Siemens UROSKOP D3 Instruction Manual

UROSKOP D3

SP

Start-up Instructions

with POLYDOROS SX and

FLUOROSPOT H with Supervision

|

|

|

|

© Siemens AG 1998 |

|

|

The reproduction, transmission or |

|

|

use of this document or its contents |

|

|

is not permitted without express |

|

|

written authority. Offenders will be |

|

|

liable for damages. |

All rights, |

|

including rights created by patent |

|

|

grant or registration of a utility |

|

|

model _or_ design,_are_ reserved. |

|

Register 4 |

English |

|

Print No.: RLL5-310.034.04.04.02 |

Doc. Gen. Date: |

12.98 |

Replaces: RLL5-310.034.04.03.02

0 - 2 |

|

|

Revision |

|

|

|

|

Chapter |

Page |

Revision |

|

|

|

|

|

1 |

all |

04 |

|

|

|

|

|

2 |

all |

04 |

|

|

|

|

|

3 |

all |

04 |

|

|

|

|

|

4 |

all |

04 |

|

|

|

|

|

5 |

all |

04 |

|

|

|

|

|

6 |

all |

04 |

|

|

|

|

|

7 |

all |

04 |

|

|

|

|

|

8 |

all |

04 |

|

|

|

|

|

9 |

all |

04 |

|

|

|

|

|

10 |

all |

04 |

|

|

|

|

|

11 |

all |

04 |

|

|

|

|

|

12 |

all |

04 |

|

|

|

|

|

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 2 of 4 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

Page

1 _______General information ____________________________________________ 1 - 1

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1 General information and information on documentation . . . . . . . . . . . . . . . . 1 - 1 Preliminary information on image quality test . . . . . . . . . . . . . . . . . . . . . . 1 - 2 Purpose: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2 Sequence of work: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2 Requirements for start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2 Required Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2 Required measuring instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

2 _______Start-up preparation ____________________________________________ 2 - 1

Protective measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1 Measuring the line voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1 Checking the on-site emergency shutdown button . . . . . . . . . . . . . . . . . . . 2 - 1 Checking the phase connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2 Measuring the internal line impedance . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2 Checking unacceptable ground connections . . . . . . . . . . . . . . . . . . . . . . 2 - 3 Switching on the generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

3 _______Generator functions ____________________________________________ 3 - 1

Checking the emergency stop switches . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1 Checking the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1 Function check of the anode starter . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1 Key to 7-segment display on board D95: . . . . . . . . . . . . . . . . . . . . . . 3 - 1

LED status display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . . 3 |

- 1 |

|||||

Checking the fluoroscopic and exposure release circuit |

. . . . . . . . . . . . . . . . 3 - 2 |

||||||||

Fluoroscopic circuit . . . . . . . . . . . . . . . . . |

. |

. . . . . . . . . . |

. |

. |

. . . 3 |

- 2 |

|||

Exposure release circuit . . . . . . . . . . . . . . . . |

. . . . . . . |

. . . . . . |

. |

. 3 |

- 2 |

||||

Controls and indicator lamps for radiation protection . . . . . . . . . . |

. . . . . . |

. |

. 3 - 3 |

||||||

Door contact for radiation disable function . . . . . . . . . . . . . . . . . . . . . 3 - 3 Indicator lamps for tube assembly selection. . . . . . . . . . . . . . . . . . . . . 3 - 3 Checking the kV/mA values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3 Checking the mAs values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4 Start-up of the automatic exposure control . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

4 _______Unit movements________________________________________________ 4 - 1

Preparation and limit values for tabletop lift . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Lifting movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . |

. |

. 4 |

- 2 |

Oblique projection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 |

- 3 |

|||

Tilting movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . |

. |

. 4 |

- 4 |

Longitudinal movement of the tabletop . . . . . . . . . . . . . . . . . . . . . . . . . 4 |

- 5 |

|||

Transverse movement of the tabletop . . . . . . . . . . . . . . . . . . . . . . . . . . 4 |

- 6 |

|||

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 3 of 6 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

Page

5 ______ Radiation geometry _____________________________________________5 - 1

Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2 Evaluation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3 Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4 Brief description of the test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4 Visual check of the fluoroscopic field limitation . . . . . . . . . . . . . . . . . . . 5 - 5 Checking the overframing of the fluoroscopic field size displayed on the monitor . 5 - 5 Checking the centering of radiation field and monitor image center . . . . . . . . 5 - 6 Evaluation of overframing in fluoroscopy . . . . . . . . . . . . . . . . . . . . . . 5 - 6 Evaluation of off-center in fluoroscopy . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

6 ______ Checking the tomographic device _________________________________6 - 1

Accuracy of the tomographic height display . . . . . . . . . . . . . . . . . . . . |

6 - 2 |

Resolution and tomographic procedure . . . . . . . . . . . . . . . . . . . . . . |

6 - 2 |

7 ______ Fluoroscopic dose rate __________________________________________7 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Preliminary remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

- 1 |

Basic information on the dose / dose rate measurement for I.I. workstations . . . |

7 - 1 |

|

Determining the dose/dose rate directly at the I.I. input . . . . . . . . . . . . . . |

