Page 1

Maintaining and

Troubleshooting

the Gateway

ALR 9200 Server

Part # 8503424 A MAN SYS US 9200 TECH REF R0 8/98

In our effort t o u se na tur e’s resources e f fici entl y a nd wi sely, we print all man uals on r ecy cled paper s t hat me et the

minimum requirements established by the Federal EP A in it s guidelines for rec ycled paper products.

Page 2

Notices

Copyright © 1998 Gateway 2000, Inc.

All Rights Reserved

610 Gateway Drive

N. Sioux City, SD 57049 USA

All Rights Reserved

This publication is protected by copyright and all rights are reserved. No part of it may be reproduced or

transmitted by any means or in any form, without prior consent in writing from Gateway 2000.

The information in this manual has been carefully checked and is believed to be accurate. However,

changes are made periodically. These changes are incorporated in newer publication editions. Gateway

2000 may improve and/or change products described in this publication at any time. Due to continuing

system improvements, Gateway 2000 is not responsible for inaccurate information which may appear in

this manual. For the latest product updates, consult the Gateway 2000 web site at www.gateway .com. In

no event will Gateway 2000 be liable for direct, indirect, special, exemplary, incidental, or consequential

damages resulting from any defect or omission in this manual, even if advised of the possibility of such

damages.

In the interest of continued product development, Gateway 2000 reserves the right to make

improvements in this manual and the products it describes at any time, without notices or obligation.

T rademark Acknowledgments

AnyKey, black-and-white spot design, CrystalScan, Destination, EZ Pad, EZ Point, Field Mouse, Solo,

T elePath, Vivitron, stylized “G” design, and “You’ve got a friend in the business” slogan are registered

trademarks and GATEWA Y, Gateway Solo, green stylized GATEWAY , gr een stylized Gateway logo, and

the black-and-white spotted box logo are trademarks of Gateway 2000, Inc. Intel, Intel Inside logo, and

Pentium are registered trademarks and MMX is a trademark of Intel Corporation. Microsoft, MS, MS-DOS,

and Windows are trademarks or registered trademarks of Microsoft Corporation. All other product names

mentioned herein are used for identification purposes only, and may be the trademarks or registered

trademarks of their respective companies.

Copyright © 1998 Advanced Logic Research, Inc. (ALR)

All Rights Reserved

9401 Jeronimo

Irvine, CA 92618 USA

All Rights Reserved

This publication is protected by copyright and all rights are reserved. No part of it may be reproduced or

transmitted by any means or in any form, without prior consent in writing from ALR.

The information in this manual has been carefully checked and is believed to be accurate. However,

changes are made periodically. These changes are incorporated in newer publication editions. ALR may

improve and/or change products described in this publication at any time. Due to continuing system

improvements, ALR is not responsible for inaccurate information which may appear in this manual. For the

latest product updates, consult the A LR web site a t www.alr.com. In no even t will ALR b e li able for dire ct,

indirect, special, exemplary, incidental, or consequential damages resulting from any defect or omission in

this manual, even if advised of the possibility of such damages.

In the interest of continued product development, ALR reserves the right to make improvements in this

manual and the products it describes at any time, without notices or obligation.

T rademark Acknowledgments

ALR is a registered trademark of Advanced Logic Research, Inc. All other product names mentioned

herein are used for identification purposes only, and may be the trademarks or registered trademarks of

their respective companies.

Some portions of this document are copyright © 1998, Intel Corporation.

Page 3

Contents

Preface .....................................................................................vii

About This Guide................................................................................ viii

Conventions Used in This Guide........................................................... ix

Important Safety Instructions.................................................................. x

Chapter 1: System Access ........................ ......... .......... ......... ...1

Static Electricity Precautions.................................................................. 2

Opening the System ................................................................................ 3

Removing the Access Cover............................................................ 3

Opening the Front Door................................................................... 4

Opening the Subchassis and Electronics Bay................................. 5

Closing the System.................................................................................. 7

Closing the Subchassis and Electronics Bay................................... 7

Installing the Access Cover.............................................................. 8

Installing the Front Door.................................................................. 8

Chapter 2: Componen ts ......... ......... .......... ..... ......... ......... ........9

System Board Features.......................................................................... 10

System Board Connectors..................................................................... 10

Drive Controllers and Connectors................................................. 12

System Jumpers (B)....................................................................... 13

Miscellaneous Connectors............................................................. 14

Expansion Slot Connectors............................................................ 15

Memory Module Connector (I)..................................................... 16

System Management Connectors.................................................. 16

Back Panel I/O Connectors............................................................ 18

Processors and Related Connectors............................................... 20

Power Connectors.......................................................................... 21

Memory.................................................................................................. 23

DIMM Installation Sequence......................................................... 24

System Memory Addressing ......................................................... 24

Memory Configuration.................................................................. 25

System Security..................................................................................... 26

Mechanical Locks and Monitoring................................................ 26

Software Locks via the SSU or BIOS Setup................................. 26

Contents i

Page 4

Chapter 3: Installing Co mponents ................................ ......... ..31

Introduction........................................................................................... 32

Replacing the Processor........................................................................ 32

Installing Another Processor................................................................ 36

Installing Hardware............................................................................... 40

Memory.......................................................................................... 40

Drives............................................................................................. 45

Installing Fans for High-Power Drives......................................... 57

Expansion Cards............................................................................ 62

Power Supplies .............................................................................. 65

Replacing the Battery .................................................................... 68

Chapter 4: Jumpers and Drivers .................... ................... ......71

Setting the Jumpers............................................................................... 72

Changing a Jumper Setting............................................................ 73

CMOS Clear Jumper..................................................................... 74

Password Clear Jumper................................................................. 75

Recovery Boot Jumper.................................................................. 75

Installing Software and Drivers............................................................ 77

Installing Video Drivers................................................................ 77

Chapter 5: BIOS Set up .................... ......... ..... ......... .......... ......79

Introduction........................................................................................... 80

Using BIOS Setup................................................................................. 81

Record Your Setup Settings.......................................................... 81

If You Cannot Access Setup ......................................................... 82

Starting Setup................................................................................. 82

Setup Menus.......................................................................................... 83

Setup Key Commands................................................................... 84

Special Display Items.................................................................... 84

Main Menu..................................................................................... 85

Advanced Menu............................................................................. 87

Security Menu................................................................................ 92

Server Menu................................................................................... 93

Boot Menu...................................................................................... 95

Exit Menu....................................................................................... 97

ii Maintaining and Troubleshooting the Gateway ALR 9200 Server

Page 5

Upgrading the BIOS.............................................................................. 98

Preparing for the Upgrade.............................................................. 98

Upgrading the BIOS..................................................................... 100

Recovering the BIOS................................................................... 101

Changing the BIOS Language..................................................... 101

Chapter 6: The Server Setup Utility ............................... ........103

Introduction.......................................................................................... 104

Using the System Setup Utility........................................................... 105

When to Run the SSU.................................................................. 105

What You Need to Do.................................................................. 106

Running the SSU................................................................................. 107

Running the SSU Locally............................................................ 107

Running the SSU Remotely......................................................... 107

Starting the SSU........................................................................... 108

Customizing the SSU.......................................................................... 109

Launching a Task ................................................................................ 111

Resource Configuration Add-in Window.......................................... 112

Using the RCA Window.............................................................. 112

Defining an ISA Board................................................................. 113

Adding and Removing ISA Boards............................................. 114

Modifying Resources................................................................... 114

System Resource Usage............................................................... 115

Multiboot Options Add-in................................................................... 115

Security Add-in ................................................................................... 116

Security Options........................................................................... 117

System Event Log Viewer Add-in...................................................... 118

Sensor Data Record Manager

Add-In.................................................................................................. 120

Field Replaceable Unit Manager Add-In........................................... 122

Exiting the SSU................................................................................... 124

Chapter 7: Other Utilities ............................ ......... .......... ........125

Introduction.......................................................................................... 126

Power-on Self Test.............................................................................. 127

Emergency Management Port Console.............................................. 129

How the EMP Console Works..................................................... 130

EMP Console Requirements........................................................ 132

Contents iii

Page 6

Setting Up the Server for the EMP.............................................. 133

Main EMP Console Window...................................................... 134

Server Control Operations........................................................... 136

Phonebook.................................................................................... 140

Management Plug-ins.................................................................. 141

FRU and SDR Load Utility................................................................ 145

