Lift-Master SL595, SL585 User Manual

CONTROLLER

GL BOARD

MODEL SL585

HEAVY DUTY SLIDE GATE OPERATOR

MODEL SL595

2 YEAR WARRANTY

HEAVY DUTY, HARSH ENVIRONMENT

SLIDE GATE OPERATOR

MODELS SL585 AND SL595 ARE FOR VEHICULAR PASSAGE GATES ONLY AND ARE NOT INTENDED FOR PEDESTRIAN PASSAGE GATE USE

T A B L E O F C O N T E N T S

OPERATOR SPECIFICATIONS

Carton Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Operator Dimensions and Horsepower Chart . . . . . . . . . . . . . . .3 UL325 Model Classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

OPERATOR WARNINGS

Safety Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . .5 Suggested Entrapment Protection Device Locations . . . . . . . . . .6 Safety Precautions for Open Roller Gates . . . . . . . . . . . . . . . . . .7 Warning Sign Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

WIRING

Power Wiring Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

INSTALLATION

Pad Mounting (SL585 & SL595) . . . . . . . . . . . . . . . . . . . . . . . . .9 Post Mounting (SL585 & SL595) . . . . . . . . . . . . . . . . . . . . . . .10 Install Gate Bracket and Drive Chain . . . . . . . . . . . . . . . . . . . . .11 On/Off Switch Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .12 Manual Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

ADJUSTMENT

Limit Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 RPM Sensor Adjustment (Hall Effect) . . . . . . . . . . . . . . . . . . . .13 Gate System Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . .13

Vent Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 UL325 Entrapment Protection . . . . . . . . . . . . . . . . . . . . . . .14-15 Control Board Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 Program Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 Control Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . .17 Accessory Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19 Sequenced Access Management System . . . . . . . . . . . . . . . . .20

OPERATION AND MAINTENANCE

Operator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 Friction Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 Solenoid Actuated Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 Control Board Programming and Features . . . . . . . . . . . . . .22-23 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-25 Single Phase Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 Single Phase Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . .27 Three Phase Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28 Three Phase Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .29

REPAIR PARTS

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Electrical Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 Repair Parts - Model SL585 . . . . . . . . . . . . . . . . . . . . . . . . . . .32 Illustrated Parts - Model SL585 . . . . . . . . . . . . . . . . . . . . . . . . .33 Repair Parts - Model SL595 . . . . . . . . . . . . . . . . . . . . . . . . . . .34 Illustrated Parts - Model SL595 . . . . . . . . . . . . . . . . . . . . . . . . .35 Safety Accessories for Secondary Entrapment Protection . . . .36 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

WARNING

WARNING

Mechanical

WARNING

WARNING

Electrical

CAUTION

When you see these Safety Symbols and Signal Words on the following pages, they will alert you to the possibility of SERIOUS INJURY or DEATH if you do not comply with the warnings that accompany them. The hazard may come from something mechanical or from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will alert you to the possibility of damage to your gate and/or the gate operator if you do not comply with the cautionary statements that accompany it. Read them carefully.

CARTON INVENTORY

Before beginning your installation check that all components were provided and received undamaged. Refer to list below for factory provided parts.

HARDWARE KIT

SL585/SL595 (K77-34846)

