Parkside PDFP 500 A1 User Manual [fi]

AIR PAINT SPRAY GUN PDFP 500 A1

AIR PAINT SPRAY GUN

Operation and Safety Notes

Translation of original operation manual

FÄRGSPRUTPIST OL, TRY CKLUFT

Bruksanvisning och säkerhetsanvisningar

Översättning av bruksanvisning i original

D

RUCKLUFT-FARbSPRITzPISTOLE

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

P

AINEILMAKÄYTTÖINEN MAALIRUISKU

Käyttö- ja turvaohjeet

Alkuperäisen käyttöohjeen käännös

TRYKLUFT-F ARVESPRØJTE

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

3

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Käännä ennen lukemista kuvallinen sivu esiin ja tutustu seuraavaksi laitteen kaikkiin toimintoihin.

Vik ut bildsidan och ha den till hands när du läser igenom anvisningarna och gör dig bekant med

apparatens / maskinens funktioner.

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE Operation and Safety Notes Page 5

FI Käyttö- ja turvaohjeet Sivu 13

SE Bruksanvisning och säkerhetsanvisningar Sidan 21

DK Brugs- og sikkerhedsanvisninger Side 29

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 37

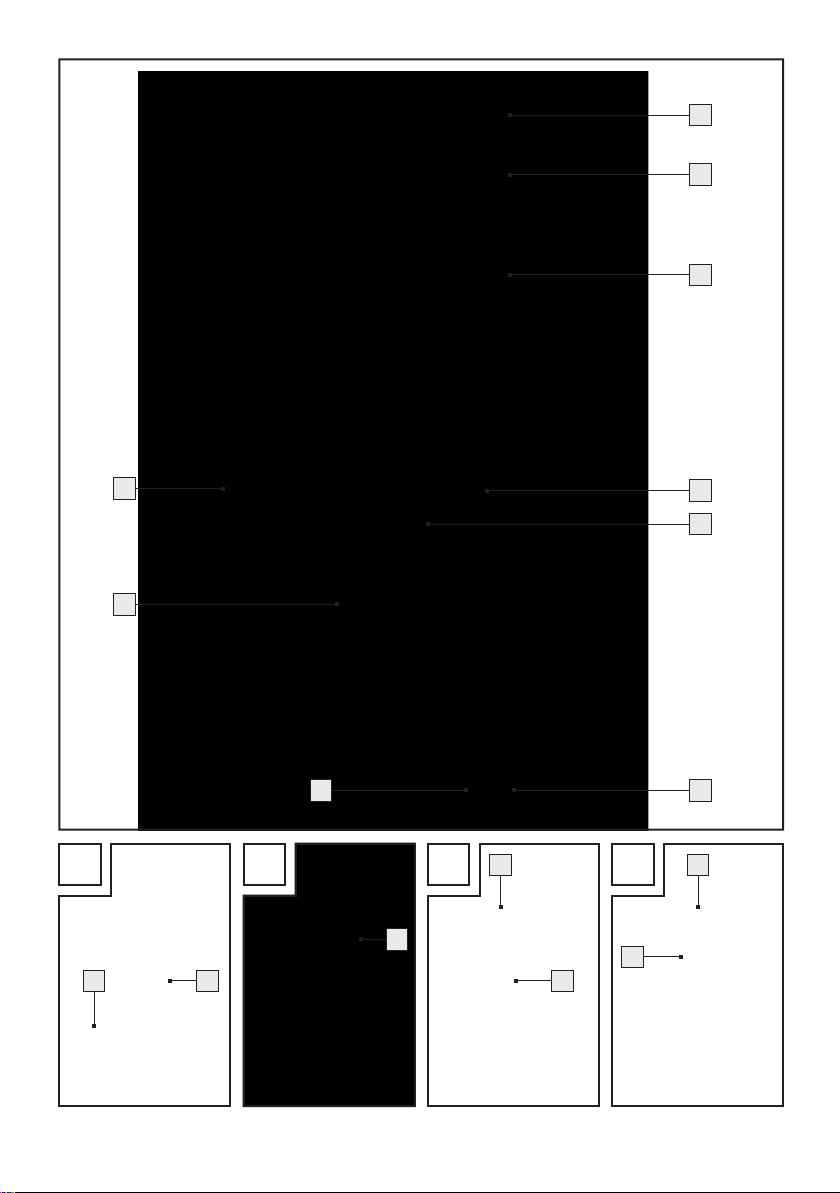

1

2

3

9

8

A B C

11

1113

4

5

67

13

12

D

10

13

Table of contents

Introduction

Correct Usage ...............................................................................................................Page 6

