Iveco F1A Repair Manual

DAILY |

F1A ENGINE 287 |

|

|

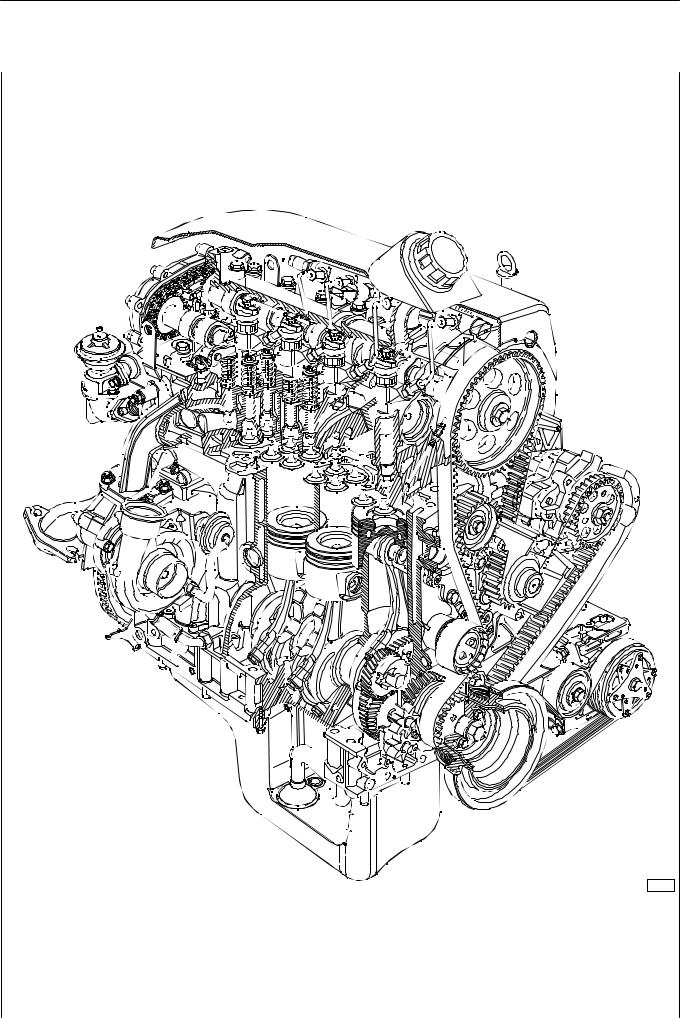

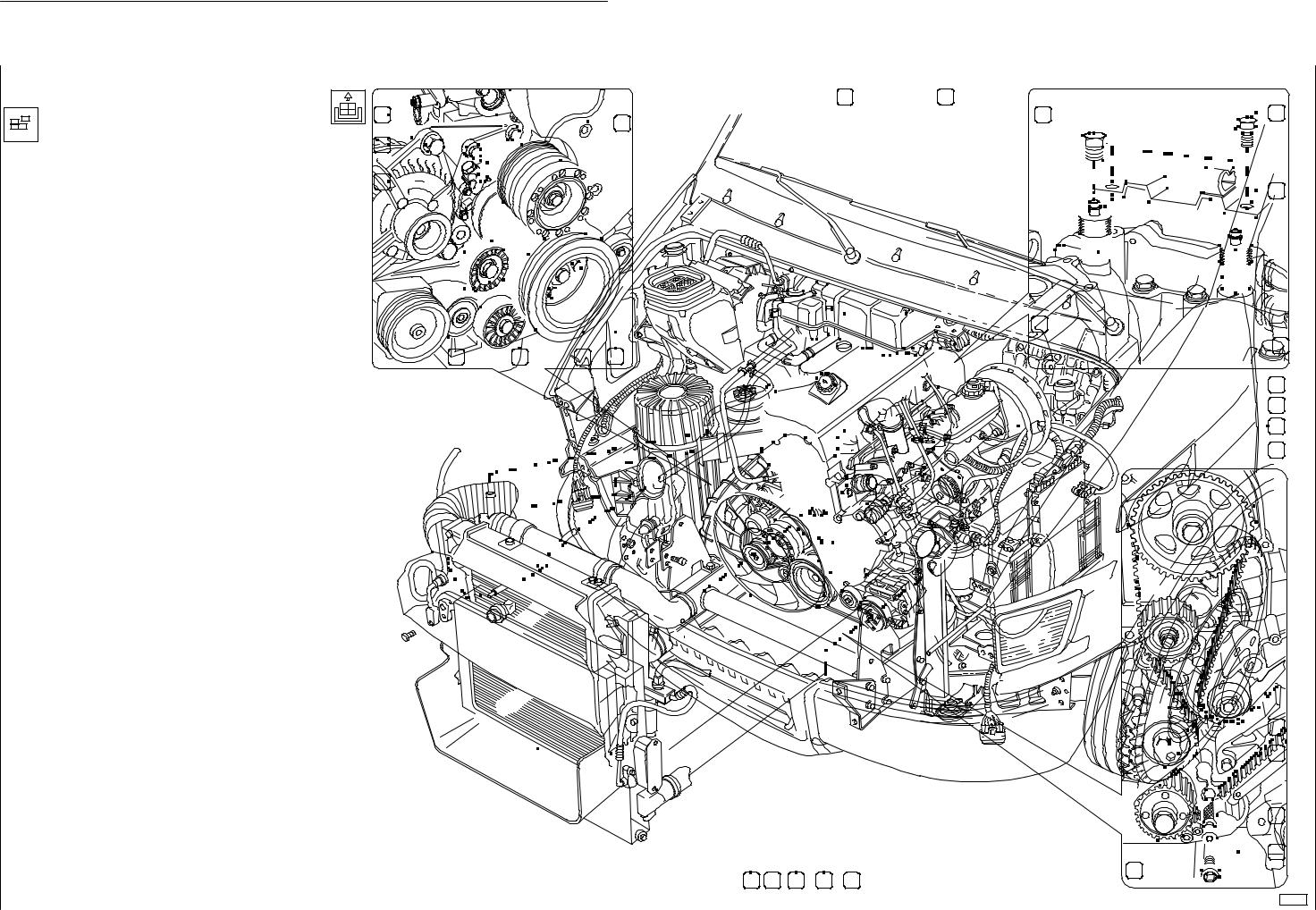

F1A engine |

|

|

Page |

MAIN OPERATIONS ON ENGINE MOUNTED |

|

ON VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . |

291 |

ENGINE REMOVAL-REFITTING . . . . . . . . . . . . . |

293 |

- Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

293 |

- Refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

297 |

- Checks and tests . . . . . . . . . . . . . . . . . . . . . . . |

297 |

- Power steering system air bleed . . . . . . . . . . . . |

297 |

REPLACING BELTS . . . . . . . . . . . . . . . . . . . . . . . |

298 |

- Replacing air-conditioning compressor drive belt |

|

(version with belt tensioner) . . . . . . . . . . . . . . |

298 |

- Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

298 |

- Assembly and adjusting belt tension . . . . . . . . . |

298 |

- Replacing air-conditioning compressor drive belt |

|

(version with elastic belt) . . . . . . . . . . . . . . . . . |

298 |

- Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

298 |

- Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

298 |

- Power steering pump-alternator belt replacement |

298 |

- Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

298 |

- Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

298 |

- Replacing timing drive belt . . . . . . . . . . . . . . . . |

299 |

- Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

299 |

- Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

300 |

REPLACING ELECTRO-INJECTORS . . . . . . . . . . |

301 |

- Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

301 |

- Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

301 |

CYLINDER HEAD REMOVAL AND REFITTING |

302 |

- Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

302 |

- Refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

304 |

REPLACING HIGH-PRESSURE PUMP CP3 . . . . . |

305 |

- Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

305 |

- Refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

305 |

REPLACING WATER PUMP . . . . . . . . . . . . . . . . |

305 |

- Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

305 |

Print 603.93.281 |

Base - May 2004 |

288 F1A ENGINE |

DAILY |

|

|

|

Page |

Print 603.93.281/A |

|

- Refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

305 |

EMISSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

306 |

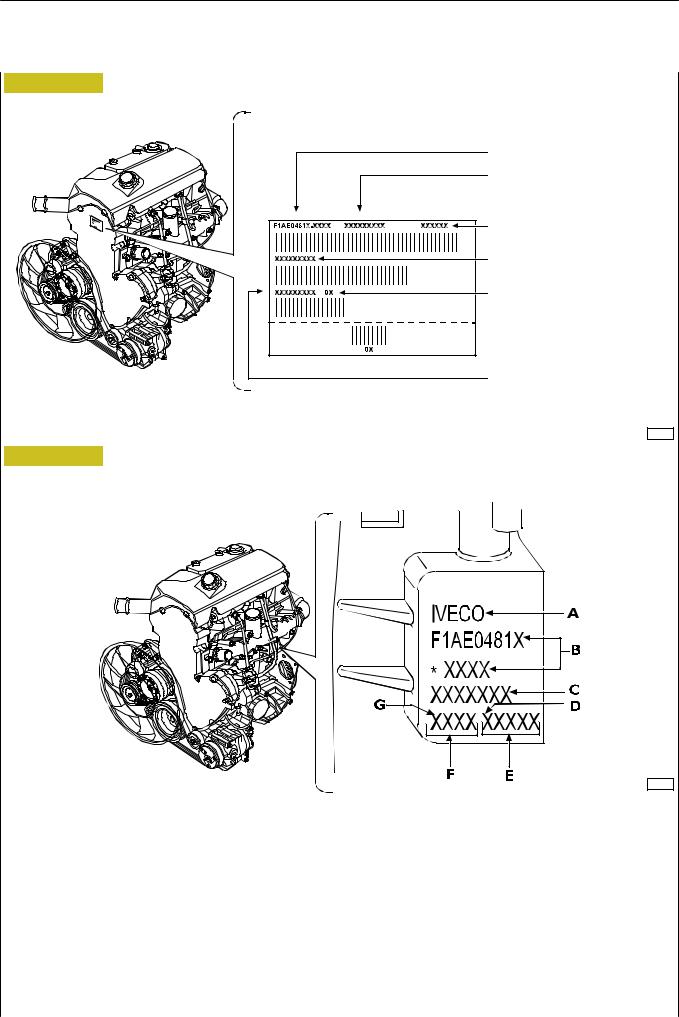

ENGINE IDENTIFICATION CODE . . . . . . . . . . . |

308 |

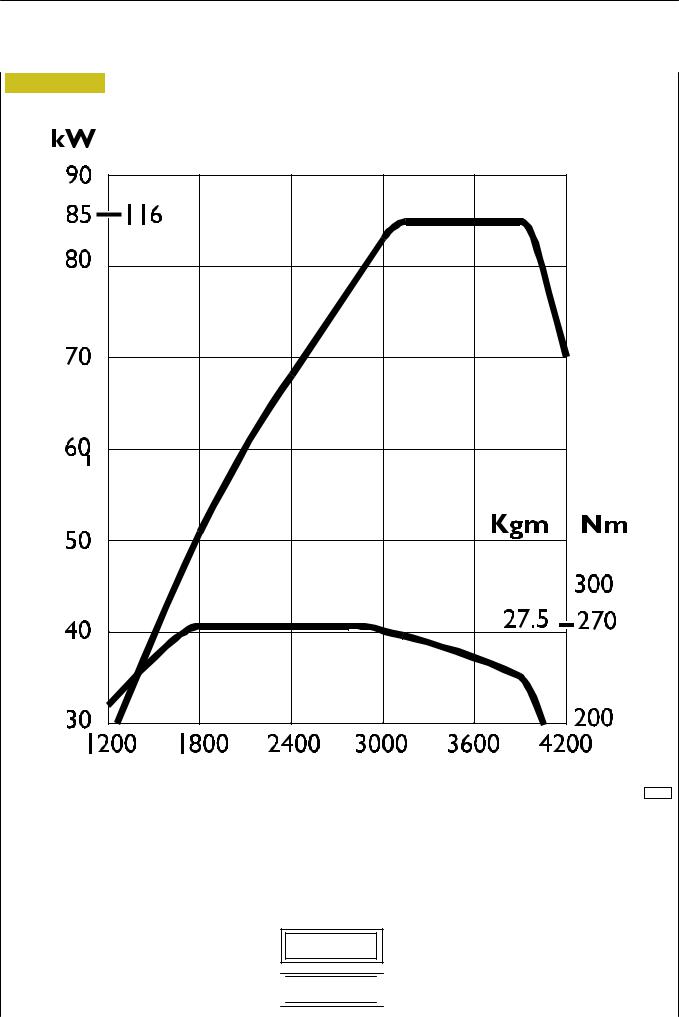

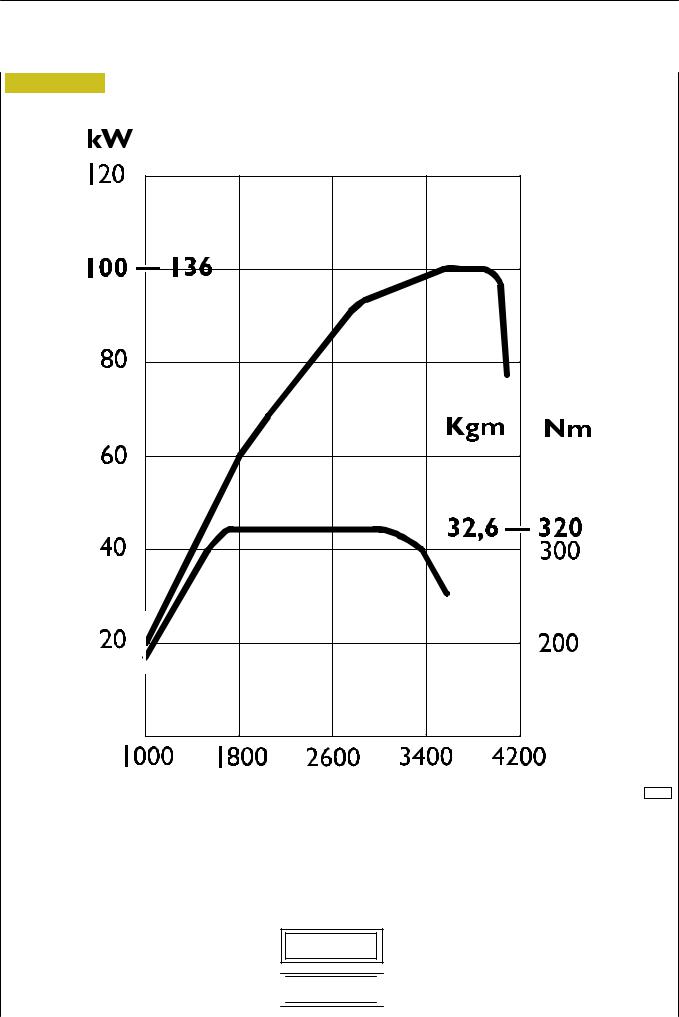

CHARACTERISTIC CURVES . . . . . . . . . . . . . . . . |

308/1 |

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . |

310 |

ASSEMBLY DATA — CLEARANCES . . . . . . . . . . |

313 |

TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

318 |

EXPERIMENTAL TOOLS . . . . . . . . . . . . . . . . . . |

323 |

TIGHTENING TORQUE . . . . . . . . . . . . . . . . . . . |

334 |

OVERHAULING ENGINE F1A . . . . . . . . . . . . . . |

339 |

DISASSEMBLING THE ENGINE AT THE BENCH |

339 |

REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

348 |

CYLINDER BLOCK . . . . . . . . . . . . . . . . . . . . . . . |

348 |

- Checks and measurements . . . . . . . . . . . . . . . . |

348 |

- Checking head mating surface on cylinder block |

349 |

CRANKSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . |

349 |

- Measuring main journals and crank pins . . . . . . |

349 |

- Checking crankshaft . . . . . . . . . . . . . . . . . . . . . |

350 |

- Replacing timing control gear . . . . . . . . . . . . . . |

352 |

ENGINE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . |

352 |

- Assembling main bearings . . . . . . . . . . . . . . . . . |

352 |

- Measuring main journal assembly clearance . . . |

352 |

- Checking crankshaft end float . . . . . . . . . . . . . . |

353 |

- Assembling rear seal . . . . . . . . . . . . . . . . . . . . . |

354 |

- Replacing bearing supporting gearbox input shaft |

355 |

ENGINE FLYWHEEL . . . . . . . . . . . . . . . . . . . . . . |

355 |

CONNECTING ROD — PISTON ASSEMBLY . . . |

355 |

- Pistons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

356 |

- Measuring piston diameter . . . . . . . . . . . . . . . . |

356 |

- Piston pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

357 |

- Conditions for correct pin-piston coupling . . . . |

357 |

- Piston rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

357 |

- Connecting rods . . . . . . . . . . . . . . . . . . . . . . . . |

