Iveco GEARBOX EuroTronic 12 AS 2301 D.D., GEARBOX EuroTronic 12 AS 2301 O.D Service Manual

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

113

STRALIS AT/AD

Print 603.93.141 Base - January 2003

Gearbox

EuroTronic 12 AS 2301 D.D./O.D.

Page

DESCRIPTION 115. . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS AND DATA 116. . . . . . . . . . . . .

TIGHTENING TORQUES 119. . . . . . . . . . . . . . . . .

TOOLS 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OVERHAULING THE GEARBOX 125. . . . . . . . . . .

- Checks 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Gearbox actuator 125. . . . . . . . . . . . . . . . . . . . . .

- Removal 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Refitting 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Removing the rear box 126. . . . . . . . . . . . . . . . . .

- Removing the rear box 127. . . . . . . . . . . . . . . . . .

- Removing the epicyclic reduction

gear train (E.R.G.) 128. . . . . . . . . . . . . . . . . . . . . .

- Fitting the epicyclic reduction gear train (E.R.G.) 130

- Adjusting epicyclic reduction gear train bearing

end float 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Adjusting main shaft end float 132. . . . . . . . . . . . .

- Synchronizing device assembly for engaging

normal or reduced gears 134. . . . . . . . . . . . . . . . .

- Removal 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Fitting 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Removing the middle box 137. . . . . . . . . . . . . . . .

- Removing the main shaft 139. . . . . . . . . . . . . . . . .

- Removing the drive input shaft 141. . . . . . . . . . . .

- Removing the splitter synchronizing device 142. . .

- Fitting the splitter synchronizing device 143. . . . . .

- Fitting the drive input shaft 144. . . . . . . . . . . . . . .

114

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

Page

- Fitting the main shaft 144. . . . . . . . . . . . . . . . . . . .

- Splitter control fork 147. . . . . . . . . . . . . . . . . . . .

- Disassembly - Assembly 147. . . . . . . . . . . . . . . . .

- Gear control forks 147. . . . . . . . . . . . . . . . . . . . .

- Removal 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Fitting 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Transmission shafts 149. . . . . . . . . . . . . . . . . . . . .

- Disassembly - Assembly 149. . . . . . . . . . . . . . . . .

- Fitting the middle box 149. . . . . . . . . . . . . . . . . . .

- Fitting the front box 152. . . . . . . . . . . . . . . . . . . .

- Front cover 154. . . . . . . . . . . . . . . . . . . . . . . . . . .

- Removal 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

- Fitting the front cover 154. . . . . . . . . . . . . . . . . . .

- Adjusting drive input shaft bearing end float 154. .

- Adjusting transmission shaft bearing end float 155

- Clutch release lever 157. . . . . . . . . . . . . . . . . . . .

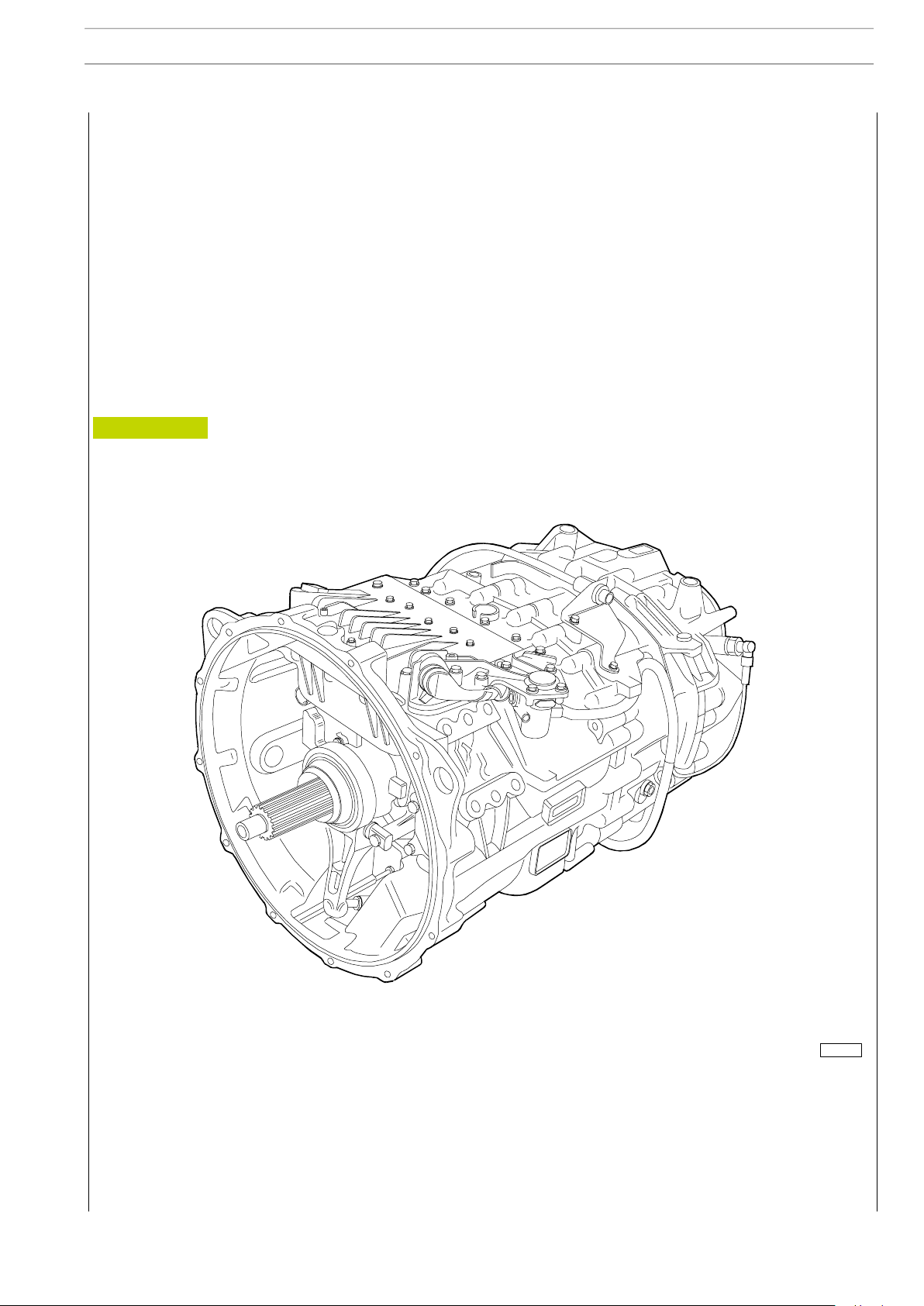

DESCRIPTION

The EuroTronic gearbox 12 AS 2301 D.D./O.D. is mechanical with electro-pneumatic control.

The driver can choose whether to program gear selection/engagement manually or automatically. The shafts and gears have

helical toothing that reduces operating noise.

The main shaft gear coupling is obtained with sleeves with front toothing.

The splitter and epicyclic reduction gear unit engagement is synchronized.

The speeds are selected with finely staggered ratios and can be engaged in succession with the coupling of the epicyclic reduction

gear unit ”ERG” and the ”Splitter” slow or fast speed unit.

On engaging the ”ERG”, the speeds of the main shaft are doubled. The ratios obtained in this way are further doubled with the

engagement of the ”Splitter”. Each single ratio is thus divided into a fast or slow ratio.

D.D. = Direct drive

O.D. = Over Drive (Multiplied)

Figure 1

000418 t

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

115

STRALIS AT/AD

Print 603.93.141 Base - January 2003

116

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

SPECIFICATIONS AND DATA

GEARBOXES EuroTronic Automated

12 AS 2301 D.D. 12 AS 2301 O.D.

Type Mechanical

Torque activated Nm

1900 2500

Forward gears

Reverse gears

12

2

Type of running control electronically-operated semi-automatic

Rear power takeoff optional

Gear engagement:

E.R.U.* and splitter engagement

by front engagement sleeves

free ring synchroniser

Gears constantly engaged straight toothed

Gear ratios

1

a

2

a

3

a

4

a

5

a

6

a

7

a

8

a

9

a

10

a

11

a

12

a

1aRM

2

a

RM

15.85

12.32

9.56

7.43

5.87

4.56

3.47

2.70

2.09

1.62

1.28

1.00

14.68

11.41

12.33

9.59

7.44

5.78

4.57

3.55

2.70

2.10

1.63

1.27

1.00

0.78

11.41

8.88

ERG* = Epicyclic Reduction Gearing

D.D. = Direct drive

O.D. = Over Drive (Multiplied)

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

117

STRALIS AT/AD

Print 603.93.141 Base - January 2003

SPECIFICATIONS AND DATA

EuroTronic Automated

12 AS 2301 D.D./O.D.

Bearings

- drive input shaft

- ERG* shaft

- transmission shafts

with balls

with cylindrical rollers

with tapered rollers

Bearing end float:

- drive input shaft

- ERG* planet shaft

- transmission shafts

0 y 0.1 mm

0 y 0.1 mm

- 0.05 y + 0.05 mm

End float:

- main shaft

- drive input shaft split ring

0.2 mm

0 y 0.1 mm

Temperature for fitting bearings or bearing

seats on the boxes

120 qC

Forced lubrication with positive displacement pump flow rate (with 12

th

speed en-

gaged and oil at a temperature of 80ºC)

pressure with 12thspeed engaged at 2400

rpm and oil at a temperature of:

