Nissan XTrail T30 2006 User Manual

BRAKE CONTROL SYST EM

F BRAKES

A

B

SECTION BRC

BRAKE CONTROL SYSTEM

CONTENTS

ABS

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Rest raint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 4

Precautions for Brake System .................................. 4

Precautions for Brake Control .................................. 4

PREPARATION ........................................................... 5

Commercial Service Tools ........................................ 5

SYSTEM DESCRIPTION ............................................ 6

System Diagram ....................................................... 6

Functions ........................ .................... ...................... 6

ABS ............................. .......................................... 6

EBD ............................. .......................................... 6

Operation That Is Not “System Error” ...................... 6

ABS ............................. .......................................... 6

Hydraulic Circuit Diagram ........................................ 7

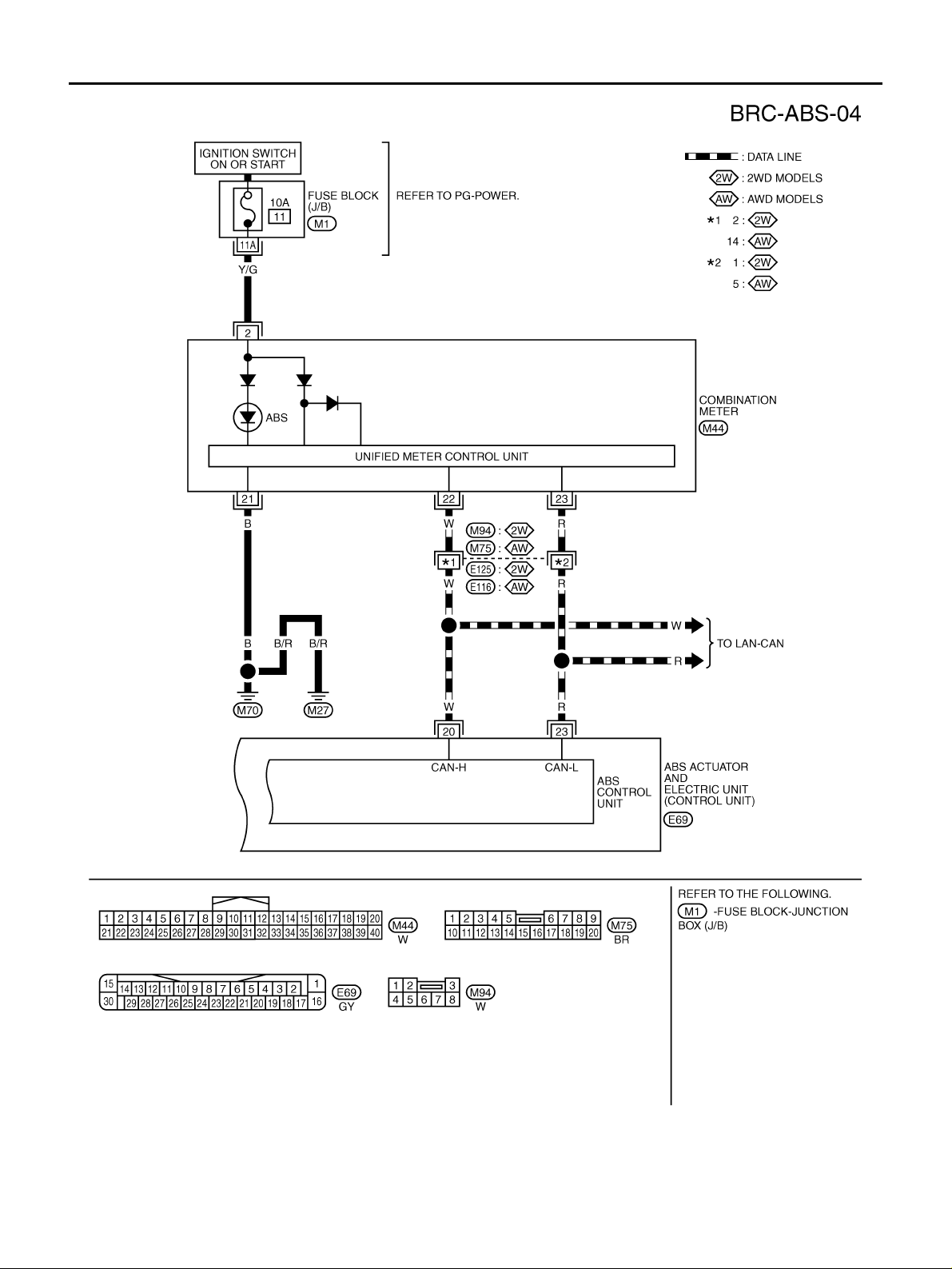

CAN Communication ................................................ 7

SYSTEM DESCRIPTION ...................................... 7

TROUBLE DIAGNOSIS .............................................. 8

Fail-Safe Function .................................................... 8

ABS, EBD .............................................................. 8

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ....................................................... 8