When to Run the FRUSDR Load Utility.................................... 145

What You Need to Do................................................................. 145

How You Use the FRUSDR Load Utility.................................. 146

Cleaning Up and Exiting............................................................. 150

Using the Firmware Update Utility.................................................... 151

Running the Firmware Update Utility........................................ 151

Using the Symbios SCSI Utility......................................................... 152

Running the SCSI Utility............................................................. 152

Chapter 8: Troubl eshoot ing .................................... .......... ....153

Introduction......................................................................................... 154

Computer Virus Notice....................................................................... 155

Viruses.......................................................................................... 155

Types of Viruses.......................................................................... 155

Virus Contamination.................................................................... 155

Protecting Your System............................................................... 156

Virus Prevention.......................................................................... 156

Troubleshooting Checklist ................................................................. 158

Verifying the Configuration........................................................ 158

Troubleshooting Guidelines........................................................ 158

Solving Problems................................................................................ 159

Resetting the System.................................................................... 159

Initial System Startup................................................................... 159

Running New Application Software........................................... 160

The System Has Been Running Correctly.................................. 161

More Problem-solving Procedures............................................. 162

Specific Problems and Corrective Actions................................. 164

Error and Informational Messages..................................................... 170

POST Codes and Countdown Codes.......................................... 170

POST Error Codes and Messages............................................... 173

iv Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 7

Appendix A: Reference Data ..................... ................... ........175

Specifications....................................................................................... 176

System Specifications.................................................................. 176

Environmental Specifications...................................................... 177

System I/O Addresses......................................................................... 178

Memory Map....................................................................................... 181

Interrupts.............................................................................................. 182

Video Modes ....................................................................................... 183

DMA Usage......................................................................................... 187

Appendix B: Regulatory Compliance Statements ................ 189

Electromagnetic Compatibility........................................................... 190

FCC Notice.......................................................................................... 191

Industry Canada Notice....................................................................... 192

CE Notice............................................................................................. 192

VCCI Notice........................................................................................ 193

Australia/New Zealand Notice ........................................................... 193

Declaration of the Manufacturer or Importer..................................... 194

Safety Compliance.............................................................................. 194

Index ..................................................................................... 195

Contents v

Page 8

vi Maintaining and Troubleshooting the Gateway ALR 9200 Server

Page 9

Preface

Contents

About This Guide .................................................viii

Conventions Used in This Guide...........................ix

Important Safety Instructions.................................. x

Page 10

About This Guide

This document pro vides step-b y-step install ation instructions along with

detailed illustrations to hel p maintain the hardw are component s and

peripherals of the computer.

Chapter 1: Sy stem Access pro vides instructions on opening a nd closing the

case.

Chapter 2: Component s covers information on maintai ning, replacing, and

upgrading the components in the system. This sect ion includes information

about options for the system and inst allation instructions.

Chapter 3: Installing Components describes the procedures for install ing or

replacing the hardwa re components.

Chapter 4: Jumpers and Drivers describes setting the jumpers and pro v ides

basic information about operating systems and sof twar e.

Chapter 5: BI OS Setup br iefly e xplains the syst em basic input/output

system (BIOS) and pro vides instructions on ho w to update the BIOS.

Chapter 6: The S erver Setup Utility describes the system setup util ity and

provides instructions on using it to set up the server .

Chapter 7: Othe r Utilities de scribes the other uti lities pro vided wit h the

system and pro vides instructions for their use.

Chapter 8: Troubleshooting provides refer ence material on troub leshooting

your system.

viii Maintaining and Troubleshooting the Gateway ALR 9200 Server

Page 11

Conventions Used in This Guide

Note:

This is an ex ampl e of an

important note that may

appear in the manual.

Throughout this document, you will see the follo wing co n ventions:

Convention Description

ENTER

CTRL+ALT+DEL

Setup

User’s Guide

Sidebars Sidebars give critical information such

Key names, which correspond to keys

on the keyboard, are printed in small

capitals.

A plus sign indicates that the keys

must be pressed simultaneously.

Commands to be entered, options to

select, and messages that appear on

your monitor are printed in bold.

Names of publications and files are

printed in italic.

as warnings and important notes.

Conventions Used in This Guid e i x

Page 12

Important Safety Instructions

Warning!

Do not attempt to se rvi ce

the system yourself except

as explained el sewh er e i n

the manual. Ad just onl y

those controls covered in

the instruct ions .

Opening or removing covers

marked “Do Not Remove”

may expose you to

dangerous voltages or other

risks.

Refer all servicing of those

compartments t o q ual ifi ed

service personnel.

Important!

The system power cord

serves as the mai n

disconnect for the

computer. The wall outlet

must be easily accessible by

the operator.

Observe the following gui delines w hen performing any w ork on y our

system:

• Foll ow all instructions marked on t he server and in the

documentation.

• Unplug this product from the w all outlet be fore cleaning. Do not

use liquid or aerosol cleaners . Use a damp cloth for cle aning.

• Do not use this product near water . Do not spill liquid on or int o the

server .

• Do not place the server on an unstab le surface.

• Openings in the system cabinet are provi ded for ventilat ion. Do not

block or co ver these openings. Do not place the server near or upon

a radiator or heat re gister .

• Use only the po w er source sho wn on the power suppl y. If you are

not certain about the po wer s ource, ask the local po we r company.

• The server is equipped with a 3-wire grounding plug (a plug wit h a

grounding pin). This plug only fits into a grounded pow er outlet.

This is a safety feature. If y ou are unab le to insert the plug into t he

outlet, contact your e lectrician to repl ace the outlet.

• Do not walk on the po w er cord or allow anything to rest on it.

• If you use an extensi on cord with this system, make sure the total

ampere ratings on the products plugged into the extens ion cord do

not exceed the extensi on cord ampere rating. Also, the total ampere

requirements for all products pl ugged into the w all outlet must not

exceed 15 amperes.

• Never insert objects of any kind i nto the system vent ilation slot s.

x Maintaining and Troubleshooting the Gate way ALR 9200 Serve r

• Unplug the system from the w all outlet and ref er servicing to

qualified personnel if:

• The power cord or plug is damaged.

• Liquid has been spilled into the system.

• The system does not operate properly when t he operating

• The system was dropped or the cabinet is damaged.

• The system’s performance changes.

instructions are follo w ed.

Page 13

Chapter 1:

System Access

Contents

Static Electricity Precautions.................................. 2

Opening the System................................................. 3

Removing the Access Cover............................ 3

Opening the Front Door................................... 4

Opening the Subchassis and Electronics Bay. 5

Closing the System.................................................. 7

Closing the Subchassis and Electronics Bay... 7

Installing the Access Cover.............................. 8

Installing the Front Door.................................. 8

Page 14

Static Electricity Precautions

Caution! Prevent Static-Electricity Damage

Static Electricity Preventions

1. WEAR A GROUNDING WRIST STRAP (a vailab le at most electronic stores).

2. Turn off the system pow er .

3. Touch the back of the power supply fan, located on the back of the case.

4. UNPLUG ALL CORDS FR OM WALL OUTLET.

5. Remove the system case cover .

Static Electricity Pr ecautions

♦ Avoid static-causing surfaces such as plastic and styrofoam in your work area.

♦ Remove the parts from their antistatic bags only when y ou are ready to use them. Do not la y

parts on the outside of antistatic bags since only the inside provides antistatic protection.

♦ Always hold cards by their edges and their metal mounting bracket. A void touching

components on the cards and the edge connectors that connect to expansion slots.

♦ Never slide cards or other parts over any surface.

2 Maintaining and Troubleshooting the Gateway ALR 9200 Server

Page 15

Opening the System

Depending on your purpose, you ma y need to remo v e the access co v er or

both the access co ver and t he bezel. You may also need to open the

subchassis or the electronics bay t o reach certain components. F oll o w the

instructions specific to the item you wish to remo ve or open as indicated in

each section.

Removing the Access Cover

You need to remov e the system access co ve r to reach components inside the

system. F acing the front of the sys tem, the access co ve r is on the right side

of the server .

To Remove the Access Cover

1. Observe the ESD precautions in “Static Ele ctricity Precauti ons” on

page 2.

2. T urn off all peripheral de vices connect ed to the system.

3. T urn off the system by us ing the po wer on/off s witch on the front pane l

and unplugging all A C po w er cords.

Caution!

