Liftmaster BMT5011E User Manual

I N S T A L L A T I O N M A N U A L

MODEL MT5011E/BMT5011E

MEDIUM DUTY DOOR OPERATOR

Now |

with |

||

|

in |

||

Built |

|||

|

|||

Radio |

Receiver |

||

|

|

||

INTENDED FOR PROFESSIONAL INSTALLATION ONLY

Radio Receiver

Built on Board

Visit www.LiftMaster.com to locate a professional installing dealer in your area.

2 Y E A R W A R R A N T Y

315MHz

Serial #

NOT FOR RESIDENTIAL USE

(located on electrical box)

Installation Date

A SAFETY DEVICE IS HIGHLY RECOMMENDED.

T A B L E O F C O N T E N T S

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 OPERATOR DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 OPERATOR SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 CARTON INVENTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8 TYPICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-14 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15 OPTIONAL SAFETY DEVICE CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-16 LOGIC BOARD LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 BASIC PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-20 TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 MANUAL DISCONNECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-23 DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 REPAIR PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 CONTROL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BACK COVER

S A F E T Y I N F O R M A T I O N

WARNING

WARNING

Mechanical

WARNING

WARNING

Electrical

When you see these Safety Symbols and Signal Words on the following pages, they will alert you to the possibility of serious injury or death if you do not comply with the warnings that accompany them. The hazard may come from something mechanical or from electric shock. Read the warnings carefully.

CAUTION

IMPORTANT NOTES:

•BEFORE attempting to install, operate or maintain the operator, you must read and fully understand this manual and follow all safety instructions.

•DO NOT attempt repair or service of your commercial door and gate operator unless you are an Authorized Service Technician.

When you see this Signal Word on the following pages, it will alert you to the possibility of damage to your door and/or the door operator if you do not comply with the cautionary statements that accompany it. Read them carefully.

2

A P P L I C A T I O N

INTRODUCTION

This Medium Duty Commercial Door Operator includes a number of features that will provide years of reliable and safe operation.

Features:

•Supports both monitored and non-monitored safety devices: Safety devices detect obstructions in the door's path and automatically reverse a closing door. Safety devices are highly recommended by the manufacturer.

•Radio receiver: A factory installed radio receiver allows remote controls, keyless entries and other remote command devices to be programmed to the operator.

•Timer To Close: The Timer To Close feature allows the door to automatically close after a preset time (only available with B2 wiring and a monitored safety device).

•Wiring Types: The functionality of the operator is based on the wiring type. The operator is shipped from the factory in standard C2 wiring type (factory default). Some wiring types will require an optional safety device. Refer to Basic Programming Section for descriptions of wiring types, requirements and programming.