INTRODUCTION ............................. ............. ......... 8

DIAGNOSIS FLOW CHART ................................. 9

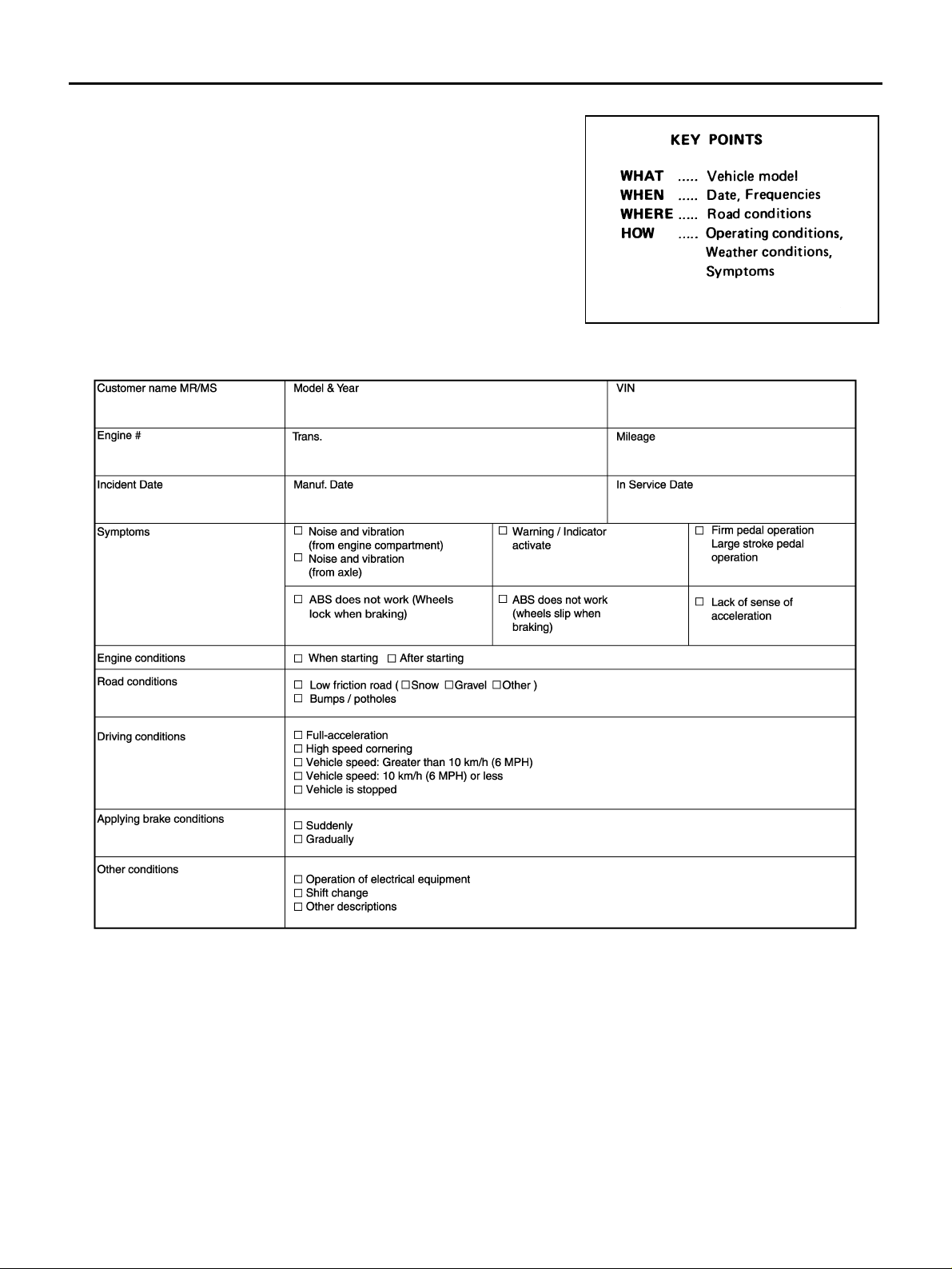

ASKING COMPLAINTS ...................................... 10

EXAMPLE OF DIAGNOSIS SHEET ................... 10

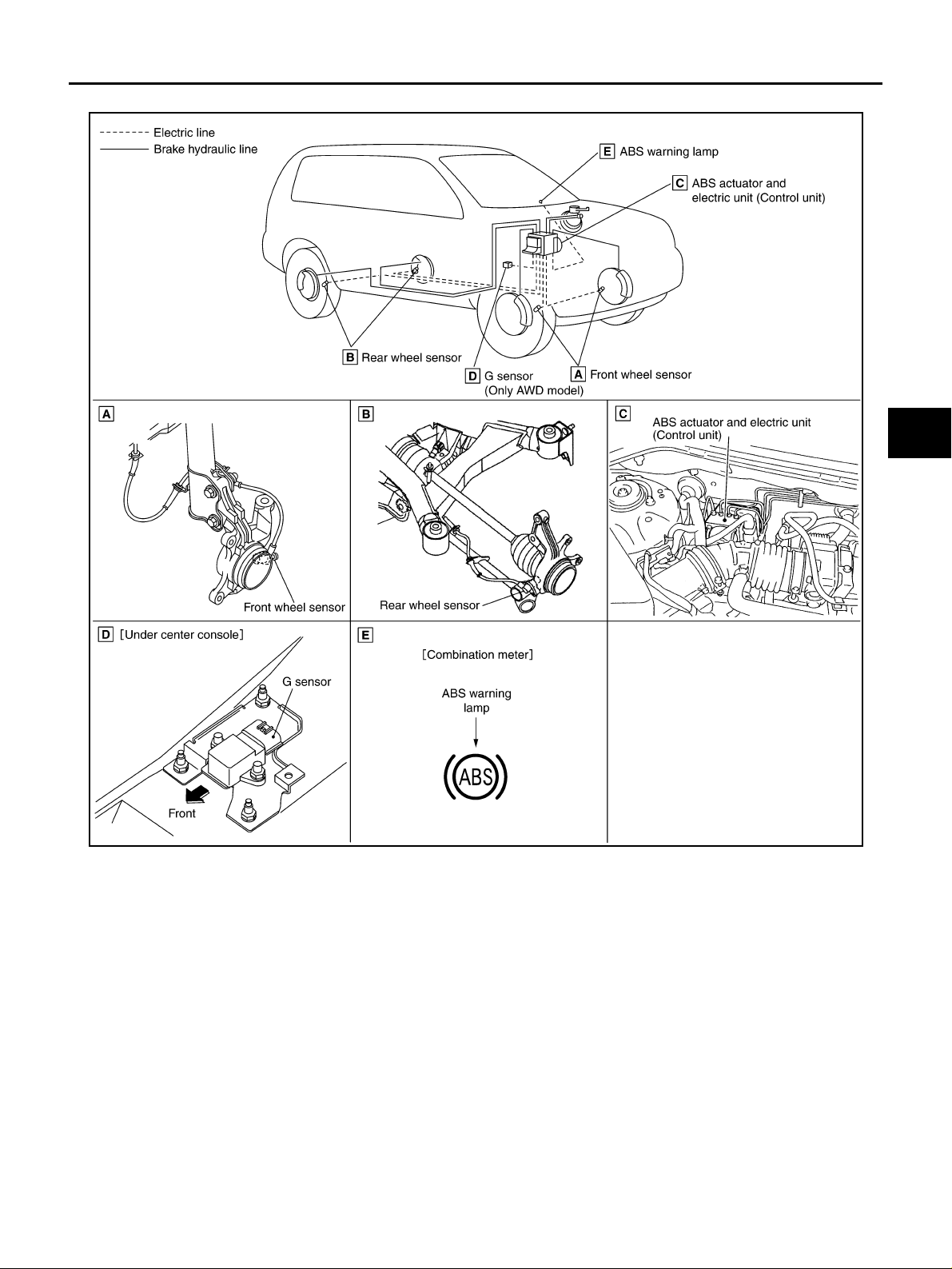

Component Parts Location ......................................11

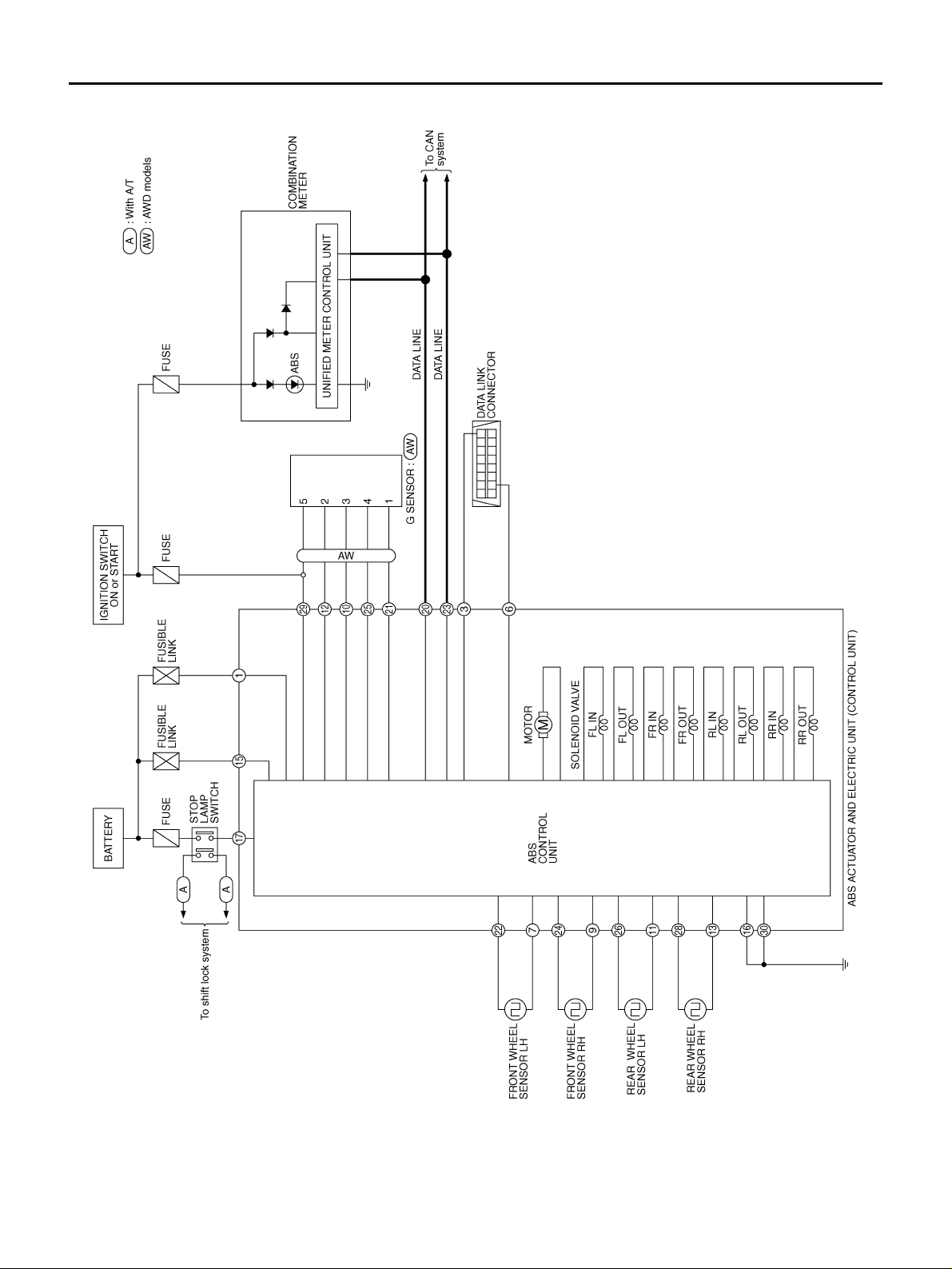

Schematic .............................................................. 12

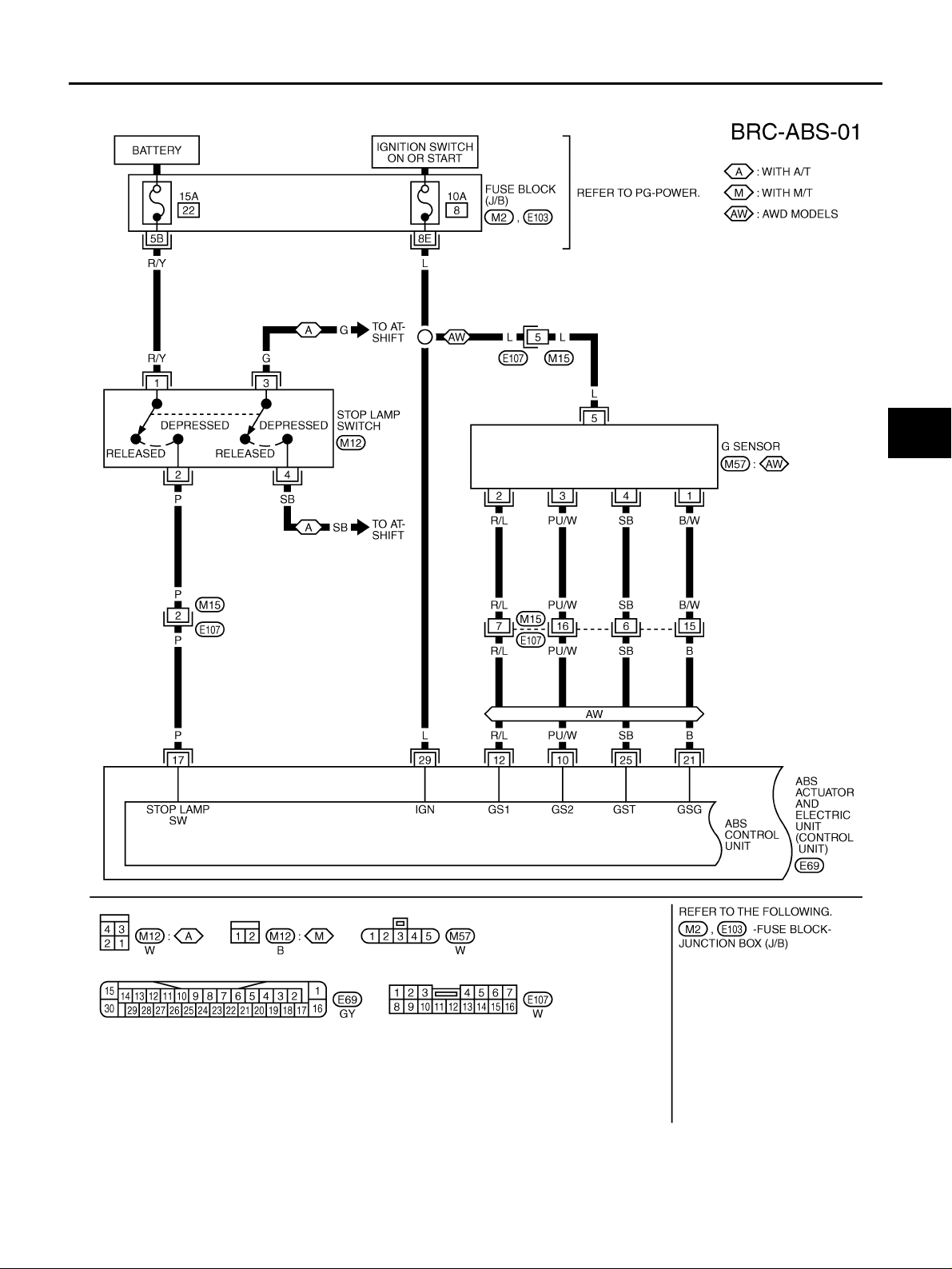

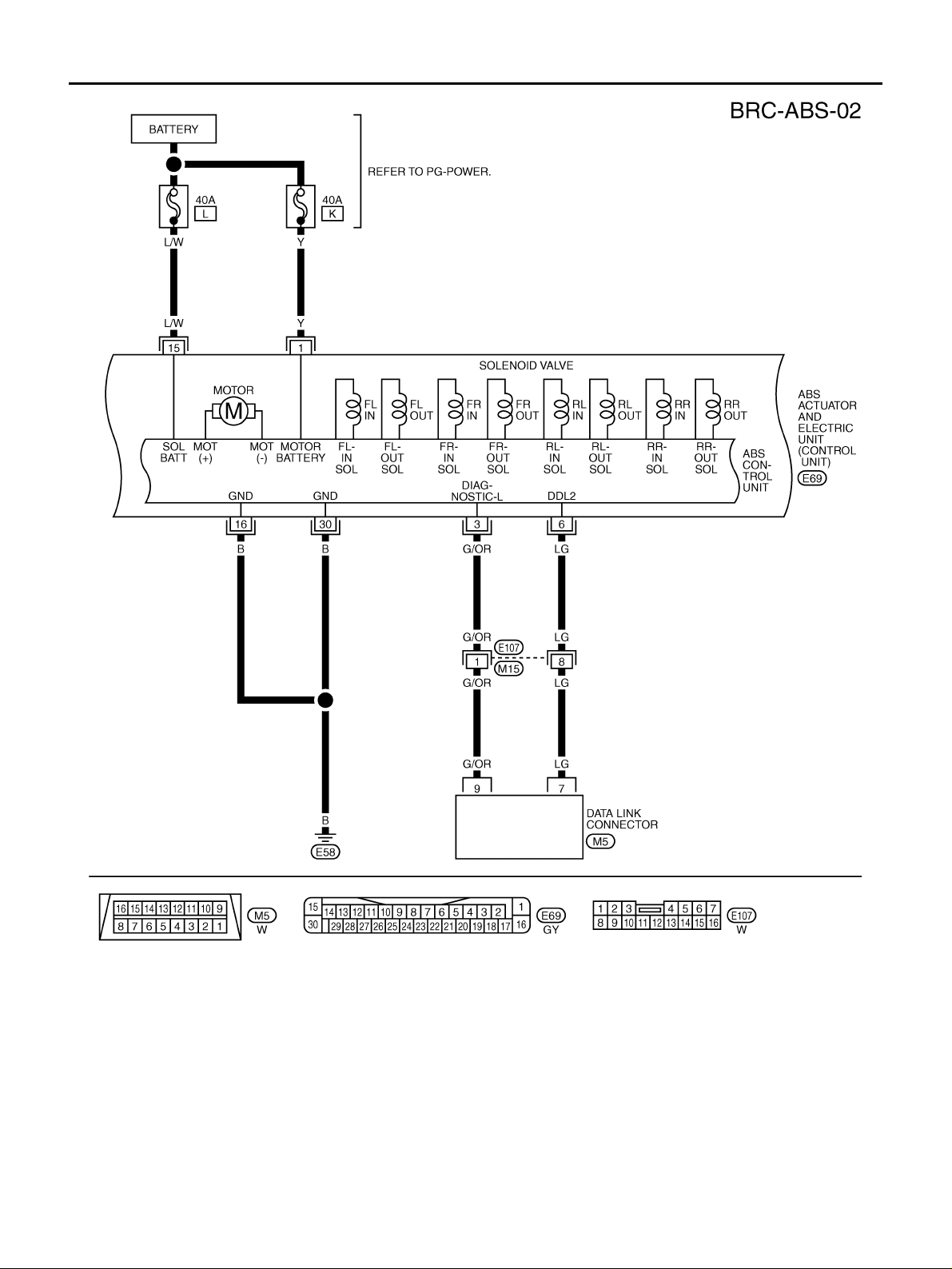

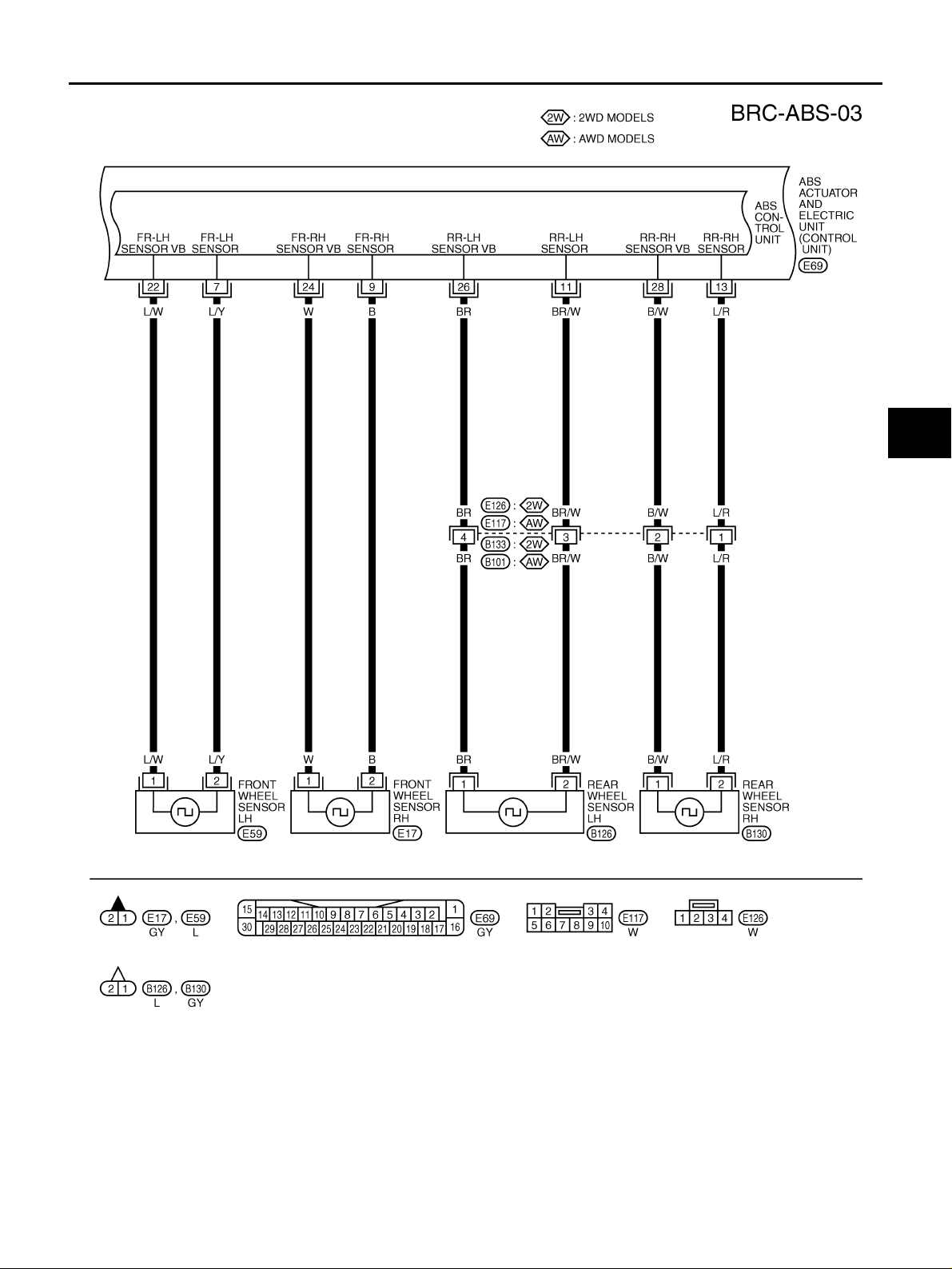

Wiring Diagram — ABS — ..................................... 13

Control Unit Input/Output Signal Standard ............. 17

REFERENCE VALUE FROM CONSULT-II ......... 17

CONSULT-II Functions (ABS) ................................ 18

CONSULT-II MAIN FUNCTION ........................... 18

CONSULT-II BASIC OPERATION PROCEDURE

... 18

SELF-DIAGNOSIS ............. ................................. 18

DATA MONITOR ................................................. 20

ACTIVE TEST ..................................................... 21

For Fast and Accurate Diagnosis ...........................23

PRECAUTIONS FOR DIAGNOSIS ..................... 23

Basic Inspection .....................................................23

BRAKE FLUID LEV EL, LEAKAGE AN D BRAKE

PAD ..................................................................... 23

POWER SUPPLY CIRCUIT TERMINAL LOOSE-

NESS AND BATTERY ......................................... 24

INSPECTION OF ABS WARNING LAMP ...........24

TROUBLE DIAGNOSIS FOR SYSTEM ... ...... ....... ....25

Wheel Sensor ......................................................... 25

INSPECTION PROCEDURE .............................. 25

ABS Actuator and Electric Unit (Control Unit) ........27

INSPECTION PROCEDURE .............................. 27

ABS Actuator and Electric Unit (Control Unit) Power

Supply and Ground .................................................27

INSPECTION PROCEDURE .............................. 27

ABS Actuator Relay or ABS Motor Relay ...............28

INSPECTION PROCEDURE .............................. 28

G Sensor (Only AWD Models) ................................29

INSPECTION PROCEDURE .............................. 29

CAN Communication ..............................................31

INSPECTION PROCEDURE .............................. 31

Component Inspection ............................................32

PARKING BRAKE SWITCH ................................32

BRAKE FLUID LEVEL SWITCH ......................... 32

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 33

Excessive ABS Function Operation Frequency ...... 33

Unexpected Pedal Reaction ................................... 33

The Stopping Distance Is Long ............................... 34

ABS Function Does Not Operate ............................35

Pedal Vibration or ABS Operation Sound Occurs ...35

ABS Warning Lamp Indication Is Not Normal .........35

WHEEL SENSORS ................................................... 36

Removal and Installation ........................................ 36

COMPONENTS ..................... .............................. 36

REMOVAL ........................................................... 36

INSTALLATION ................................................... 36

SENSOR ROTOR ..................................................... 37

Removal and Installation (2WD Models) ................37

REMOVAL ........................................................... 37

C

D

E

BRC

G

H

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

BRC-1

INSTALLATION ....................................................37

Removal and Installation (AWD Models) ................37

REMOVAL ...........................................................37

INSTALLATION ....................................................37

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY) ...38

Removal and Installation ........................................38

COMPONENTS .................. .................................38

REMOVAL ...........................................................39

INSTALLATION ....................................................39

G SENSOR ................................................................ 40

Removal and Installation (Only AWD Models) ........40

REMOVAL ...........................................................40

INSTALLATION ....................................................40

VDC/TCS/ABS

PRECAUTIONS ........................ ...... ....... ...... ....... .......41

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................... .......................... .................... 41

Precautions for Brake System ................................41

Precautions for Brake Control ................................ 41

PREPARATION .........................................................42

Commercial Service Tools .................. ...... ..............42

ON-VEHICLE SERVICE ............................................ 43

Adjustment of Steering Angle Sensor Neutral Posi-

tion ...................... .................................................... 43

SYSTEM DESCRIPTION .......................................... 44

System Diagram .....................................................44

Functions ................................................................ 44

ABS .....................................................................44

EBD .....................................................................44

ABLS (ACTIVE BRAKE LSD) ..............................44

TCS ..................................................................... 44

VDC ..................................................................... 45

Operation That Is Not “System Error” .....................45

ABS .....................................................................45

TCS ..................................................................... 45

VDC ..................................................................... 45

Hydraulic Circuit Diagram .......................................46

CAN Communication ..............................................46

SYSTEM DESCRIPTION ....................................46

TROUBLE DIAGNOSIS ............................................47

Fail-Safe Function ..................................................47

ABS, EBD, ABLS .................................................47

VDC/TCS ............................ .................................47

How to Perform Trouble Diagnosis For Quick and

Accurate Repair ......................................................47

INTRODUCTION ...................... ...........................47

DIAGNOSIS FLOW CHART ................................48

ASKING COMPLAINTS .......................................49

EXAMPLE OF DIAGNOSIS SHEET ....................49

Component Parts Location .....................................50

Schematic ................. ..............................................51

Wiring Diagram — VDC — .....................................52

Control Unit Input/Output Signal Standard ..............58

REFERENCE VALUE FROM CONSULT-II .........58

CONSULT-II Functions (ABS) .................................60

CONSULT-II MAIN FUNCTION ....... ...... ....... .......60

CONSULT-II BASIC OPERATION PROCEDURE

...61

SELF-DIAGNOSIS .......... .....................................61

DATA MONITOR .................................................64

ACTIVE TEST ......................................................66

For Fast and Accurate Diagnosis ............................68

PRECAUTIONS FOR DIAGNOSIS .....................68

Basic Inspection ......................................................69

BRAKE FLUID LEVEL, L EAKAGE AND BRAKE

PAD .................... .............................................. ....69

POWER SUPPLY CIRCUIT TERMINAL LOOSE-

NESS AND BATTERY .........................................69

ABS WARNING LAMP, BRAKE WARNING

LAMP , VDC OFF INDICA T OR LAMP, A ND SLIP

INDICATOR LAMP ...............................................69

TROUBLE DIAGNOSIS FOR SYSTEM ....................71

Wheel Sensor ........................................ ...... ....... ....71

INSPECTION PROCEDURE ........................... ....71

Engine System ........................................................73

INSPECTION PROCEDURE ........................... ....73

VDC/TCS/ABS Control Unit ....................................73

INSPECTION PROCEDURE ........................... ....73

Pressure Sensor .....................................................73

INSPECTION PROCEDURE ........................... ....73

Steering Angle Sensor ............................................74

INSPECTION PROCEDURE ........................... ....74

Yaw Rate/Side G Sensor ........................................76

INSPECTION PROCEDURE ........................... ....76

Solenoid and VDC Switching Valve ........................77

INSPECTION PROCEDURE ........................... ....77

Actuator Motor and Motor Relay .............................79

INSPECTION PROCEDURE ........................... ....79

Actuator Relay ........................................................80

INSPECTION PROCEDURE ........................... ....80

Stop Lamp Switch Circuit ........................................81

INSPECTION PROCEDURE ........................... ....81

VDC/TCS/ABS Control Unit Power And Ground ....82

INSPECTION PROCEDURE ........................... ....82

Park/Neutral Position (PNP) Switch (Only A /T Mod-

els) ..........................................................................83