Description |

Qty. |

Safety Gate Brochure |

1 |

Gate Bracket |

2 |

Take-Up Bolt |

2 |

Nickel Plated Chain #50 |

1 |

U-Bolt 2" 5/16-18 |

4 |

U-Bolt 3" 3/8-16 |

4 |

Square Head Set Screw 7/16-14 |

4 |

Hex Nut 1/2-13 |

4 |

Flange Nut 5/16"-18 |

8 |

Flange Nut 3/8"-16 |

8 |

Flat Washer 3/8" |

8 |

Flat Washer 1/2" |

4 |

Lock Washer 1/2" |

4 |

2

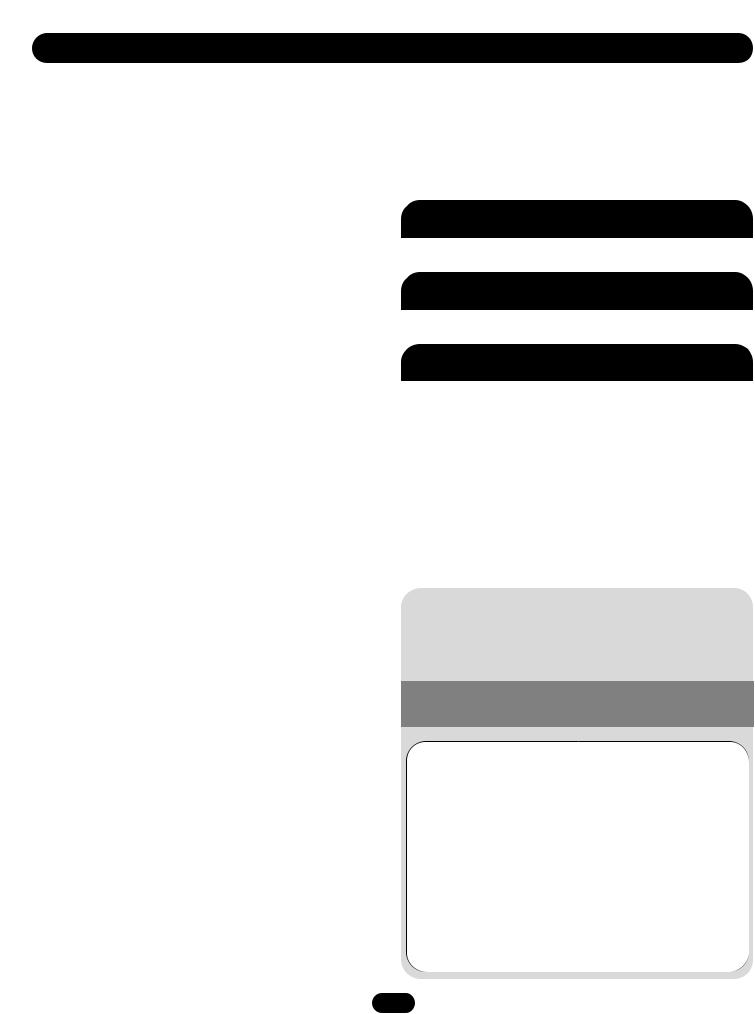

O P E R A T O R D I M E N S I O N S A N D H O R S E P O W E R C H A R T

28.9" |

|

(73.4 cm) |

17.2" |

|

|

27.5" |

(43.7 cm) |

(69.9 cm) |

|

37.7" (95.8 cm)

14.1" |

12.9" |

14.9" |

(35.8 cm) |

(32.8 cm) |

(37.9 cm) |

Opposite Gate Side

Gate Side

3

U L 3 2 5 M O D E L C L A S S I F I C A T I O N S

CLASS I – RESIDENTIAL VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a home of one-to four single family dwellings, or a garage or parking area associated therewith.

CLASS II – COMMERCIAL/GENERAL ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a commercial location or building such as a multi-family housing unit (five or more single family units) hotel, garage, retail store or other building servicing the general public.

CLASS III – INDUSTRIAL/LIMITED ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a industrial location or building such as a factory or loading dock area or other location not intended to service the general public.

CLASS IV – RESTRICTED ACCESS VEHICULAR GATE OPERATOR

A vehicular gate operator (or system) intended for use in a guarded industrial location or building such as an airport security area or other restricted access locations not servicing the general public, in which unauthorized access is prevented via supervision by security personnel.

SAFETY ACCESSORY SELECTION

All UL325 compliant LiftMaster gate operators will accept external entrapment protection devices to protect people from motorized gate systems. UL325 requires that the type of entrapment protection correctly matches each gate application. Below are the six types of entrapment protection systems recognized by UL325 for use on this operator.

ENTRAPMENT PROTECTION TYPES

Type A: Inherent obstruction sensing system, self-contained within the operator. This system must sense and initiate the reverse of the gate within two seconds of contact with a solid object.

Type B1: Connections provided for a non-contact device, such as a photoelectric eye can be used as a secondary protection.

Type B2: Connections provided for a contact sensor. A contact device such as a gate edge can be used for secondary protection.

Type C: Inherent adjustable clutch or pressure relief valve.

Type D: Connections provided for a control requiring continuous pressure to operate the operator open and close.

Type E: Built-in audio alarm. Examples include sirens, horns or buzzers.

NOTE: UL requires that all installations must have warning signs placed in plain view on both sides of the gate to warn pedestrians of the dangers of motorized gate systems.

Moving Gate Can Cause

Injury or Death

KEEP CLEAR! Gate may move at any time without prior warning.

Do not let children operate the gate or play in the gate area.

