SHARP ARD28, ARD27, ARMU2 Service Manual

q SERVICE MANUAL

CODE : 00ZARD28//A1E

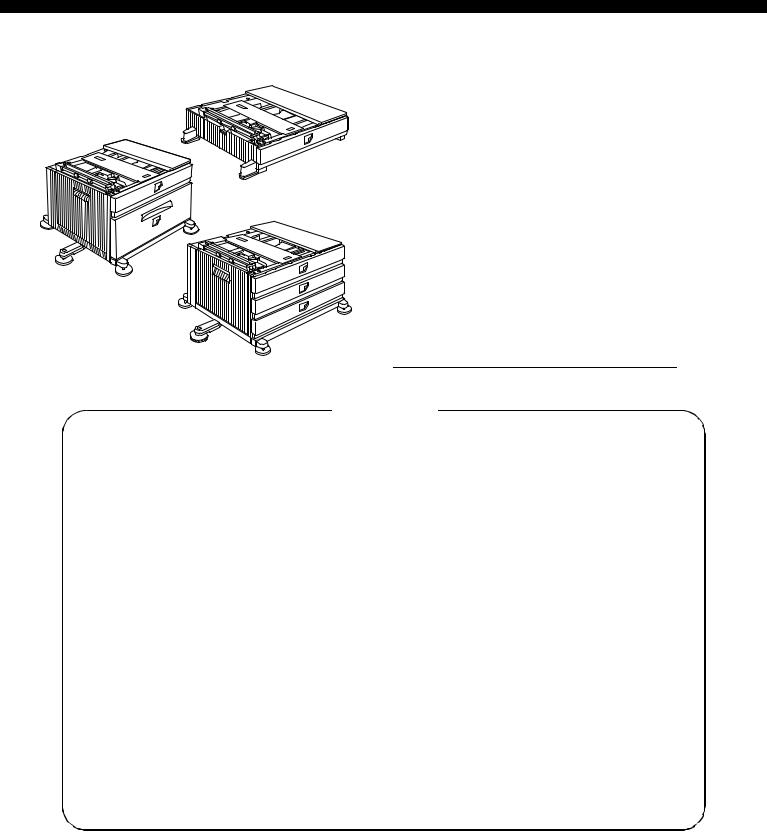

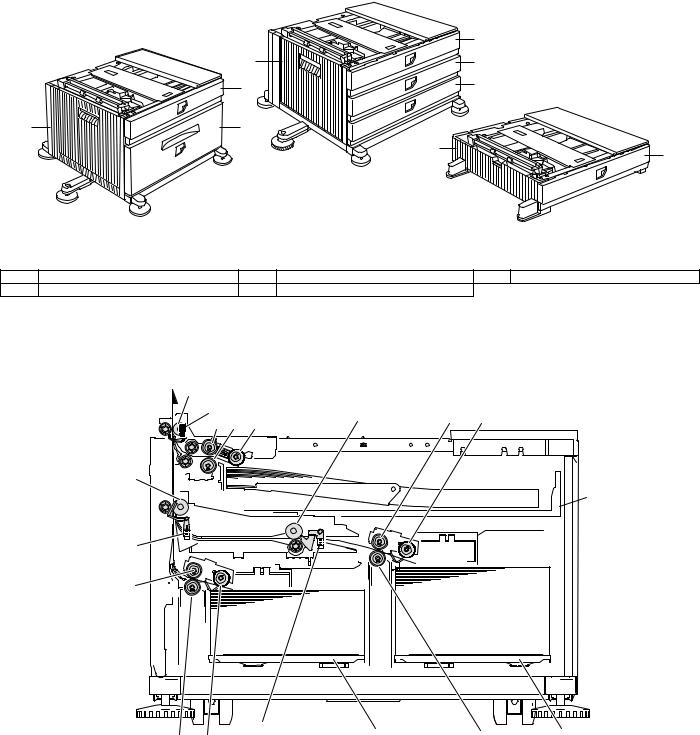

AR-MU2

AR-D28

LASER PRINTER OPTIONS

PAPER FEED UNIT

OPTIONAL POWER SUPPLY UNIT

AR-D27

AR-D28

AR-D27

MODEL AR-MU2

CONTENTS

[1] |

PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 - 1 |

[2] |

CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 - 1 |

[3] |

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 - 1 |

[4] |

UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . |

4 - 1 |

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . |

5 - 1 |

|

[6] |

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 - 1 |

[7] DISASSEMBLY AND ASSEMBLY, MAINTENANCE . . . . . . . . . |

7 - 1 |

|

[8]BLOCK DIAGRAM, WIRING DIAGRAM,

CIRCUIT DIAGRAM, PARTS ARRANGEMENT . . . . . . . . . . . . . 8 - 1

PARTS GUIDE

Parts marked with "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

|

|

|

This document has been published to be used |

SHARP CORPORATION |

for after sales service only. |

The contents are subject to change without notice. |

[1] PRODUCT OUTLINE

This unit is installed to one of the following machines to serve as a Paper feed module.

When installing the unit to one of the following machines, one of the multi-purpose tray (AR-MU2), the large capacity paper feed desk (AR-D28), and the 3-stage paper feed desk (AR-D27) must be installed in advance.

Applicable models |

AR-M351N/M451N/M355N/M455N |

|

AR-M351U/M451U/M355U/M455U |

|

|

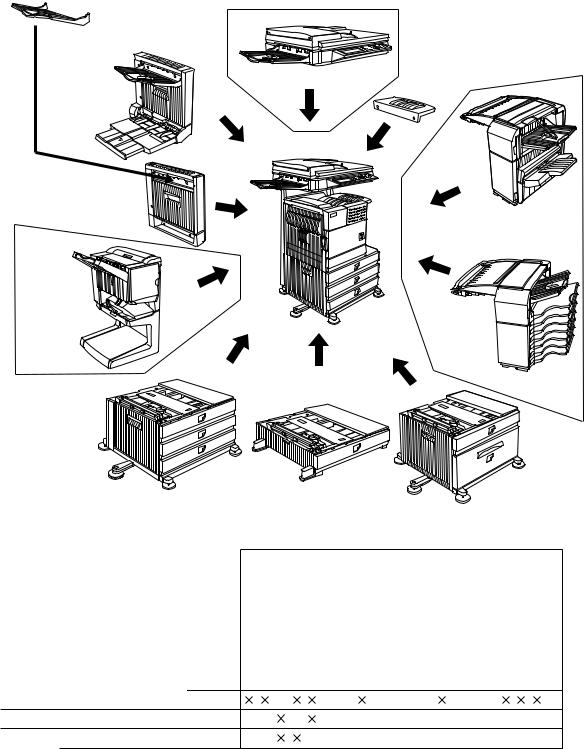

[2] CONFIGURATION

1. The AR-MU2 cannot be installed together with the saddle finisher (AR-FN7)/Scanner unit (AR-EF3).

Exit tray |

|

(AR-TE3 or AR-DU4 Standard) |

B/W scanner module/DSPF(AR-EF3) |

|

|

Duplex |

|

module/bypass tray |

Upper exit tray |

|

extension |

|

(AR-TE4) |

Finisher

(AR-FN6)

Duplex module (AR-DU3)

Saddle stitch |

Mail-bin |

finisher |

|

(AR-FN7) |

stacker |

|

(AR-MS1) |

|

Multi purpose drawer |

|

(AR-MU2) |

Stand/3 x 500 sheet |

|

|

paper drawer |

Stand/MPD & 2000 sheet |

|

(AR-D27) |

||

paper drawer |

||

|

||

|

(AR-D28) |

Related to paper feed unit

Multi purpose drawer |

AR-MU2 |

Stand/3 x 500 sheet paper drawer |

AR-D27 |

Stand/MPD & 2000 sheet paper drawer |

AR-D28 |

|

|

B/W scanner module/DSPF |

Scanner rack |

|

Multi purpose drawer |

|

Stand/3 x 500 sheet paper drawer |

|

Stand/MPD & 2000 sheet |

Duplex module/bypass tray |

Duplex module |

Saddle stitch finisher |

Finisher |

Mail-bin stacker |

Exit tray |

Upper exit tray extension |

Punch unit |

Multi-function controller board |

Print server card |

PS3 expansion kit |

Network scanner expansion kit |

Facsimile expansion kit |

Fax memory (8 MB) |

Hard disk drive |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AR-D28/D27/MU2 PRODUCT OUTLINE