7 - 1 |

|

Formulas for calculating the dose/dose rate in the measurement plane for |

|

|

dose/dose rate setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

- 2 |

Indirect dose rate test at the customer site . . . . . . . . . . . . . . . . . . . . . . . |

7 - 3 |

|

Setting when the indirect dose rate is out of tolerance . . . . . . . . . . . . . . . . . |

7 - 3 |

|

Maximum skin dose rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

- 4 |

8 ______ Television system ______________________________________________8 - 1

Function check of ambient light sensor. . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1 B-signal values (without bias light/dark current component) . . . . . . . . . . . . . . 8 - 1 Image artifacts (Para. 5.10 Chapter 5D) . . . . . . . . . . . . . . . . . . . . . . 8 - 2

9 ______ Digital Fluoro Radiography/FLUOROSPOT H ________________________9 - 1

General information and remarks . . . . . . . . . . |

. . . . . . . . . . . . . . . . . 9 - 1 |

|

Dose/pulse test during start-up (indirect dose check) |

. . . . . . . . . . . . . . . . . 9 - 5 |

|

BA (video+blanking) signal values / setting the iris diaphragm in DR operation . . . . |

9 - 6 |

|

Dynamic test . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . |

9 - 7 |

Edge enhancement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 11 Mean value assessment (GGM= sliding weighted averaging) . . . . . . . . . . .9 - 11 Resolution and minimum contrast . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 12 Checking the DSA system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 14 Checking the hardcopy camera . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 16 Adjusting the hardcopy camera. . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 16

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 4 of 6 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

Page

Preparing and evaluating the SMPTE test image . . . . . . . . . . . . . . . . . 9 - 16 Image artifacts and transmission interference. . . . . . . . . . . . . . . . . . . 9 - 17 Image artifacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 18 Definition of the rating numbers:. . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 18 Description of the artifacts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 18

10 ______Nominal values _______________________________________________ 10 - 1

I.I. nominal values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1 ADC measuring field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1 MPL system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1 SDM system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Fluoroscopic dose rate at the I.I. input |

. . . . . . . . . |

. . . . . |

. . . |

. . . . . . |

. |

10 - 2 |

VIDEOMED SX, H1X Emulation . . . |

. . . . . . . . . |

. . . . . |

. . . |

. . . . . . |

. |

10 - 3 |

TV monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3 TV camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

B signal value (interlaced - Bypass) . . . . . . . . . . . . . . . . . . . . . . . |

10 - 3 |

Vignetting (with bias light) (interlaced - Bypass) . . . . . . . . . . . . . . . . . |

10 - 4 |

AGC measuring field sizes in grid units (GU) . . . . . . . . . . . . . . . . . . . |

10 - 4 |

Pedestal and AGC function |

|

Pedestal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . 10 |

- 4 |

|||||

Fixed gain TV unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

. . 10 |

- 4 |

|||||

Dynamic test . . . . . . . . . . . . |

. . . . . . . . . . . . . . |

. . . |

. . . . . . |

. |

10 |

- 5 |

|||

Capillary test . . . . . . . . . . . . |

. . . . . . . . . . . . . . |

. . . |

. . . . . . |

. |

10 |

- 5 |

|||

Resolution and minimum contrast of the I.I.-TV system (interl. - Bypass) . . . . 10 - 6

Image artifacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 - 6 |

||||

Digital Fluoro Radiography / DFR . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 |

- 6 |

||||

FLUOROSPOT H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

- 6 |

|||

Dose/pulse at the I.I. input . . . . . |

. . . . . . . . . . . . . . . . . . . . |

. . . |

. |

10 |

- 6 |

Amplification of DFR system. . . . |

. . . . . . . . . . . . . . . . . . . . |

. . . |

. |

10 |

- 7 |

Monitor adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8 BA signal values / Adjustment of iris diaphragm in DR mode . . . . . . . . . . . 10 - 8 Dynamic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 9

Black level cutoff (noise halo) . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 - 10 |

|

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

- 10 |

Minimum contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

- 10 |

Checking the DSA equipment . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 - 11 |

|

Image artifacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

- 11 |

11 ______Final steps and electrical safety _________________________________ 11 - 1

Final work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 1 Measuring the protective conductor resistance . . . . . . . . . . . . . . . . . . . . 11 - 1

12 ______Changes to previous version ____________________________________ 12 - 1

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 5 of 6 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

Page

This page intentionally left blank.

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 6 of 6 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

Safety information

CAUTION

When performing service work and tests, please adhere to the product-specific safety information contained in the document, as well as the general safety information contained in Register 2 of the TI binder.

Tests and adjustments performed with radiation ON are identified with the radiation warning symbol

. Radiation protection must be worn during these types of adjustments.

. Radiation protection must be worn during these types of adjustments.

General information and information on documentation

These instructions contain the checks necessary for system startup.The sequence in which they are given must be maintained.

The unit movements necessary for these procedures must be carried out very carefully to avoid damaging the equipment in the event of a malfunction.