This entrance is for vehicles only. Pedestrians must use separate entrance

UL325 ENTRAPMENT PROTECTION REQUIREMENTS

GATE OPERATOR ENTRAPMENT PROTECTION

|

UL325 |

Slide Gate Operator |

Swing & Gate Barrier |

|||

Installation |

|

|

(Arm) Operator |

|||

|

Class |

|

|

|

|

|

Primary |

Secondary |

Primary |

Secondary |

|||

|

|

|

Type |

Type |

Type |

Type |

|

|

|

|

|

|

|

|

Class |

A |

B1, B2 |

A or C |

A, B1, B2, |

|

|

I & II |

or D |

or C |

|||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

A, B1 or |

A, B1, B2, |

A, B1, B2 |

A, B1, B2, |

|

Class III |

|

||||

|

|

B2 |

D or E |

or C |

C, D or E |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

A, B1, B2 |

A, B1, B2, |

A, B1, B2, |

A, B1, B2, |

|

Class IV |

|

||||

|

|

or D |

D or E |

C or D |

C, D or E |

|

|

|

|

||||

|

|

|

|

|

|

|

4

S A F E T Y I N S T A L L A T I O N I N F O R M A T I O N

5

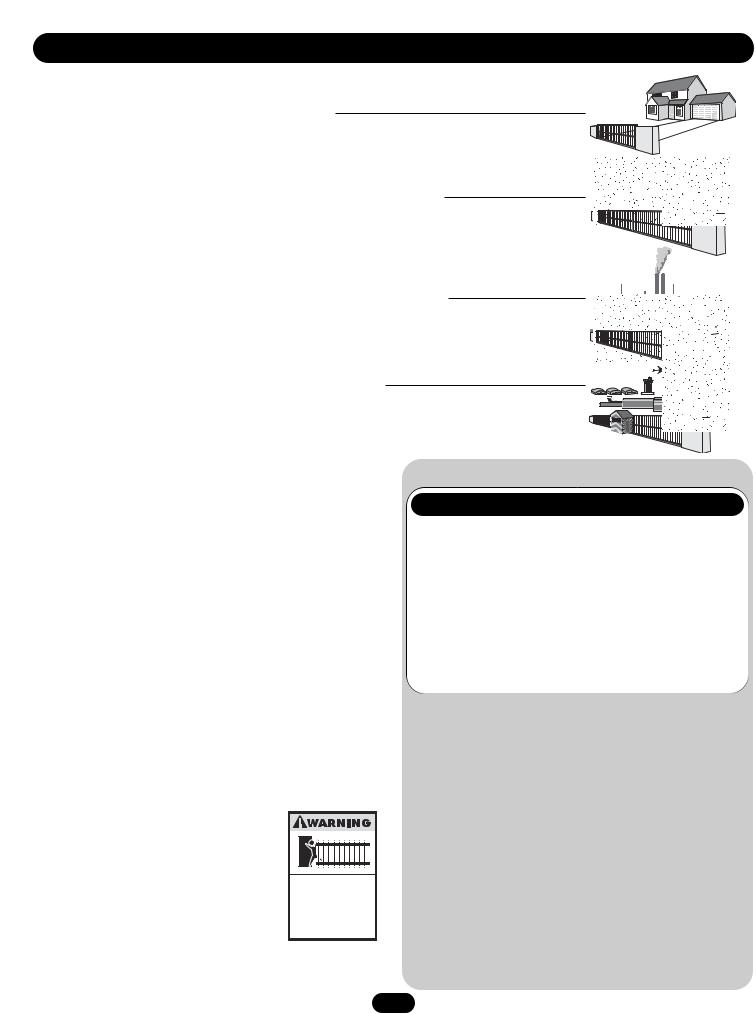

