IVECO STRALIS AS EURO 4, STRALIS AS EURO 5, STRALIS AT EURO 4, STRALIS AT EURO 5, STRALIS AD EURO 4 Instruction Manual

...

STRALIS AS/AT/AD

EURO 4/5

BODYBUILDERS INSTRUCTIONS

<![if ! IE]><![endif]> H E A V Y R A N G E

H E A V Y R A N G E

EDITION 2008

Publication Edited by: Technical Application

Strada delle Cascinette, 424/34 10156 Turin - Italy

Publication Nr. 603.93.721 - 2nd Edition

Printed in Italy - 01/08

Produced by:

B.U. TECHNICAL PUBLISHING

Iveco Technical Publications

Lungo Stura Lazio, 15/19

10156 Turin - Italy

STRALIS AS/AT/AD EURO 4/5

Bodybuilders instructions

Print 603.93.721 - 2nd edition

Base - January 2008

UPDATE DATA

Section |

Description |

Page |

Revision date |

|

|

|

|

2 |

Frame |

Paragraph 2.16 moved to chapter 5 |

January 2008 |

|

|

|

|

3 |

Structures |

3-34: paragraph added 3.5.4.3 |

January 2008 |

|

|

|

|

4 |

Power take-off |

Full overhaul chapters 4.6 and 4.7 |

January 2008 |

|

|

|

|

4 |

Power take-off |

4-17: Control unit added |

January 2008 |

|

|

Expansion Module (EM) (*) |

|

|

|

|

|

5 |

Electronic subsystems |

5-4: Cab Module (CM) |

January 2008 |

|

|

integrated in the Body Computer (BC) (*) |

|

|

|

|

|

5 |

Electronic subsystems |

5-8,5-9: connectors ST14A e ST14B |

January 2008 |

|

|

|

|

5 |

Electronic subsystems |

5-40: note added to paragraph 5.4.8 |

January 2008 |

|

|

|

|

6 |

Exhaust systems with SCR |

Chapters 6.6 and 6.7 added. |

January 2008 |

|

|

Full overhaul chapter 6.5 |

|

|

|

|

|

(*) Specific parts only for OBD1 Phase 2.

NOTE The eighth digit of the PIC (Product Identification Code) indicates STEP 2 of the vehicle:

3 - 4 |

- C - B |

Stralis AS |

3 - 4 |

- C |

Stralis AT/AD |

|

|

|

|

|

|

Update data

Print 603.93.721 |

Base - January 2008 |

Update data

Base - January 2008 |

Print 603.93.721 |

Foreword

This manual contains instructions and data for fitting body structures/ancillaries and Vehicle modifications and is intended for skilled and qualified personnel.

The bodybuilder is responsible for the design and fitting and any modifications necessary for the installation. The bodybuilder must ensure full compliance with the requirements set out in this manual and with national and international regulations (Construction and Use, and EEC Standards) in force.

Before starting any work make sure you are working form the latest Iveco Bodybuilders Instruction manual for the model. Make sure that all safety equipment e.g. eye protection, hard hat, shoe, gloves etc are used. Check that all mechanical equipment e.g. lifts and handling gear is in good working order and is used. Finally work on the vehicle in good conditions and ensure maximum safety at all times.

Any change, modification or installations not covered by this manual and not expressly authorized in writing by IVECO will relieve the latter of any responsibility and make, in particular, the vehicle warranty null and void.

For installations / modifications and general information not covered by this manual contact Iveco.

On completion of the installation e.g. body, crane, wheelbase modification the vehicle and systems must be checked to ensure vehicle operation and safety is as designed by Iveco and has not been compromised. If a vehicle system needs to be set up i.e. engine control for PTO installation then contact your local Iveco Service Department.

IVECO shafl not be responsible for any change, modification or fittings concerning the vehicle.

Due to continuing vehicle improvements and changes in regulations which cover or affect the vehicle, the information in this publication may not always be up to date.

If the bodybuilder has any queries regarding the information contained in this manual regarding the vehicle that is to be worked on he should contact Iveco thbiveco@iveco.com before starting.

Symbols - Warnings

Danger to people:

failure to fully comply with these precautions can involve serious danger for personal safety.

Danger of serious damage to the vehicle

Partial or complete non observance of these precautions can cause serious damage to the vehicle and invalidate the Iveco warranty.

Warning / Precaution:

!failure to fully comply with these precautions can result in serious danger to personal safety and damage to the vehicle with the loss of the vehicle warranty.

This indicates the correct use of materials in order to make the vehicle as environmentally friendly as possible.

NOTE Indicates additional information.