1 – 1

[3] SPECIFICATIONS

1. AR-D28

|

|

|

|

AR-D28 |

|

|

|

|

|

||

Type |

|

Stand MPD&2000 Sheet Paper Drawer |

|||

|

|

|

(large capacity tray + multi purpose drawer) |

||

|

|

|

|||

Transport speed |

To support 35-45 sheet/minute |

||||

|

|

|

|||

Transport alignment |

Center alignment |

||||

|

|

|

|

||

Paper size |

1 Tray |

A3, B4, A4, A4R, B5, B5R, A5R |

|||

|

|

|

11"x17", 8.5"x14", 8.5"x13", 8.5"x11", |

||

|

|

|

8.5"x11"R, 5.5"x8.5"R |

||

|

|

|

Executive, Japanese p/c, Monarch(envelope) |

||

|

|

|

Com-10(envelope), DL(envelope), |

||

|

|

|

C5(envelope), ISO B5(envelope) |

||

|

|

|

|

||

|

|

2 Tray |

A4, 8.5" x 11" |

||

|

|

|

|

||

How to change |

|

Guide adjustment by user/ |

|||

the paper size |

|

Software setting by user |

|||

|

|

|

|

|

|

F a c t o r y |

1 Tray |

8.5" x 11" |

|

||

default paper |

|

|

|

||

|

2 Tray |

The size guide plate is packed together. |

|||

size setting |

|

|

|

||

Media avail- |

1 Tray |

Plain paper |

: 60-128g/m² / 16-34lbs |

||

able for paper |

|

Index paper : 176g/m² / 47lbs |

|||

feeding |

|

Cover paper : 200-205g/m² / 54-55lbs |

|||

|

|

|

Envelope |

: 75-90g/m², 20-24lbs |

|

|

|

|

Transparency film |

||

|

|

|

*Media heavier than 105g/m² should be |

||

|

|

|

A4/8.5x11" or smaller. Media heavier than |

||

|

|

|

128g/m² should be fed from shorter edge. |

||

|

|

|

*Only single paper feed is enabled for over- |

||

|

|

|

lay copy or copy on back-side of printed |

||

|

|

|

paper. |

|

|

|

|

|

|

||

|

|

2 Tray |

Plain 60-105g/m² / 16-28lbs |

||

|

|

|

|||

Paper capacity |

1 Tray |

Standard: 500sheets(80g/m²) |

|||

|

|

|

Post card: 40sheets |

||

|

|

|

Envelope: 40sheets |

||

|

|

|

Transparency film: 40sheets |

||

|

|

|

|

||

|

|

2 Tray |

880+1,320sheets (64g/m²) / |

||

|

|

|

800+1,200sheets (80g/m²) |

||

|

|

|

|||

Paper type |

1 Tray |

Plain, recycled, pre-printed, pre-punched, |

|||

|

|

|

color, letter head, labels, heavy, transpar- |

||

|

|

|

ency, Japanese p/c, envelope |

||

|

|

|

(User can set bi-type for each of the above |

||

|

|

|

paper type.) |

|

|

|

|

|

|

||

|

|

2 Tray |

Plain, recycled, pre-printed, pre-punched, |

||

|

|

|

color, letter head (User can set bi-type for |

||

|

|

|

each of the above paper type.) |

||

|

|

|

|||

Sizes to be |

1 Tray |

Auto detection-AB: |

|||

detected |

|

A3, B4, A4, A4R, B5, B5R, 8.5"x13", A5R |

|||

|

|

|

|

||

|

|

|

Auto detection-Inch: |

||

|

|

|

11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R, |

||

|

|

|

7.25"x10.5"R, 5.5" x 8.5R |

||

|

|

|

|

||

|

|

|

Manual (input detection): |

||

|

|

|

postal card, Monarch(envelope), |

||

|

|

|

Com-10(envelope), DL(envelope), |

||

|

|

|

C5(envelope), ISO B5(envelope) |

||

|

|

|

|

||

|

|

|

Ignore detection selectable: |

||

|

|

|

|

||

|

|

2 Tray |

Size setting by the serviceman |

||

|

|

|

|||

P a p e r b a l - |

1 Tray |

Provided (paper empty and 3 steps) |

|||

ance detec- |

|

|

|

|

|

|

2 Tray |

Enable (Paper empty and |

|||

tion |

|||||

|

6 steps (3 steps + 3 steps)) |

||||

|

|

|

|||

|

|

|

|

|

|

|

|

AR-D28 |

|

|

|

Paper loading system |

To be loaded from the upper side with |

|

|

|

front loading system |

|

|

|

Tray ascent/ |

Ascent |

Within 12 seconds |

descent time |

|

|

|

At paper empty, required time from |

|

|

|

|

|

|

tray insert to the empty detection |

|

|

|

|

Descent |

Own weight descent |

|

|

|

Dehumidification heater |

Not provided |

|

|

|

|

Power consumption |

32.2W or lower |

|

|

|

|

Power source |

Supplied from main unit |

|

|

|

(DC24V 1.3A / DC5V 0.2A) |

|

|

|

External dimensions |

589 x 630 x 404 (mm) |

|

|

|

|

Occupied dimensions |

963 x 665 (mm) |

|

|

|

|

Weight |

Approx. 34kg |

|

|

|

|

2. AR-D27

|

|

|

AR-D27 |

|

|

|

|

Type |

|

Stand /3x500 Sheet Paper Drawer |

|

|

|

(2 paper trays + 1 multi purpose drawer) |

|

|

|

||

Transport speed |

To support 35-45 sheet/minute |

||

|

|

||

Transport alignment |

Center alignment |

||

|

|

|

|

Paper size |

1 Tray |

A3, B4, A4, A4R, B5, B5R, A5R |

|

|

|

11"x17", 8.5"x14", 8.5"x13", 8.5"x11", |

|

|

|

8.5"x11"R, 5.5"x8.5"R |

|

|

|

Executive, Japanese p/c,Monarch(envelope) |

|

|

|

Com-10 (envelope), DL (envelope), |

|

|

|

C5 (envelope), ISO B5 (envelope) |

|

|

|

|

|

|

2 or 3 |

A3, B4, A4, A4R, B5, B5R |

|

|

Tray |

11"x17", 8.5"x14", 8.5"x13", 8.5"x11", |

|

|

|

8.5"x11"R, 7.25"x10.5"R |

|

|

|

|

|

How to change the |

Unit is delivered with paper guide set at max. |

||

paper size |

|

position in width. (Both of two cassettes.) |

|

|

|

||

Factory default paper |

To be set to maximum paper guide width at |

||

size setting |

|

factory default status (for both trays) |

|

|

|

|

|

Media avail - |

1 Tray |

Plain paper |

: 60-128g/m² / 16-34lbs |

able for paper |

|

Index paper : 176g/m² / 47lbs |

|

feeding |

|

Cover paper : 200-205g/m² / 54-55lbs |

|

|

|

||

|

|

Envelope |

: 75-90g/m², 20-24lbs |

|

|

Transparency film |

|

|

|

*Media heavier than 105g/m² should be |

|

|

|

A4/8.5x11" or smaller. |

|

|

|

Media heavier than 128g/m² should be |

|

|

|

fed from shorter edge. |

|

|

|

*Only single paper feed is enabled for |

|

|

|

overlay copy or copy on back-side of |

|

|

|

printed paper. |

|

|

|

|

|

|

2 or 3 |

Plain 60-105g / m² / 16-28lbs |

|

|

Tray |

|

|

|

|

|

|

Paper capacity |

1 Tray |

Standard:500sheets(80g/m²) |

|

|

|

Post card:40sheets |

|

|

|

Envelope:40sheets |

|

|

|

Transparency film:40sheets |

|

|

|

|

|

|

2 or 3 |

Standard paper:500sheets x 2 (64g/m²) |

|

|

Tray |

|

|

|

|

|

|

AR-D28/D27/MU2 SPECIFICATIONS

3 – 1

|

|

|

AR-D27 |

|

|

|

|

Paper type |

1 Tray |

Plain, recycled, pre-printed, pre-punched, |

|

|

|

|

color, letter head, labels, heavy, |

|

|

|

transparency, Japanese p/c, envelope |

|

|

|

(User can set bi-type for each of the above |

|

|

|

paper type.) |

|

|

|

|

|

|

2 or 3 |

Plain, recycled, pre-printed, pre-punched, |

|

|

Tray |

color, letter head |

|

|

|

(User can set bi-type for each of the above |

|

|

|

paper type.) |

|

|

|

|

Sizes to be |

1 Tray |

Auto detection-AB: |

|

detected |

|

A3, B4, A4, A4R, B5, B5R, 8.5"x13", A5R |

|

|

|

|

|

|

|

|

Auto detection-Inch: |

|

|

|

11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R, |

|

|

|

7.25"x10.5"R, 5.5" x 8.5R |

|

|

|

|

|

|

|

Manual (input detection): |

|

|

|

postal card, Monarch(envelope), |

|

|

|

Com-10(envelope), DL(envelope), |

|

|

|

C5(envelope), ISO B5(envelope) |

|

|

|

|

|

|

|

Ignore detection selectable: |

|

|

|

|

|

|

2 or 3 |

Auto detection-AB |

|

|

Tray |

A3, B4, A4, A4R, B5, B5R, 8.5"x13" |

|

|

|

|

|

|

|

Auto detection-inch |

|

|

|

8.5"x14", 8.5"x13", 8.5"x11", 8.5"x11"R, |

|

|

|

7.25"x10.5"R |

|

|

|

|

Paper balance detection |

Provided (paper empty and 3 steps) |

||

|

|

||

Paper loading system |

To be loaded from the upper side with front |

||

|

|

|

loading system |

|

|

|

|

Tray ascent |

Ascent |

Within 7 seconds |

|

/descent time |

|

|

|

|

At paper empty, required time from |

||

|

|

|

|

|

|

|

tray insert to the empty detection |

|

|

|

|

|

|

Descent |

Own weight descent |

|

|

|

|

Dehumidification heater |

Not provided. |

||

|

|

||

Power consumption |

32.2W or lower |

||

|

|

|

|

Power source |

|

Supplied from main unit |

|

|

|

|

(DC24V 1.3A / DC5V 0.2A) |

|

|

||

External dimensions |

589 x 630 x 404 (mm) |

||

|

|

||

Occupied dimensions |

963 x 665 (mm) |

||

|

|

|

|

Weight |

|

Approx. 32kg |

|

|

|

|

|

3. AR-MU2

|

|

|

AR-MU2 |

|

|

||

Type |

Multi purpose drawer |

||

|

|

||

Transport speed |

To support 35-45 sheets/minute |

||

|

|

||

Transport alignment |

Center alignment |

||

|

|

||

Paper size |

A3, B4, A4, A4R, B5, B5R, A5R |

||

|

|

11"x17", 8.5"x14", 8.5"x13", 8.5"x11", |

|

|

|

8.5"x11"R, 5.5"x8.5"R |

|

|

|

Executive, Japanese p/c, Monarch(envelope) |

|

|

|

Com-10(envelope), DL(envelope), |

|

|

|

C5(envelope), ISO B5(envelope) |

|

|

|

||

How to change the |

Guide adjustment by user / |

||

paper size |

Software setting by user |

||

|

|

||

Factory default paper |

To be set to maximum paper guide width at |

||

size setting |

factory default status. |

||

|

|

|

|

Media available for |

Plain paper |

: 60-128g/m² / 16-34lbs |

|

paper feeding |

Index paper : 176g/m² / 47lbs |

||

|

|

Cover paper : 200-205g/m² / 54-55lbs |

|

|

|

Envelope |

: 75-90g/m², 20-24lbs |

|

|

Transparency film |

|

|

|

*Media heavier than 105g/m² should be |

|

|

|

A4/8.5x11" or smaller. |

|

|

|

Media heavier than 128g/m² should be fed |

|

|

|

from shorter edge. |

|

|

|

*Only single paper feed is enabled for overlay |

|

|

|

copy or copy on back-side of printed paper. |

|

|

|

||

Paper capacity |

Standard:500sheets(80g/m²) |

||

|

|

Post card:40sheets |

|

|

|

Envelope:40sheets |

|

|

|

Transparency film:40sheets |

|

|

|

||

Paper type |

Plain, recycled, pre-printed, pre-punched, |

||

|

|

color, letter head, labels, heavy, |

|

|

|

transparency, Japanese p/c, envelope |

|

|

|

(User can set bi-type for each of the above |

|

|

|

paper type.) |

|

|

|

||

Sizes to be detected |

Auto detection-AB: |

||

|

|

A3, B4, A4, A4R, B5, B5R, 8.5"x13", A5R |

|

|

|

|

|

|

|

Auto detection-Inch: |

|

|

|

11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R, |

|

|

|

7.25"x10.5"R, 5.5" x 8.5R |

|

|

|

|

|

|

|

Manual (input detection): |

|

|

|

postal card, Monarch(envelope), |

|

|

|

Com-10(envelope), DL(envelope), |

|

|

|

C5(envelope), ISO B5(envelope) |

|

|

|

|

|

|

|

Ignore detection selectable: |

|

|

|

||

Paper balance detection |

Provided (paper empty and 3 steps) |

||

|

|

||

Paper loading system |

To be loaded from the upper side with front |

||

|

|

loading system |

|

|

|

||

Tray ascent/ |

Ascent |

Within 7 seconds |

|

descent time |

|

|

|

|

At paper empty, required time from |

||

|

|

||

|

|

tray insert to the empty detection |

|

|

|

|

|

|

Descent |

Own weight descent |

|

|

|

|

|

Dehumidification heater |

Not provided. |

||

|

|

||

Power consumption |

24.5W or lower |

||

|

|

||

Power source |

Supplied from main unit |

||

|

|

(DC24V 1A / DC5V 0.1A) |

|

|

|

||

External dimensions |

654 x 567 x 144 (mm) |

||

|

|

||

Occupied dimensions |

654 x 567 (mm) |

||

|

|

||

Weight |

Approx. 11kg |

||

|

|

|

|

AR-D28/D27/MU2 SPECIFICATIONS

3 – 2

[4] UNPACKING AND INSTALLATION

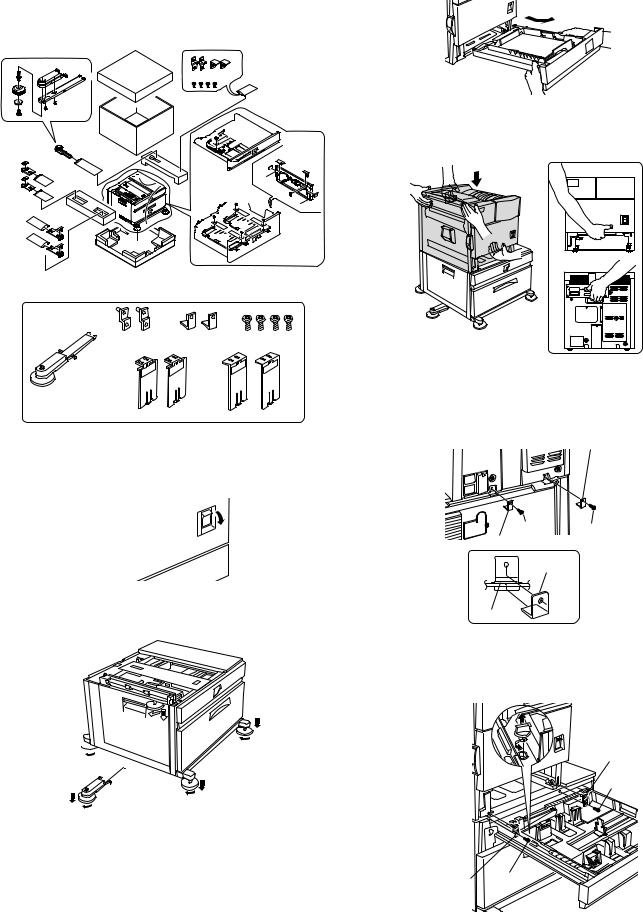

1. AR-D28

<Before installation>

•Start installation after checking that the DATA and COMMUNICATION indicators on the operation panel are neither lit nor blinking.