Since the unit has been adjusted completely at the factory, only the functioning and factory settings (accuracy of tolerance) are checked; the unit must be adapted to on-site requirements, if necessary.

If any mechanical or electrical malfunctions occur or if tolerances are exceeded (damages caused by transport etc.), perform service work and adjustments according to adjustment instructions RLL5-310.071.01... or the service instructions for the corresponding components.

Measurement results marked”

” must be entered in the UROSKOP test certificate.

” must be entered in the UROSKOP test certificate.

For the acceptance test which is required in Germany in accordance with §16 of the Röntgenverordnung (x-ray ordinance) and for the acceptance test required in the USA, the following checks have already been performed in the factory test area and documented in the test certificate:

•Visual check of the filter values.

•Check of the SID display.

•Brightness of the light localizer.

•Coincidence of light field and radiation field.

•Accuracy of the manual format collimation.

•Coincidence of radiation field and film center.

•Accuracy of positive beam limitation (PBL) system for cassette formats.

•Fluoroscopic field limitation.

•Centering of the radiation field and monitor image center.

•Function check of the Iontomat measurement fields.

•Unit attenuation factor.

•Check of the tomographic device.

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 1 of 4 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

NOTICE |

|

Enter the measurement values and the additional values deter- |

|

|

mined during system start-up from the test certificate into the |

|

|

|

|

|

acceptance certificate (Germany) or in the acceptance test certifi- |

|

|

cate (USA). |

|

|

|

Preliminary information on image quality test

Purpose:

•The image quality test provides objective data as a basis for image quality and facilitates system start-up.

•The test certificate is valid for system acceptance and for future service and maintenance work.

Sequence of work:

•Follow the sequence of measurements and checks exactly as describes in order to ensure correct measurements.

•Enter the results of each measurement into the test certificates.

•Compare the measured values with the values indicated in the list of nominal values.

•If the limit values are exceeded, you must determine the cause and correct the error or the erroneous setting before continuing the test. Otherwise the measurements that follow may be incorrect.

Requirements for start-up

•The system must be cabled completely.

•Switch on high voltage only if radiation is necessary.

Required Documents

• Operating instructions |

UROSKOP D3 |

RL5-340.208.01... |

|

• Wiring diagram |

UROSKOP D3 |

G5403 |

|

• Wiring diagram |

POLYDOROS SX X2075 |

|

|

• Service software |

|

|

|

operation |

UROSKOP D3 |

RLL5-310.113.02... |

Logbook, Reg. 10 |

• Setting Instructions |

POLYDOROS SX RX63-050.032.02... |

|

|

• System configuration |

POLYDOROS SX RX63-050.034.06... |

|

|

• IQ Test certificate |

|

RXD0-000.037.01... |

Logbook, Reg. 9 |

• Test certificate |

UROSKOP D3 |

RLL5-310.035.01... |

Logbook, Reg.3 |

• Test certificate |

POLYDOROS SX X2075 |

Logbook, Reg. 4 |

|

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 2 of 4 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

Required measuring instruments

• 3-Phase field rotation meter, electronic |

97 02 713 |

Y7933 |

• Internal line impedance meter |

84 28 104 |

RE999 |

• Service PC |

|

|

• Oscilloscope > 50 MHz, e.g. Tektronix 2232 |

97 02 234 |

Y3155 |

with delayed time base |

|

|

• Multimeter 8060 A (Fluke) |

97 02 101 |

Y4290 |

• mAs meter |

81 60 400 |

RE999 |

• Water level |

28 69 436 |

RE999 |

• Set of Cu filters |

44 06 120 |

RV090 |

• 17 m Cu strips (included in the LOG book) |

11 67 663 G5247 |

|

• cm scale |

|

|

• Tomographic cube with resolution test |

44 06 054 |

RV 090 |

• Protective conductor meter |

44 15 899 |

RV090 |

• 8x magnifying glass |

44 14 850 |

RH090 |

• Precision radiation filter |

99 00 598 |

XE999 |

• Centering cross or lead ruler |

96 60 051 |

RE999 or 28 63 025 RE999 |

• Mavo monitor, direct ordering |

97 02 432 |

Y0526 |

• Resolution test patterns, types 41 |

28 71 820 |

RE999 |

• Dynamic test case |

37 90 156 |

X1963 |

• heart contour diaphragm |

37 90 172 |

X1963 |

• Capillary test |

37 90 180 |

X1963 |

• DSA displacement test (with DSA capillary |

97 50 019 |

X1963 (only with DSA) |

test) |

|

|

• Aperture plate for tomography |

|

|

|

|

|

|

Successful system start-up can only be ensured by using the |

|

CAUTION |

|

|

|

|

|

|

|

above measurement instruments. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 3 of 4 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

This page intentionally left blank.

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 4 of 4 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

Protective measures

•Observe the protective measures described in Register 1 of the UROSKOP D Logbook.

•Prior to performing any service work on the generator, switch it off with the power OFF switch on D200.

•In order to deenergize all parts of the system, set the system switch to the OFF position.

CAUTION

With the generator switched off, line voltage is still present at transformer T1 and fuse panel D200 (refer to wiring diagram X2075-11).