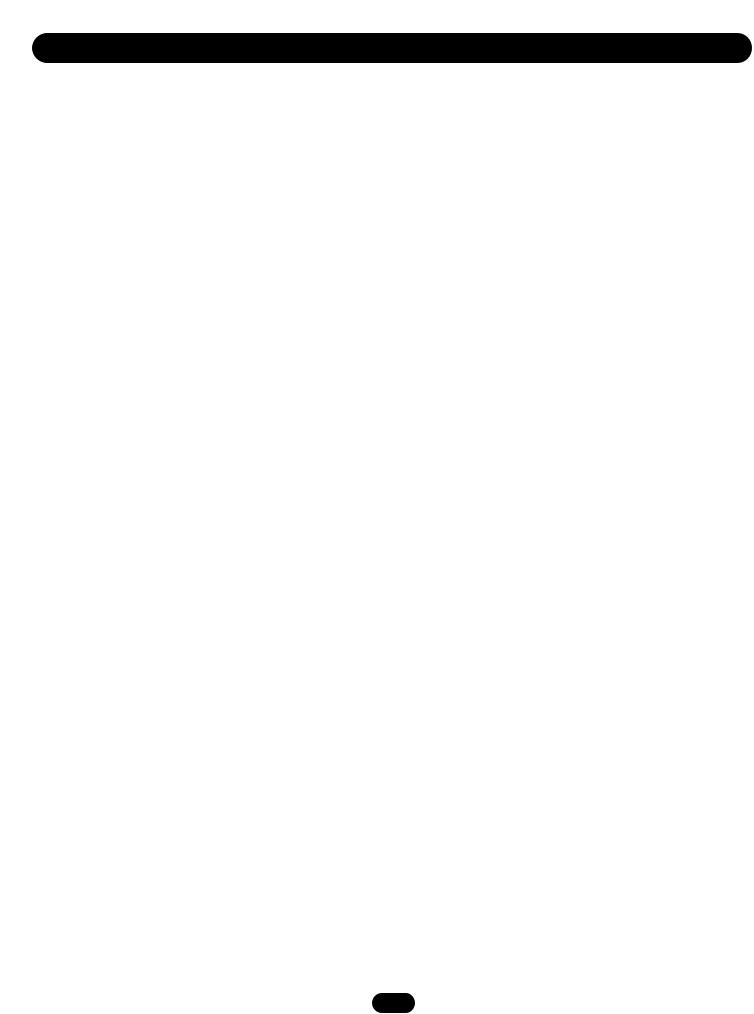

S U G G E S T E D E N T R A P M E N T P R O T E C T I O N D E V I C E L O C A T I O N S

Telephone |

Open |

Entry |

Edge |

System |

|

|

Close |

|

Edge |

STREET 4'

8'

Interrupt

(Safety) 4'

Loop Typical

Photo eye for |

4' |

Interrupt |

Typical |

||

close cycle |

|

(Safety) |

|

|

Loop |

COMPLEX

4'

Typical

OR

PARKING LOT

Photo eye for open cycle

Run twisted wire from Loop

to Operator*

Seal Loops*

1-1/2"

Loop wire* layer

1/4" or larger for Loop wire width depending on Loop wire size

6

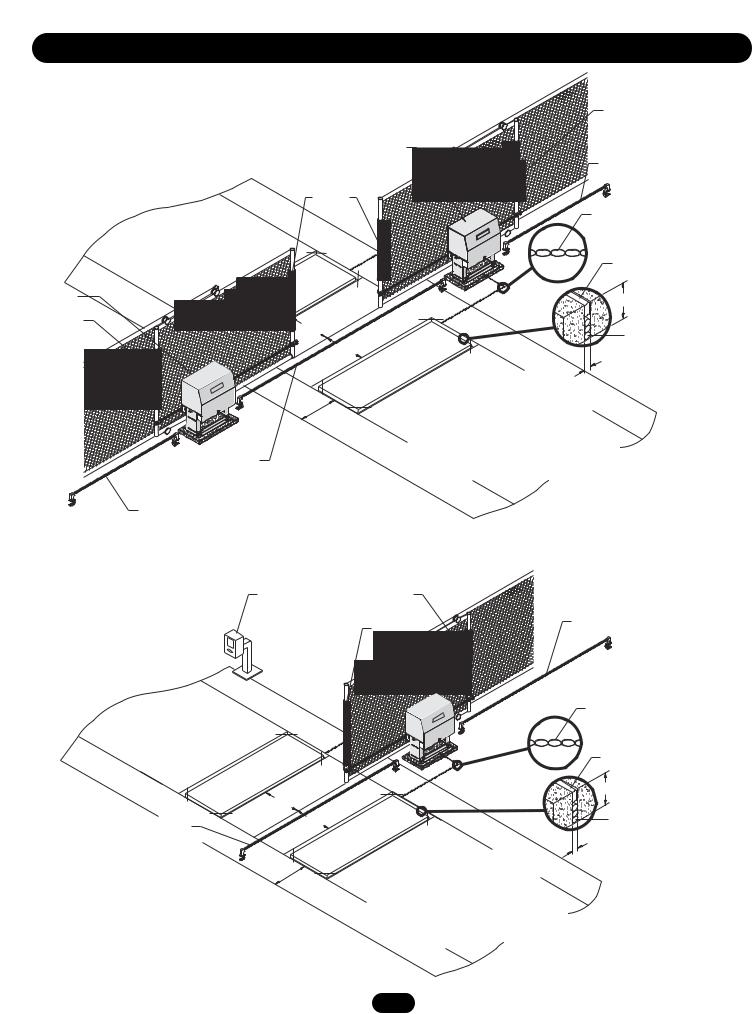

SAFETY PRECAUTIONS FOR OPEN ROLLER GATES

WARNING

WARNING

•Injuries occur when people get their hands or feet caught between the top or bottom of the gate and the gate roller. These potential pinch-points should be guarded against at all times. Enclosed style gate tracks are available for refitting of these rollers from many fence suppliers. Also, roller guards are available for installing over the rollers.