<Parts included>

Front mounting |

Rear mounting |

Screws (M4x6): |

plates: 2 pcs. |

plates: 2 pcs. |

4 pcs. |

Left adjuster: 1 pc.

Left paper guides: 2 pcs. |

Right paper guides: 2 pcs. |

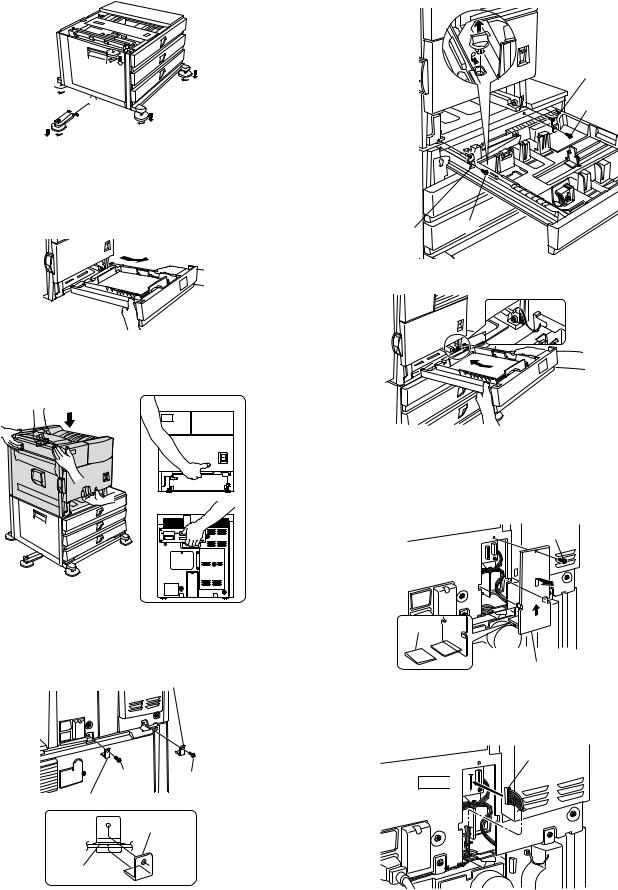

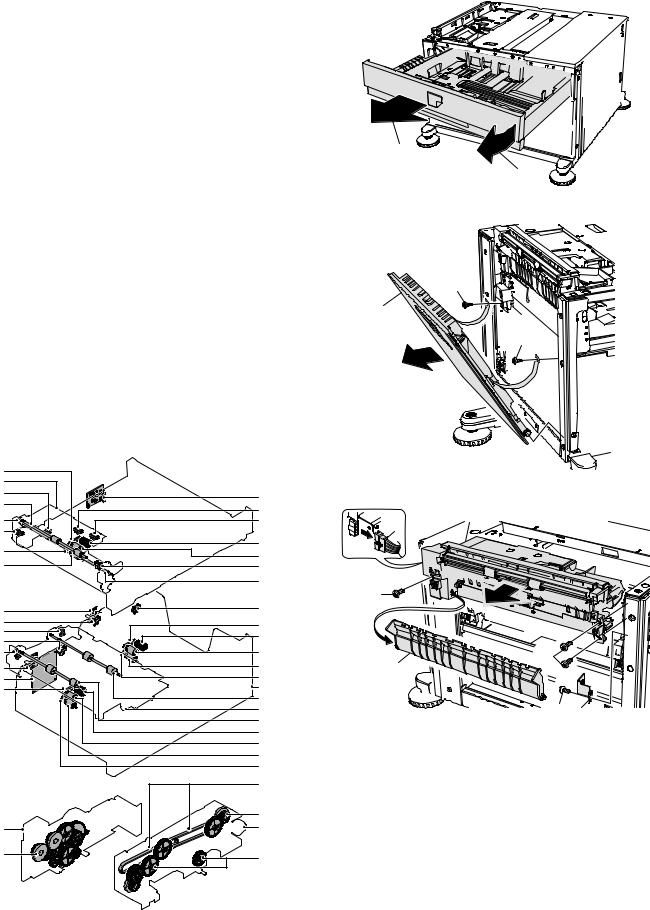

1)Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the printer to the "OFF" position.

Then remove the power plug from the outlet.

"OFF"

2) Attach the adjusters and adjust them.

<1>Insert the left adjusters to the stand/paper drawer.

<2>Turn the each adjusters to lower them until they touch the floor.

2

2 2

2 2

1 |

2 |

|

*Be sure to attach the left adjuster to prevent overturning.

Caution: The lower tray cannot be pulled out unless the adjuster is lowered to the specified position.

3) Put the main unit of the printer on the stand/paper drawer.

<1>Pull out the paper tray of the main unit until it stops and then remove it by lifting both ends of the tray.

<2>Hold the main unit of the printer at the positions shown in the illustration and put the main unit on the stand/paper drawer so that the front side and the left side of the main unit are aligned to those of the stand/paper drawer.

Front side

Rear side

Caution: For installation of the main unit, it must be held by two persons and installed without haste.

4) Connect the main unit to the stand/paper drawer.

<1>Attach the rear mounting plates using a supplied screw for each.

Rear mounting plate

Screw Screw

Rear mounting plate

Rear

mounting plate

Desk frame

Caution: Insert the rear mounting plates under the desk frame.

<2>Pull out the upper paper tray of the stand/paper drawer until it stops and attach the front mounting plates using a supplied screw for each. Then, remove the lock of the paper tray and close the tray.

Front mounting plate

Screw

Front mounting |

Screw |

|

plate |

||

|

AR-D28/D27/MU2 UNPACKING AND INSTALLATION

4 – 1

<3>Reattach the paper tray of the main unit.

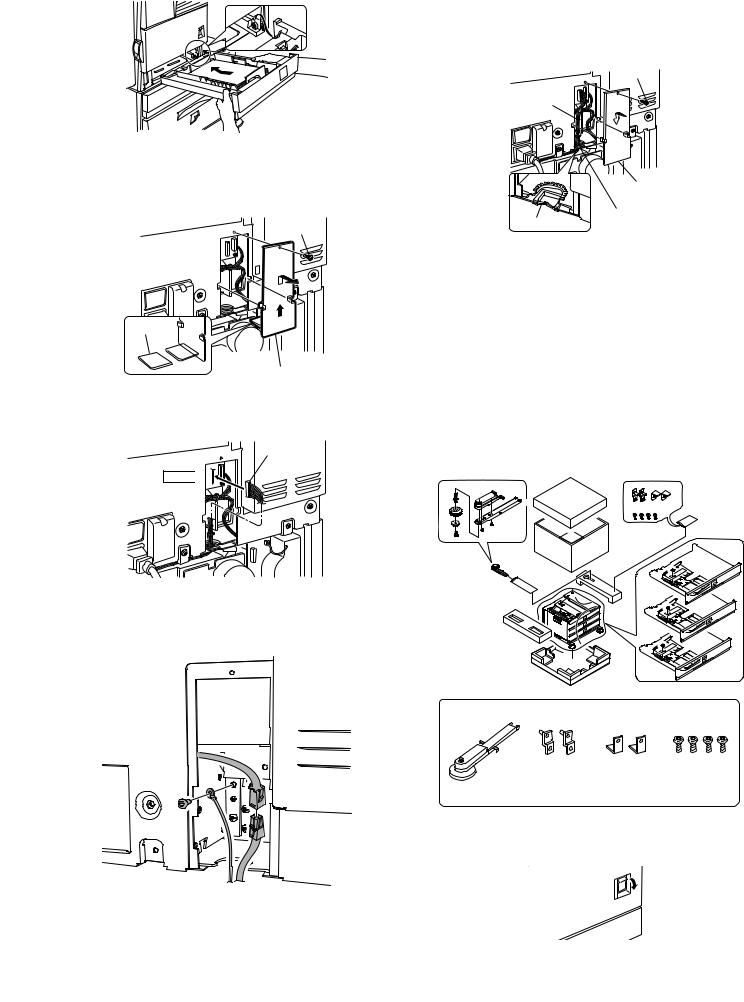

5)Connect the power supply I/F harness to the PCU PWB of the main unit of the printer.

<1>Remove the screw that fixes the harness cover of the main unit of the printer and slide the harness cover up to remove it.

Process the harness cover as shown in the illustration.

Screw

Cut out.

Harness cover

<2>Connect the power supply I/F harness connector (red, 22pin) to CN11 (red connector) of the PCU PWB of the main unit of the printer.

Connector

CN11

Connect the connector (white, 4pin) of power supply I/F harness to the I/F connector (white, 4pin) of the main unit.

Remove the M4 screw shown in the illustration, insert the circle terminal of ground harness, and it fixes again.

<3>Reattach the power supply I/F harness cover to its original position and fix it with the removed screw.

At this time, ensure that the power supply I/F harness are arranged as shown in the illustration.

• Fix the harness securely to the wire saddle.

Screw

Power supply

I/F harness

Harness cover

Wire saddle

Wire saddle

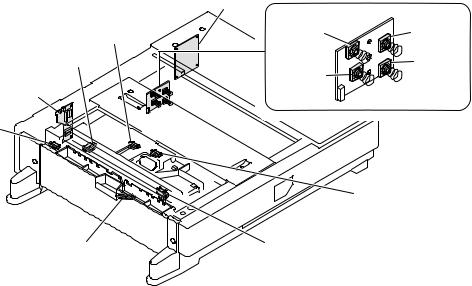

6)Attach the paper guides to the lower tray (large capacity tray) and set the size.

Refer to "Setting and adjustment" described later.

*If another peripheral device must be installed, carry out the following step at the end of the installation work.

7)Adjust the position of the paper guides of the upper paper tray of the stand/paper drawer.

Refer to "Setting and adjustment" described later.

8)Carry out the off center adjustment.