After switching off the generator, approx. 600 V DC voltage are still present at the inverter; indicated by LEDs V8 and V9 on board D250 (see X2075-17).

Within approx. 1 1/2 minutes the voltage drops to 0 V; the LEDs go out at approx. 30 V.

•To prevent unintentional release of high voltage or radiation, set switch SS on D200 to OFF (no actuation of the inverters).

•Remove or insert boards only with the generator switched off. When doing so, observe the ESD guidelines (see TI 219, Info RA.5. RA0-000.012.19... on microfilm).

•On D211: switch S1

INT OFF (position 2).

INT OFF (position 2).

•On D200: switch SS OFF.

Measuring the line voltage

•Remove fuses F1, F2 and F3 from the fuse board in M16 (generator).

•System contactor ON.

•Measure the line voltage.

The voltage must correspond to the values indicated in the test certificate (logbook, Reg. 3).

Checking the on-site emergency shutdown button

•Actuate the emergency shutdown button installed by the customer. The entire system must be disconnected from the power line.

•System contactor OFF.

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 1 of 4 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

Checking the phase connection

•Check the correct phase connection of the power lines at M16.F1, F2, F3 (X2075-11), using the rotating field instrument:

•In M16, remove the cover from the fuse holders.

•Connect the3-phase field rotation meter to the lower connections of F1, F2, F3 (on the side of the power supply).

•System contactor ON.

•Perform the measurement.

•System contactor OFF.

•Disconnect the rotating field instrument.

Measuring the internal line impedance

•Measure the internal line impedance at M16. F1. F2. F3 (X2075-11):

-Connect the internal line impedance meter between two phases of F1, F2, F3 (at the lower connections of the fuse holders).

-System contactor ON.

-Perform the measurement.

-System contactor OFF.

• Record the measured values in the test certificate (logbook Reg. 3)

•Enter the measured values into the ”LINE PARAMETER” module of the system programming.

Important: In order to obtain the full generator power, the internal line impedance measured may not exceed the following values:

Uline |

max. Rline withPOLYDOROS |

measured |

||

SX 50 |

SX 80 |

|||

|

|

|||

|

|

|

|

|

400 V |

0.18 Ohm |

0.12 Ohm |

|

|

|

|

|

|

|

440 V |

0.20 Ohm |

0.16 Ohm |

|

|

|

|

|

|

|

480 V |

0.24 Ohm |

0.20 Ohm |

|

|

|

|

|

|

|

Internal line impedances of > 250 mOhm reduce power. Refer to RX63050.034.05.01.05... Configuration ”LINE PARAMETER”

•Reinsert fuses F1, F2 and F3.

•Reattach the cover.

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 2 of 4 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

Checking unacceptable ground connections

(connection between  and 0VL ).

and 0VL ).

•Disconnect the connection lead between the upper and lower grounding bus (in the generator power cabinet).

•Using the multimeter, measure the resistance between  and 0VL: The measured resistance must be approx. > 50 kΩ.

and 0VL: The measured resistance must be approx. > 50 kΩ.

•Reconnect the upper and the lower grounding bus.

Switching on the generator

•System contactor ON:

-LED V26 (via fuse F11) must light up on fuse board D200. In case of an error, check the fuses in M16 and on D200 (X2075-11 and 12).

•Generator ON:

-On fuse board D200, press key  and actuate button

and actuate button  .

.

-The LED’s must light up as follows on the service panel of D211:

The +5 V, ± 15 V, +24 V supply voltages are immediately present.

If the +5 V voltage is missing, the generator is disabled.

In this case, check the fuses on D200 (X2075-12). All LED’s on D200 must light up.

-Following connection of the intermediate circuit (activation of charging contactor and power contactor), LEDs V9 and V8 on board D250 must light up (X2075-17).

|

|

|

|

A DC voltage > 500 V is applied to the intermediate circuit. |

|

CAUTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

-Following correct initialization (after approx. 10 sec.), the following LEDs must light on the service panel of D211:

(

) (

) (  ) TU1 (after system programming) GEN-OK,+24 V, +15 V, -15 V, +5 V

) TU1 (after system programming) GEN-OK,+24 V, +15 V, -15 V, +5 V

If no error has occurred, the 7-segment displays on D210 indicate ”E000”. In case of an error, the three-digit error code is displayed.

- When programing the generator, "ALP" appears on the kV display of the control deck.

•Check the primary voltage for the supply voltages (X2075-12) at the coil connections of

the GS contactor (X2075-11) in M16: 230 V ± 10 % at 50 Hz

250 V ± 10 % at 60 Hz

•Check the blocking:

On D200: Generator OFF

The generator cannot be switched on again from the deck.

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 3 of 4 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

This page intentionally left blank.

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 4 of 4 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

Checking the emergency stop switches

•System ON.

•Press the three system emergency stop switches consecutively: With the emergency stop switch pressed in,

-error code ’’U01’’ must appear in the area dose product display on the control console;

-all system movements must be blocked.

Checking the control panel

•System ON.

•Select from 40 kV to the max. kV value on the kV control console by pressing the ± kV keys.

•Check the mAs display by pressing the ± mAs keys.

