Futaba CGY750 User Manual

1M23N24914

|

V2.0~ |

|

TABLE OF CONTENTS |

|

|

• Introduction------------------------------------------------------------------ |

2 |

|

• Warranty and Repair Service (in U.S.A.)--------------------------------- |

2 |

|

• Features----------------------------------------------------------------------- |

|

2 |

• Contents---------------------------------------------------------------------- |

|

2 |

• Precautions------------------------------------------------------------------- |

3 |

|

• Specifications---------------------------------------------------------------- |

3 |

|

• Replacement and Optional Items--------------------------------------- |

4 |

|

• Gyro Sensor Installation------------------------------------------------------ |

4 |

|

• Connecting the CGY750---------------------------------------------------- |

5 |

|

• TX Set-up-------------------------------------------------------------------------- |

|

6 |

• Governor Installation------------------------------------------------------ |

6 |

|

• Governor Fuselage Setting Precautions------------------------------ |

6 |

|

• First Map-------------------------------------------------------------------------- |

|

7 |

• Opening Screen------------------------------------------------------------- |

7 |

|

• Home Screen----------------------------------------------------------------- |

7 |

|

• Warning Display------------------------------------------------------------- |

8 |

|

• Setting Menus--------------------------------------------------------------- |

9 |

|

• S.BUS Basic Setting------------------------------------------------------- |

10 |

|

• Swash Servo Installation and Setup--------------------------------- |

11 |

|

• Aileron/Elevator Gyro Setup------------------------------------------- |

11 |

|

• Swash Basic Setting------------------------------------------------------ |

12 |

|

• Swash Detail Setting----------------------------------------------------- |

14 |

|

• Linkage Compensation-------------------------------------------------- |

15 |

|

• Flight Tuning Setting---------------------------------------------------- |

16 |

|

• Tail Rotor Gyro Set Up and Rudder Basic Setting----------------- |

17 |

|

• Governor Basic Setting-------------------------------------------------- |

18 |

|

• Governor Speed Setting------------------------------------------------ |

20 |

|

• Governor Operation------------------------------------------------------ |

20 |

|

• Recommended Gyro Gain Settings----------------------------------- |

20 |

|

• Before Flight Checklist-------------------------------------------------- |

20 |

|

• Adjustments During the Test Flight---------------------------------- |

20 |

|

• Tunning Guidelines for CGY750--------------------------------------- |

21 |

|

• Tips for Using the CGY750 Governor with Electric Models----- |

21 |

|

• Flight Tune Expert Setting---------------------------------------------- |

22 |

|

• Rudder Gyro Expert Setting-------------------------------------------- |

22 |

|

• Governor Expert Setting------------------------------------------------ |

23 |

|

• Condition Menu----------------------------------------------------------- |

24 |

|

• CGY750V2-3D-MAP------------------------------------------------------- |

26 |

|

• CGY750V2-F3C-MAP----------------------------------------------------- |

28 |

|

• F3C Style Tuning Section------------------------------------------------ |

30 |

|

|

: Instructions for gyro functions |

|

Gyro |

|

|

Governor : Instructions for governor functions |

|

|

Technical updates and additional programming examples can be found at: |

||

|

www.futaba-rc.com/faq |

|

INTRODUCTION

INTRODUCTION

The Futaba® CGY750 is a combined 3-axis heading hold AVCS gyro and head speed governor in one box. Its cutting-edge MEMS (Micro Electro Mechanical System) sensor design, ultra high-speed processing speed and advanced PID control algorithm put it a quantum leap ahead of all other heading hold gyros in size, weight and performance. The CGY750 has been optimized to work for flybarless helicopters.

WARRANTY & REPAIR SERVICE (IN U.S.A.)

WARRANTY & REPAIR SERVICE (IN U.S.A.)

If any difficulties are encountered while setting up or operating your CGY750, please consult the instruction manual first. For further assistance you may also refer to your hobby dealer or contact the Futaba Service Center at the web site, fax or telephone number listed below:

www.futaba-rc.com or www.hobbyservices.com

Fax (217)-398-7721, Tel (217) 398-0007

If you are unable to resolve the issue, pack the system in its original container with a note enclosed and a thorough, accurate description of the difficulty. Include the following in your note:

•Symptoms (including when the problem occurred)

•System (Transmitter, Receiver, Servos and model numbers)

•Model (Model name)

•Model numbers and quantity

•Your Name, Address and Telephone number

Send the respective items to the authorized Futaba Service Center Address below:

Futaba Service Center

3002 N Apollo Drive Suite 1

Champaign, IL 61822

FEATURES

FEATURES

•Combined 3-Axis Gyro and Governor in one box.

•High speed operation and extremely low latencies result in greater stability.

•Low profile, small size and light weight.

•Small size of the gyro and governor controller, 44 x 29 x 12mm, 13 g

•Utilizes a 128 x 36 dots graphical white color OLED (Organic Light Emitting Display), high brightness and contrast even in direct sunlight.

•Settings divided into Basic and Expert menus. The basic setting is for initial setting and Expert setting is for more advanced settings.

•Firmware can be updated from a Windows based personal computer when used with the optional CIU-2 interface.

•S.BUS compatible. Only one connection is necessary between the S.BUS receiver and CGY750 control box for operation.

•Gyro section

•Advanced and adaptive PID control loop is utilized

•Small and low profile 3-axis gyro sensor. 21 x 21 x 8.5mm, 8g

Rudder (yaw) section:

•Capable of sensing angular velocity up to +/- 1,200 deg/sec.

•Compatible with 1520μS Analog (70Hz), 1520μS Digital (280Hz), and 760μS Digital (560Hz) tail rotor servos.

•3D and Sports flight mode

•Feed Forward Option allows the CGY750 to consider other control functions during operation. This results in more accurate corrections and precise operation.

•Cutting edge control algorithm provides a consistent pirouette rate, precise operation, and smooth yaw control in any flight condition.

Aileron, Elevator (roll, pitch) section:

•Developed specifically for flybarless helicopters.

•Included preset parameters for helicopter types (450-550, 600-700, and 750+) along with control feel preset parameters make initial setup as easy as pressing a button.

•Supports H3-120, H3-140, H3-90, H4-00, and H4-45 swashplate types.

•Governor section

•Advanced and adaptive PID control loop is utilized.

•High speed operation and extremely low latencies provide a more consistent and accurate operation.

•Capable of governing head speeds from 700 RPM through 4000 RPM

•Compatible with 1520μS Analog (70Hz) and 1520μS Digital (280Hz) throttle servo types.