Equipment ......................................................................................................................Page 6

Scope of Delivery ..........................................................................................................Page 6

Technical Data ..............................................................................................................Page 6

Safety advice

Original accessories / attachments ..............................................................................Page 7

Safety instructions for fine spray systems .....................................................................Page 8

Initial use

HVLP properties .............................................................................................................Page 8

Connecting the device ..................................................................................................Page 8

Preparing the spraying surface ....................................................................................Page 9

Turning the device On / Off ..........................................................................................Page 9

Adjusting the paint jet ...................................................................................................Page 9

Regulating the quantity of paint ...................................................................................Page 9

Regulating the quantity of air .......................................................................................Page 9

Maintenance and Cleaning ........................................................................Page 10

Service .........................................................................................................................Page 10

Warranty ...................................................................................................................Page 10

Disposal ......................................................................................................................Page 11

Declaration of Conformity / Manufacturer....................................Page 11

5 GB/IE

Introduction

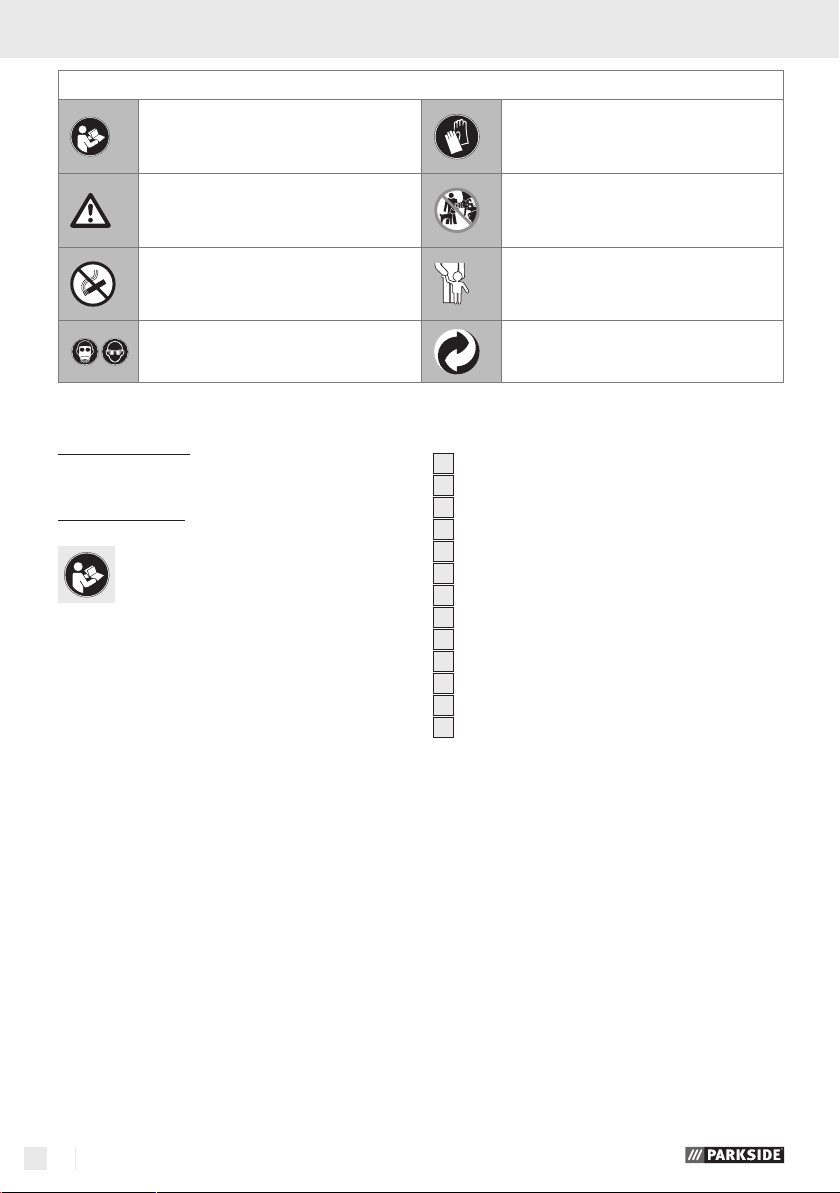

The following pictograms are used in these operating instructions / on the device:

Read instruction manual! Wear protective gloves.