40ºC

80ºC

50 dm3/min

1.7 bar

1.2 bar

Oil type

litres

kg

Tutela Truck Fe-Gear

Tutela ZC 90

12

11

ERG* = Epicyclic Reduction Gearing

D.D. = Direct drive

O.D. = Over Drive (Multiplied)

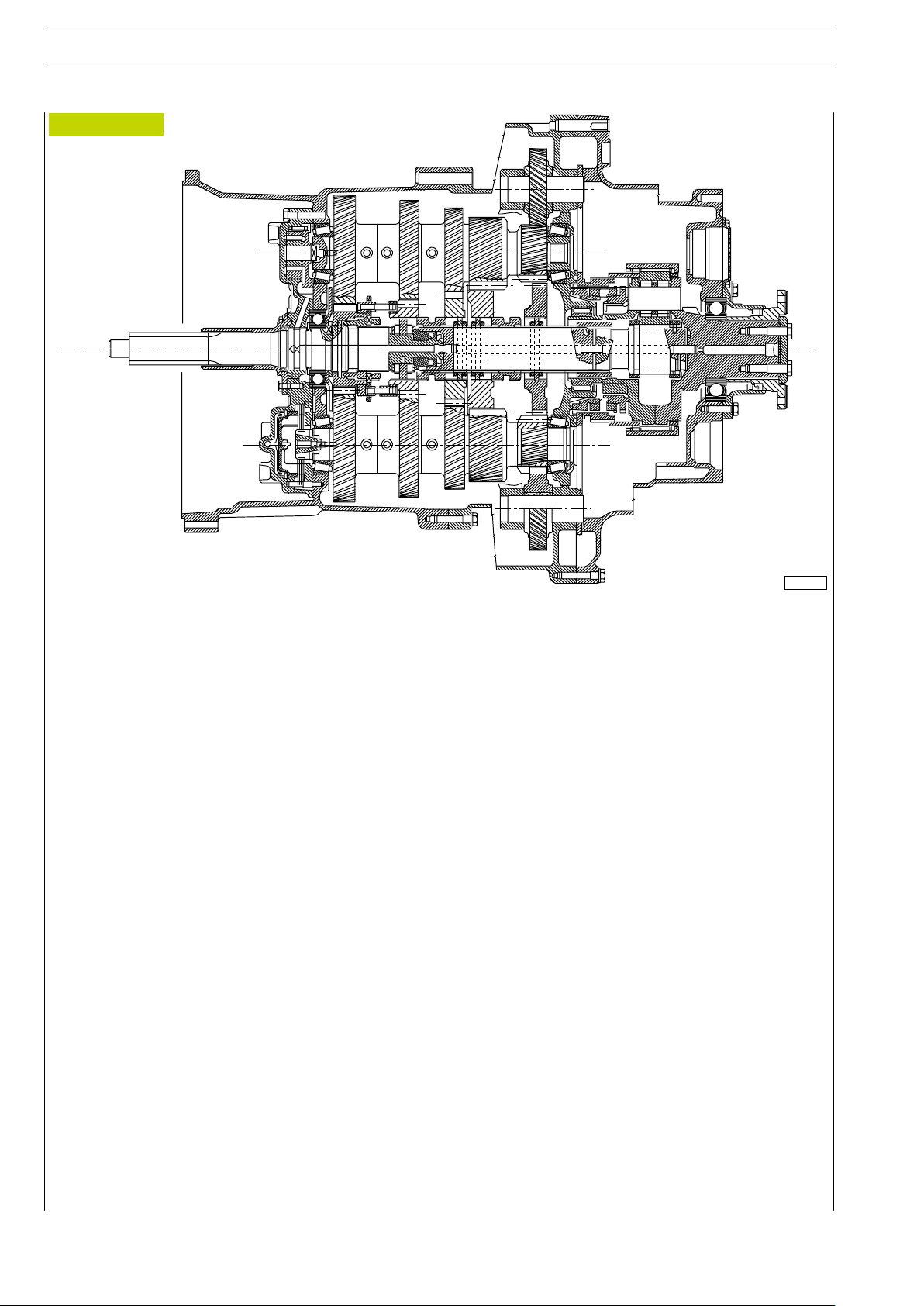

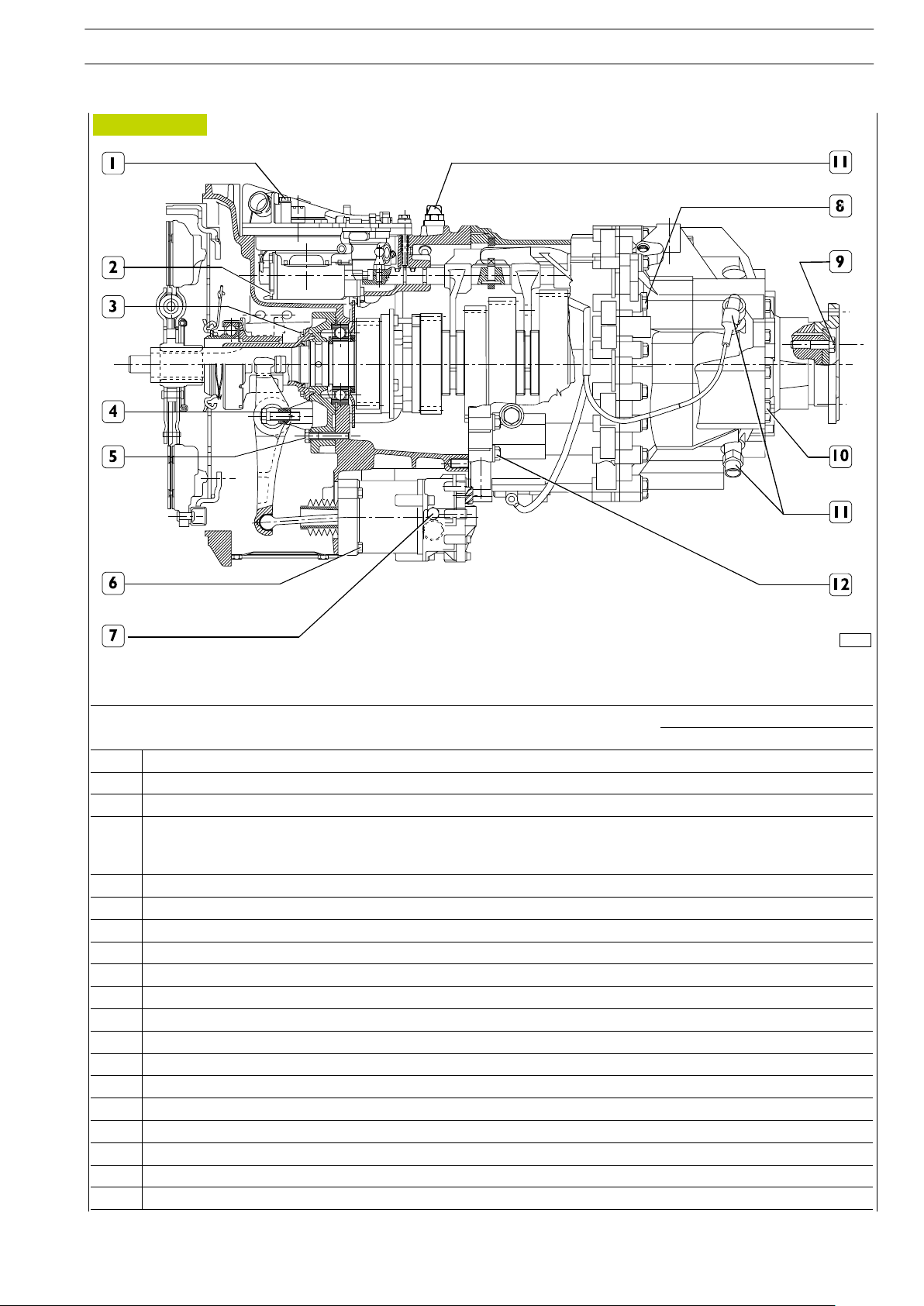

Figure 2

LONGITUDINAL CROSS-SECTION OF EUROTRONIC 12AS 2301 GEARBOX

001396 t

118

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

GEARBOX EuroTronic 12 AS 2301 D.D./O.D. 119

STRALIS AT/AD

Print 603.93.141 Base - January 2003

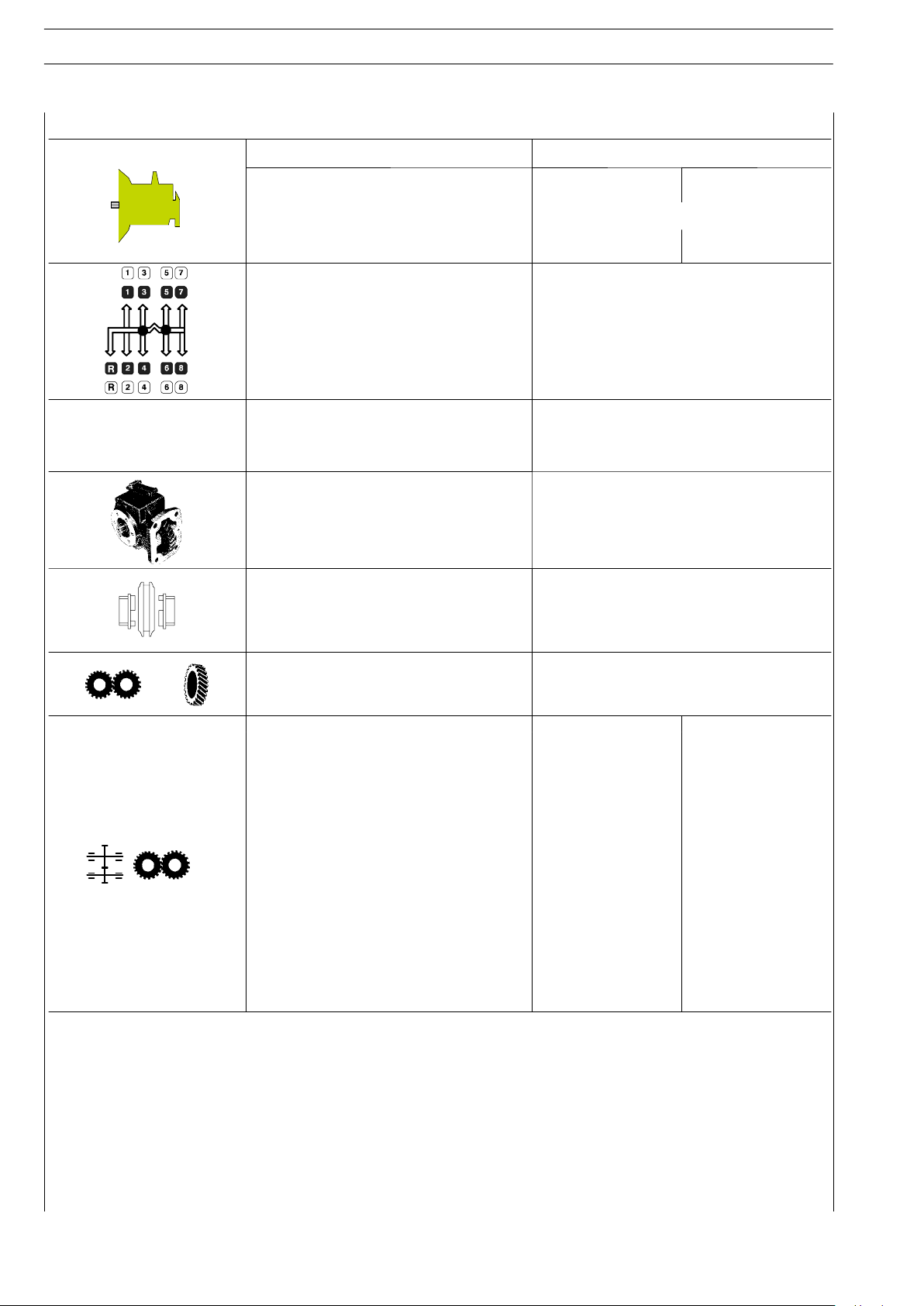

TIGHTENING TORQUES

TORQUE

DESCRIPTION

Nm kgm

1 Screws fixing gearbox actuator 23 2.3

2 Screw fixing oil pump 10 1

3 Screws fixing drive input shaft cover 23 2.3

4

Screw fixing clutch uncoupling lever control pin:

- M 12 8.8

- M 12 10.9

79

115

7.9

11.5

5 Screws fixing cover (spread LOCTITE 241 on the thread) 79 7.9

6 Screws fixing clutch actuator 23 2.3

7 Screw cap to discharge air from clutch actuator 22 2.2

8 Screws fixing rear box to middle box 46 4.6

9 Screws fixing flange retaining plate 120 12

10 Screws fixing rear cover 5 4.6

11 Speed sensor 45 4.5

12 Screws fixing middle box to front box 50 5

Pin on rod (spread LOCTITE 262 on the thread) 23 2.3

Oil vapour vent 10 1

Screw plug M 10x1 on rear box 15 1.5

Screw plug M 24x1 on rear box 60 6

Screw M12 fixing power take-off bay cover 79 7.9

Screw plug M 24x1.5 on middle box 60 6

Screw fixing plates retaining fork joint pins on rear box 23 2.3

70824

Figure 3

120

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

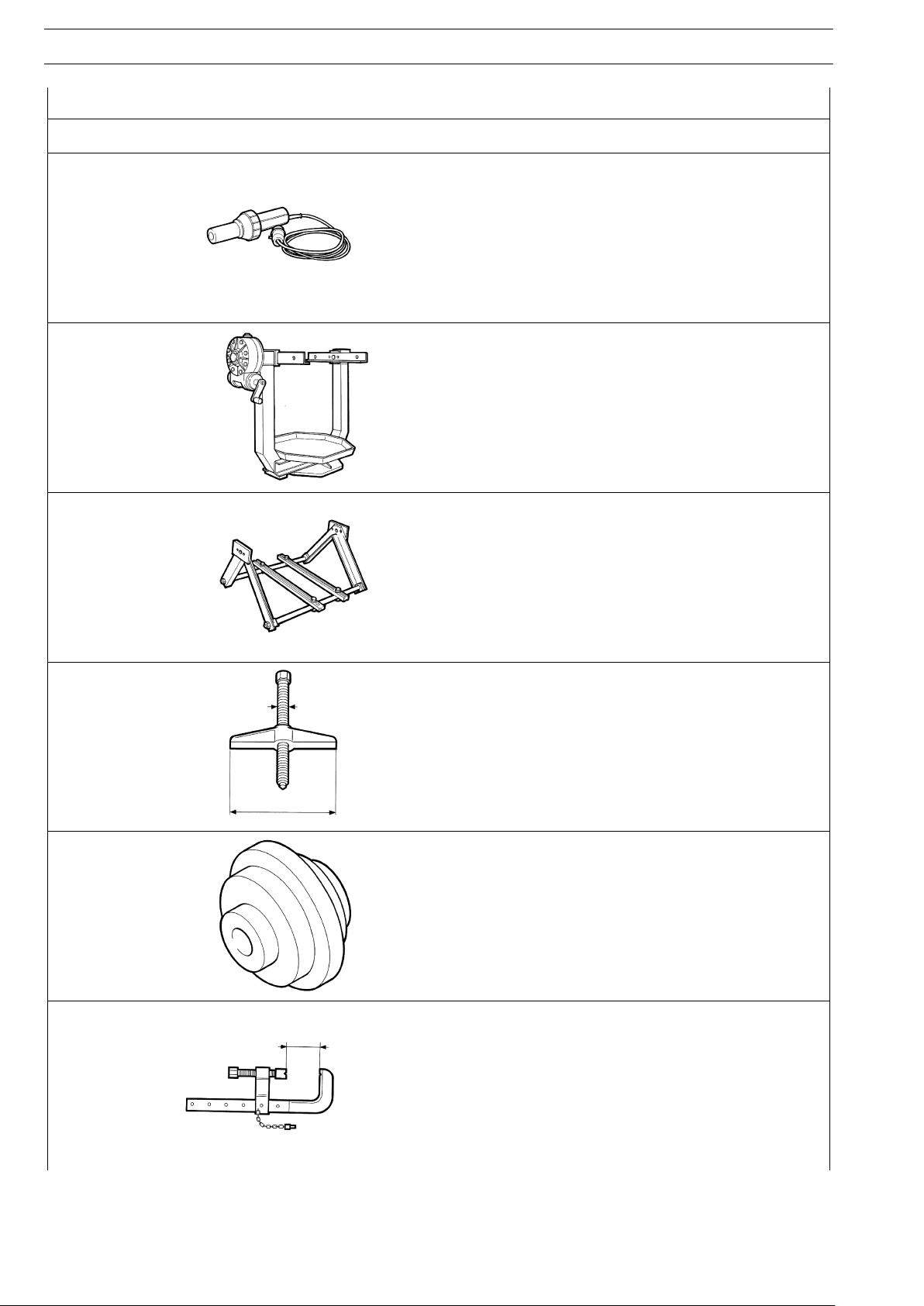