•Feed Forward Option allows the CGY750 to consider other control functions during operation. This results in precise governing of the head speed.

•Governor or Revolution Limiter mode selectable.

•Supports gear ratios from 1.00 through 50.00.

•Cutting edge control algorithm provides more consistent RPM governing.

•Revolution sensor is compatible with the GV-1. The CGY750 also supports a optional back plate revolution sensor and brushless phase sensor.

•Other functions

•Maximum RPM memory.

•Cumulative engine operation timer.

•Power saving OLED.

CONTENTS

CONTENTS

Your CGY750 includes the following components:

Type of set

•Gyro & Governor set w/R6303SB

•Gyro & Governor set

•Gyro set w/R6303SB

•Gyro set

SET CONTENTS |

CGY750 Control Amp

*Mini Screwdriver |

X |

X |

X |

X |

|

*Dust Covers (x3) |

|

|

|

|

|

Gyro Sensor |

X |

X |

X |

X |

|

*Mounting Pads (x3) |

|||||

|

|

|

|

||

|

|

|

|

|

|

Revolution Sensor |

|

|

|

|

|

*Sensor Mounting Hardware |

--- |

--- |

X |

X |

|

*Magnet (x2) |

|

|

|

|

|

R6303SB Receiver |

--- |

X |

--- |

X |

|

|

|

|

|

|

|

Extension Cord |

X |

X |

X |

X |

|

|

|

|

|

||

X: supplied |

---: not supplied |

|

|

||

CGY750 Control Box

|

|

|

|

Gyro Sensor |

Mounting Pads |

||||

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Revolution Sensor |

Extension Cord |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dust Cover

Magnets (2) |

Sensor Mounting Bracket |

R6303SB Receiver |

|

|

Adjustment Screwdriver |

2

PRECAUTIONS

PRECAUTIONS

Meaning of Special Markings

Pay special attention to safety where indicated by the following marks:

DANGER - Procedures which may lead to dangerous conditions and cause death/serious injury if not carried out properly.

DANGER - Procedures which may lead to dangerous conditions and cause death/serious injury if not carried out properly.

WARNING - Procedures which may lead to a dangerous condition or cause death or serious injury to the user if not carried out properly

WARNING - Procedures which may lead to a dangerous condition or cause death or serious injury to the user if not carried out properly

or procedures where the probability of superficial injury or physical damage is high.

CAUTION - Procedures where the possibility of serious injury to the user is small, but there is a danger of injury, or physical damage, if

CAUTION - Procedures where the possibility of serious injury to the user is small, but there is a danger of injury, or physical damage, if

not carried out properly.

: Prohibited

: Prohibited  : Mandatory

: Mandatory

WARNING

WARNING

Failure to follow these safety precautions may result in severe injury to yourself and others.

• Read through the entire manual before operating this product.

BEFORE EACH FLIGHT:

Always check the transmitter and receiver battery voltage to ensure they have enough remaining capacity to complete the flight.

Always check the transmitter and receiver battery voltage to ensure they have enough remaining capacity to complete the flight.

Always exit programming mode before attempting to fly the model.

Always exit programming mode before attempting to fly the model.

Only use the CGY750 with a 2.4GHz system such as the Futaba FASST™ system, or a PCM system. Use with an FM system is strongly discouraged since interference can cause serious operational problems.

Only use the CGY750 with a 2.4GHz system such as the Futaba FASST™ system, or a PCM system. Use with an FM system is strongly discouraged since interference can cause serious operational problems.

Gyro operating precautions: Gyro

The CGY750 requires 5-10 seconds to initialize when the power is turned on. Do not move the helicopter and do not move the tail rotor, aileron and elevator sticks during this initialization or the gyro may not initialize properly. Once the initialization process has been completed the swash servos and tail servo will move several times indicating that the CGY750 is now ready for flight.

The CGY750 requires 5-10 seconds to initialize when the power is turned on. Do not move the helicopter and do not move the tail rotor, aileron and elevator sticks during this initialization or the gyro may not initialize properly. Once the initialization process has been completed the swash servos and tail servo will move several times indicating that the CGY750 is now ready for flight.

Verify that the gyros are operating and compensating in the correct direction before each flight. If the compensation direction is incorrect on any axis the model will become uncontrollable after takeoff.

Verify that the gyros are operating and compensating in the correct direction before each flight. If the compensation direction is incorrect on any axis the model will become uncontrollable after takeoff.

Verify that the gyro is operating in the desired mode.

Verify that the gyro is operating in the desired mode.

Verify that the gyro mounting pads are in good condition.

Verify that the gyro mounting pads are in good condition.

Verify that the gyro wires are not contacting the frame of the helicopter.

Verify that the gyro wires are not contacting the frame of the helicopter.

The servo type parameters within the CGY750 must match the type of servo you are using. Incorrect setting may damage the CGY750 or the servos, possibly resulting in a loss of control during flight.

The servo type parameters within the CGY750 must match the type of servo you are using. Incorrect setting may damage the CGY750 or the servos, possibly resulting in a loss of control during flight.

Always ensure that there is some slack in the gyro cables to help maximize performance. Always use the supplied gyro mounting pads to attach the gyro to the helicopter mechanics. Do not use a strap that encompasses the CGY750 sensor. This may affect the overall performance of the gyro.

Always ensure that there is some slack in the gyro cables to help maximize performance. Always use the supplied gyro mounting pads to attach the gyro to the helicopter mechanics. Do not use a strap that encompasses the CGY750 sensor. This may affect the overall performance of the gyro.

Always allow the gyro to adjust to the surrounding environmental temperature before flight. A large temperature change during use will cause drift and other operational issues.

Always allow the gyro to adjust to the surrounding environmental temperature before flight. A large temperature change during use will cause drift and other operational issues.

The gyro sensor and control box have a electroconductive coating. Do not allow any power leads or other wiring to come into contact with these items.

The gyro sensor and control box have a electroconductive coating. Do not allow any power leads or other wiring to come into contact with these items.

If you are switching between Normal Mode and AVCS Mode in flight, please keep in mind that you must have the gyro re-learn the center position after making a trim change within the transmitter. To memorize the new center position simply flip the gain switch on the transmitter three times between Normal Mode and AVCS Mode (NormalAVCSNormalAVCS) within one second. The servo will center indicating that the new center position has been memorized.