358 |

- Bushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

359 |

Base - May 2004

Revi - February 2005

|

Page |

- Checking connecting rods . . . . . . . . . . . . . . . . |

359 |

- Checking torsion . . . . . . . . . . . . . . . . . . . . . . . |

359 |

- Checking bending . . . . . . . . . . . . . . . . . . . . . . . |

359 |

- Assembling connecting rod-piston assembly . . . |

359 |

- Checking for connecting rod — piston distortion |

360 |

- Assembling piston rings . . . . . . . . . . . . . . . . . . |

360 |

- Assembling connecting rod — piston assemblies |

|

in cylinder barrels . . . . . . . . . . . . . . . . . . . . . . . |

360 |

- Measuring crankpin assembly clearance . . . . . . |

361 |

- Checking piston protrusion . . . . . . . . . . . . . . . |

361 |

CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . |

362 |

- Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . |

362 |

- Removing valves . . . . . . . . . . . . . . . . . . . . . . . . |

362 |

- Checking cylinder head seal . . . . . . . . . . . . . . . |

363 |

- Checking cylinder head mating surface . . . . . . . |

363 |

VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

363 |

- Removing deposits, refacing and checking valves |

363 |

- Checking clearance between valve stem and |

|

valve guide and centring valves . . . . . . . . . . . . . |

364 |

VALVE GUIDES . . . . . . . . . . . . . . . . . . . . . . . . . . |

364 |

- Replacing valve guides . . . . . . . . . . . . . . . . . . . |

364 |

- Boring valve guides . . . . . . . . . . . . . . . . . . . . . . |

364 |

VALVE SEATS . . . . . . . . . . . . . . . . . . . . . . . . . . . |

365 |

- Regrinding - replacing valve seats . . . . . . . . . . . |

365 |

VALVE SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . |

366 |

ROCKER ARMS — TAPPETS . . . . . . . . . . . . . . . . |

366 |

- Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

367 |

ASSEMBLING CYLINDER HEADS . . . . . . . . . . . |

367 |

- Overhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

368 |

- Overhead removal . . . . . . . . . . . . . . . . . . . . . . |

368 |

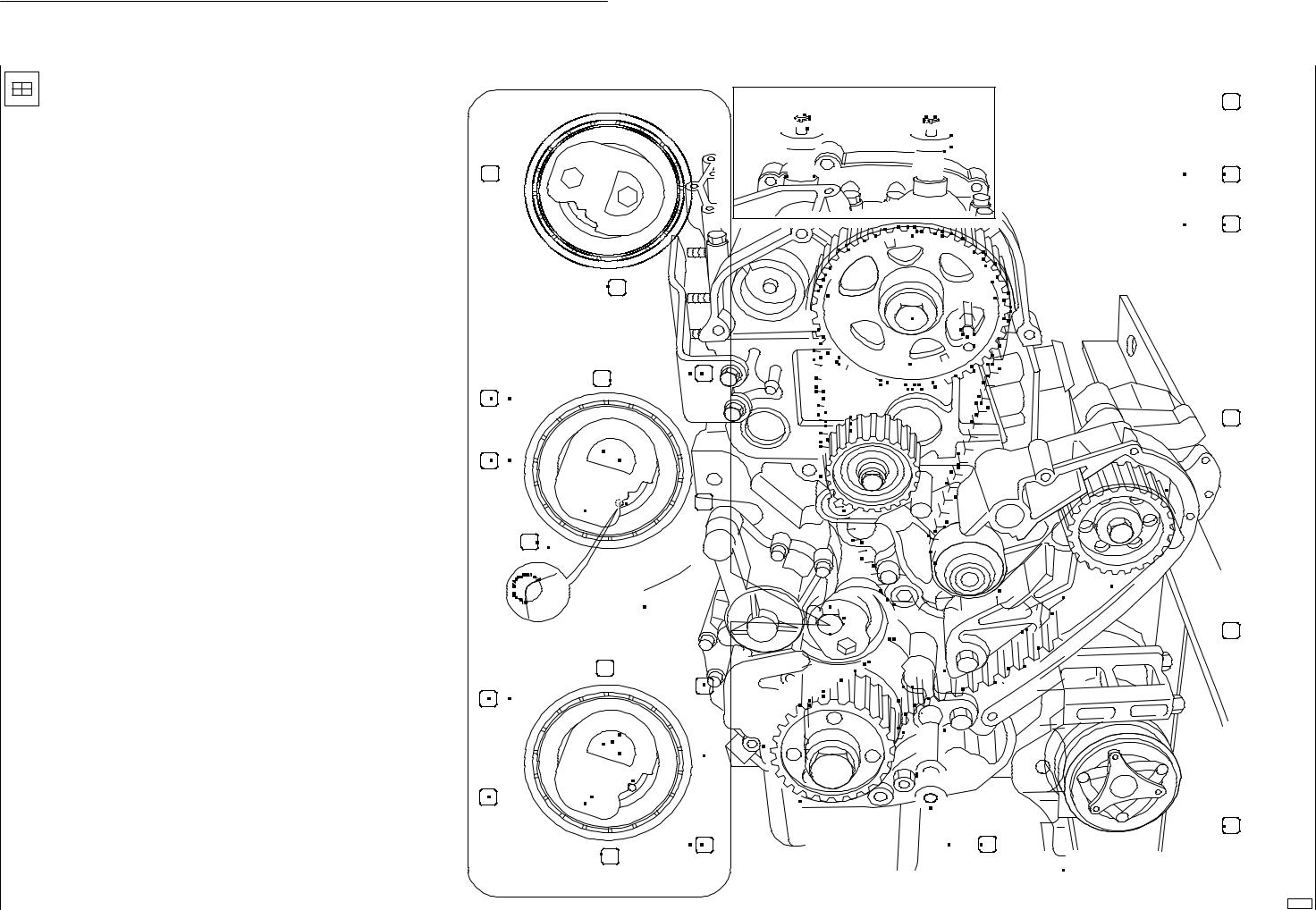

TIMING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . |

369 |

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

369 |

- Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

370 |

- Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

370 |

- Checking cam lift and pin alignment . . . . . . . . . |

370 |

Print 603.93.281/A

DAILY |

F1A ENGINE 289 |

|

|

|

Page |

- Assembling overhead . . . . . . . . . . . . . . . . . . . . |

371 |

- Assembling front seal ring . . . . . . . . . . . . . . . . . |

372 |

- Refitting cylinder head . . . . . . . . . . . . . . . . . . . |

375 |

- Adjusting air-conditioner — |

|

compressor drive belt tension . . . . . . . . . . . . . |

378 |

- Timing speed sensor . . . . . . . . . . . . . . . . . . . . . |

382 |

- Engine speed sensor . . . . . . . . . . . . . . . . . . . . . |

382 |

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . |

383 |

- General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

383 |

OIL VACUUM PUMP ASSEMBLY (GPOD) . . . . . |

385 |

- Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

385 |

- Characteristic data . . . . . . . . . . . . . . . . . . . . . . |

385 |

- Vacuum pump . . . . . . . . . . . . . . . . . . . . . . . . . |

385 |

- Oil pressure control valve . . . . . . . . . . . . . . . . |

386 |

- Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

386 |

- Modine heat exchanger . . . . . . . . . . . . . . . . . . |

386 |

- Oil vapour recirculation system . . . . . . . . . . . . |

387 |

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

387 |

COOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

388 |

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

388 |

- Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

388 |

- Electromagnetic pulley . . . . . . . . . . . . . . . . . . . |

389 |

- Water pump . . . . . . . . . . . . . . . . . . . . . . . . . . |

389 |

- Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . |

389 |

TURBOCHARGING . . . . . . . . . . . . . . . . . . . . . . |

390 |

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

390 |

- Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . |

391 |

REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

392 |

- Pressure relief valve . . . . . . . . . . . . . . . . . . . . . |

392 |

- Checking and adjusting pressure relief valve . . . |

392 |

- Replacing pressure relief valve . . . . . . . . . . . . . |

392 |