Function check of the anode starter

•Generator ON : On D95, display1→2→3

•Set release button S27 to preparation: the rotating anode boosts. Display 3→4→5

Let go of the release button S27 again: the rotating anode should brake. Display 6→3

NOTICE |

|

The rotational speed must be checked with the tube assembly |

|

|

warmed up. |

|

|

|

|

|

|

Key to 7-segment display on board D95:

1= |

Initialization |

4= |

Start-up |

2= |

Init-brakes |

5= |

Continued run |

3= |

Stand-by |

6= |

Brakes |

If the ERROR message flashes, please refer to the information contained in the service software.

LED status display

light up depending on the operating condition

Tube assy. 2 selected |

* |

* |

Tube assy. 1 selected |

|

|

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 1 of 4 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

Checking the fluoroscopic and exposure release circuit

Fluoroscopic circuit

•On board D200: SS switch OFF.

•On D211: FL switch ON.

•On D211: the following LED’s must light up (X2075-23):

- TU1/TU2 |

TU 1/ TU 2 (acc. to selected workstation/tube assembly) |

|||

- |

|

|

|

small focus |

- |

|

|

|

large focus |

|

|

|

||

|

|

|

||

- GEN-OK |

Generator enable state |

|||

- DL |

Fluoroscopy (FL) "on" (FL request) |

|||

- EXT-HW |

Radiation enable state/safety circuit |

|||

- SWR |

Start/inverter |

|||

|

|

|

|

|

NOTICE |

|

SWR "start/inverter" is not illuminated as long as Kathotest |

||

|

|

|

|

(module J05) is programmed. |

|

|

|

|

|

|

|

|

|

The "radiation indicator" lights up only with radiation ON. |

|

|

|

|

|

•FL switch OFF

•SS switch ON

•FL ON

•Measure the minimum and maximum kV and mA values and enter them into the generator certificate.

Exposure release circuit

With preparation:

•Set the release button S27 to preparation  .

.

•On D211, the following LEDs must light up:

- TU1/TU2 |

TU1/TU2 (acc. to selected workstation/tube assembly) |

|||||

- |

|

|

/ |

|

|

(depending on focus selection) |

- GEN-OK |

Generator enable state |

|||||

- ZB |

|

|

|

ZB "ON" (exposure preparation (ZB) request) |

||

With exposure release:

•Press the release button S27 all the way down.

•On D211, the following LED’s must light up

- VH: |

Exposure request to unit |

- AR: |

Exposure enable state from unit |

- EXT-HW: |

Radiation enable state/safety circuit |

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 2 of 4 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

NOTICE |

|

SWR "start/inverter" is not illuminated as long as Kathotest |

|

|

(module J05) is programmed. |

|

|

|

|

|

The "radiation indicator" lights up only with radiation on. |

|

|

|

• Release radiation release button S27.

Controls and indicator lamps for radiation protection

At the customer’s request, the following controls and indicators can be connected in the power cabinet according to the installation instructions RLL5-310.031.03..., page 4-6.

Door contact for radiation disable function

(e.g. at the door of the examination room)

• |

Check: |

When the door is open, radiation release must not be possible. |

Indicator lamps for tube assembly selection |

||

• |

Check: |

For fluoroscopy or exposure preparation, the respective indicator lamp |

|

|

associated with the tube assembly must light up. |

Checking the kV/mA values

•System OFF.

•Connect oscilloscope to test points MP.kVact and MP.mAact on service board D211.

•System ON.

•SS switch ON.

• On the control console, select 77 kV, 32 mAs for |

|

and |

|

focus respectively. |

|

|

•Release one exposure in each case and check the kV/mA values of test points MP.kVact and MP.mAact with the oscilloscope.

•Enter the measured kV values into the test generator test certificate and compare them with the values recorded at the factory. They must be within the specified tolerances.

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 3 of 4 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

Checking the mAs values

•System OFF.

•On PC board D220 (over H1), remove the jumper from the mAs jacks.

•Connect the mAs meter to the mAs jacks.

•System ON.

•On the control console, select  , 77 kV, 80 mAs.

, 77 kV, 80 mAs.

•Release an exposure and check the mAs value on the mAs meter.

•Enter the measured value into the generator test certificate.

Start-up of the automatic exposure control

Check the functions of the IONTOMAT P and PLANI-IONTOMAT P automatic exposure

control systems according to the generator setting instructions RX63-050.032....

NOTICE

NOTICE

The installation procedures described in the start-up instructions may be disregarded since both subassemblies have already been installed at the factory.

Since the UROSKOP has no selection for the film-screen keys H-D-U, identical values must be programmed for H-D-U in the IONTOMAT.

Checking the reproducibility of the automatic exposure control

•Attach 2.1 mm Cu to the multileaf collimator.

•Set 77 kV, 100%, large focus.

§16 • Select Iontomat.

•Release 5 exposures consecutively.

•Enter the measured dose values into the generator test certificate.

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 4 of 4 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

Preparation and limit values for tabletop lift

•Connect the service PC to connector X10 of board D1.

•System  (When the emergency stop switch is actuated,”U01” appears in the display).