•UL325 requires that, when used, contact sensors shall be located at the leading edge, trailing edge, and be post mounted both inside and outside of a vehicular horizontal slide gate. Non-contact sensors such as photo eyes must protect during both open and close gate cycles.

•Injuries occur when people put their hands and arms through openings in the grill while the gate is operating. They cannot retract their arm and it gets caught between the moving gate grill and the stationary fence post or fence. This potential hazard can be averted by placing a 4' (1.2 m) screen mesh on the gate to prevent access through openings anywhere the gate may travel. See Safety Brochure for details. To prevent entrapment injuries, mount controls at least 6' (1.8 m) from the gate or any moving parts of the gate.

Gate Edge on |

Gate Edge on Fence |

|

||

Post for Open Direction |

Gate Edge On |

|||

Rear of Gate for |

||||

|

|

Leading Edge of Gate |

||

Open Direction |

|

|

||

|

|

For Close Direction |

||

|

|

|

||

Photo Beam |

|

|

Photo Beam for |

|

|

|

Close Direction |

||

for Open |

Unit |

|

||

|

|

|||

Direction |

|

Additional Post Mounted Gate |

||

Additional Post Mounted Gate |

||||

Edge for Close Direction |

Edge for Open Direction |

|||

Pinch-Point

Hazard

Always Test Gate Edges And

Photo Beams Anytime They Are

Adjusted Or Serviced

|

|

Gate Edge |

Pinch-Point |

|

For Close |

Gate Edge |

Direction |

|

Hazard |

|

|

For Open Direction |

|

|

|

|

Gate Edge

Vertical Post Placed On Both

Sides of the Exposed

Rollers Can Prevent Hands

From Reaching These

Pinch-points

Gate Edge for

Close Direction

WARNING

WARNING

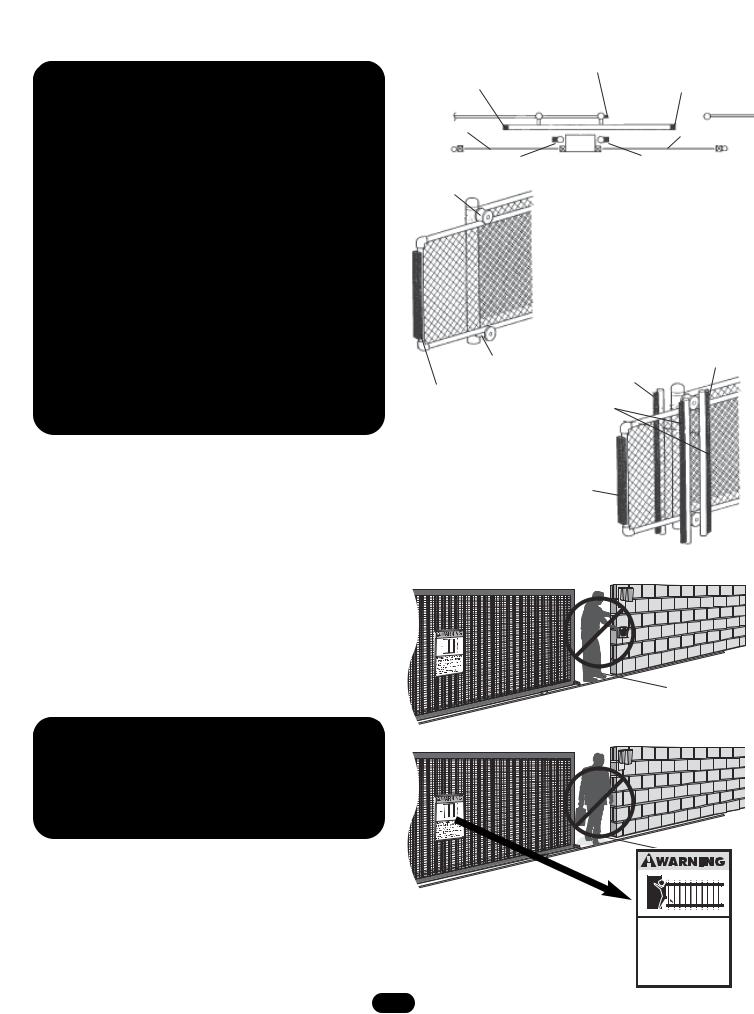

NOT FOR USE AS PEDESTRIAN PASSAGE! This operator is intended for vehicular use only. To prevent INJURY to pedestrians, a separate pedestrian access should be supplied, visible from the gate. Locate the pedestrian access where there is not a chance of INJURY at any point during full movement of the gate.

