Poly-Tex KOOL MART User Manual

KOOL MART

INSTALLATION INSTRUCTIONS

Poly-Tex Inc.

27725 Danville Avenue

P.O. Box 458

Castle Rock, MN 55101

REV: AC-120311

US & Canada Toll Free

800-852-3443

(651) 463-7009

fax (651) 463-2479

SAFETY GUIDELINES

PLEASE READ THE INSTALLATION INSTRUCTIONS CAREFULLY BEFORE

ASSEMBLING THE STRUCTURE. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

WARNING

This structure is intended to be self-supporting once constructed with all frames,

hardware, sheathing, sheeting, bracing, cables, and membrane in place and secured to the

foundation as shown in the manual. Stability during construction, from winds and loads

imposed during erection, is the sole responsibility of the installer. Observe safety codes

required by your jurisdiction, and relevant safety practices for working at heights. Avoid the

risk of electrical shock from overhead lines or electrical storms. Poly-Tex recommends

contracting a licensed electrician to perform electrical work. Eye protection is recommended

under all circumstances and hearing protection is recommended when cutting components

with power tools.

Foundations

These instructions include minimum guidance for foundations based on the International

Building Code. These minimums are suitable for some areas of the country but not all.

Obtain a building permit if required in your jurisdiction. Engineered Certified foundation plans

may be required by a building official before issuing a permit. Even if not required, seeking

guidance from a qualified structural or civil engineer for the foundation design may improve

the life of the structure.

DANGER

No part of this structure is engineered to function as an anchorage point for a fall arrest

system. Use a safety net or work from a safe work platform (i.e. scaffolding). Select a calm

day for work. Wind can be sufficient enough to knock materials or workers off a work platform

or ladder, resulting in a potentially deadly fall.

Overview of assembly procedure

While each structure and site is unique, and may require special considerations, these

instructions are for a tilt-up method (where frames are assembled on the ground and tilted

onto ground stakes or anchor rods using ropes or lifts). If installer is not confident to erect the

structure, Poly-Tex suggests you hire a general contractor, carpenter, or similar licensed

business familiar with construction to assemble and erect the structure.

DANGER

Do not overload structure. Consult with a Poly-Tex representative prior to adding any

amount of weight over the specified capacity of this structure. Basket purlins, shelving or any

objects of significant weight shall not be hung, attached, or secured to roof or truss members

in a manner that will overload the structure.

WARNING

Do not walk on polycarbonate sheets. If the structure is to be covered with polycarbonate

sheets,always use scaffolding for the erection process to avoid damage to sheeting and to

ensure safety. Polycarbonate sheeting has UV coating protected with vinyl film on the

exterior surface. Install sheets with the film intact and toward the exterior. Remove film once

the sheet has been fastened in place.