INSPECTION PROCEDURE ........................... ....83

Brake Fluid Level Switch .........................................84

INSPECTION PROCEDURE ........................... ....84

CAN Communication ..............................................85

INSPECTION PROCEDURE ........................... ....85

Component Inspection ............................................85

VDC OFF SWITCH ..............................................85

PA RKING BRAKE SWITCH .................................86

BRAKE FLUID LEVEL SWITCH ..........................86

MOTOR RELAY AND ACTUATOR RELAY .........86

VDC ACTUATOR .................................................87

TROUBLE DIAGNOSIS FOR SYMPTOMS ..............88

Excessive ABS Function Operation Frequency ......88

Unexpected Pedal Reaction ...................................88

The Stopping Distance Is Long ...............................89

ABS Function Does Not Operate ............................90

Pedal Vibration or ABS Operation Sound Occurs ...90

Vehicle Jerks During VDC/TCS/ABS Control ..........90

ABS Warning Lamp Indication Is Not Normal .........91

Revision: 2006 July 2006 X-Trail

BRC-2

Slip Indicator Lamp Indication Is Not Normal ......... 91

VDC OFF Indicator Lamp Indication Is Not Normal ... 92

Brake Warning Lamp Indication Is Not Normal ...... 92

WHEEL SENSORS ................................................... 93

Removal and Installation ........................................ 93

COMPONENTS .................................................. 93

REMOVAL ........................................................... 93

INSTALLATION ................................................... 93

SENSOR ROTOR ..................................................... 94

Removal and Installation ........................................ 94

REMOVAL ........................................................... 94

INSTALLATION ................................................... 94

VDC/TCS/ABS CONTROL UNIT .............................. 95

Removal and Installation ........................................ 95

REMOVAL ........................................................... 95

INSTALLATION ................................................... 95

ACTUATOR ................................. .............................. 96

Removal and Installation ........................................ 96

COMPONENTS ..................... .............................. 96

REMOVAL ........................................................... 97

INSTALLATION ................................................... 97

G SENSOR ................................................................ 98

Removal and Installation ........................................ 98

REMOVAL ........................................................... 98

INSTALLATION ................................................... 98

STEERING ANGLE SENSOR .................................. 99

Removal and Installation ........................................ 99

REMOVAL ........................................................... 99

INSTALLATION ................................................... 99

VDC OFF SWITCH ..................................................100

Removal and Installation ......................................100

REMOVAL .........................................................100

INSTALLATION .................................................100

A

B

C

D

E

BRC

G

H

K

M

I

J

L

Revision: 2006 July 2006 X-Trail

BRC-3

PRECAUTIONS

[ABS]

[ABS]

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front sea t belt , helps t o redu ce th e r isk or s everi ty of injury to th e driv er an d front passenge r for c ertain

types of collision. Info rmation necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

● To avoid rendering the SRS inoperativ e, which cou ld increase the risk of persona l injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, in cluding incorrect removal a nd installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For rem ova l of Sp iral Ca ble an d Air

Bag Module, see the SRS section.

● Do not use electrical test equipme nt on any circuit related to the SRS unle ss instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors .

AFS002PO

Precautions for Brake System AFS002LO

● Recommended fluid is brake fluid “DOT 3”. Refer to MA-10, "RECOMMENDED FLUIDS AND LUBRI-

CANTS"

● Do not reuse drained brake fluid.

● Be careful not to splash brake fluid on painted areas such as body. If brake fluid is splashed, wipe it off

and flush area with water immediately.

● Do not use mineral oils such as ga soline or kerosene. They will ruin rubber parts of the hydraulic system.

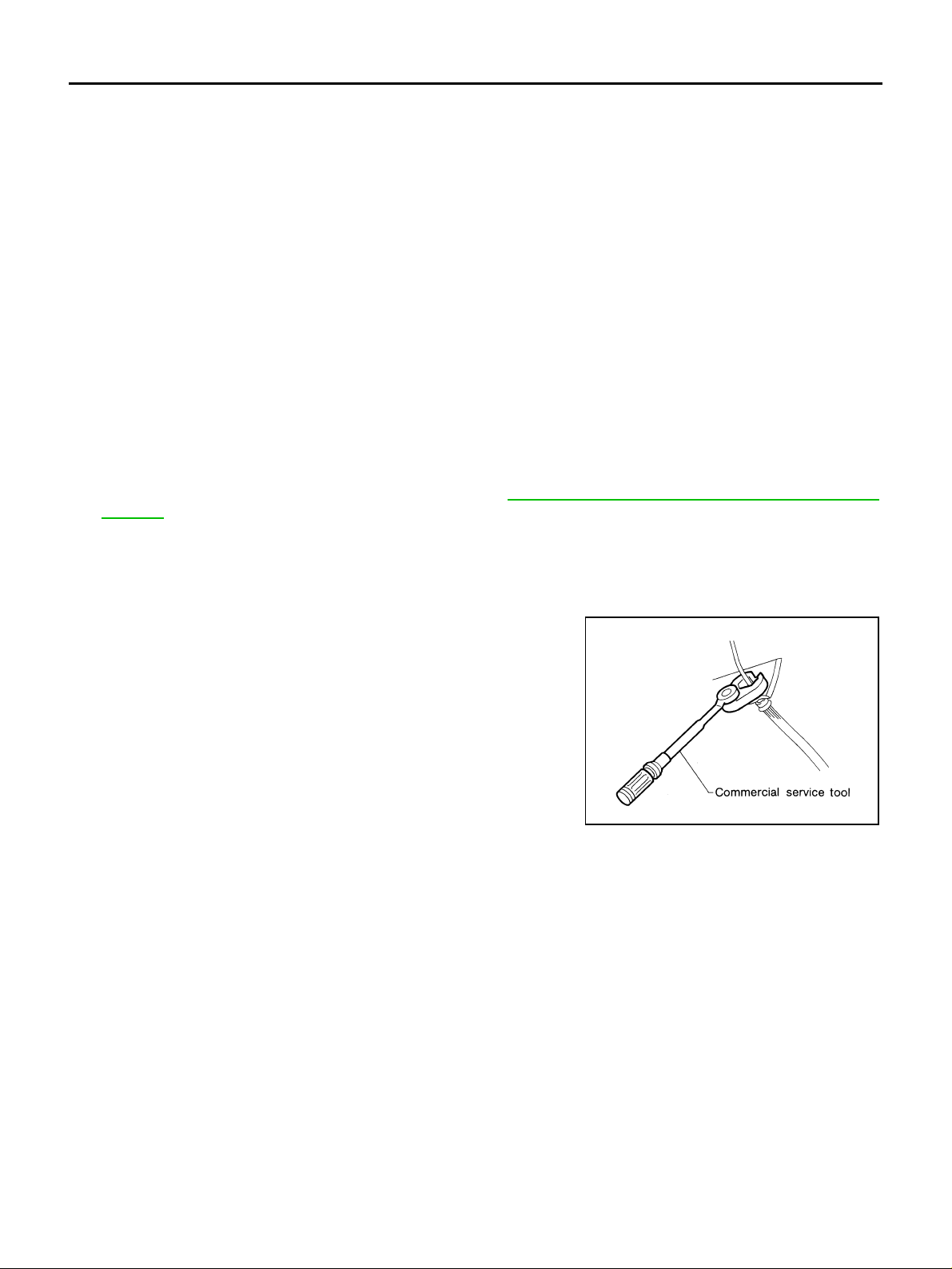

● Use flare nut torque wrench when removing and installing brake

tube.

● Brake system is an important saf ety part. If a b rake fluid leak is

detected, always dis assembl e the affected part. If a malf unction

is detected, replace part with a new one.

● Before working, turn ignition switch OFF and disconnect con-

nectors of ABS a ctua tor and electric u ni t (con trol unit) or batter y

cables.

● When installing brake piping, be sure to check torque.

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with

a dust collector.

SBR686C

Precautions for Brake Control AFS002LP

● Just after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operating noise may

be heard from engine room. This is a normal status of opera tion check.

● When an error is indicated by ABS or another warning lamp, collect all necessary information from cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting

diagnostic servicing. Besides electrical system inspection, check brake booster operation, brake fluid

level, and fluid leak s.

● If tire size and type are us ed in an imprope r combinat ion, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

● If there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, ABS function

may have a malfunction or error.

● If aftermarket parts (car st ereo, CD pl ayer, etc.) have bee n installe d, ch eck f or inc iden ts such as h arness

pinches, open circuits, and improper wiring.

Revision: 2006 July 2006 X-Trail

BRC-4

PREPARATION

[ABS]

PREPARATION PFP:00002

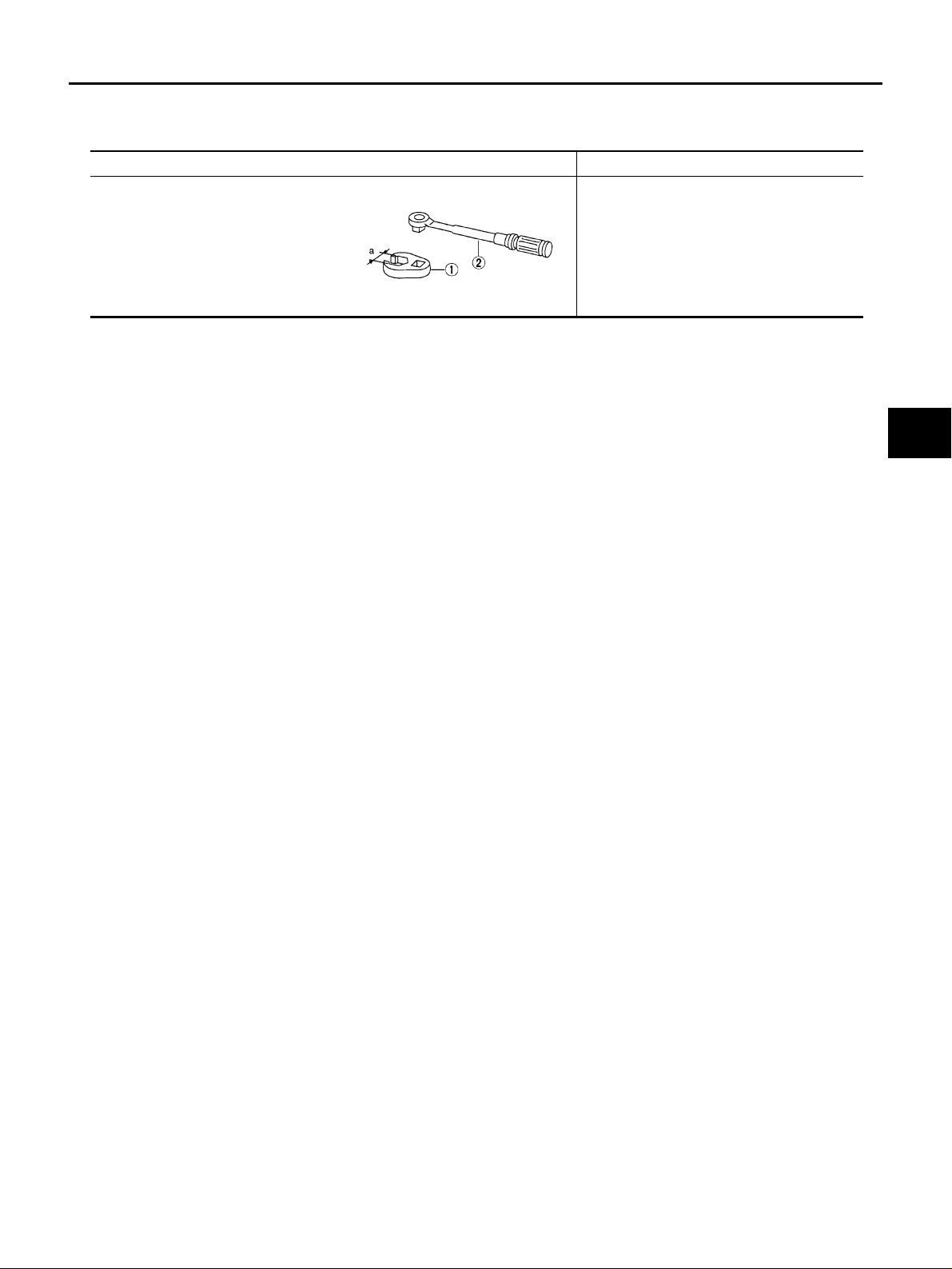

Commercial Service Tools AFS002PB

Tool name Description

1.Flare nut crowfoot

a: 10 mm (0.39 in)

2.Torque wrench

Removing and installing each brake piping

A

B

C

S-NT360

D

E

BRC

G

H

I

J

K

Revision: 2006 July 2006 X-Trail

BRC-5

L

M

SYSTEM DESCRIPTION

[ABS]

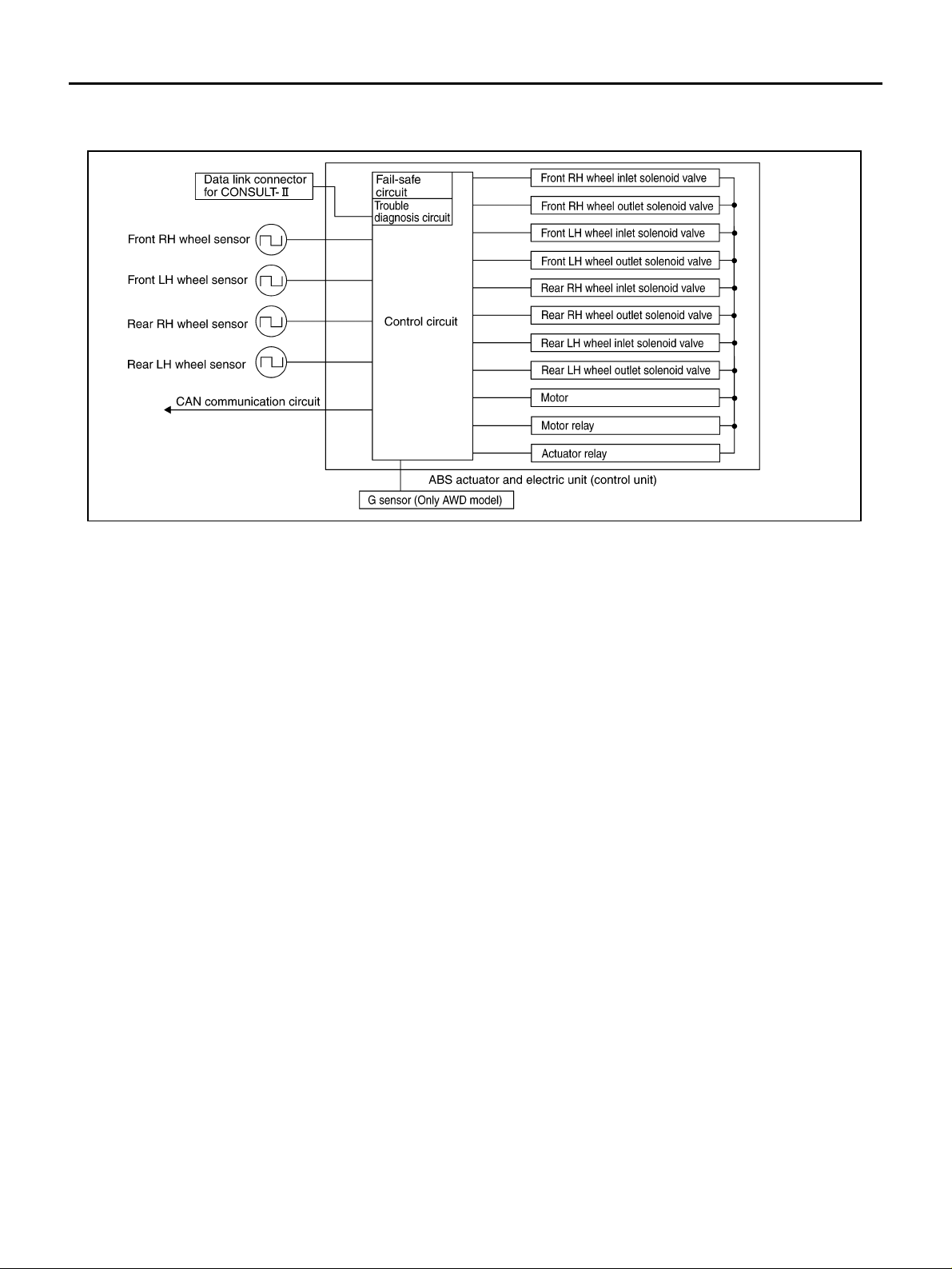

SYSTEM DESCRIPTION PFP:00000 System Diagram AFS002LR

SFIA2390E

Functions AFS002P6

ABS

● The Anti-Lock Brake System is a function that detects wheel revolution while braking, and it improves

handling stability during sudden braking by el ectrically preventing 4 whe el lock. Maneuverabilit y is also

improved for avoiding obstacles.

● Electrical System Diagnosis by CONSULT-II is av ailable.

EBD

● Electronic B rak e Dist ribut ion is a fu ncti on that det ect s subt le sl ipp ag es bet ween f ront and rea r whee ls du r-

ing braking, and it improves handling stability by electronically controlling Brake Fluid Pressure which

results in reduced rear wheel slippage.