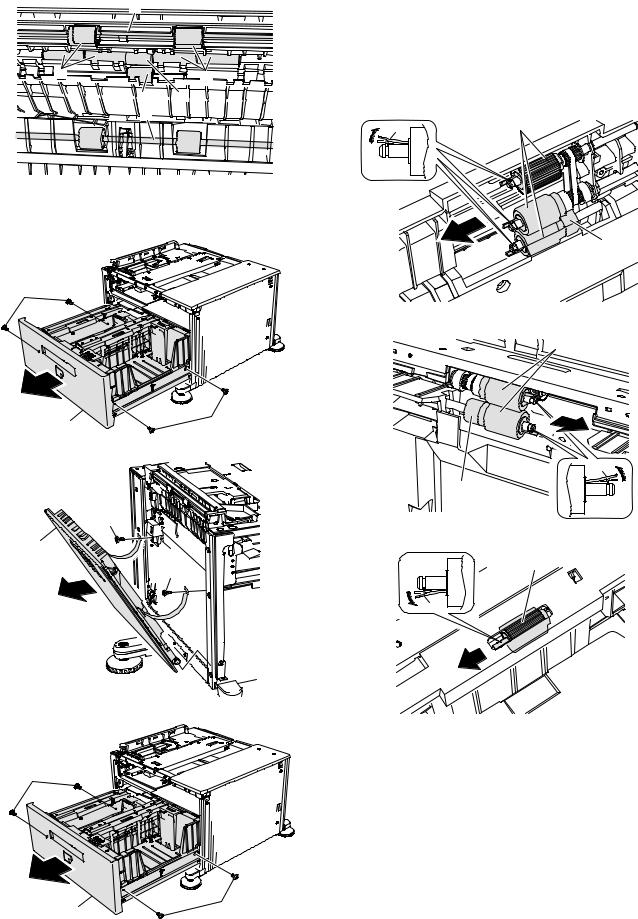

2. AR-D27

<Before installation>

•Start installation after checking that the DATA and COMMUNICATION indicators on the operation panel are neither lit nor blinking.

<Parts included>

Front mounting |

Rear mounting |

Screws (M4x6): |

plates: 2 pcs. |

plates: 2 pcs. |

4 pcs. |

Left adjuster: 1 pc.

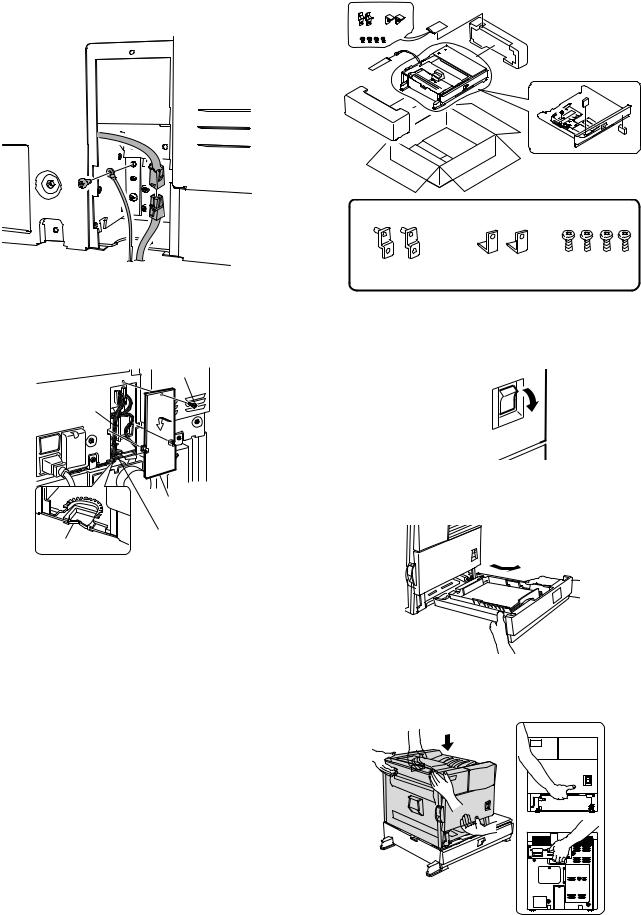

1)Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the printer to the "OFF" position.

Then remove the power plug from the outlet.

"OFF"

AR-D28/D27/MU2 UNPACKING AND INSTALLATION

4 – 2

2) Attach the adjusters and adjust them.

<1>Insert the left adjusters to the stand/paper drawer.

<2>Turn the five adjusters to lower them until they touch the floor.

<2>Pull out the upper paper tray of the stand/paper drawer until it stops and attach the front mounting plates using a supplied screw for each. Then, remove the lock of the paper tray and close the tray. Remove the locks of the middle tray and the lower tray similarly.

2

2 2

2 2

1 |

2 |

|

*Be sure to attach the left adjuster to prevent overturning.

Caution: The lower tray cannot be pulled out unless the adjuster is lowered to the specified position.

3) Put the main unit of the printer on the stand/paper drawer.

<1>Pull out the paper tray of the main unit until it stops and then remove it by lifting both ends of the tray.

Front mounting plate

Screw

Front mounting |

|

plate |

Screw |

<2>Hold the main unit of the printer at the positions shown in the illustration and put the main unit on the stand/paper drawer so that the front side and the left side of the main unit are aligned to those of the stand/paper drawer.

Front side

Rear side

<3>Reattach the paper tray of the main unit.

5)Connect the power supply I/F harness to the PCU PWB of the main unit of the printer.

<1>Remove the screw that fixes the harness cover of the main unit of the printer and slide the harness cover up to remove it.

Process the harness cover as shown in the illustration.

Screw

Caution: For installation of the main unit, it must be held by two persons and installed without haste.

4) Connect the main unit to the stand/paper drawer.

<1>Attach the rear mounting plates using a supplied screw for each.

Rear mounting plate

Screw Screw

Rear mounting plate

Mounting plate

Desk frame

Caution: Insert the rear mounting plates under the desk frame.

Cut out.

Harness cover

<2>Connect the power supply I/F harness connector (red, 22pin) to CN11 (red connector) of the PCU PWB of the main unit of the printer.

Connector

CN11

AR-D28/D27/MU2 UNPACKING AND INSTALLATION

4 – 3

Connect the connector (white, 4pin) of power supply I/F harness to |

3. AR-MU2 |

the I/F connector (white, 4pin) of the main unit. |

|

Remove the M4 screw shown in the illustration, insert the circle ter- |

|

minal of ground harness, and it fixes again. |

|

<Parts included>

<3>Reattach the harness cover to its original position and fix it with the removed screw.

At this time, ensure that the power supply I/F harness is arranged as shown in the illustration.

• Fix the harness securely to the wire saddle.

Screw

Power supply

I/F harness

Harness cover

Wire saddle

Wire saddle

6)Adjust the position of the paper guides of the upper paper tray of the stand/paper drawer.

Refer to "Setting and adjustment" described later.

7)Carry out the off center adjustment.

Front mounting plates: Rear mounting plates: Screws (M4x8): 2 pcs. 2 pcs. 4 pcs.

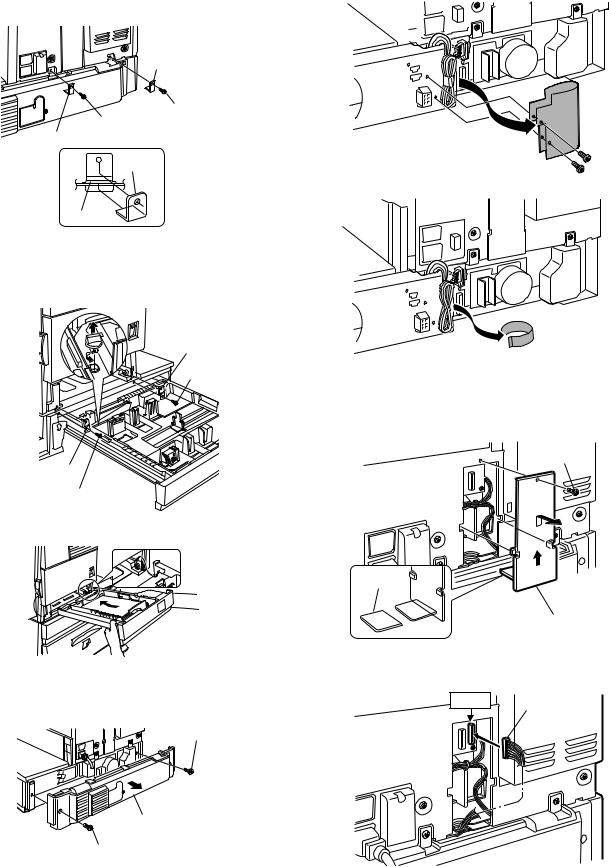

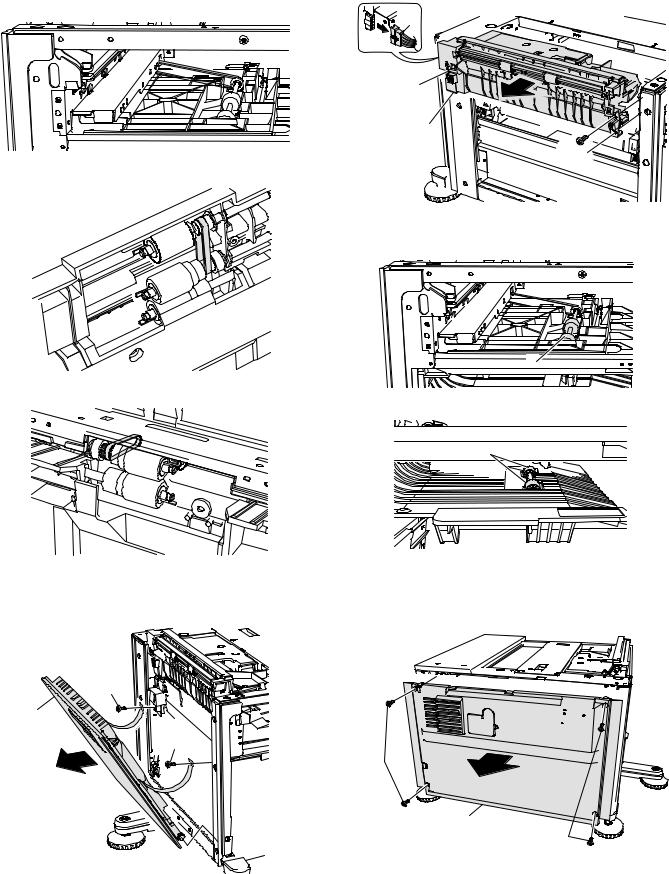

1)Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the main unit to the "OFF" position.

Then, remove the power plug of the main unit from the outlet.

"OFF"

2) Put the main unit of the printer on the multi purpose drawer.

<1>Pull out the paper tray of the main unit until it stops and then remove it by lifting both ends of the tray.

<2>Hold the main unit of the printer at the positions shown in the illustration and put the main unit on the multi purpose drawer so that the front side and the left side of the main unit are aligned to those of the multi purpose drawer.

Front side

Rear side

Caution: For installation of the main unit, it must be held by two persons and installed without haste.

AR-D28/D27/MU2 UNPACKING AND INSTALLATION

4 – 4

3) Connect the main unit of the printer to the multi purpose drawer.

<1>Attach the rear mounting plates using a supplied screw for each.

<2>Remove the two screws that secure the Harness protection sheet.

Rear mounting plate

Screw

Screw

Rear mounting plate

Mounting

plate

Tray frame

Caution: Insert the mounting plate under the desk frame.