Observe caution and safety notes!

No smoking! Keep children away from the device!

Wear respiratory protection with

active charcoal filters and goggles.

Air paint spray gun PDFP 500 A1

Q

Introduction

Before initial use please acquaint your-

self with the functions of the compressed

air paint spray gun and learn about the

correct handling of compressed air paint spray guns.

Please read the following operating instructions.

You should keep these instructions.

Q

Correct Usage

This compressed air-operated device is only intended

for the application / spraying of solvent-containing

and water-dilutable paints, glazes, primers, varnishes,

automotive topcoats, stains, wood preservatives,

pesticides, oils and disinfectants. The device is not

suitable for working with dispersion and latex paints,

alkalis, acidic coating materials, granular and particulate spraying material or injection and non-drip

materials. Any other use or modification shall be

deemed to be improper use and could give rise to

considerable risk of accident. We will not accept liability for loss or damage arising from improper use.

The device is intended for private, domestic use only.

Never point the device at people or

animals.

Dispose packaging and appliance in

an environmentally-friendly way!

Q

Equipment

Vent

1

Lid of the gravity flow cup

2

Gravity flow cup

3

Stroke stop screw (paint quantity regulation)

4

Regulator for round/broad jet

5

Compressed air connection

6

Regulator for air quantity control

7

Trigger

8

Nozzle head

9

Nozzle

10

Installation spanner

11

Needle

12

Brush

13

Q

Scope of Delivery

1 Air paint spray gun PDFP 500 A1

1 Gravity flow cup

1 Lid for the gravity flow cup

1 Installation tool

1 Cleaning brush

1 Operating Instructions

Q

Technical Data

6 GB/IE

Required air quality: purified, free of condensate

and oil

Air consumption: max. 380 l / min

Working pressure: max. 3 bar

Introduction / Safety advice

Volume flow: typically 130 - 160 ml / min

Nozzle size: Ø 1.4 mm

Gravity flow cup: 500 ml

Sound pressure level: 64 dB(A)

Sound power level: 76 dB(A)

Values determined in accordance with EN 14462

(EN1953/A1:2009).

Safety advice

Read all the safety ad-

vice and instructions. Failure to observe the

safety advice and instructions could result in serious

injury and / or damage to property.

Keep all the safety advice and instructions

in a safe place for future reference!

High working pressures can give rise to recoil

forces that under certain conditions can result

in danger from continuous loading.

TION! Working with nitrogen presents

a danger of suffocation! Work in well

ventilated spaces only.

Never exceed the maximum allowable working

air pressure of 3 bar. Use a pressure reducer

to set the working air pressure.

J

J

open flames.

Never use oxygen or other combustible gas as

the energy source.

First disconnect the hose from the

compressed air source and only then

disconnect the compressed air supply

RISK OF RECOIL FORCES!

DANGER OF SUFFOCA-

DANGER OF INJURY!

DANGER OF INJURY!

IMPROPER USE! Never point the

device at people or animals.

DANGER OF / EXPLOSION

AND FIRE SMOKING PROHIBITED! Do not ignite any sparks or

DANGER OF INJURY!

DANGER OF INJURY!

hose from the device. This will ensure that

the compressed air supply hose does not wave

around or recoil in an uncontrolled manner.

J

equipment. Wear respiratory protection with

J Keep children and other peo

you to lose control of the device.

J Disconnect the device from the compressed air

J When removing the hose coupling, hold the

J Look out for damage on the device.

J Do not kink the device’s hose, otherwise you

J

J Remain alert at all times, pay attention

J Do not remove rating plates or labels - they

J If you are inexperienced in the use of this type

Q

For your own safety, wear

suitable personal protective

active charcoal filters and goggles.

ple

away while you are operating

the device. Distractions can cause

source before carrying out any repair or maintenance work, during interruptions to operations

and before transporting the device.

hose tightly in your hand to avoid injury

caused by the hose shooting backwards.

Check the device for damage before bringing

it into use. Do not use the device if you discover

any defects.

may damage it.