(When the emergency stop switch is actuated,”U01” appears in the display).

•If necessary, release the emergency stop switch.

•Service PC  .

.

•Start the service program

(refer to the service software instructions RLL5-310.113.02...).

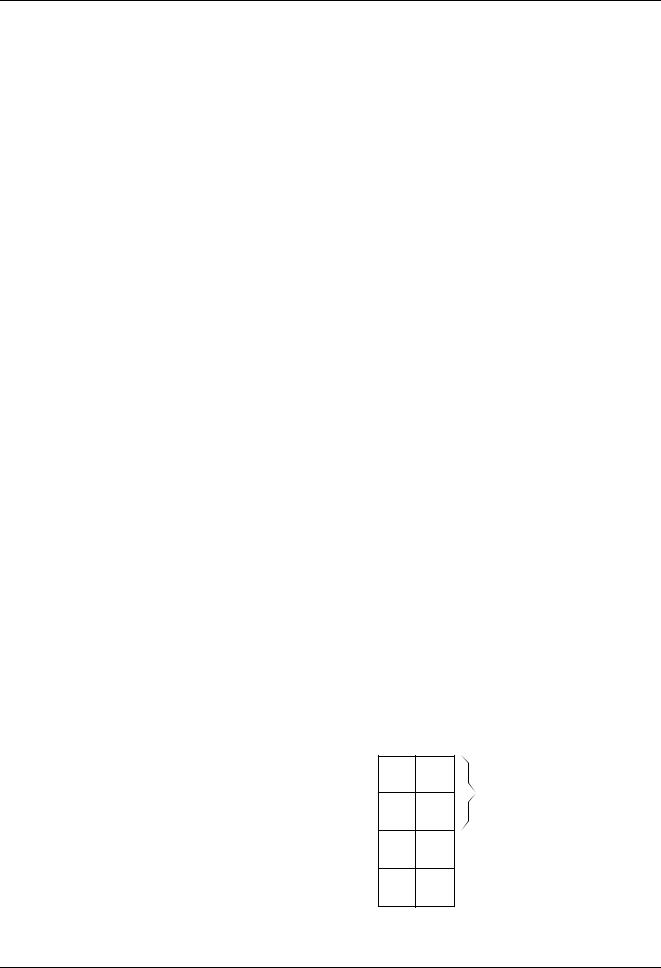

Main menu

|

|

Info database |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit parameters |

|

|

|

|

|

|

Load from unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit state |

|

|

|

|

Load from file |

||||

|

|

|

|

|

|

||||||

|

|

Unit errors |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

|

Calibration |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

|

Options |

|

|

|

|

|

|

|||

|

|

Download |

|

|

|

|

|

|

|||

Unit parameters |

|

|

|

|

|

|

|||||

|

|

Load from unit |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

|

Load from file |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

|

|

Show |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Modify |

|

|

|

|

|

|

Tomography |

||

|

|

|

|

|

|

|

|

||||

|

|

Send to unit |

|

|

|

|

|

Memoskop 2K/100 |

|||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Write to file |

|

|

ceiling height |

|

|

||||

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Output |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

•For ceiling height enter the actual room height available

•Press return.

•Press <F4>. Initial questions with Yes.

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 1 of 6 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

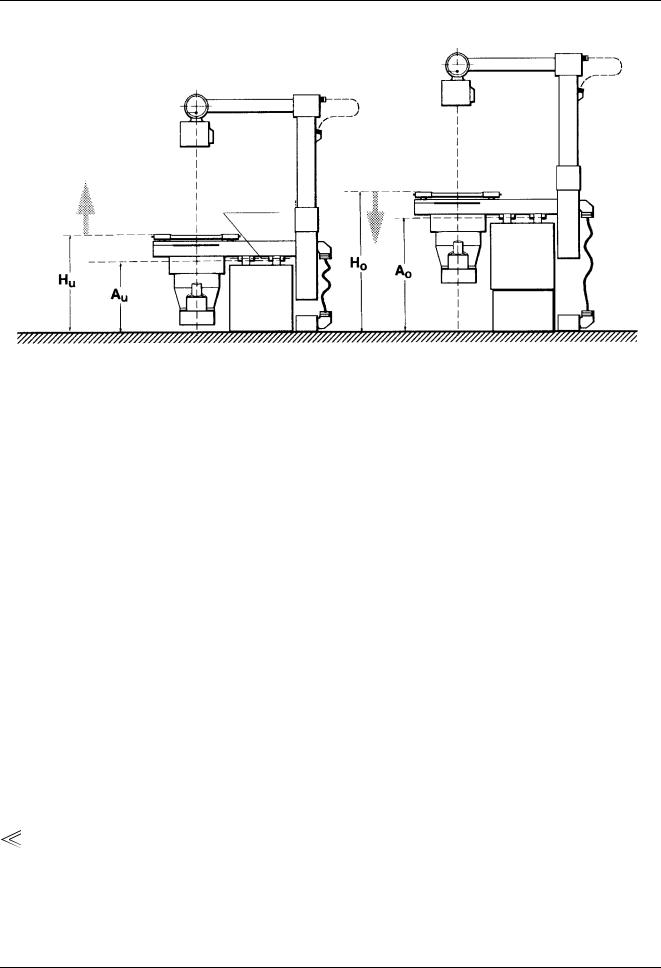

Lifting movement

Rotating axis

Lifting movement

|

|

|

|

Move into the end positions in gradual increments. |

|

CAUTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

•Tilt the unit into the 0° position.