Moving Gate Can Cause

Injury or Death

KEEP CLEAR! Gate may move at any time without prior warning.

Do not let children operate the gate or play in the gate area.

This entrance is for vehicles only. Pedestrians must use separate entrance

7

W I R I N G

WARNING

WARNING

WIRE GAUGE 6

SINGLE PHASE |

|

THREE PHASE |

|

|

115 Vac |

230 Vac |

230 Vac |

460 Vac |

575 Vac |

• |

1/2 HP Motor ------ |

425 ft. (129.5 m) |

1845 ft. (562.4 m) |

2557 ft. (779.4 m) |

12789 ft. (3898.1 m) |

15987 ft. (4872.8 m) |

• |

1 HP Motor---------- |

213 ft. (64.9 m) |

852 ft. (259.7 m) |

1278 ft. (389.5 m) |

5115 ft. (1559.1 m) |

7993 ft. (2436.3 m) |

• |

2 HP Motor---------- |

|

|

639 ft. (194.8 m) |

2557 ft. (779.4 m) |

4441 ft. (1353.6 m) |

WIRE GAUGE 8

• |

1/2 HP Motor ------ |

269 ft. (82 m) 1165 ft. (355.1 m) |

1614 ft. (492 m) |

8072 ft. (2460.4 m) |

10089 ft. (3075.1 m) |

• |

1 HP Motor---------- |

134 ft. (40.8 m) 537 ft. (163.7 m) |

807 ft. (246 m) |

3228 ft. (983.9 m) |

5044 ft. (1537.4 m) |

• |

2 HP Motor---------- |

|

403 ft. (122.8 m) |

1614 ft. (492 m) |

2525 ft. (769.6 m) |

WIRE GAUGE 10

• |

1/2 HP Motor ------ |

168 ft. (51.2 m) |

730 ft. (222.5 m) |

1012 ft. (308.5 m) |

5064 ft. (1543.5 m) |

6330 ft. (1929.4 m) |

• |

1 HP Motor---------- |

84 ft. (25.6 m) |

337 ft. (102.7 m) |

506 ft. (154.2 m) |

2025 ft. (617.2 m) |

3165 ft. (964.7 m) |

• |

2 HP Motor---------- |

|

|

252 ft. (76.8 m) |

1012 ft. (308.5 m) |

1582 ft. (482.2 m) |

WIRE GAUGE 12

• |

1/2 HP Motor ------ |

105 ft. (32 m) |

458 ft. (139.6 m) |

634 ft. (193.2 m) |

3171 ft. (966.5 m) |

3964 ft. (1208.2 m) |

• |

1 HP Motor---------- |

53 ft. (16.2 m) |

211 ft. (64.3 m) |

316 ft. (96.3 m) |

1269 ft. (386.8 m) |

1982 ft. (604.1 m) |

• |

2 HP Motor---------- |

|

|

157 ft. (47.9 m) |

634 ft. (193.2 m) |

990 ft. (301.8 m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8

I N S T A L L A T I O N

PAD MOUNTING (SL585 ONLY)

RETRO-FIT INSTALLATION

The operator is shipped from the factory with the lower mounting angles configured out (Figure 1). If you have pad constrictions, either angle can be unbolted and reversed to ‘angle in’.

NOTE: If you are replacing an SL580 and wish to use the same pad mounting hardware, the gate side mounting angle must be installed angle in.

NEW INSTALLATION

CONCRETE PAD PREPARATION:

1.Lay out concrete pad. (Figure 2).

2.Locate electrical conduit, as required, prior to pouring concrete.

3.Pour concrete pad.

4.Secure operator (Figure 3) to the concrete pad using four 1/2" (1.3 cm) concrete anchors (not provided).