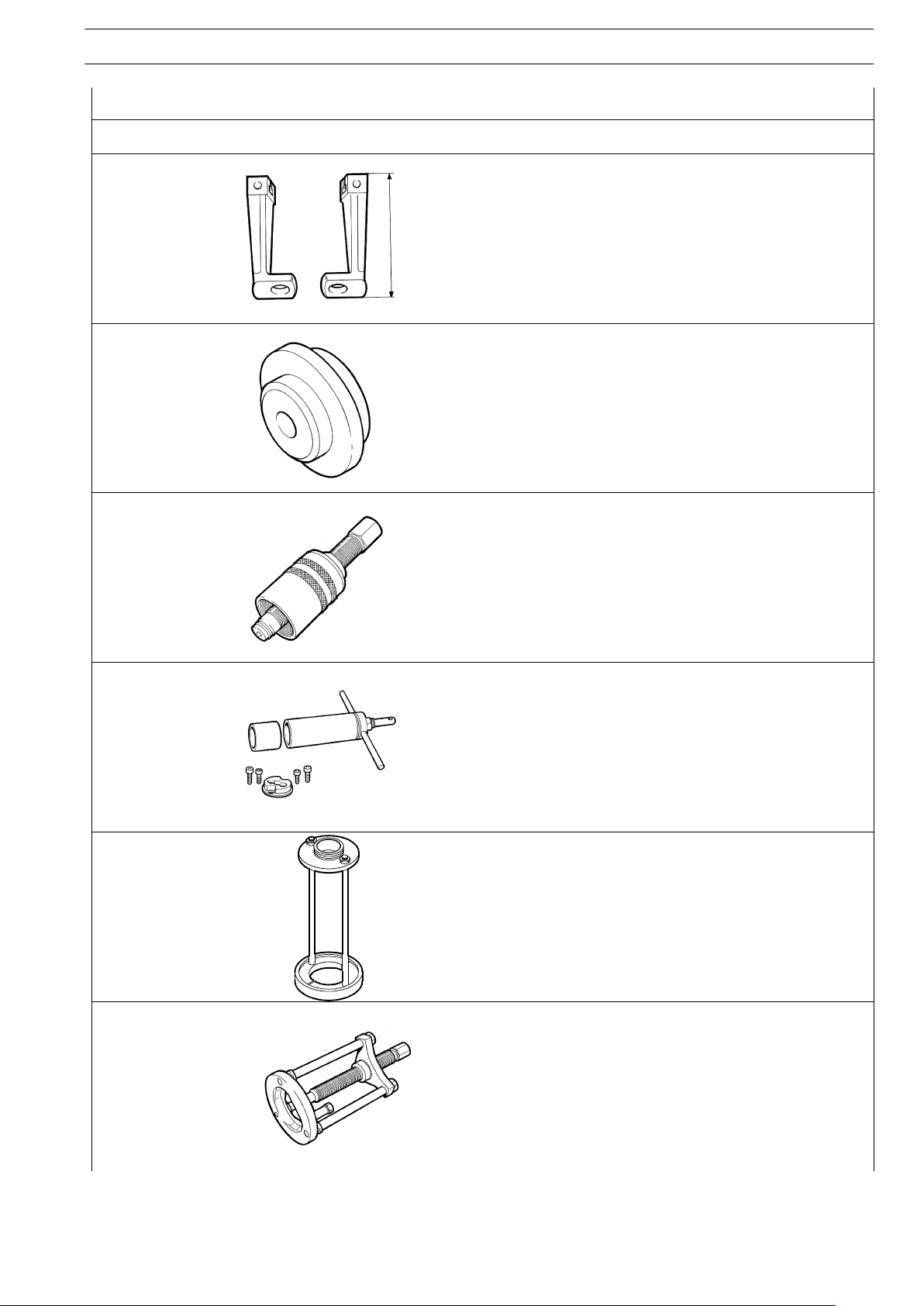

TOOLS

TOOL NO. DESCRIPTION

Hot air device

99305121

99322205

Rotary stand for overhauling assemblies

99322225

Mount to support assemblies (to fit onto stand 99322205)

99341003

Single-acting bridge

99341013

Reaction block

99341015

Clamp

GEARBOX EuroTronic 12 AS 2301 D.D./O.D. 121

STRALIS AT/AD

Print 603.93.141 Base - January 2003

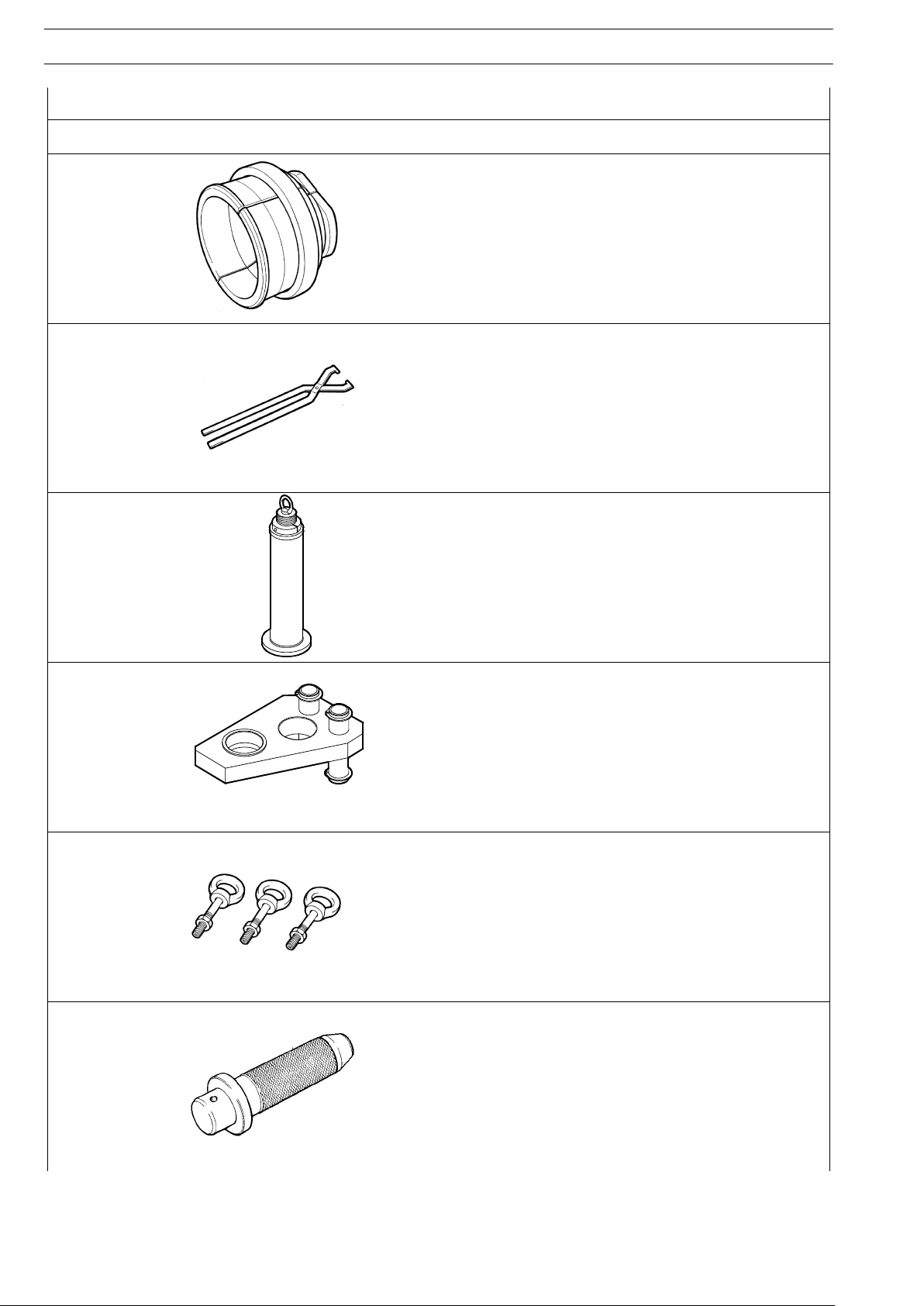

TOOLS

TOOL NO. DESCRIPTION

99341018

Pair of brackets with hole

99345057

Extractor reaction block

99345078

Extractor to remove drive input shaft bearing (use with 99345105)

993450998

Inserter to fit bearing on main shaft, rear side and to insert rear flange

of gearbox

99345105

Extractor for gearbox drive input shaft bearing (use with 99345078)

99347100

Small extractor (use with specific rings with 99347132)