EXHAUST GAS RECIRCULATION (EGR) SYSTEM |

393 |

- EGR system operation . . . . . . . . . . . . . . . . . . . |

393 |

Page

- Operating principles . . . . . . . . . . . . . . . . . . . . . |

393 |

- Air flow meter . . . . . . . . . . . . . . . . . . . . . . . . . |

394 |

FUEL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . |

395 |

HIGH-PRESSURE ELECTRONIC |

|

INJECTION SYSTEM (MS 6.3 - EDC 16) . . . . |

395 |

- General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

395 |

SYSTEM OPERATION . . . . . . . . . . . . . . . . . . . . |

397 |

- Self-diagnosis — BLINK CODE . . . . . . . . . . . . . |

397 |

- Immobilizer recognition . . . . . . . . . . . . . . . . . . |

397 |

- Checking fuel temperature . . . . . . . . . . . . . . . . |

397 |

- Checking engine coolant temperature . . . . . . . |

397 |

- Checking quantity of fuel injected . . . . . . . . . . . |

397 |

- Checking idling adjustment . . . . . . . . . . . . . . . . |

397 |

- Fuel cut-off in release phase . . . . . . . . . . . . . . . |

397 |

- Checking cylinder balancing on idling . . . . . . . . |

397 |

- Checking regular engine rotation (anti-sawing) . |

397 |

- Checking smokiness at exhaust on acceleration |

397 |

- Checking exhaust gas recirculation |

|

(E.G.R. if present) . . . . . . . . . . . . . . . . . . . . . . . |

397 |

- Checking top speed limit . . . . . . . . . . . . . . . . . |

397 |

- Checking regular rotation on acceleration . . . . |

397 |

- Checking glow plug control unit . . . . . . . . . . . . |

397 |

- Checking activation of air-conditioning system . |

397 |

- Checking fuel pump . . . . . . . . . . . . . . . . . . . . . |

397 |

- Checking diesel warming . . . . . . . . . . . . . . . . . |

398 |

- Checking cylinder position . . . . . . . . . . . . . . . . |

398 |

- Checking pilot and main injection timing . . . . . |

398 |

- Checking injection pressure closed cycle . . . . . |

398 |

- Fuel supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

398 |

- Correcting flow rate according |

|

to water temperature . . . . . . . . . . . . . . . . . . . . |

398 |

- Correcting flow rate to avoid noise, |

|

smoke or overloading . . . . . . . . . . . . . . . . . . . . |

398 |

Print 603.93.281/A |

Base - May 2004 |

|

Revi - February 2005 |

290 F1A ENGINE |

DAILY |

|

|

|

Page |

- De-rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

398 |

- Injection timing electronic test . . . . . . . . . . . . . |

398 |

- Speed governor . . . . . . . . . . . . . . . . . . . . . . . . |

398 |

- Engine starting . . . . . . . . . . . . . . . . . . . . . . . . . |

398 |

- Cold starting . . . . . . . . . . . . . . . . . . . . . . . . . . . |

399 |

- Warm starting . . . . . . . . . . . . . . . . . . . . . . . . . |

399 |

- Run up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

399 |

- After run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

399 |

- Cut-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

399 |

- Cylinder balancing . . . . . . . . . . . . . . . . . . . . . . |

399 |

- Synchronization search . . . . . . . . . . . . . . . . . . . |

399 |

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

401 |

HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . |

403 |

- Fuel pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

403 |

- Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . |

403 |

- Fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

404 |

- Tightening torques . . . . . . . . . . . . . . . . . . . . . . |

404 |

- Fuel pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

404 |

- High-pressure pump . . . . . . . . . . . . . . . . . . . . . |

405 |

- High-pressure pump internal structure . . . . . . . |

407 |

- Working principle . . . . . . . . . . . . . . . . . . . . . . . |

408 |

- Pressure control valve . . . . . . . . . . . . . . . . . . . |

411 |

- Replacing pressure regulator. . . . . . . . . . . . . . . |

411 |

MECHANICAL SUPPLY PUMP . . . . . . . . . . . . . . |

412 |

- Hydraulic accumulator (rail) . . . . . . . . . . . . . . . |

413 |

- Overpressure valve |

|

(for forged hydraulic accumulator) . . . . . . . . . . |

413 |

ELECTRO-INJECTORS . . . . . . . . . . . . . . . . . . . . |

413 |

- Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

414 |

ELECTRIC/ELECTRONIC COMPONENTS . . . . . |

414 |

- Electronic control unit MS6.3 or EDC 16 . . . . . |

414 |

- Glow plug electronic control unit . . . . . . . . . . . |

415 |

- Glow plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

415 |

SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