● Electrical System Diagnosis by CONSULT-II is av ailable.

Operation That Is Not “Sy stem Error” AFS002P7

ABS

● When starting engine or just after starting veh icle, brake pe dal may vibrate or the motor operatin g noise

may be heard from engine room. This is a normal states of the operation check.

● During ABS operation, brake pedal lightly vibrates and a mechanical noise may be heard. This is normal.

● Stopping distance may be longer th an that o f vehi cles with out ABS when vehi cle d rives on rou gh, gra vel,

or snow-covered (fresh, deep snow) roads.

Revision: 2006 July 2006 X-Trail

BRC-6

SYSTEM DESCRIPTION

[ABS]

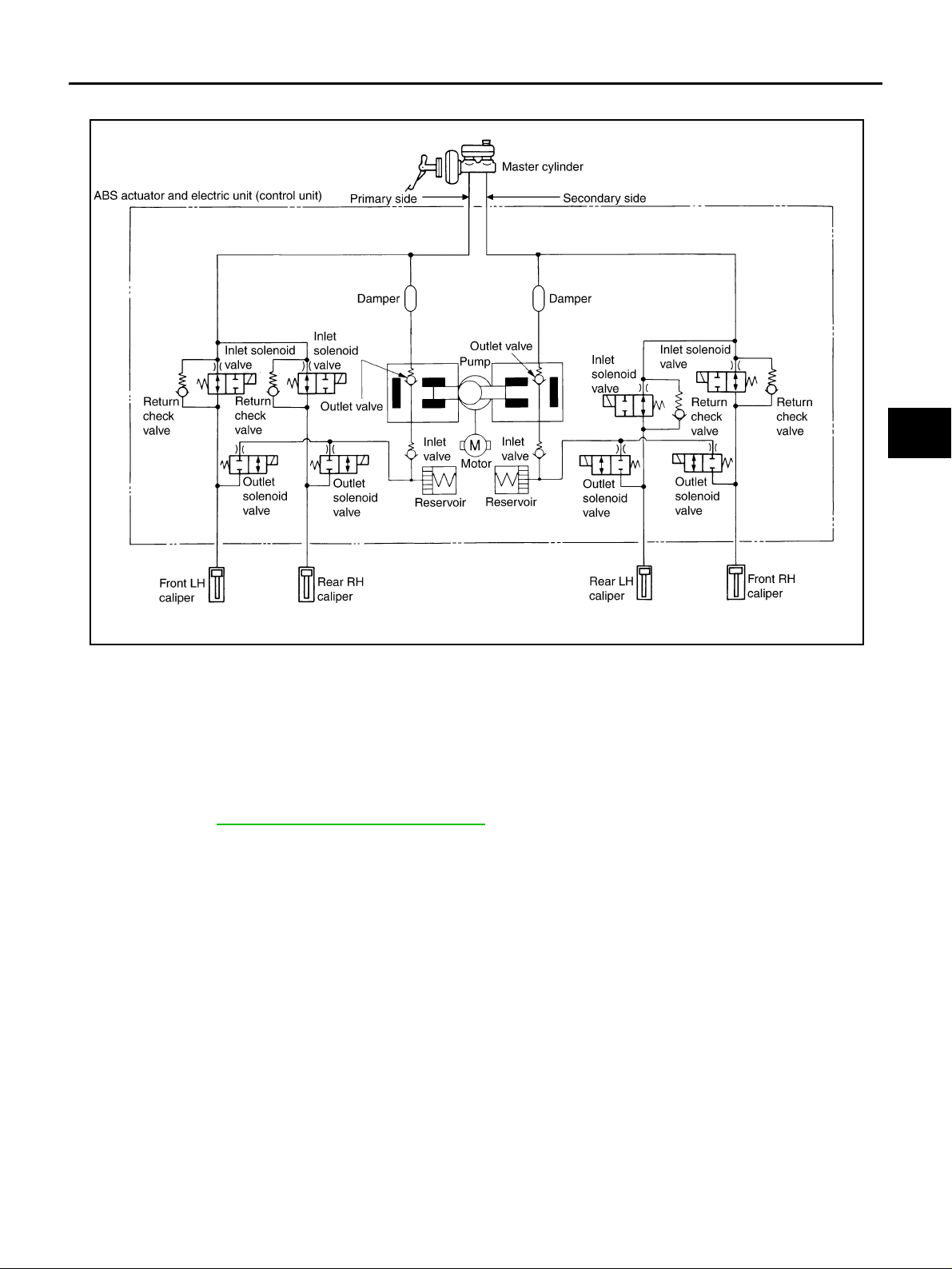

Hydraulic Circuit Diagram AFS002LV

A

B

C

D

E

BRC

G

SFIA2479E

CAN Communication AFS0035N

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle multiplex communication line with high data communication speed and excellent error detection ability. Many electronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during opera tion (not independent). In CA N communication, cont rol units are connected with 2

communicatio n lines ( CAN H lin e, CAN L li ne) all owi ng a high ra te of in forma tion tr ans missi on wit h less wir ing.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer to LAN-21, "

CAN Communication Unit" .

H

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

BRC-7

TROUBLE DIAGNOSIS

[ABS]

TROUBLE DIAGNOSIS PFP:00004 Fail-Safe Function AFS0038H

ABS, EBD

In case of electrical malfunction with ABS, ABS warning lamp will turn on. In case of electrical incident with

EBD, ABS warning lamp will turn on. Simultaneously, ABS become one of following conditions of Fail-Safe

function.

1. For ABS malfunction, o nl y EB D is activ at ed an d c on di tio n o f ve hi cl e i s sam e c o nd iti on of veh ic le s wi tho ut

ABS function.

NOTE:

In step 1 shown abov e, self -diag nosi s wh en ig nitio n sw itch is t urned ON and when v ehic le starts at in itial

time is performed. ABS self-d iagnosis noise may be heard as usual.

2. For EBD malfunction, EBD and ABS become inoperative, and condition of vehicle is same as condition of

vehicles without ABS, EBD function.

How to Perform Trouble Diagnosis for Quick and Accurate Repair AFS002LX

INTRODUCTION

● To perform trouble diagnosis, it is the mos t important to have un derstandin g about veh icle syst ems (con -

trol and mechanism) thoroughly.

● It is also important to cla rify c ustom er compla ints befo re insp ec-

tion.

First of all, reproduce symptom, and understand it fully.

Ask customer about his/her complaint s carefully. I n some cases,

it will be necessary to check symptom by driving vehicle with

customer.

NOTE:

Customers are no t professionals. Do not assum e “maybe customer means...” or “maybe cus tomer mentioned this symptom”.

● It is essential to check symptoms right from beginning in order to

repair a malfunction completely.

For an intermittent malfunction, it is important to reproduce

symptom based o n interv iew wi th cust omer and past exam ples.

Do not perform inspection on ad hoc basis. Most intermittent

malfunctions are c a us ed b y poor contacts. In this c a se, it will be

effective to shake suspected harness or connector by hand.

When repairs are performed without any symptom check, no

one can judge if malfunction has actually been eliminated.

● After diagnosis, make sure to perfo rm “e rase me mory”. Refer t o

BRC-19, "

● For an intermitten t malfunction, move harness or harness c on-

ERASE MEMORY" .

nector by hand to check poor contact or false open circuit.

● Always read “ GI section” to confirm general precautions. Refer to GI-4, "General Precautions" .

EFJ0028D

SEF233G

Revision: 2006 July 2006 X-Trail

BRC-8

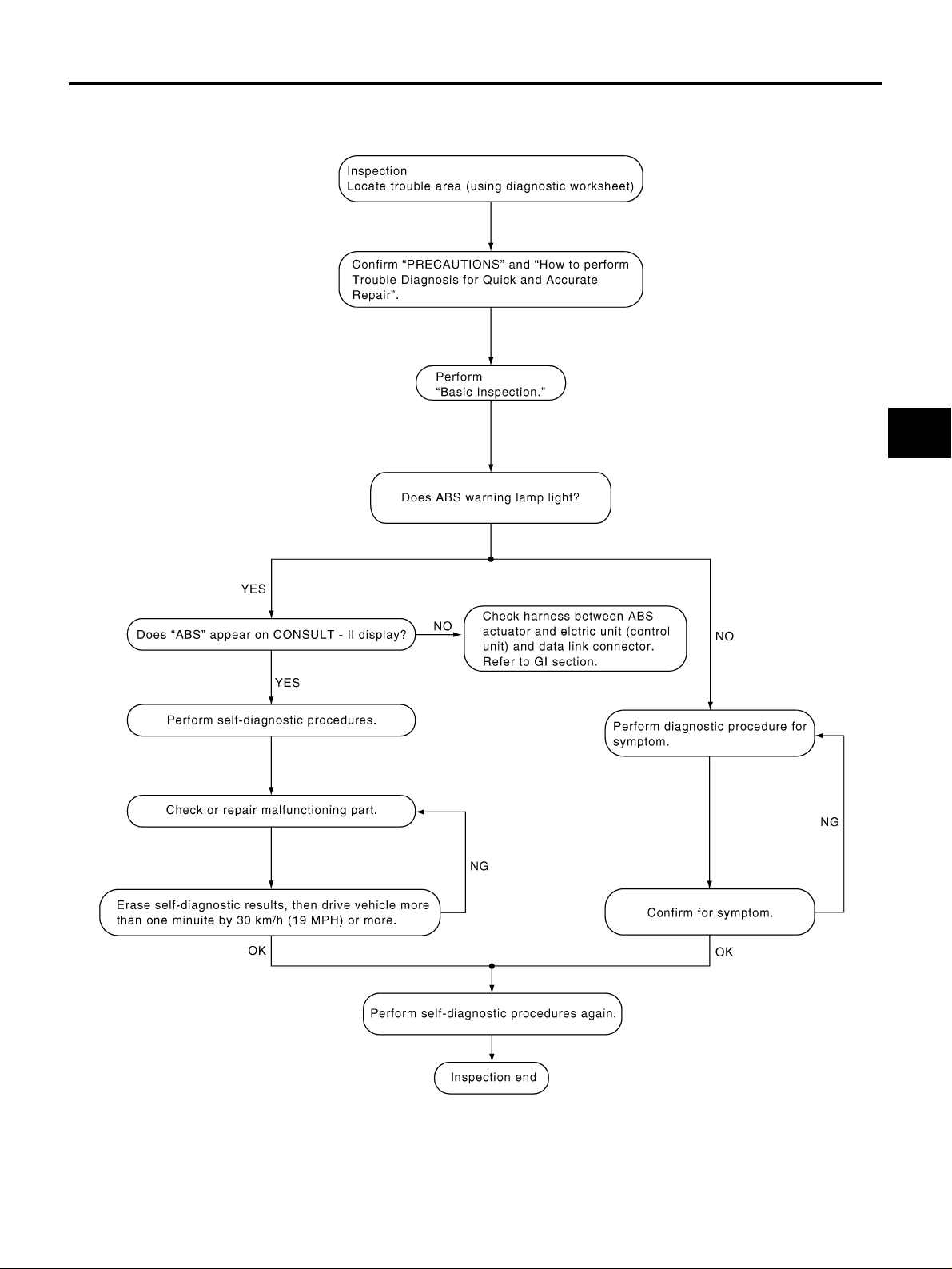

DIAGNOSIS FLOW CHART

TROUBLE DIAGNOSIS

[ABS]

A

B

C

D

E

BRC

G

H

K

M

I

J

L

PFIA0701E

Revision: 2006 July 2006 X-Trail

BRC-9

TROUBLE DIAGNOSIS

ASKING COMPLAINTS

● Complaints vary depending on the person. It is important to clar-

ify the customer's actual remarks.

● Ask the customer about what symp toms are presen t and under

what conditions. Use the information to reproduce the symptom

while driving.

● It is also imp ortant to us e diagnosis sheet so as not to miss vital

information.

EXAMPLE OF DIAGNOSIS SHEET

[ABS]

SBR339B

LFIA0176E

Revision: 2006 July 2006 X-Trail

BRC-10

TROUBLE DIAGNOSIS

[ABS]

Component Parts Location AFS002LY

A

B

C

D

E

BRC

G

SFIA2391E

H

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

BRC-11

TROUBLE DIAGNOSIS

[ABS]

Schematic AFS002LZ

TFWB0019E

Revision: 2006 July 2006 X-Trail

BRC-12

TROUBLE DIAGNOSIS

[ABS]

Wiring Diagram — ABS — AFS002M0

A

B

C

D

E

BRC

G

H

K

M

I

J

L

TFWB0020E

Revision: 2006 July 2006 X-Trail

BRC-13

TROUBLE DIAGNOSIS

[ABS]

TFWB0003E

Revision: 2006 July 2006 X-Trail

BRC-14

TROUBLE DIAGNOSIS

[ABS]

A

B

C

D

E

BRC

G

H

K

M

I

J

L

TFWB0021E

Revision: 2006 July 2006 X-Trail

BRC-15

TROUBLE DIAGNOSIS

[ABS]

TFWB0022E

Revision: 2006 July 2006 X-Trail

BRC-16

TROUBLE DIAGNOSIS

[ABS]

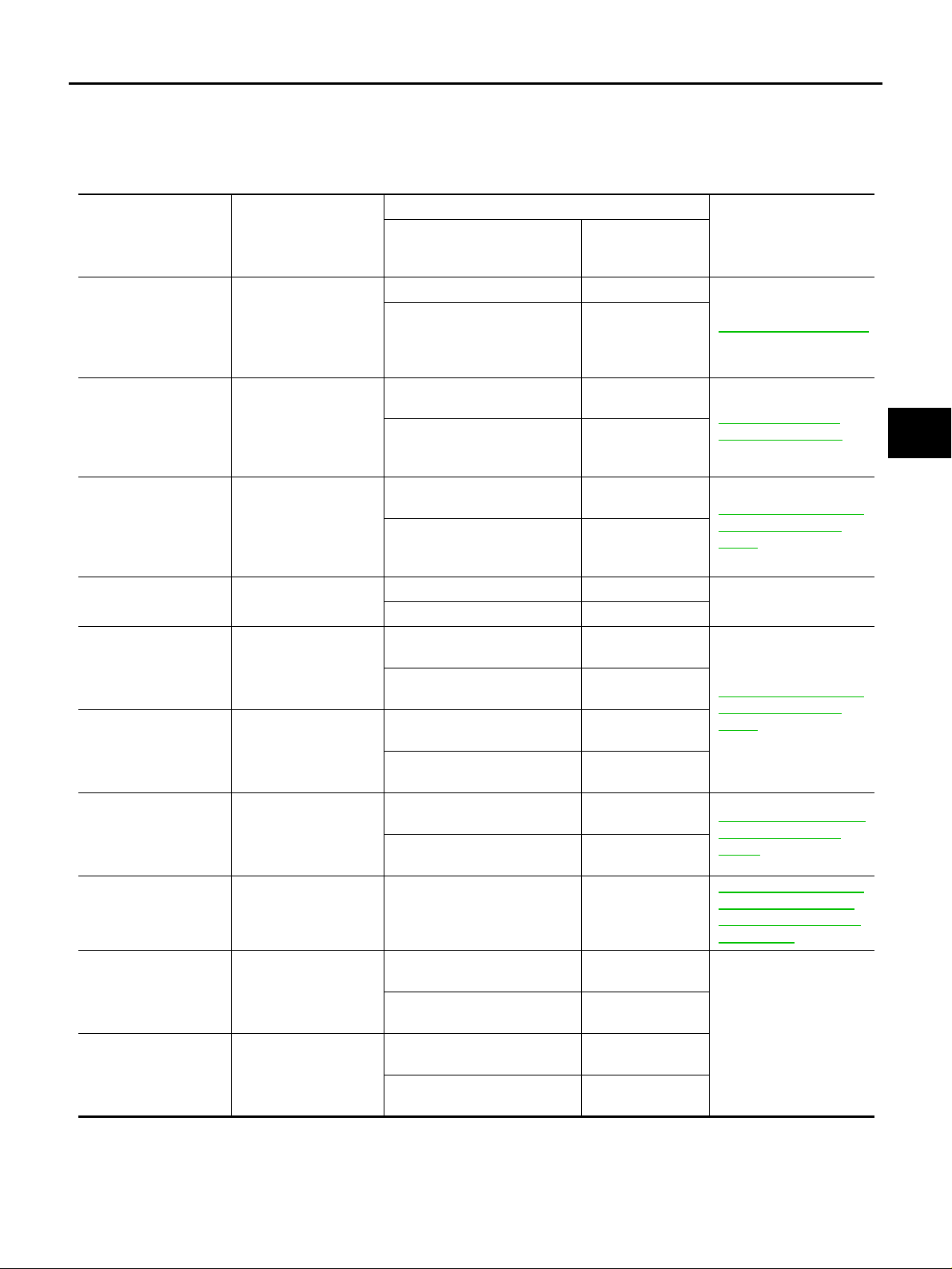

Control Unit Input/Output Signal Standard AFS002M1

REFERENCE VALUE FROM CONSULT-II

CAUTION:

The display shows the co ntrol unit ca lcula tion data, so a normal valu e might be displa yed ev en in the

event the output circuit (harness) is open or short - circulated.