If you are switching between Normal Mode and AVCS Mode in flight, please keep in mind that you must have the gyro re-learn the center position after making a trim change within the transmitter. To memorize the new center position simply flip the gain switch on the transmitter three times between Normal Mode and AVCS Mode (NormalAVCSNormalAVCS) within one second. The servo will center indicating that the new center position has been memorized.

When operating the gyro in AVCS Mode, all compensation and revolution mixing must be disabled and any tail rotor or swash offsets for flight modes must be disabled.

When operating the gyro in AVCS Mode, all compensation and revolution mixing must be disabled and any tail rotor or swash offsets for flight modes must be disabled.

When the CGY750 is operated in AVCS mode the tail rotor or swashplate servos will not center when tail rotor, aileron or rudder stick is released. This is normal operation for AVCS mode. The servos

When the CGY750 is operated in AVCS mode the tail rotor or swashplate servos will not center when tail rotor, aileron or rudder stick is released. This is normal operation for AVCS mode. The servos

may also move to the extent while the model is being carried out to the flight line. Before take off, you must visually center the tail rotor pitch slider and level the swash plate by using the transmitter control sticks. You can also center the servos by moving the tail rotor stick full left, then full right, back to full left and then allow the stick to center within one second; the same method applies for aileron and elevator servos.

Do not drop the CGY750 sensor onto a hard surface or subject the

Do not drop the CGY750 sensor onto a hard surface or subject the

CGY750 sensor to a strong shock as this may damage the sensor.

Always use the supplied mounting pads or the Futaba replacement mounting pads available from your local Futaba dealer.

Always use the supplied mounting pads or the Futaba replacement mounting pads available from your local Futaba dealer.

Governor operating precautions: Governor

When the throttle servo is connected to the CGY750, the battery failsafe function within the CGY750 must be setup and enabled.

When the throttle servo is connected to the CGY750, the battery failsafe function within the CGY750 must be setup and enabled.

Throttle fail safe function (transmitter setting): Use the fail safe function for the channel that turns the governor on and off to set the fail safe position to the point at which the governor is turned off. With this setting, when the system enters the fail safe state, the governor will be turned off, and the receiver throttle signal (fail safe position preset) will be output directly.

Throttle fail safe function (transmitter setting): Use the fail safe function for the channel that turns the governor on and off to set the fail safe position to the point at which the governor is turned off. With this setting, when the system enters the fail safe state, the governor will be turned off, and the receiver throttle signal (fail safe position preset) will be output directly.

When using the condition hold function on the transmitter, always set the throttle servo maximum operating point to less than the point at which the governor is activated. If this is not done the governor may activate while in condition hold.

When using the condition hold function on the transmitter, always set the throttle servo maximum operating point to less than the point at which the governor is activated. If this is not done the governor may activate while in condition hold.

While preparing for flight or starting the engine, always ensure the throttle remains below the governor activation point and do not select any flight modes that may activate the governor.

While preparing for flight or starting the engine, always ensure the throttle remains below the governor activation point and do not select any flight modes that may activate the governor.

If you prefer to activate the governor while the model is still on the ground, always ensure that you have at least -5 degrees of pitch in the model before activating the governor. This negative pitch is necessary to prevent an unexpected lift off as the governor activates and the head speed increases to the desired RPM.

If you prefer to activate the governor while the model is still on the ground, always ensure that you have at least -5 degrees of pitch in the model before activating the governor. This negative pitch is necessary to prevent an unexpected lift off as the governor activates and the head speed increases to the desired RPM.

Periodically check the RPM sensor output to ensure proper governor operation. Due to the high level of vibration and centrifugal forces the magnet may come loose or the sensor alignment may change. Every 10th flight verify that the magnet and sensor are properly mounted.

Periodically check the RPM sensor output to ensure proper governor operation. Due to the high level of vibration and centrifugal forces the magnet may come loose or the sensor alignment may change. Every 10th flight verify that the magnet and sensor are properly mounted.

SPECIFICATIONS

SPECIFICATIONS

Width (Controller): 1.14in [29mm] (Gyro sensor): 0.83in [21mm] (Revolution sensor): 0.30in [7.5mm] Length (Controller): 1.73in [44mm] (Gyro sensor): 0.83in [21mm] (Revolution sensor): 0.63in [16mm] Height (Controller): 0.47in [12mm] (Gyro sensor): 0.33in [8.5mm] (Revolution sensor): 0.39in [10mm]

Weight (Controller): 0.459oz [13g] (Gyro sensor): 0.282oz [8g] (Revolution sensor): 0.141oz [4g]

Operating Voltage: 3.8V to 8.4V DC* Current Drain: 70mA

Selectable Servo Frame: 70Hz, 280Hz and 560Hz (Rudder Gyro only) Rate

Center Pulse Width: 1520µS (70Hz & 280Hz) 760μs (560Hz)

Governor Resolution: 0.1Hz (6rpm) (Engine RPM)

RPM Accuracy: 1%

Head Speed Range: 700-4,000rpm Operating Temperature: 14°F to 113°F

(-10°C to +45°C) Control System: Digital advanced control

Sensor: Micro Electromechanical Systems (MEMS) Gyro Hall effect sensor

Angular Velocity Range: ±1,200 Degrees Per Second (Gyro)

*The operating voltage shown only applies to the CGY750. Always verify that your receiver, servos, tail rotor servo, switch and any other electronic components used in your installation are capable of operating at the voltage you plan to use.

3

REPLACEMENT & OPTIONAL ITEMS

REPLACEMENT & OPTIONAL ITEMS

Futaba PC Interface CIU-2: FUTM0951

Extension 200 mm:

Extension 350 mm:

Extension 55 mm:

Extension 80 mm:

Extension 130 mm:

Mounting Pad: 1x22x22 mm (10)

WARNING

WARNING

Newer high end servos and other radio equipment are capable of placing large demands on the power systems in use today. When using a regulator you must ensure that the regulator is capable of supplying the current demands of the equipment you have selected. In addition to this make sure the wiring and switch you have selected are capable of handling high current draws.

Newer high end servos and other radio equipment are capable of placing large demands on the power systems in use today. When using a regulator you must ensure that the regulator is capable of supplying the current demands of the equipment you have selected. In addition to this make sure the wiring and switch you have selected are capable of handling high current draws.

•The servo current draw can be up to 50% higher on a flybarless helicopter. Always ensure your receiver battery is fully charged before each flight.

Even though the CGY750 is a high performance gyro and governor, it will be necessary to ensure that the helicopter mechanics are also in optimum operating condition. Please use the guidelines below and address all issues before installing and flying the CGY750.