•Successively move the unit into both end positions.

•Measure the distance between the floor or top surface of the installation plate and the top surface of the tabletop or rotating axis for both system positions:

|

Nominal distance between the floor or top surface of the installation plate |

||||

|

and top surface of the tabletop |

|

and rotating axis |

||

|

|

||||

|

|

|

|

|

|

|

Hu |

Ho |

|

Au |

Ao |

|

82 cm ± 5 mm |

128 cm ± 5 mm |

|

62 cm ± 5 mm |

108 cm ± 5 mm |

|

|

|

|

|

|

for I.I. 40 |

86 cm ± 5 mm |

128 cm ± 5 mm |

|

66 cm ± 5 mm |

108 cm ± 5 mm |

|

|

|

|

|

|

! minimum distance I.I. floor: 4 cm !

NOTICE |

|

Ho = 128 cm, possible only for room heights 2.60 m and above. |

|

|

|

Read the values displayed on the PC and compare them with the factory test values on the test certificate.

•Initial the comparison as confirmation.

Lowest point: 62 cm to center of rotation with tilted table (+88°).

•Correction: UROSKOP D adjustment instructions

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 2 of 6 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

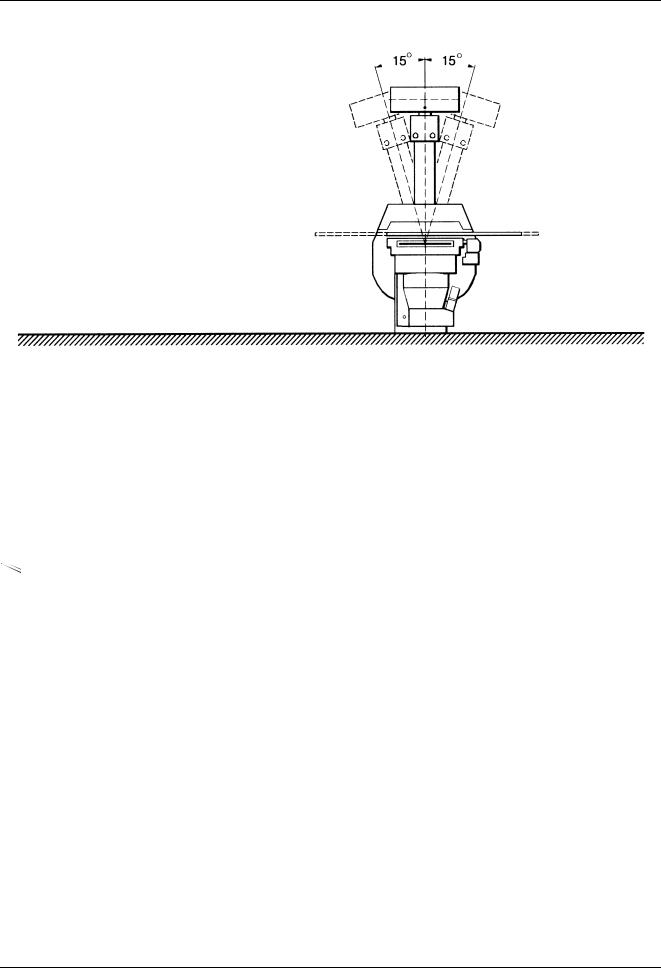

Oblique projection

|

|

|

|

Move into the end positions in gradual increments. |

|

CAUTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

•Swivel the tube assembly support arm in each case from the 0° position into both end positions, -15° and +15°.

The 15° values must be indicated on the system control console; at the same time, the safety limit switch must not be pressed.

•Read the values displayed on the PC under menu item [Unit state], [Current] and compare them with the factory test values in the test certificate.

•Initial the comparison as confirmation.

•Correction: UROSKOP D adjustment instructions.

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 3 of 6 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