Figure 1

Angle Out

Angle In

Figure 2

Rear of Gate or Back Frame

Fence Line

1" (2.5 cm)

4" (10.2 cm)

10-7/8" |

|

(27.6 cm) |

18" (45.7 cm) |

7" |

21-1/8" (53.7 cm) |

Concrete |

|

Anchor Holes |

|||

(17.8 cm) |

|

||

36" (91.4 cm) |

|

||

|

|

Figure 3

Using Suitable Hardware

To Secure Operator To

Concrete Anchors

Concrete

Drive and Idler

SprocketToward

SprocketToward

Gate Side

Power and Control

Wiring Should Be

Run In Separate Conduit

2" to 4"

2" to 4"

(5.1 to 10.2 cm) Above Grade

Depth Required By

Depth Required By

Local Codes or

Below Frost Line

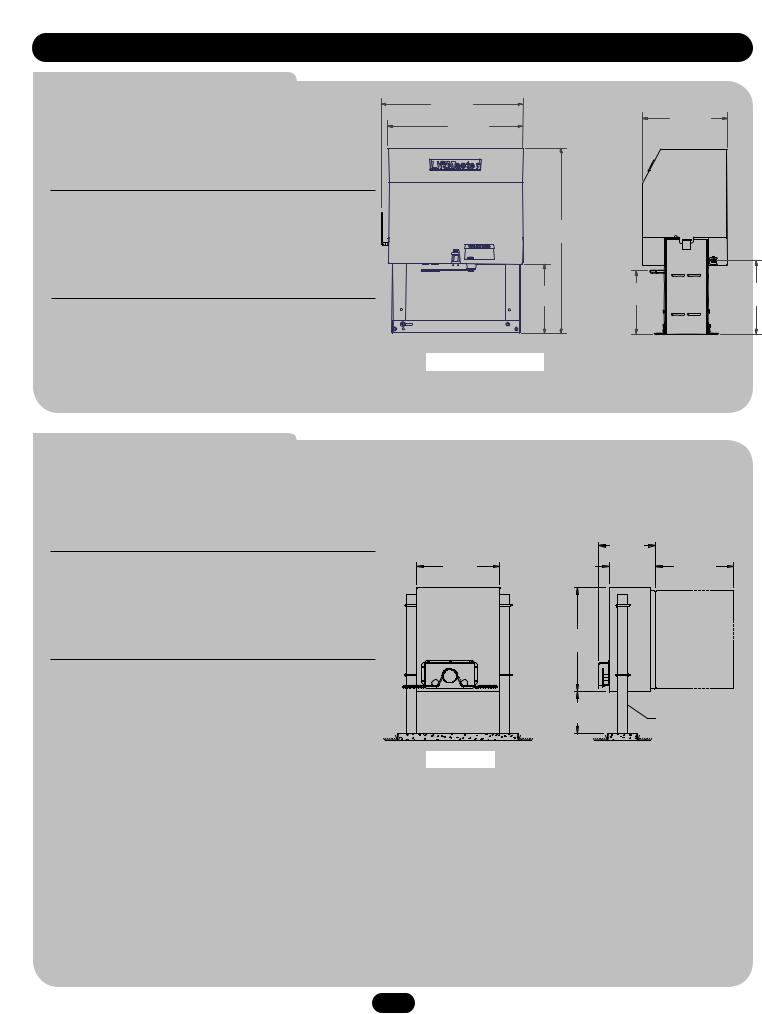

POST MOUNTING (SL585 AND SL595)

RETRO-FIT INSTALLATION

The operators come from the factory configured to mount to an inside the frame post mount dimension of 26" (outside to outside of posts). The frame comes slotted to accommodate posts 24 1/8" to 26", outside to outside (Figure 1).

NOTE: If you are replacing a SL580, the frame will require adjustment to 24 1/8".

NEW INSTALLATION (FIGURES 2 AND 3)

1.Locate and anchor two posts made of 3" (7.6 cm) outer diameter heavy walled pipe. Posts should be parallel and square to the gate.

2.Locate electrical conduit, as required, prior to pouring concrete.

3.Secure operator to posts using four 3" (7.6 cm) U-bolts and hardware provided.

Figure 2 |

End Post |

Fence Line |

|

||

|

|

|

8.5" (21.6 cm) |

|

Gate |

|

|

|

6" (15.2 cm) |

26" (66 cm) |

|

|

Outside To Outside |

|

3" (7.6 cm) Outside Diameter Heavy

Wall Fence Pipe

14" (35.6 cm) Min.

Ground Level

Depth As Required By

Local Codes or Below

Frost Line

Figure 1

26" (66 cm)

Post to Post Adjustment

24 1/8" (61 cm)

Figure 2

Drive and Idler

Sprocket Toward

Gate Side

Angle

Bracket

3" (7.6 cm) U-bolt (4 required)

SL585 ONLY

Figure 3

8.5" (21.6 cm)

6" (15.2 cm)

3" (7.6 cm) Outside Diameter Heavy Wall Fence Pipe

End Post |

Fence Line |

|

Gate

24" (61 cm)

Inside to inside

39" (99.1 cm) Min.