Data monitor

Data monitor item Display item

FR LH SENSOR

FR RH SENSOR

RR LH SENSOR

RR RH SENSOR

DECEL G-SEN 1

DECEL G-SEN 2

ABS IN SOL

ABS OUT SOL

STOP LAMP SW

MOTOR RELAY

ACTUATOR RELAY

ABS WARN LAMP

BATTER Y VOLT

EBD SIGNAL

ABS SIGNAL

EBD FAIL SIG

ABS FAIL SIG

Note 1: Confirm tire pressure is the standard value.

Note 2: ABS warning lamp ON/OFF timing.

ON: When the ignition switch is turned ON or when an err or is detect ed.

OFF: After the ignition switch is turned ON (when syst em is norm al).

Wheel speed calculated using signals

from all four wheel

sensors

Fore-and-aft gravity

detected by G sensor

Operation status of all

solenoid valve

Brake pedal operation

status

Motor and motor relay

operation status

Actuator relay operation status

ABS warning lamp on

condition (Note 2)

Battery voltage supplied to ABS actuator

and electric unit (control unit)

EBD operation

ABS operation

System fail signal status

Vehicle stopped 0 [km/h]

Vehicle running (Note 1)

When vehicle is stopped on

level ground

When G sensor is tilted toward

the front with G sensor mounting nuts removed

When the actuator solenoid

operates or during a fail-safe

When the actuator relay operates and the actuator solenoid

does not operate

Brake pedal depressed ON

Brake pedal not depressed OFF

When the motor relay and

motor are operating

When the motor relay and

motor are not operating

When the actuator relay is

operating

When the actuator relay is not

operating

When ABS warning lamp is

ON

When ABS warning lamp is

OFF

Ignition switch ON 10 - 16 V

EBD active

ABS active

EBD not active

ABS not active

EBD Fail

ABS Fail

EBD normal

ABS normal

Condition

Reference values

in normal opera-

tion

Nearly matches

the speedometer

display (± 10 % or

less)

OFF

ON

ON

OFF

ON

OFF

OFF

ON

ON

OFF

ON

OFF

ON

OFF

Reference: Inspection

item

BRC-25, "

BRC-29, "

(Only AWD Models)"

BRC-28, "

Relay or ABS Motor

Relay"

Stop lamp switch circuit

BRC-28, "

Relay or ABS Motor

Relay"

BRC-24, "

OF ABS WARNING

LAMP"

BRC-27, "

and Electric Unit (Control Unit) Power Supply

and Ground"

EBD system

ABS system

Wheel Sensor"

G Sensor

ABS Actuator

ABS Actuator

INSPECTION

ABS Actuator

A

B

C

D

E

BRC

G

H

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

BRC-17

TROUBLE DIAGNOSIS

[ABS]

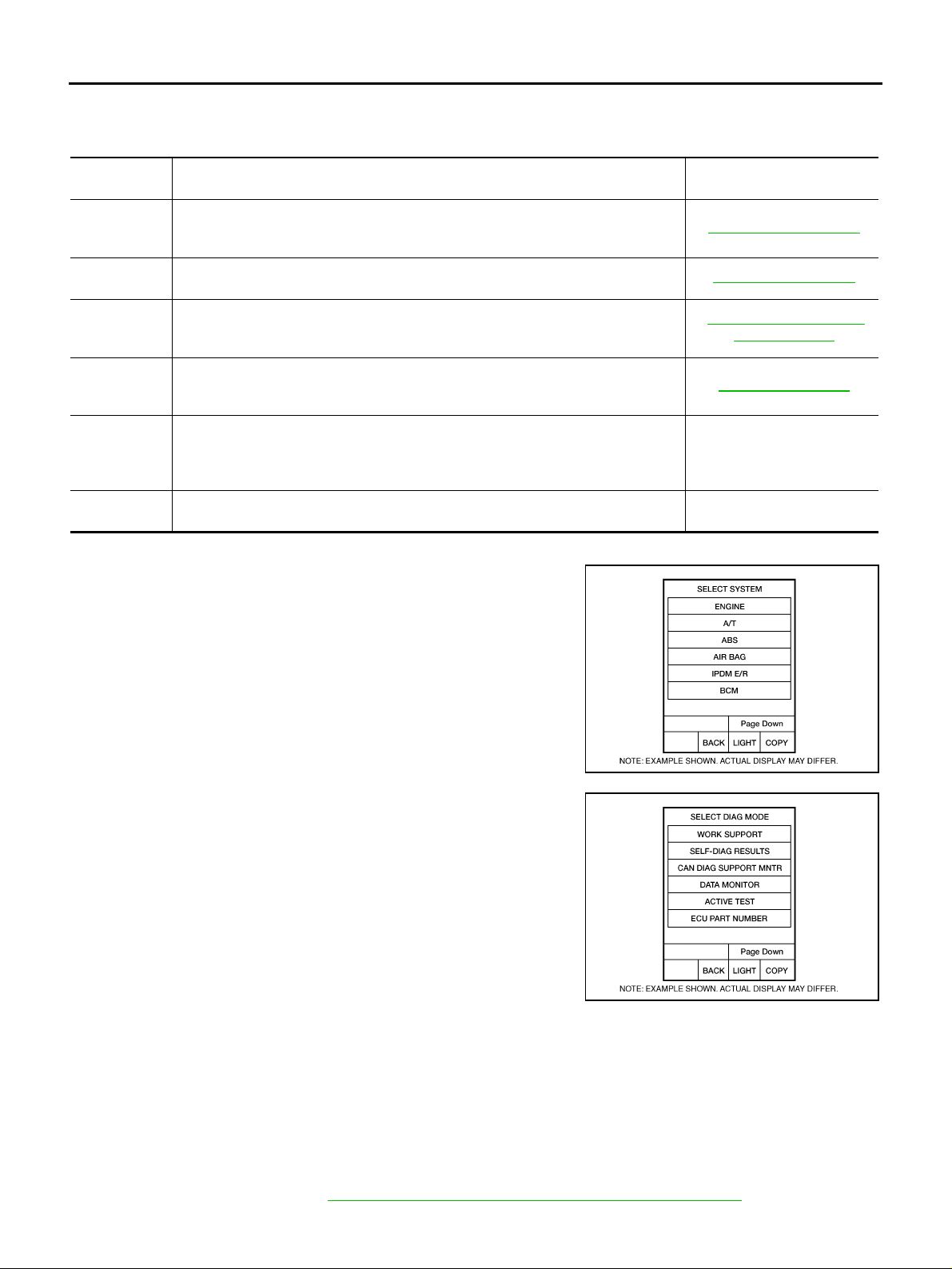

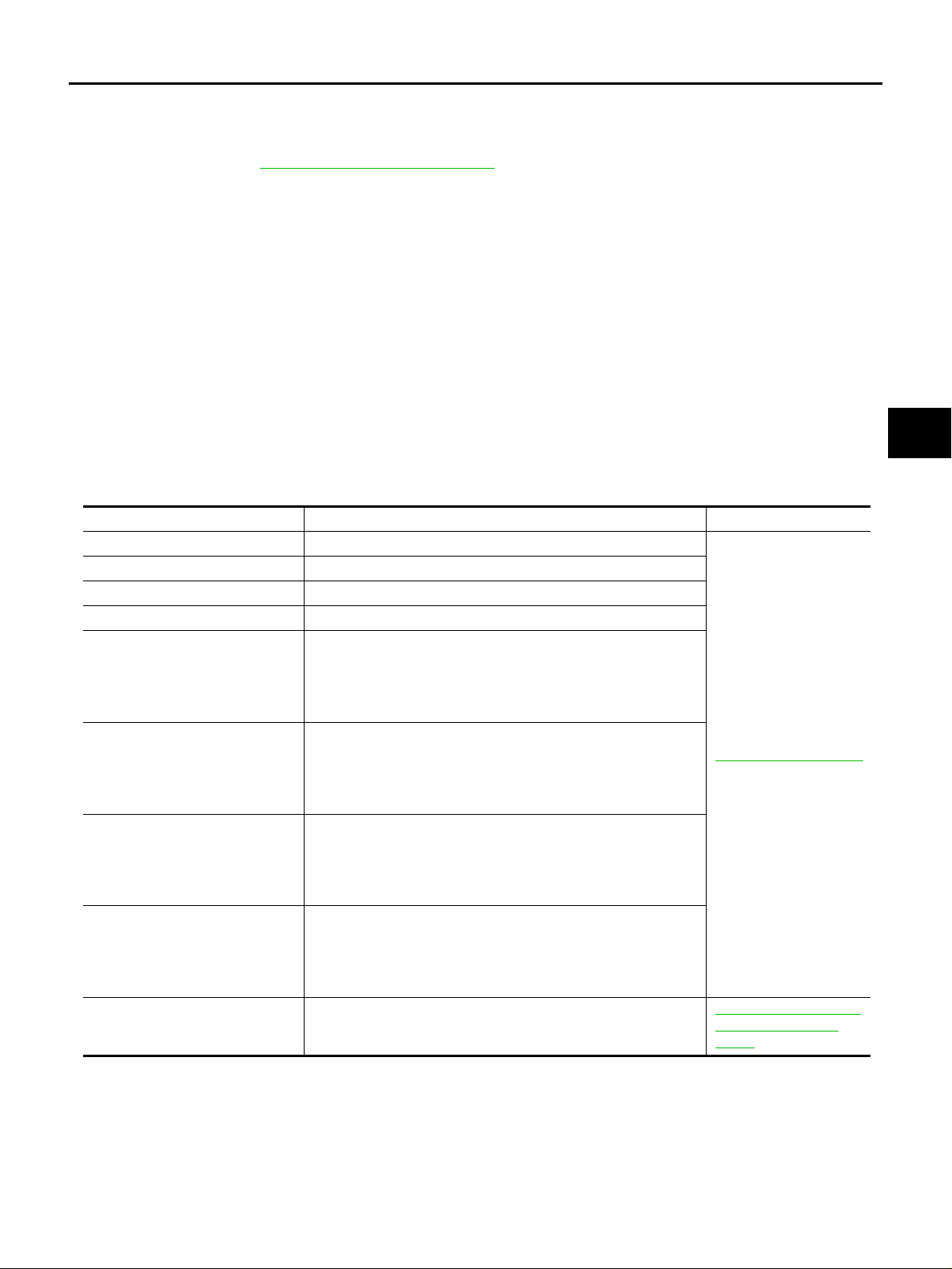

CONSULT-II Functions (ABS) AFS002M2

CONSULT-II MAIN FUNCTION

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

Diagnostic

test mode

SELF-DIAGNOSTIC

RESULTS

DATA MONITOR

CAN DIAG

SUPPORT

MNTR

ACTIVE TEST

FUNCTION

TEST

ECU PART

NUMBER

Self-diagnostic results can be read and erased quickly. BRC-18, "

Input/Output data in the ABS actuator and electric unit (control unit) can be read. BRC-20, "

The result of transmit/receive diagnostic of CAN com m uni cation can be read.

Diagnostic Test Mode in which CONSULT-II drives some actuators apart from the

ABS actuator and electric unit (control unit) and also shifts some parameters in a

specified range.

This mode is used to inform customers when their vehi cl e condition requires periodic maintenance.

ABS actuator and electric unit (control unit) part number can be read. —

Function Reference

Self-Diagnosis"

Data Monitor"

LAN-13, "

“CONSULT-II OPERATION

MANUAL (FUNCTION

CAN Diagnostic

Support Monitor"

BRC-21, "Active Test"

Separate volume

TEST)”

CONSULT-II BASIC OPERATION PROCEDURE

1. Touch “ABS” in the “SELECT SYSTEM” screen.

2. Select the required diagnostic location from the “SELECT DIAG

MODE” screen.

BCIA0030E

BCIA0031E

SELF-DIAGNOSIS

OPERATION PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition sw itch ON.

4. Start engine and drive vehicle at 30 km/h (19 MPH) or more for appro xi ma tely 1 minute.

5. After stopping vehicle, with the engine running, touc h “START (NISSAN BASED VHCL)”, “ABS”, “SELFDIAG RESULTS” in order on the CONSULT-II screen.

If “ABS” is not indicated, go to GI-37, "

Revision: 2006 July 2006 X-Trail

CONSULT-II Data Link Connector (DLC) Circuit" .

BRC-18

TROUBLE DIAGNOSIS

[ABS]

6. The self-dia gn os ti c resu lt s ar e d is pla yed . ( Touch “PRINT” to pr in t out se lf -d ia gn os tic r e sul t s, i f nece ss ar y. )

● Check ABS warn ing lamp if “NO FAILURE” is displayed.

7. Perform the appropriate inspection from the display item list, and repair or replace the malfunction ing

component. Refer to BRC-19, "

8. Start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute.

CAUTION:

When the wheel sensor malfunc tions, a fter inspec ting the w heel se nsor sys tem, the ABS warni ng

lamp will not turn off even when the s ystem is normal unless the vehicle is driving at approx imately 30 km/h (19 MPH) or more for approximately 1 minute.

DISPLAY ITEM LIST" .

A

B

C

ERASE MEMORY

1. Turn ignition switch OFF.

2. Start engine and touch “START (NISSAN BASED VHCL)”, “ABS”, “SELF-DIAG RESULTS”, “ERASE

MEMORY” in order on the CONSULT-II screen to erase the error memory.

CAUTION:

If the error memory is not erased, re-perform the operation from step 4.

3. Perform sel f-diagnosis again, and make sure that diagnostic memory is erased.

4. Drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute as the final inspection, and make

sure that the ABS warning lamp is turned off.

DISPLAY ITEM LIST

Diagnostic item Malfunction is detected when... Check circuit

FR LH SENSOR – 1 Circuit of front LH wheel sensor is open.

RR RH SENSOR – 1 Circuit of rear RH wheel sensor is open.

FR RH SENSOR – 1 Circuit of front RH wheel sensor is open.

RR LH SENSOR – 1 Circuit of rear LH wheel sensor is open.

When the circuit in the front LH wheel sensor is short -circ ui te d.

Or when the sensor power voltage is outside the standard. When

FR LH SENSOR – 2

RR RH SENSOR – 2

FR RH SENSOR – 2

RR LH SENSOR – 2

MAIN RELAY When the control unit detects an error in the actuator relay circuit.

the distance between the wheel sensor and sensor rotor is too

large and the sensor pulse cannot be recogniz ed by t he control

unit.

When the circuit in the rear RH wheel sensor is short- circ ui te d.

Or when the sensor power voltage is outside the standard. When

the distance between the wheel sensor and sensor rotor is too

large and the sensor pulse cannot be recogniz ed by t he control

unit.

When the circuit in the front RH wheel sensor is shor t-ci rcu ited.

Or when the sensor power voltage is outside the standard. When

the distance between the wheel sensor and sensor rotor is too

large and the sensor pulse cannot be recogniz ed by t he control

unit.

When the circuit in the rear LH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When

the distance between the wheel sensor and sensor rotor is too

large and the sensor pulse cannot be recogniz ed by t he control

unit.

BRC-25, "

(Note 1)

BRC-28, "

Relay or ABS Motor

Relay"

Wheel Sen sor"

ABS Actuator

D

E

BRC

G

H

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

BRC-19

TROUBLE DIAGNOSIS

[ABS]

Diagnostic item Malfunction is detected when... Check circuit

FR LH IN ABS SOL

FR LH OUT ABS SOL

RR RH IN ABS SOL

RR RH OUT ABS SOL

FR RH IN ABS SOL

FR RH OUT ABS SOL

RR LH IN ABS SOL

RR LH OUT ABS SOL

LOW POWER VOLTAGE

ABS CONTROLLER

CAN COMM CIRCUIT When there is an error in the CAN communication circuit.

PUMP MOTOR

G SENSOR (Only AWD model)

Note 1: After completing repairs of shorted sensor circuit, when ignition switch is turned ON, ABS warning lamp turns on. Make sure that

ABS warning lamp turns off w hile driving vehi cle at 30 km/h (19 MPH) or m ore for approximat ely 1 minute according to se lf-diagnosis

procedure. In addition, if wheel sensor 2 is displ ay ed fo r wheel s, check wheel sensor circuit and also check control unit power voltage.

Note 2: When e rrors ar e detected in seve ral syst ems, in cluding CAN com municat ion c ircuit [ U1000 ], troubl eshoot CA N co mmun ication

circuit. Refer to LAN-16, "

CAN COMMUNICATION" .

When the control unit detects an error in the front left inlet solenoid circuit.

When the control unit detects an error in the front left outlet solenoid circuit.

When the control unit detects an error in the rear right inlet solenoid circuit.

When the control unit detects an error in the rear right outlet solenoid circuit.

When the control unit detects an error in the front right inlet solenoid circuit.

When the control unit detects an error in the front right outlet

solenoid circuit.

When the control unit detects an error in the rear left inlet solenoid circuit.

When the control unit detects an error in the rear left outlet solenoid circuit.

When the ABS actuator and electric unit (control unit)

power voltage is lower than normal.

When there is an internal error in the ABS actuator and electric

unit (control unit).

During actuator motor operation with ON, when actuator motor

turns OFF or when control line for actuator motor relay is open.

G sensor is malfunctioning, or signal line of G sensor is ope n or

shorted.