Power the system off and

disconnect all powe r cords

before proceeding. Installing

any component while the

power is on may cause

permanent damage to the

system.

4. Label and disconnect all peripheral ca bles a ttached to the input/ou tput

(I/O) panel on the back of the syst em.

Opening the System 3

Page 16

5. Remove and sa ve the three scr ews from the ba ck of the access co v er

(see Figure 1); you will need them later to reat tach the co v er .

Figur e 1: Remo ving the Acces s Cover

6. Place the fingertips of your right hand under the built-in handle on t he

back of the co ver. A rounded , rectangular depres sion in the front

middle of the access co ver serves as another handle.

7. Using an even pull, sl ide the co v er backward, about an inch, until it

stops.

8. Pull the entire co ver outw ard, straight aw a y from the chassi s, to

disengage the ro ws of tabs from the notches i n the top and bottom

edges of the chassis. Set t he co ver a side.

Opening the Front Door

The front door is secured to the bezel b y a ke y lock. This lock has thr ee

positions: full y locked , f ront door unlock ed , and fro nt and access co ve r

unlocked. When the front door is unlock ed , y ou can remo ve it by opening it

fully and lift ing the hinges out of the s lots that hold them.

4 Maintaining and Troubleshooting the Gateway ALR 9200 Server

Page 17

Opening the Subchassis and Electronics Bay

The chassis is comprised of three pa rts: the main chassis, a s wing-out

subchassis at the front, and a s wing-out subchassi s, called the electr onics

bay, at the rear . To access components in some inst ances, you must re mo ve

the foam cov ers and s wing a wa y and/or completely remo ve the subchassi s

and electronics ba y.

T o open the subchas sis and electron ics ba y, you must first remov e the foam

cov ers. The subchassis and el ectronics ba ys are se cured using phillips hea d

screws.

T o Open the Subchassis and Electronics Bay

1. Observe the safety and ESD precautions in “Stati c Electricity

Precautions” on page 2.

2. T urn off all peripheral de vices connect ed to the system.

3. T urn off the system po w er b y using the po w er o n/off s witch on the

front panel and unplugging all A C po w er c ords.

4. Label and disconnect all peripheral ca bles a ttached to the I/O panel on

the back of the system.

5. Remove and sa ve the three scr ews from the ba ck of the access co v er;

you will need them later t o reattach the co ver.

6. Remove the access co ver.

7. Remove the foam blocks b y pulling t hem out of the subchassis and

electronics ba y . These blocks form an important part of the airflo w and

electromotiv e compatibility (EMC) characteristics o f the system. The

foam in the subchassis also forms the support structure for most of the

system fans.

Opening the System 5

Page 18

8. Loosen the two sc rews on the t op and bottom edges of t he chassis (A

Caution!

Y ou must di sconnect all

cabling to the e l ect r oni cs

bay before rotating/

removing the bay. Failur e t o

do so can result in serious

damage to system

components. The location of

the main connectors in the

electronics bay is marked as

D in Figure 2.

Note:

It may be easier to

disconnect the cables if you

remove the foam pad first.

in Figure 2). These screws attach the front subcha ssis and the

electronics ba y to the main chassis.

A

B

C

D

Figur e 2: Opening t he Subchassis and Elec tr onics Bay

9. Using the edges of the subchas sis as handles, rotate the front

subchassis left, a w a y from the main chassis, un til it stops (B in

Figure 2).

10. Disconnect all cabling to the el ectronics ba y (D in Fi gure 2).

11. Using the vertical edge of the electr onics ba y as a handle, rotate t he

bay right, a w a y from the main chassis, unt il it stops (C in F igure 2).

12. If necessary , completel y remo v e the subchassis and el ectronics ba y:

rotate the ba ys outward unt il the tw o pins tha t function as hinges for

the bays sli de out of their slots . Set the ba ys aside.

6 Maintaining and Troubleshooting the Gateway ALR 9200 Server

Page 19

Closing the System

Before closing the system, ver ify that all connect ors and boards are

properly instal led and firmly seated.

Closing the Subchassis and Electronics Bay

As you close the subchassi s and electronics ba y, carefully observe the

internal components to ensure that y ou do not pinch or twist an y of the

cables or components.

To Close the Subchassis and Electronics Bay

1. Verify that all internal components are f ully ins talled and secured.

2. Press down on t he tab on the top of the electronics ba y to release it and

swing it closed.

3. Attach any cab les to the electr onics ba y components.

4. Press down on the tab at the top of the subchassis to free it an d swing it

closed.

5. Secure the subchassis with the two screws you re mo ved earlie r .

6. If necessary , reins tall the foam brack eting for the fans i n the

subchassis and reinstall the fans.

7. Reinstall the foam o ver t he subchassis and electr onics ba y.

8. Replace the access co ver a nd po we r up the system.

Closing the System 7

Page 20

Installing the Access Cover

Note:

The bezel key lock must be

in the open position before

reinstall ing the a cce ss co ver.

Be careful to a void pinching a ny in ternal cables in the a ccess co ve r when

closing the system.

T o Replace the Access Cover

1. Before replacing the access co v er , check that you ha ve not left loose

tools or parts inside the system.

2. Check that cables, e xpansion cards, f oam pad , and other components

are properly inst alled.

3. Position t he co ver over the chassis so that th e ro ws of tabs align with

slots in the chassis. While pressing inw ard , sli de the co ver to war d the

front of the system until the t abs on the co v er firmly engage in the

chassis.

4. Attach the co ver to the ch assis with the th ree screws y ou remo v ed

earlier, and t ighten them firmly .

5. Connect all external cabl es and the po w er cords to the system.

Installing the Front Door

T o replace th e front door , insert the hinges into the slots on the f ront of the

chassis and close the door . Sec ure it by turning the bezel keylock to the

second locked position. The first position allo ws you to open the front door

and locks the side access panel. The f ully lock ed position pre v ents all

access to the system controls b y lockin g both the access panel and t he bezel

door .

8 Maintaining and Troubleshooting the Gateway ALR 9200 Server

Page 21

Chapter 2:

Components

Contents

System Board Features...................................................10

System Board Connectors..............................................10

Drive Controllers and Connectors..........................12

System Jumpers (B)................................................13

Miscellaneous Connectors......................................14

Expansion Slot Connectors ....................................15

Memory Module Connector (I)..............................16

System Management Connectors...........................16

Back Panel I/O Connectors ....................................18

Processors and Related Connectors .......................20

Power Connectors...................................................21

Memory...........................................................................23

DIMM Installation Sequence .................................24

System Memory Addressing..................................24

Memory Configuration...........................................25

System Security ..............................................................26

Mechanical Locks and Monitoring ........................26

Software Locks via the SSU or BIOS Setup..........26

Page 22

System Board Featur es

The system board functions as the main int erface betw een the processor ,

memory , and peripherals.

T able1 lists the features of the system board. F igure 3 on page 11 shows the

components on the system board and their locati ons.

Table 1: System Board Features

Feature Description

Processor Installed: Up to four Pentium® II Xeon™ processors, in single

Main memory Single plug-in module containing 16 dual in-line memory module

Video memory Installed: 2 MB of video memory.

PCI bus(es) PCI-A—Three expansion connectors

ISA bus One expansion slot for expansion boards (shared with a

Server management Thermal/voltage monitoring and error handling.

Graphics Integrated onboard Cirrus Logic GD5480 super video graphics

SCSI Two embedded small computer systems interface (SCSI)

System I/O PS/2-compat ib l e keyboard and mous e p or t s , pa r all el port,

edge contact (SEC) car t r idges installed in Slot 2 connectors.

Includes co nn e ctors for six VRM 8. 3 - co mpliant plug -i n v o lt ageregulator modules (VRMs).

(DIMM) sockets for up to 4 GB of extended data output (EDO)

dynamic ra n dom access memory (DRA M).

Installed: 256 MB–4 GB of EDO error correcting code (ECC)

random access memory (RAM).

PCI-B—Four expansion connectors (one shared with the

ISA slot)

PCI-B slot).

Front panel controls an d indicator light emitting diodes (LE Ds ).

array (SVGA) controller.

controllers:

Symbios SYM53C810AE—narrow SCSI controller providing

support for legacy 8-bit SCSI devices

Symbios SYM53C896—dual-channel wide low voltage

differential (LVD)/single-ended (SE) (ultra2/ultra) SCSI controller

driving one SCSI backplane in the system and providing support

for external expansi o n.

video port, USB port, and two serial ports (serial port 1 is the left

connector).