Even though the CGY750 is a high performance gyro and governor, it will be necessary to ensure that the helicopter mechanics are also in optimum operating condition. Please use the guidelines below and address all issues before installing and flying the CGY750.

•The CGY750 must be used with a rigid tail rotor drive system. Any modern torque tube or belt drive system should be adequate. Do not attempt to fly the CGY750 using a wire driven tail rotor system.

•Always ensure the drive gears, torque tube, pulleys, belt, bearings and shafts are in proper working condition. If any of these items are damaged or worn they must be replaced.

•The linkage rod, tail rotor bell crank, pitch slider and tail rotor grips must operate without friction to obtain the best performance from the CGY750. Binding in the tail rotor control linkage will decrease the performance of the CGY750 gyro and this may also shorten the servo lifespan. Please take the time now to ensure the tail rotor system on your helicopter is working correctly and without friction or binding.

•Vibration will affect the CGY750’s overall performance. All rotating components on the helicopter should be balanced to minimize vibrations in flight. Ensure that your engine or electric motor is running smoothly and that all vibrations have been addressed before installing and test flying the CGY750.

Gyro sensor replacement:

• Each CGY750 gyro control box is calibrated specifically for the gyro sensor included. Do not attempt to use another CGY750 sensor with the control box as performance will suffer due to being out of calibration. The calibration process must be completed by an authorized service center.

If your sensor needs replacement, please send the complete unit to your region’s support center for repair.

GYRO SENSOR INSTALLATION

GYRO SENSOR INSTALLATION

The gyro sensor should be mounted on a rigid platform, at least 6in [152mm] away from a Nitro Engine. It is not necessary to mount the gyro near the main shaft of the helicopter but it is very important that the mounting area chosen is rigid. Please refer to your helicopter manufacturer’s instructions for recommended mounting locations.

Test fit the gyro sensor, ensuring that the sensor is in perfect alignment with the helicopter on the roll and pitch axis. The cable from the gyro sensor must exit toward the front or the rear of the helicopter since this is the pitch axis. Any misalignment will cause a loss of performance, so it is very important to ensure that everything is aligned properly.

Once you are certain everything is properly aligned and that the sensor lead can be routed to the gyro, go ahead and mount the gyro sensor to the helicopter using one of the supplied gyro pads. Route the gyro sensor lead to the CGY750 control box and plug the lead into the gyro sensor port. Verify that the connector is firmly locked in place.

• Elevator (Pitch) axis

• Rudder (Yaw) axis

• Aileron (Roll)

axis

Gyro Sensor

Important: The CGY750 gyro sensor must be mounted so that the roll and pitch sensing axis are in alignment with the helicopter. Any misalignments over 1/2 of a degree will cause a loss in performance. Please take extra care in this step to ensure the optimum flight performance.

•The bottom of the CGY750 Gyro Sensor must be perpendicular to the main shaft.

•The roll axis must be parallel to the tail boom and the pitch axis must be perpendicular to the side frame.

TROUBLESHOOTING

If any issues are noted during flight (such as drifting, inconsistent hold or inconsistent control rates) then please review the following troubleshooting recommendations.

1.Always verify that the tail rotor and swash plate mechanisms operate, and that the drive system is in proper working order.

2.Electromagnetic interference could be causing the problem. If you feel everything is set up correctly and that the helicopter is vibration free, then consider moving the gyro sensor to a new location away from servos, ESC and drive motors.

3.Vibrations will decrease the performance of all gyro systems. Even though the CGY750 gyro sensor is the most vibration resistant gyro sensor available, eliminating vibrations will always improve performance. Throughout extensive testing it has been found that the CGY750 gyro sensor performs best when the sensor is mounted rigidly to the airframe. This is mainly due to the sensing of all 3 axes. It is highly recommended to avoid using soft foam pads as this may allow the gyro to bounce around on the roll and pitch axis, causing instabilities and possible loss of control during flight.

4

CONNECTING THE CGY750

CONNECTING THE CGY750

OLED Display |

(1) Gyro Sensor: |

|

• Displays menus, parame- |

||

• Connect the gyro sensor. |

||

ters and status information. |

||

*Insert the sensor connector until it is |

||

|

||

|

firmly locked. |

|

(1) |

(2) Rsen (Revolution sensor): |

|

|

(2) |

||

|

• Connect the revolution sensor. |

||

|

(3) |

||

|

|

||

|

|

(3) S.BUS: |

|

|

|

• Connect to the S.BUS output of the |

|

|

|

receiver with the supplied extension. |

|

Edit Keys |

(4) |

(4) AIL Output: |

|

• Used when setting data. |

|

• Connect the aileron servo. |

|

• Use the included plastic ad- |

(5) |

(5) ELE Output: |

|

justment screwdriver to press |

|||

|

• Connect the elevator servo. |

||

the buttons. |

|

||

* This diagram shows the various con- |

(6) |

(6) PIT Output: |

|

nections between the CGY750 and |

|

• Connect the pitch servo. |

|

receiver, servo, or sensors. |

|

||

|

|

||

* If the governor and limiter functions are |

|

(7) TH Output: |

|

disabled when using the [Gyro+THR] |

|

• Connect the throttle servo. |

|

mode then the throttle signal is sent |

|

||

|

• Connect the ESC w/BEC and set the |

||

directly to the TH/E2 connection on the |

|

||

CGY750. In this case you may connect |

(7) |

operation mode to Gyro+THR mode. |

|

the throttle servo to the appropriate |

|

(7) E2 2nd ELE Output: |

|

channel on the receiver or to the CGY |

|

• Connect the second elevator servo. |

|

TH/E2 connector. |

|

||

|

(Swash mode: H4-00 or H4-45) |

||

*When the swash mode is set to H4-xx |

|

||

mode, the TH terminal is changed to |

|

|

|

2nd elevator output. In this case, the |

(8) |

(8) RUD Output: |

|

governor function is inhibited. |

|

• Connect the rudder servo. |

|

|

|

Installing the Sensor Connector

WARNING

WARNING

You will feel resistance at two points when inserting the connector. Make sure that you plug in the connector completely, or connection problems may result.

You will feel resistance at two points when inserting the connector. Make sure that you plug in the connector completely, or connection problems may result.

1) First resistance (incomplete connection)

Locking tab

2) Second resistance (fully connected)

●Continue pushing the connector until you hear the locking tab “click.”

Your transmitter should be reset to the default settings and the swash plate type selected with the transmitter should be set to Normal

(H-1) or single servo mode. All

CCPM mixing is set up and handled with the CGY750, and the transmitter functions should not be used. Before starting helicopter set-up, be sure that all dual rates, pitch curve, and endpoint values are set to 100/100.