Foreword

Print 603.93.721 |

Base - January 2008 |

Page header and footer interpretation

Vehicle type |

|

Section title |

|

Section number - |

|

|

|

page number |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chapter title |

|

Basic edition - |

|

number |

|

|

month year |

|

|

|

|

||

|

|

|

|

|

Foreword

Base - January 2008 |

Print 603.93.721 |

INDEX OF SECTION

|

|

Section |

General |

specifications |

1 |

|

|

|

Chassis |

modifications |

2 |

|

|

|

Building & Mounting the structures |

3 |

|

|

|

|

Power |

Take-offs |

4 |

|

|

|

Special instructions for electronic subsystems |

5 |

|

|

|

|

Special instructions for -SCR- exhaust system |

6 |

|

|

|

|

Index of section

Print 603.93.721 |

Base - January 2008 |

Index of section

Base - January 2008 |

Print 603.93.721 |

STRALIS AS/AT/AD Euro 4/5 |

GENERAL SPECIFICATIONS 1-1 |

|

|

SECTION 1

General specifications

|

|

Page |

1.1 |

Aim of bodybuilders instructions |

1-3 |

|

|

|

1.2 |

IVECO “no objection” for changes and fittings |

1-3 |

|

|

|

1.3 |

Liabilities |

1-4 |

|

|

|

1.4 |

Guarantees |

1-4 |

|

|

|

1.5 |

Request for a “no objection” |

1-4 |

|

|

|

1.6 |

IVECO technical documents available by means of computer |

1-5 |

|

|

|

1.7 |

Trademarks and Logos |

1-5 |

|

|

|

1.8 |

Legal Provisions |

1-5 |

|

|

|

1.9 |

Prevention of accidents |

1-6 |

|

|

|

1.10 |

Choice of material to use: Ecology - Recycling |

1-6 |

|

|

|

1.11 |

Vehicle delivery |

1-7 |

|

|

|

1.12 |

Vehicles Identification |

1-8 |

|

|

|

1.13 |

Dimensions and weights |

1-9 |

|

|

|

1.13.1 |

General Specifications |

1-9 |

|

|

|

1.13.2 |

Determining the Centre of Gravity of the Body and Payload |

1-9 |

|

|

|

1.13.3 |

Observing the Permitted Weights |

1-13 |

|

|

|

1.14 |

Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance |

1-14 |

|

|

|

1.15 |

Quality System management |

1-15 |

|

|

|

1.16 |

Vehicle maintenance |

1-15 |

|

|

|

1.17 |

Conventions |

1-16 |

|

|

|

Index

Print 603.93.721 |

Base - January 2008 |

1-2 GENERAL SPECIFICATIONS |

STRALIS AS/AT/AD Euro 4/5 |

|

|

Index

Base - January 2008 |

Print 603.93.721 |

STRALIS AS/AT/AD Euro 4/5 |

GENERAL SPECIFICATIONS 1-3 |

|

|

1.1Aim of bodybuilders instructions

The purpose of this publication is to provide data, specifications and instructions for the bodybuilding and conversion of an original IVECO vehicle to ensure the functionality, safety and reliability of the vehicle and its components.

1.2IVECO “no objection” for changes and fittings

Changes must be carried out in accordance with the requirements set out in the following guidelines.

The following may be carried out only with IVECO’s authorisation after submitting a copy (two for English Market) of the documentation required for technical evaluation of the proposed change (drawings, calculations, technical report etc.):

-wheelbase modifications, where the new wheelbase does not fall within the minimum and maximum wheelbase available within the IVECO range for the same vehicle;

-work carried out on the braking system;

-work carried out on the suspension system;

-steering wheel modifications;

-changes to the stabiliser bars and suspensions;

-changes to the cab, cab supports, locking and tipping devices;

-changes to the intake systems, engine exhaust and SCR components;

-engine cooling system modifications;

-power unit and driving component modifications;

-work carried out on front and rear axles;

-fitting additional axles;

-fitting decelerator brakes;

-fitting power take-offs;

-changing the tyre dimensions;

-coupling device (hooks, fifth wheels) modifications;

-electric/electronic unit modifications.

The other modifications of fittings covered by the following standards and made in compliance with the same do not require specific authorisation from IVECO. Any modification or fitting not covered by these standards shall, on the contrary, be authorized by IVECO in advance.

Aim of bodybuilders instructions

Print 603.93.721 |

Base - January 2008 |

1-4 GENERAL SPECIFICATIONS |

STRALIS AS/AT/AD Euro 4/5 |

|

|

1.3Liabilities

The authorizations issued by IVECO concern solely the technical/conceptual feasibility of the modification and/or fitting to be made on a genuine IVECO vehicle.

The bodybuilder is responsible for the:

-project of the modification or fitting;

-choice and features of the products used;

-workmanship of the modification or fitting;

-compliance of the project and its implementation with all the instructions provided by IVECO;

-compliance of the project and its implementation with all the current regulations in the country where the vehicle is registered;

-the operation, safety and reliability and in general the effective performance of the vehicle and also the effects that the changes and the conversion may have on the performance and specifications of the vehicle.

1.4Guarantees

The bodybuilder/chassis converter who has built the body or who has modified the chassis must guarantee that the work was undertaken in a professional manner in full compliance with the specifications contained in this manual. IVECO reserves the right to declare void its own warranties for the vehicles where:

-these specifications have not been adhered to or where unauthorised equipment was installed, or unauthorised modifications were carried out;

-an unsuitable vehicle/model has been used for the required conversion or application;

-the specifications, standards or instructions issued by the Manufacturer for the flawless execution of the operations have not been followed;

-original spare parts or components which IVECO has made available for specific conversions were not used.

Maintaining the functionality of vehicle components.

The effective operation of vehicle components, all component safety and running conditions, compliance with national and international regulations (e.g. EC Directives) and accident prevention standards must be guaranteed in all permitted conversions and applications.

All our vehicles are covered by a warranty as laid down in the specific documents.

The bodybuilder must carry out operations at least in an equivalent manner.