System Board Connectors

Figure 3 shows the connectors on the system board. Some of thes e

connectors may not be used, depending on the configuration of the server .

The table belo w pro vi des the key t o Figure3.

10 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 23

LL

C DA E FB

G

GG

JJ

KK

II

HH

H

I

FF

EE

DD

CC

AA

W

BB

Z

Y

X

V

P

J

K

Q

L

R

S

T

M

N

O

U

Figur e 3: Syst em Board Component s and Connectors

A Wide SCSI B connector (J9J1) T VRM connector for processors 2 & 1 (J4A2)

B System jumpers (J6J1) U VRM connector for processor 1 (J4A1)

C Hard drive input LED connector (J6J3) V Processor 1 Slot 2 connector (J9A1)

D System speaker connector (J6J2) W Main power connector, primary (J9B1)

E Lithium battery (B4H1) X Processor 2 Slot 2 connector (J9B2)

F Wake-on-LAN technology connector (J4H1) Y Processor 3 Slot 2 connector (J9D1)

G ISA slot (J1J1) Z Main power connector, secondary (J9D2)

H PCI slots B4 (top), B3, B2, B1, A3, and A2 AA Front panel connector (J8E1)

I Memory module connector (J3G1) BB Processor 4 Slot 2 connector (J9E1)

J ICMB connector (J1E1) CC IDE connector (J9E2)

K PCI slot A1 (J2D1) DD Diskette drive connector (J9E3)

L Video and parallel port connectors (J1C1) EE Auxiliary power connector (J9E4)

M Serial port connectors (J1B2) FF USB internal header (JC9F14)

N Keyboard and mouse connectors (J1B1) GG SMBus connector (J9F2)

O USB external connector (J1A1) HH F16 expansion connector (J7G1)

P VRM connector for processor 4 (J4E1) II Narrow SCSI connector (J9H1)

Q VRM connector for processors 4 & 3 (J4C2) JJ External IPMB connector (J7H1)

R VRM connector for processor 3 (J4C1) KK SMM connector (J8H1)

S VRM connector for processor 2 (J4B1) LL Wide SCSI A connector (J9H2)

System Board Connect or s 11

Page 24

Drive Controllers and Connectors

The system board supports sev eral controllers an d connectors for the

control of the var ious driv es that are or can be installed in th e system.

SCSI Connectors

The system board includes tw o SCSI controllers. A narro w SCSI controller

(SYM53C810AE) is on the PCI-A bus, and a dual-channel wide LVD/SE

(Ultra2/Ultra) SCSI controller (SYM53C896) is on t he PCI-B bus. The

narrow controller pro vide s support for lega cy 8-bit SCSI de vices that ma y

be installed in the 5.25-inch dri ve ba ys. The wide cont roller dri ves one

SCSI backplane and pro vides support for external expansion .

Each controller has its o wn set of PCI c onfiguration registers and SCSI I/O

registers. As a PCI 2.1 bus master, the wide controller supports burst dat a

transfers on PCI up to the maximum rate of 132 MB/sec using on-chip

buffers.

No logic, termination, or res istor loads are requi red to connect de vices to

the SCSI controller other than te rmination in the devic e at the end of the

cable. The SCSI bus is terminated on the syste m board with acti ve

terminators that can be disable d.

Wide SCSI A (LL) and Wide SCSI B Connectors (A)

Internally, each wide channel is identi cal, capab le of operations u sing either

8- or 16-bit SCSI pro viding 10 MB/sec ( F ast-10) or 20 M B/sec (F a st-20)

throughput, or 20 MB/sec (Ultra) or 40 MB/sec (Ultra-wide).

The wide controller contains a high-perf ormance SCSI bus interface. It

supports SE mode with 8-bit (10 or 20 MB/sec) or 16-bit (20 or 40 MB/sec)

transfers and LVD mode with 8-bit (40 MB/sec) or 16-bit (80 MB/ sec)

transfers.

Narrow SCSI Connector (II)

The narrow controller contai ns a high-performance SCSI core capab le of

F ast 8-bit SCSI transfer s in single-ended mode. It pr o vides pro grammable

active ne gation, PCI zero w ait- state bursts of faster th an 110 MB/sec at 33

MHz, and SCSI transfer rates from 5 to 10 M B/sec.

12 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 25

IDE Connector (CC)

Y

This is an integrated Ultra-DMA PCI/I DE interface with an IDE connector

capable of controll ing up to tw o IDE de vices. Ultra-DMA pro vid es faster

access to IDE devices that are Ultra-DMA complian t while maintaining

support for IDE devices that do not support the Ultr a-DMA specification.

The IDE controller supports:

• PIO and IDE DMA/bus master operations

• Mode 4 timings

• Transfer ra tes up to 33 MB/sec

• Buffering for PCI/IDE burs t transfers

• Master/slav e IDE mode

• Up to two dri ves f or one IDE channel

Diskette Drive Connector (DD)

The diskette dri ve controlle r and connector on the syst em board can support

up to two disk ette dri ves of 1.44-MB and 2.88-MB formats.

Note:

ou can connect an IDE

signal cable, up t o a

maximum of 18 inches, to

the IDE connec tor on the

system board . The cabl e

can support two devices,

one at the end of the cable

and one six inches from the

end.

System Jumpers (B)

These jumpers allo w you to set c ertain characteristics of the s ystem. Some

jumpers are reserved and are not descr ibed in this section. Do not change

any jumper unless it i s necessary to configure the system. In some cases,

changing the settings of reserved j umpers can cause damage to t he system

board.

Clear CMOS Jumper

This jumper allo ws you t o clear the complim entary metal-oxide

semiconductor (CMOS) memory. You should only do this if you cannot

access the normal methods of modifying the CMOS and modifications to

the CMOS are necessary . Clea ring CMOS memory returns all BIOS Setup

settings to the default v alues. This jumper occupi es pins 1-3 of the

connector . See “Setting the J umpers” on page 72 for more information on

setting the CMOS clear jumper.

System Board Connect or s 13

Page 26

Password Clea r Jumper

Momentarily sett ing this jumper allows you to clear the pass w ords. The

normal jumper position protects the passwords. Use this jumper only if y ou

have f orgotten the pass w ords and cannot a ccess the system. This jumper

occupies pins 5-7 of the connector . Se e “Setting the Jumpers” on page72

for more information on setting the pass w ord clear jumper.

Recovery Boot Jumper

The recov ery boot jumper should be used only i n the ev ent of a fail ed BIOS

update. If you attempt a BIOS update and t he update fails, set this jumper

and reboot the system. The system attempts to recover the previous v ersion

of the BIOS as it boots up. This jumper occupies pins 9-11 of the connect or .

See “Setting the Jumpers” on page 72 for more information on setting the

recov ery boot jumper .

Miscellaneous Connectors

Hard Drive Input LED Connector (C)

This connector allo ws you to connect a cable from an add-in hard di sk

controller to the system board t o allo w the add-in cont roller to acti v ate the

hard drive activit y LED on the control panel .

System Speaker Connector (D)

Connects the internal speaker to the s ystem board.

Wake-on-LAN Technology Connector (F)

The wake on local ar ea netw ork (LAN) technolo gy con nector allo ws y ou to

connect a magic packet-en abled LAN adapter to the system board to

support wake on LAN functionality. Wake on LAN functionality all ows a

system in pow er conserv ation mode to be a w akened b y an incoming

message on the netw ork.

14 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 27

Front Panel Connector (AA)

The front panel connector pro vides the signals for the f ront co ver indicator

LEDs and the front co ver buttons.

USB Internal Connector (FF)

This connector allo ws you to connect internal devi ces that use the USB

interface to the USB controller on the s ystem board.

Lithium Battery (E)

Provides the po w er to maintain t he CMOS memory when the sy stem is

turned off or unplugged.

