Teka LSE-1200 S User Manual

0020505090C

LSE-1200 S

Automatic Drum Washing Machine

INSTRUCTION MANUAL

23

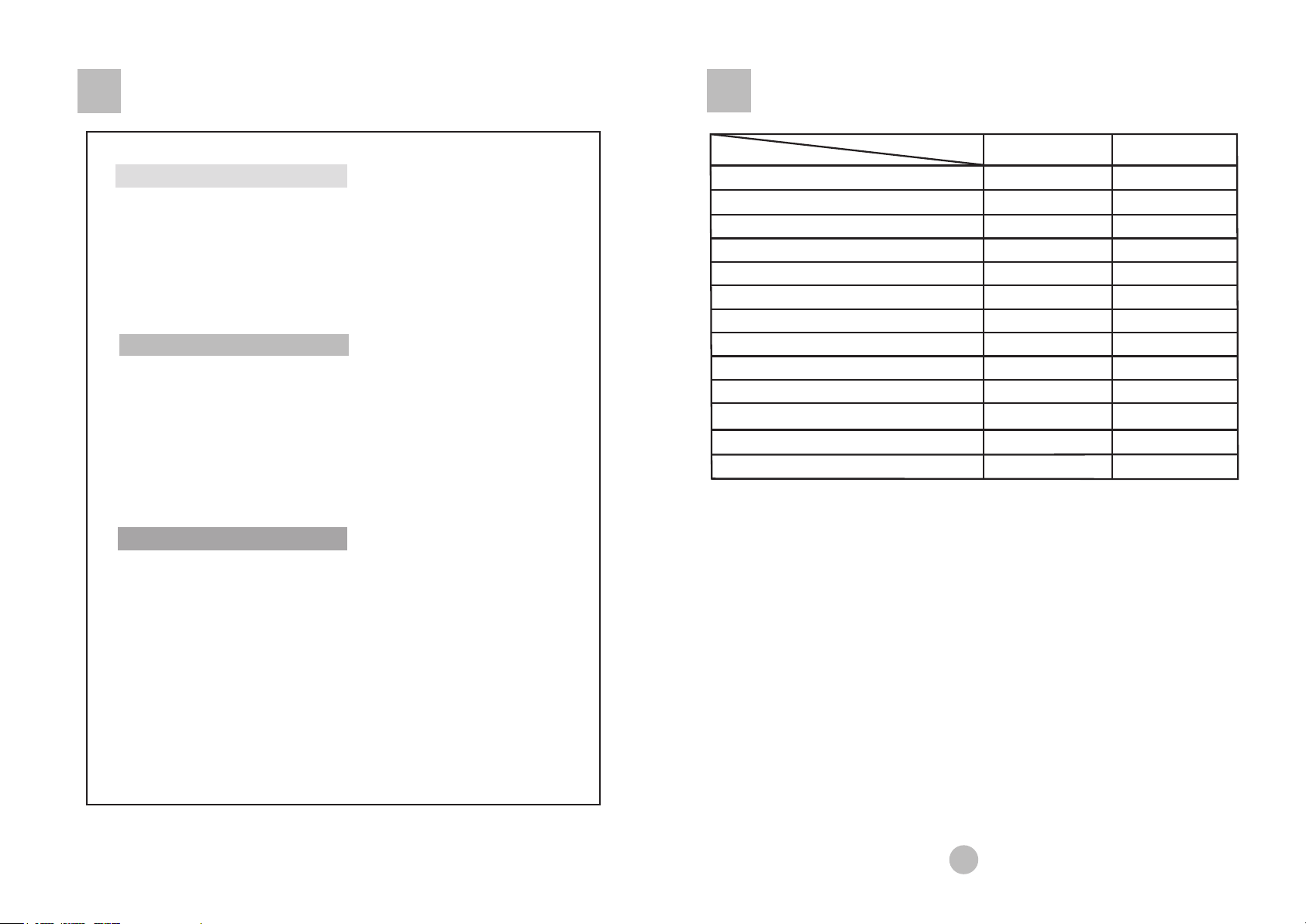

ITEM

MODEL

LSE-1200 S

220-240V~/50H

Z

10

350

550

6

1200

11

1800

88

LSE-1000 S

220-240V~/50H

Z

10

350

IPX4 IPX4

450

6

1000

11

1800

88

850×600×595

850×600×595

0.03≤P≤1

0.03≤P≤1

10001000

Content

Pre-usage

Part Names ………………………………1

Precaution……………….2-4

Installation………………5-6

Control Panel ……..7-8

Display Screen …………….….9

Using Process

Program Setting…..10-11

Preparation…………………………….….12

Washing Methods……………………...13-14

Flexible Applications ………15

Laundry Operation Illustrations……….….16

Other Functions ……………..17

Repair and Maintenance

Maintenance………………..18-19

Trouble-shooting……………….….20

Wiring Circuit …………….…21

Codes on Display Screen………………….22

Specification…………..……23

Power Source

Maximal Working Current Ampere (A)