1.5Request for a “no objection”

The requests for approval or support to carry out work or make modifications or fittings shall be forwarded to the IVECO marketing offices in charge.

To obtain the approval, the body builder shall provide adequate documents that illustrate the anticipated implementation, utilization and conditions of use on the vehicle. The drawings shall highlight any item differing from the instructions contained in this manual.

The body builder shall submit the modification and/or fitting to the competent authorities for approval.

Liabilities

Base - January 2008 |

Print 603.93.721 |

STRALIS AS/AT/AD Euro 4/5 |

GENERAL SPECIFICATIONS 1-5 |

|

|

1.6IVECO technical documents available by means of computer

The following technical documents are available on the Internet at www.thbiveco.com:

-bodybuilder instruction manuals;

-specification sheets;

-chassis cab diagrams in .dwg and tiff formats;

-chassis diagrams in tiff formats;

-other specifications concerning the vehicle range.

1.7Trademarks and Logos

Trademarks, nameplates and denominations must not be modified or displaced in relation to the original design. The appearance of the vehicle must not be changed or modified.

The application of trademarks tied to the transformation or trim levels must be authorised by IVECO. They must not be applied near to the IVECO tradenames or logos.

IVECO reserves the right to withdraw the tradenames and logos if the fitting or conversion fails to conform with requirements. The bodybuilder accepts all responsibility for the entire vehicle.

Instruction for added assemblies

Where assemblies are added, the bodybuilder must provide the necessary service and maintenance instructions when the vehicle is delivered.

1.8Legal Provisions

On completing the vehicle, the bodybuilder/chassis converter must check the work (modifications, body + equipment etc.) to ensure that the legal provisions required in the country of registration are observed (e.g. weights, dimensions, braking, noise, emissions etc.). Information regarding these matters may be obtained from the competent Authorities or the IVECO Area Network.

The vehicles manufactured at our plant (except some versions for Extra-European countries) comply with the EC directives. Converted vehicles must also comply with these directives. The only permissible exception is granted where local type approval differs from EC homologation.

IVECO technical documents available by means of computer

Print 603.93.721 |

Base - January 2008 |

1-6 GENERAL SPECIFICATIONS |

STRALIS AS/AT/AD Euro 4/5 |

|

|

1.9Prevention of accidents

The structures and devices fitted to the vehicles must comply with the current regulations concerning the prevention of accidents and safety regulations in force in the countries where the vehicle is to be used.

All the precautions dictated by technical awareness must be adopted to prevent malfunction and functional defects. Compliance with these regulations will be the responsibility of the manufacturers of the structures and devices.

Components such as seats, coverings, linings, protective panels etc. may present a potential fire hazard

!if they are exposed to an intense heat source.

They should be removed before working with welding equipment and flames.

1.10Choice of material to use: Ecology - Recycling

Increasingly greater attention should be paid, at the study and design stage, to the choice of materials to be used.

This is especially the case as regards the aspects connected with ecology and recycling in the light of domestic and international regulations that are constantly being developed in the sector.

In this connection:

-everyone must be aware of the prohibitions on using harmful or potentially hazardous materials, such as ones containing asbestos, lead, halogen additives, fluorocarbons, cadmium, mercury, hexavalent chrome, etc.

-Use materials whose processing produces limited waste and that permit easy recycling after their first use.

-With composite synthetic materials, use components that are compatible with each other, envisaging also their possible utilization with the addition of other salvaged components. Affix the markings required in compliance with the current regulations.

In order to comply with EC directive 2000/53 (ELVs), IVECO S.p.A. prohibits fitting parts containing lead, mercury, cadmium and hexavalent chrome to vehicles (except for the departures referred to in Attachment II of the above directive).

Prevention of accidents

Base - January 2008 |

Print 603.93.721 |

STRALIS AS/AT/AD Euro 4/5 |

GENERAL SPECIFICATIONS 1-7 |

|

|

1.11Vehicle delivery

Prior to delivering the vehicle, the body builder shall:

-verify that the work has been made correctly;

-perform vehicle and/or equipment set-up;

-check the operation and safety of the vehicle and/or equipment;

-prepare and deliver the necessary instructions for service and maintenance of the fitting and any additional units to the end customer;

-write the new data down on the special tags;

-confirm that the work carried out complies with the indications provided by the vehicle manufacturer and with all legal requirements;

-carry out the checks included in the ”IVECO Pre-Delivery inspection” list (available from the IVECO network) with regard to the items affected by the work done;

-provide a guarantee for the modifications made;

-in the event that the connections originally provided with screws have been mounted and restored, the same screws must not be used. In such an instance, and in the event that rivets have been replaced with screws, you must again check the tightness of the connection after travelling approximately 500-1000 km, to ensure it is to the correct torque.

-measure the battery voltage. Ensure there is a minimum charge of 12.5 V. If the voltage reading is between 12.1 and 12.49 V, recharge the battery (slow charge). If the voltage is less than 12.1 V, the battery must be scrapped and replaced with a new one.