415 |

|

Page |

- Engine speed sensor . . . . . . . . . . . . . . . . . . . . . |

415 |

- Camshaft timing sensor . . . . . . . . . . . . . . . . . . |

415 |

- Air temperature and pressure sensor . . . . . . . . |

415 |

- Fuel temperature sensor . . . . . . . . . . . . . . . . . |

415 |

- Fuel pressure sensor . . . . . . . . . . . . . . . . . . . . . |

415 |

- Atmospheric pressure sensor . . . . . . . . . . . . . . |

415 |

- Engine coolant temperature sensor . . . . . . . . . |

416 |

- Throttle pedal position sensor . . . . . . . . . . . . . |

416 |

- Clutch pedal position sensor . . . . . . . . . . . . . . |

416 |

- Brake pedal position sensor . . . . . . . . . . . . . . . |

416 |

- Vehicle speed sensor . . . . . . . . . . . . . . . . . . . . |

416 |

ACTUATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . |

416 |

- PWM (Pulse Width Modulation) controls . . . . |

416 |

GUIDE TO TROUBLESHOOTING . . . . . . . . . . . |

417 |

Base - May 2004 |

Print 603.93.281/A |

Revi - February 2005 |

|

DAILY |

F1A ENGINE 291 |

|

|

MAIN OPERATIONS ON ENGINE MOUNTED ON VEHICLE

Keep to the following instructions before doing any work on the engine involving components of the fuel supply system.

- Before doing any work on the engine, perform the engine/vehicle fault diagnosis with specific IVECO diagnosis equipment and print out the results.

-Replacement of the MS6.3 or EDC 16control unit must be authorized by the Help Desk.

-Following components in feed system cannot be overhauled but have to be replaced: pressure relief valve, if present, fuel pressure sensor, hydraulic accumulator, complete CP1 high pressure feed pump, pressure control valve, electric injectors.

-All the parts of the Common Rail system are packaged by the supplier in sheets of oiled paper and are stored in cardboard boxes. They must therefore be protected against moisture and unpacked just prior to assembly.

-The greatest care must be taken over the cleanliness of parts, making sure that when handling or assembling (starting with straightforward filter and pre-filter replacement) no dirt of foreign bodies can get inside. For this reason, the plugs protecting the hydraulic parts and sensors must be removed just prior to positioning in their seats.

-Take care over the direction of assembly for all electrical connections.

-All threaded connections must be tightened to the prescribed torque.

-All the quick-coupling connectors (on the engine they are found on the high-pressure pump and on the diesel drain manifold) must be fully inserted. To drive them out, press on the tabs at the base of the connectors.

Electro-injector

None of the couplings/unions/nuts on the injector body may be handled. It is neither necessary nor permitted to dismantle the nozzle body or the electromagnet.

If working on the high-pressure pipe, the hexagon on the injector side must be kept stationary with a wrench. Before working on pipes, make sure the injector is stationary in its seat on the cylinder head.

When assembling/disassembling the injector drain, the retaining spring must not be removed from its seat in the injector: pushing the spring towards the engine and applying a vertical force on the connector frees the recirculation. When assembling, rest the recirculation connector in its seat and apply a vertical force while keeping the retaining spring pressed in the direction of the engine. Fitting in has to be easy.

CP3 High-pressure pump

If working on the high-pressure pipe, the hexagon on the pump side must be kept stationary with a wrench. Before working on the high-pressure pipe, make sure the pump is secured in its seat.

High-pressure pipes

Each high-pressure pipe must be replaced after disassembly operations.

The couplings must be tightened or loosened with the injectors, hydraulic accumulator (rail) and high-pressure pump well secured and taking care to keep the hexagon on the component side stationary, space permitting.

Hydraulic accumulator (rail) and accessories

Pressure sensor, as well as pressure relief valve (if present) can be successively mounted 5 times. Thereafter, they need to be replaced. They must be lubricated with a thin layer of oil before being mounted.

Pressure relief valve, if present, must also be lubricated before being mounted and its gasket must compulsorily be replaced.

Toothed timing drive belt

If the engine has run for a period equivalent to over 25,000 km, the toothed timing drive belt must be replaced with a fresh one, no matter what its state of wear, whenever it gets removed or any work is done on its automatic tightener.