<2>Pull out the paper tray of the multi purpose drawer until it stops and attach the front mounting plates using a supplied screw for each. Then, remove the lock of the paper tray and close the tray.

Front mounting plate

Screw

Front mounting plate

Screw

<3>Reattach the paper tray of the main unit of the printer.

<3> Remove the filament tape that secure the the power supply I/F harness.

5) Connect the harness to the main unit of the printer.

<1>Remove the screw that fixes the harness cover of the main unit of the printer and then slide the harness cover up to remove it. Process the harness cover as shown in the illustration.

Screw

Cut out.

Harness cover

4)Remove the multi rear cabinet.

<1>Remove the two screws that secure the multi rear cabinet.

Screw

<2>Connect the connector of the relay harness of the multi purpose drawer to the connector of the PCU PWB of the main unit of the printer.

CN10 Connector

Multi rear cabinet

Screw

AR-D28/D27/MU2 UNPACKING AND INSTALLATION

4 – 5

<3>Connect the connector (white, 4pin) of power supply I/F harness to the I/F connector (white, 4pin) of the main unit.

Connect the power supply I/F harness connector (red, 22pin) to CN11 (red connector) of the PCU PWB of the main unit of the printer.

Remove the M4 screw shown in the illustration, insert the circle terminal of ground harness, and it fixes again.

Connector

CN11

CN11

*For installation of a finisher or a mail-bin stacker, see its installation manual.

6)Attach the harness cover.

Reattach the harness cover to its original position and fix it with the removed screw.

At this time, ensure that the power supply I/F harness is arranged as shown in the illustration.

• Fix the harness securely to the wire saddle.

Screw

Harness cover

Wire saddle

Wire saddle

*If another peripheral device must be installed, carry out the following step at the end of the installation work.

7)Adjust the position of the paper guides of the paper tray. Refer to "Setting and adjustment" described later.

8)Carry out the off center adjustment.