Connection to the receiver, servos and sensors

The CGY750 requires an S.BUS receiver or the optional PWM Receiver to S.BUS adapter available separately.

Using the supplied extension connect the S.BUS receiver port (or from the S.BUS PWM adapter) to the CGY750 S.BUS port. Install your receiver battery, regulator, switch and any other necessary electronics now. Connect the power lead of your switch / regulator to the battery connector on the receiver.

Plug the cyclic servos (AIL-[Aileron], ELE-[Elevator], PIT [Pitch], RUD [Tail Rotor] and if using the H4xx swash plate type TH/E2- [Elevator 2]) into the appropriate port on the CGY750.

Determine the best location to place the receiver and CGY750 control box. Mount the receiver and the CGY750 control box to the helicopter mechanics using vibration adsorbing self adhesive foam pads. The CGY750 gyro sensor will be installed in a later step.

Using wire mounts, wiring fixtures molded into the helicopter, or hook and loop material, route the servo leads and extensions. Make sure the wires are not rubbing against metal or carbon fiber which may damage the wires.

S.BUS channel setting

Since the S.BUS protocol uses a single wire to transmit all channel information to the CGY750 it is necessary to assign each channel number (1 through 16) a function (such as aileron, pitch, collective, gain, ail gain, ele gain, rpm, gv on/off) within the CGY750 control box. The default CGY750 S.BUS channel assignments should work properly with most Futaba transmitters. If you experience any problems please refer to the S.BUS section of the manual to set/verify each channel number for each function.

If your transmitter does not offer enough channels to operate all of the CGY750’s functions, it is possible to operate the CGY750 without the GV On/Off, Ail Gain, and Ele Gain channels connected. When any these functions are not used, it is necessary to set the channel number to [INH] within the CGY750’s S.BUS menu to disable the function and to use the setting value inside the CGY750 menu instead.

If your transmitter does not offer enough channels to operate all of the CGY750’s functions, it is possible to operate the CGY750 without the GV On/Off, Ail Gain, and Ele Gain channels connected. When any these functions are not used, it is necessary to set the channel number to [INH] within the CGY750’s S.BUS menu to disable the function and to use the setting value inside the CGY750 menu instead.

When the GV On/Off channel is not used, the governor on/off control is handled by the [Stick Switch] function.

When the remote Ail or Ele Gain channels are not used, the operating mode (NOR/AVCS) and gain value can be set in the appropriate AIL / ELE Basic menu option by using the Data +/- keys when the function is displayed.

Using the CGY750 with a electric helicopter

DANGER

DANGER

It is necessary to remove the pinion gear from the electric motor or disconnect the motor from the ESC before powering the model up for setup or bench testing. Electric motors are extremely powerful and capable of delivering the power instantly, causing injury to yourself, others, or the surroundings.

It is necessary to remove the pinion gear from the electric motor or disconnect the motor from the ESC before powering the model up for setup or bench testing. Electric motors are extremely powerful and capable of delivering the power instantly, causing injury to yourself, others, or the surroundings.

If the CGY750 is being installed into an electric helicopter and the ESC’s own internal governor is to be used, you may want to consider connecting the ESC to the [TH/E2] (throttle / elevator 2) output of the CGY750. Before doing this you must remove the pinion gear from the electric motor or disconnect the motor from the ESC before powering the model up the first time. Once the model has been powered up, navigate to the gyro mode function and set it to [GYRO+THR]. This sets the CGY750 to act as a gyro and throttle output. The CGY750 will simply pass the throttle signal from the receiver through to the TH/E2 port on the CGY750.

Once your ESC is connected to the CGY750, you must complete all necessary transmitter setup (ATV / EPA / REV / ETC) per your ESC instructions. Please refer to the end of this manual for further suggestions for the use of the CGY750’s governor with electric powered models.

5

TX Set-up

TX Set-up

Condition selection

Condition selection incorporates two adjustable values for a given parameter (displayed c1/c2). This is dictated by the digital channel number “1” within the Function Menu of your transmitter (DG1). Assigning DG1 to a switch or flight mode allows the use of two separate variables on the condition selectable parameters.

Rotor Head Gyro Gain “RotHd.Gn”

In the SBUS menu assigning “RotHd.GN” to a channel will allow the Rotor head gain to be adjusted via the TX. If you are using a 6CH or less TX, setting “RotHd.Gn” to “INH” will then default the gain to “BaseGain” in the Flight Tuning menu. Suggested setting and default is CH9.

Tail Rotor Gain “RGn”

In the SBUS menu assigning “RGn” to a free TX channel will allow for the tail rotor gain to be adjusted via the TX. Suggested setting and default is CH5.

Note - Before starting helicopter set-up, be sure that all dual rates, pitch curve, and endpoint values are set to 100/100.

GOVERNOR INSTALLATION

GOVERNOR INSTALLATION

Modify the cooling fan and install the accessory magnet and attach the magnetic sensor to the engine at the position shown below. Balance the cooling fan as needed following magnet installation.

Cooling fan

Magnet (Embedded in cooling fan.)

Sensor (Attached to engine flange

through a stay.)

When installing the sensor magnet to the muffler side, also refer to the needle side mounting.

Magnet operating side check

Bring the magnet near the end of the sensor and check the operating side.

Bring the magnet near the end of the sensor and check the operating side.

Sensor

Magnet

This is the side at which the displayed value increases in the “Revolution sensor testing” menu within the “Governor Basic Setting” section earlier in this manual. Install the magnet with this side facing the sensor. Mark this side of the magnet with a felt tip pen.

Cooling fan modification

Drill a hole in the fan at the magnet mounting position. Make the hole about 4.1mm in diameter and 1.5 to 1.7mm deep.

Drill a hole in the fan at the magnet mounting position. Make the hole about 4.1mm in diameter and 1.5 to 1.7mm deep.

Embed the magnet in this hole in the direction in which an output is obtained. Use epoxy adhesive that cures in 30 minutes or longer. Do not use epoxies that contain metal such as JB Weld.

Embed the magnet in this hole in the direction in which an output is obtained. Use epoxy adhesive that cures in 30 minutes or longer. Do not use epoxies that contain metal such as JB Weld.

Cement the magnet to the cooling fan so that the magnet is level with this side of the cooling fan.

Magnet

If the cooling fan is unbalanced and vibrates, etc., balance it by mounting the spare magnet to the opposite side of the cooling fan in the opposite polarity (so that it does not output a signal).