Tap Water Pressure Megapascal(Mpa)

Waterproof Degree

Washing Power Watts (W)

Spining Power Watts (W)

Rating Laundry Quantity Kilogram (kg)

Velocity Revolutions /minute(r/min)

Washing Procedure

Drying Power Watts (W)

Water Heating Power Watts (W)

External Dimension(H*D*W Millimeter(mm))

Weight Kilogram (kg)

Specification

1

22

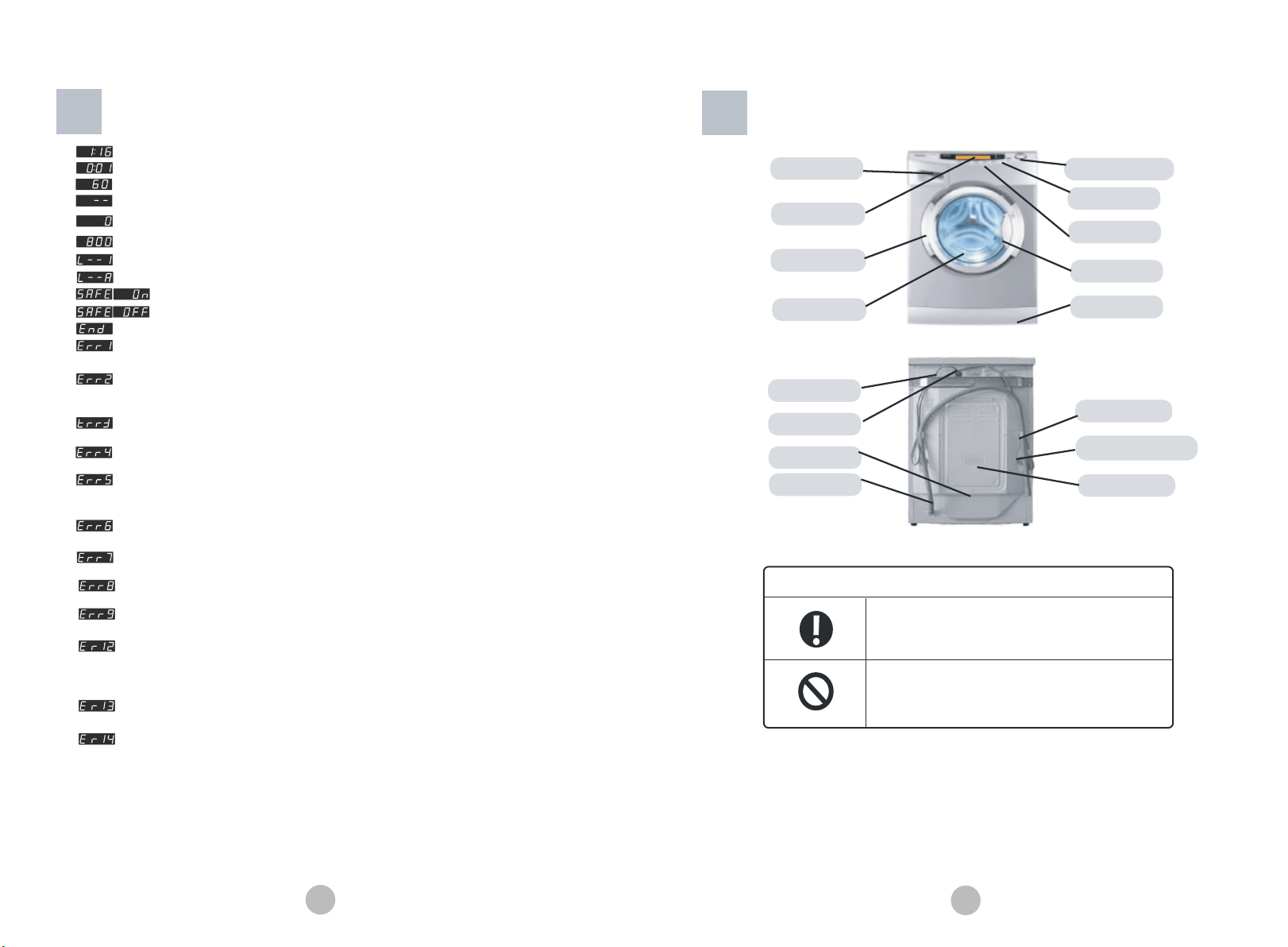

Remaining time 1 hour and 16 minutes

Remaining time 1 minute

Setting washing temperature at 60

Setting washing without heating process

Setting no Spin process

Setting dehydration revolutions 800r/min

Code for manual selection of weight, when clothes are less than 1kg

Code for manual selection of weight, when clothes are almost full of the roller

Start-up keyboard locking function

Cancel keyboard locking function

Procedure is entirely finished

Failure information: locking door function abnormity

Processing mode: reclose the door, if there is still any alarm, please contact service people

Failure information: draining malfunction

Processing mode: rinse the filter of draining pump, examine whether the drainpipe

is blocked if there is still any alarm, please contact service people.

Failure information: temperature pickup malfuntion

Processing mode: please contact the service people.

Failure information: fuser malfunction (display after procedure operation)

Processing mode: please contact the service people.

Failure information: water intake abnormity

Processing mode: check whether the water hydraulic pressure is too low or water

supply is cut off. Please contact the service people.

Failure information: dehumidification and heating abnormity.