Please note the safety instructions

of the manufacturer of the sprayed

material.

to what you are doing and use com

sense in your work. Do not use any

device when you are tired or under the

influence of drugs, alcohol or medications.

are safety-relevant parts of the device.

of device, you should seek out information or

training to learn how to handle it safely.

mon

Original accessories /

attachments

J Use only the accessories and attach-

ments detailed in the operating instructions. The use of accessories other than

those recommended in the operating instructions

could lead to you being in danger of injury.

7 GB/IE

Safety advice / Initial use

Safety instructions for

fine spray systems

J Keep your work area clean, well lit

and free of paint or solvent containers,

rags and other combustible materials.

Potential danger of spontaneous combustion.

Keep fully functioning fire extinguishers / extinguishing equipment available at all times.

J Ensure good ventilation in the spray-

ing area and sufficient quantities of

fresh air through-out the room. Evapo-

rating flammable solvents create an explosive

environment.

J Do not spray or clean with materials

with a flashpoint below 21°C. Use

materials on the basis of water, lowvolatile hydrocarbons or similar materials. Highly volatile evaporating solvents

create an explosive environment.

J Do not spray in the area of ignition

sources such as static electricity sparks,

open flames, pilot lights, hot objects,

motors, cigarettes and sparks from inserting and disconnecting power cords

or the operation of switches. Such

of sparks can lead to ignition of the surrounding area.

J Do not spray any materials for which

it is not known whether they pose a

danger. Unknown materials can create dan-

gerous conditions.

J Wear additional personal protective equipment

such as appropriate protective gloves and protective masks or respirators when spraying or

handling chemicals. The wearing of protective

equipment in such conditions reduces exposure

to harmful substances.

J Do not spray on yourself, other people

or animals. Keep hands and other body

parts away from the spray jet. If the

spray penetrates the skin, seek medical help immediately. The material being

sprayed can even penetrate the skin through a

glove and be injected into your body.

J Do not treat an injection as a simple cut.

A high pressure jet may inject toxins

into the body and cause serious inju

8 GB/IE

sources

ries.

If the spray is injected into the skin, seek medical

help immediately.

J Pay attention to any possible dangers

of the material being sprayed. Note

the markings on the container or the

manufacturer’s information relating

to the material being sprayed, including the instruction to use personal

protective equipment. The manufacturer’s

in-structions must be followed to reduce the risk

of fire, as well as injuries caused by toxins, carcinogens, etc.

J Never spray without the nozzle head

in place. The use of a special nozzle insert

with the appropriate nozzle head reduces the

probability of a high-pressure jet penetrating

the skin and injecting toxins into the body.

Q

Initial use

Q

HVLP properties

This device uses an HVLP system (High Volume Low

Pressure). It ensures the increased application of

(paint) materials with lower consumption.

Important: Do not exceed the maximum working

pressure of 3 bar.

Q

Connecting the device

J Operate the product only with cleaned, con-

densate- and oil-free compressed air and never

exceed the maximum working air pressure at

the device of 3 bar.

J The compressed air source must be fitted with a

(filter) / pressure reducer so that the air pressure

can be regulated.

In order to operate this device you require a flexible

compressed air hose with quick-release coupling

and an appropriate source of compressed air.

Observe the operating and safety instructions of the

compressed air source and any special instructions

concerning paint preparation.

Note: Ensure the correct working pressure. An

excessive working pressure leads to increased fine

Initial use

dispersion and results in too rapid evaporation of

the liquid. The surfaces become rough and develop

poor adhesion properties. If the working pressure is

too low on the other hand, the paint material is not

sufficiently atomised. Undulating surfaces and the

formation of drops are the result.

j Connect the compressed air hose with the

rapid-release coupling to the compressed air

connection

of the device. This automatically

6

locks into place.

j Use the filter pressure reducer of the compressed

air source to set the working pressure to 3 bar.

Q

Preparing the spraying surface

j Mask off the surroundings of the spraying sur-

face thoroughly over a wide area. Otherwise

all non-covered areas or surfaces may become

soiled.

j Make sure that the spraying surface is clean,

dry and free of grease.

j Roughen smooth surfaces and then remove the

sanding dust.

Q

Turning the device On / Off

j Press the trigger

to start spraying and keep

8

it held down.

j In order to stop spraying, release the trigger

8

again.