If the cooling fan is unbalanced and vibrates, etc., balance it by mounting the spare magnet to the opposite side of the cooling fan in the opposite polarity (so that it does not output a signal).

Sensor mounting

The sensor mounting method depends on the helicopter and engine.

Mount the sensor to the sensor stay. (Temporary assembly)

Mount the sensor to the sensor stay. (Temporary assembly)

Drill a hole in the fan cover at the part corresponding to the sensor so that the distance between the sensor and magnet can be made 1 to 2mm.

Drill a hole in the fan cover at the part corresponding to the sensor so that the distance between the sensor and magnet can be made 1 to 2mm.

Tighten the sensor stay together with the engine mounting flange. (Temporary assembly)

Tighten the sensor stay together with the engine mounting flange. (Temporary assembly)

Select the mounting method so that the sensor does not touch the frame, or other parts of the helicopter. Temporarily mount the sensor and select the magnet mounting posi-

Select the mounting method so that the sensor does not touch the frame, or other parts of the helicopter. Temporarily mount the sensor and select the magnet mounting posi-

tion.

Install the sensor to the sensor stay using the accessory screws and washers.

Install the sensor to the sensor stay using the accessory screws and washers.

Tighten the sensor stay together with the engine using the

Tighten the sensor stay together with the engine using the

engine mount screw.

Sensor adjustment

Adjust the sensor position to obtain a sensor output of at least 60% in the

Adjust the sensor position to obtain a sensor output of at least 60% in the

“Revolution sensor testing” menu within the “Governor Basic Setting” section earlier in this manual.

Sensor

Magnet

1-2mm |

Center of sensor is offset.

Sensor case

2.2 |

|

mm |

|

3.7mm |

3.7mm |

The center of the sensor is different from the center of the sensor case so be careful when mounting the sensor.

The center of the sensor is different from the center of the sensor case so be careful when mounting the sensor.

If the display is less than 60% when the magnet is directly below the sensor, bring the sensor closer to the magnet so that the 60% or more is displayed. The magnet and sensor gap criteria is approximately 1 to 2mm. If a sensor output is not obtained even when the sensor is brought close to the magnet, the magnet and sensor center positions may have changed.

Complete assembly of the sensor by securely tightening the screws that were temporarily tightened.

Complete assembly of the sensor by securely tightening the screws that were temporarily tightened.

Recheck the sensor output.

Recheck the sensor output.

GOVERNOR FUSELAGE SETTING PRECAUTIONS

GOVERNOR FUSELAGE SETTING PRECAUTIONS

Throttle servo linkage precautions

To effectively use the governor, observe the following precautions when connecting the servo linkage.

Make the servo operating range as wide as possible. Make the throw of the transmitter EPA(ATV) function andAFR function as close as possible to 100%.

Make the servo operating range as wide as possible. Make the throw of the transmitter EPA(ATV) function andAFR function as close as possible to 100%.

Fly with the governor turned OFF and adjust the needle so that the engine smoothly reacts to movement of the transmitter stick.

Fly with the governor turned OFF and adjust the needle so that the engine smoothly reacts to movement of the transmitter stick.

If there is a point at which the reaction of the engine is considerably different due to a too rich or too lean mixture, the governor may not operate to its maximum potential.

Fuselage vibration countermeasures

If the helicopter frame is weak, or the engine mount is deformed or not installed properly, the vibrations applied by the engine will increase. Engine vibrations will lead to unstable speed and prevent the governor from providing maximum performance. Therefore, make sure that the engine is vibration free and that the carburetor provides linear throttle control because the governor cannot correct engine problems.

Use of a tuned silencer

The use of a tuned pipe type silencer may cause the engine throttle response to be substantially different from that of a normal muffler. Adjust the needle (and pipe length) so that engine speed changes are proportional to the throttle opening. The governor will not perform satisfactorily with a muffler or a pipe that does not allow the carburetion to be linear.

6

FIRST MAP |

Home screen |

The figure shows the first layer of the editing |

|

sequence. |

Rudder gain display |

|

|

|

|

|

|

|

Push MODE |

|

|

|

+/– key |

Push DATA |

Thick line |

||

shows MODE. |

|||

+/– key |

|

|

Engine |

|

|

|

|

|

|

|

runtime |

|

|

|

OLED |

|

|

|

Setting |

Push DATA |

Push DATA |

Setup style |

|

+ key |

|

+ key |

|

|

|

- key |

Condition |

|

|

|

|

|

|

|

Menu |

|

|

|

Maximum |

|

|

|

Roll Rate |

Push DATA |

|

|

|

+/– key |

|

|

Maximum |

|

|

|

|

|

|

|

elevator rate |

|

|

|

Maximum |

|

|

|

RPM |

Push DATA

+/– key

Thin line shows DATE.

Swash

Flight Tuning Expert

Gyro (RUD)

Gyro (RUD)

CondData |

When CondMenu is ON, this |

Cond. 1 |

changes into CondMenu. |

|

Governor

|

|

|

|

|

|

|

|

|

Condition# |

|

|

|

|

Push MODE +/– key |

|

|

|

|

|

|

|||

|

indication |

|

|

|

|

for 1 second |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPENING SCREEN

OPENING SCREEN

Verify that all of the connections are correct between the CGY750, receiver, and power supply. If your helicopter is using an electric motor for propulsion, remove the pinion gear now for safety.

If this is the first time the helicopter has been powered up, remove the servo arms and linkages to prevent damaging the servos if any binding is present. Power up the transmitter and allow it to initialize. Turn the receiver on or connect the flight battery and allow the helicopter to remain motionless while the CGY750 initializes.

The display will first show the ID number of your CGY750 and the Firmware Version.

After the CGY750 has powered up the screen will change to show an animation of a helicopter performing a stationary flip. This indicates that the initialization process is taking place. The helicopter must remain perfectly still so the controller can determine the gyro’s center position for each axis.

Once the initialization process has been completed the Home Screen will be displayed and the cyclic + tail rotor servos will move several times in quick succession.

If the CGY750 is set to the [Gyro+THR] mode or if the H4-xx swash plate type has been selected then the governor will be disabled and the screen will look like (d) below instead. The display will cycle through and show the currentAIL, ELE and RUD gains.