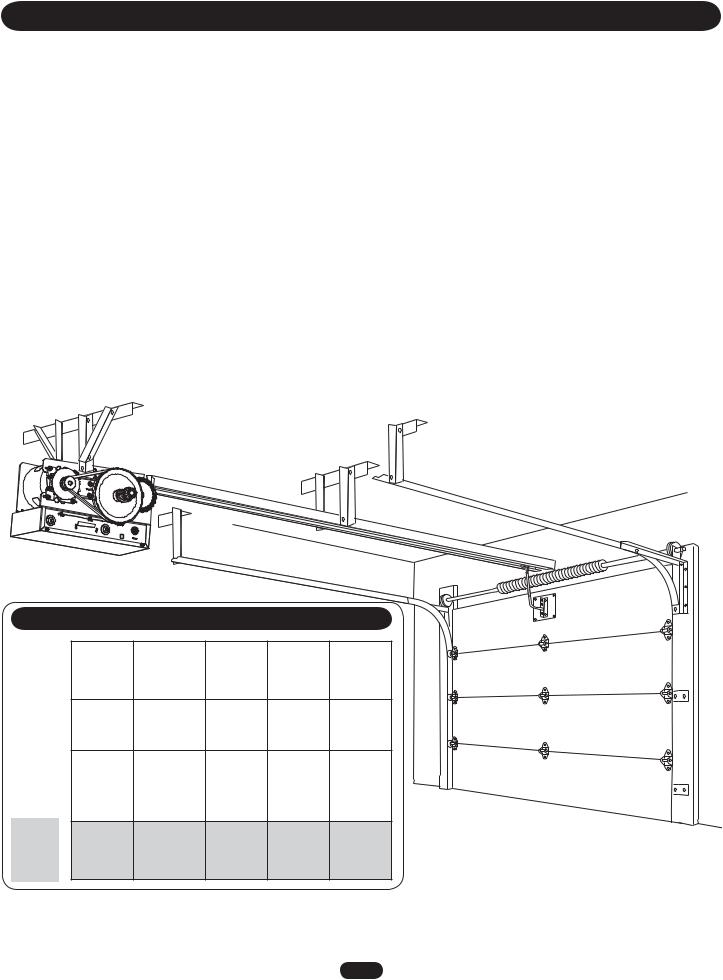

MAXIMUM DOOR AREA AND MAXIMUM DOOR HEIGHT 14'

|

STANDARD SECTIONAL |

SQUARE |

FEET |

--- |

24 ga. |

20 ga. |

16 ga. |

|

|

22 ga. |

--- |

|

|||

Steel |

Steel |

|

|||

|

Steel |

|

|

||

|

|

|

|

|

|

Fiberglass |

Aluminum |

Wood |

--- |

--- |

|

Doors |

Doors |

|

|||

|

|

|

|

||

|

|

24 ga. |

20 ga. |

16 ga. |

|

--- |

--- |

Steel |

Steel |

Steel |

|

|

|

Insulated |

Insulated |

Insulated |

|

310 |

260 |

225 |

150 |

100 |

NOTE: Actual track length will exceed door height by 2'. |

3

O P E R A T O R D I M E N S I O N S

WEIGHTS AND DIMENSIONS

HANGING WEIGHT:80-110 LBS. (36.29-49.9 kg) (Including Track)

12-1/2"

(31.75 cm)

9-1/2"

(24.13 cm)

16-3/16"

(41.12 cm)

Door Height Plus 4 feet (1.22 m) (minimum)

4" |

(10.16 cm) |

Path Of Highest Point On

Door

O P E R A T O R S P E C I F I C A T I O N S

MOTOR |

ELECTRICAL |

TYPE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Limited duty HORSEPOWER: . . . . . . . . . . . . . . . . . . . . . . . . 1/2 Horsepower VOLTAGE: . . . . . . . . . . . . . . . . . . . .115Vac, Single Phase, 60Hz FULL LOAD AMPS: . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 Amps

OPERATOR VOLTAGE: . . . . . . . . . 115 Vac, Single Phase, 60 Hz

WIRING TYPE: . . . . . . . C2 Standard B2 configurable (see Basic Programming section)

CONTROL WIRING: . . . . . . . . . . . . . . . . . . . . . . . . . .16-22 AWG

MECHANICAL |

SAFETY |

DOOR SPEED:. . . . . . . . . . . . . . . . . . . . 12" (30.48 cm) / second OUTPUT FORCE:. . . . . . . . . . . . . . . . . . . . . . . . . 125 ft. lbs/ sec.

BRAKE (BMT ONLY): . . . . . . . . . . Solenoid actuated disc brake LIMIT ADJUST: . . . . . .Fully adjustable up to 14' door maximum DUTY: . . . . . . . . . . . . . . . . . . . . . . 12 Cycles per hour maximum 50 Cycles per day maximum

BEARINGS: . . . . . . . . . . . . . . . . . . . . . . . . . . . Maintenance Free FINISH: . . . . . . . . . . . Powder coated, Corrosion Resistant Steel

DISCONNECT . . . . . . . . . . . . . . . . . . Quick disconnect door arm for emergency manual door operation.

ENTRAPMENT PROTECTION: . . . . Supports both monitored and non-monitored safety devices including LiftMaster CPS photo-eyes and industry standard sensing edges.