Processing mode: Please contact the service people.

Failure information: superabundant spume in the roller or motor failure

Processing mode: inflow water and vent the spume or please contact the service people.

Failure information: drying temperature sensor malfunction

Processing mode: Please contact the service people.

Failure information: waterlevel sensor malfunction

Processing mode: Please contact the service people.

Failure information: drying waterlevel sensor abnormity

Processing mode: check whether the clothes is dried or not, and whether there is water

in the roller,Dry it again after the dehumidifying process. If there is still any alarm, please

contact the service people.

Failure information: The door is not properly closed after the activation of the procedure

Processing mode: Reclose the door. If there is still any alarm, please contact the service people.

Failure information: when spined, clothes is unevenly distributed

Processing mode: Quiver and scatter the clothes to make it even. If there is still any

alarm, please contact the service people

Codes on Display Screen

Part names

Detergent dis-

tribution drawer

Display

Door

Glass

Power cable

Screws for rear

panel

Bolts for transport

Drainage hose

Caution and Warning Symbols

For your safety, any instructions in this manual with this "Warning"

sign shall be strictly followed.

For your safety and to prevent damages to the washing machine,

any instructions in this manual with this "Stop" sign shall be strictly

followed.

This diagram may vary slightly with the layout of the washing machine you have just purchased

due to technical improvements.