122

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

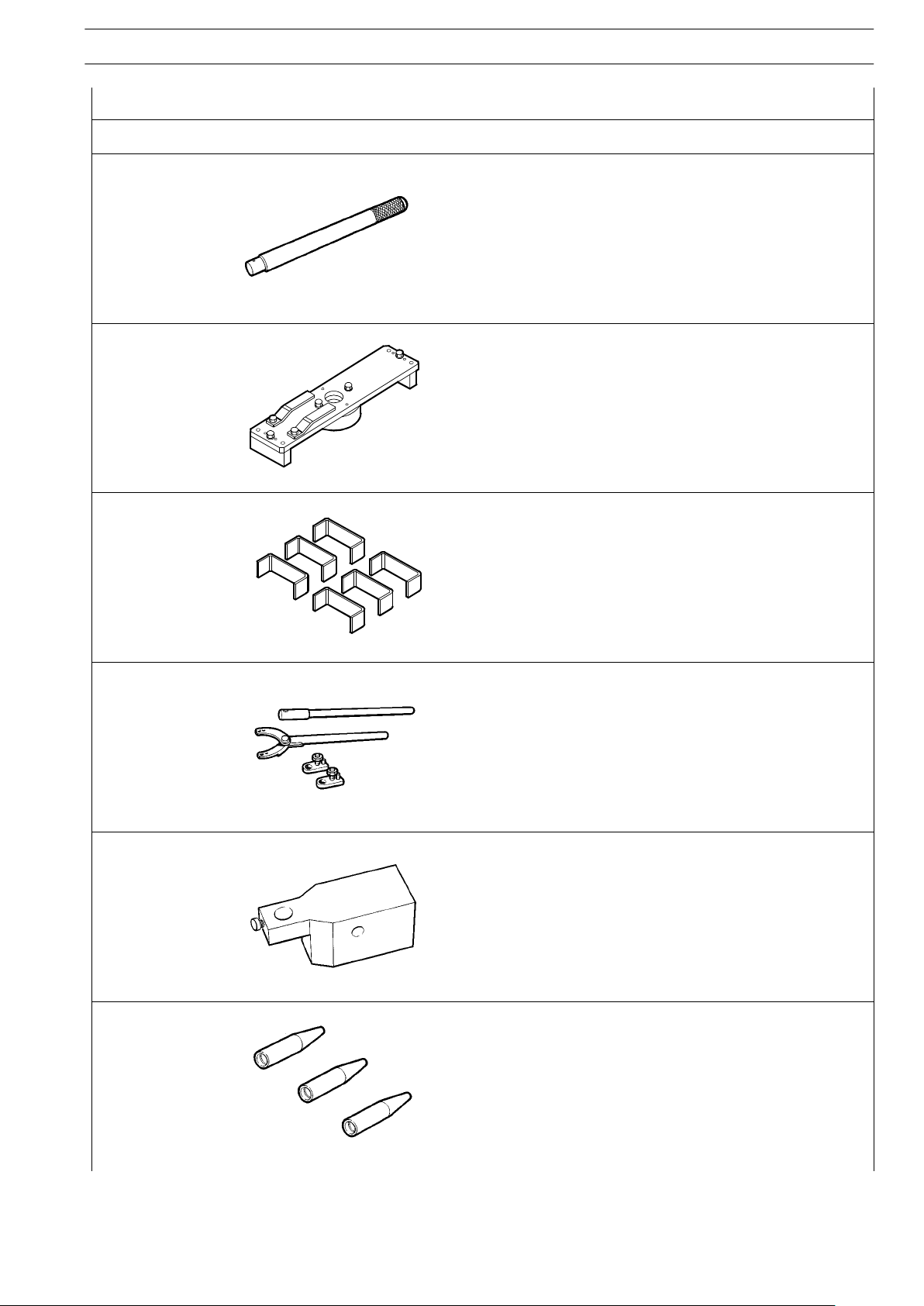

TOOLS

TOOL NO. DESCRIPTION

99347132

Ring grips to extract gearbox transmission shaft bearings (use with

99345057 - 99347100)

99360323

Tool to turn drive input shaft when refitting the gearbox to the

engine

99360526

Tool to extract and insert main shaft (use with 99360527) and to

drive in gearbox drive input shaft bearing (use with 99345098)

99360527

Tool retaining gearbox main shaft forks (use with 99360526)

99366811

Set of M10 eyebolts (3) to remove and refit gearboxes

99370006

Grip for interchangeable drifts

GEARBOX EuroTronic 12 AS 2301 D.D./O.D. 123

STRALIS AT/AD

Print 603.93.141 Base - January 2003

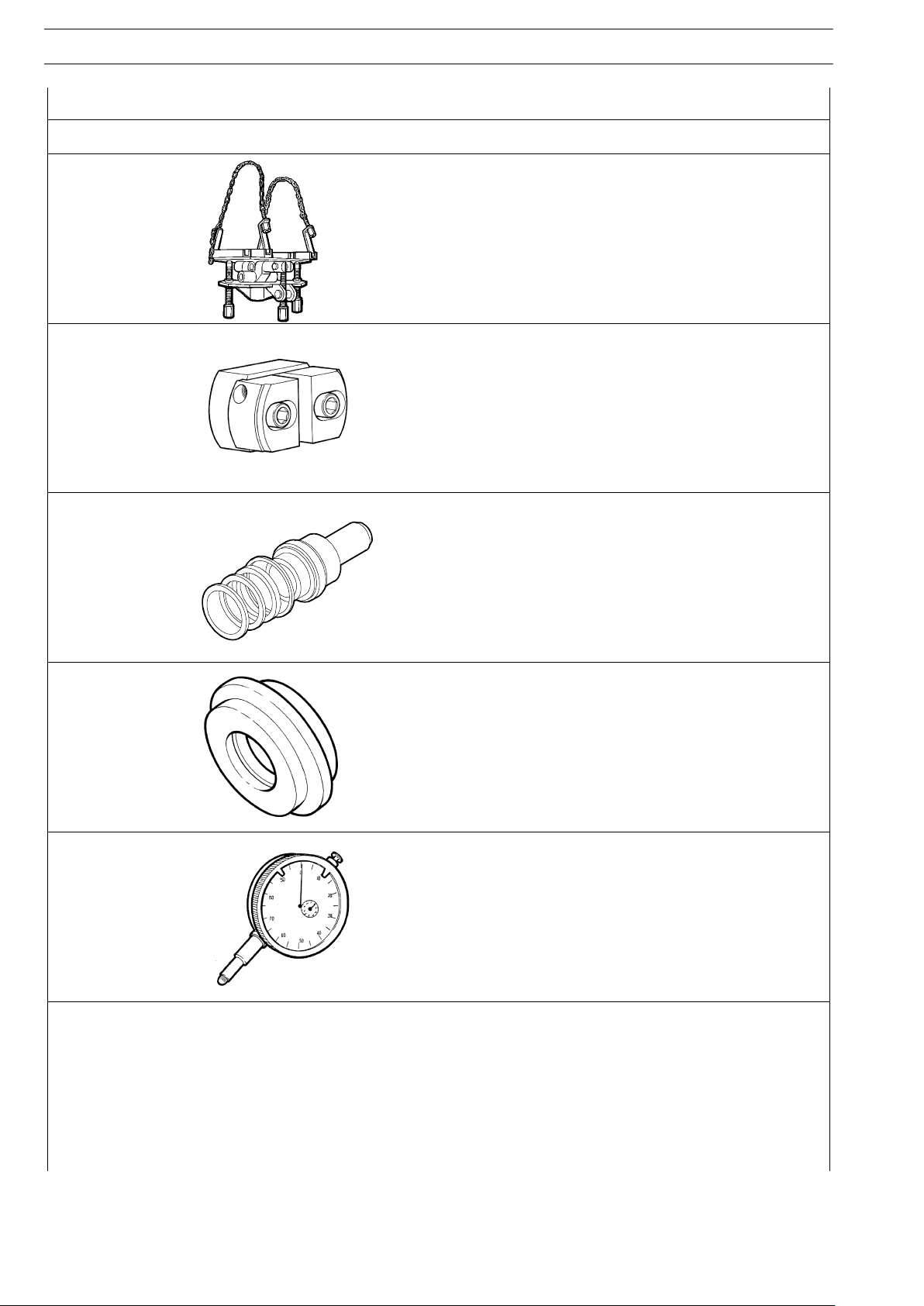

TOOLS

TOOL NO. DESCRIPTION

99370007

Grip for interchangeable drifts

99370153

Tool for positioning main shaft when removing the transmission

shafts and for retaining gearbox reverse gear pins

99370172

Tools (6) to mount gearbox epicyclic reduction gear train

synchronizer rings

99370317

Reaction lever with extension to fasten drive output flange

99370415

Dial gauge base to adjust transmission shaft bearings (use with

99395604)

99370499

Guides (no. 3) to mount Splitter synchronizing device assembly

124

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

TOOLS

TOOL NO. DESCRIPTION

99370629

Mount to support gearbox when removing and fitting it back on the

vehicle

99374092

Drift to mount outer races of bearings (69 y 91) (use with

99370007)

99374221

Driver to mount seals on back cover

99374336

Driver to fit seals on the front cover of the gearbox (use with

99370006)

99395604

Dial gauge (0 - 10 mm)

Figure 4

Checks

The gears, synchronizer rings, coupling bodies and sliding

couplings must show no sign of failure or excessive toothing

wear.

The main shaft must have no indentation, especially on the

sliding surfaces of the gear rotation and coupling sleeves.

The reverse idle gear shafts must have a polished surface free

from scoring.

The gearboxes must show no sign of cracking and the bearing

seats must be neither damaged nor worn, so as to prevent the

outer rings of the bearings from turning in their seats.

Check the shoulder spacers are neither worn nor damaged.

The gear coupling forks must show no sign of cracking and the

relevant control rods must slide freely, but without any

appreciable play, in their guide seats.

Check that the shoes of the drive forks are fully efficient.

Check that the holes, grooves and lubrication pipes are not

obstructed by grease or foreign bodies.

Check the bearings are not worn, damaged or overheated.

530210 OVERHAULING THE

GEARBOX

!

Wash the assembly thoroughly before overhauling.

The specific and/or general tools must be used in the

way for which they were designed.

To facilitate assembly, put the removed parts away on

the specific tray in their order of removal.

Upon assembly, the following must always be

replaced with new parts: the gaskets and seals, spring

pins, safety plates and springs. Nuts and screws must

be tightened to the prescribed torque with their

thread dry and degreased.

Keep to the specific regulations when disposing of

lubricant and detergents.