ENVIRONMENTAL

LOCATION: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Indoor, dry location OPERATING TEMPERATURE: . . . . . . . . . . . . . . . -4˚ F to +122˚F (-20C˚ to + 50˚C)

4

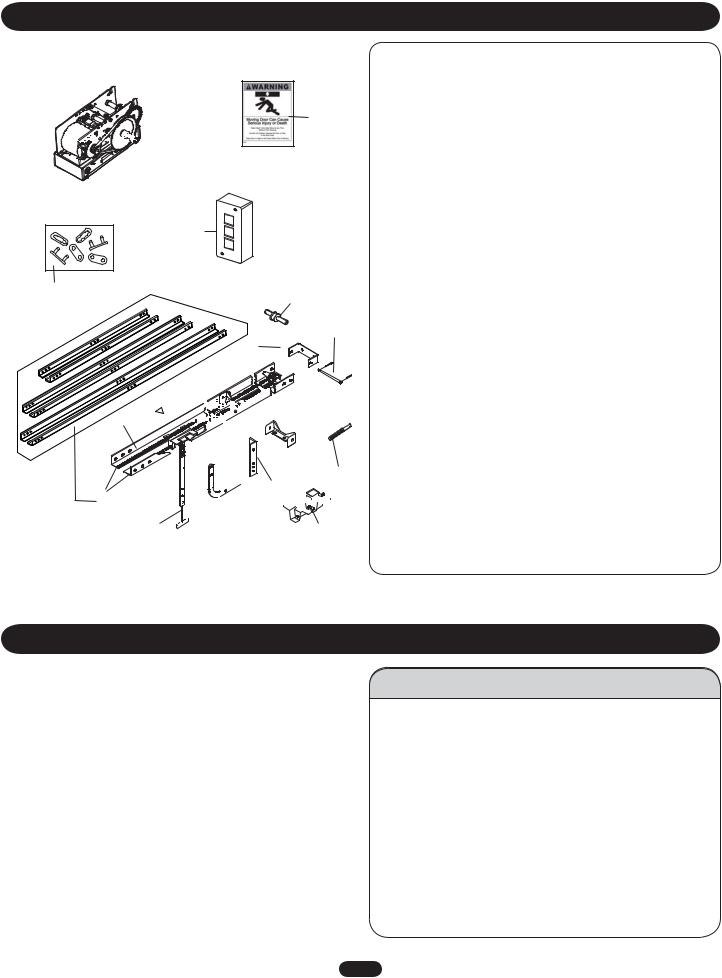

C A R T O N I N V E N T O R Y

Before beginning your installation check that all components were provided.

15

1

1

|

^ |

14 |

OPEN |

CLOSE |

|

|

^ |

|

O |

|

STOP |

8 |

4 |

10

9

3 7

3 7

6

13 2

13 2

11 12

11 12

5

NOTE: The tracks are shipped separately. Actual track length will exceed door height by 2'. Example: The track for

12' door will be 14'.

ITEM |

DESCRIPTION |

QTY |

1 |

Operator |

1 |

2Track (left & right)

|

Door height plus 2' |

2 |

3 |

Track Spacers |

2 |

4 |

Front Idler |

1 |

5 |

Trolley |

1 |

6 |

Take-up Bolt |

1 |

7 |

Chain |

1 |

8 |

Master Links |

2 |

9 |

Header Bracket |

1 |

10 |

Header Pivot Shaft |

1 |

11 |

Curved Door Arm |

1 |

12 |

Straight Arm |

1 |

13 |

Door Bracket |

1 |

14 |

3-Button Station |

1 |

15 |

Warning Sign |

2 |

|

NOT SHOWN |

|

|

Installation Manual |

1 |

|

Quickstart Guide |

1 |

|

User’s Guide |

1 |

|

Caution Label |

1 |

|

Installation Hardware Bag |

1 |

|

Complete with: Bolts 3/8"-16 x 3/4 " (10), |

|

|

Flanged Hex Nuts 3/8"-16 (14), Bolt 3/8"-16 x 1 |

|

|

(3), Lockwashers 3/8" (3), Cotter Pins (2) and |

|

|

Carriage Bolts (2) |

|

NOTE: Depending on door height, the quantity of track spacers and hardware may vary.

PREPARING YOUR DOOR

P R E P A R A T I O N

WARNING

WARNING

The manufacturer recommends 3' (91.4 cm) of clearance around the operator for serviceability. Before you begin:

•Disable locks.

•Remove any ropes connected to door.

•Before the operator is installed, be sure the door has been properly aligned and is working smoothly. Although each installation will vary due to particular building characteristics, refer to the following general procedures to install the operator.

To prevent possible SERIOUS INJURY or DEATH:

•DO NOT connect electric power until instructed to do so.

•If the door lock needs to remain functional, install an interlock switch.

•ALWAYS call a trained professional door serviceman if door binds, sticks or is out of balance. An unbalanced door may not reverse when required.