Vehicle delivery

Print 603.93.721 |

Base - January 2008 |

1-8 GENERAL SPECIFICATIONS |

STRALIS AS/AT/AD Euro 4/5 |

|

|

1.12Vehicles identification

The commercial designation of IVECO vehicles is not the same as the type approval (homologation) designation. Two types of commercial designation are shown below with the meaning of the codes used:

|

Cab |

|

|

|

|

Model |

|

|

|

|

Power |

|

|

Version |

|

Suspension |

|

||||||||

|

Range |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAB VERSIONS |

A |

|

S |

|

2 |

|

6 |

|

0 |

|

S |

|

4 |

|

2 |

|

Y |

|

|

|

/ |

|

P |

|

S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

TRACTOR |

A |

|

S |

|

4 |

|

4 |

|

0 |

|

S |

|

4 |

|

5 |

|

T |

|

X |

|

/ |

|

P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/TN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

/P |

|

|

|

AS |

|

|

PTT-Cab versions |

|

|

|

|

|

|

|

|

|

|

|

|

|

/PT |

|

||||||

|

|

|

(n˚/10 → hung in ton) |

|

|

|

|

|

|

|

|

T |

|

|

|

/PS |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

AD |

|

|

|

|

|

|

|

|

STRALIS |

|

Engine power |

|

|

|

|

|

|

|

/FP |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

AT |

|

|

|

PTC-Tractors |

|

|

|

|

|

|

|

|

|

X |

|

|

|

/FS |

|

|||||

|

|

|

|

|

(with semitrailers) |

|

|

|

|

|

|

|

|

Y |

|

|

|

|

|

|

|||||

|

|

|

|

|

(n˚/10 → hung in ton) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

(n˚ x 10 → HP) |

|

|

Z |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXTERNAL NAMEPLATE ON

VEHICLE

CAB RANGE |

|

VERSION |

|

MISSION |

|||||

|

|

|

|

|

|

|

|

|

|

AS |

= |

Active Space |

|

T = Tractor |

|

GV |

= |

Bulky Goods |

|

AT |

= |

Active Time |

|

X = 6x2C |

|

|

|

transport |

|

AD |

= |

Active Day |

|

Y = 6x2P |

CM |

= |

Mobile Boxes |

||

|

|

|

|

(Z= 6x4) |

LT |

= |

Low Tractor |

||

|

|

|

|

|

|

RR |

= |

Rough Roads |

|

|

|

|

|

|

|

HM |

= |

Heavy Mission |

|

|

|

|

|

|

|

D |

= |

Delivery |

|

|

|

|

|

|

|

CT |

= |

With Transporter |

|

|

|

|

|

|

|

HR |

= |

Hub Reduction |

|

SUSPENSION |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

||||

/TN = |

6x2P, mechanics with third fixed axle to twinned wheels |

|

|

|

|

||||

/P |

= |

4x2, 6x4, 6x2P, air suspension at rear. 6x2P with single wheels fixed third axle |

|

|

|

|

|||

/PT |

= |

Only for 6x2P, air suspension at rear with twin wheels fixed third axle |

|

|

|

|

|||

/PS |

= |

Only for 6x2P, air suspension at rear with single wheels third axle, controlled steering |

|

|

|||||

/FP |

= |

4x2, 6x4, 6x2P, full air |

|

|

|

|

|

|

|

/FS |

= |

Only for 6x2P full air with single wheels third axle, controlled steering |

|

|

|

|

|||

Vehicles identification

Base - January 2008 |

Print 603.93.721 |

STRALIS AS/AT/AD Euro 4/5 |

GENERAL SPECIFICATIONS 1-9 |

|

|

1.13Dimensions and weights

1.13.1General Specifications

The dimensions and maximum permissible weight on the axles are indicated on drawings, on technical specifications and, in greater details, on the official documentation issued by IVECO.

The kerb weights refer to vehicles with standard equipment. Special equipment may involve considerable modification to the weight and its distribution on the axles.

Lights and rear-view mirrors positioning on our vehicles is designed for widths of 2,550 mm. This dimension may also be applied to special body versions with a width of 2,600 mm (e.g. refrigerator vans).

Weighing the Chassis

As a result of production factors there may be a variation in weight of approx. 5%.

It is, therefore, advisable to determine the weight of the vehicle with its cab before fitting the body and equipment and establishing their distribution on the axles.

1.13.2Determining the Centre of Gravity of the Body and Payload

Positioning on longitudinal plane

To establish the location of the centre of gravity of the body and payload the following examples below may be used as guidelines.

The technical documentation specific to each model (chassis cab drawing) give the positions permitted with the vehicle in its standard form. The weight and positioning of the single components of the vehicle are given in the chassis and weight distribution diagram.