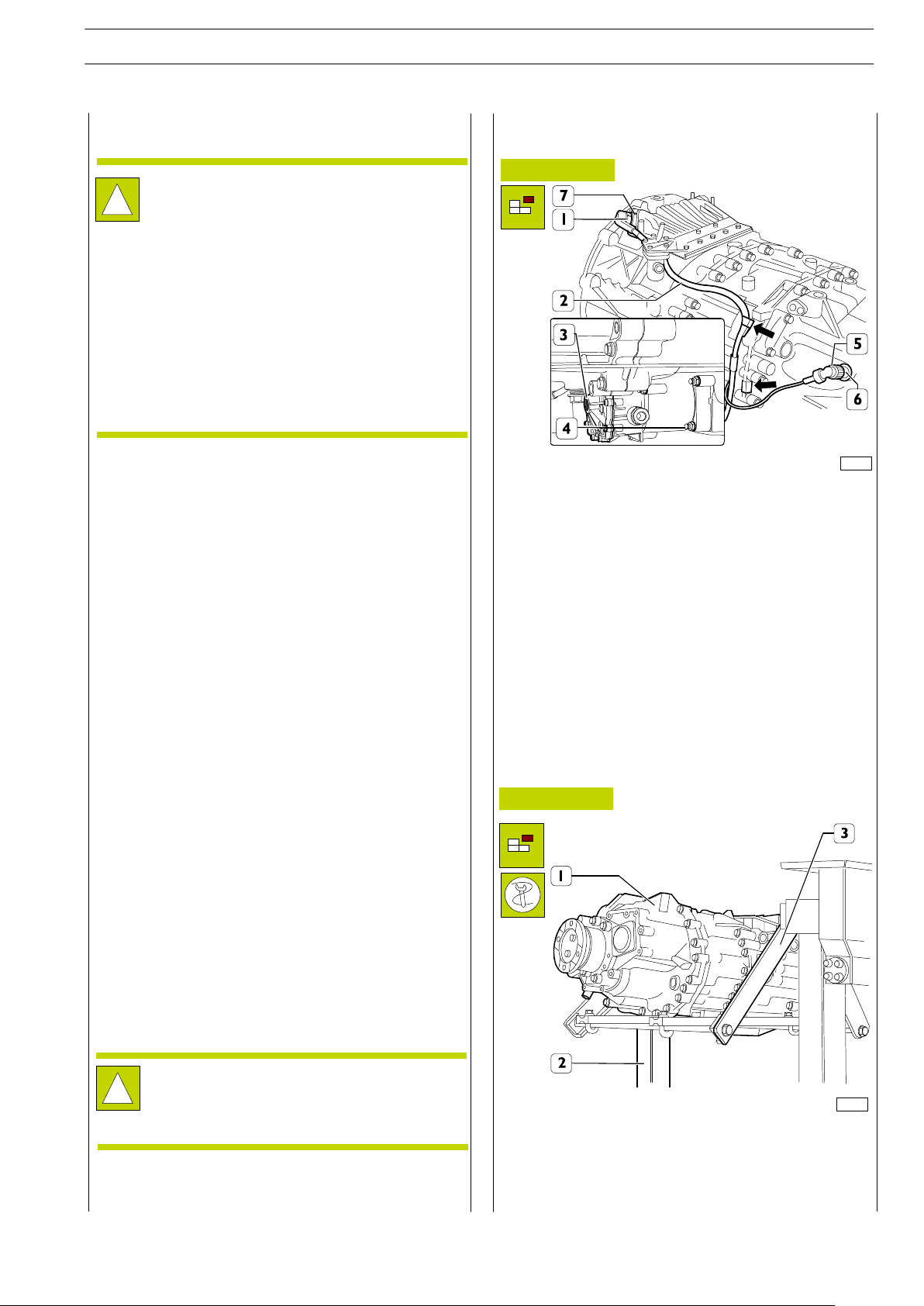

530520 Gearbox actuator

Removal

Unscrew the ring nut (1 and 5) and disconnect the electric

wiring (2) from the speed sensor (6 and 7).

Detach the wiring (2) from the clips (o) securing it to the

middle box.

Remove the nuts (4) and detach the actuator (3) from the

front box.

Figure 5

78649

78650

Fasten the gearbox (1) to brackets 99322225 (3) on the

rotating stand 99322205 (2).

Remove the plug and bleed the lubrication oil.

The following described and illustrated overhaul

operations regard transmission 16 A6 2601 and, save

different indications, are valid also for transmission 12

AS 2301.

!

GEARBOX EuroTronic 12 AS 2301 D.D./O.D. 125

STRALIS AT/AD

Print 603.93.141 Base - January 2003

70828

70863

70830

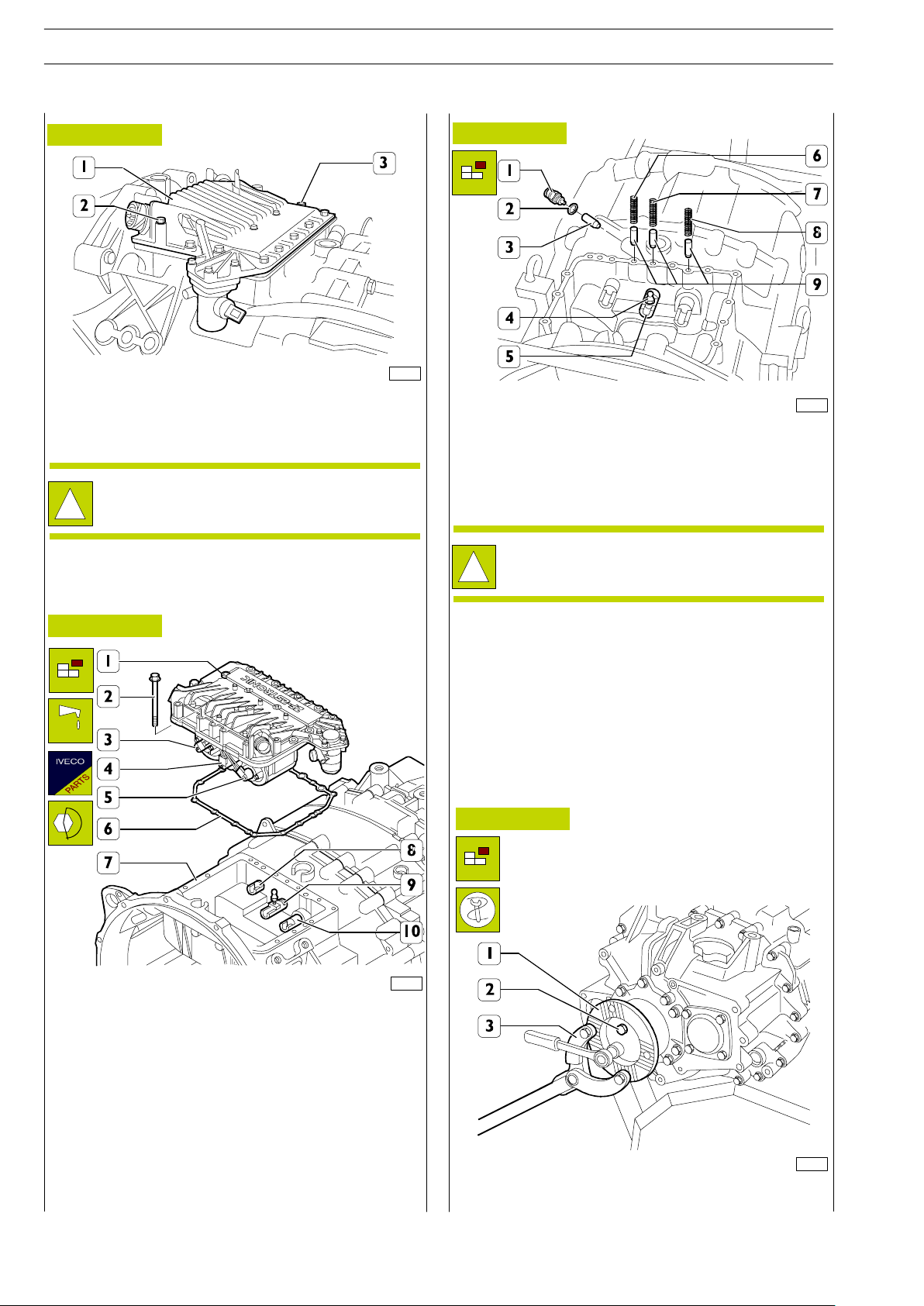

Figure 6

Figure 7

Figure 8

Figure 9

Set a new gasket (6) on the front case (7).

Lubricate the stems of the solenoid valves (3-4-5) with silicone

grease and put them into a neutral position. Put the rods

(8-9-10) into a neutral position. Fit the actuator (1) on the

front box (7) verifying thatthe end of the stems of the solenoid

valves is correctly positioned in the seats of the rods (8-9-10).

Tighten the fixing screws (2) to the prescribed torque. After

removing the gearbox from the stand used for overhaul, refit

the clutch actuator (3, Figure 4) and make sure the wiring (2,

Figure 4) is not damaged.

Extract the springs (6-7-8) and the pawls (6).

Block rotation of the sleeve (1) by applying the lever

99370317 (3) and slightly loosen the screws (2).

!

The springs (7 and 8) are of equal length, the spring

(6) is larger.

Remove the pin (4) from the rod (5).

Remove the switch (1) together with the gasket (2) and

extract the cap (3).

78651

Take out the screws (2) and detach the actuator (1) with its

gasket.

!

The electronic control unit is integrated in the

actuator and these cannot be overhauled. See under

the diagnosis heading for the check.

Check that the oil vapour vent (3) is not clogged; if it is, clean

it.

Disconnect speed actuators (1) as described in the relevant

chapter.