Ground Level

Depth As Required By

Local Codes or Below

Frost Line

SL595 ONLY

Power and Control

Wiring Should Be Run In

Separate Conduit

|

Drive and Idler |

Figure 3 |

Sprocket Toward |

Gate Side |

|

|

3" (7.6 cm) |

|

U-bolt |

|

(4 required) |

12" (30.5 cm) Minimum |

|

From Ground |

|

Power and Control

Wiring Should Be Run

In Separate Conduit

SL595 ONLY

10

INSTALL GATE BRACKET AND DRIVE CHAIN

CAUTION

To prevent damage to the operator or gate, DO NOT drive the limit (nuts) actuators on the shaft past their normal positions.

1.Mount gate brackets to the vertical front and rear posts of the gate (Figure 1).

2.Remove the operator cover or open access door.

3.Locate and engage the manual disconnect and lock it in place (refer to page 12).

4.Connect chain take-up bolt to the end of the chain and attach to the rear gate bracket (Figure 2).

5.Ensure that the drive and idler sprockets are in line with each other. Thread the chain through the plastic chain guide, around drive and idler sprockets, and then through the second plastic chain guide toward front gate bracket (Figure 3).

6.Adjust the chain to proper length and attach second take-up bolt to chain end. Secure the take-up bolt to the front gate bracket as shown.

Adjust nuts on chain take-up bolts to remove chain slack. A general rule of thumb is to leave a maximum of 1" (2.5 cm) of chain slack for every 10' (3.1 m) of chain length.

Do not overtighten chain.

NOTE ABOUT SOME TYPES OF CANTILEVER GATES:

With some cantilever gates over 20' (6.1 m) long, you may need to add a brace along the length of the gate to prevent the gate from bowing when chain is tightened. This may also be required on some styles of gates that are constructed out of aluminum. If positioned properly, this brace can also be used as a chain support.

Figure 3 |

Gate Bracket |

|

Idler Sprocket

Insert Chain Through Plastic Guides

Figure 1

“Outside”

Gate

“Inside”

2" (5.1 cm) U-bolts With Lock Washers

With Lock Washers

and Nuts

Gate Bracket |

Anti-Rotation |

Set Screw |

Figure 2

* *

*Gate brackets must be level and centered with bottom of idler sprocket

Drive Sprocket

Gate Post

Idler Sprocket

Safety Bracket

11

AVAILABLE CONDUIT ACCESS FOR THE ELECTRICAL BOX

The accessory tray is equipped with several 1-1/2" pass though holes as well as 3/4" and 1" knock outs for conduit connectors. The electrical box is equipped with 3/4" and 1" knock outs for conduit connectors.

ON/OFF SWITCH POWER WIRING

NOTES: Before running power wiring refer to wiring specifications on page 8 for correct wire gauges.

Secure all electrical power connections inside the disconnect switch electrical box. Refer to electrical wiring diagrams on pages 26-29.

SINGLE PHASE

All single phase 115V/208/230V operators will have the following:

•L1 WHITE

•L2 BLACK

•GROUND, GREEN

115V SINGLE PHASE POWER SWITCH ASSEMBLY

THREE PHASE

All three phase operators will have the following:

• L1 BLACK

•L2 BLACK

•L3 BLACK

•GROUND, GREEN

230V SINGLE PHASE &

THREE PHASE

POWER SWITCH ASSEMBLY

IMPORTANT NOTE: This operator is shipped from the factory as a right hand mounted unit, unit MUST be phased correctly. On three phase operators, power connections must be properly phased. If phased incorrectly, the gate operator will run reversed. To correct this situation, shut off power at main power source and at the operators electrical disconnect switch. Then reverse any two of the three power leads.

MANUAL DISCONNECT

MODEL SL585 |

|

MODEL SL595 |

|

DISENGAGEMENT: |

Rotate disconnect handle 90˚ to |

DISENGAGEMENT: |

Open the hinged door and pull the |

|

disengage. The gate may now be |

|

disconnect lever and lock it in place. |

|

moved manually. |

|

The gate my now be moved manually. |

RE-ENGAGEMENT: |

Rotate handle back to original |

RE-ENGAGEMENT: |

Release the lever and close the door. |

|

position. (Some operator output |

|

(Some operator output sprocket |

|

sprocket rotation may be required for |

|

rotation may be required for |

|

engagement). |

|

engagement). |

Pull the handle to release

12

Loading...

Loading...