Dimensions and weights

Print 603.93.721 |

Base - January 2008 |

1-10 GENERAL SPECIFICATIONS |

STRALIS AS/AT/AD Euro 4/5 |

|

|

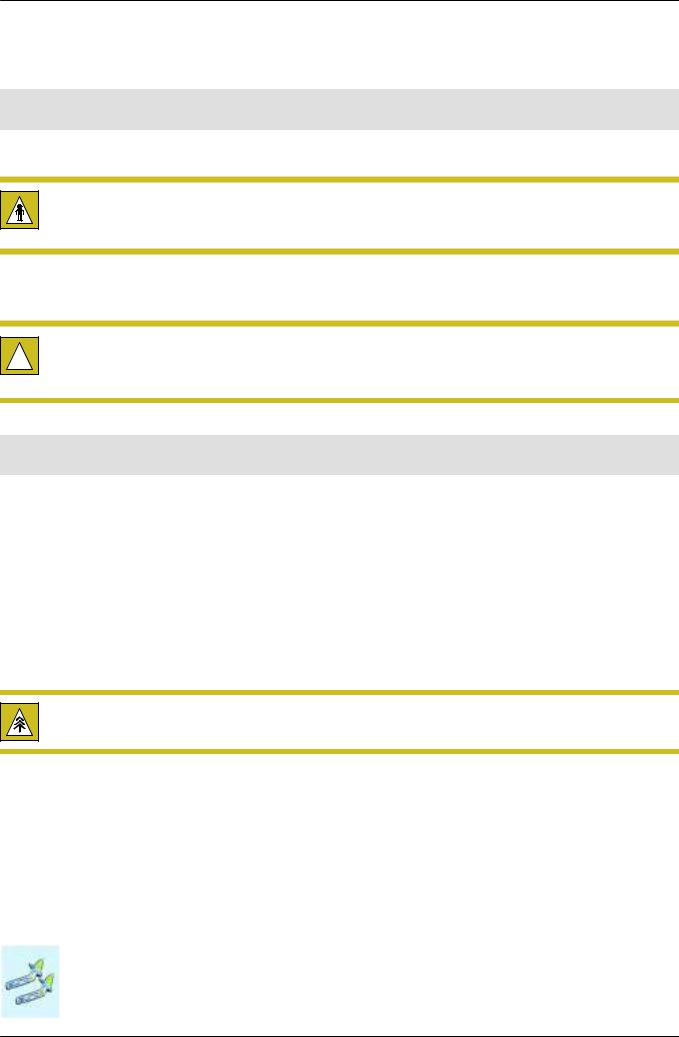

Figure 1.1 |

Vehicles with 2 axles; vehicles with 3 axles with an equal load on the two |

|

rear axles |

Example to determine the position of the centre of gravity of the payload plus body

A |

= Rear axle or tandem mid axle |

L1 |

= |

Distance of centre of gravity from |

|

W |

= Payload + body |

|

|

centre-line of rear axle |

|

W1 |

= |

Share of payload on front axle |

|

|

(or tandem centre-line) |

W2 |

= |

Share of payload on rear axle (or tandem) |

L |

= |

Actual wheelbase |

L1 = |

W1 |

L |

W |

|

|

|

|

|

respectively L1 = L - |

W2 |

L |

W |

|

|

|

|

Figure 1.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vehicles with 3 or more axles with a constant mass distribution ratio on |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the two rear axles. For these vehicles the ”ideal” values of the wheelbase |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and centreline between the axles, resulting from mass distribution, is de- |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

termined by the Manufacturer. |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

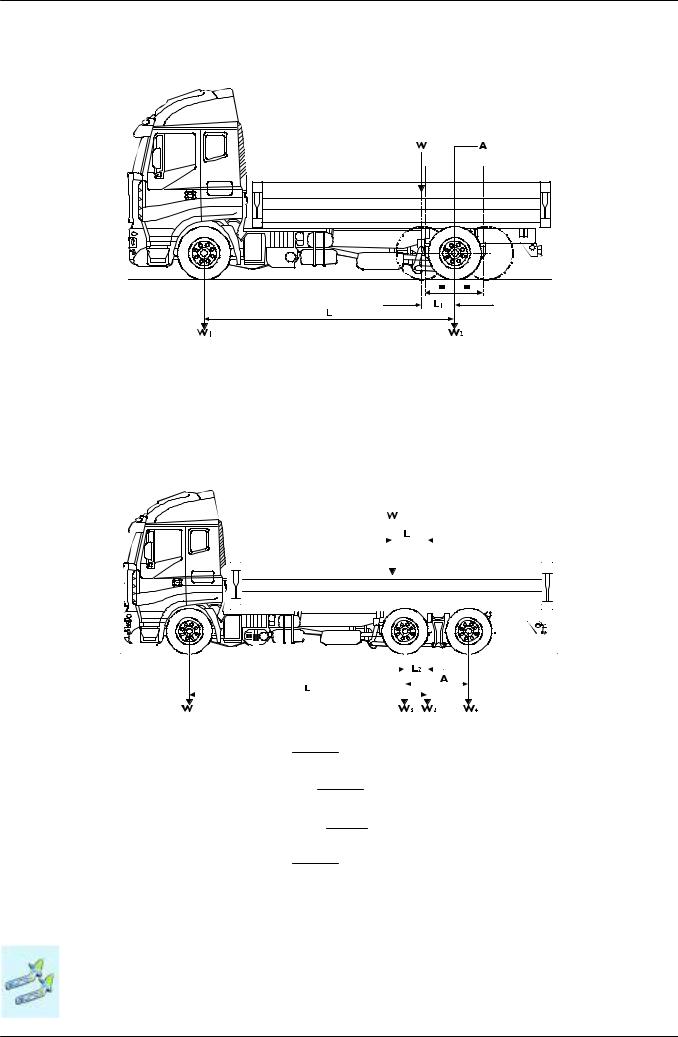

Example to verify compliance of admitted weight on the axles

W |

= Payload + body |

|

W1 |

= Share of payload on front axle |

|

W2 |

= Share of payload on rear axles |

|

W3 |

= Share of payload on first rear axle |

|

W4 |

= Share of payload on second rear axle |

|

L1 |

= |

Distance of centre of gravity relative |

|

|

calculated centreline |

L |

= |

Calculated wheelbase (ideal) |

L2 |

= |

Calculated centreline (ideal) |

A |

= Distance between rear axles |

|

W1 =

W x L1

L

W2 = W x

(L - L1)

L

W3 = W2 x

(A - L2)

A

W4 =

W2 x L2

A

Attention:

On vehicles with three or more axles, with a variable mass distribution ratio on the two rear axles depending on the load, the ”ideal” values of wheelbase and centreline between the axles will have to be calculated on the basis of the information given in the chassis cab diagram, or in the specific documentation specially prepared by IVECO. In this way, for special versions (e.g. cranes on rear overhang) it will be possible to determine the correct positioning of the centre of gravity of the equipment and payload on the basis of the actual load (see point 5.4 in section 5).