Home SCREEN

Home SCREEN

Initial Home screen

1. Axis indication |

|

|

|

2. Gyro operation mode |

|

|

|

|

|

3. Gyro gain |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. on/off switch |

|

|

|

|

|

|

7. Setting Menus |

||||||

|

|

|

|

|

|

||||||||

5.Yaw rate comp |

|

|

|

|

|

6. Battery voltage |

|||||||

|

(b) Aileron gain |

|

(c) Elevator gain |

|

(d) Gyro only |

||||||||

|

display |

|

|

display |

|

|

mode |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Axis indicator Gyro

The axis indicator will cycle every two seconds and show the axis (AIL, ELE or RUD) and their respective current gain values.

7

2. Gyro operation mode Gyro

The display indicates either [A] forAVCS or [N] for Normal operating modes. If the [A] is shown in inverted colors then the rudder neutral is offset and re-learning the center position should be completed immediately.

|

|

|

|

|

RUD AVCS Mode |

RUD NOR Mode |

|

Neutral offset at |

|

at 100% gain |

at 100% gain |

|

AVCS mode |

|

When using the AVCS operating mode, the servos will not re-center when the control stick is released. If you need to center the servo, you can move the appropriate control stick to its full extent (left & right or up & down) twice and allow the control stick to return to center within a one second period of time, and the servo(s) for that axis will return to center position.

For example if you move the tail rotor stick full left, full right, full left, full right and allow it to come back to center within one second, then the display will change to show [--------], and the tail rotor servo will center.

Return servo to center position

When using the AVCS operating mode and if trim changes have been made on any axis, then the neutral position must be read and memorized by the CGY750. To do this simply change the operating mode twice within one second (for example Normal → AVCS → Normal → AVCS) and the display will change to [********] to indicate that the current stick position has been memorized as the new neutral position.

Read and memorize the current neutral position.

3. Gyro gain Gyro

This indicates the current gyro gain for the axis noted in the Axis Indicator position.

4. Operating condition Governor

This indicates whether the governor is [ON] or [OFF].

5.Yaw rate comp. Governor

This indicates that the Governor yaw feed forward function is enabled.

6. Battery voltage

This indicates the battery voltage. The display will change to show [LOW BAT] once the voltage has fallen below the Battery fail safe voltage setting (BFS).

7. Setting Menus

Pushing this button will exit the normal operating mode and enter the settings menu mode.

RPM display Governor

The battery voltage display automatically changes to the engine RPM display once the engine is running and returns to battery voltage display once the engine has stopped running. The RPM display can be either the head speed or the engine speed depending on the setting in the revolution display mode setting found in the governor Expert menu.

Home screen options

When the home screen is shown the mode [+] and [-] keys can be used to cycle the bottom line through the following items; Battery voltage, Max RPM, Engine runtime, OLED display options, Operating Mode, Roll rate maximum display, and Elevator rate maximum display.

1. Engine runtime Governor

From the home screen press the mode [+] key twice to show the engine runtime display. The time shown is how long the engine has been running. This is a cumulative timer and the value is maintained in memory. To reset the timer simply press the data [+] or [-] key for more than one second and the timer will reset back to 0.

2. OLED display options [default: Saver]

When the [Saver] option is selected, the display will dim after 60 seconds of inactivity. Once a button is pressed on the CGY750 controller box, the OLED will switch back to full brightness. The [Saver] option helps to conserve power and extend the life of the display. When the [Light] option is selected the display will remain at full brightness at all times.

3. Setup style

3D Mode is a known configuration of parameters for 3D and F3C flying. F3C Mode is forAdvanced F3C tuning only.

Push DATA |

Push DATA |

+/– key |

+key |

– key

*The changed menu is indicated on a map.

*When the style is changed, setting of AIL/ELE/RUD is initialized.

4. Condition menu [default: OFF]

2 conditions can be established by the switch (DG1) of the transmitter. When the condition menu is turned on, [CondMenu] appears newly.

It becomes possible to change the function indicated by a map of [CondMenu] to 2 conditions.

The function included in [CondMenu] disappears from the usual menu.

5. Roll rate maximum display Gyro

This screen displays the maximum roll rate recorded during flight. This value is reset back to 0 when the CGY750 is powered up.

6. Elevator rate maximum display Gyro

This screen displays the maximum elevator rate recorded during flight. This value is reset back to 0 when the CGY750 is powered up.

7. Maximum RPM Governor

From the home screen press the mode [+] button once to show maximum recorded RPM [Mrpm]. The [Mrpm] value is maintained until you clear it by pressing the data [+] or [-] key for at least one second. This function allows you to check for over speeding during flight.

8. Condition #

Current condition# is indicated.

WARNING DISPLAY

WARNING DISPLAY

Governor warning display Governor

The warning symbol is displayed when the governor is activated during power up. Immediately switch to a condition that has the governor disabled, and the symbol will disappear. When this warning symbol is shown, the governor will be disabled until the flight condition has been turned off. The engine must be started with the governor turned off.

Sensor Error Gyro

WARNING

WARNING

The helicopter must remain motionless during the initialization process or a [SensorER] sensor calibration error may occur.

The helicopter must remain motionless during the initialization process or a [SensorER] sensor calibration error may occur.

If a sensor error occurs during initialization, the sensor itself may be defective.

Please contact your region’s technical support center (the contact information can be found in the beginning of this manual).

Low battery

WARNING

WARNING

The [Low Batt] warning is displayed if the receiver battery voltage falls

The [Low Batt] warning is displayed if the receiver battery voltage falls

below the [BAT/FS] voltage set within the CGY750 Governor Expert menu. If this condition lasts for more than one second, then the Battery Fail Safe function activates, and the throttle servo is brought back to idle position. This is done to warn you that the battery voltage is dangerously low and that you must land immediately.

8

The throttle operation can be temporarily reactivated by bringing the transmitter control stick all the way back to idle; normal throttle function will return. After 30 seconds the Battery Fail Safe function will activate again requiring you to repeat this process if necessary. The model should be landed as soon as possible.

Memory writing indicator

WARNING

WARNING

Do not power off the CGY750 when the Memory writing symbol is displayed.

Do not power off the CGY750 when the Memory writing symbol is displayed.

When a setting is changed within the CGY750 the new value must be written to memory. The “Memory writing indicator” is displayed during this process. This process may take up to two seconds, and the power must not be switched off during this time.

If the power is switched off during the writing process, then all of the settings may be lost.

SETTING MENUS

SETTING MENUS

WARNING

WARNING

Always exit the Setting Menu and return to the home screen before fly-

Always exit the Setting Menu and return to the home screen before fly-

ing your model. The gyro operation is disabled within several of the settings menus to ease set up.