Print 603.93.281 |

Base - May 2004 |

292 F1A ENGINE |

|

|

|

|

|

|

|

|

|

|

|

|

|

DAILY |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

72446

Base - May 2004 |

Print 603.93.281 |

DAILY |

ENGINE F1A 293 |

Print 603.93.281

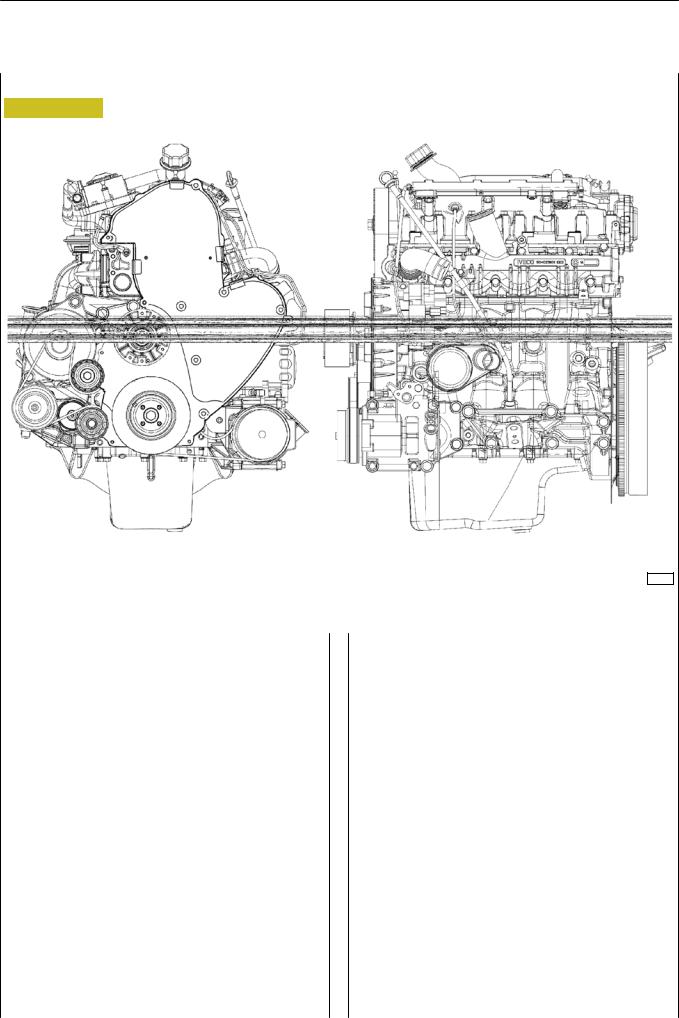

540110 ENGINE REMOVAL-REFITTING

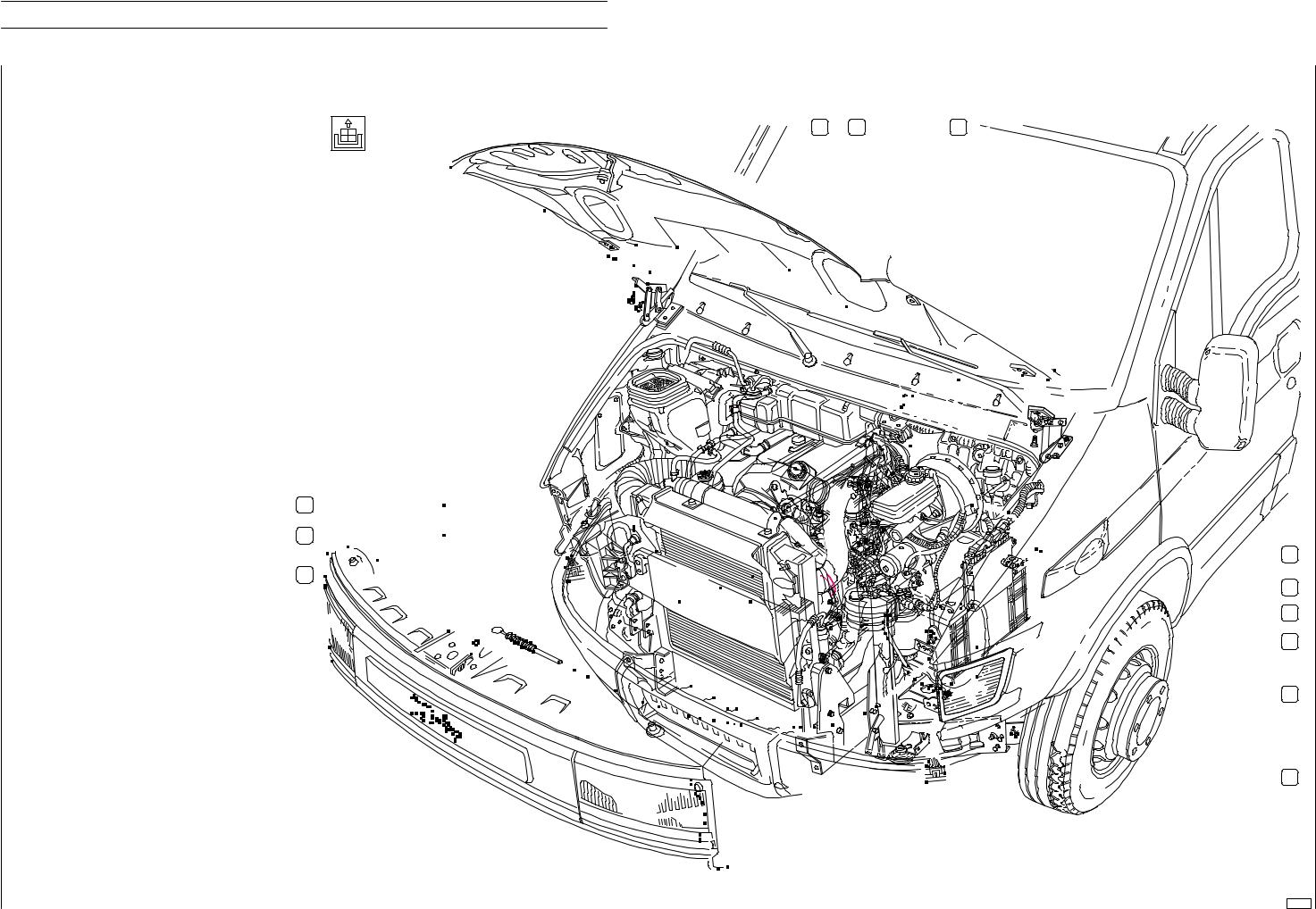

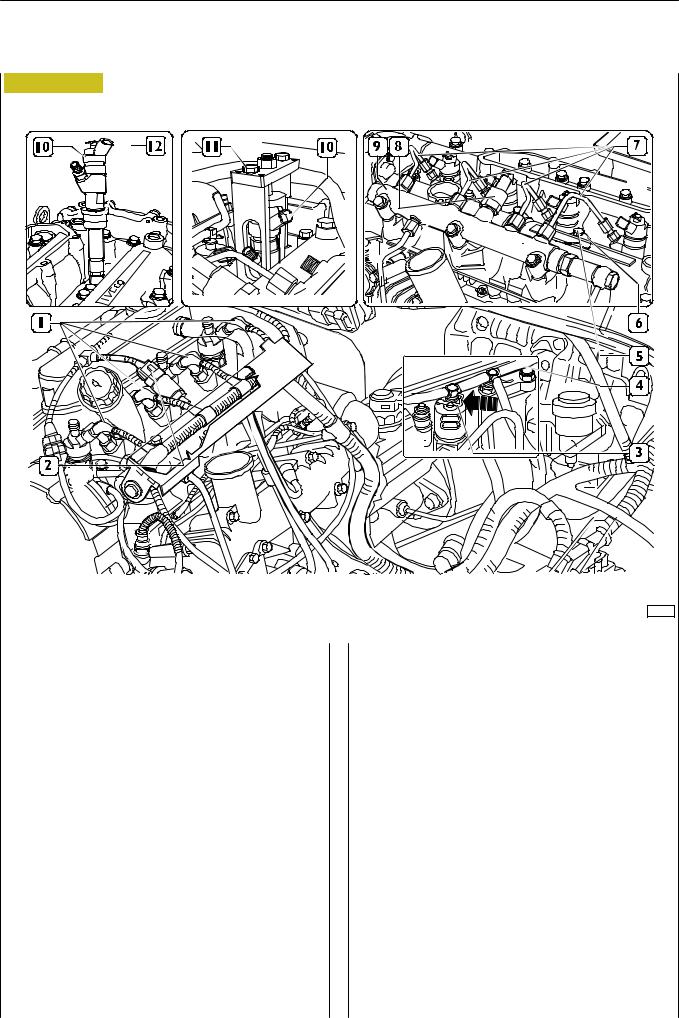

Removal |

Figure 1 |

|

Set the vehicle over the pit or on the lift.

Lift up the bonnet (2), unscrew the screws (1) securing it and take it off. Remove the prop (3).

Disconnect the negative cable (4) and the positive cable (6) from the battery (5) and detach this from the engine bay.

Unhook the cable (11) from the bonnet opening control devices.

Disconnect the electrical connections (12) of the front headlamps.

Unscrew the nuts (7) and screws (8), then remove the front cross member (10) with the light clusters.

Unscrew the screws (10, 12 and 14) and remove the bottom side guards (11 and 13).

Underneath the vehicle (see Figure 4):

- Unscrew the screws ( ) and remove the central guard (12).