Dimensions and weights

Base - January 2008 |

Print 603.93.721 |

STRALIS AS/AT/AD Euro 4/5 |

GENERAL SPECIFICATIONS 1-11 |

|

|

In order to apportion the payload on the axles, it must be uniformly distributed except when the shape of the loading surface itself entails a different distribution of the load.

As for equipment, the actual location of the centre of gravity is used.

When building bodies or containers, loading and unloading systems for the transported goods must be devised which preclude excessive variations in the distribution of the load and/or excessive loads on the axles, also giving the relevant instructions to the users.

The bodybuilder will also need to install suitable payload securing systems on the body so that transport can be made with the utmost safety.

Figure 1.3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Uniform distribution of the load |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Non-uniform distribution of the load due to the |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

lack of rear overhang |

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Uniform distribution of the load |

Non-uniform distribution of th e load (beware of load on axles |

|

and minimum ratio) |

Dimensions and weights

Print 603.93.721 |

Base - January 2008 |

1-12 GENERAL SPECIFICATIONS |

STRALIS AS/AT/AD Euro 4/5 |

|

|

Height of the Centre of Gravity

The height of the centre of gravity of the chassis cab is given in the technical documentation specific to each model (chassis drawing).

For testing the vehicle complete with superstructure, the bodybuilder must check that the height of the centre of gravity of the equipment including the payload, or of the entire vehicle when fully loaded, falls within the maximum permitted values.

These limits are defined in compliance with the national or international regulations (e.g. as amended by the current EC braking Directive) or requested by the Manufacturer to ensure good handling of the vehicle (e.g. transverse stability of the moving vehicle).

In order to comply with the current EC Directive, IVECO provides information for the various models (wheelbase and specific body) on computer, regarding:

-height of centre of gravity of chassis cab (e.g. chassis cab diagram, braking data);

-maximum height of centre of gravity of complete vehicle at full load (e.g. national type-approval document);

-braking capacity of each single axle (e.g. braking data).

Figure 1.4

Verification with full load:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ht = Wv . Hv + Ws . Hs |

||||||||||

|

|

|

|

|

|

Wv + Ws |

|||||||||

Wv |

= Chassis cab vehicle kerb weight |

||||||||||||||

Hv |

= Height of centre of gravity of chassis cab vehicle (laden condition) |

||||||||||||||

Ws |

= Body and payload |

||||||||||||||

Hs |

= Height of centre of gravity of body and payload in relation to ground |

||||||||||||||

Wt |

= Vehicle weight when fully loaded |

||||||||||||||

Ht |

= Height of centre of gravity of vehicle fully laden to gvw |

||||||||||||||

Hs = (Wv + Ws) . Ht − Wv . Hv

Ws

To check the vehicle with its body but no payload, use above formula but for Ws use only the body kerb weight (The position for Hv will depend on the load and deflection of the suspension).

The height of the centre of gravity indicated in Tabella 2.6 represents values which are not to be exceeded for each given equipment level. These values have been calculated only in terms of the transverse stability of the vehicle and are applicable to a mid wheelbase. Any other possible restrictive specification, e.g. braking regulation, should be taken into consideration.

The values given in Tabella 2.6 refer to the superstructure with fixed payload. In versions where the payload tends to move on side (e.g. suspended loads, fluid loads etc.) especially when turning, higher dynamic stress is generated which makes the vehicle less stable. This must be taken into consideration when providing vehicle operating instructions or for possible reduction in the height of the centre of gravity.

Dimensions and weights

Base - January 2008 |

Print 603.93.721 |

STRALIS AS/AT/AD Euro 4/5 |

GENERAL SPECIFICATIONS 1-13 |

|

|

Using Stabiliser Bars

Supplementary stabilising or anti-roll bars, where available, spring reinforcements or the application of rubber components (in compliance with point 2.7) may increase the height of the centre of gravity of the payload which must be defined as each occasion arises. The modification must be carried out after careful consideration has been given to the specifications of the version, to the wheelbase and to the distribution of the cross-stresses acting on the suspension both at the front and at the rear of the vehicle. It must be borne in mind that it is often advisable to modify the rear axle only since a modified front axle would give the driver a false sense of stability making it more difficult to perceive the safety limits. Modification to the front axle may be made where the load is positioned behind the cab (e.g. crane) or where the superstructures are very rigid (e.g. van conversion).

Exceeding the Limits

When transporting goods with an exceptionally high centre of gravity (e.g. machinery, indivisible cargo etc.) from a technical point of view it is possible to exceed the values indicated in the table provided that the steering system of the vehicle is suitably adapted to this condition (e.g. reduced speed, gradual changes on the steering wheel, etc.).