BRC-28, "

Relay or ABS Motor

Relay"

BRC-27, "

and Electric Unit (Control

Unit) Power Supply and

Ground"

BRC-27, "

and Electric Unit (Control

Unit)"

BRC-31, "CAN Communication" (Note 2)

BRC-28, "

Relay or ABS Motor

Relay"

BRC-29, "

(Only AWD Models)"

ABS Actuator

ABS Actuator

ABS Actuator

ABS Actuator

G Sensor

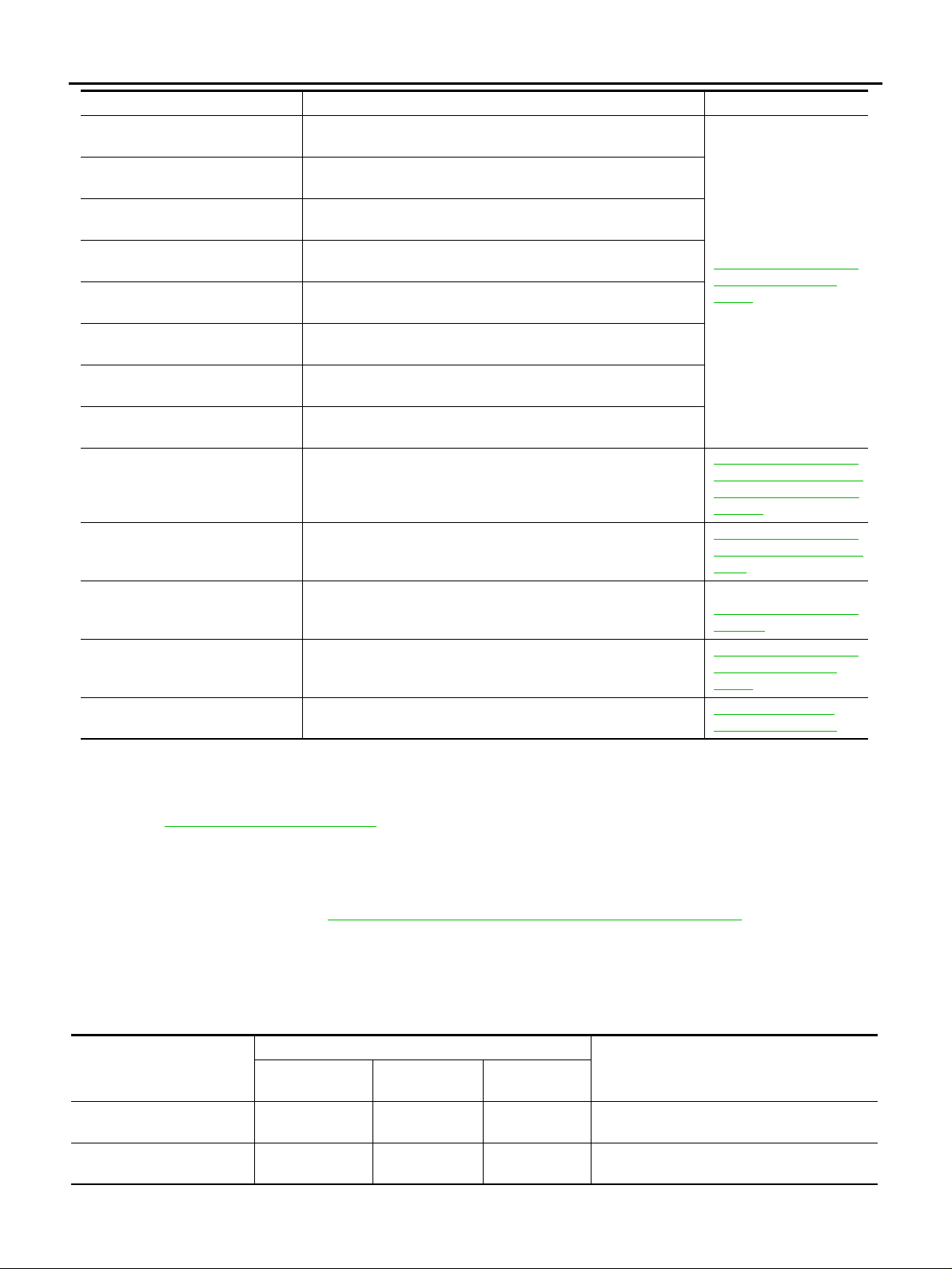

DATA MONITOR

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DATA MONITOR” in order on the CONSULT-II screen.

If “ABS” is not indicated, go to GI-37, "

CONSULT-II Data Link Connector (DLC) Circuit" .

2. At the monitor item selecti on screen, touch one of th e items “ECU INPUT SIGNALS”, “MA IN SIGNALS”

or. “SELECTION FROM MENU”.

3. Touch “START” to proceed to the data monitor screen.

DISPLAY ITEM LIST

×: Standard –: Not applicable

SELECT MONITOR ITEM

Data monitor item (Unit )

FR LH SENSOR

[km/h]

FR RH SENSOR

[km/h]

Revision: 2006 July 2006 X-Trail

ECU INPUT SIG-

NALS

×××

×××

MAIN SIGNALS

SELECTION

FROM MENU

BRC-20

Wheel speed calculated by front LH whee l

sensor signal is displayed.

Wheel speed calculated by front RH wheel

sensor signal is displayed.

Remarks

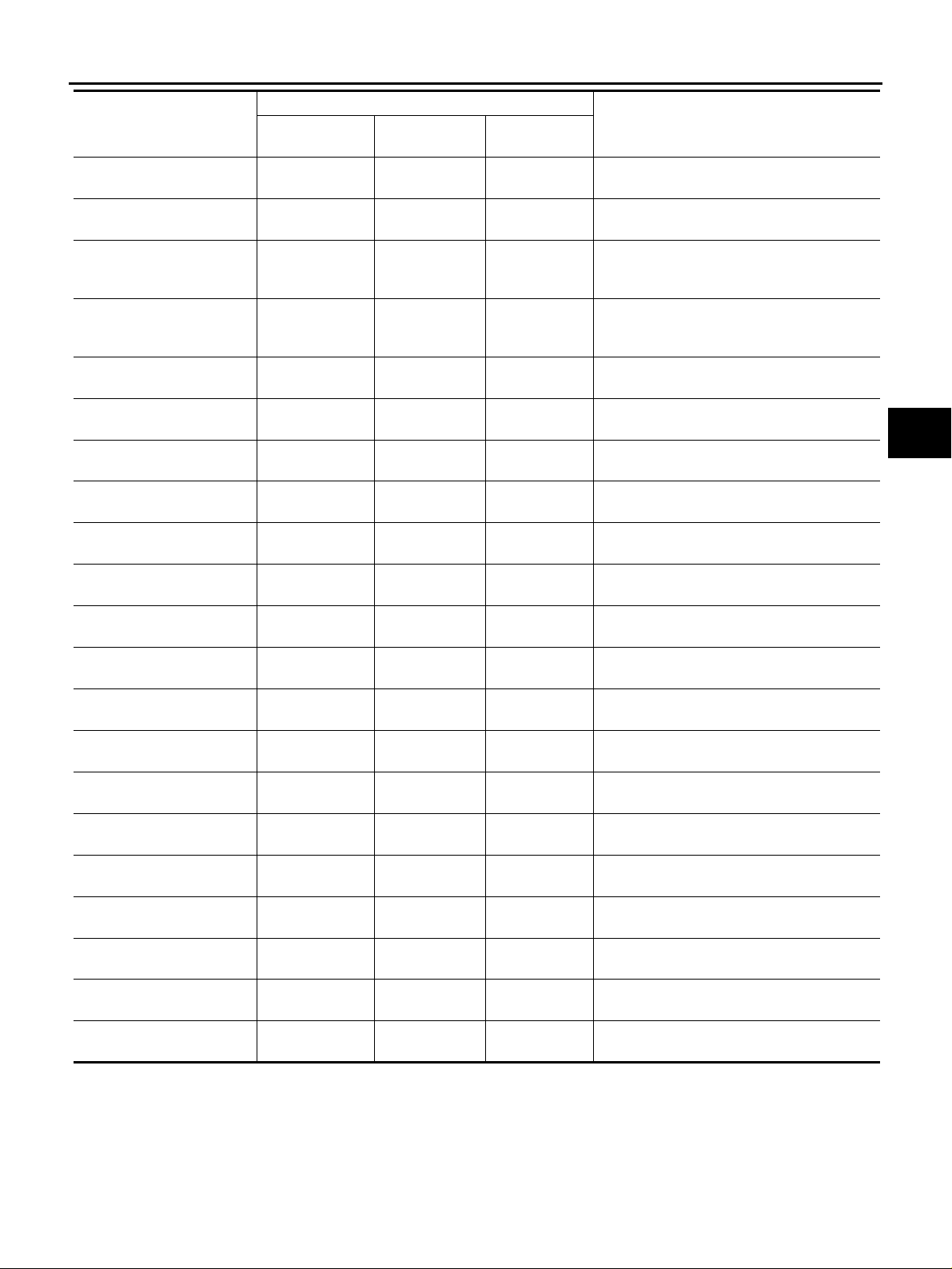

TROUBLE DIAGNOSIS

[ABS]

Data monitor item (Unit)

RR LH SENSOR

[km/h]

RR RH SENSOR

[km/h]

DECEL G-SEN 1

(ON/OFF)

(Only AWD model)

DECEL G-SEN 2

(ON/OFF)

(Only AWD model)

FR LH IN SOL

(ON/OFF)

FR LH OUT SOL

(ON/OFF)

RR RH IN SOL

(ON/OFF)

RR RH OUT SOL

(ON/OFF)

FR RH IN SOL

(ON/OFF)

FR RH OUT SOL

(ON/OFF)

RR LH IN SOL

(ON/OFF)

RR LH OUT SOL

(ON/OFF)

STOP LAMP SW

(ON/OFF)

MOTOR RELAY

(ON/OFF)

ACTUATOR RLY

(ON/OFF)

ABS WARN LAMP

(ON/OFF)

BATTERY VOLT

(V )

EBD SIGNAL

(ON/OFF)

ABS SIGNAL

(ON/OFF)

EBD FAIL SIG

(ON/OFF)

ABS FAIL SIG

(ON/OFF)

SELECT MONITOR ITEM

ECU INPUT SIG-

NALS

×××

×××

×××G sensor 1 (ON/OFF) status is displayed.

×××G sensor 2 (ON/OFF) status is displayed.

– ××

– ××

– ××

– ××

– ××

– ××

– ××

– ××

×××

– ××

– ××

– ××

×××

––× EBD operation (ON/OFF) status is displayed.

––× ABS operation (ON/OFF) status is displayed.

––×

––×

MAIN SIGNALS

SELECTION

FROM MENU

Wheel speed calculated by rear LH wheel

sensor signal is displayed.

Wheel speed calculated by rear RH wheel

sensor signal is displayed.

Front left inlet ABS solenoid valve (ON/OFF)

status is displayed.

Front left outlet ABS solenoid valve (ON/OFF)

status is displayed.

Rear right inlet ABS solenoid valve (ON/OFF)

status is displayed.

Rear right outlet ABS solenoid valve (ON/

OFF) status is displayed.

Front right inlet ABS solenoid valve (ON/OFF)

status is displayed.

Front right outlet ABS solenoid valve (ON/

OFF) status is displayed.

Rear left inlet ABS solenoid valve (ON/OFF)

status is displayed.

Rear left outlet ABS solenoid valve (ON/OFF)

status is displayed.

Stop lamp switch (ON/OFF) status is displayed.

ABS motor relay (ON/OFF) condition is displayed.

ABS actuator relay (ON/OFF) status is displayed.

ABS warning lamp (ON/OFF) status is displayed.

The voltage supplied to the ABS actuator and

electric unit (control unit) is displayed.

EBD fail-safe signal (ON/OFF) status is displayed.

ABS fail-safe signal (ON/OFF) status is displayed.

Remarks

A

B

C

D

E

BRC

G

H

I

J

K

L

M

ACTIVE TEST

CAUTION:

● Do not perform ACTIVE TEST while driving vehicle.

● Make sure to completely bleed air from the brake system.

● Active test cannot be performed when ABS or EBD operation is malfunction.

Revision: 2006 July 2006 X-Trail

BRC-21

TROUBLE DIAGNOSIS

[ABS]

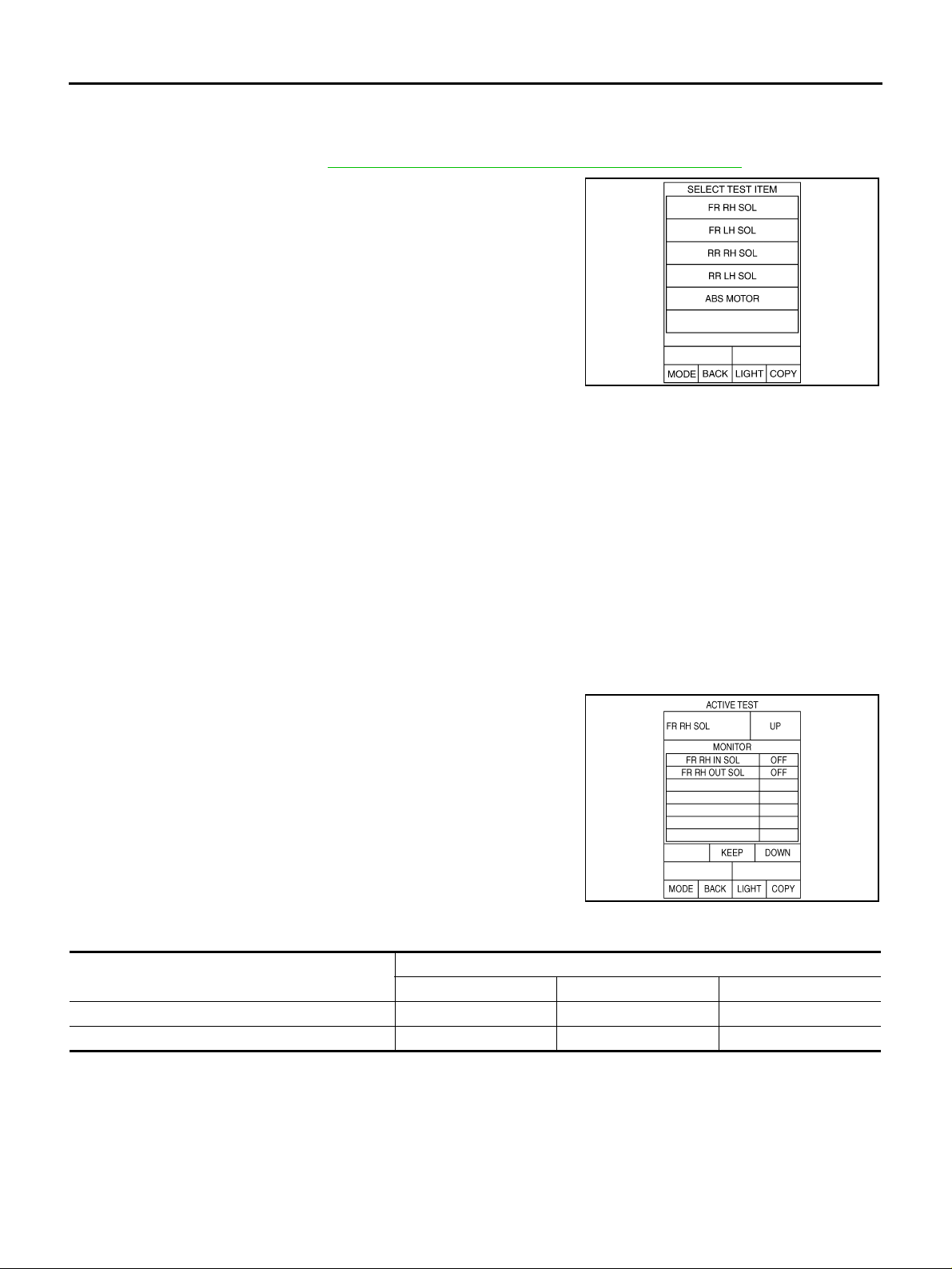

OPERATION PROCEDURE

1. Connect CONSULT-II and CONVERTER to data link connector and start engine.

2. Touch “START (NISSAN BASED VHCL)”, “ABS”, “ACTIVE TEST” in order on the CONSULT-II screen.

If “ABS” is not indicated, go to GI-37, "

3. The “ SELECT TEST ITEM” screen is displayed.

4. Touch necessary test item.

5. Touch “START” with “MAIN SIGNALS” line inverted.

6. ACTIVE TEST screen will be displayed, so perform the following test.

● Solenoid valve

● ABS motor

NOTE:

● When active tes t is pe r for me d whi l e de pre ssi n g peda l, pe da l dep r ess io n amou nt wil l cha ng e, bu t t hi s

is normal.

● Approximately 10 seconds after operation has begun, “TEST STOP” will be displayed.

● To perform a retest after “TEST STOP” is displayed, touch “BACK” and perform test from step 3.

CONSULT-II Data Link Connector (DLC) Circuit" .