REV: AC-120311

INDEX

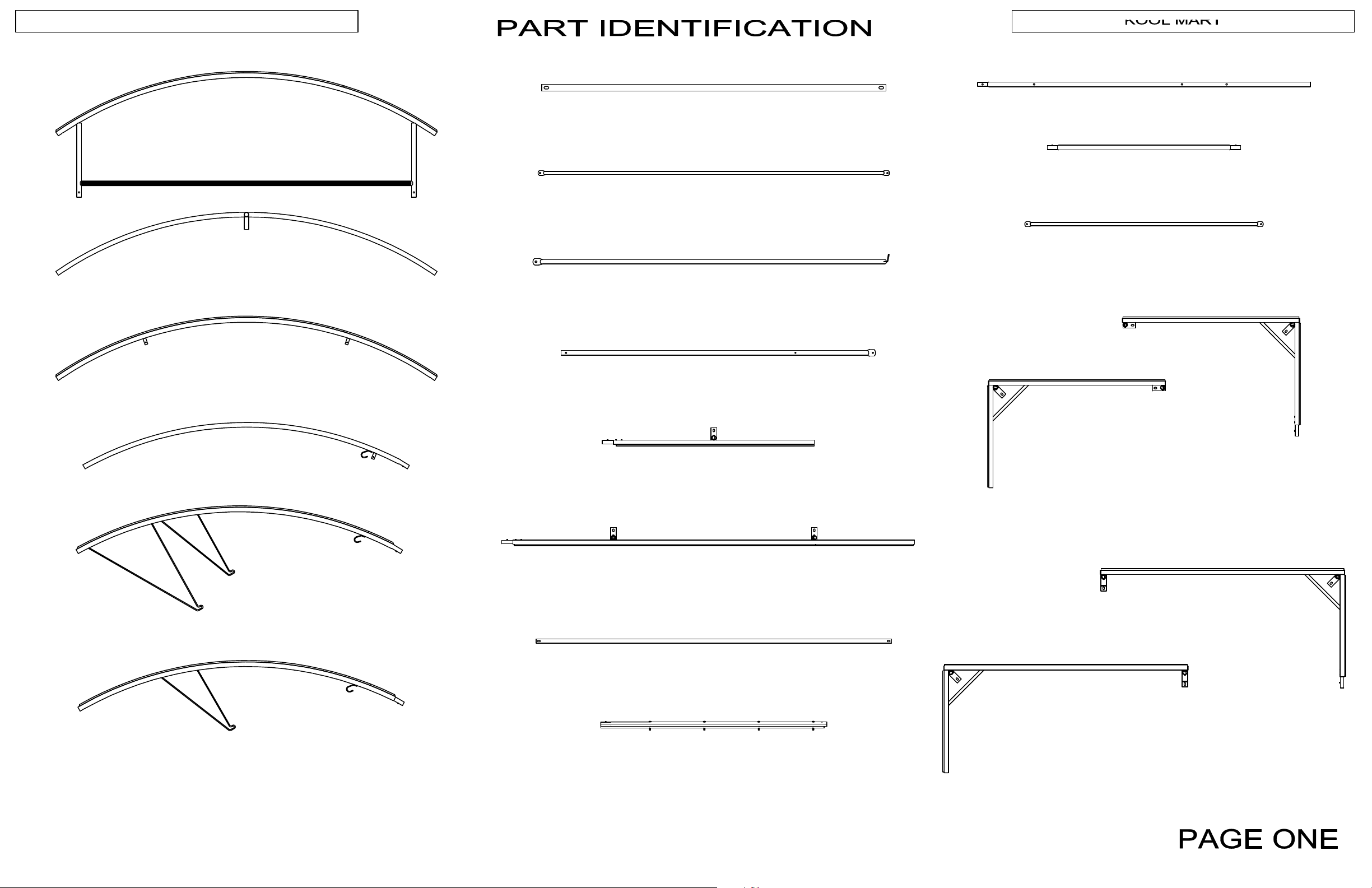

Part Identification....................................................................................1

Part Identification...............................................................................2

Layout & Base Assembly...................................................................3

Frame Section Assembly......................................................................4

Stand up Frame Sections....................................................................5

Door Installation..................................................................................6

“V” Bracket & Basket Purlin.................................................................7

Basket Purlin &“V” Bracket &Ballast Frame..........................................8

Concrete Block Installation.............................................................9

Water Tube Installation.................................................................10

Poly Installation....................................................................................11

REV AC-130311

KM2001 - TOP END HOOP

KHR1040 - POWER POLE

KM2008 - 6' DOOR SPACER

KHR1044 - RIDGE PURLIN

KM2021 - ROLL UP DOOR PIPE (126")

KHR1046 - DIAGONAL BRACE (85 1/2")

KM2000 - TOP INTERMEDIATE HOOP

KM2005 - TOP END HOOP W/TABS

KM2002 - INTERMEDIATE HOOP

KM2010 - SLIDING DOOR END BRACE (95 1/2")

KHR1012 - LEFT CORNER BASE

KHR1010 - RIGHT CORNER BASE

KM2009 - SLIDING DOOR VERTICAL

KHR1014 - 6' SIDE BASE

KM2007 - LEFT CORNER BASE (SLIDING DOOR)

KHR1016 - 12' SIDE BASE

KHR1020 - END HOOP

KHR1021 - END HOOP W/WWR (BALLAST)