Q

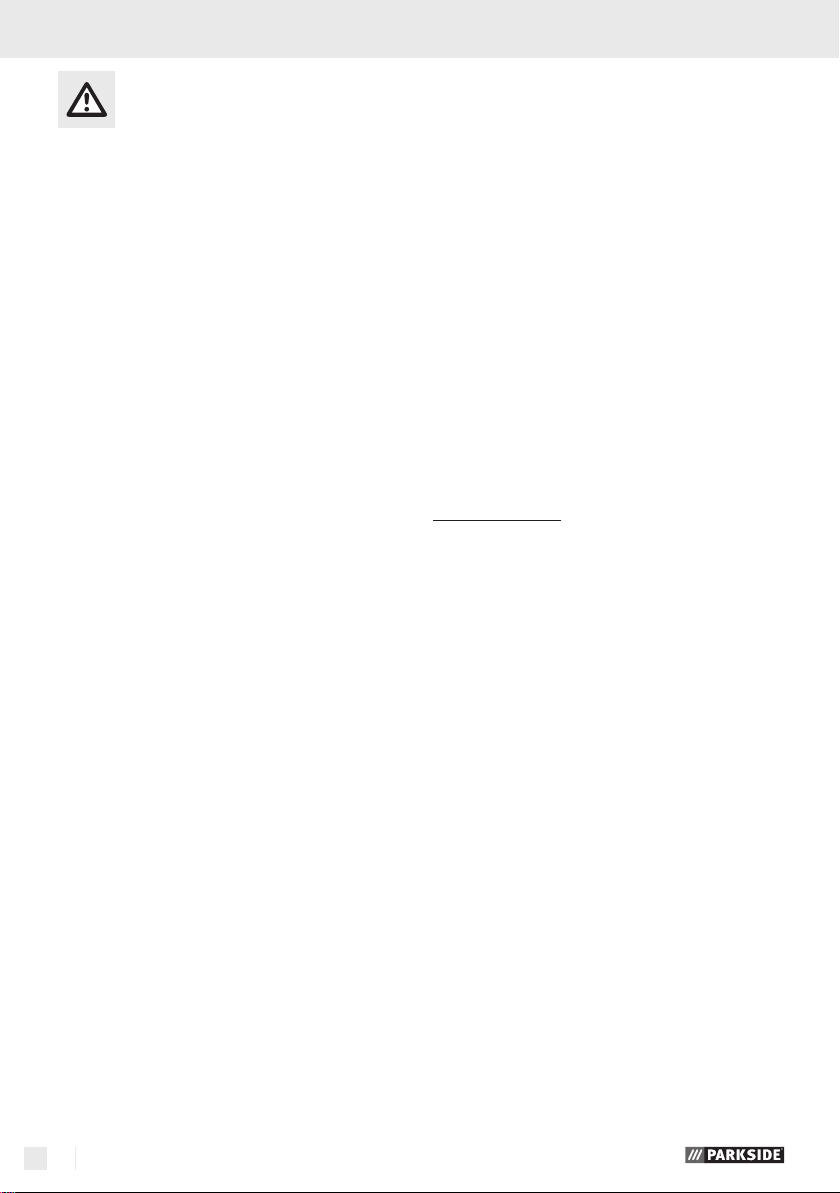

Adjusting the paint jet

The device has the settings round and broad jet.

Round jet Broad jet

Adjusting the round jet:

j Use the round jet, for example, for small surfaces,

corners and edges.

j Turn the regulator

in a clockwise direction .

5

Adjusting the broad jet:

j Use the broad jet vertically and horizontally

over larger areas.

j Turn the regulator

tion

. The nozzle head 9 can be continuously

in an anticlockwise direc-

5

adjusted vertically and horizontally by turning

to the desired position.

Working Instructions:

- When working with the device you should open

the vent

.

1

- When diluting the material, make sure that the

spraying material and the dilution are suitable

for one another. If an incorrect dilution is used,

lumps may form and clog the gun as a result.

- Screw the flow cup

clockwise firmly on to

3

the gun.

- Fill the spraying material into the flow cup

and screw the lid

on tight.

2

3

- Always hold the paint spray gun at the same

distance from the object. The ideal spraying

distance is approximately 15 cm.

- Determine the appropriate settings in each

case by experimenting.

- Do not turn the device on / off when it is over

the spraying surface, but start and end the

spraying process approximately 10 cm outside

of the spraying area.

Q

Regulating the

quantity of paint

Note: The front locking screw is used to limit the

adjustment range of the stroke stop screw

Increasing the quantity of paint:

j Turn the stroke stop screw

direction.