1.13.3Observing the Permitted Weights

All limits indicated in our documentation must be adhered to. The load of the front axle is of particular importance under varying load conditions, in order to ensure the correct steering characteristics on road surfaces of all types.

Particular attention must therefore be paid to vehicles with a weight which is concentrated on the rear overhang (e.g. cranes, tail-lifts, centre axle trailers) and to vehicles with a short wheelbase and a high centre of gravity (e.g. silo vehicles, cement mixers).

When positioning the body and equipment, the loads must be correctly distributed transversally. For each wheel a variation in the rated load (1/2 of the axial load) of 4% is permitted (e.g. admitted load on axle: 10,000 kg load admitted on each wheel: 4,800 to 5,200 kg) provided that the tyres permit it, without impairing braking or driving stability.

For vehicles with an added rear lift axle it must be remembered that, with the axle in the raised position, the effective wheelbase is reduced, whereas the rear overhang is increased. It is therefore advisable that the centre of gravity of the body and payload is located in front of the centre line of the driving axle. In addition to this it is not advisable to equip a vehicle which has its load concentrated at the rear, with a lifting device.

Apart from different specifications for specific individual vehicles, the following may be taken to be the minimum values for the front axle:

-20% of the total vehicle weight with uniformly distributed loads

-25% of the total vehicle weight for loads that are concentrated on the rear overhang.

The rear overhang of the body must be built in strict observance of the permitted axle loads, the limitations in length, the positioning of the tow hook and of the underride guard stipulated by the relevant regulations and legal requirements.

Variations in the Permissible weight

Special exceptions to the maximum permissible weight may be granted for particular applications for which, however, precise limitations regarding the use will be imposed in addition to possible vehicle reinforcements.

Such exemptions, if they exceed the limits imposed by law, must be authorised by the Administrative Authority.

A reduction in admissible vehicle load (downrating) may require modifications on some parts, such as the suspension. In these circumstances, the necessary information may be supplied.

The request for authorisation must include:

-Vehicle type, wheelbase, identification number, designated use.

-Weight distribution on the axles (e.g. vehicles equipped with crane and body) including positions of the centre of gravity of the payload.

-Proposals concerning the reinforcement of the vehicle components where necessary.

Dimensions and weights

Print 603.93.721 |

Base - January 2008 |

1-14 GENERAL SPECIFICATIONS |

STRALIS AS/AT/AD Euro 4/5 |

|

|

1.14Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance

As a rule, when modifying or installing any type of equipment, nothing must be altered which prevents the correct functioning of assemblies and parts of the vehicle under all operational conditions.

For example:

-Ready access to all parts requiring inspection or maintenance and periodic servicing must be provided. In the case of closed body types suitable opening doors must be provided.

-For tilting cabs, adequate space permitting tilting must be assured. In the case of structures which involve the space above the driver’s cab, adequate space for the passage of intake air must be guaranteed (see 1.5).

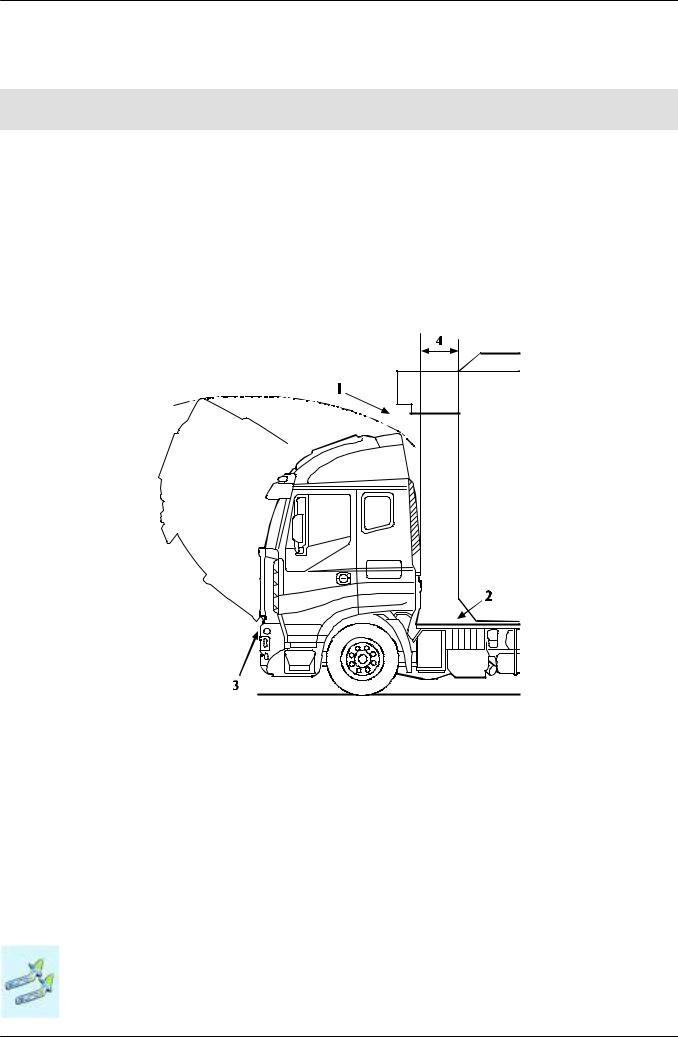

Figure 1.5

1. Retain adequate room for tilting the driver’s cab - 2. Retain the free space above the gearbox (for tractors with semitrailers consider the movement between tractor and semitrailer) - 3. Cab pivot point - 4. Min. distance to be met

-Service access to chassis/driveline components must be retained. For instance repairing the gearbox or clutch must be possible without necessitating the removal of major components of the added structure.