AR-D28/D27/MU2 UNPACKING AND INSTALLATION

4 – 6

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES

A. EXTERNAL VIEW

|

|

|

|

1 |

|

5 |

|

|

2 |

|

1 |

|

|

3 |

|

|

|

|

|

5 |

4 |

|

|

|

|

|

|

5 |

1 |

|

|

|

|

|

|

|

AR-D27 |

|

|

AR-D28 |

|

|

|

AR-MU2 |

1 Multi-purpose tray (No. 2 tray) |

2 |

No. 3 tray |

|

3 No. 4 tray |

4 Large capacity tray |

5 |

Desk left door |

|

|

B. INTERNAL STRUCTURE

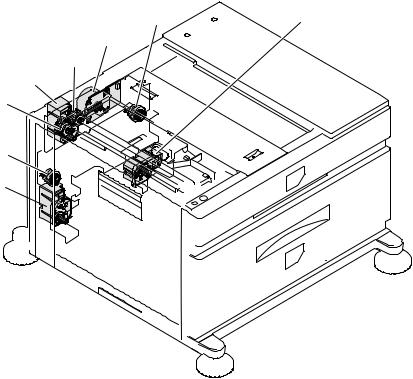

(1) AR-D28

4

1.TPFD1 |

8 |

9 |

10 |

|

|

|

|||

5 |

6 |

7 |

|

|

15

16

16

2.TPFD2

14

|

|

3.TPFD3 |

17 |

11 |

|

18 |

|

|

13 |

12 |

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

1 |

Tandem tray paper transport sensor 1 (TPFD1) |

7 |

Multipurpose tray paper take-up roller |

|

13 |

Tandem tray 1 separation roller |

|

2 |

Tandem tray paper transport sensor 2 (TPFD2) |

8 |

Tandem tray transport roller 2 |

|

14 |

Tandem tray 1 paper feed roller |

|

3 |

Tandem tray paper transport sensor 3 (TPFD3) |

9 |

Tandem tray 2 paper feed roller |

|

15 |

Tandem tray paper transport roller 1 |

|

4 |

Multipurpose tray paper transport roller |

10 |

Tandem tray 2 paper take-up roller |

|

16 |

Multipurpose tray |

|

5 |

Multipurpose tray paper feed roller |

|

11 |

Tandem tray 2 separation roller |

|

17 |

Tandem tray 1 |

6 |

Multipurpose tray separation roller |

|

12 |

Tandem tray 1 take-up roller |

|

18 |

Tandem tray 2 |

AR-D28/D27/MU2 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 1

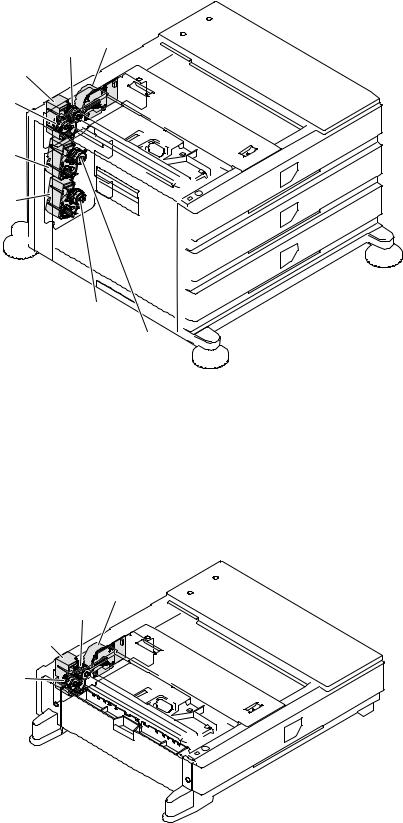

(2) AR-D27

4 |

|

|

|

|

|

1.DPFD1 |

|

|

|

||

5 |

6 |

7 |

9 |

10 |

11 |

|

|

|

|||

2.DPFD2 |

|

|

|

|

|

8 |

|

|

|

|

16 |

3.DPFD3

17

15

18

|

|

|

14 |

13 |

12 |

|

|

|

|

|

|

|

|

||

1 |

Desk paper transport sensor 1 (DPFD1) |

7 |

Multipurpose tray paper take-up roller |

13 |

Desk tray 3 paper feed roller |

||

2 |

Desk paper transport sensor 2 (DPFD2) |

8 |

Desk transport roller 2 |

14 |

Desk tray 3 paper feed roller |

||

3 |

Desk paper transport sensor 3 (DPFD3) |

9 |

Desk tray 2 paper feed roller |

15 |

Desk tray 3 paper transport roller |

||

4 |

Desk paper transport roller 1 |

10 |

Desk tray 2 paper separation roller |

16 |

Multipurpose tray |

||

5 |

Multipurpose tray paper feed roller |

11 |

Desk tray 2 take-up roller |

17 |

Desk tray 2 |

||

6 |

Multipurpose tray separation roller |

12 |

Desk tray 3 take-up roller |

18 |

Desk tray 3 |

||

(3) AR-MU2

2 1.MCPPD

3 4 5

6

1 |

Multipurpose tray paper transport sensor (MCPPD) |

3 |

Multipurpose tray paper feed roller |

5 |

Multipurpose tray paper take-up roller |

2 |

Multipurpose tray paper transport roller |

4 |

Multipurpose tray separation roller |

6 |

Multipurpose tray |

AR-D28/D27/MU2 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 2

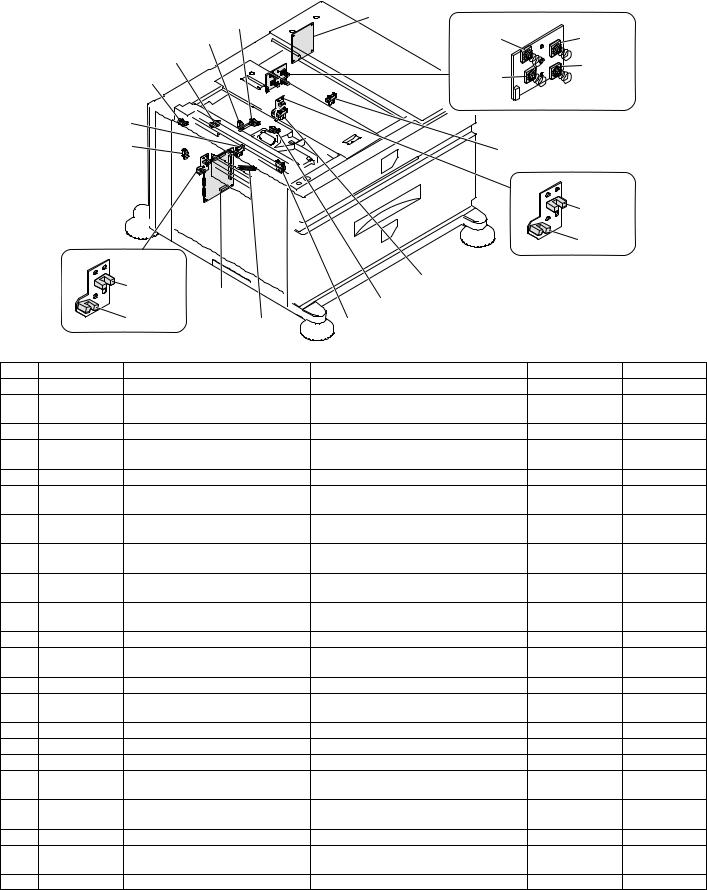

C. PWB, SENSOR

(1) AR-D28

|

|

|

21. |

|

|

|

|

6.MCLUD |

22. |

|

|

|

|

|

|

|

|

|

|

5.TPFD3 |

7.MCSS1 |

8.MCSS2 |

|

|

|

4.MCSPD |

|

10.MCSS4 |

|

|

|

3.TDRS |

|

||

|

|

9.MCSS3 |

|

|

|

|

2.TSPD1 |

|

|

|

|

|

1.TPFD2 |

11.TTSD |

|

||

|

|

|

|

||

|

|

|

|

12.TLUD2 |

|

|

|

|

|

13.TPED2 |

|

|

|

19.TLUD1 |

14.TSPD2 |

|

|

|

|

|

|

|

|

|

|

18. |

15.MCPED |

|

|

|

|

|

|

|

|

|

|

20.TPED1 |

16.TPFD1 |

|

|

|

|

17.MCPWS |

|

|

|

|

Code |

Name |

Function |

Active condition |

Remark |

1 |

TPFD2 |

Tandem tray paper transport sensor 2 |

Tandem tray paper transport detection |

L : Paper detected |

|

2 |

TSPD1 |

Tandem 1 tray |

Tandem 1 tray |

|

|

|

|

remaining paper quantity sensor |

remaining paper quantity detection |

|

|

3 |

TDRS |

Side door open/close sensor |

Side door open/close detection |

H : Door closed |

|

4 |

MCSPD |

MP tray remaining paper quantity |

MP tray remaining paper quantity detection |

|

|

|

|

sensor |

|

|

|

5 |

TPFD3 |

Tandem tray paper transport sensor 3 |

Tandem tray paper transport detection |

L : Paper detected |

|

6 |

MCLUD |

MP tray upper limit sensor |

MP tray upper limit detection |

H : Upper limit |

|

|

|

|

|

detected |

|

7 |

MCSS1 |

MP tray rear edge sensor 1 |

MP tray rear edge size detection |

L : When pressed |

In MP tray rear |

|

|

|

|

|

edge size PWB |

8 |

MCSS2 |

MP tray rear edge sensor 2 |

MP tray rear edge size detection |

L : When pressed |

In MP tray rear |

|

|

|

|

|

edge size PWB |

9 |

MCSS3 |

MP tray rear edge sensor 3 |

MP tray rear edge size detection |

L : When pressed |

In MP tray rear |

|

|

|

|

|

edge size PWB |

10 |

MCSS4 |

MP tray rear edge sensor 4 |

MP tray rear edge size detection |

L : When pressed |

In MP tray rear |

|

|

|

|

|

edge size PWB |

11 |

TTSD |

Tandem tray open/close sensor |

Tandem tray open/close detection |

H : Tray closed |

|

12 |

TLLD2 |

Tandem 2 tray upper limit sensor |

Tandem tray 2 upper limit detection |

L : Upper limit |

|

|

|

|

|

detected |

|

13 |

TPED2 |

Tandem 2 tray paper empty sensor |

Tandem tray 2 paper empty detection |

H : Paper loaded |

|

14 |

TSPD2 |

Tandem 2 tray |

Tandem 2 tray |

|

|

|

|

remaining paper quantity sensor |

remaining paper quantity detection |

|

|

15 |

MCPED |

MP tray paper empty sensor |

MP tray paper empty detection |

L : Paper loaded |

|

16 |

TPFD1 |

Tandem tray paper transport sensor 1 |

Tandem tray paper transport detection |

L : Paper detected |

|

17 |

MCPWS |

MP tray width sensor |

MP tray paper width detection |

|

Slide volume |

18 |

Control PWB |

Control PWB |

Communication with the machine, |

|

|

|

|

|

machine operation control |

|

|

19 |

TLLD1 |

Tandem 1 tray upper limit sensor |

Tandem tray 1 upper limit detection |

L : Upper limit |

|

|

|

|

|

detected |

|

20 |

TPED1 |

Tandem 1 tray paper empty sensor |

Tandem tray 1 paper empty detection |

H : Paper loaded |

|

21 |

MP tray rear |

MP tray rear edge size PWB |

Multi-purpose tray rear edge size detection |

|

|

|

edge size PWB |

|

|

|

|

22 |

Power I/F PWB |

Power I/F PWB |

Distributed the power supply from the main unit. |

|

|

AR-D28/D27/MU2 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 3

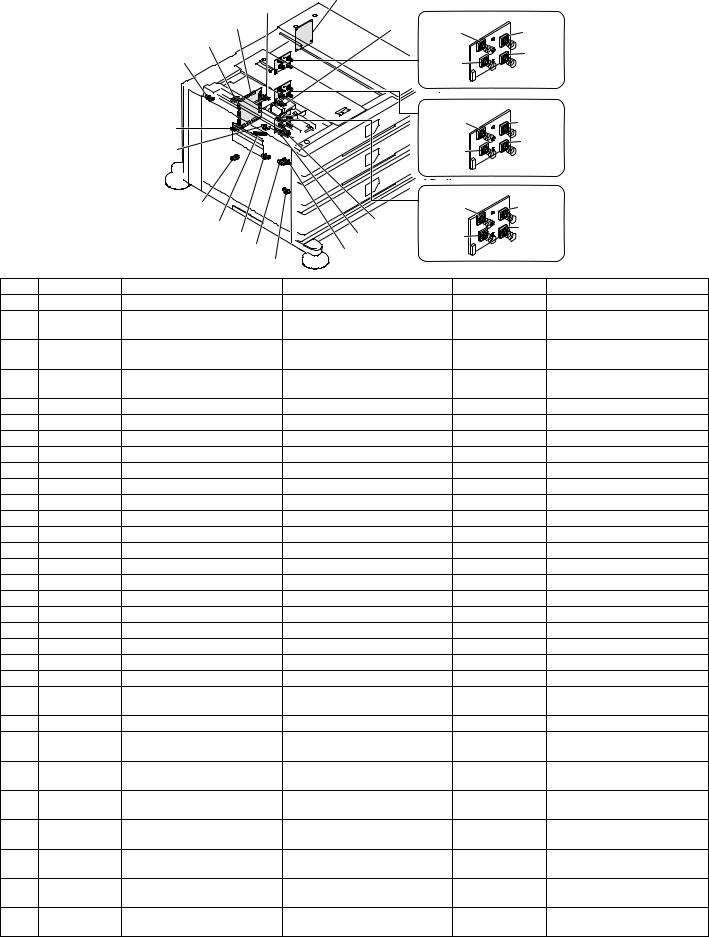

(2) AR-D27

|

|

|

31. |

|

|

|

|

|

|

4.MCLUD |

|

28. |

|

|

|

|

|

3. |

5.MCPED |

|

|

|

|

|

|

|

|

6.MCSS1 |

7.MCSS2 |

||

|

|

2.MCSPD |

|

|

|

|

|

|

|

1.DDRS |

|

8.MCSS3 |

9.MCSS4 |

||

|

|

|

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

29. |

|

|

|

|

|

27.DSPD1 |

|

10.DCSS11 |

11.DCSS12 |

||

|

|

|

|

|

|

|

|

|

|

26.DLUD1 |

|

|

|

13.DCSS14 |

|

|

|

|

12.DCSS13 |

|

|

||

|

|

|

|

30. |

|

|

|

|

|

25.DSPD2 |

|

14.DCSS21 |

15.DCSS22 |

||

|

|

24.MCPWS |

18.DPFD1 |

|

|

17.DCSS24 |

|

|

|

|

|

|

|

||

|

|

23.DLUD2 |

19.DPED1 |

16.DCSS23 |

|

|

|

|

|

22.DPED2 |

20.DPFD2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21.DPFD3 |

|

|

|

|

|

|

Code |

Name |

Function |

|

Active condition |

Remark |

|

1 |

DDRS |

Side door open/close sensor |

Side door open/close detection |

H : Door closed |

|

||

2 |

MCSPD |

MP tray |

MP tray |

|

|

|

|

|

|

remaining paper quantity sensor |

remaining paper quantity detection |

|

|

|

|

3 |

Control PWB |

Control PWB |

Communication with the machine, |

|

|

|

|

|

|

|

machine operation control |

|

|

|

|

4 |

MCLUD |

MP tray upper limit sensor |

MP tray upper limit detection |

|

H : Upper limit |

|

|

|

|

|

|

|

detected |

|

|

5 |

MCPED |

MP tray paper empty sensor |

MP tray paper empty detection |

L : Paper loaded |

|

||

6 |

MDSS1 |

MP tray rear edge sensor 1 |

MP tray rear edge size detection |

L : When pressed |

In MP tray rear edge size PWB |

||

7 |

MCSS2 |

MP tray rear edge sensor 2 |

MP tray rear edge size detection |

L : When pressed |

In MP tray rear edge size PWB |

||

8 |

MCSS3 |

MP tray rear edge sensor 3 |

MP tray rear edge size detection |

L : When pressed |

In MP tray rear edge size PWB |

||

9 |

MCSS4 |

MP tray rear edge sensor 4 |

MP tray rear edge size detection |

L : When pressed |

In MP tray rear edge size PWB |

||

10 |

DCSS11 |

No. 3 tray rear edge sensor 1 |

No. 3 tray rear edge size detection |

L : When pressed |

In No. 3 tray rear edge size PWB |

||

11 |

DCSS12 |

No. 3 tray rear edge sensor 2 |

No. 3 tray rear edge size detection |

L : When pressed |

In No. 3 tray rear edge size PWB |

||

12 |

DCSS13 |

No. 3 tray rear edge sensor 3 |

No. 3 tray rear edge size detection |

L : When pressed |

In No. 3 tray rear edge size PWB |

||

13 |

DCSS14 |

No. 3 tray rear edge sensor 4 |

No. 3 tray rear edge size detection |

L : When pressed |

In No. 3 tray rear edge size PWB |

||

14 |

DCSS21 |

No. 4 tray rear edge sensor 1 |

No. 4 tray rear edge size detection |

L : When pressed |

In No. 4 tray rear edge size PWB |

||

15 |

DCSS22 |

No. 4 tray rear edge sensor 2 |

No. 4 tray rear edge size detection |

L : When pressed |

In No. 4 tray rear edge size PWB |

||

16 |

DCSS23 |

No. 4 tray rear edge sensor 3 |

No. 4 tray rear edge size detection |

L : When pressed |

In No. 4 tray rear edge size PWB |

||

17 |

DCSS24 |

No. 4 tray rear edge sensor 4 |

No. 4 tray rear edge size detection |

L : When pressed |

In No. 4 tray rear edge size PWB |

||

18 |

DPFD1 |

Desk paper transport sensor 1 |

Desk paper transport detection |

L : Paper detected |

|

||

19 |

DPED1 |

N. 3 tray paper empty sensor |

N. 3 tray paper empty detection |

L : Paper loaded |

|

||

20 |

DPFD2 |

Desk paper transport sensor 2 |

Desk paper transport detection |

L : Paper detected |

|

||

21 |

DPFD3 |

Desk paper transport sensor 3 |

Desk paper transport detection |

L : Paper detected |

|

||

22 |

DPED2 |

No. 4 tray paper empty sensor |

No. 4 tray paper empty detection |

L : Paper loaded |

|

||

23 |

DLUD2 |

No. 4 tray upper limit sensor |

No. 4 tray upper limit detection |

H : Upper limit |

|

||

|

|

|

|

|

detected |

|

|

24 |

MCPWS |

MP tray width sensor |

MP tray paper width detection |

Analog voltage |

Slide volume |

||

25 |

DSPD2 |

No. 4 tray |

No. 4 tray |

|

|

|

|

|

|

remaining paper quantity sensor |

remaining paper quantity detection |

|

|

|

|

26 |

DLUD1 |

No. 3 tray upper limit sensor |

No. 3 tray upper limit detection |

H : Upper limit |

|

||

|

|

|

|

|

detected |

|

|

27 |

DSPD1 |

No. 3 tray |

No. 3 tray |

|

|

|

|

|

|

remaining paper quantity sensor |

remaining paper quantity detection |

|

|

|

|

28 |

MP tray rear |

MP tray rear edge size PWB |

MP tray rear edge size detection |

|

|

|

|

|

edge size PWB |

|

|

|

|

|

|

29 |

No. 3 tray rear |

No. 3 tray rear edge size PWB |

No. 3 tray rear edge size detection |

|

|

|

|

|

edge size PWB |

|

|

|

|

|

|

30 |

No. 4 tray rear |

No. 4 tray rear edge size PWB |

No. 4 tray rear edge size detection |

|

|

|

|

|

edge size PWB |

|

|

|

|

|

|

31 |

Power I/F PWB |

Power I/F PWB |

Distributed the power supply from |

|

|

|

|

|

|

|

the main unit. |

|

|

|

|

|

|

AR-D28/D27/MU2 EXTERNAL VIEWS AND INTERNAL STRUCTURES |

|

|

|||

5 – 4

(3) AR-MU2

12.

|

13. |

|

4.MCLUD |

5.MCSS1 |

6.MCSS2 |

|

|

|

3.MCSPD |

|

8.MCSS4 |

|

7.MCSS3 |

|

2.