Reducing the quantity of paint:

j Turn the stroke stop screw

direction.

Q

Regulating the quantity of air

Note: It is advisable to start with the maximum

amount of air. In order to do this, open the air volume

in an anticlockwise

4

in a clockwise

4

.

4

9 GB/IE

Initial use / Maintenance and Cleaning / Service / Warranty

regulator 7 as described below under “Increasing the air quantity” up to the maximum setting.

Increasing the air quantity:

Note: Increasing the amount of air is generally

advisable when the degree of atomization is too

coarse.

j Turn the air quantity regulator

in an anti-

7

clockwise direction.

Reducing the air quantity:

Note: Reducing the amount of air is generally

advisable when the paint spray is too strong.

j Turn the air quantity regulator

in a clock-

7

wise direction.

Q

Maintenance and Cleaning

Note: Thorough cleaning after each use is very

important for safety and operation. Otherwise, for

example, the nozzle will become clogged and the

proper functioning of the device can no longer be

guaranteed.

J

Wear suitable protective gloves

when carrying out cleaning work.

J Do not use any hydrocarbon-containing halogen

solvents such as trichloromethyl, ethyl chloride,

etc., as they undergo chemi-cal reactions with

some materials in the paint spray gun. This can

lead to dangerous reactions

CAUTION! Never place the paint spray gun

completely in solvent.

J After every use spray thinner (only in the

open air – danger of explosion!) or

water through the device.

j Use the cleaning brush supplied or a cloth to

clean the housing. Never use petrol, solvents or

cleaning agents which attack plastic.

j First unscrew the nozzle head

an anticlockwise direction

j Loosen and remove the nozzle

it with the installation spanner

by turning in

9

.

by unscrewing

10

in an anti-

11

clockwise direction - see also Figure B. Clean

the needle

with the brush

and the nozzle 10 carefully

12

- see also figures C and D.

13

10 GB/IE

After cleaning, screw the nozzle head 9 back

on by turning it in a clockwise direction, and

tighten it with the spanner

fest.

11

j For rust protection you can spray sewing

machine oil through the device after cleaning.

j Lubricate all moving parts from time to time.

j After the nozzle has been cleaned the thread

and seal have to be lightly treated with grease.

j Do not use any silicone-containing lubricants.

j Store compressed air equipment only in dry

areas.

Q

Service

J

ated equipment should only be re

by qualified specialists and with origi

Compressed air-oper-

paired

nal

spare parts. This will ensure that devices

remain safe.

Q

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for

private use only and is not intended for commercial

use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering

not carried out by our authorized service branch.

Your statutory rights are not restricted in any way

by this warranty.

Warranty / Disposal / Declaration of Conformity / Manufacture

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP/Min.)

e-mail: kompernass@lidl.gb

IAN 64576

IE

Service Ireland

Tel: 1890 930 034

(0,08 EUR/Min. (peak)

0,06 EUR/Min. (off peak))

e-mail: kompernass@lidl.ie

IAN 64576

Q

Disposal

The packaging is wholly composed of

environmentally-friendly materials that can

be disposed of at a local recycling centre.

j Consider their environmental compatibility

when buying paints, varnishes etc.

Q

Declaration of Conformity /

Manufacturer

We, Kompernaß GmbH, the person responsible for

documents: Mr Felix Becker, Burgstr. 21, D-44867

Bochum, Germany, hereby declare that this product

complies with the following standards, normative

documents and EU directives:

Machinery Directive

(2006 / 42 / EC)

Applicable harmonized standards

DIN EN 1953:1998+A1:2009

(EN 1953:1998+A1:2009)

Type / Machine designation:

Air paint spray gun PDFP 500 A1

Date of manufacture (DOM): 03 - 2011

Serial number: IAN 64576

Bochum, 31.03.2011

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

Environmental compatibility and

disposal of materials:

j Paint, varnishes etc. are special wastes which

must be disposed of in the appropriate manner.

j Observe the regulations applicable in your area.

j Observe the manufacturer’s instructions.

j Environmentally damaging chemicals must not

be allowed to enter the soil, groundwater or

watercourses.

j Carrying out spraying at the edge of water-

courses or adjoining areas (catchments) is

therefore prohibited.

Hans Kompernaß

- Managing Director -

We reserve the right to make technical modifications

in the course of product development.