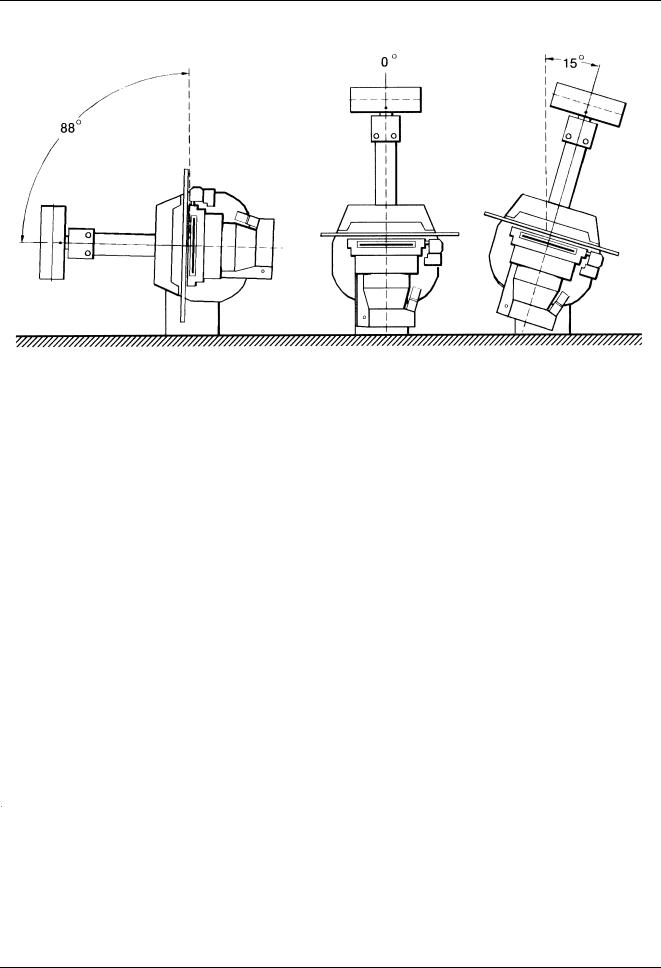

Tilting movement

Requirement: The installation plate must be level.

|

|

|

|

Move into the end positions in gradual increments. |

|

CAUTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

•Tilt the unit in each case from both directions into the 0° position.

•Check the 0° position in each case with the precision water level after the automatic stop. Nominal: 0° ± 0.3°

•Swivel from the 0° position into the +88° end position; the switching cam must not touch the limit switch.

•Check the +88° end position with the precision water level.

Nominal: 88° ± 0.5°

•Swivel from the +88° end position into the -15° end position; the switching cam must not touch the limit switch.

•Check the -15° end position with the precision water level.

Nominal: - 15° ± 0.5°

•Read the values displayed on the PC and compare them with the factory test values in the test certificate.

•Initial the comparison as confirmation.

•Correction: UROSKOP D adjustment instructions.

UROSKOP D3 |

Register 4 |

RLL5-310.034.04 |

Page 4 of 6 |

Siemens AG |

|

|

Rev. 04 12.98 |

TD PS 24 |

Medical Engineering |

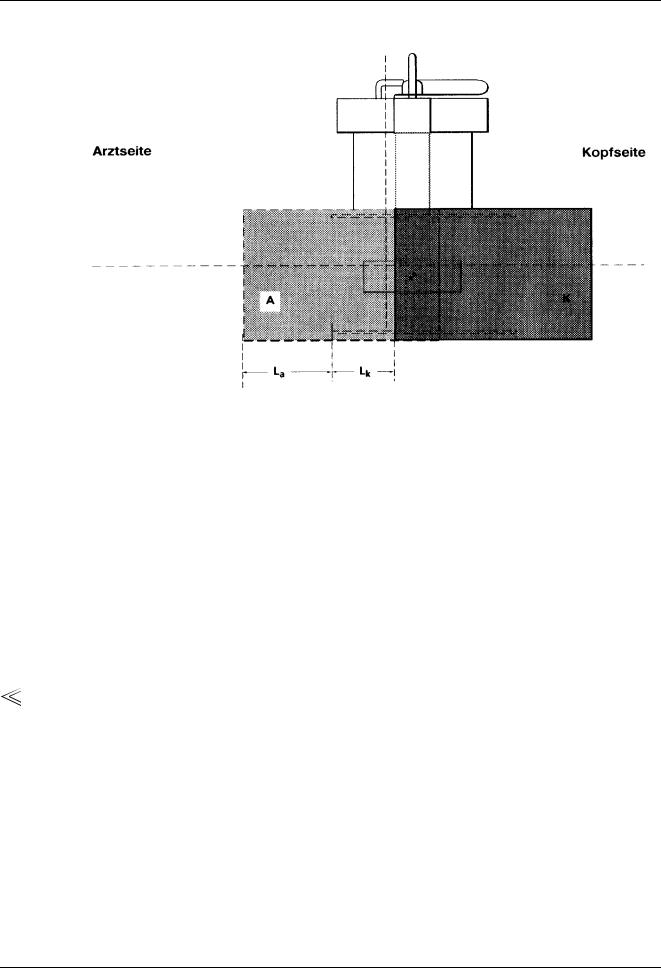

Wall side

|

|

|

Head end |

Physician‘s side |

Longitudinal movement of the tabletop

|

|

|

|

Move to the end positions in gradual increments. |

|

CAUTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

•Move the tabletop successively into end positions A and K.

•Measure the distance between the left tabletop edge and the left front of the front guide rail for both table positions.

Nominal: La = 573 mm ± 5 mm

Lk = 573 mm ± 5 mm

•Read off the values displayed on the PC and compare them with the factory test values of the test certificate.

•Initial the comparison as confirmation.

•Correction: UROSKOP D adjustment instructions.

Siemens AG |

Register 4 |

RLL5-310.034.04 |

Page 5 of 6 |

UROSKOP D3 |

Medical Engineering |

|

Rev. 04 12.98 |

TD PS 24 |

|

Loading...

Loading...