•NEVER try to loosen, move or adjust doors, door springs, cables, pulleys, brackets or their hardware, ALL of which are under extreme tension and can cause SERIOUS personal INJURY.

•Disable ALL locks and remove ALL ropes connected to door BEFORE installing and operating door operator to avoid entanglement.

5

A S S E M B L Y

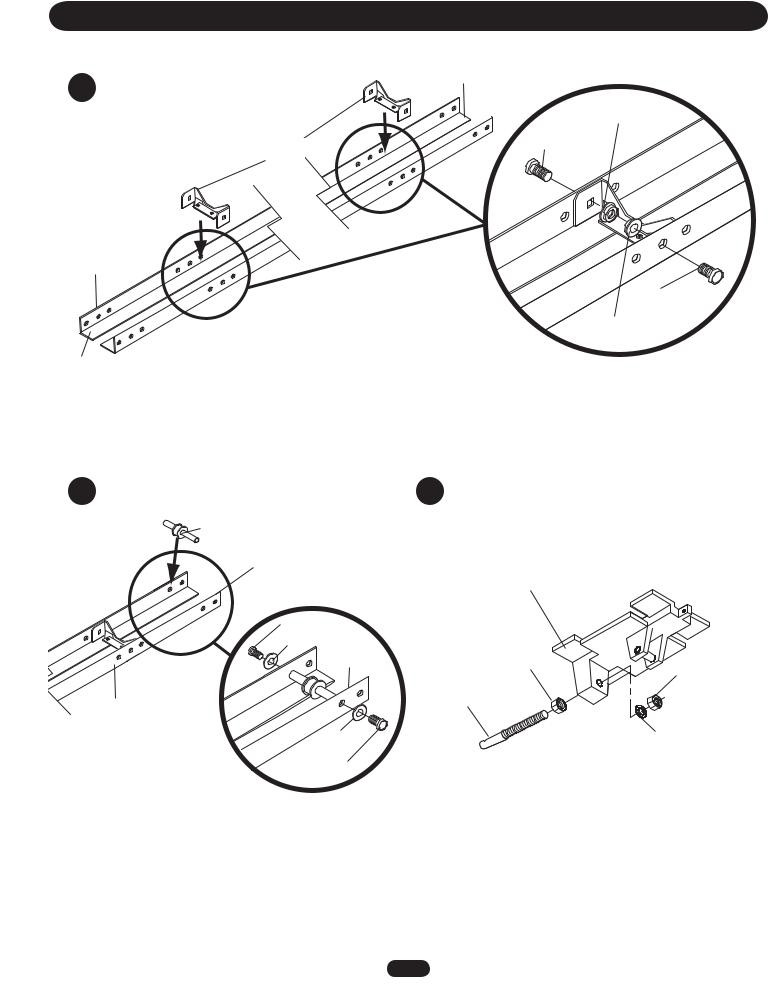

1 Install track spacers

Position the track spacers evenly over the length of the track using the pre-punched holes. For doors up to 12' use 2 track spacers, for 14' doors use 3 spacers.

Header End

Track

Spacers

Flange

Hex Nut

Bolt

3/8" - 16 x 3/4"

Track

Bolt

3/8" - 16 x 3/4"