75818

Print 603.93.281 |

Base - May 2004 |

294 ENGINE F1A |

DAILY |

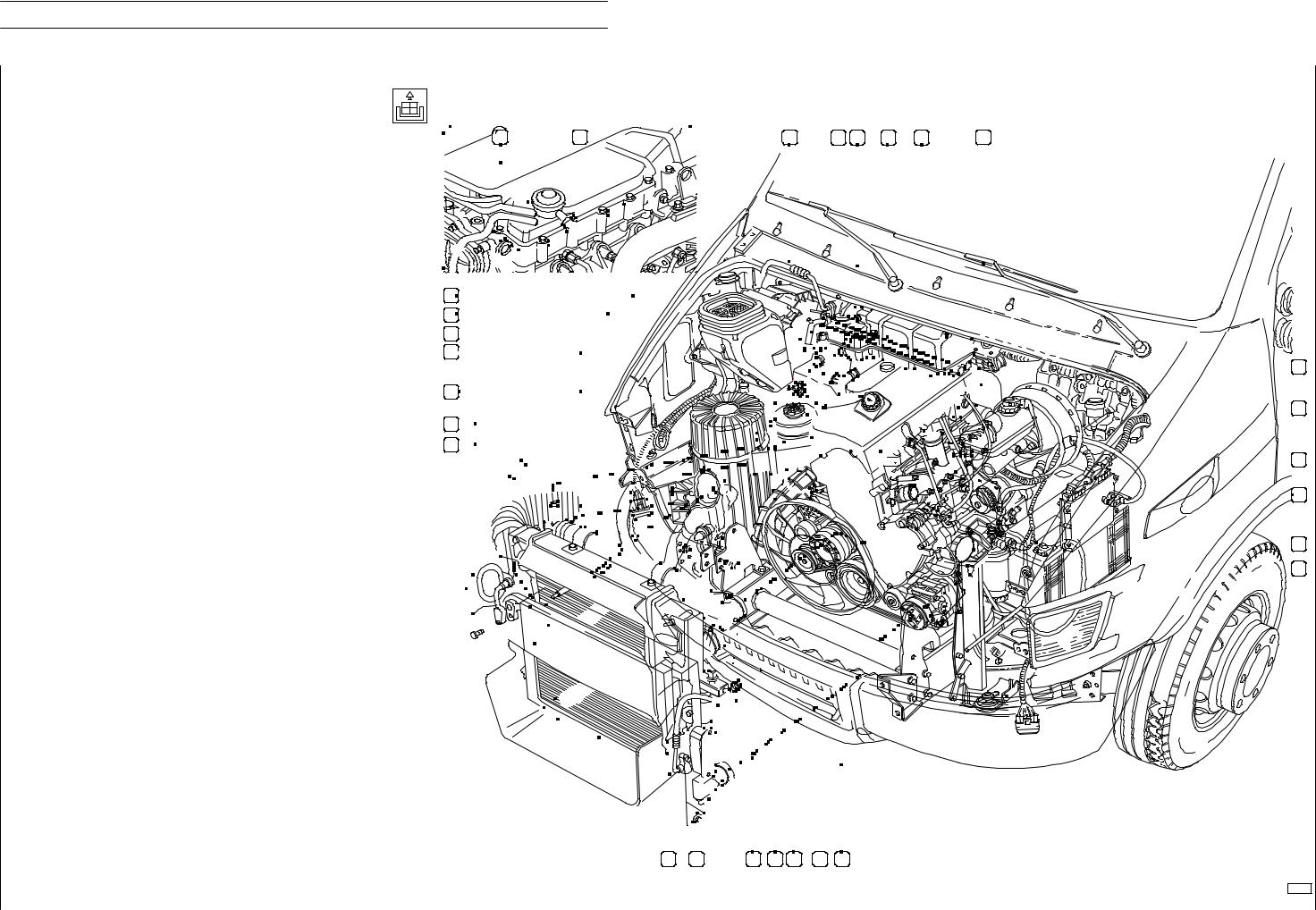

- Take the cap (2) off the expansion tank (4). |

Figure 2 |

- Unscrew the coolant plug (16), under the radiator (17), |

|

and drain the cooling system. |

|

- Disconnect the pipe (25) from the coalescence filter (26) |

|

and from the air intake pipe (14). |

|

- Disconnect the pipes (12) and (13) from the heat |

|

exchanger, intake manifold and turbocharger. |

|

NOTE Close the turbocharger air outlet appropriately to prevent foreign bodies accidentally getting inside and damaging it.

- Disconnect the coolant pipes (9 and 10).

NOTE Vehicles with an air-conditioner in the cab should have the electrical connection (15) disconnected from the drier filter.

- Unscrew the air filter bracket fasteners (20) to help extract the air intake pipe (21) from the duct (18) on the radiator assembly.

- Disconnect the pipe (22) from the duct (19) and (23) from the engine.

- Disconnect the tube (3) from the expansion tank (4).

- Unscrew the screws (11) to remove the radiator assembly (17) together with the heat exchanger.

NOTE In case of vehicles equipped with cabin internal conditioner, proceed as follows:

- vehicles equipped with drying filter separated from the condenser:

put the radiator (complete with the condenser and drying filter) back in the engine compartment, taking care not to subject the conditioning system pipes to tension;

- vehicles equipped with drying filter built into the condenser:

blow gas off the air-conditioning system, as described in the relevant chapter in the “Bodywork and chassis” section, then disconnect the pipes from the condenser and seal both the pipes and their respective fittings on the condenser to prevent moisture and impurities from penetrating into the system.

-Disconnect the coolant pipes (8) and (24) from the rigid three-way pipe (27), freeing them from any clamps (7).

-Disconnect the heater delivery pipe (1).

-Unscrew the fasteners (6) to remove the expansion tank

(4), disconnecting the level sensor’s electrical connection.

- Take the soundproofing cover (5) off the cylinder head

75817

after removing the oil filler cap.

Base - May 2004 |

Print 603.93.281/A |

Revi - February 2005 |

|

DAILY |

ENGINE F1A 295 |

|

|

Place a container under the power steering pump to recover Figure 3 the oil from the system. Then disconnect the oil inlet and

outlet pipes (16 and 17).

- Disconnect the pipes (7) recovering diesel from the high-pressure-pump.

- Disconnect the pipe (8) delivering diesel to the high-pressure-pump.

- Disconnect the vacuum pipe (23) from the vacuum pump.

- Disconnect the air intake duct (19).

NOTE Close the turbocharger air outlet appropriately to prevent foreign bodies accidentally getting inside.

- Free the wiring harness of the engine (15) from the clamps (←) on the timing cover, disconnect the connections of the alternator (21) and from the sensors on the thermostat (22), from the electromagnetic coupling of the fan hub (20) and move the wiring to one side so it will not interfere with the disassembly of the engine.

- Disconnect the wiring (2) from the water temperature and timing sensors, from the injectors, intake air temperature sensor and rail pressure sensor. Move the wiring to one side.

- Disconnect the high-pressure pump electrical connection (10).

- Disconnect the engine speed sensor (9).

- Disconnect the engine earth cable (6).

- Disconnect the positive cable from the starter motor (5).

The remaining electrical connections of the engine cable are disconnected from the associated electrical components after removing the engine.

- Disconnect the oil fillpipe by undoing the fastenings (1).

- Undoing the fastenings (18), remove the fan from the electromagnetic coupling (20).

- Attach tool 99360544 (4) to the brackets on the engine to extract it from the engine bay and put it slightly under traction.

NOTE In case of vehicles equipped with conditioner,

proceed as follows:

- as regards the vehicles equipped with drying

filter separated from the condenser, remove compressor (11) by proceeding as follows:

- loosen the belt stretcher by acting on screw (13), then remove belt (14);

- act on fasteners (12) to remove compressor (11), then put the latter back into the compartment without

disconnecting the pipes of the system itself; - as regards the vehicles equipped with drying

filter built into the condenser, disconnect the pipes from the compressor, then seal the pipes

and their respective fittings on the compressor to prevent moisture and impurities from

penetrating into the system.

75820

Print 603.93.281/A |

Base - May 2004 |

|

Revi - February 2005 |

296 ENGINE F1A |

DAILY |

|

|

- Disconnect the screws (16 and 20) securing the brackets Figure 4 (17 and 19) and disconnect the ”bowdens” (18 and 21)

from the gearbox.

- Unscrew the fixing screws (22), move the clutch control cylinder (23), with its bracket, and fasten it to the chassis frame appropriately.

- Remove the sealing from the ring nut (1), unscrew it and disconnect the speedometer control cable.

-Disconnect the electrical connection (4) from the reversing light switch.

NOTE As regards automatic transmission, disconnect gearbox-chassis cable connector (27) from the control unit.

- Disconnect the exhaust pipe (9) from the turbocharger outlet pipe.

- Put a jack under the gearbox to support it.

- Disconnect the bracket supporting the gearbox on the rear crosspiece by undoing the four screws (5).

- Unscrew the fixing screws (6) and remove the crosspiece

(7) supporting the gearbox complete with the gearbox/support bracket.

- Remove nuts (14) securing elastic supports (13) to the chassis.

- Remove bolts (3) securing drive shaft (2) to the gearbox; remove, if necessary, screws (24) securing elastic support (25) to the chassis, then properly secure the drive shaft to the chassis.

- Take the jack out from under the gearbox.

- Lift the engine assembly and take it out of the engine bay.

NOTE The power unit must be removed from the engine compartment with the greatest care, to avoid damaging the remaining parts on the vehicle, in particular the steering box oil pipes.

If it is necessary to detach the gearbox from the engine, take out the fixing screws and remove the starter motor.

Take out the fixing screws and detach the gearbox from the engine.

NOTE As far as automatic transmission is concerned, strictly adhere to the operations described in the relevant chapter in the “Gearbox” section.