11 GB/IE

12

Sisällysluettelo

Johdanto

Määräystenmukainen käyttö .........................................................................................Sivu 14

Varustus ..........................................................................................................................Sivu 14

Toimitukseen kuuluu ....................................................................................................... Sivu 14

Tekniset tiedot ................................................................................................................. Sivu 14

Turvallisuusohjeet

Alkuperäiset varusteet / -lisälaitteet ............................................................................... Sivu 15

Hienoruiskujärjestelmien turvallisuusohjeet ...................................................................Sivu 16

Käyttöönotto

HVLP-ominaisuudet ......................................................................................................... Sivu 16

Laitteen liitäntä ...............................................................................................................Sivu 16

Ruiskutettavan pinnan valmistelu ...................................................................................Sivu 17

Laitteen päälle- / poiskytkentä ....................................................................................... Sivu 17

Värisuihkun säätö ........................................................................................................... Sivu 17

Maalimäärän säätö ....................................................................................................... Sivu 17

Ilmamäärän säätö .......................................................................................................... Sivu 17

Huolto ja puhdistus ............................................................................................Sivu 18

Huolto............................................................................................................................Sivu 18

Takuu ............................................................................................................................. Sivu 18

Hävittäminen .......................................................................................................... Sivu 19

Vaatimustenmukaisuusvakuutus / Valmistaja ...........................Sivu 19

13 FI

Johdanto

Tässä käyttöohjeessa / laitteessa käytetään seuraavia kuvakkeita:

Lue käyttöohje! Käytä suojakäsineitä.

Huomioi varoitus- ja turvaohjeet!

Tupakointi kielletty! Pidä lapset loitolla laitteesta!

Käytä hengityssuojainta aktiivihiilisuodattimella sekä suojalaseja.

Paineilmakäyttöinen maaliruisku

PDFP 500 A1

Q

Johdanto

Tutustu ennen ensimmäistä käyttöönottoa

paineilmakäyttöisen maaliruiskupistoolin

kaikkiin toimintoihin ja ota selvää, miten

paineilmakäyttöisiä maaliruiskupistooleja käsitellään

oikealla tavalla. Lue tätä varten seuraava käyttöohje

tarkkaavaisesti läpi. Säilytä tämä käyttöohje huolellisesti.

Q

Määräystenmukainen käyttö

Älä suuntaa laitetta ihmisiä ja / tai

eläimiä kohti.

Hävitä pakkaus ja laite

ympäristöystävällisesti!

Q

Varustus

Ilmanvaihto

1

Maaliastian kansi

2

Maaliastia

3

Säätöruuvi (värimäärän säätö)

4

Pyörösuihkun / viuhkasuihkun säädin

5

Paineilmaliitäntä

6

Ilmamäärän säädin

7

Liipaisuvipu

8

Suutinpää

9

Suutin

10

Asennusavain

11

Neula

12

Harja

13

Paineilmakäyttöinen laite soveltuu levittämään / ruiskuttamaan vain liuotinainepitoisia ja vesiohenteisia

lakkoja, kuultovärejä, pohjustusvärejä, kirkaslakkaa,

moottoriajoneuvojen peitemaaleja, petsivärejä,

puunsuoja-aineita, kasvinsuojeluaineita, öljyjä ja

desinfiointiaineita. Tämä laite ei sovellu dispersio- ja

lateksimaalien, lipeän, happopitoisten pinnoitteiden,

rakeisten ja kiinteää ainetta sisältävien aineiden tai

ruiskutusestoisten ja tiksotrooppisten aineiden ruiskutukseen. Kaikki muunlainen käyttö tai muutosten

teko laitteeseen on määräystenvastaista ja voi aiheuttaa huomattavia tapaturmavaaroja. Emme ota mitään vastuuta määräystenvastaisesta käytöstä aiheutuneista vahingoista. Laite on tarkoitettu ainoastaan

yksityiskäyttöön.

14 FI

Q

Toimitukseen kuuluu

1 paineilmakäyttöinen maaliruisku PDFP 500 A1

1 maaliastia

1 maaliastian kansi

1 asennustyökalu

1 puhdistusharja

1 käyttöohje

Q

Tekniset tiedot

Vaadittava ilmanlaatu: puhdistettu, lauhteeton

ja öljytön

Ilmankulutus: max. 380 l / min

Loading...

Loading...