Flange

Hex Nut

Operator End

2 |

Install front idler |

3 |

Assemble trolley |

|

|

Front Idler |

|

|

|

|

Header End |

|

|

|

|

|

|

Trolley |

|

|

Bolt 3/8" -16 x 1" |

|

|

|

|

Lock Washer |

|

|

|

|

Header End |

|

Flange Nut |

Flange Nut |

|

|

3/8" - 16 |

||

|

|

|

3/8" - 16 |

|

|

|

|

|

|

|

Track |

Take-Up Bolt |

|

|

|

|

|

|

|

|

Lock |

|

|

Lock Washer |

|

Washer |

|

|

|

|

Bolt 3/8" -16 x 1" |

|

|

|

6

A S S E M B L Y

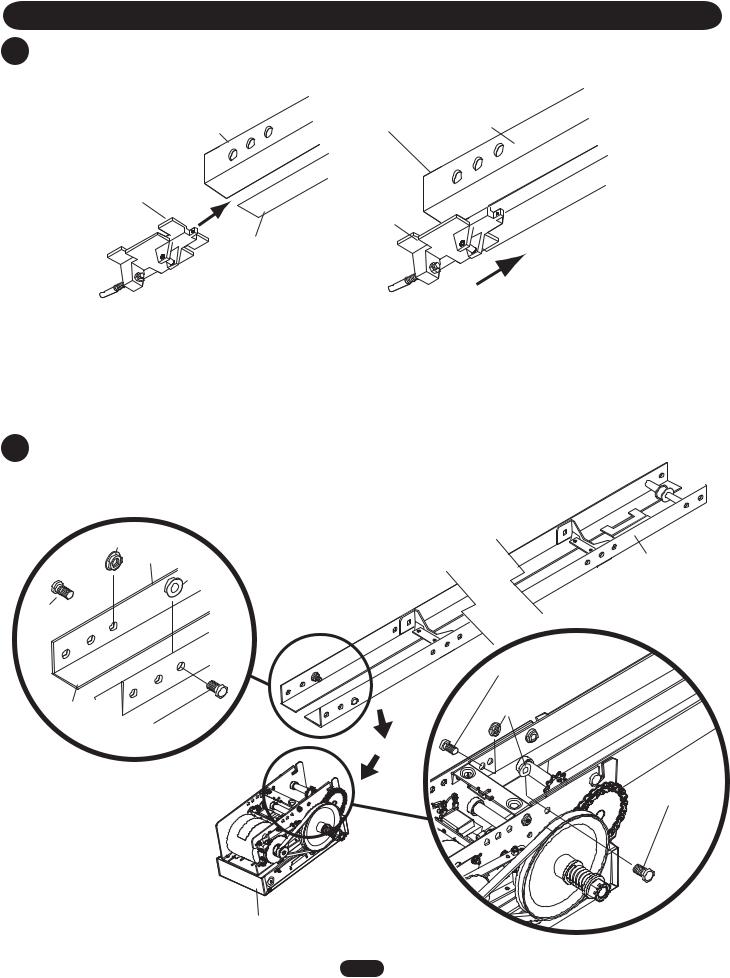

4 Slide trolley onto the track

Track |

Operator End |

Track |

|

Trolley

Trolley

Operator

End

5 Attach track to operator

Flange Hex Nut

Track

Flange

Hex Nut

Bolt  3/8" - 16 x 3/4"

3/8" - 16 x 3/4"

Operator

End

Bolt

3/8" - 16 x 3/4"

Operator

Header

End

Bolt

3/8" - 16 x 3/4"

Flange Hex

Nut

Bolt

3/8" - 16 x 3/4"