102184

Base - May 2004 |

Print 603.93.281/A |

Revi - February 2005 |

|

DAILY |

F1A ENGINE 297 |

|

|

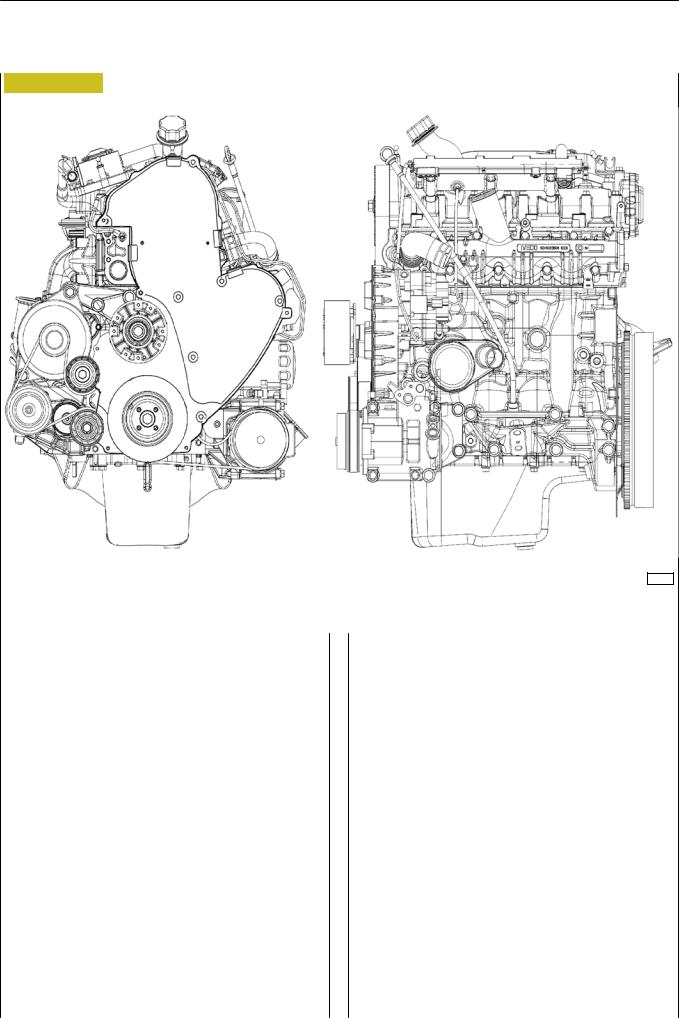

Refitting

To refit the engine assembly, carry out the operations described for removal in reverse order, following these instructions:

-Before refitting the gearbox to the engine, it is necessary to remove the pressure plate bearing from the diaphragm spring by opening out the retaining circlip.

Fit the pressure plate bearing on the sleeve of the drive input shaft cover, connecting it to the clutch release lever. Spread the gearbox input shaft with Molikote molybdenum disulphide grease.

Engage a gear to let the main shaft turn, rotating the propeller shaft connecting flange. Push the gearbox fully in so that the pressure plate bearing couples with the diaphragm spring correctly.

-Pay special attention to the operations needed to install the engine assembly in the engine bay.

-Check the conditions of the coolant pipes or sleeves and of the air ducts. Replace them if they show any sign of deterioration.

-Check the flexible mountings of the assemblies: engine and gearbox. Replace them if they show any sign of deterioration.

-Check that the exhaust pipe members have not deteriorated and are not about to deteriorate. If this is so, replace them along with the flexible parts for securing them.

-Tighten the screws or nuts to the required torque.

-Meticulously check the state of the vacuum pipe. It must show no sign of cracking, cutting, scoring or of being crushed. Replace it if there is any doubt at all about its soundness. When mounting it, make sure the pipe does not come into contact with sharp metal parts or corners or with any particularly hot parts. In addition, after assembly, the pipe must have no bends or constrictions, its radius of curvature should be broad and it must be secured to the vacuum pump fitting with a suitable clamp.

-Make sure the quick-coupling fittings of the fuel pipes are thoroughly clean and, after connection to the relevant high-pressure pump unions or fuel filter mount, are fully inserted and do not come loose.

-Fill the cooling system with coolant.

-Fill the hydraulic power steering circuit and bleed the air as described under the relevant heading.

-Check the level of oil in the engine and gearbox.

-Adjust the tension of the drive belt of the compressor for the air-conditioner as described in “Replacing Belts” (if present).

NOTE When positioning the engine in the engine bay, take special care not to damage the top pipe of the power steering and the soundproof-heatproof cladding of the engine bay.

Once positioned, meticulously check that the top pipe of the power steering is sound.

Before using it again, check that the power steering oil and coolant contain no impurities. If they do, filter with suitable mesh filters. For any topping up, refer to the REPLENISHING FLUIDS table in the “GENERAL” section.

Checks and tests

Start up the engine, leave it running just a little faster than idling speed and wait for the coolant temperature to reach the value for opening the thermostat, then check that:

-No water leaks from the connecting sleeves of the engine cooling and cab heating circuit pipes; tighten the collars if necessary.

-No oil leaks from between the cover and cylinder head, oil sump and crankcase, oil filter and its seat, heat exchanger and crankcase or from between the various pipes of the lubricating circuit.

-No fuel leaks from injection pump and injector lines. Tighten fittings if necessary.

-Check the indicator and warning lights on the instrument panel and the devices disconnected on removing the engine all work properly.

501430 Power steering system air bleed

Check the level of oil in the tank and top it up if necessary. Lift the vehicle at the front, start up the engine and let it idle for some time.

Check there is no oil leakage from the hydraulic circuit and check the level in the tank.

Slowly turn the steering wheel in both directions of steering so that the air in the hydraulic system comes out.

Check the level of oil in the tank again and top up if necessary.

Print 603.93.281 |

Base - May 2004 |

298 F1A ENGINE |

DAILY |

|

|

REPLACING BELTS

543910 Replacing air-conditioning compressor drive belt (version with belt tensioner)

Disassembly

Figure 5

75247

Set the vehicle on a lift or over a pit. From underneath the vehicle, detach the middle soundproofing guard.

Loosen the screw (2) fixing the tightener (1) and remove the belt (4) driving the air-conditioner compressor (3).

Assembly and adjusting belt tension

Figure 6

75502

Mount the drive belt, taking care to position its ribs properly in the respective races of the pulleys.

With the tool SP.2341 (2) inserted in the holes of the tightener (1) and a torque wrench (3), turn the tightener (1) with a torque of 8.2-10 Nm; in this condition, tighten the screw (4) to a torque of 25 Nm.

Turn the engine in its direction of rotation to have the belt

(5) make two full turns.

Using tool 99395849, measure the tension of the belt (5) in the section A, which must be 204 ± 10 Hz, corresponding to a load of 1010 ± 10 N on the tightener.

Fit the middle soundproofing guard back on.

543910 Replacing air-conditioning compressor drive belt (version with elastic belt)

Disassembly

Figure 7

90155

Take elastic belt (3) off pulleys (1 and 4).

Assembly

Fit the flexible belt (3) equipped with tool 99360191

(2) on the pulley (4) and apply the tool on the pulley (1).

Fit the drive ring (5) on the flexible belt (3) and fasten the ring on the compressor support.

Turn the drive shaft clockwise until the belt fits perfectly on the pulley (1).

543910 Power steering pump-alternator belt replacement

Disassembly

Figure 8

75248

Disassemble the compressor drive belt, if there is one, as described under the relevant heading.

Slacken off the tension of the belt (1) using a specific wrench on the automatic tightener (2) and remove the belt.

Assembly

Mount the drive belt (1) taking care to position its ribs correctly in the respective races of the pulleys. Release the automatic tightener (2). Turn the crankshaft by one turn to settle the belt.

Mount the compressor drive belt, if there is one, and adjust the tension as described under the relevant heading.

Fit the middle soundproofing guard back on.

Base - May 2004 |

Print 603.93.281 |

DAILY |

ENGINE F1A 299 |

|

|

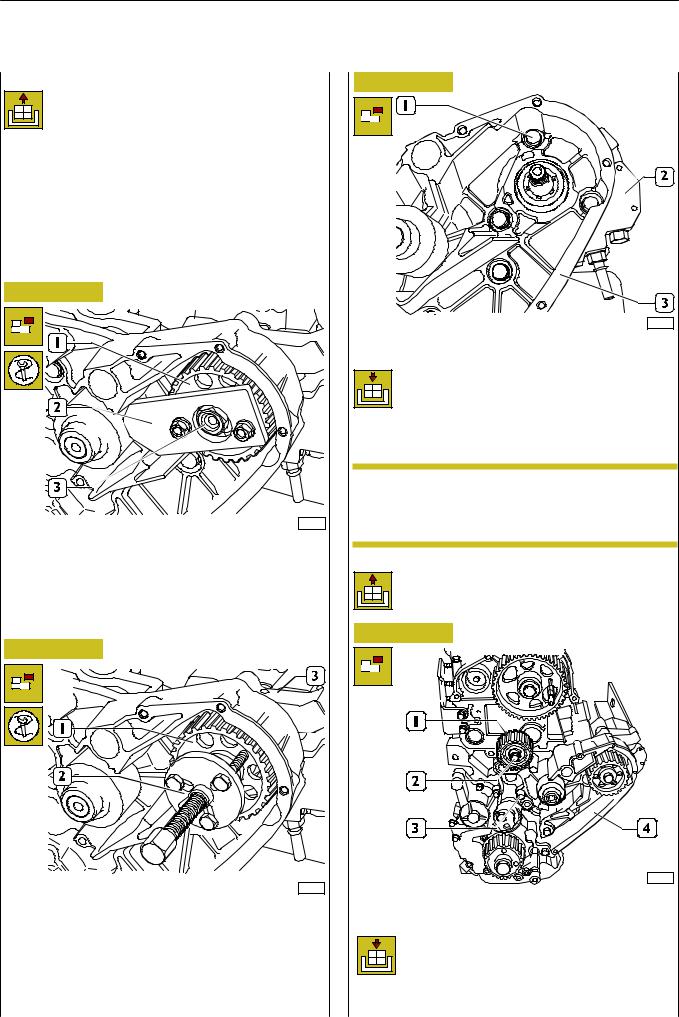

541257 Replacing timing drive belt |

Figure 9 |

Disassembly

Following the procedures described for removing the engine, take out the radiator assembly without disconnecting the air-conditioning system pipes from the condenser or from the drier filter and put it appropriately aside in the engine bay.