Expansion Slot Connectors

ISA Slot (G)

The system board has one industry standard archite cture (ISA) slot that is

full-length if y ou do not use the wide SCSI-B connector (and half-length if

you use the wide SCSI-B connector); t he ISA slot supports sla ve-onl y

boards and is shared with PCI-B slot 4. The ISA bus also supports three

embedded devices: the SuperI/O chip, system board management

controller (BMC), and flash me mory for the system BIOS. ISA bus

features:

• Bus speed up to 8.33 MHz

• 16-bit memory addressing

• Type A transfers at 5.33 MB/sec

• Type B transfers at 8 MB/sec

• 8- or 16-bit data transfers

• Plug and Play rea dy

System Board Connect or s 15

Page 28

PCI slots B4 (top), B3, B2, B1, A3, A2 (H), A1 (K)

The system board has tw o 32-bit peripheral component interconnect (PCI)

bus segments: PCI-A and PCI-B . These pro vide se ven slots for PCI

expansion cards: three on PCI-A and fo ur on PCI-B. PCI-B4 is shared with

the ISA slot. PCI-A1 supports half-length boards onl y. The other slots

support full-length boards. PCI bus features:

• 33 MHz bus speed

• 32-bit memory addressing

• 5 V signaling en vironment

• Burst transfers of up to 133 MB/se c

• 8-, 16-, or 32-bit data transfers

• Plug and Play read y

• Parity enabl ed

Memory Module Connector (I)

The memory module connector supports the memory module. The

memory module is a proprietary card that supports all of the main memory

for the system. The memory module is described in “Memory” on page 23.

System Management Connectors

Server Management features are implemented using one micr ocontroller ,

the system board management controller (BMC).

The BMC and associated circuitry are po w ered from the 5 V standb y line,

which remains acti ve when the sys tem po w er is sw itched off .

The primary function of the BMC is to autonomously monitor system

management events a nd log thei r occurrence in the non vola tile system

event lo g (SEL). These e vents i nclude o vertemperature and o v ervoltage

conditions, fan failure, or chassis intrusion. While monitoring, the BMC

maintains the non vola tile sensor data record r epository (SDRR), from

which run-time information can be retrie ved. The BMC pro vides an ISA

16 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 29

host interface to SDRR information, so softwa re running on the server can

poll and retrie ve the current status of the ha rdware. A sh ared registe r

interface is defined for this purpose.

SEL contents can be retrie ved after system failure for anal ysis b y field

service personnel using system management tools lik e Intel

Server Manager . Because the BMC is po w ered b y 5V_Standby, SEL (and

SDRR) information is also av ailab le via the interperipheral management

bus (IPMB). An emergency management board l ike the Intel LANDesk

server management module (SMM) board can obtain the SEL and make it

remotely accessib le using a LAN or telephone l ine connection.

During monitoring, the BMC performs the follo wing functions:

®

LANDesk®

• System board temperature and v oltage monitoring

• Processor presence monitoring and fault r esilient boot (FRB)

control

• System board fan failure detection and indicator c ontrol

• SEL interface management

• SDRR interface management

• SDR/SEL timestamp clock

• System board field replaceable unit (FR U) information interface

• System management watchdo g timer

• Periodic s ystem management interrupt (SMI) timer

• Front panel non-maskabl e interrupt (NMI) handling

• Event recei ver

• ISA host and IPMB interface management

• Secure mode control, front panel lock/unlock initiation, and video

blank and diskett e write protect monitor ing and control

• Sensor event initialization a gent

• W ake-on-LAN v ia Magic Packet support

• ACPI Support

• Emergency Management P ort (EMP) support

System Board Connect or s 17

Page 30

ICMB Connector (J)

The intelligent chassis management bus ( ICMB) connector allo ws t he

connection of a system management component to monitor the chassis

characteristics including temperature , voltages, int rusion detection, and fan

speeds.

SMBus Connector (GG)

This connector supports an SMBus card that pro vides system management

functions.

F16 Expansion Connector (HH)

The F16 expansion connector allo ws y ou to connect a component to t he

F16 bus which communicates betw een the memory and I/O controller

(MIOC) and the PCI expansion brid ge (PXB).

External IPMB connector (JJ)

This connector allo ws you to connect an “external” de vice to the IPMB to

help determine the cause of a system failure from a re mote terminal.

SMM connector (KK)

The SMM connector allows y ou to connect a s ystem management module

to the system board to monitor the system and perf orm other system

management functions.

Back Panel I/O Connectors

Video Port Connector (L)

The onboard , integrated Cirrus Logic CL-GD5480 64-bit VGA chip

contains an SV GA controller th at is fully c ompatible with the V GA video

standard. The system board pro vides 2 MB of 10 ns onboar d video

18 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 31

memory . The video controller supports pix el resoluti ons of up to

1600 x 1200 and up to 16.7 M colors. You cannot add video memory to this

system.

The SV GA controller supports analo g V GA monitors ( single and multiple

frequency, interlaced and noninterlaced) wi th a maximum vertical retrace

noninterlaced frequency of 100 Hz. Dependi ng on the en vironment, the

controller displa ys up to 16.7 M colors in some video r esolutions.

Compatible video dri vers are provided with the operating system or the

utilities.

Parallel Port Connector (L)

The 25/15-pin connector stacks the parallel port beside the V GA video port.

BIOS programming of the super I/O chip registers ena bles the par allel port

and determines the port address and interrupt. The system BIOS provides

fields in the setup utility to easily enab le the parall el port and set the port

address and interrupt. When disabled , the interrupt is av ailable to exp ansion

cards.

Serial Port Connectors (M)

Both serial ports are relocatab le. By default, port 1 is the left connec tor ,

port 2 on the right. Each serial port can be set to one of four dif ferent

COMx ports, and each can be enabled separatel y. The system BIOS

provides fields in the setup utility to easily enable bot h serial ports and set

the port addresses and interrupts. When disabled , s erial port interrupts are

av ailable to expansion cards .

Keyboard and Mouse Connectors (N)

The PS/2-compatible ke yboard and mouse connectors are mounted in a

single-stacked housing with the mouse connector to the le ft of the

keyboard. External to the system, the y appear as tw o connectors.

You can plug in the keyboard and mouse to either connector before

pow ering up the syst em. BIOS detects the de vice connected at each

connector and configures the keyboard controller accor dingly.

System Board Connect or s 19

Page 32

The keyboard controll er is functionall y compatib le with the 8042A

Note:

A second USB port internal

to the system chassis is

provided at position FF as

shown in Figure 3 on

page 11

microcontroller . The system can be lock ed automaticall y if no ke yboard or

mouse activity occur s for a predefined length of time, if specified through

the SSU . Once the inact ivity ( lockout) timer has expired, the keyboard and

mouse do not respond until the pre viousl y stored pass w ord is entered.

USB External Connector (O)

One universal serial bus (USB) port pro vides conne ction for a gro wing list

of peripheral components including mouse, ke yboard , j o ystick, monitor ,

tape and diskette dri ves. Up to 127 de vices can be dai sy-chained from the

port. The USB port also provides hot-sw ap capability and dynamic resource

allocation for all periphe rals attached to it with data transfer ra tes of up to

12 Mbps. USB drivers are provided as a part of most major operating

systems and should require no special procedures for impleme ntation or

use.

Processors and Related Connectors

VRM Connectors (P , Q, R, S, T, U)