7

A S S E M B L Y

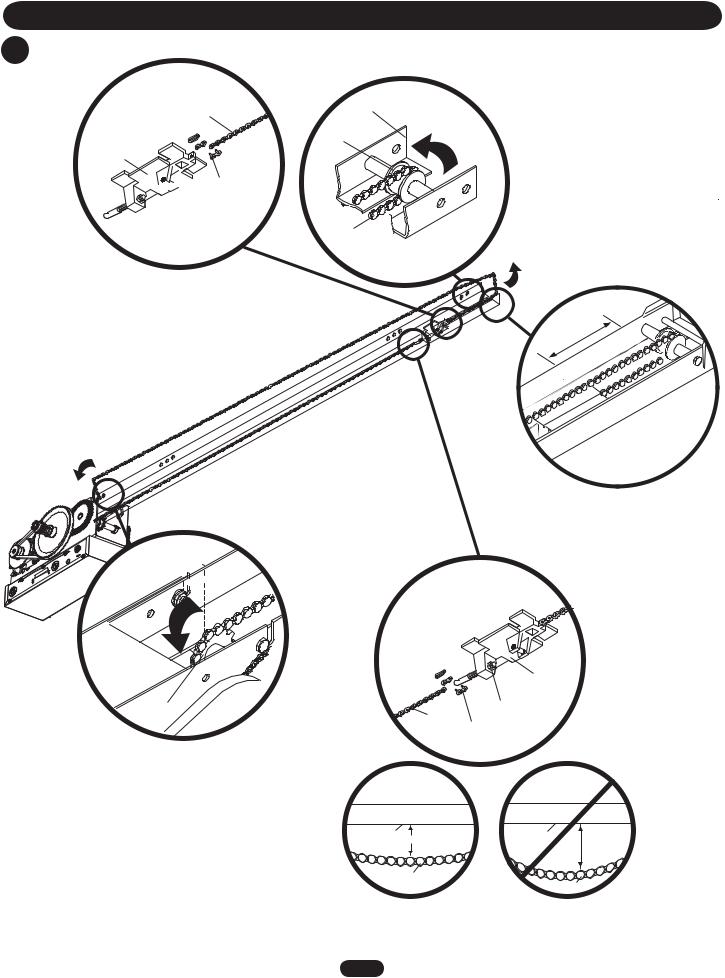

6 Install chain

Attach chain |

|

|

Wrap chain |

to front of |

|

|

|

trolley |

Chain |

Track |

around front |

|

|

|

idler |

|

|

Front Idler |

|

Trolley

Master Link

Master Link

Chain

Run chain around |

|

track in the direction |

|

indicated |

Slide trolley 2" away from front idler |

|

2"

Wrap chain  around drive

around drive

sprocket

sprocket

Operator

Drive

Sprocket

Attach chain to back of trolley

Adjust the chain by tightening the inner nut

Trolley

Inner Nut

Chain

Master Link

Bottom of |

Bottom of |

More |

||

Track |

3" |

Track |

||

than 3" |

||||

|

|

|

||

|

Chain |

|

Chain |

|

|

|

|

||

8

T Y P I C A L I N S T A L L A T I O N

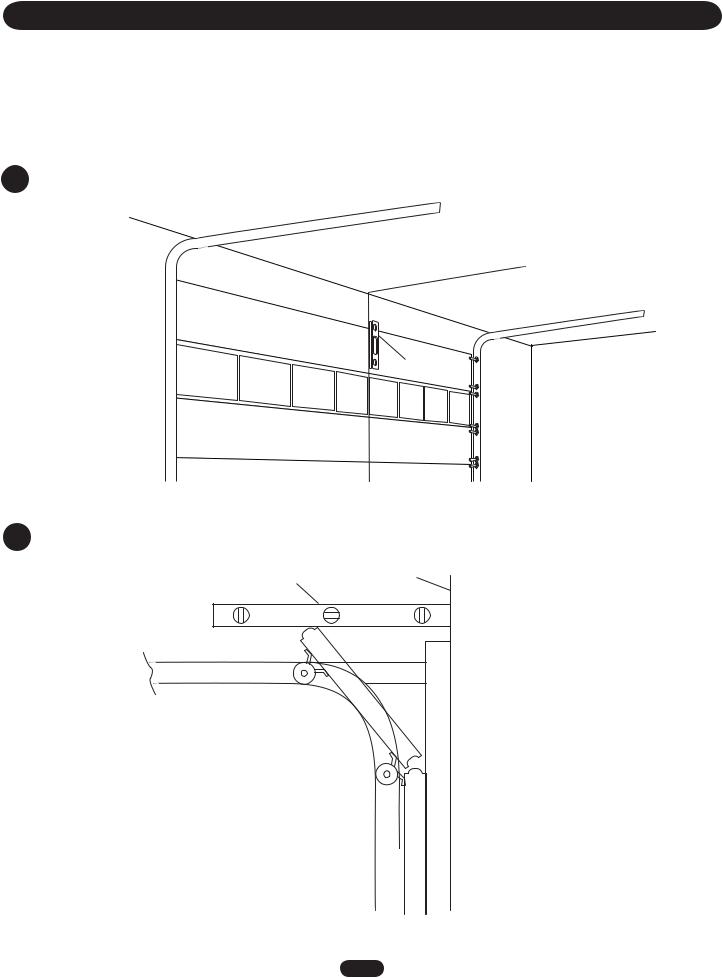

DETERMINE HEADER BRACKET MOUNTING LOCATION

The trolley operator is generally mounted over the center of the door. However, off center mounting may be required due to interfering structures or location of door stile / top section support. Typically, the operator may be mounted up to 24" (60.96 cm) off center on torsion spring doors. Extension springs require center mounting.

1 Mark the center of the door

Mark the center line of the door.

Mark the center line of the door.

Extend the line on to the header wall and the ceiling.

Level (Optional)

2 Determine and mark the highest point of door travel

Header Wall

Level

High Point of

High Point of

Door Travel

9

Loading...

Loading...