1.MCDRS

9.MCPED

11.MCPWS |

10.MCPPD |

|

|

Code |

Name |

Function |

Active condition |

Remark |

|

|

|

|

|

|

1 |

MCDRS |

MP door open / close |

MP left door open / close detection |

H : Door closed |

|

|

|

sensor |

|

|

|

|

|

|

|

|

|

2 |

Control PWB |

Control PWB |

Communication with the machine, |

|

|

|

|

|

machine operation control |

|

|

|

|

|

|

|

|

3 |

MCSPD |

MP tray remaining paper |

MP tray remaining paper quantity detection |

L : When |

|

|

|

quantity sensor |

|

pressed |

|

|

|

|

|

|

|

4 |

MCLUD |

MP tray upper limit sensor |

MP tray upper limit detection |

H : Upper limit |

|

|

|

|

|

detected |

|

|

|

|

|

|

|

5 |

MDSS1 |

MP tray rear edge sensor 1 |

MP tray rear edge size detection |

L : When |

In MP tray rear edge size PWB |

|

|

|

|

pressed |

|

|

|

|

|

|

|

6 |

MCSS2 |

MP tray rear edge sensor 2 |

MP tray rear edge size detection |

L : When |

In MP tray rear edge size PWB |

|

|

|

|

pressed |

|

|

|

|

|

|

|

7 |

MCSS3 |

MP tray rear edge sensor 3 |

MP tray rear edge size detection |

L : When |

In MP tray rear edge size PWB |

|

|

|

|

pressed |

|

|

|

|

|

|

|

8 |

MCSS4 |

MP tray rear edge sensor 4 |

MP tray rear edge size detection |

L : When |

In MP tray rear edge size PWB |

|

|

|

|

pressed |

|

|

|

|

|

|

|

9 |

MCPED |

MP tray paper empty |

MP tray paper empty detection |

L : Paper loaded |

|

|

|

sensor |

|

|

|

|

|

|

|

|

|

10 |

MCPPD |

MP transport sensor |

Detection of paper on the path |

L : Paper |

|

|

|

|

|

detected |

|

|

|

|

|

|

|

11 |

MCPWS |

MP tray width sensor |

MP tray paper width detection |

Analog voltage |

Slide volume |

|

|

|

|

|

|

12 |

MP tray rear |

MP tray rear |

MP tray rear edge size detection |

|

|

|

edge size PWB |

edge size PWB |

|

|

|

|

|

|

|

|

|

13 |

Power I/F PWB |

Power I/F PWB |

Distributed the power supply from the main unit. |

|

|

|

|

|

|

|

|

AR-D28/D27/MU2 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 5

D. MOTOR, CLUTCH

(1) AR-D28

7.TPCL2 |

8.TLUM2 |

6.TMM

5.MCPCL

4.MCLUM

3.TPFCL

2.TPCL1

1.TLUM1

|

Code |

Name |

Function |

Remark |

|

|

|

|

|

1 |

TLUM1 |

Tandem tray 1 lift-up motor |

Tandem tray 1 lift-up |

|

|

|

|

|

|

2 |

TPCL1 |

Tandem tray 1 paper feed clutch |

Clutch for paper feed from tandem tray 1 |

|

|

|

|

|

|

3 |

TPFCL |

LCC transport clutch |

Clutch for transport from LCC desk |

|

|

|

|

|

|

4 |

MCLUM |

Multi-purpose tray lift-up motor |

Multi-purpose tray lift-up |

|

|

|

|

|

|

5 |

MCPCL |

Multi-purpose paper feed clutch |

Clutch for paper feed from Multi-purpose tray |

|

|

|

|

|

|

6 |

TMM |

LCC transport motor |

LCC desk paper transport |

|

|

|

|

|

|

7 |

TPCL2 |

Tandem tray 2 paper feed clutch |

Clutch for paper feed from tandem tray 2 |

|

|

|

|

|

|

8 |

TLUM2 |

Tandem tray 2 lift-up motor |

Tandem tray 2 lift-up |

|

|

|

|

|

|

AR-D28/D27/MU2 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 6

(2) AR-D27

6.DMM

5.MCPCL

4.MCLUM

3.DPFCL

2.DLUM1

1.DLUM2

8.DPCL2

7.DPCL1

|

Code |

Name |

Function |

Remark |

|

|

|

|

|

1 |

DLUM2 |

Desk 2 tray lift-up motor |

Gate switch between duplex and paper exit |

|

|

|

|

|

|

2 |

DLUM1 |

Desk 1 tray lift-up motor |

Cooling the machine and inside of ADU |

|

|

|

|

|

|

3 |

DPFCL |

Desk transport clutch |

Clutch for transport |

|

|

|

|

|

|

4 |

MCLUM |

Multi-purpose tray lift-up motor |

Multi-purpose tray lift-up |

|

|

|

|

|

|

5 |

MCPCL |

Multi-purpose paper feed clutch |

Clutch for paper feed from Multi-purpose tray |

|

|

|

|

|

|

6 |

DMM |

3 tray desk transport motor |

No. 3 tray desk paper transport |

|

|

|

|

|

|

7 |

DPCL1 |

Desk 1 tray paper feed clutch |

Clutch for paper feed from desk tray 1 |

|

|

|

|

|

|

8 |

DPCL 2 |

Desk 2 tray paper feed clutch |

Clutch for paper feed from desk tray 2 |

|

|

|

|

|

|

(3) AR-MU2

4.MCM

3.MCPCL

2.MCLUM

1.MCFCL

|

Code |

Name |

Function |

Remark |

|

|

|

|

|

1 |

MCFCL |

Multi-purpose tray transport clutch |

Multi-purpose tray transport clutch |

|

|

|

|

|

|

2 |

MCLUM |

Multi-purpose tray lift-up motor |

Multi-purpose tray lift-up |

|

|

|

|

|

|

3 |

MCPCL |

Multi-purpose paper feed clutch |

Clutch for paper feed from Multi-purpose tray |

|

|

|

|

|

|

4 |

MCM |

Multi-purpose tray transport motor |

Multi-purpose tray paper transport |

|

|

|

|

|

|

AR-D28/D27/MU2 EXTERNAL VIEWS AND INTERNAL STRUCTURES

5 – 7

[6] ADJUSTMENTS

1. CHANGING THE PAPER SIZE

[Upper tray(Tray2)]

•A3 to A5R(11x7 to 5-1/2x8-1/2R) size plain paper can be set.

•Special paper can be set.

•Two maximum height lines are indicated: one for plain paper and one for special paper.

[Middle/Lower tray(Tray3/4)]

• A4, B5 or 8-1/2" x 11" size plain paper can be set.

Use the following procedure to change the size as needed.

1)Pull out paper tray.

If paper remains in the tray, remove it.

2)Adjust the guide plates A and B in the tray to the length and width of the paper.

The guide plates A and B are slidable. Adjust them to the paper size to be loaded while squeezing their lock levers.

3)Load paper into the tray.

Do not exceed red line when loading special paper to upper tray.

4)Gently push tray into the machine.

Push the tray firmly all the way into the machine.

5)Set the paper size.

Be sure to set the paper size and paper type referring to "2.Setting the paper type and paper size".

If this is not done, paper misfeeds will occur.

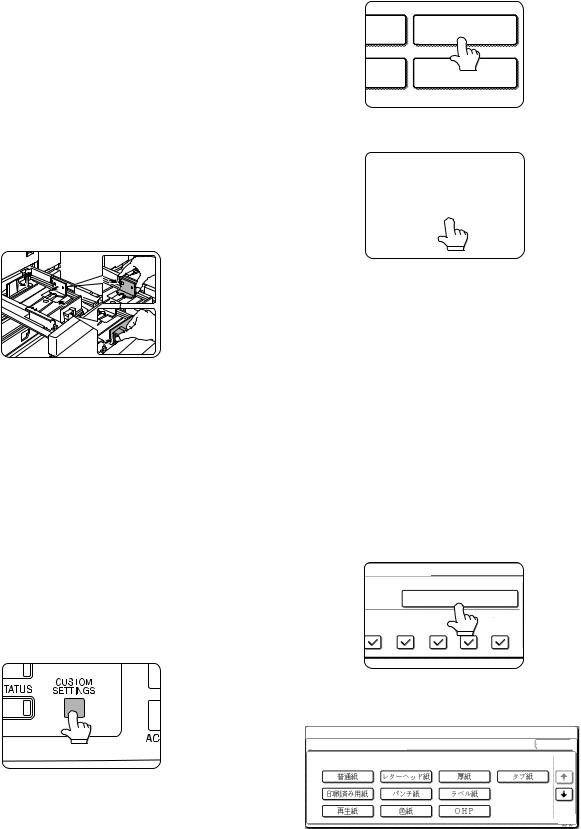

2.SETTING THE PAPER TYPE AND PAPER SIZE

Follow these steps to change the paper type setting if the paper type is changed in either paper tray. For the paper types that can be used in each tray.

1)Press the [CUSTOM SETTINGS] key.

The custom setting menu screen will appear.

2)Touch the [PAPER TRAY SETTINGS] key. The paper tray selection screen will appear.

RINT

PAPER TRAY

SETTINGS

TA |

PRINTER |

ORWARD |

CONDITION |

3) Touch the [TRAY SETTINGS] key.

CUSTOM SETTINGS

PAPER TRAY SETTINGS

TRAY SETTINGS

4) Display the setting screen of the desired paper tray.

CUSTOM SETTINGS

PAPER TRAY SETTINGS |

|

OK |

|

|

|

TYPE / SIZE

FIXED PAPER SIDE 1/4

TRAY 1 |

PLAIN / A4 |

DISABLE DUPLEX

COPY |

FAX |

I-FAX |

DOC. |

DISABLE STAPLE |

||

FILING |

||||||

|

|

|

|

|

DISABLE PUNCH

Touch the  key or

key or  key to display the setting screen of the desired paper tray.

key to display the setting screen of the desired paper tray.

Note: To automatically switch to a tray with the same size and type of paper (if there is one) in the event that the paper tray runs out of paper, display the last screen with the  key and select [AUTO TRAY SWITCHING].

key and select [AUTO TRAY SWITCHING].

5) Touch the [TYPE/SIZE] key.

PER TRAY SETTINGS

TYPE / SIZE

TRAY 2 |

PLAIN / A4 |

DOC.

PRINT COPY FAX I-FAX FILING

6)Select the type of paper that was loaded in the tray. Example: The paper type of tray 2 is selected

CUSTOM SETTINGS

TRAY 2 TYPE/SIZE SETTING |

CANCEL |

SELECT THE PAPER TYPE.

1/2

PLAIN |

|

|

LETTER HEAD |

|

|

HEAVY PAPER |

|

ENVELOPE |

|

|

|

|

|

|

|

|

|

PRE-PRINTED |

|

|

PRE-PUNCHED |

|

|

LABELS |

|

|

|

|

|

|

|

|

|

|

|

RECYCLED |

|

|

COLOUR |

|

|

TRANSPARENCY |

|

|

1/2

Touch the desired paper type to select it.

The paper size setting screen will appear.

Note: Heavy paper, label sheets and transparency film cannot be used in trays 1, 3, and 4. Envelopes can only be placed in tray 2.