In this system each processor mus t ha ve one VRM to adj ust the vo ltage

supplied to the processor core an d one to adjust the v oltage suppli ed to the

second-lev el cache in the SEC cartridge. The first VRM is dedicated to a

single processor and pro vides the correct pow er to t he processor core. Th e

second VRM pro vides po w er to the inte grated second-le vel cache a nd can

support the cache on tw o SEC cartridges. There fore each processor req uires

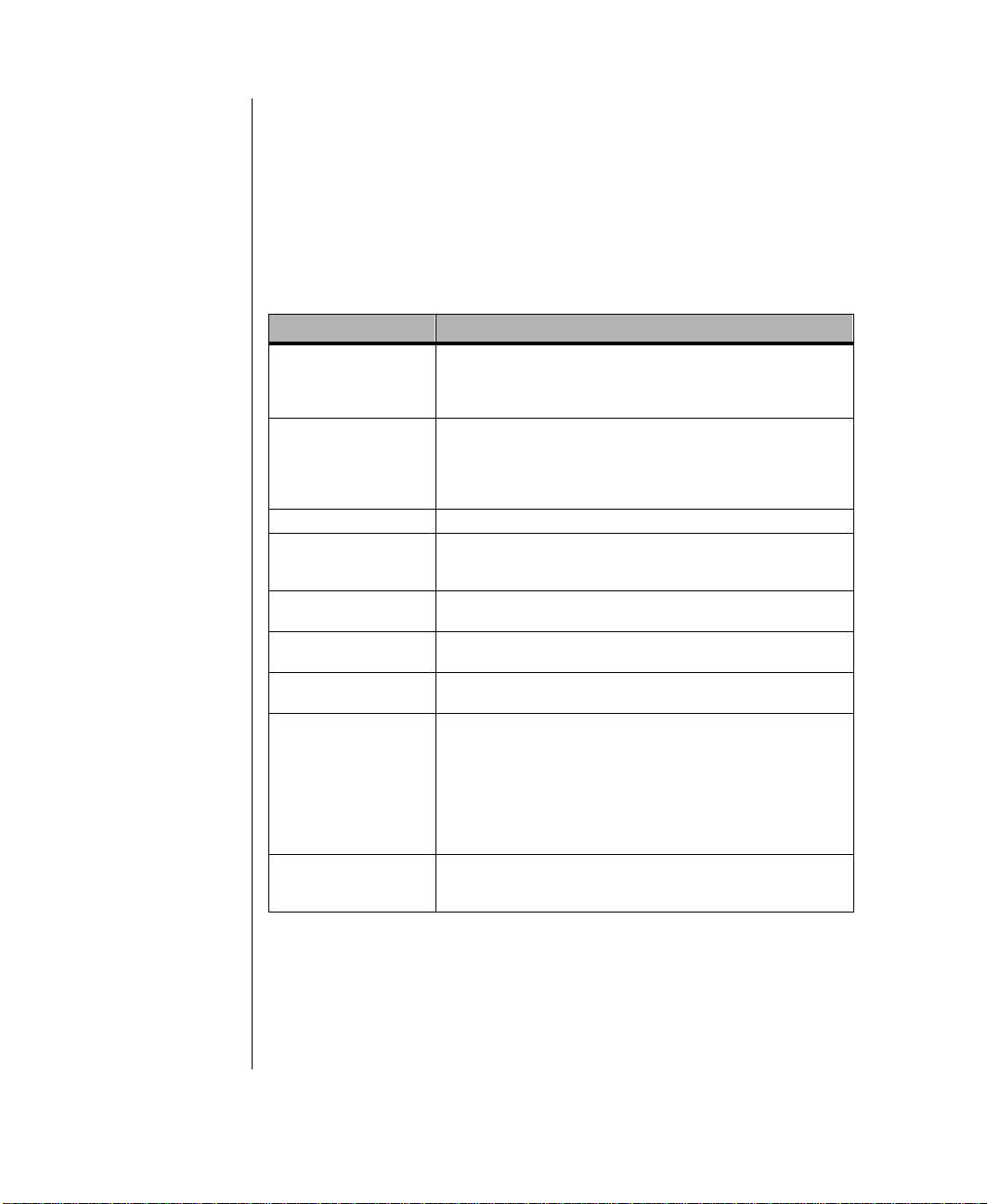

1.5 VRMs. See T ab le 2 for the allow ed processor and VRM configurations.

Processor

Installed

Processor 1 VRM 1 Powers the processor core for processor 1

Processor 2 VRM 3 Powers the processor core for processor 2

Processor 3 VRM 4 Powers the processor core for processor 3

Processor 4 VRM 6 Powers the processor core for processor 4

20 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Table 2: Processors and VRMs

VRM

VRM Function

Installed

VRM 2 Powers the second-level cache for processors 1 and 2

VRM 5 Powers the second-level cache for processors 3 and 4

Page 33

Processor Slots (V, X, Y, AB)

Each Pentium® II Xeon™ processor is packaged in a SEC cartridge. The

cartridge includes the processor core with an inte grated 16 KB primary

(L1) cache; the secondary (L2) cache; a thermal plat e; and a back co ver.

™

The processor implements MMX

backward compatibilit y with the 8086, 80286, Intel386

Pentium, and P e ntium Pro processors.

Each SEC cartridge connects to the system board through a Slot 2 edge

connector . The cartridge is se cured b y a retention brack et attached to the

system board. Depending on configuration, the server has one to four

processors.

The processor external interface is multiprocessor (MP) -ready and operates

at 100 MHz. The processor contains a loc al advanced programmabl e

interrupt controller (APIC) for interrupt handling in MP and uniprocessor

(UP) environments. The system SMP design supports up to four processors

and is Intel MP Specification v1.1 and 1.4 compliant.

The second-lev el cache is located i nside the SEC cartridge. Th e cache

includes burst pipelined synchronous stat ic RAM (BSRAM) and is offered

in 512 KB, 1 MB, and 2 MB configurations, with ECC that operates at the

full core clock rate.

technolog y and maintains full

™

, Intel486™,

Each processor cartridge require s tw o VRMs to pro vide pow e r to the

processor core and the second-le vel cache, respecti vel y. The full details of

the installation of process ors and VRMs are pro vi ded in “VRM Connectors

(P, Q, R, S, T , U)” on page 20.

Power Connectors

There are sev eral po w er connectors tha t pro vide po w er for t he system

board. Some of these connectors provide pow er for specia lized functions.

Main Power Connector , Primary (W)

The primary pow er connectors provide the majority of the po w er to the

system board. These connectors are designed to a ccommodate the po w er

supply installe d in the system.

System Board Connect or s 21

Page 34

Main Power Connector , Secondary (Z)

The primary pow er connectors provide the majority of the po w er to the

system board. These connectors are designed to a ccommodate the po w er

supply installe d in the system.

Auxiliary Power Connector (EE)

The auxiliary pow er connector pr o vides for the c onnection of an additional

pow er source .

22 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 35

Memory

The system comes standard with 256-MB of ECC RAM. System RAM is

expandable up to 4 -GB using ECC 50- or 60-ns 72-bit EDO DIMMs

(16 DIMM sockets) with gold contact s.

Main memory resides on an expansion card , calle d a memory module,

designed specifically for this server . The memory module contains sl ots for

16 DIMMs, each of which must be at least 32 MB , and is attached t o the

system board through a dedicated connector. Memory amounts from

128 MB to 4 GB of RAM are supported, with a 64/72-bit

four-wa y-inter leav ed pathw a y to main m emory.

The 16 slots are divided in to four banks of four slot s each, labeled A

through D . These banks support 4:1 inte rlea ving. The memory controller

supports EDO DRAMs. The ECC used for the memory module is capable

of correcting single-bit errors (SBEs) and detecting 100 percent of doublebit errors ove r one code w ord. Nibb le error detection is also pro vide d.

J16

J15

J12

J11

E

D

J8

J7

J4

J3

C

B

A

J14

J13

J10

J9

J6

J5

J2

J1

Figur e 4: Memory Banks

Memory 23

Page 36

DIMM Installation Sequence

Note:

Each memory bank includes

two DIMM sockets in each

row of connectors. When

installing DIMMs, be careful

to install the DIMMs in the

correct sockets for the bank.

You must install DIMMs in the correct order and in entire banks. All

DIMMs in the bank must be the same size and speed. DI MMs in other

banks may dif fer in size. If y ou use slo w er DIMMs in another ba nk, all

DIMMs operate at the slo w er speed (see Figure4 on page 23).

The sequence in which y ou must fill the banks is:

1. Memory bank A

2. Memory bank B

3. Memory bank C

4. Memory bank D

System Memory Addressing

System memory begins at address 0 and is continuous (fl at addressing) up

to the maximum amount of DRAM installed (exception: system memory is

noncontiguous in the ranges defined as memory holes using configuration

registers). The system supports both base (co nv entional) and e xtended

memory.

• Base memory is located at addresses 00000h to 9FFFFh (th e first

1MB).

• Extended memory begins at address 0100000h (1 MB) and

extends to FFFFFFFFh (4 GB), which i s the limit of supported

addressable memory. The top of physical memory is a maximum

of 4 GB (to FFFFFFFFh)

Memory holes can be configured in Setup or the SSU and are used by some

legacy ISA boards. I f you do not need to set up a memory hole for an ISA

expansion board , le av e the memory in a contiguous state for opti mal

performance.

24 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 37

Memory Configuration

BIOS automatically dete cts, sizes, and ini tializes the memory array,

depending on the type, size, and speed of the ins talled DIMMs, and reports

memory size and allocation to the system via configuration registers.

In a 4 GB configuration, a small part of memory (typically 32 MB) is not

remapped abov e 4 GB. I f your OS does not su pport more than 4 GB of

physical memory, this small part of the memory is effecti vel y lost.

