above condensing unit, maximum lift should not exceed sixty (60) feet (liquid line).

NOTE:

Refer to “Refrigerant Piping Software” Pub. No. 32-3312-0* (the position of the * denotes the latest revision number).

8.Locate and install indoor coil or air handler in accordance with instruction included with that unit.

Installer’s Guide

2BASEPAN TAB REMOVAL

b.Isolation hangers should also be used when refrigerant lines are run in stud spaces or enclosed ceilings.

c.Where the refrigerant lines run through a wall or sill, they should be insulated and isolated.

d.Isolate the lines from all ductwork.

D.SERVICE VALVE OPERATION

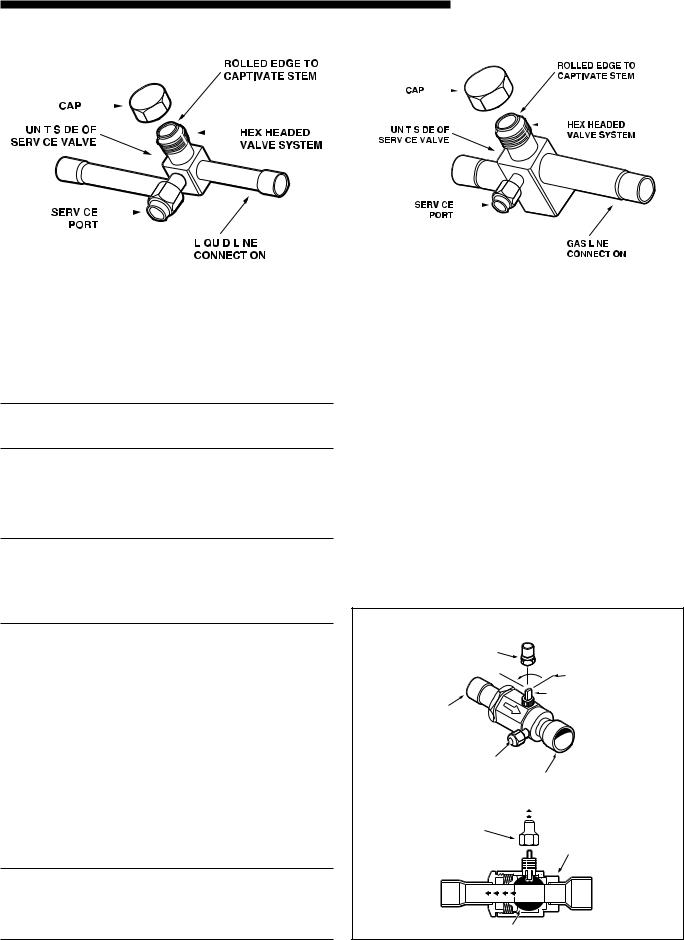

BRASS LIQUID AND GAS LINE SERVICE VALVES

The Brass Liquid and Gas Line Service Valves are factory shipped in the seated position to hold factory charge. The pressure tap service port (when depressed) opens only to the field brazing side of the valve when the valve is in the seated position. The liquid line valve is not a back seating valve (see WARNING below).

C. INSTALLING REFRIGERANT LINES

!CAUTION

If using existing refrigerant lines make certain that all joints are brazed, not soldered.

Condensing units have provisions for braze connections.

Pressure taps are provided on the service valves of outdoor unit for compressor suction and liquid pressures.

The indoor end of the recommended refrigerant line sets may be straight or with a 90 degree bend, depending upon situation requirements. This should be thoroughly checked out before ordering refrigerant line sets.

The gas line must always be insulated.

!CAUTION

In scroll compressor applications, dome temperatures may be hot. Do not touch top of compressor, may cause minor to severe burning.

The units are factory charged with the system charge required when using fifteen (15) feet of rated connecting line. Unit nameplate charge is the same.

Final refrigerant charge adjustment is necessary. Use the Subcooling Charging procedure on page 6 or in the outdoor unit Service Facts.

1.Determine the most practical way to run the lines.

2.Consider types of bends to be made and space limitations.

NOTE:

Large diameter tubing will be very difficult to rebend once it has been shaped.

3.Determine the best starting point for routing the refrigerant tubing — INSIDE OR OUTSIDE THE STRUCTURE.

4.Provide a pull-thru hole of sufficient size to allow both liquid and gas lines.

5.Be sure the tubing is of sufficient length.

6.Uncoil the tubing — do not kink or dent.

7.Route the tubing making all required bends and properly secure the tubing before making connections.

8.To prevent a noise within the building structure due to vibration transmission from the refrigerant lines, the following precautions should be taken:

a.When the refrigerant lines have to be fastened to floor joists or other framing in a structure, use isolation type hangers.

©2005 American Standard Inc. All Rights Reserved

!WARNING

Extreme caution should be exercised when opening the Liquid Line Service Valve. Turn valve stem counterclockwise only until the stem contacts the rolled edge. (See Figure 3) No torque is required.