Remove the air-conditioner compressor drive belt (22) (if there is one) and the water pump / alternator drive belt as described under the relevant headings.

Remove the fan (25) from the electromagnetic coupling (6). Disconnect the electrical connection (24) from the electromagnetic coupling (6).

Take out the fixing screws (2) and (3) and remove the mounting together with the electromagnetic coupling (6). Take out the screws and remove the fixed tightener (5) and the automatic tightener (4).

Remove screws (26), then disassemble pulley (27). Remove the wiring from the timing cover (23) and dismantle this.

Take off the cap (13) and remove the soundproofing cover (14).

Disassemble valve gear cover (23). Disconnect the pipes (15) from the pipe (16).

Take out the fixing screws (8) and remove the expansion tank (7); disconnect the electrical connection for the level indicator from the expansion tank and put the tank (8) aside appropriately.

Take out the screws (10) and remove the bracket (11) fixing the soundproofing cover (14).

Remove the plugs (9) from the overhead and the plug (20) from the oil pump — vacuum pump assembly mounting. Turn the crankshaft clockwise so as to be able to insert the pins 99360614 (12) through the holes in the plugs (9) into the relevant holes of the camshafts and pin 99360615 (19) through the hole in the plug (20) into the crankshaft. Loosen the screw (17) securing the automatic tightener (18) and remove the timing belt (21).

102093

Print 603.93.281/A |

Base - May 2004 |

|

Revi - February 2005 |

300 ENGINE F1A |

DAILY |

|

|

Figure 10

Assembly

Insert tool 99360608 (8) into the hole of the toothed pulley

(7) and into the corresponding hole of the overhead to prevent changing the assembly position of the toothed pulley

(7) in the following operations.

Loosen the screw (9) fixing the toothed pulley (7) and, using tool 99340028, drive the pulley (7) out of the camshaft. Turn the automatic tightener (1) clockwise, positioning it as shown in frame A.

Turn the timing belt (10) as shown in the figure observing the precautions below.

Do not bend the timing belt. Arrows indicating the direction of assembly of the timing belt on the engine are shown on the back of the belt. The arrows must correspond to the direction of rotation of the belt and the notches must coincide with those on the pulley (7) and the gear (12).

If required to fit the timing belt (10) on the pulley (7), remove tool 99360608 (8) and turn the pulley (7) clockwise by no more than half a pulley tooth.

On completing assembly, adjust the toothed pulley (7) to put the section X of the belt under tension and tighten the screw

(9) to a torque of 90 Nm.

Keeping the screw (2) stationary and using a suitable wrench on the hexagon of the plate (3) of the tightener, turn it anticlockwise to cover the reference hole (5) located on the fixed portion of the tightener (see frame B).

In the above conditions, tighten the fixing screw (2) to a torque of 36 ± 4 Nm.

Remove the tools 99360614 (6) and 99360615 (11) for the timing.

Turn the engine in its direction of rotation by 8 turns to be able to put the tools (6) and (11) back in to do the timing.

In these conditions, the notches of the timing belt (10) must coincide with those of the pulley (7) and the gear (12).

NOTE Do not turn the engine in the opposite direction; if, on turning the engine, you pass the point for inserting the tools (6) and (11), turn the engine clockwise by another two turns.

See frame C: holding the tightener plate (3) stationary with the wrench inserted in its hexagon, loosen the fixing screw (2). Keeping the fixing screw (2) stationary, turn the plate (3)

clockwise until its reference mark (4) coincides with the reference hole (5) of the fixed portion of the tightener.

In the above conditions, tighten the screw (2) to a torque of 30 ± 4 Nm.

Then complete assembly by carrying out the steps described for disassembly in reverse order.

After assembly, the belt (10) tension measured using tool 99395849 must be as follows in the following points: X, 212

± 12 Hz - X1, 178 ± 10 Hz.

x = direction of movement of the tightener |

|

y = direction of rotation of the wrench |

85844 |

Base - May 2004 |

Print 603.93.281 |

DAILY |

F1A ENGINE 301 |

|

|

775010 REPLACING ELECTRO-INJECTORS

Figure 11

Disassembly

Partly drain the coolant off from the radiator.

Remove the plug (13, Figure 9) and detach the soundproofing cover (14, Figure 9).

Disconnect the pipes (15, Figure 9) from the pipe (16, Figure 9).

Take out the fixing screws (8, Figure 9) and remove the expansion tank (7, Figure 9). Disconnect the level indicator electrical connection from the expansion tank.

Disconnect the pipe (17, Figure 12) from the coalescence filter (2, Figure 12).

Disconnect the electrical connections (1) from the electro-injectors (10) and (2) from the fuel pressure sensor

(8).

Press the springs (3) in the direction shown by the arrow and disconnect the fittings of the pipe (4) to recover fuel from the electro-injectors (10).

Disconnect the fuel pipes (7) from the electro-injectors (10) and from the hydraulic accumulator (9).

Take out the screws (6) and the brackets (5) fixing the electro-injectors (10) to the cylinder head.

Using tool 99342153 (11) extract the electro-injectors (10) from the overhead.

75564

Assembly

Thoroughly clean the seat of the electro-injectors, taking care no foreign bodies get into the cylinder barrels.

Fit a fresh gasket (12) onto the electro-injector (10) and fit this in the overhead.

Complete assembly by carrying out the operations described for disassembly in reverse order, taking the following precautions:

-With each disassembly, the fuel pipes must be replaced with fresh ones.

-Tighten the nuts, screws and fittings to the prescribed torque.

-To tighten the fittings of the fuel pipes, use the wrench in the 99317915 series and the torque wrench 99389829.

-After assembly, replenish the coolant as described under the relevant heading.

Check assembly of the timing sensor as described under the relevant heading.

Print 603.93.281 |

Base - May 2004 |

302 F1A ENGINE |

DAILY |

|

|

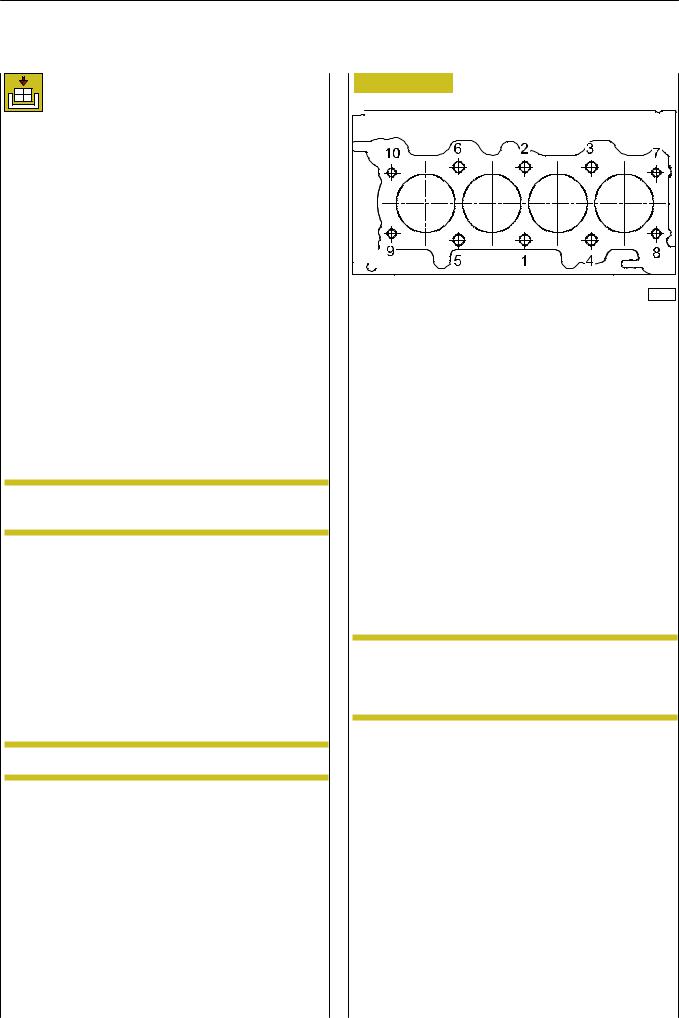

540610 CYLINDER HEAD REMOVAL AND REFITTING

Figure 12

Removal

Remove the timing belt as described under the relevant heading (operation 541257).

Disconnect the coolant pipes (12) and (13) from the pipe (11).

Take out the fixing screws and remove the expansion tank (16), disconnecting the level sensor electrical connection from this.

Remove the pipe (18) for the oil dipstick from the intake manifold.

Disconnect the pipes (1) and (17) from the coalescence filter

(2) and detach this from the overhead.

75567

Disconnect the pipe (3) from the fitting.

Remove the electro-injectors (4) as described in “Replacing electro-injectors” (operation 775010).