Table 3: Sample DIMM Component Combinations

Bank A

(slots J1 - 4)

4x64 256 MB

4x64 4x32 384 MB

4x64 4x32 4x32 512 MB

4x64 4x64 512 MB

4x64 4x64 4x32 4x32 768 MB

4x64 4x64 4x64 4x64 1024 MB

4x128 4x64 4x32 4x32 1024 MB

4x128 4x128 4x64 4x64 1536 MB

4x128 4x128 4x128 4x128 2048 MB

4x256 4x128 4x64 4x64 2048 MB

4x256 4x256 4x128 4x128 3072 MB

4x256 4x256 4x256 4x256 4096 MB

Bank B

(slots J5 - 8)

Bank C

(slots J9 - 12)

Bank D

(slots J13 - 16)

Total

Memory

Note:

Use DIMMs that have been

tested for compatibility with

the system boar d . Co ntact

your sales representative or

dealer for a list of approved

DIMMs. T able 3 lists some

sample size combinations.

Memory 25

Page 38

System Security

T o help pre v ent unauthorized entry or use of the system, the system

includes a three-position k ey lock/s witch to permit select ed access to dri ve

bays (positi on is communicated to the BMC, see “Sys tem Management

Connectors” on page 16). The system also includes server management

software that monito rs the chassis i ntrusion switch.

Mechanical Locks and Monitoring

The system includes a chassis intrusion s witch. When the acces s co ver i s

opened , the switc h transmits an alarm signal to the sys tem board , w here

server management software pr ocesses the signal. You can pro gram a

response to an intrusion, for example, the syst em may po w er do wn or loc k

the keyboard.

Software Locks via the SSU or BIOS Setup

The system setup utility (SSU) pro vide s a number of security feat ures to

prevent unau thorized or accidental access to the system. Once the security

measures are enabled, access to the system is al lo w ed only aft er you enter

the correct password( s). F or e xample, the SSU allo ws you to:

• Enable the ke yboard lockout ti mer so the server requi res a

passw ord to reacti v ate the ke yboard and mouse after a s pecified

time-out period of 1 to 120 minutes

• Set and enable administrator and user passw ords

• Set secure mode to pre vent k eyboard or mouse inpu t and to pre vent

use of the front panel reset an d pow e r switc hes

• Activa te a hot-ke y combination to ente r secure mode quickl y

• Disable writing to the diskette dri v e when secure mode i s set

26 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 39

Using Passwords

If you set and enab le a user pass w ord but not an admi nistrator pass w ord ,

enter the user passw ord to boot t he system and run the SSU.

If you set and enab le both a user and an a dministrator pass w ord:

• Enter either one to boot the server and enable the keyboard and

mouse

• Enter the administrator pass w ord to access the SSU or BI OS Setup

to change the system configuration

Secure Mode

Configure and enable the secure boot mode by using the SSU . When secure

mode is in effect, y ou:

• Can boot the system and run the OS, but you must enter the user

passw ord to use the k eyboard or mouse

• Cannot turn off system po w er or reset the s ystem from the front

panel switches

Secure mode has no effect on functions enab led via the Server Manage r

Module or pow er control via the real-t ime clock (R TC) .

T aking the syst em out of secure mode does not change the state of system

pow er . Tha t is, if you pr ess and release the po w er switch w hile sec ure mode

is in effect, t he system will not po w er of f w hen secure mode is later

remov ed. Ho w ev er , if the front panel po w er s witch remai ns depressed w hen

secure mode is remo v ed , the sys tem will po w er of f.

System Security 27

Page 40

Summary of Software Security Featur es

T abl e 4 lists the software security feature s and describes w hat protection

each offers. In general, to ena ble or set the feat ures listed here, you must run

the SSU and go to the Security Menu (descr ibed in “Security Ad d-in” on

page 116). The table also refers to other SSU menus and to the Setup utility.

For more i nformation on setting the sec urity features, see “Se curity Menu”

on page 92, and “Security Add-in” on page 116.

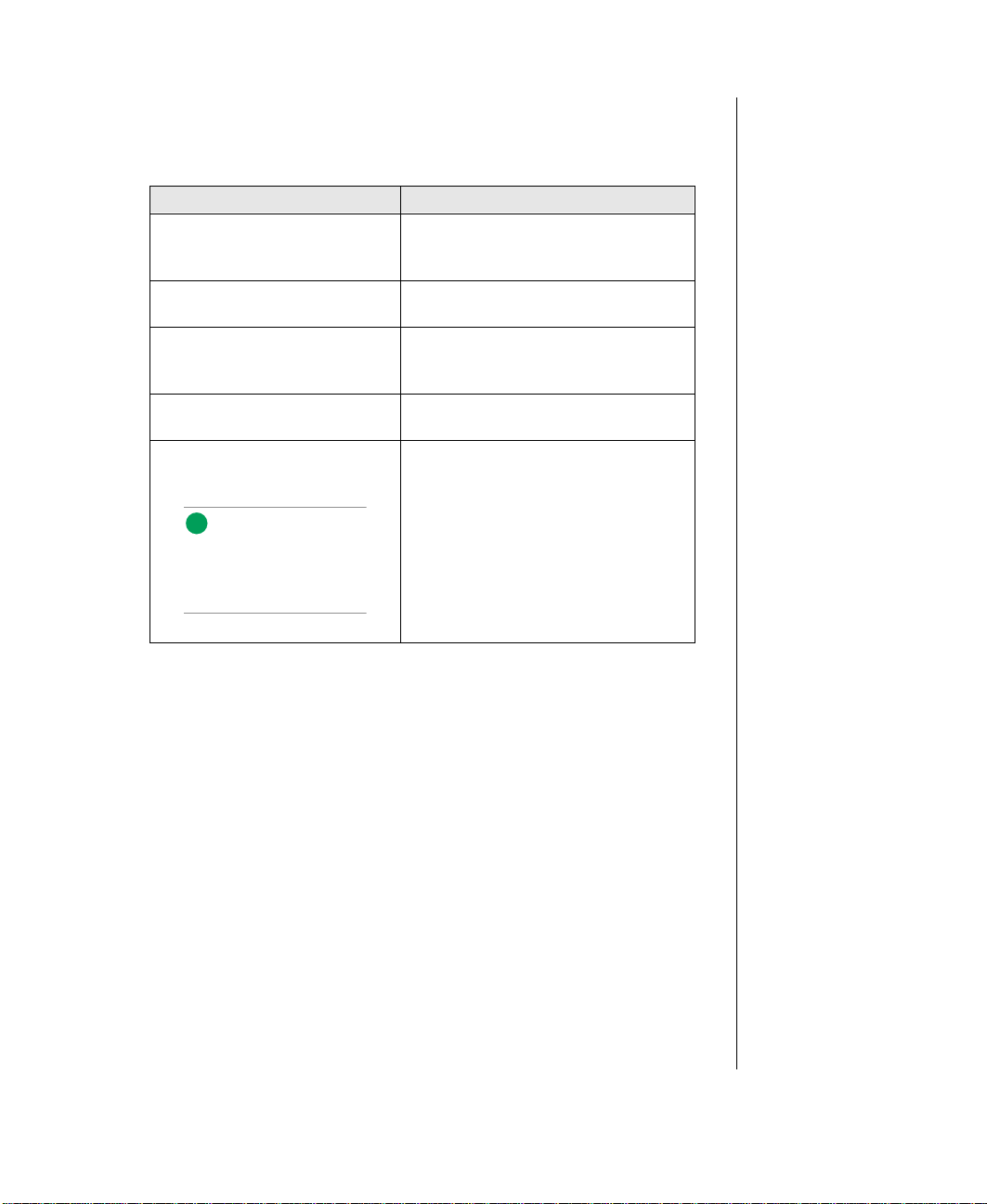

Table 4: Software Security Features

Feature Description

Secure boot mode To enter secure mode:

Disable writing to diskette In secure mode, the system will not boot from or write to a diskette

Disable the power and reset

buttons

Set a time-out period so that

keyboard and mouse input

are not accepted.

Also, blank screen and inhibit

writes to diskette

Control access to the SSU:

set administrator password

Set and enable a password to automatically put the system into secure

mode.

If you set a hot-key combination, you can secure the system by pressing

the key combination. This means you do not have to wait for the

inactivity time-out period. See “Security Menu” on page 92.

When the system is in secure mode:

The system boots and runs the OS, but does not accept mouse or

keyboard input until you enter the user password.