BRASS GAS LINE BALL SERVICE VALVE

The Brass Gas Line Ball Service Valve is shipped in the closed position to hold the factory refrigerant charge. The pressure tap service port (when depressed) opens only to the field brazing side when the valve is in the closed position. The Gas Line Ball Service Valve is full open with a 1/4 turn. See Figure 4.

BRAZING REFRIGERANT LINES

1.Remove lower access cover to access service valves.

2.Before brazing, remove plugs from external copper stub tubes. Clean internal and external surfaces of stub tubes prior to brazing.

3.Cut and fit tubing, minimizing the use of sharp 90° bends.

4.Insulate the entire gas line and its fittings.

5.Do NOT allow uninsulated liquid line to come in direct contact with bare gas line.

6.Precautions should be taken to avoid heat damage to the pressure tap valve core during brazing. It is recommended that the pressure tap port valve core be removed and a wet rag wrapped around the valve body.

NOTE:

Use care to make sure that no moisture enters pressure tap port, while wet rag is being used.

NOTE:

Precautions should be taken to avoid heat damage to basepan during brazing. It is recommended to keep the flame directly off of the basepan.

7.Use a Dry Nitrogen Purge and Brazing Alloy without flux when brazing the field line to the copper factory connection. Flow dry nitrogen into either valve pressure tap port, thru the tubing and out the other port while brazing.

8.Braze using accepted good brazing techniques.

LEAK CHECK

IMPORTANT:

Replace pressure tap port valve core before attaching hoses for evacuation.

18-AC56D1-1

Installer’s Guide

3 |

|

LIQUID LINE SERVICE VALVE |

GAS LINE SERVICE VALVE |

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

After the brazing operation of refrigerant lines to both the outdoor and indoor unit is completed, the field brazed connections must be checked for leaks. Pressurize through the service valve ports, the indoor unit and field refrigerant lines with dry nitrogen to 350-400 psi. Use soap bubbles or other leak-checking methods to see that all field joints are leak-free! If not, release pressure; then repair!

SYSTEM EVACUATION

NOTE:

Since the outdoor unit has a refrigerant charge, the gas and liquid line valves must remain closed.

1.Upon completion of leak check, evacuate the refrigerant lines and indoor coil before opening the gas and liquid line valves.

2.Attach appropriate hoses from manifold gauge to gas and liquid line pressure taps.

NOTE:

Unnecessary switching of hoses can be avoided and complete evacuation of all lines leading to sealed system can be accomplished with manifold center hose and connecting branch hose to a cylinder of HCFC-22 and vacuum pump.

3.Attach center hose of manifold gauges to vacuum pump.

4.Evacuate until the micron gauge reads no higher than 350 microns.

5.Close off valve to vacuum pump and observe the micron gauge. If gauge pressure rises above 500 microns in one (1) minute, then evacuation is incomplete or system has a leak.

6.If vacuum gauge does not rise above 500 microns in one (1) minute, the evacuation should be complete.

7.With vacuum pump and micron gauge blanked off, open valve on HCFC-22 cylinder and charge refrigerant lines and indoor coil with vapor to tank pressure of HCFC-22 supply.

8.Close valve on HCFC-22 supply cylinder. Close valves on manifold gauge set and remove refrigerant charging hoses from liquid and gas pressure tap ports.

NOTE:

A 3/16" Allen wrench is required to open liquid line service valve. A 1/4" Open End or Adjustable wrench is required to open gas line valve. A 3/4" Open End wrench is required to take off the valve stem cap.

9.The liquid line shut-off valve can now be opened. Remove shut-off valve cap. Fully insert hex wrench into the stem and backout counterclockwise until valve stem just touches rolled edge (approximately five [5] turns) observing WARNING statement on page 2. See Figure 3.

10.Replace liquid service pressure tap port cap and valve stem cap. These caps MUST BE REPLACED to prevent leaks. Replace valve stem cap and pressure tap cap finger tight, then tighten an additional 1/6 turn.

11.The gas valve can now be opened. Open the gas valve by removing the shut-off valve cap and turning the valve stem 1/4 turn counterclockwise, using 1/4" Open End or Adjustable wrench. See Figure 4.

12.The gas valve is now open for refrigerant flow. Replace valve stem cap to prevent leaks. Again, these caps MUST BE REPLACED to prevent leaks. Replace valve stem cap and pressure tap cap finger tight, then tighten an additional 1/6 turn. See Figure 4.

If refrigerant lines are longer than 15 feet and/or a different size than recommended, it will be necessary to adjust system refrigerant charge upon completion of installation. See page 6 or in the unit Service Facts.

4GAS LINE BALL SERVICE VALVE

CAP |

1/4 TURN ONLY |

|

COUNTERCLOCKWISE |

|

FOR FULL OPEN |

|

POSITION |

|

VALVE STEM |

UNIT SIDE

OF VALVE

PRESSURE TAP PORT

GAS LINE CONNECTION

CAP

BODY

COOLING

CORE

18-AC56D1-1 |

3 |

Loading...

Loading...