SFIA2085E

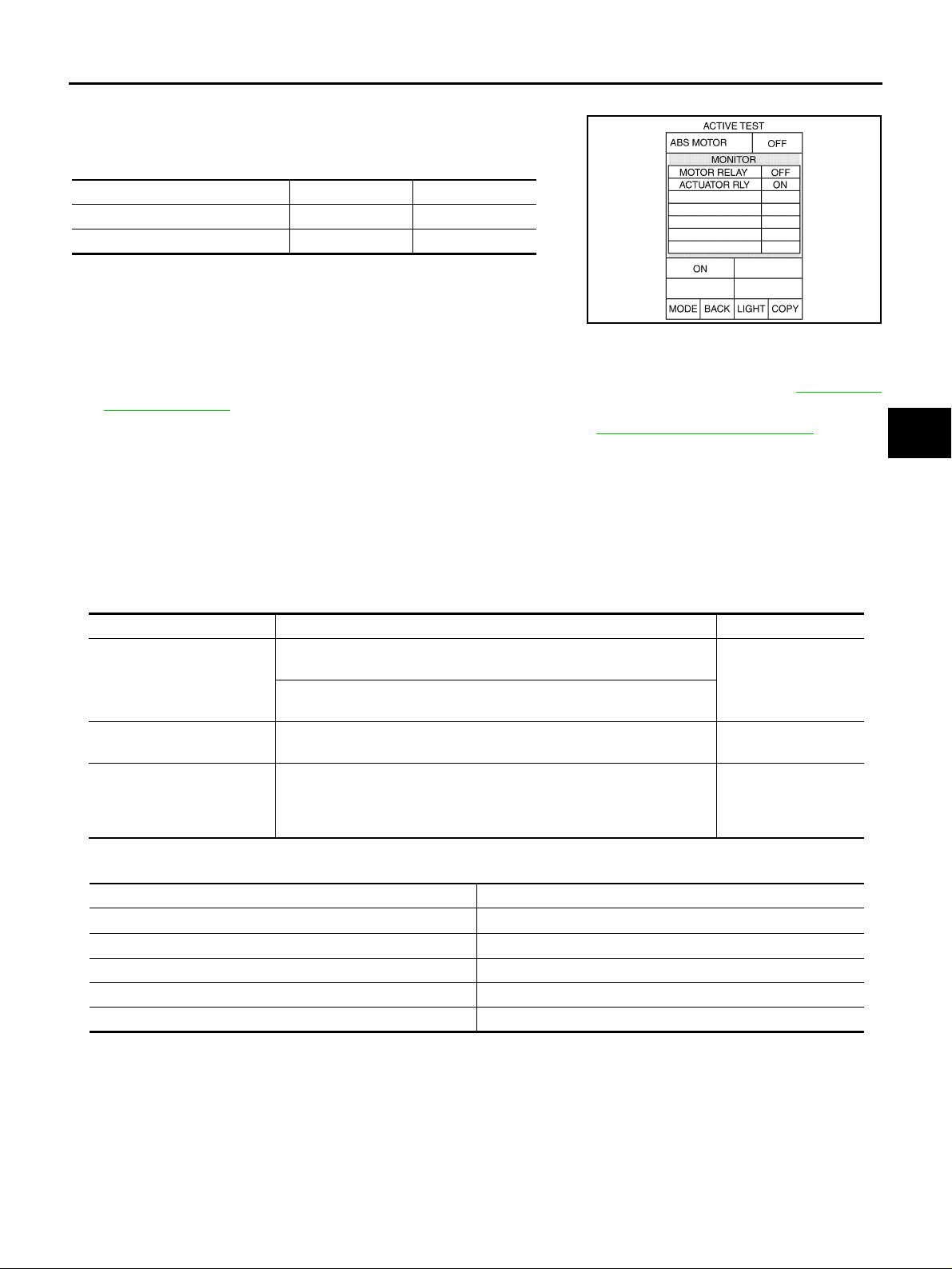

SOLENOID VALVE

NOTE:

The example shown is for the front right wheel. The procedure for the other wheels is the same as given

below.

1. For ABS solenoid valve, touch “UP”, “KEEP”, and “DOWN”.

Then use screen monitor to make sure solenoid valve op erates

as shown in Solenoid Valve Operation Chart.

SFIA0678E

Solenoid Valve Operation Chart

Operation

FR RH IN SOL OFF ON ON

FR RH OUT SOL OFF OFF ON*

*: ON for 1 to 2 seconds after the touch, and then OFF

UP KEEP DOWN

ABS solenoid valve

Revision: 2006 July 2006 X-Trail

BRC-22

TROUBLE DIAGNOSIS

ABS MONITOR

Touch “ON”, “OFF” of the display screen, and make sure if ABS

motor relay and ABS actuator relay are operating as given in the following table.

Operation ON OFF

MOTOR RELA Y ON OFF

ACTUATOR RLY ON ON

[ABS]

A

B

C

SFIA0593E

For Fast and Accurate Diagnosis AFS002M4

PRECAUTIONS FOR DIAGNOSIS

● Be sure to check the procedures of “How to Perform Trouble Diagnosis” in advance. Refer to GI-4, "Gen-

eral Precautions" .

● Always erase memory after completing trouble diagnosis. Refer to BRC-19, "ERASE MEMORY" .

● When checking continuity and voltage between units, be sure to check for disconnection, looseness,

bend, or collapse for connector terminals. Repair or replace applicable part if any non-standard condition

is detected.

● Intermittent malfunctions may be caused by a poor connection in the harness, connectors, and terminals.

Move harnesse s, ha rness co nnector s, an d termin als by hand to make sure all conne ctions are sol id and

undamaged.

● Do not to forcibly extend any connector terminal if a circuit tester is used for the check.

● The symptom shown in the table be low may occur, but the system is operat ing normally.

Symptom Symptom description Result

This is the operation noise of the motor in the actuator, and there may

Motor operation noise

System operation check

noise

ABS operation (Longer stopping distance)

be a slight sound during ABS operation.

Just after the engine starts, the motor operating noise may be hea rd.

This is a normal status of the system operation check.

When engine starts, “click” noise may be heard from engine room. This

is normal status of system operation check.

When driving on roads with a low coefficient of friction, suc h as snow y

roads or gravel roads, the stopping distance is sometimes longer for

vehicles equipped with ABS. Therefore, when driving on such roads,

drive at a sufficiently reduced speed to be safe.

Normal

Normal

Normal

D

E

BRC

G

H

I

J

K

L

ON and OFF Timing for ABS Warning Lamp

×: ON —: OFF

Condition ABS warning lamp

Ignition switch OFF −

When ignition switch is turned ON ×

After ignition switch is turned ON (Whe n syst em is norm al ) −

ABS error ×

EBD error ×

Basic Inspection AFS002M5

BRAKE FLUID LEVEL, LEAKAGE AND BRAKE PAD

1. Check fluid le vel in the brake fluid reservoir tank. Refill the brake fluid if fluid level is low.

2. Check the area around the brake piping and ABS actuator and electric unit (control unit) for leakage. If

leakage or oozi ng is detected, check as follows:

● If ABS actuator and electric unit (control unit) connections are loose, tighten piping to the specified

torque. Check again for leakage, and make sure that there is no fluid leakage.

Revision: 2006 July 2006 X-Trail

BRC-23

M

TROUBLE DIAGNOSIS

[ABS]

● If the flare nuts a t t he co nnec tion s and the thread s of the a ctua tor are dam aged , repl ace t he da mag ed

parts. Then check again for leakage, and make sure that there is no fluid leakage.

● If leakage or oozing is detected on parts other than actuator connections, wipe with a clean cloth and

check again. I f there is still leakage or oozing, replace the damaged part.

● If leakage o r oozing is detected on actuator bo dy, wipe with a clean clot h and chec k again. If t here is

still leakage or oozing, replace ABS actuator and electric unit (control unit).

CAUTION:

ABS actuator and electric unit (control unit) cannot be disassembled.

3. Check brake disc ro to r an d pads . F ron t di sc ro tor: BR-30, "

25, "PAD WEAR INSPECTION" , Rear disk rotor: BR-35, "DISC ROTOR INSPECTION" , Rear pad : BR31, "PAD WEAR INSPECTION" .

POWER SUPPLY CIRCUIT TERMINAL LOOSENESS AND BATTERY

Check battery for looseness on the battery positive/negative terminals and ground connection. Also make sure

that battery voltage does not drop.

INSPECTION OF ABS WARNING LAMP

1. Make sure that when the ignition switch is turned ON, the ABS warning lamp turns on. If it is does not turn

on, perform CAN communication circuit diagnosis. Refer to BRC-31, "

warning lamp if there is no malfunction in CAN commu nication circuit. Refer to BRC-35, "

Lamp Indication Is Not Normal" .

2. Check if the ABS warning lamp turns off after the ignition switch is turned ON after the engine is started. If

it does not turn off, perform self-diagnosis.

3. If ABS warning lamp has not turned off after 10 seconds the engine has been started, perform self-diagnosis of the ABS actuator and electri c un it (co ntro l un it).

4. Always erase the self-diagnostic results after completing self-diagnosis. Refer to BRC-19, "

ORY" .

DISC ROTOR INSPECTION" , Front pad: BR-

CAN Communication" . Check ABS

ABS Warning

ERASE MEM-

Revision: 2006 July 2006 X-Trail

BRC-24

TROUBLE DIAGNOSIS FOR SYSTEM

[ABS]

TROUBLE DIAGNOSIS FOR SYSTEM PFP:00000

Wheel Sensor AFS002M6

INSPECTION PROCEDURE

Check each part according to CONSULT-II self-diagnostic results, and then identify the parts to be replaced.

CAUTION:

Do not check between wheel sensor terminals.

1. CHECK TIRES

Check air pressure, wea r and size.

Are air pressur e, wear and size within standard values?

YES >> GO TO 2.

NO >> Adjust air pressure, or replace tire.

A

B

C

D

2. CHECK SENSOR AND SENSOR ROTOR

● Check sensor rotor for damage.

● Check wheel sensor for damage, disc onnection or looseness.

OK or NG

OK >> GO TO 3.

NG >> Repair wheel sensor mount or replace sensor rotor. Refer to BRC-37, "

36, "WHEEL SENSORS" .

3. CHECK SELF-DIAGNOSTIC RESULTS

Check the self-diagnostic results.

Self-diagnostic results

FR RH SENSOR-1, -2

FR LH SENSOR-1, -2

RR RH SENSOR-1, -2

RR LH SENSOR-1, -2

Is above displayed on self-diagnosis display?

YES >> GO TO 4.

NO >> INSPECTION END

4. CHECK CONNECTOR

SENSOR ROTOR" , BRC-

E

BRC

G

H

I

J

K

L

1. Turn ignition switch OFF and di sconnect ABS actuator and el ectric unit (cont rol unit) conne ctor and malfunctioning wheel sensor connector. Check terminal to see if it is deformed, disconnected, loose, etc., and

repair or replace it if any malfunction condition is found.

2. Reconnect connectors, drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute, and then

perform self-diagnosis.

Is the result of self-diagnosis normal?

YES >> Connector terminal contact is loose, dama ged, open or shorted.

NO >> GO TO 5.

Revision: 2006 July 2006 X-Trail

BRC-25

M

TROUBLE DIAGNOSIS FOR SYSTEM

5. CHECK WHEEL SENSOR HARNESS

1. Turn ignition switch OFF and disconnect malfunctioning wheel

sensor connector and ABS actuator and electric unit (control

unit) connector.

2. Check continuity between terminals. (Also check continuity

when the steering wheel is turned right and left and when the

sensor harness inside the wh eel house is moved.)

Power supply circuit Signal circuit Gr ound circuit

ABS actuator

and electric

Wheel

Front RH (E17) 24 1 9 2 24, 9

Front LH (E59) 22 1 7 2 22, 7

Rear RH (B130) 28 1 13 2 28, 13

Rear LH (B126) 26 1 11 2 26, 11

unit (control

unit)

harness con-

nector E69

Wheel sensor

(harness con-

nector)

ABS actuator

and electric

unit (control

unit)

harness con-

nector E69

Wheel sensor

(harness con-

nector)

ABS actuator and elec-

tric unit (control unit)

harness connector E69

(signal)

[ABS]

SFIA2015E

Ground

—

Power supply circuit : Continuity should exist.

Signal circuit : Continuity should exist.

Ground circuit : Continuity should not exist.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace harness and connector that have malfunction.

6. CHECK WHEEL SENSOR

1. Replace w heel sensor tha t resulted in malfunction by self-diagnosis.

2. Reconnect conn ectors, dri ve vehicle a t 30 km/h (19 MPH) or mo re for approx imately 1 min ute, and th en

perform self-diagn os is .

Self-diagnostic results

FR RH SENSOR-1, -2

FR LH SENSOR-1, -2

RR RH SENSOR-1, -2

RR LH SENSOR-1, -2

Is above displayed on self-diagnosis display?

YES >> Wheel sensor has malfunction.

NO >>

● Replace ABS actuator and electric unit (control unit).

● Perform to self-diagnosis again, and make sure that the result shows “NO DTC IS DETECTED.

FURTHER TESTING MAY BE REQUIRED”.

Revision: 2006 July 2006 X-Trail

BRC-26

TROUBLE DIAGNOSIS FOR SYSTEM

[ABS]

ABS Actuator and Electric Unit (Control Unit) AFS002M7

INSPECTION PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

A

Check self-diagn os tic res ults.

Self-diagnostic results

ABS CONTROLLER

Is above displayed on self-diagnosis display?

YES >> Replace ABS actuator and electric unit (control unit), and perform self-diagnosis again.

NO >> INSPECTION END

ABS Actuator and Electric Unit (Control Unit) Power Supply and Ground AFS002M8

INSPECTION PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Check self-diagn os tic res ults.

Self-diagnostic results

LOW POWER VOLTAGE

Is above displayed on self-diagnosis display?

YES >> GO TO 2.

NO >> INSPECTION END

2. CHECK CONNECTOR

1. Turn ignition switch OFF, disconnect the ABS actuator and electric unit (control unit) connector, and

check the terminal for deformation, disconnection, looseness, and so on. If there is a malfunction, repair

or replace the terminal.

2. Connect the connector securely and perform se lf-diagnosis again.

Is the result of self-diagnosis normal?

YES >> Connector terminal contact is loose, dama ged, open or shorted.

NO >> GO TO 3.

B

C

D

E

BRC

G

H

I

J

K

Revision: 2006 July 2006 X-Trail

BRC-27

L

M

TROUBLE DIAGNOSIS FOR SYSTEM

[ABS]

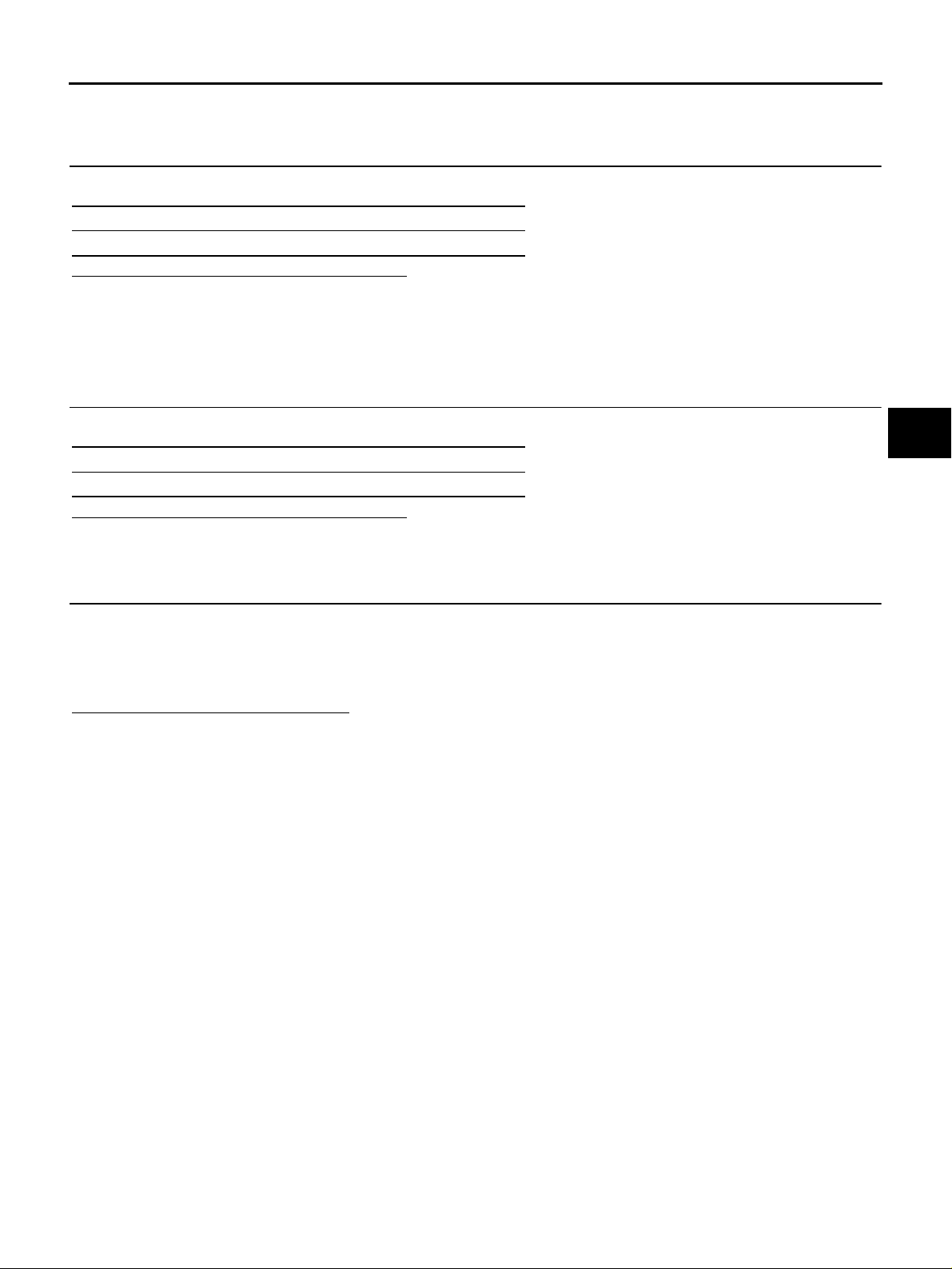

3. CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY AND GROUND

1. Turn ignition s witch OFF and disconnect ABS actuator and electric unit (control unit) connector.

2. Turn ignition switch ON or OFF, and then check continuity and voltage between each connector terminal

and ground.