Rear panel

Programme selector

Function button

Door handle

Skirting

Control panel

Hose clip

Earth terminal

2

21

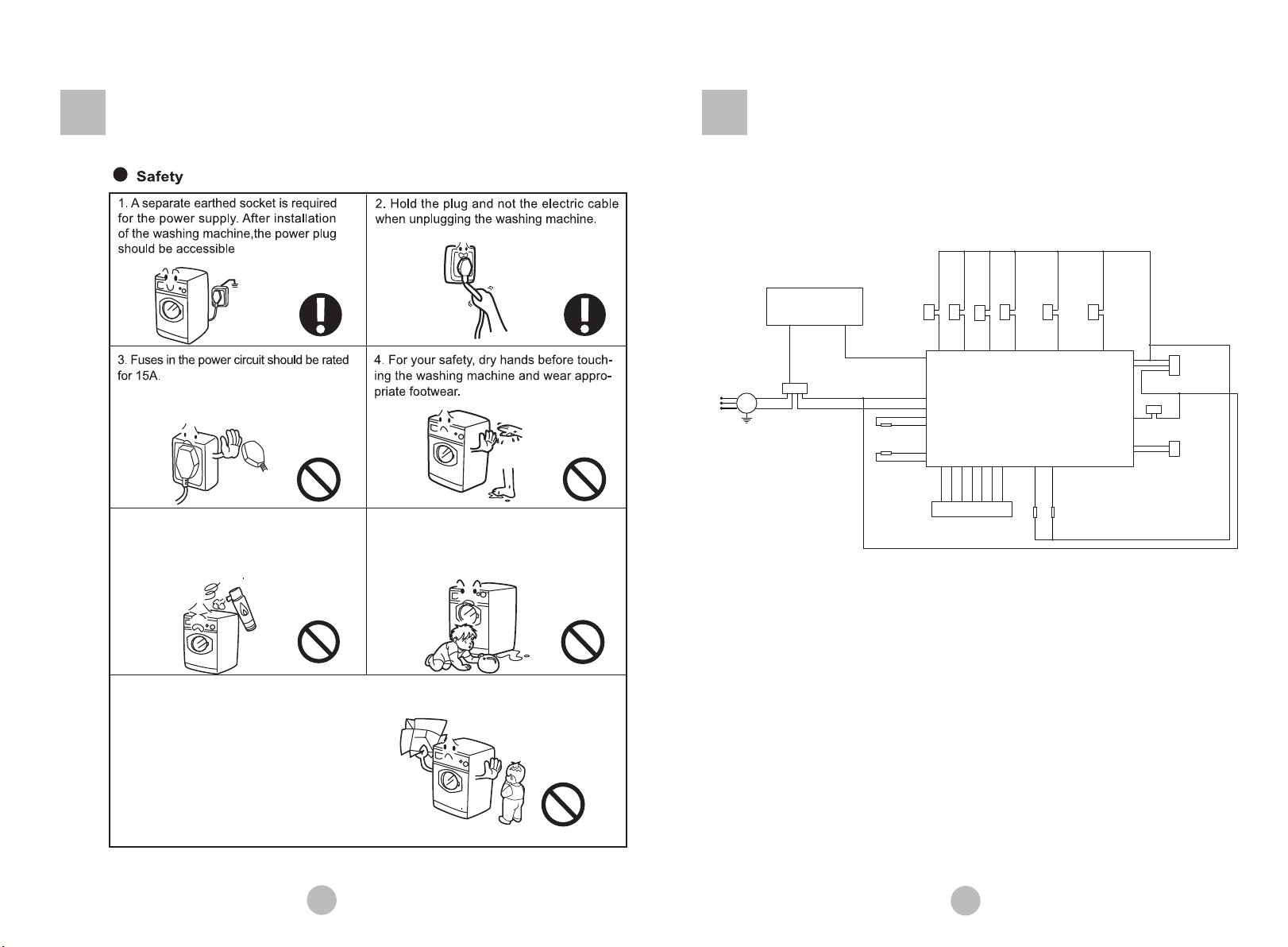

PCB

JA1

JA2

JA3

JA4

JA5

JA6

JA7

JB10

1

2

Water supply

Solenoid Valve

1

2

JB1

JB2

1

2

JB4

JB7

Heating Temperature Sensor

JC4

JC2

JC3

N

G

L

1

2

Drain Pump

JB5

1

2

Drying Fan

JB8

JB11

1

2

3

2-

1

2

1-

3-

N'

1

2

3

4

Program Selector

L

N

N

N'

JC1

VFD

X1

JB9

JB6

X3

JC5

X4

JC6

1

2

VCC

L

N

Precaution

.

The power cable must be replaced

by a qualifed engineer; if not, please

consult the Service Center.

5. Do not use inflammable detergents or

dry-cleaning agents. Do not use inflammable

spray containers in close vicinity to the

washing machine. In the event of gas leaks,

remove the washing machine plug and do not

connect.

6. The door of the washing machine will

become very hot during the water-heating

process. Avoid contact with the door during

the heating process. For safety, keep children

away from the washing machine.

7. Do not allow children play with the packing materials after unpacking.

Wiring Circuit

Water supply

Solenoid Valve

Water supply

Solenoid Valve

Heater

Drying Heater125

Motor

Pressure Switch

Drying Switch

Drying Temperature Sensor

Filter

MRC

MRL

MRN

1

2

JB3

Water supply

Solenoid Valve

3

●Use

8. The washing machine must not be installed

outside or in a very humid areaas drops of

water may form on electricalcomponents,

If drops of water have splashed on the

warming on the washing machine,leave it

dry before use.

10. Keep away from heat sources and di-

rect sunlight to prevent plastic and rubber

components from aging.

2. Keep the door slightly open when the

washing machine is not being used. Never

cover the machine with a plastic sheet.

1. Before starting the wash programme,

ensure that the washing machine is

correctly connected to the water supply. In

the event of water leakage, turn off the

water supply and reconnect, or call the

Service Center.

precaution

Loading...

Loading...