-The cooling system (radiator cowling, radiator, air passages, cooling circuit etc.), fuel supply (pump position, filters, pipe diameter, etc.) and the engine air intake must not be altered.

-The anti-noise panels must not be altered or moved in order to prevent changes in the approved noise levels of the vehicle. Should it be necessary to make openings (e.g. for the longitudinal runner of the body to pass through) these must be properly closed off using material with inflammability and soundproofing characteristics equivalent to those used originally.

Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance

Base - January 2008 |

Print 603.93.721 |

STRALIS AS/AT/AD Euro 4/5 |

GENERAL SPECIFICATIONS 1-15 |

|

|

-Adequate ventilation of the brakes and battery case (especially in the case of box bodies) must be guaranteed.

-The positioning of the mud-guards and wheel-arches must allow free movement of the rear wheels even when chains are being used. Sufficient space must also be ensured with lifting axles. Some of our models have 3rd axle steering which also steers in the raised position; and it is necessary to leave space for this function (see point 2.20).

-When the vehicle has been set up, for safety reasons, headlight attitude must be checked and adjusted as necessary. Perform the adjustment according to the instructions provided in the user and maintenance manual.

-In the case of parts which are supplied loose (e.g. spare wheel, chocks) it will be the responsibility of the bodybuilder to position and secure them in an accessible and safe manner in compliance with possible national regulations.

1.15Quality System management

For some time IVECO has been promoting Quality System development and training for bodybuilders.

This is a requirement due not only to compliance with domestic and international regulations on product liability, but also the growing demand for increasingly higher quality levels. The creation of new forms of organization in the various sectors and the quest for increasingly more advanced levels of efficiency.

IVECO believes it essential for bodybuilders to be equipped and organised where the following are defined and available:

-organization charts for functions and responsibilities.

-Quality System.

-quality goals.

-technical design documentation.

-process and control phases with relevant resources.

-product improvement plan, obtained also with corrective actions.

-after sales service.

-staff training.

-manufacturer liability documentation.

1.16Vehicle maintenance

In addition to making the necessary checks on the body/structure in keeping with customary working procedures, the bodybuilder shall perform the checks specified in the “IVECO pre-delivery inspection” list, which can be obtained from the IVECO network, for the aspects affected by the modifications performed.

Instructions for the Correct Functioning of the Parts of the Vehicle and Accessibility for Maintenance

Print 603.93.721 |

Base - January 2008 |

1-16 GENERAL SPECIFICATIONS |

STRALIS AS/AT/AD Euro 4/5 |

|

|

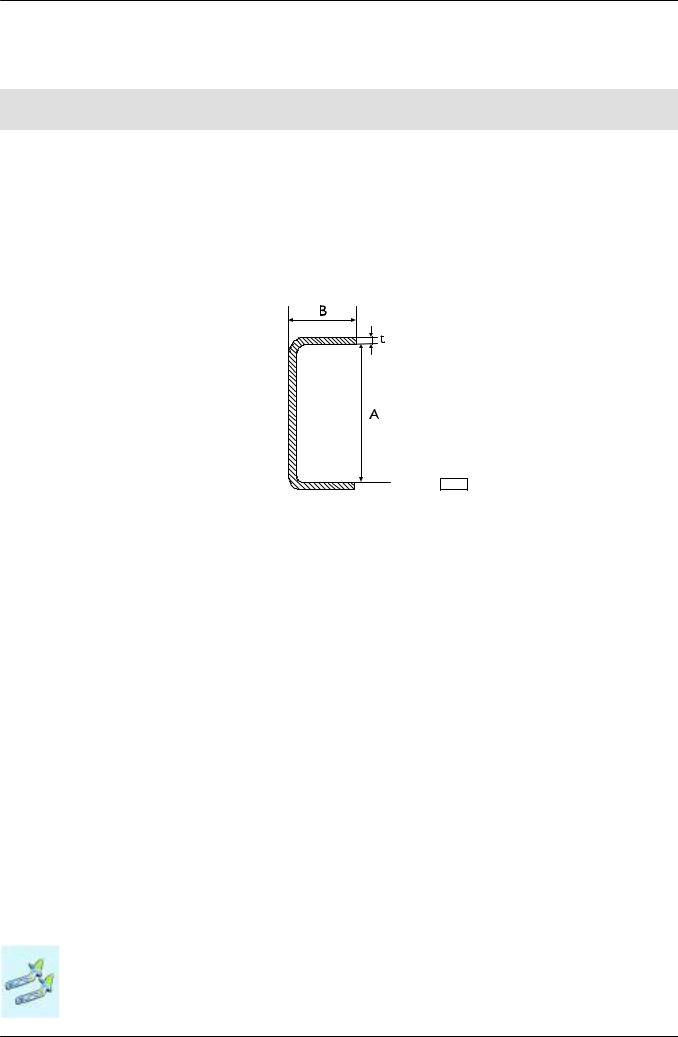

1.17Conventions