At bootup, if the system detects a CD in the CD-ROM drive or a diskette

in drive A, it requests a password. When you enter the password, the

system boots from CD or diskette and disables secure mode.

If you have not installed a CD-ROM drive or if there is no CD in the drive

or diskette in drive A, the system boots from drive C and automatically

enters secure mode. All enabled secure mode features go into effect at

bootup.

To leave secure mode:

Enter the correct password(s).

unless a password is entered. To set these features, see “Security

Menu” on page 92 and “Security Options” on page 117.

If you enable this protection feature in the SSU, the system disables the

power and reset buttons when in secure mode. See “Security Options”

on page 117.

You can specify and enable an inactivity time-out period of from 1 to

120 minutes. If no keyboard or mouse action occurs for the specified

period, keyboard and mouse input is not accepted. To set this feature,

see “Security Menu” on page 92.

If video blanking is enabled, the monitor display goes blank until you

enter the correct password(s). To set this feature, see “Security Menu”

on page 92.

To control access to the system configuration, set an administrator

password and enable it through Setup or the SSU.

If both the administrator and user passwords are enabled, either can be

used to boot the system or enable the keyboard and/or mouse, but only

the administrator password allows changes to Setup and the SSU.

Once set, passwords can be disabled by setting the password to a null

string or by changing the Clear Password jumper. See “Security Add-in”

on page 116 to set the password to a null string; or, to change the

jumper, see “Password Clear Jumper” on page 75.

28 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 41

Table 4: Software Security Features (Continu ed)

Feature Description

Control access to the system

other than SSU: set user

password

Boot without keyboard The system can boot with or without a keyboard. During POST and

Specify the boot sequence The sequence you specify in the BIOS (see “Boot Device Priority

To control access to the system, set a user password and enable the

Password on Boot field through Setup or the SSU.

Once set, passwords can be disabled by setting the password to a null

string or by changing the Clear Password jumper. See “Security Add-in”

on page 116 to set the password to a null string; or, to change the

jumper, see “Password Clear Jumper” on page 75.

before the system boots, BIOS automatically detects and tests the

keyboard, if present, and displays a message. No entry exists in the SSU

for enabling or disabling a keyboard. Do not plug in a keyboard while

power is applied to the system.

Submenu” on page 96) or the SSU (see “Multiboot Options Add-in” on

page 115) determines the boot order. If secure mode is enabled (user

password is set), you are prompted for a password before the system

boots fully. If secure mode is enabled and the Secure Mode Boot option

is also enabled, the system boots fully but requires a password before

accepting any keyboard or mouse input.

System Security 29

Page 42

30 Maintaining and Troubleshooting the Gateway ALR 9200 Se rver

Page 43

Chapter 3:

Installing Components

Contents

Introduction............................................................ 32

Replacing the Processor........................................ 32

Installing Another Processor................................. 36

Installing Hardware............................................... 40

Memory........................................................... 40

Drives.............................................................. 45

Installing Fans for High-Power Drives..........57

Expansion Cards............................................. 62

Power Supplies............................................... 65

Replacing the Battery..................................... 68

Page 44

Introduction

Caution!

ESD can damage disk

drives, expansio n cards, and

other components. The

server can withstand normal

levels of envir o nmenta l ESD

while you hot-swap SCSI

hard drives. However, we

recommend doing all

procedure s at an ESD protected workstation. If one

is not availa ble , y ou ca n

provide some ESD

protection by wearing an

antistatic w ris t st ra p

attached to chassis ground

of the server when handli ng

components.

Note:

If the server has less than

four processors and you ar e

adding one, then you must

remove the termin ation

board assembly fr om the

next Slot 2 connector before

you install the new

processor. If you plan to

reduce the nu mb er of

processors in your system,

then you must replace a

processor with a termination

board assembly.

This chapter pro vides step-b y-step instruction for ins talling, remo ving, or

replacing sever al system components. Onl y authorized service personnel

should perform these procedures. F ollo w all standard sa fety and ESD

precautions when servicing the server. See “Static Electricit y Precautions”

on page 2 for more information on ESD precautions.

“Opening the System” on page 3 provides detailed instructions for openi ng

the system. All procedures in this c hapter assume that an y necessary access

cov ers ha ve been remo ved a nd that the subchassis and el ectronics ba ys ha v e

been remov ed , if nece ssary .

Replacing the Processor

The system is compatible wit h Intel P entium® II Xeon™ processors. You

can either upgrade the existing P enti um II Xeon processor or i nstall up to

three more processors of the same spee d and cache size as the first

processor .

When replacing a processor , order a Pentiu m II Xeon processor upgrade kit.

The kit includes the P entium II Xeon processor, a heat sink, and latches.

It is critical that a he at sink be installed o n each processor . The Pentium II

Xeon processor o verheats and fail s if it is not cool ed sufficiently. The heat

sink pro vided with the processor i n the system pro vides all necessary

cooling for the processor.

For t he latest details on the a vai lability of the upgrade kits, cont act one of

the sources listed in the Assistanc e Resour ces document.

32 Maintaining and Troubleshooting the Gateway ALR 9200 Server

1. T urn off the system and disconnec t all the po w er cords.

2. Open the case, observing the static electri city precautions in “Stati c

Electricity Precautions” on page2 and remove t he foam co ver on the

electronics ba y.

T o Replace the Processor

Page 45

3. Wear an anti-static wristband grounded to the syste m chassis and

place processors on a grounded, stat ic-free surface or conducti ve foam

pad.

4. With y our right thumb on the face of the ret ention module bracket (A

in Figure 5), wrap your right index finger around the tab (B in

Figure 5) protruding from the right edge of the bracket.

A

B

Latch

Figur e 5: Rele asing the Retention Module Br ac ket

5. Use your index finger to slightly pull the t ab outward and t o the left.

You should not try to pull the entire bracket; rather , the ba ck of the tab

has a latch (C in Figure5) that releases when the tab is pulled slightl y.

6. When you ha ve releas ed the right edge of the brack et, rotate it 90 ° to

the left until it is perpendicular to the fr ont of the retention module .

The left edge of the brack et has an open hinge tha t can release from

the module when y ou rotate the brack et to the left.

7. Disengage the open hinge b y mo ving (not rotating) the ent ire bracket

to the right. Remo ve the bracket and set i t aside.

Replacing the Processor 33

Page 46

8. Pull the two tabs attached to the si ngle edge c ontact (SEC) cartridge

(visible after you remo v e the bracket —C in Figur e 6) straight awa y

from the system board. As you do, the cartrid ge disengages from the

connector on the system board.

T ab on SEC c artridge

Retention module guide rails

SEC cartridge

Retention module guide rails

T ab on SEC cartridge

Processor heat sink

Figur e 6: Remo ving a Pr ocessor

9. Slide the SEC cartridge straight a w a y from the system board , o ut of

the retention module. Put it on a piec e of conducti ve foam and store i t

in an antistatic package.

10. Remove the replac ement processor cartrid ge from its protecti ve

wrapping.

11. Orient the SEC cartridge so that the heat sink faces a wa y from the

center of the system board.

If you are install ing a termination card assemb ly, orient it so that the

side with the label faces to w ard the center of the system board.

34 Maintaining and Troubleshooting the Gateway ALR 9200 Server

Page 47

12. With the tabs at the top of the SEC cartridge complet ely open (pulled

outward, aw ay fr om the center of the cartridge—C in F igure 7), slide

the cartridge into the guide rai ls of the retentio n module (B in

Figure 7). When done properly , the triangular ends of the tabs (with

two round pe gs on each) fit into the entrance to the guide rail s.

SEC cartridge

Retention module guide rails

T ab on SEC cartridge

Processor heat sink (must fa ce away

from the center of t h e s ystem bo ard

Figur e 7: Inst alling a Pr ocessor

13. When the cartridge meets resistance, push the tw o t abs to war d each

other (E in Figure7) until the processor is full y seated.

14. Reattach the retention module bracket:

a. With the brac ket in an open pos ition (perpendicular to the front of

the retention module), slide the open hinge at the left of the bracket

into its receptacle at the left of the retention module .

b. Rotate the bracket to the right until it reaches the retenti on module.

With y our right thumb on th e face of the bracket and your right inde x

finger around the tab at the right of the bracket, slight ly pull t he tab

outward and to the lef t to open the latch at the back of the tab .