AR-D28/D27/MU2 ADJUSTMENTS

6 – 1

[7] DISASSEMBLY AND ASSEMBLY, MAINTENANCE

(1) AR-D28

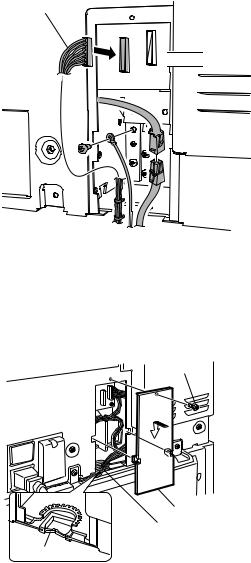

A. MAJOR PARTS AND SIGNAL FUNCTIONS

|

|

|

|

|

|

|

|

2 |

MCLUM/ |

|

|

|

|

|

|

|

|

|

|

|

1 |

+24V |

|

|

|

|

|

|

|

|

|

|

|

PHR-2 |

|

|

|

|

|

|

|

|

|

|

|

|

2 |

2 |

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

|

|

|

|

|

|

|

SMP-02V-NC SMR-02V-N |

|

|

|

||

|

|

|

|

|

|

|

|

2 |

2 |

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

|

|

|

|

|

|

|

SMP-02V-BC SMR-02V-B |

|

|

|

||

|

|

|

|

|

|

|

MCLUM |

TMM |

MPT LD PWB |

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

MCPCL |

MCSS1 |

MCSS2 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MCSS3 |

MCSS4 |

|

|

|

|

|

|

|

|

|

TPFCL |

|

|

|

|

|

|

|

|

|

11 |

11 |

|

|

|

|

|

|

|

|

|

|

|

10 |

10 |

|

|

|

MCSPD |

|

|

TAN Control PWB |

|

|

9 |

9 |

|

|

|

|

|

|||

|

|

8 |

8 |

|

|

|

MCLUD |

|

||||

|

|

|

|

|

7 |

7 |

|

|

|

|

|

|

CN-D |

|

|

|

|

6 |

6 |

5 |

TMMCLK/ |

|

|

MCPED |

|

|

|

|

|

5 |

5 |

|

|

|

||||

VB(+24V) |

|

1 |

|

|

4 |

4 |

4 |

TMM-T |

|

|

|

|

TPFCL/ |

|

2 |

|

|

3 |

3 |

3 |

TMM/ |

TDRS |

|

|

|

VB(+24V) |

|

3 |

|

|

|

|

|

|||||

MCPCL/ |

|

4 |

|

|

2 |

2 |

2 |

GND1 |

|

|

|

|

|

|

|

1 |

1 |

1 |

+24V |

|

|

|

|

||

+24V(MCLUM) |

|

5 |

|

|

|

|

|

|

||||

|

|

SMP-11V-NC |

SMR-11V-N |

PHR-5 |

|

|

|

|

||||

MCLUM/ |

|

6 |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

VB(+24V) |

|

7 |

|

|

|

|

1 |

+5V |

|

|

|

|

GND1(P-GND) |

|

8 |

|

|

|

|

2 |

MCSPD |

|

|

|

|

TMM/ |

|

9 |

|

|

|

|

3 |

GND2 |

|

|

TPFD1 |

|

TMMCLK/ |

|

10 |

|

|

|

|

179228-3 |

|

|

|

||

TMM-T |

|

11 |

|

|

|

|

1 |

N.C. |

|

MCPWS |

|

|

MCSPD |

|

12 |

|

|

|

|

|

|

|

|||

VD(+5V) |

|

13 |

|

|

|

|

2 |

GND2 |

|

|

|

|

GND2(S-GND) |

|

14 |

|

|

|

|

3 |

MCSS1 |

|

|

|

|

MCSS1 |

|

15 |

|

|

|

|

4 |

MCSS2 |

|

|

|

|

GND2(S-GND) |

|

16 |

|

|

|

|

5 |

MCSS3 |

|

|

|

|

MCSS2 |

|

17 |

|

|

|

|

6 |

MCSS4 |

|

|

|

|

MCSS3 |

|

18 |

|

|

|

|

PHR-6 |

|

|

|

|

|

MCSS4 |

|

19 |

|

|

|

|

|

|

|

TPFD3 |

|

|

F-GND |

|

20 |

|

|

|

|

|

|

|

|

|

|

PHDR-20VS-1 |

|

|

|

18 |

18 |

|

1 |

+5V |

|

|

|

|

|

|

|

SRA-21T-4 |

|

|

|

|

|

||||

|

|

|

17 |

17 |

|

2 |

MCLUD |

|

|

|

|

|

CN-E |

|

|

|

16 |

16 |

|

3 |

GND2 |

TPFD2 |

|

|

|

|

|

|

|

|

|

179228-3 |

|

|

|

|||

GND2(S-GND) |

|

1 |

|

|

|

|

1 |

+5V |

|

|

|

|

MCLUD |

|

2 |

|

15 |

15 |

|

|

|

|

|

||

VD(+5V) |

|

3 |

|

14 |

14 |

|

2 |

TPFD1 |

|

|

|

|

VD(+5V) |

|

4 |

|

13 |

13 |

|

3 |

GND2 |

|

|

|

|

GND2(S-GND) |

|

5 |

|

|

|

|

179228-3 |

|

|

|

|

|

MCPED |

|

6 |

|

9 |

9 |

|

1 |

+5V |

|

|

|

|

GND2(S-GND) |

|

7 |

|

|

|

|

|

|

||||

|

|

8 |

8 |

|

2 |

TDRS |

|

|

|

|

||

TDRS |

|

8 |

|

7 |

7 |

|

3 |

GND2 |

|

|

|

|

VD(+5V) |

|

9 |

|

|

|

|

|

|

||||

|

|

|

|

|

179228-3 |

|

|

|

|

|||

VD(+5V) |

|

10 |

|

|

|

|

|

|

|

|

||

|

|

6 |

6 |

|

1 |

+5V |

|

|

|

|

||

GND2(S-GND) |

|

11 |

|

|

|

|

|

|

||||

TPFD1 |

|

12 |

|

5 |

5 |

|

2 |

MCPED |

|

|

|

|

MCPWS2 |

|

13 |

|

4 |

4 |

|

3 |

GND2 |

|

|

|

|

MCPWS |

|

14 |

SMP-18V-BC |

SMR-18V-B |

179228-3 |

|

|

|

|

|||

VD(+5V) |

|

15 |

|

3 |

3 |

|

2T MCPWS |

|

|

|

|

|

N.C. |

|

16 |

|

|

|

|

|

|

||||

|

|

2 |

2 |

|

1T MCPWS2 |

|

|

|

|

|||

PHDR-16VS-1 |

|

|

|

|

|

|

|

|

||||

|

|

|

1 |

1 |

|

3T VAREF |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||||

CN-I |

|

|

SMP-03V-BC |

SMR-03V-B |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

S-GND |

|

1 |

1 |

VD(+5V) |

|

|

|

|

|

|

|

|

TPFD3 |

|

2 |

2 |

TPFD3 |

|

|

|

|

|

|

|

|

VD(+5V) |

|

3 |

3 |

S-GND |

|

|

|

|

|

TPCL2 |

|

|

S-GND |

|

4 |

179228-3 |

|

|

|

|

|

|

|

||

TLUD1 |

|

5 |

1 |

TPED1 |

|

|

|

|

|

|

|

|

VD(+5VR) |

|

6 |

|

|

|

|

|

|

|

|

||

N.C |

|

7 |

2 |

TLUD1 |

|

|

|

|

|

TAN Sensor PWB |

|

|

TPED1 |

|

8 |

3 |

S-GND |

|

|

|

|

|

|

||

VD(+5V) |

|

9 |

4 |

VD(+5VR) |

|

|

|

|

|

|

|

|

PHR-9 |

|

|

5 |

VD(+5V) |

|

|

|

|

|

|

TLUD2 |

TTSD |

|

|

PHR-5 |

|

|

|

|

|

|

||||

CN-B |

|

|

|

|

|

|

|

TPED2 |

|

|||

|

|

1 |

VD(+5V) |

|

|

|

|

|

|

|

||

S-GND |

|

1 |

|

|

|

|

|

|

|

|||

TSPD1 |

|

2 |

2 |

TSPD1 |

|

|

|

|

|

|

|

|

VD(+5V) |

|

3 |

3 |

S-GND |

|

|

|

|

|

|

|

|

TLUM2/ |

|

4 |

179228-3 |

|

|

|

|

|

|

|

|

|

VB(TLUM2) |

|

5 |

1 |

VB(+24V) |

|

|

|

|

|

TSPD2 |

|

|

N.C. |

|

6 |

|

|

|

TLUM2 |

|

|||||

S-GND |

|

7 |

2 |

TLUM2 |

|

|

|

|

|

|

||

TPFD2 |

|

8 |

PHR-2 |

|

|

|

|

|

|

|

|

|

VD(+5V) |

|

9 |

1 |

VD(+5V) |

|

|

|

TPCL1 |

|

|

|

|

S-GND |

|

10 |

|

|

|

|

|

|

||||

TTSD |

|

11 |

2 |

TPFD2 |

|

|

|

|

|

|

|

|

|

3 |

S-GND |

|

|

|

|

|

|

|

|

||

VD(+5V) |

|

12 |

|

|

|

|

|

|

|

|

||

|

179228-3 |

|

|

|

|

TAN Sensor PWB |

|

|

||||

PHR-12 |

|

|

|

|

|

|

|

|

||||

|

|

1 |

VD(+5V) |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

2 |

TTSD |

|

|

|

|

|

TLUD1 |

|

|

|

|

|

3 |

S-GND |

|

|

|

|

|

|

|

|

CN-C |

|

|

179228-3 |

|

|

|

|

TPED1 |

TSPD1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

VB(+24V) |

|

1 |

1 |

1 |

|

|

|

|

|

|

|

|

TPCL1/ |

|

2 |

2 |

2 |

|

|

|

|

|

|

|

|

PHR-2 |

|

|

SMP-02V-BC SMR-02V-B |

|

|

|

|

|

|

|

||

CN-G |

(RED) |

|

|

|

|

|

|

|

|

|

|

|

VB(+24V) |

|

1 |

1 |

1 |

|

|

TLUM1 |

|

|

|

|

|

TPCL2/ |

|

2 |

2 |

2 |

|

|

|

|

|

|

||

PHR-2-R(RED) |

|

SMP-02V-NC |

SMR-02V-N |

|

|

|

|

|

|

|

||

CN-J |

|

|

1 |

VB(+24V) |

|

|

|

|

|

|

|

|

TLUM1/ |

|

1 |

|

|

|

|

|

|

|

|

||

VB(TLUM1) |

|

2 |

2 |

TLUM1/ |

|

|

|

|

|

|

|

|

N.C. |

|

3 |

PHR-2 |

|

|

|

|

|

|

|

|

|

N.C. |

|

4 |

|

|

|

|

|

|

|

|

|

|

N.C. |

|

5 |

|

|

|

|

|

|

|

|

|

|

N.C. |

|

6 |

|

|

|

|

|

|

|

|

|

|

N.C. |

|

7 |

|

|

|

|

|

|

|

|

|

|

N.C. |

|

8 |

|

|

|

|

|

|

|

|

|

|

N.C. |

|

9 |

|

|

|

|

|

|

|

|

|

|

N.C. |

|

10 |

|

|

|

|

|

|

|

|

|

|

PHR-10 |

|

|

|

|

|

|

|

|

|

|

|

|

CN-A |

|

|

1 |

VD(+5V) |

|

|

|

|

|

|

|

|

S-GND |

|

1 |

|

|

|

|

|

|

|

|

||

TSPD2 |

|

2 |

2 |

TSPD2 |

|

|

|

|

|

|

|

|

VD(+5V) |

|

3 |

3 |

S-GND |

|

|

|

|

|

|

|

|

S-GND |

|

4 |

179228-3 |

|

|

|

|

|

|

|

|

|

TLUD2 |

|

5 |

|

|

|

|

|

|

|

|

||

|

1 |

TPED2 |

|

|

|

|

|

|

|

|

||

VD(+5VR) |

|