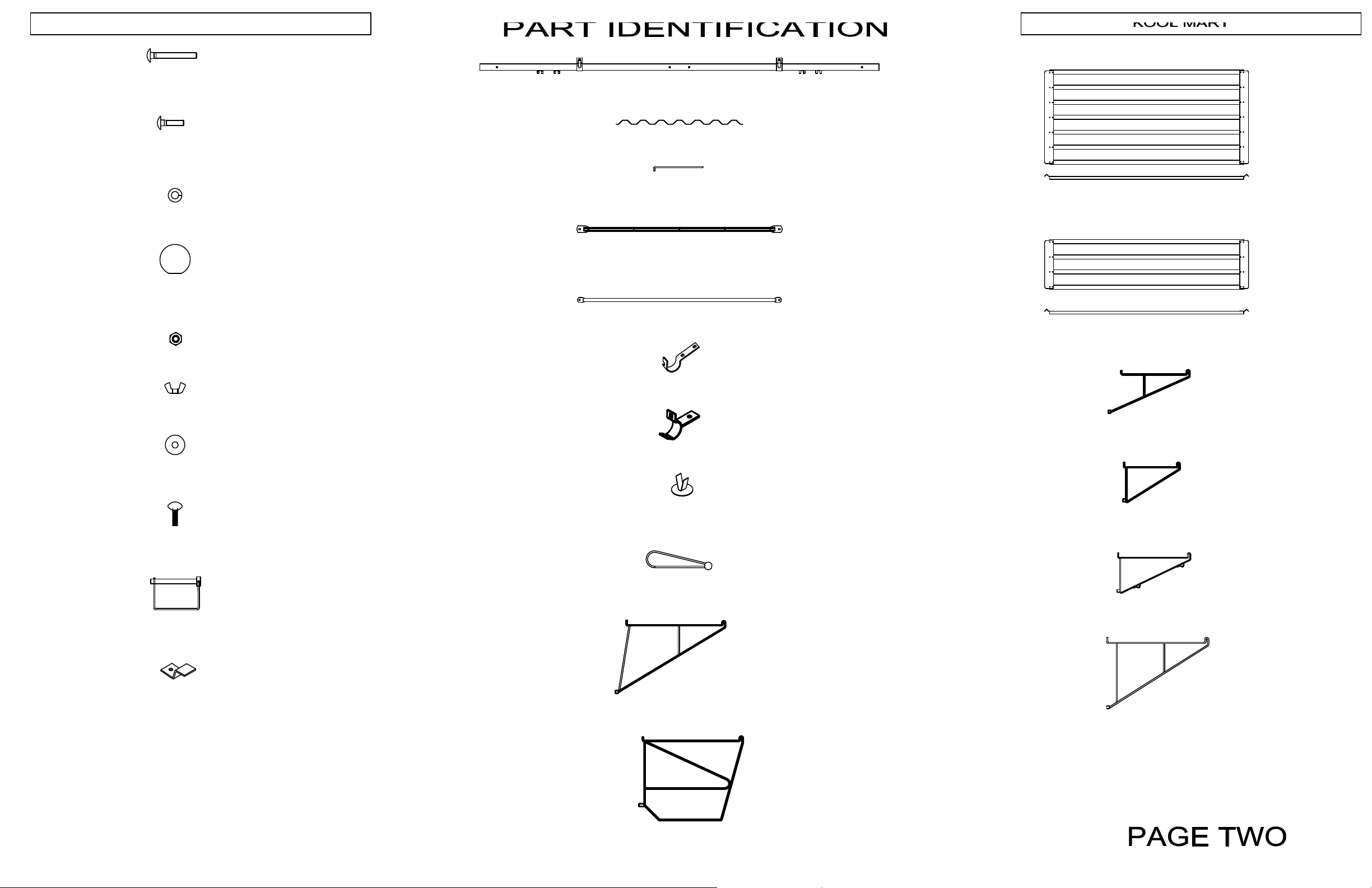

REV: AC-130311

KM2006 - RIGHT CORNER BASE (SLIDING DOOR)

KHR1018 - DOOR SPACER

KHR1036 - DOOR JAMB

NB1816 - 5/16" x 2 1/2" CARRIAGE BOLT

GM2802 - ROLLING DOOR RAIL

NB1832 - 5/16" x 1 1/4" CARRIAGE GRD 5

NB1862 - 5/16" LOCK WASHER

NB1927 - CUSHION BALL

NB1872 - 5/16" HEX NUT

NB1901 - 3/8" WING NUT

WIGGLE WIRE ™

BMS1130 - 18" SPIKE

GM2803 - ROLLING DOOR HEADER

GM4000 - 6'-1 1/2" BASKET PURLIN -95

FT2080 - 1.66 HOOK

FT2087 - 1.66 INLINE SPEED HOOK

RF2552 - 3' x 6' BENCH TOP

RF2554 - 1'6" x 6' BENCH TOP

KM2003 - 24" KM BENCH BRACKET

NB1923 - NYLON WASHER

NB1924 - 5/16" x 1" THUMB SCREW

NB1925 - SNAPPER PIN

FT3200 - FLAT STACKER CLIP

GM2970 - HOOP PAD

PT2521 - 10" BUNGEE BALL

KM2004 - 36" KM BENCH BRACKET

BMS1120 - 18" V BRACKET

KHR1048 - HANGING BASKET "V" BRACKET

BMS1121 - 36" V BRACKET

REV: AC-130311

KM2015 - 36" KM BENCH FRAME

Loading...

Loading...