ABS actuator and electric

Signal

Power

supply

Signal

Ground 16, 30 —

unit (control unit)

harness connector E69

29

ABS actuator and electric

unit (control unit)

harness connector E69

Ground

—

—

Ground

Measure-

ment con-

dition

Ignition

switch ON

Ignition

switch

OFF

Measure-

ment con-

dition

Ignition

switch OFF

Volrtage

Battery voltage

(Approx. 12 V)

Approx. 0 V

SFIA2087E

Continuity

Yes

OK or NG

OK >> Check battery for terminal looseness, low voltage, etc. If

any malfunction is found, repair malfunctioning parts.

NG >> Corresponding harness circuit malfunctions. Repair cir-

cuit, and perform self-diagnosis again.

SFIA2089E

ABS Actuator Relay or ABS Motor Relay AFS002M9

INSPECTION PROCEDURE

1. CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY AND GROUND

CIRCUIT

Check the self-diag nostic results.

Self-diagnostic results

FR LH IN ABS SOL

FR LH OUT ABS SOL

RR RH IN ABS SOL

RR RH OUT ABS SOL

FR RH IN ABS SOL

FR RH OUT ABS SOL

RR LH IN ABS SOL

RR LH OUT ABS SOL

MAIN RELAY

PUMP MOTOR

Is above displayed on self-diagnosis display?

YES >> GO TO 2.

NO >> INSPECTION END

Revision: 2006 July 2006 X-Trail

BRC-28

TROUBLE DIAGNOSIS FOR SYSTEM

[ABS]

2. CHECK CONNECTOR

1. Turn ignition switch OFF, disconnect the ABS actuator and electric unit (control unit) connector, and check

the terminal for deformation, disconnection, looseness, and so on. If there is a malfunction, repair or

replace the terminal.

2. Connect the connector securely and perform se lf-diagnosis again.

Is the result of self-diagnosis normal?

YES >> Connector terminal contact is loose, dama ged, open or shorted.

NO >> GO TO 3.

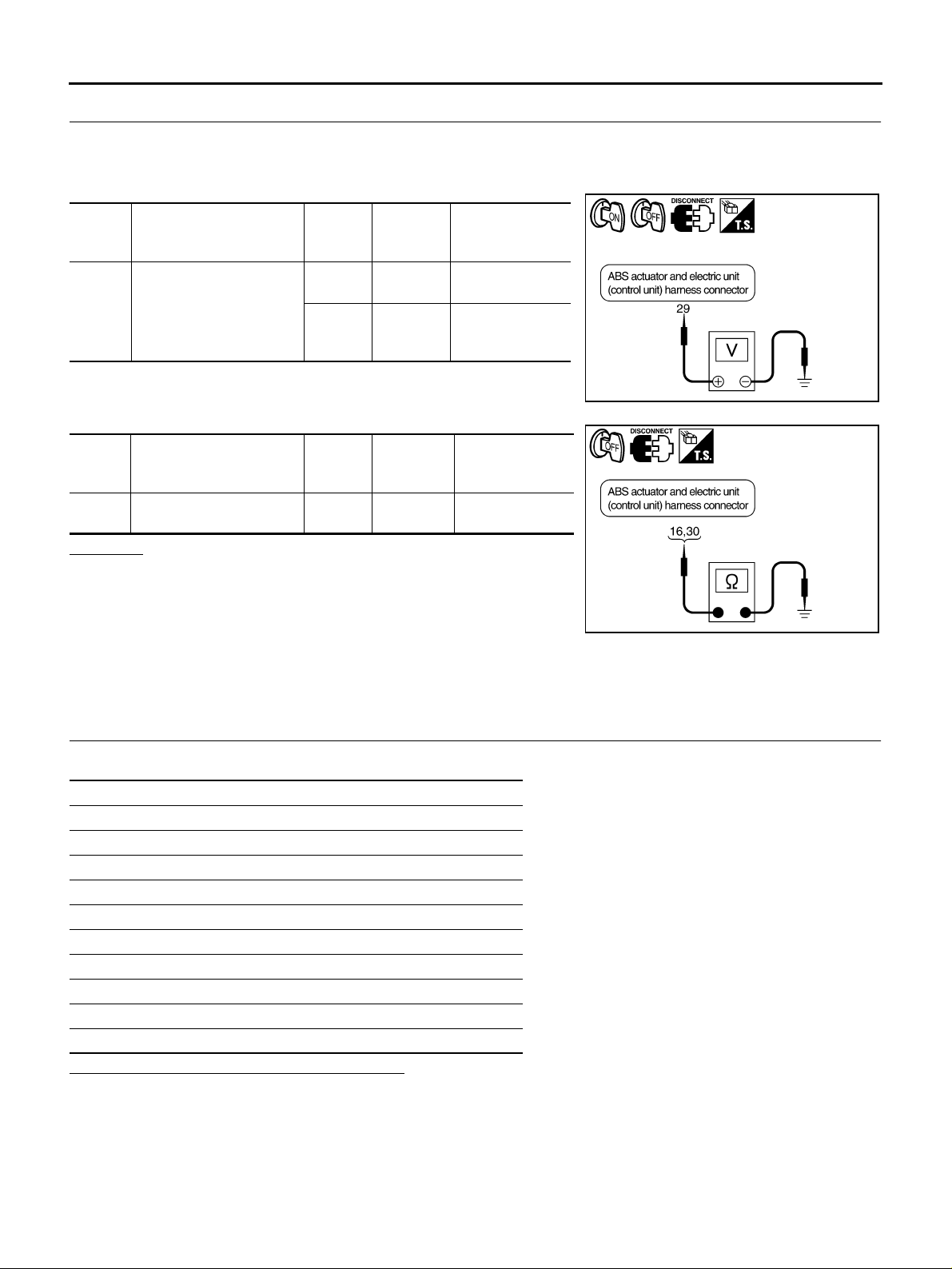

3. CHECK ABS ACTUATOR RELAY OR ABS MOTOR RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector.

2. For the ABS actuator relay, measure voltage between the harness connector terminal 15 and ground. For the ABS motor

relay, measure voltage between the harn ess conn ector term inal

1 and ground.

ABS actuator and electric unit (control

unit) harness connector E69

1, 15 —

OK or NG

OK >> GO TO 4.

NG >> Circuit malfunction between t he battery and ABS actua-

tor and electric unit (control unit). Repair circuit.

Ground Voltage

Battery voltage (Approx.

12 V)

SFIA2110E

A

B

C

D

E

BRC

G

H

4. CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) GROUND CIRCUIT

Check continuity between ABS actuator and electric unit (control

unit) harness connector E69 terminals 16, 30 and ground.

ABS actuator and electric unit (control

unit) harness connector E69

16, 30 — Yes

Ground Continuity

OK or NG

OK >> Replace ABS actuator and electric unit (control unit).

NG >> Open or short in harness. Repair or replace the harness,

and perform self-diagnosis again.

SFIA2089E

G Sensor (Only AW D Models) AFS002P9

INSPECTION PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Check the self-diagnostic results.

Self-diagnostic results

G SENSOR

Is above displayed on self-diagnosis display?

YES >> GO TO 2.

NO >> INSPECTION END

I

J

K

L

M

Revision: 2006 July 2006 X-Trail

BRC-29

TROUBLE DIAGNOSIS FOR SYSTEM

[ABS]

2. CHECK CONNECTOR

1. Turn ignition switch OFF, disconnect the ABS actuator and electric unit (control unit) and G sensor connector, and check th e t erm in al for def orm at ion , di sc on nect i on , loo sen es s, and so o n. If th er e is a ma lf u nction, repair or replace the terminal.

2. Reconnect connector securely, and perform self-diagnosis.

Is the result of self-diagn os is norm al ?

YES >> Connector terminal contact is loose, damaged, open or shorted.

NO >> GO TO 3.

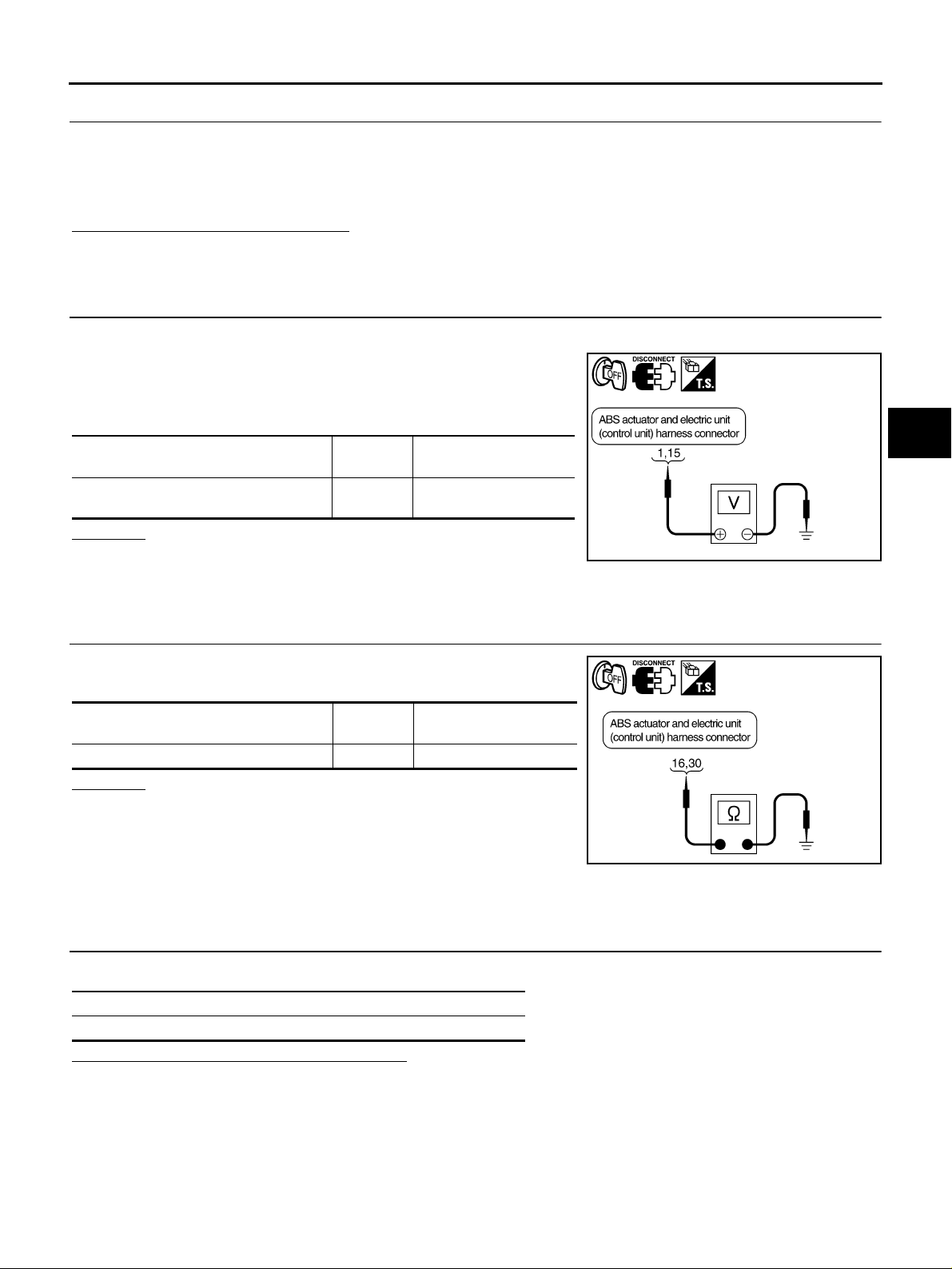

3. CHECK G SENSOR HARNESS

1. Turn ignition switch OFF and disconn ect G sensor and ABS a ctuator and elec tric unit (control u nit) connectors.

2. Check continuity betwee n G sensor harness connecto r M57 and ABS actuator and electric unit (control

unit) harness connector E69.

G sensor harness

connector M57

1 21

2 12

3 10

425

ABS actuator and elec-

tric unit (control unit) har-

ness connector E69

Continuity

Yes

SFIA2438E

OK or NG

OK >> GO TO 4.

NG >> Circuit malfun ction between G sensor and ABS actua tor and electric unit (control un it). Repair

harness.

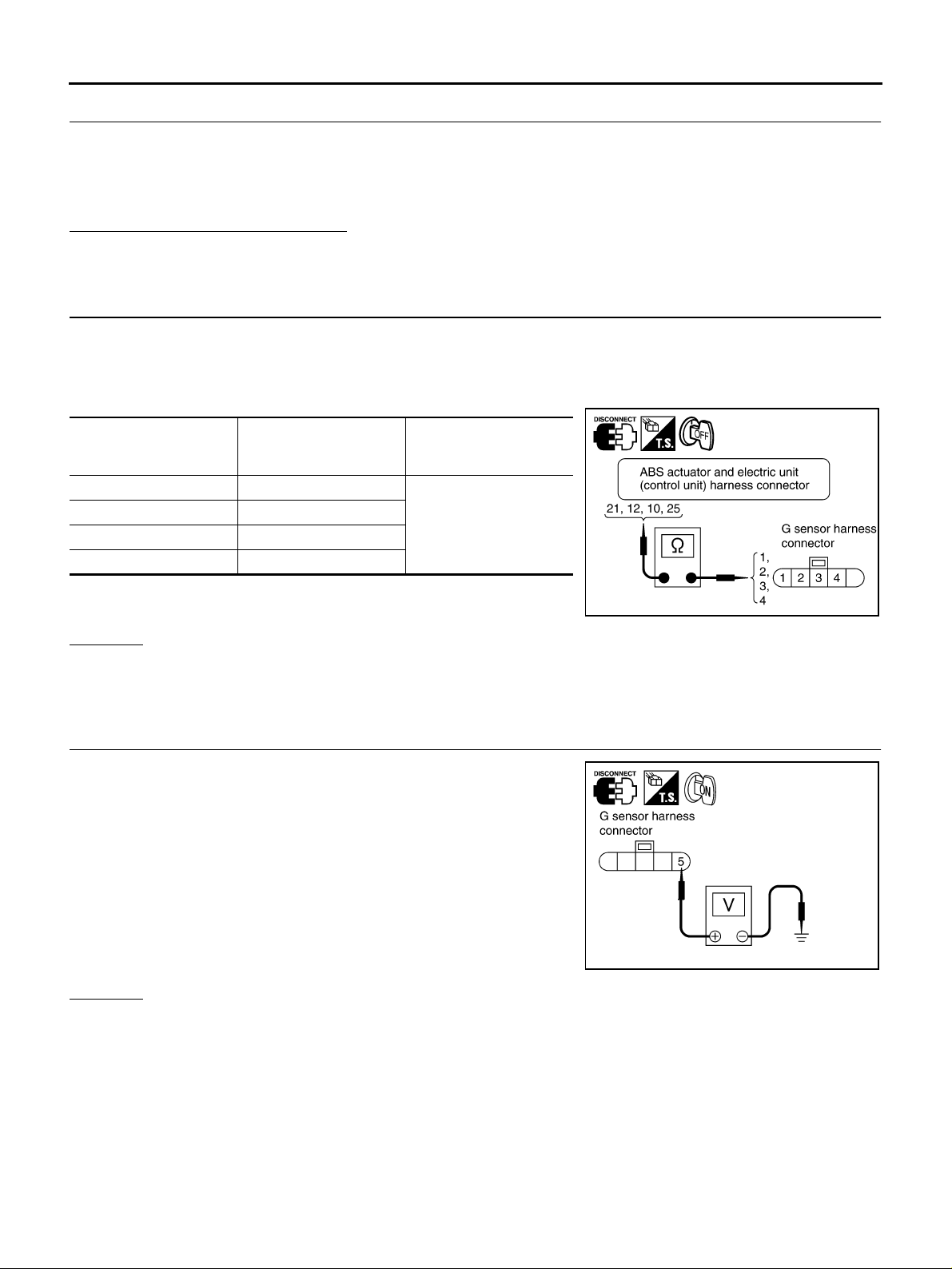

4. CHECK G SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition sw itch ON.

2. Check voltage between G sensor harness connector M57 terminal 5 and ground.

Voltage : Battery voltage (Approx. 12 V)

SFIA2439E

OK or NG

OK >> GO TO 5.

NG >> G sensor power supply circuit malfunction. Repair circuit.

Revision: 2006 July 2006 X-Trail

BRC-30

Loading...

Loading...