Refitting

126

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

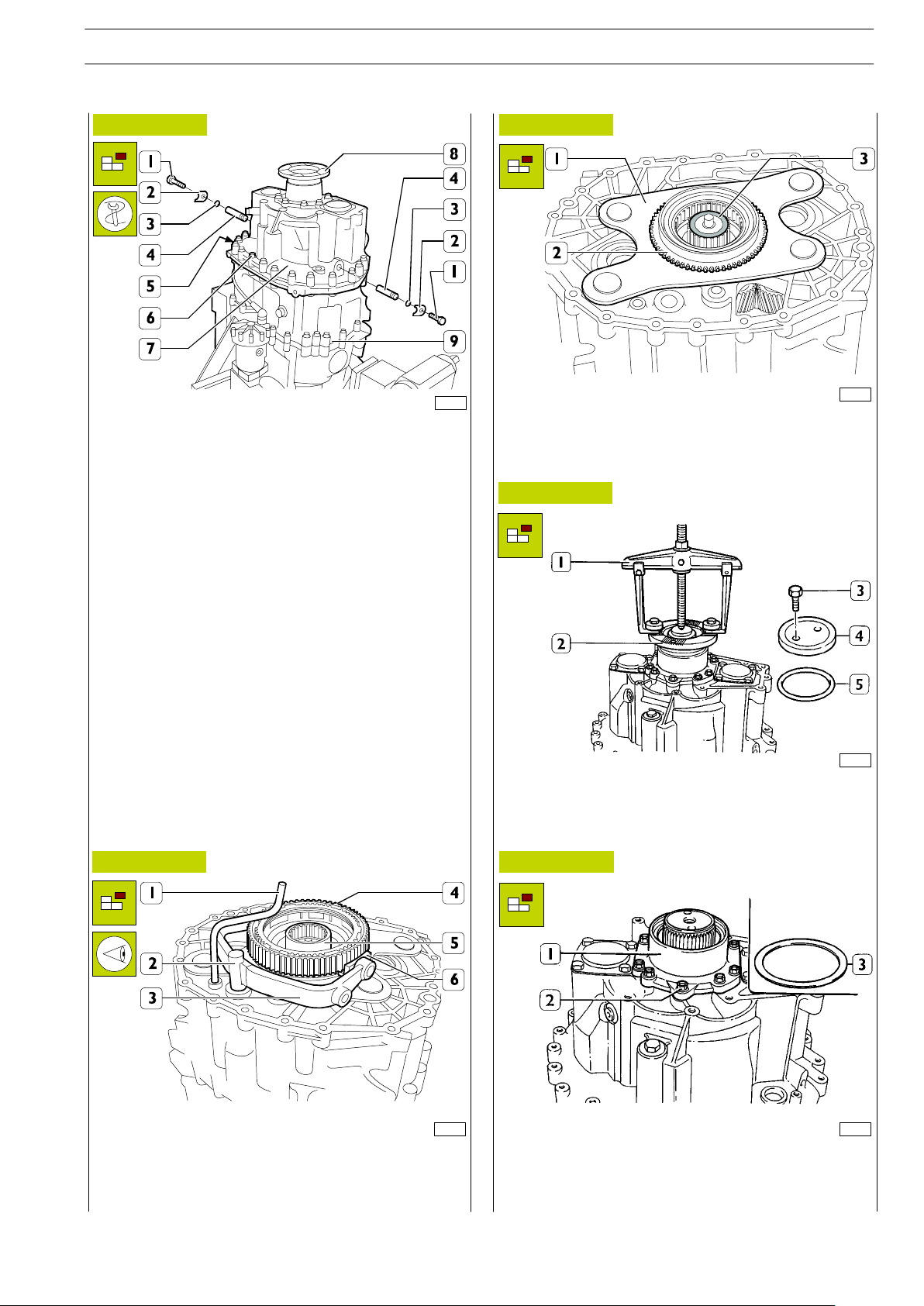

Removing the rear box

70831

70832

70833

70834

70835

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Remove the screws (1) fixing the plates (2) fastening the pins

(4) and extract these together with the seal (3) from the rear

box (7).

Extract the two centring pins (5). Remove the screws (6).

Fit the eyebolt 99366811 to the sleeve (8) and, using special

ropes and lifter, detach the rear box (7) from the middle one

(9).

Remove the oil pipe (1). Note down the assembly position of

the fork (3) and plugs (6) and remove them. Remove: the rod

(2), synchronizing device assembly (4) and connecting sleeve

(5).

Remove the adjustment ring (3) and the plate (1) together

with the coupling body (2).

Removing the rear box

Remove the screws (3), disc (4) and seal (5) and extract the

sleeve (2) from the spider shaft. Should extraction prove

difficult, use an extractor (1) applied as illustrated in the figure.

Remove the screws (2) andtake off the cover (1). Remove the

spider shaft bearing end float adjustment ring (3).

GEARBOX EuroTronic 12 AS 2301 D.D./O.D. 127

STRALIS AT/AD

Print 603.93.141 Base - January 2003

45946

70837

70836

70838

70839

70840

Figure 15

Figure 16

Figure 17

Figure 18

Figure 19

Figure 20

Using a press, extract the spider shaft (1) from the supporting

roller bearing (2). Turn the rear box (3) upside-down and

extract the roller bearing (2).

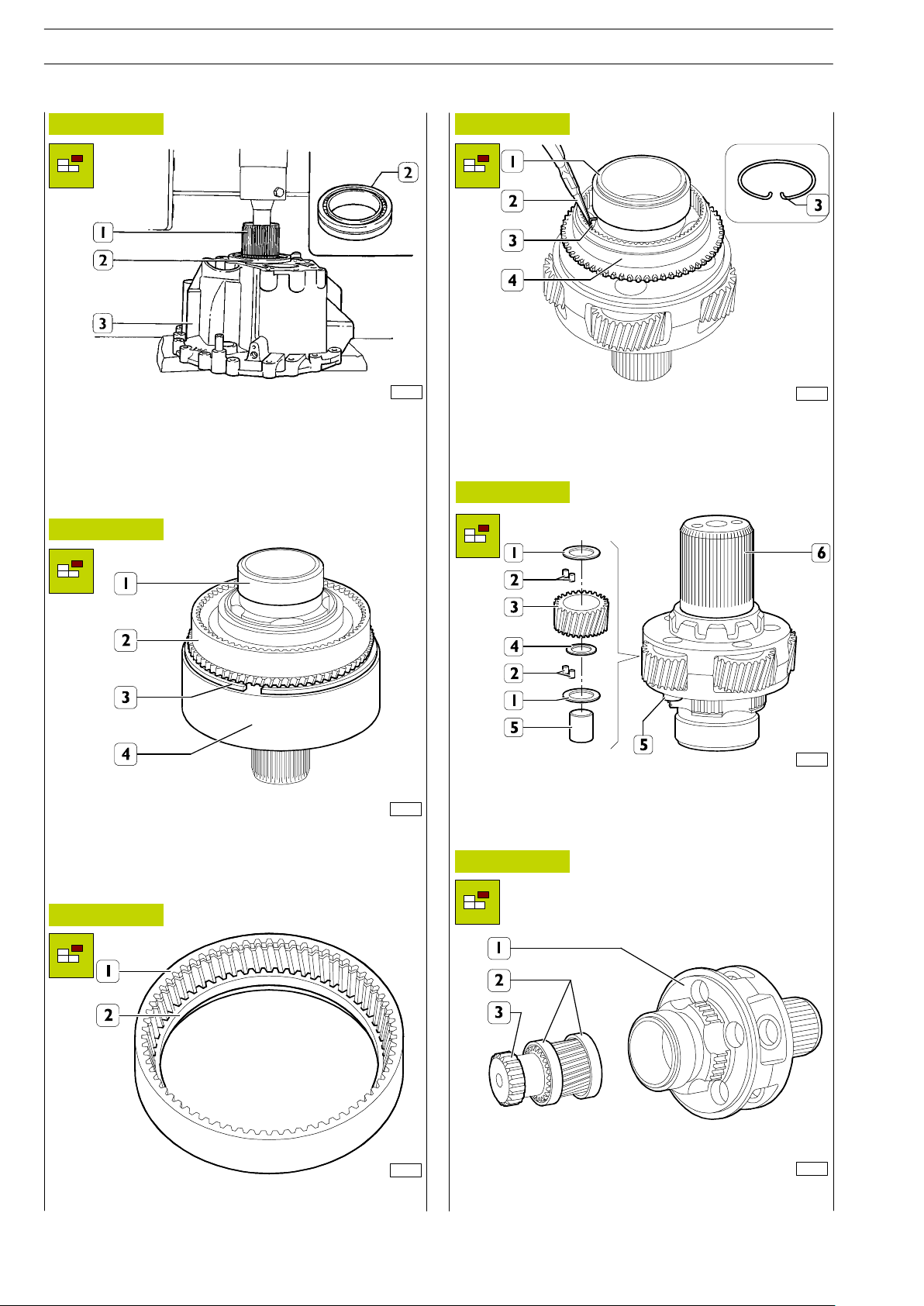

Removing the epicyclic reduction gear train

(E.R.G.)

Using a screwdriver, remove the circlip (3) fastening the ring

gear with internal toothing (4) to the ring gear with external

toothing (2) and remove them from the E.R.G. (1).

Extract the toothed ring (2) from the ring gear with internal

toothing (1).

Using pliers (2), tighten the ends of the circlip (3) and remove

the coupling body (4) from the E.R.G. shaft (1).

Using a punch, extract the pins (5) from the spider shaft (6).

Remove the planetary gears (3) from the spider shaft (6),

together with the rollers (2) and shim adjustment rings (1 and

4).

Extract the toothed shaft (3) from the spider shaft (1) together

with the rings (2).

128

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

70841

70843

70842

Figure 21 Figure 22

Extract one of the pins (1) from the toothed shaft (2) and

extract the rings (3) from this.

Using a suitable extractor, remove the roller bearing ring (1)

from the spider shaft (2).

Using a punch, extract the disc (3) from the inside of the spider

shaft (2).