Always check the operation of the CGY750, verify that the controls are operating the correct direction and ensure the gyros are correcting in the proper direction for all axes prior to attempting to fly the model.

Always check the operation of the CGY750, verify that the controls are operating the correct direction and ensure the gyros are correcting in the proper direction for all axes prior to attempting to fly the model.

The data [+] and [-] keys are used to navigate through the Setting Menus: [RUD.Gyro], [AIL.Gyro], [ELE.Gyro], [SWASHset], [Governor]* and [S.BUS] Basic menus. Once the desired menu is shown press and release the mode [+] or [-] key to show the next or setting items respectively.

The expert menus are entered or exited by pressing and holding the mode [+] or [-] key for one second. To exit the current menu simply go back to the Basic Settings Menu for the function (for example, [AIL.Gyro - Basic]) and press and release the mode [+] or [-] key until the home screen is shown.

Please see the Setting Menus diagram for a complete listing of the Home Screen, Basic and Expert menus.

*The [Governor] setting menu is not displayed if the Operating Mode has been set to [Gyro+Thr] or if the swash plate type has been set to the H4 xx type.

9

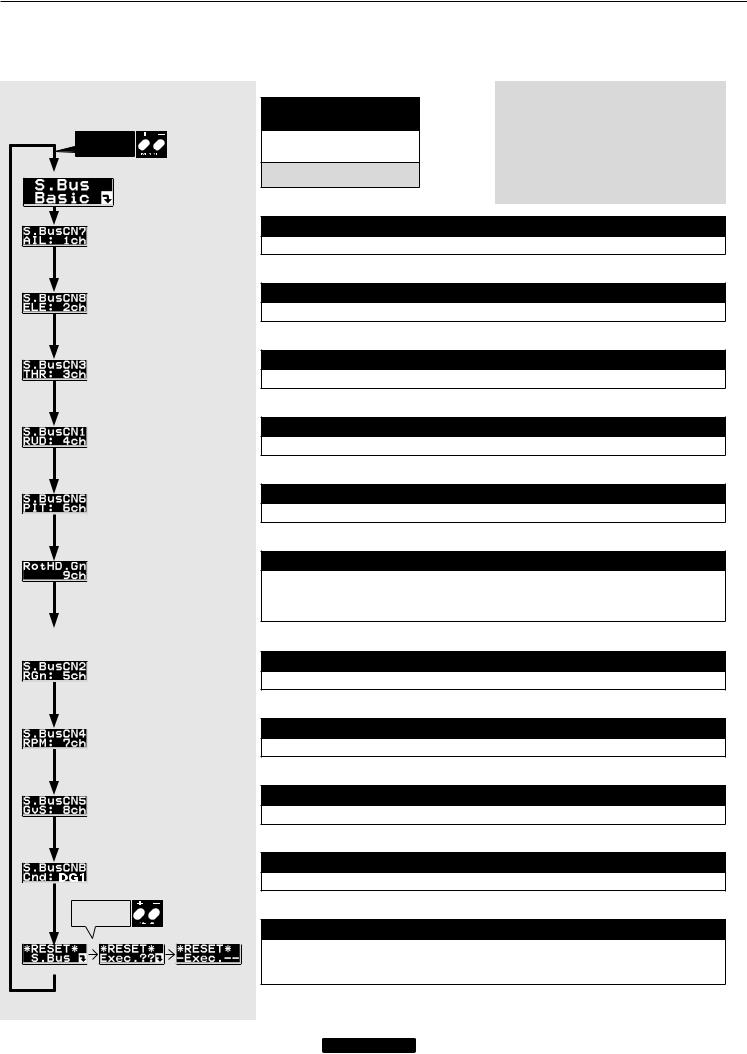

S.BUS BASIC SETTING

S.BUS BASIC SETTING

Since S.BUS sends all 18 channels (may be limited by your transmitter) over a single wire, it is necessary to assign a CGY750 function (such as AIL, ELE or PIT) to each channel. The channel assignments are performed within the [S.BUS].Basic menu.

If a function is not going to be used, then it must be set to [INH]. For example, if theAGN and EGN remote gain functions are not going to be used, then set them to [INH] and the CGY750 will then allow you to make gain adjustments within the respective menu.

S.BUS BASIC MAP

Push MODE

+/– key

Push DATA

+/– key

(1) S.BUS connection setting: start display

Use the mode [+] or [-] keys to navigate through the menu.

Setting ranges common: 1 ~ 16ch, DG1,

DG2, INH

WARNING

WARNING

Always verify that the S.BUS function assignments match your transmitter’s function (in the FUNCTION menu) assignments. If any changes are made within the transmitter function assignments, then it will also be necessary to make the changes within the S.BUS function assignments.

Always verify that the S.BUS function assignments match your transmitter’s function (in the FUNCTION menu) assignments. If any changes are made within the transmitter function assignments, then it will also be necessary to make the changes within the S.BUS function assignments.

(2) S.BUS setting: Aileron channel [default: 1ch]

Using the data [+] or [-] keys to set the correct channel number.

(3) S.BUS setting: Elevator channel [default: 2ch]

Using the data [+] or [-] keys to set the correct channel number.

(4) S.BUS setting: Throttle channel [default: 3ch]

Using the data [+] or [-] keys to set the correct channel number.

(5) S.BUS setting: Rudder channel [default: 4ch]

Using the data [+] or [-] keys to set the correct channel number.

(6) S.BUS setting: Pitch channel [default: 6ch]

Using the data [+] or [-] keys to set the correct channel number.

(7) Rotor head gain: AIL and ELE gain channel [default: 9ch]

“RotHd.GN” to a channel will allow the Rotor head gain to be adjusted via the TX. If you are using a 6CH or less TX, setting “RotHd.Gn” to “INH” will then default the gain to “BaseGain” in the Flight Tuning menu. Suggested setting and default is CH9.

(8) S.BUS setting: RUD gain channel [default: 5ch]

Using the data [+] or [-] keys to set the correct channel number.

(9) S.BUS setting: RPM channel [default: 7ch]

Using the data [+] or [-] keys to set the correct channel number.

(10)S.BUS setting: GOV. on/off channel [default: 8ch]

Using the data [+] or [-] keys to set the correct channel number.

(11)S.BUS setting: Conditionon change channel [default: DG1]

Using the data [+] or [-] keys to set the correct channel number.

(12)S.BUS data reset

This resets the S.BUS channel assignments back to the defaults. Press the data [+] key and [Exec ??] will be displayed as a confirmation. Press data [+] to confirm the reset back to the default settings.

10

Loading...

Loading...