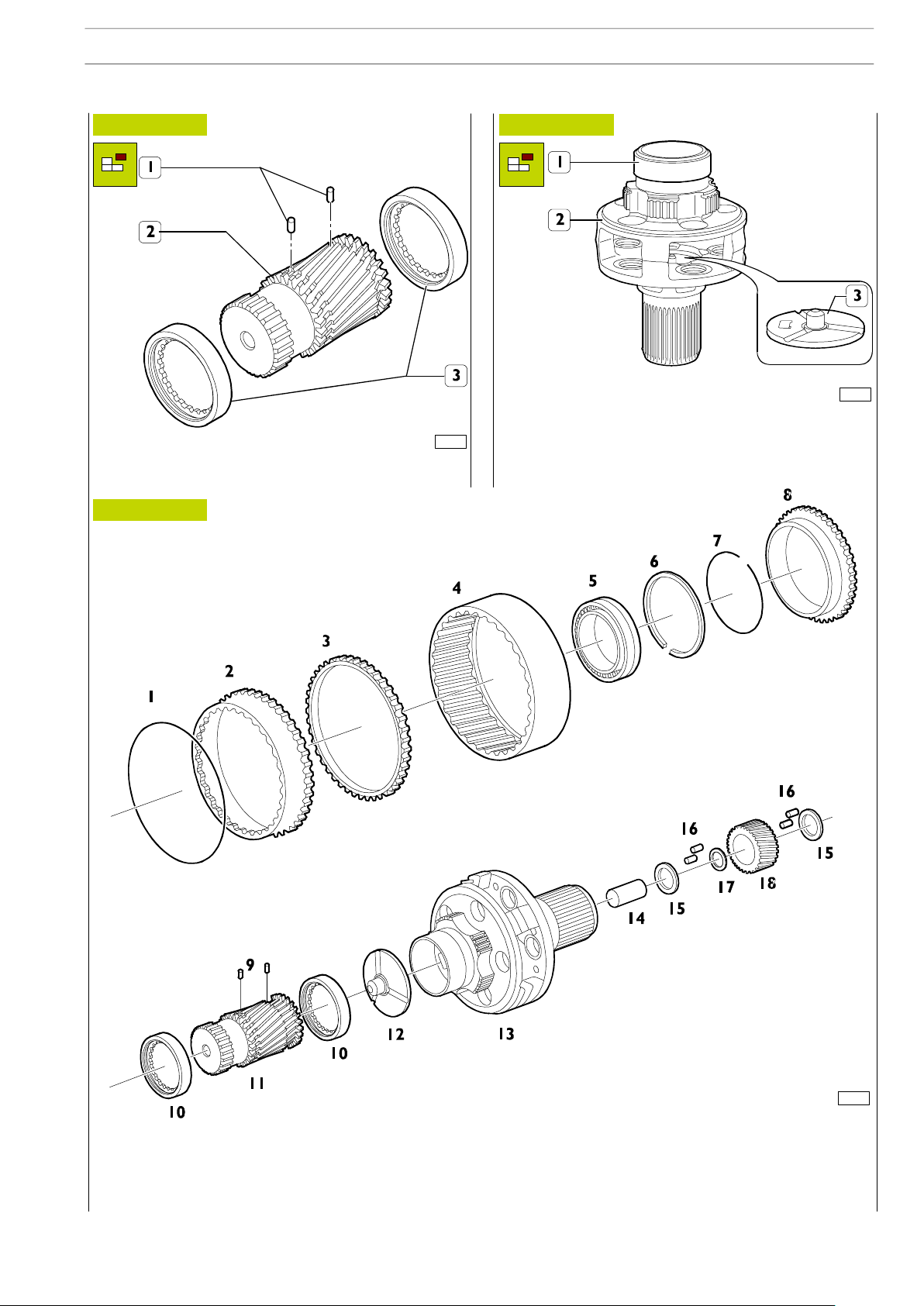

PARTS COMPRISING THE E.R.G.

1. Circlip - 2. Ring gear with external toothing - 3. Toothed ring - 4. Ring gear with internal toothing - 5. Bearing - 6. Circlip - 7.

Circlip - 8. Coupling body - 9. Pins - 10. Ring - 11. Toothed spindle - 12. Disc - 13. Spider shaft - 14. Pin - 15. Shim adjustment

ring - 16. Rollers - 17. Shim adjustment ring - 18. Planetary gear.

Figure 23

GEARBOX EuroTronic 12 AS 2301 D.D./O.D. 129

STRALIS AT/AD

Print 603.93.141 Base - January 2003

70844

70840

70845

70982

70838

70983

Figure 24

Figure 25

Figure 26

Figure 27

Figure 28

Figure 29

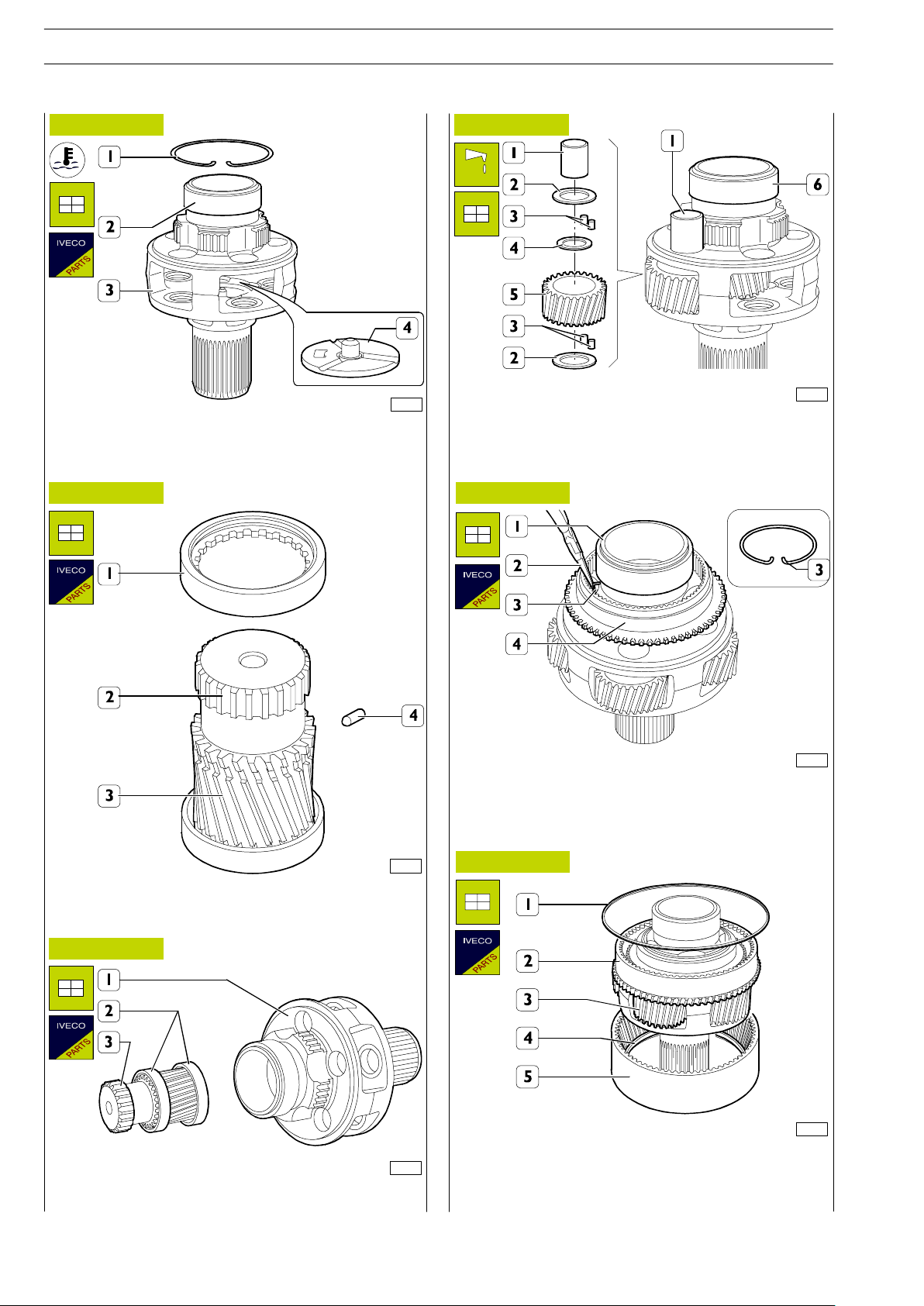

Heat the inside ring (2) of the roller bearing to 120qC and fit

it on the spider shaft (3).

Fit on the circlip (1). Fit on the disc (4).

Drive the rings (1 and 3) onto the toothed spindle (2) and fit

on the pin (4).

Insert the spindle (3) together with the rings (2) onto the

spider shaft (1).

Smear grease into the hole of the planetary gear (5) and insert

the rollers (3) with the associated shim adjustment rings (2 and

4). Fit the planetary gears (5) onto the spider shaft (6),

fastening them to it with the pins (1).

Using pliers (2), tighten the ends of the circlip (3) and fit the

coupling body (4) onto the E.R.G. shaft (1).

Fit the ring gear with internal toothing (5) onto the spider shaft

(3) together with the toothed ring (4), and the ring gear with

external toothing (2) and fasten the two ring gears with the

circlip (1).

130

GEARBOX EuroTronic 12 AS 2301 D.D./O.D.

STRALIS AT/AD

Base - January 2003 Print 603.93.141

Fitting the epicyclic reduction gear train (E.R.G.)

Loading...

Loading...